Biomass gasification residue formed activated carbon and preparation method thereof

A technology for forming activated carbon and residues, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of poor binding force with binders, high temperature resistance, low reactivity, etc., to improve adsorption capacity and increase Strong binding force and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

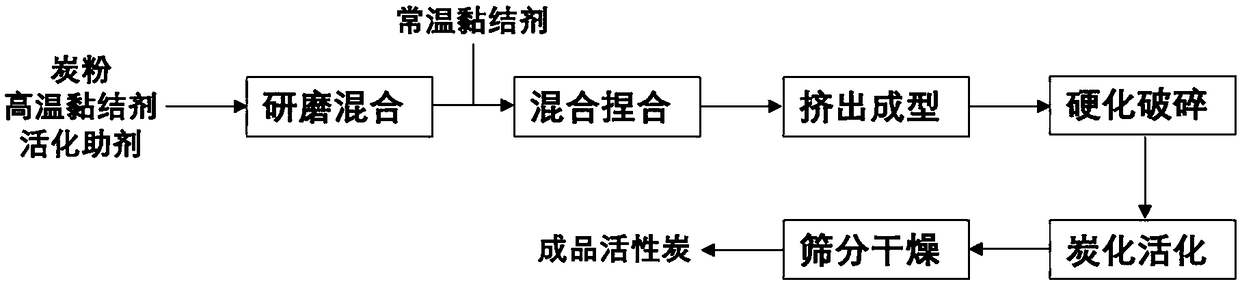

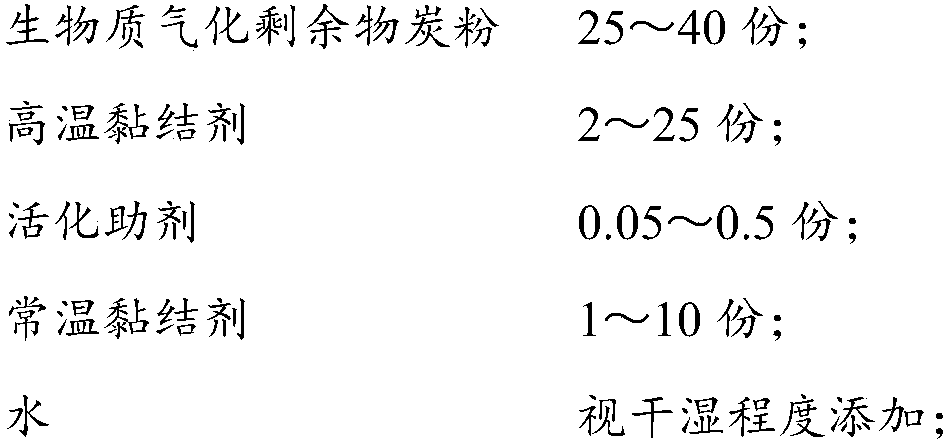

Method used

Image

Examples

Embodiment

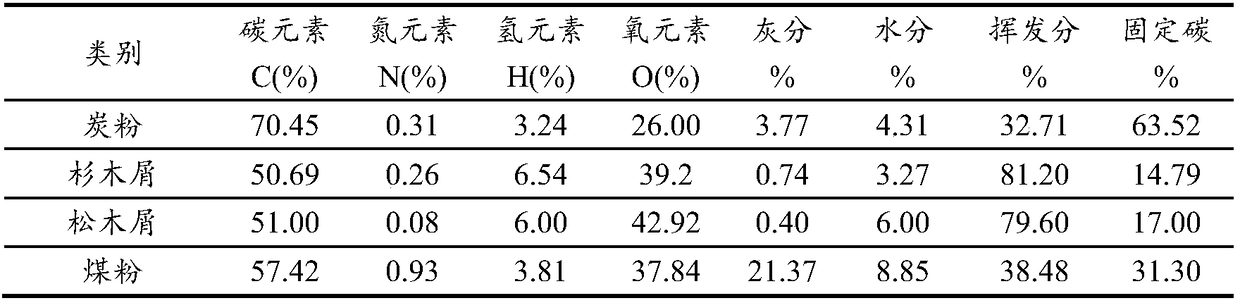

[0038] Table 2 Example

[0039]

[0040]

[0041] It can be seen from Table 2 that both asphalt and resin can be used to prepare high-strength activated carbon, and the amount of asphalt used as a binder is larger than that of resin, but the prepared activated carbon has better adsorption performance. The activation temperature has a great influence on the yield of activated carbon. If the temperature is too high, the yield of activated carbon will drop seriously, and the resin will be severely ablated above 900 °C. The addition of activation aids is beneficial to improve the adsorption performance of activated carbon, but affects the strength and yield of activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption value of blue | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com