Preparation method of ultrafine dry powder extinguishing agent with good water repellency

A technology of ultra-fine dry powder and fire extinguishing agent, applied in fire protection equipment and other directions, can solve the problems of shortened shelf life, high moisture absorption rate, product caking, etc., and achieve the effect of excellent caking resistance, low production cost and material cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

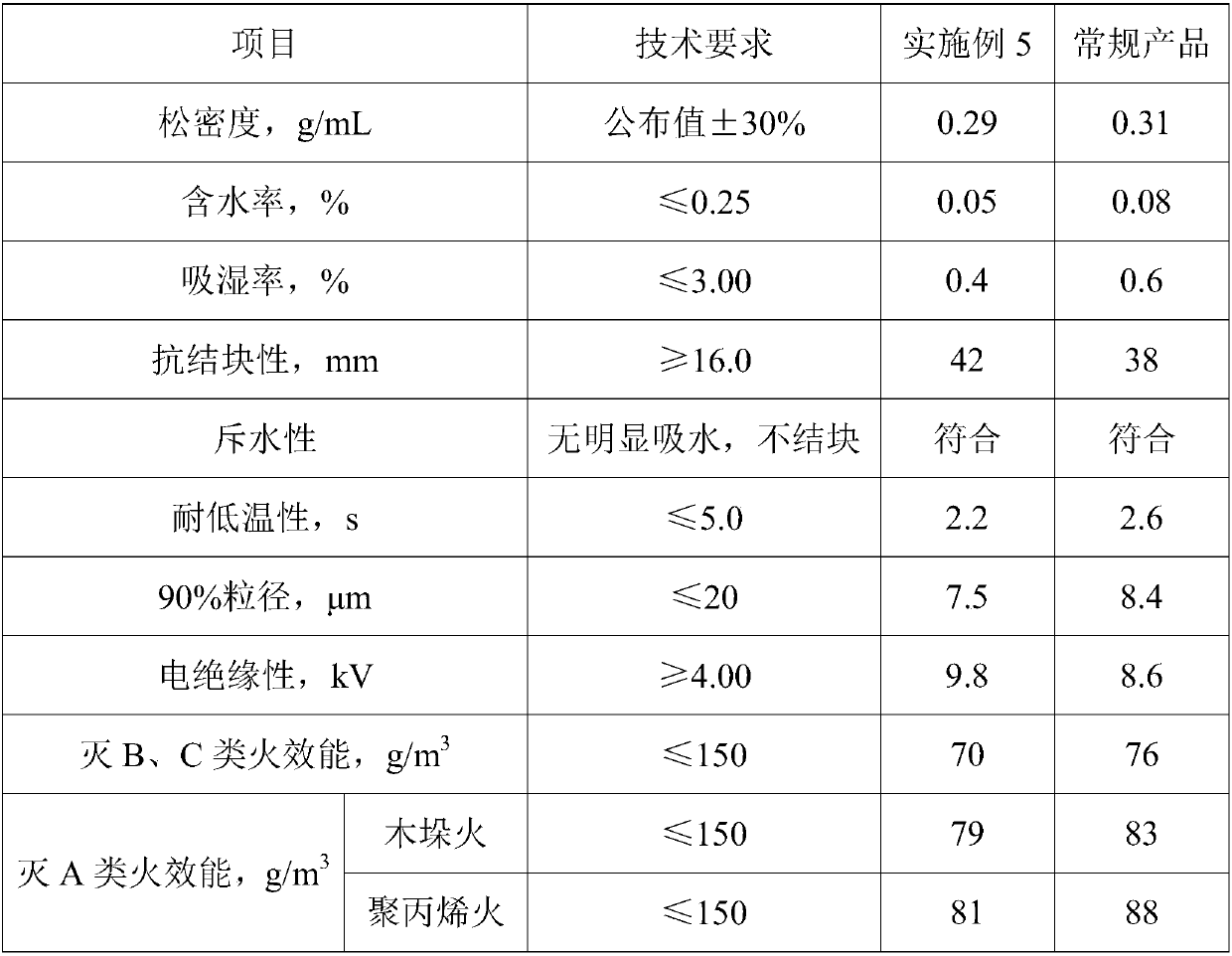

Examples

Embodiment 1

[0020] A preparation method of superfine dry powder fire extinguishing agent with good water repellency, including the following steps:

[0021] S1. Mix 4g of raw gypsum, 6g of carbon nanotubes, 1g of phosphomolybdic acid, and 2g of magnesium carbonate powder uniformly, dry at 100°C, and grind to obtain a preform;

[0022] S2. Preheat 40g preform to 105°C, add 30g sodium bicarbonate, 18g monoammonium phosphate, 10g alum complex, 10g magnesium carbonate powder, 5g ammonium sulfate at a stirring speed of 1700r / min, and continue to stir for 50min. Sprinkle 2g of silicone oil into it while stirring, continue stirring for 15 minutes, add 4g of pentaerythritol and continue stirring for 50 minutes, dry, pulverize, and sieving. The mesh aperture is 25 μm to obtain an ultrafine dry powder fire extinguishing agent with good water repellency.

[0023] The alum complex is prepared by the following process: add 20g of alum to 80g of 40wt% ethanol solution and mix well, then add 15g of liquid para...

Embodiment 2

[0025] A preparation method of superfine dry powder fire extinguishing agent with good water repellency, including the following steps:

[0026] S1. Mix 8kg of raw gypsum, 2kg of carbon nanotubes, 2kg of phosphomolybdic acid, and 1kg of magnesium carbonate powder uniformly, dry at 118°C, and grind to obtain a preform;

[0027] S2. Preheat 20kg of preformed material to 115°C, add 50kg sodium bicarbonate, 10kg monoammonium phosphate, 20kg alum complex, 4kg magnesium carbonate powder, 10kg ammonium sulfate at a stirring speed of 1200r / min, and continue stirring for 30min. Spray 4kg of silicone oil into it while stirring, continue to stir for 5 minutes, add 10kg of pentaerythritol and continue stirring for 30 minutes, dry, pulverize, and sieving. The screen mesh has an aperture of 25 μm to obtain an ultrafine dry powder fire extinguishing agent with good water repellency.

[0028] The alum complex is prepared by the following process: add 30kg of alum to 60kg of 60wt% ethanol solution an...

Embodiment 3

[0030] A preparation method of superfine dry powder fire extinguishing agent with good water repellency, including the following steps:

[0031] S1. Mix 5kg of raw gypsum, 5kg of carbon nanotubes, 1.2kg of phosphomolybdic acid and 1.8kg of magnesium carbonate powder, dry at 105°C, and grind to obtain a preform;

[0032] S2. Preheat 35kg of preform to 108°C, add 35kg sodium bicarbonate, 16kg monoammonium phosphate, 12kg alum complex, 8kg magnesium carbonate powder, 6kg ammonium sulfate at a stirring speed of 1600r / min, and continue to stir for 45min. Sprinkle 2.5 kg of silicone oil into it under stirring, continue stirring for 12 minutes, add 6 kg of pentaerythritol and continue stirring for 45 minutes, dry, pulverize, and sieving. The mesh aperture is 25 μm to obtain an ultrafine dry powder fire extinguishing agent with good water repellency.

[0033] The alum complex is prepared by the following process: add 22kg of alum to 75kg of 45wt% ethanol solution and mix well, then add 12kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com