Outlet flowing intersecting surface changing adjustable turbo nozzle ring

A turbine nozzle and blade ring technology, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of reduced efficiency of the adjustment range turbine stage, difficulty in ensuring the reliability of the structure and operating system, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, the technical content of the present invention will be further described through the embodiments and in conjunction with the accompanying drawings.

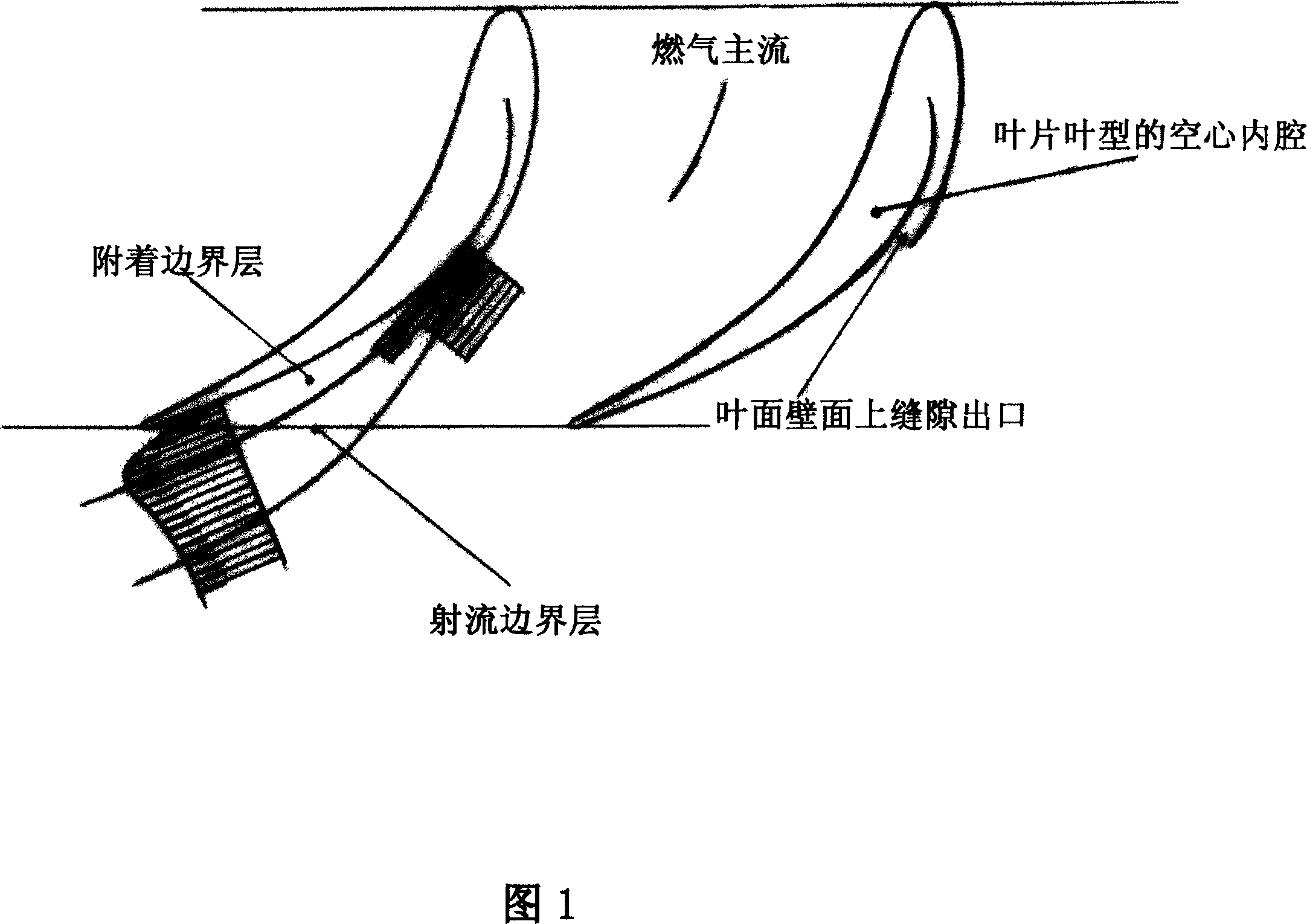

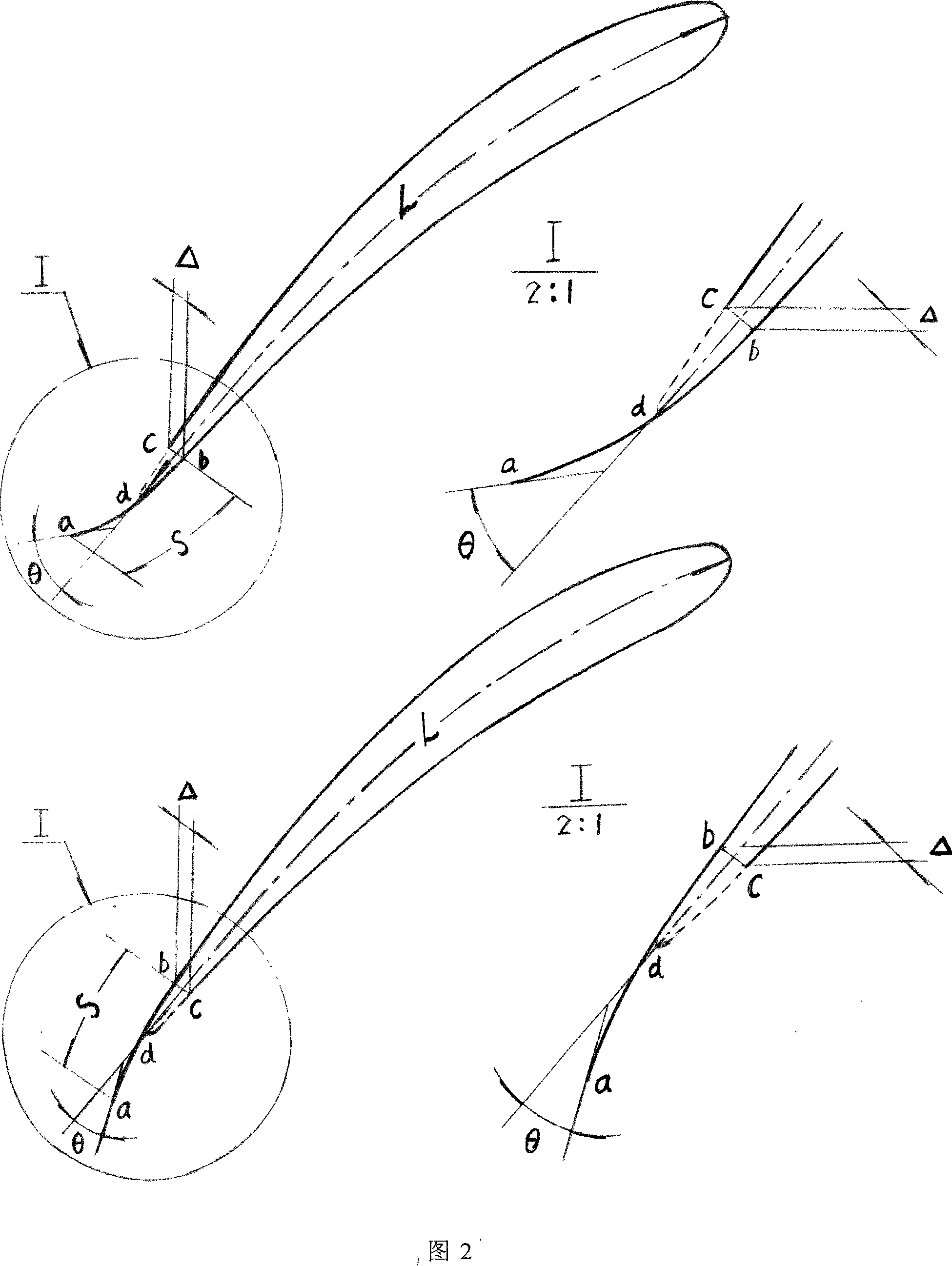

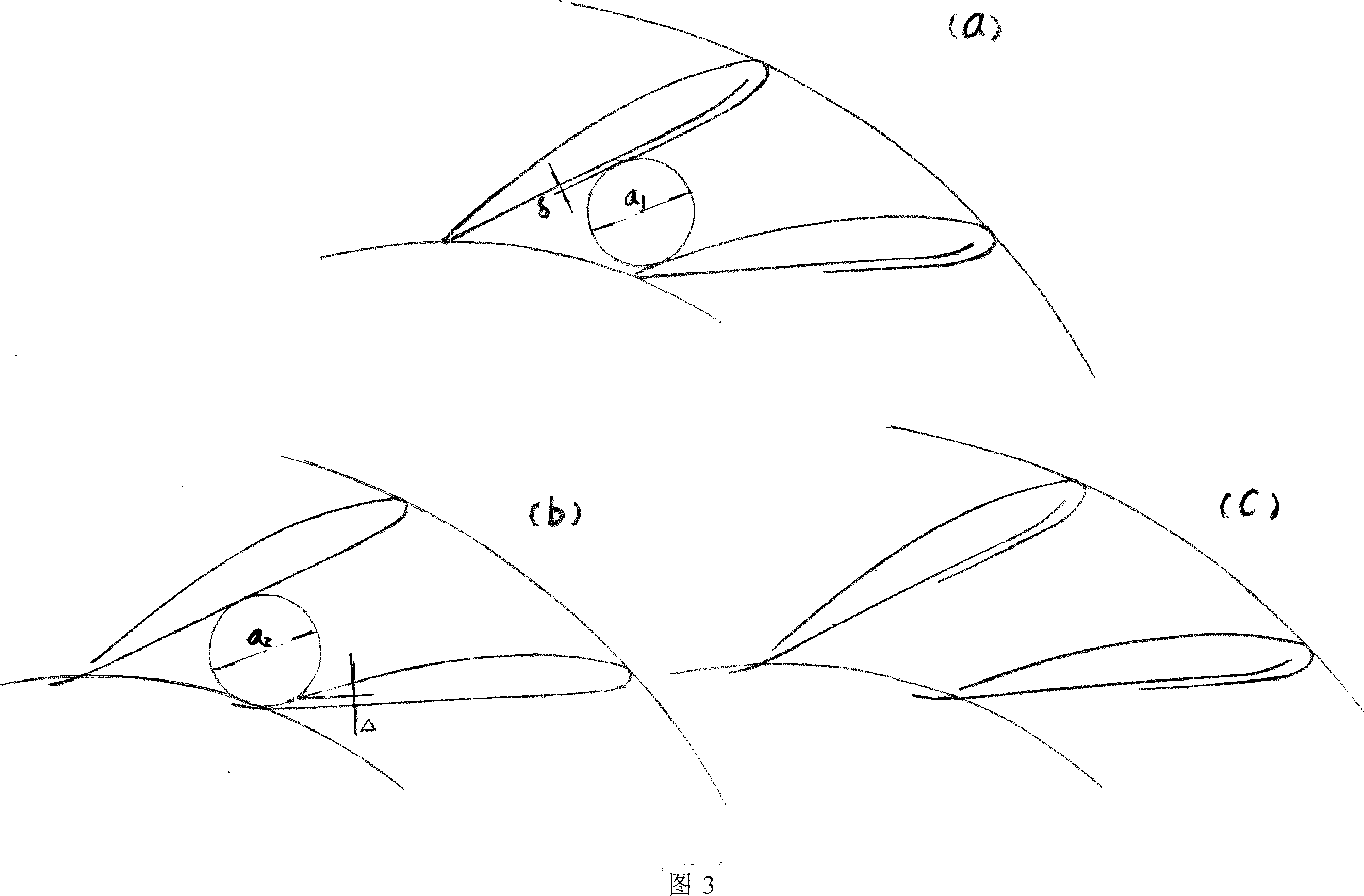

[0065] As mentioned above, the technical core of the present invention is to use externally compressed air to pass through the hollow cavity of the nozzle vane of the turbine nozzle blade ring (vane nozzle) or the cavity at the inner wall of the turbine bladeless volute (blade nozzle ring) inlet pipe. Cavity interlayer, the flow slot cut by the airfoil surface and / or trailing edge of the nozzle blade ring or the annular arc-shaped gap at the outlet of the cavity interlayer at the zero-degree section of the bladeless volute inlet pipe outlet tongue (generally at the tail The edge slot or interlayer outlet gap is equipped with an arc-shaped deflector) and blows the main flow of gas in the flow channel of the nozzle ring cascade and / or the outlet of the cascade along the flow or the main flow of gas flowing out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com