High-temperature casting molded coal and method for producing the same

A production method and briquette technology, which are applied in the petroleum industry, solid fuels, coke ovens, etc., can solve the problems of resource reduction, shortage of main coking coal, large proportion of bituminous coal, etc. Effects of increased transport, fixed carbon content

Inactive Publication Date: 2008-03-12

赵宜文

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the distribution of coal varieties in my country is extremely unreasonable. The main coking coal used for coking coal is very short, accounting for only 1% of the total coal, and the anthracite lump coal used for chemical industry accounts for only 2% of the total coal. This is inevitable. Leading to higher and higher prices of main coking coal and anthracite, resource reduction

Although our country is rich in anthracite clean coal, and the price is low, in order to reduce the manufacturing cost of machinery and chemical products, it has not yet developed a wide source, large quantity, low cost, which can meet the requirements of the forming process and practical strength requirements. Binders that can meet the combustion characteristics, so it is impossible to use cheap raw materials to produce briquettes that meet environmental protection requirements

For example, Chinese patent 01130.992.X discloses a kind of "environmentally friendly high-temperature briquette", whose composition ratio is: anthracite 35-40%, bituminous coal 45-55%, binder 10-15%, and the proportion of bituminous coal is large, so the smoke and dust Pollution is relatively large and the cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0015] Anthracite clean coal 50% Coking coal 20% Coke foam 25%

[0016] Binder 4% Active Agent 1%

Embodiment 2

[0018] Anthracite clean coal 70% Coking coal 10% Coke foam 12%

[0019] Binder 7.5% Active agent 0.5%

Embodiment 3

[0021] Anthracite clean coal 80% Coking coal 6% Coke foam 8.3%

[0022] Binder 5% Active agent 0.7%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

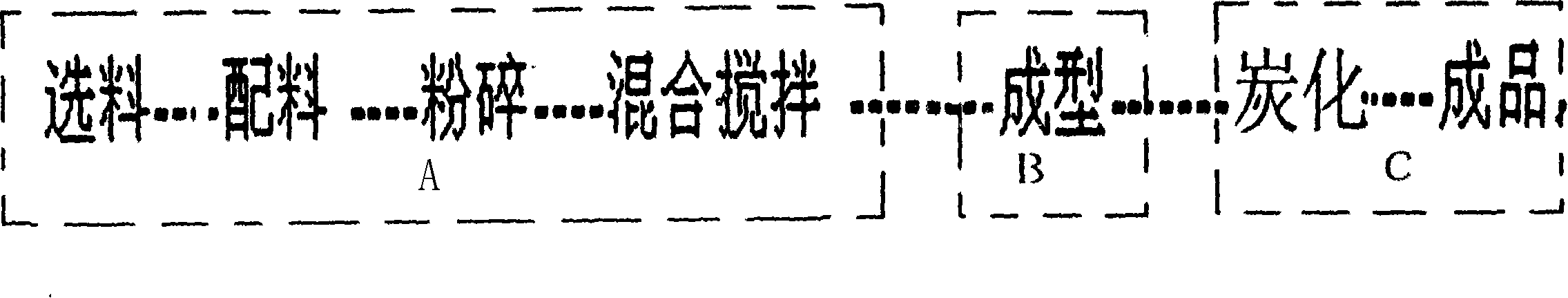

The invention discloses a high-temperature casting coal and a production method for the coal. The product from the invention comprises 50-90% fine anthraciferous coal, 1-12% coke coal, 5-25% peacoke, 1-10% binder and 0.1-1% active agent. The production method of the invention comprises selecting material, blending materials, crushing, mixing and agitating, forming, carbonizing and getting finished product. The invention can reduce about 10% ash, so that the fixed carbon content of the product can be increased greatly, and the product is of very good water proofness and cold and hot strength, is easy to store and transport; meanwhile, a lot of microholes are produced during the carbonizing, this is good for active reaction during casting and production of chemical fertilizer plant, is both useful for gas making and casting, and can save about 50% coke.

Description

technical field [0001] The invention relates to a high-temperature cast molded coal and a production method thereof. Background technique [0002] Briquette is one of the directions of deep processing in the coal industry and has a long history. However, general industrial briquettes are mainly used to replace lump coal in the production of chemical and other industries, and considerable results have been achieved. With the rapid development of my country's economy, the degree of industrialization will become higher and higher, the demand for machinery and chemical products will increase, and the demand for lump coal and foundry coke will continue to increase. However, the distribution of coal varieties in my country is extremely unreasonable. The main coking coal used for coking coal is very short, accounting for only 1% of the total coal, and the anthracite lump coal used for chemical industry accounts for only 2% of the total coal. This is inevitable. As a result, the pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10L5/04C10L5/10C10B57/06

Inventor 赵宜文

Owner 赵宜文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com