Filtration column for treating phosphorus-containing sewage, and treatment method for phosphorus-containing sewage

A treatment method and filter column technology are applied in the field of treatment of phosphorus-containing sewage in chemical fertilizer plants, methods and supporting equipment, which can solve the problems of slow natural settlement, short service period, slow treatment speed, etc., so as to alleviate pollution and pressure and prolong use. The effect of cycle and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

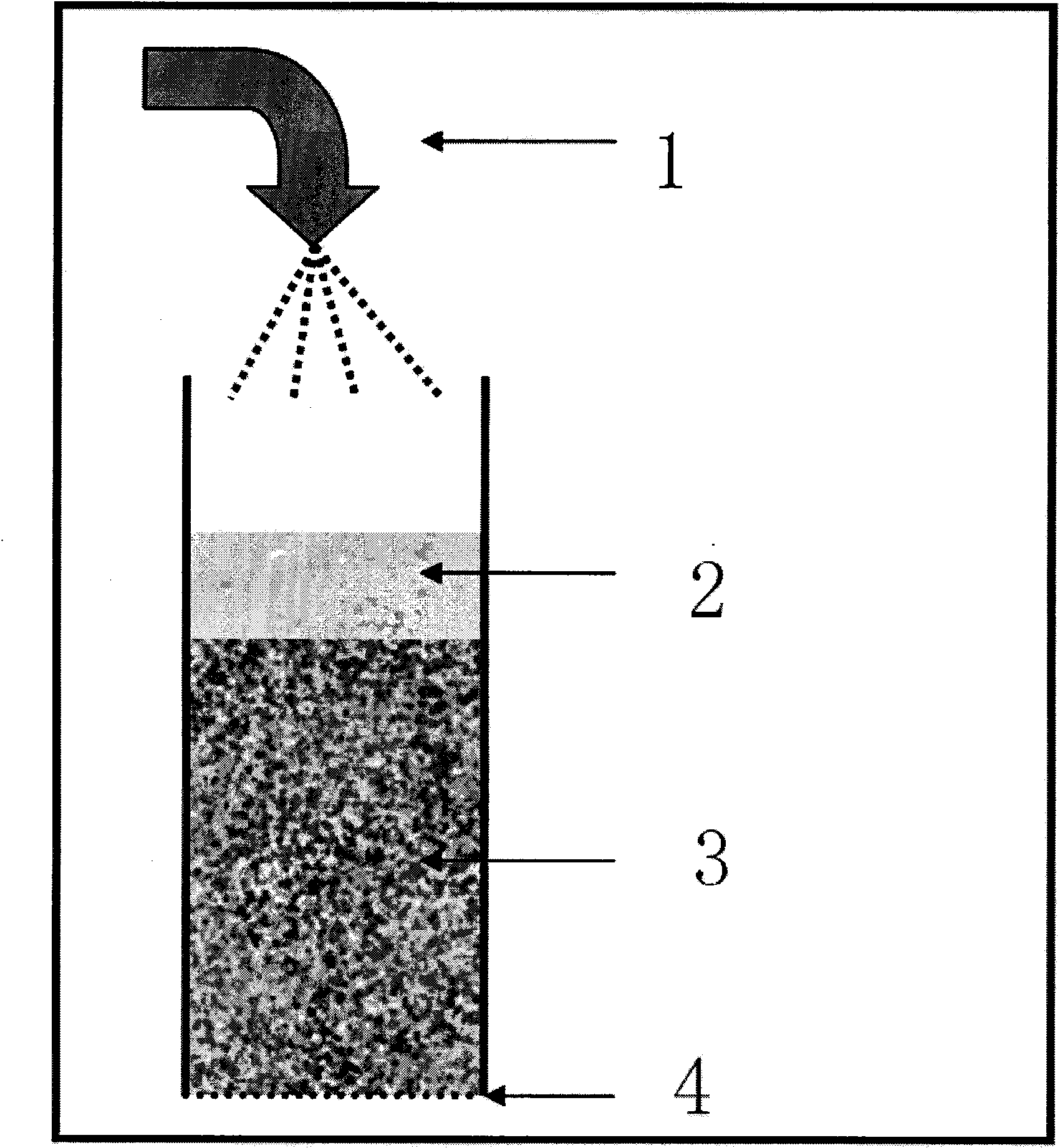

[0021] According to the mass fraction ratio, 30 parts of perlite (10 orders), 10 parts of ferric chloride (20 orders) and 10 parts of straw ash (50 orders), wherein the mass fraction of charcoal is 5%, the mass fraction of silicon dioxide 20%) mix uniformly, form reaction layer 3 in the PVC pipe of packing into, and the diameter of described PVC pipe is 5cm, height is 50cm, and the lower end has 200 order gauze 4, and the height of reaction layer 3 is controlled at about 20cm, in The reaction layer 3 is covered with a quartz sand layer 2, and the height of the quartz sand layer 2 is 5 cm. The phosphorus-containing sewage 1 of the chemical fertilizer plant is sprayed over the filter column and introduced through the filter column. The flow rate of the phosphorus-containing sewage 1 is set to 0.5L / min, and the water temperature of the phosphorus-containing sewage 1 is maintained at about 10°C. When the phosphorus-containing sewage 1 flows through the reaction layer 3, part of th...

Embodiment 2

[0023] According to the mass fraction ratio, 20 parts of perlite (20 orders), 10 parts of ferric chloride (30 orders) and 10 parts of straw ash (100 orders, wherein the mass fraction of charcoal is 6%, and the mass fraction of silicon dioxide is 30 %) mix evenly, pack into PVC pipe and form reaction layer 3, the diameter of described PVC pipe is 7cm, height is 60cm, and the lower end has 250 order gauze 4, and the height of reaction layer 3 is 25cm, is covered on reaction layer 3 The quartz sand layer 2, the height of the quartz sand layer 2 is 7cm. Phosphorus-containing sewage 1 from the fertilizer plant is introduced and passed through the filter column by spraying on the top of the filter column. The flow rate of phosphorus-containing sewage 1 is set to 0.7L / min, and the temperature of phosphorus-containing sewage 1 is maintained at about 15°C. The initial concentration of phosphorus in the phosphorus-containing sewage 1 in this embodiment is 10mg / L, after treatment, the wa...

Embodiment 3

[0025] According to the mass fraction ratio, 10 parts of perlite (40 orders), 10 parts of ferric chloride (50 orders) and 20 parts of straw ash (200 orders, wherein the mass fraction of carbon is 10%, and the mass fraction of silicon dioxide is 20%) mix evenly, pack into PVC pipe to form reaction layer 3, the diameter of described PVC pipe is 10cm, height is 70cm, and the lower end has 300 order gauze 4, and the height of reaction layer 3 is 30cm, above reaction layer 3 Covered with a quartz sand layer 2, the height of the quartz sand layer 2 is 10 cm. Phosphorus-containing sewage 1 from the fertilizer plant is introduced and passed through the filter column by spraying on the top of the filter column. The flow rate of phosphorus-containing sewage 1 is set to 1L / min, and the water temperature of phosphorus-containing sewage 1 is maintained at about 25°C. The concentration of phosphorus in the phosphorus-containing sewage 1 in the present embodiment is 3mg / L, after the treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com