Low-smoke halogen-free flame-retardant waterproof board, drain board and preparation method thereof

A technology of waterproof board and drainage board, which is applied in the field of drainage board and its preparation, and low-smoke, halogen-free, flame-retardant waterproof board. It can solve the problems of lack of smoke indicators and insufficient attention, so as to increase self-extinguishing performance and improve safety. , Optimize the effect of the weak interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 A low-smoke, halogen-free, flame-retardant waterproof board

[0039] A low-smoke, halogen-free, flame-retardant waterproof board is a flat board with smooth sides. Its raw material composition is shown in Table 1, and it is prepared by the following method:

[0040] Prepare each raw material according to the ratio shown in Table 1, put it into a high-speed mixer and mix evenly, transfer the mixture to a single-screw extruder, extrude, draw, and then calender and form it through a three-roll calender to obtain the waterproof board .

Embodiment 2~6

[0041] Embodiment 2~6 A low-smoke, halogen-free, flame-retardant waterproof board

[0042] For the low-smoke, halogen-free, flame-retardant waterproof boards described in Examples 2 to 6, see Table 1 for the composition of raw materials.

[0043] The low-smoke, halogen-free, flame-retardant waterproof boards of the above-mentioned embodiments were prepared by the same method and steps as in Example 1.

[0044] Table 1 Raw material ratio of each layer of the waterproof board of Examples 1-6 (1 part by weight=1kg)

[0045] Raw materials (parts by weight)

Embodiment 7

[0046] Example 7 A low-smoke, halogen-free, flame-retardant drainage board

[0047] The low-smoke halogen-free flame-retardant drainage board described in this embodiment, such as figure 1As shown, the side surface of the drainage board body (1) has regularly arranged cylindrical solid bosses (2); the raw material composition of the drainage board is the same as that of Example 1, and the preparation method is also similar to that of Example 1, except that The surface of the last roller of the three-roll calender has regularly arranged cylindrical grooves.

[0048] Those skilled in the art should understand that the solid boss on the surface of the low-smoke, halogen-free, flame-retardant drainage board of the present invention, in addition to the cylindrical shape, can also be other geometric shapes suitable for industrial manufacturing, such as cuboid, cube, rhombus, rhombus Platform, triangular cone, triangular platform, circular platform and so on.

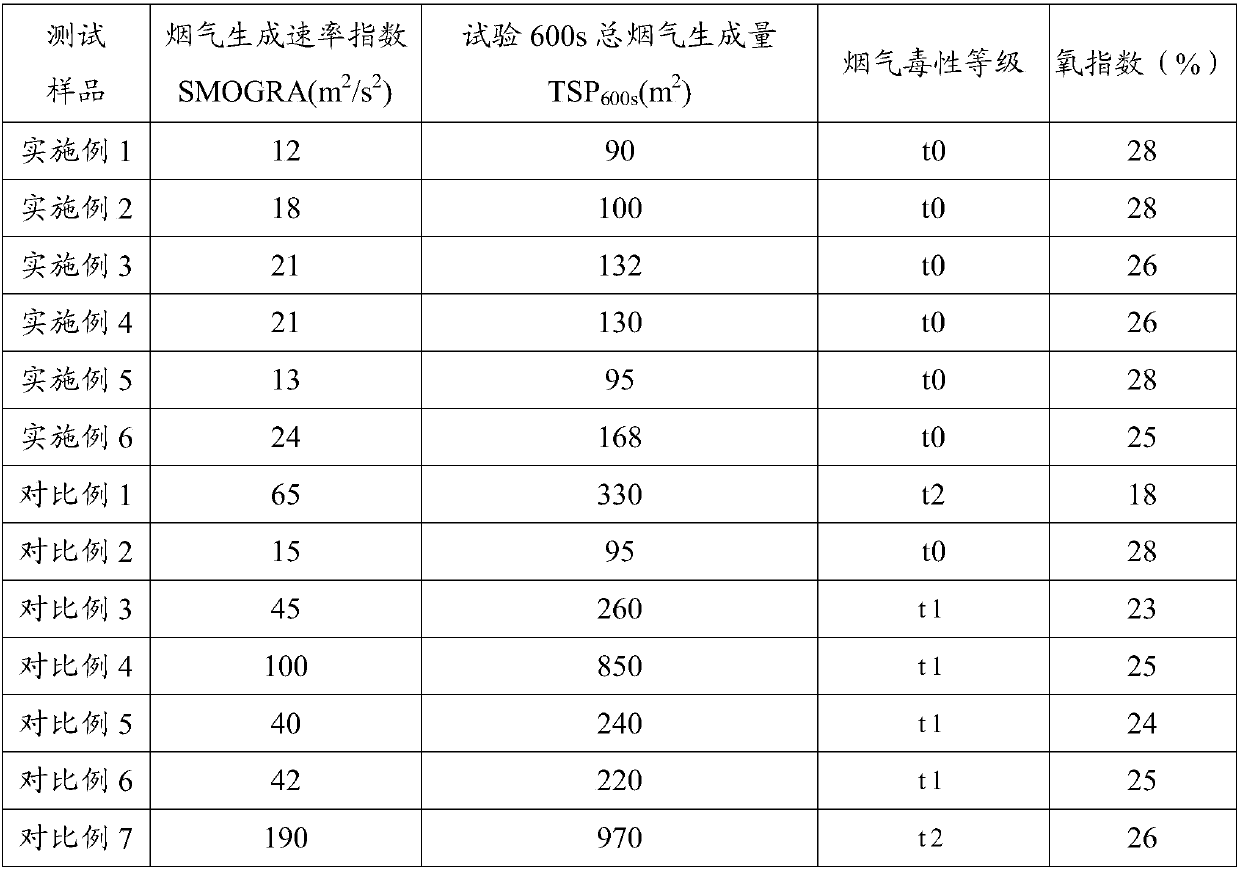

[0049] The raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com