Low-temperature-difference mass concrete suitable for articulated chute construction and preparation process of low-temperature-difference mass concrete

A large-volume concrete and low-temperature technology, applied in the field of high-performance concrete, can solve the problems of large ground drop in the working surface, long chute delivery distance, small chute inclination angle, etc., to reduce the amount of cement, delay the hydration reaction, and connect holes Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

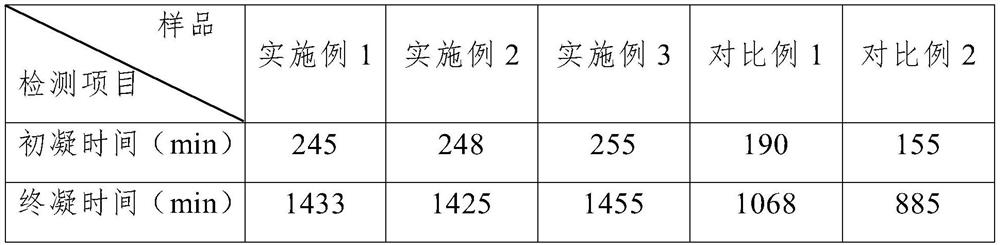

Embodiment 1

[0025] The low-temperature-difference large-volume concrete suitable for chute construction in this embodiment is prepared from the following components by mass: 180 parts of cement, 320 parts of mineral powder, 120 parts of fly ash, 100 parts of water, and 1000 parts of crushed stone , 750 parts of sand, 10 parts of pumping agent.

[0026] The preparation process of the low-temperature-difference mass concrete applicable to the slide pipe construction of the present embodiment comprises the following steps:

[0027] Step 1. Uniformly mix 750 parts of sand, 1000 parts of gravel and 100 parts of water to obtain a mixture; the temperature of the water is 0°C to 10°C;

[0028] Step 2: Add 180 parts of cement, 120 parts of fly ash, 320 parts of mineral powder and 10 parts of pumping agent to the mixture obtained in step 1 and stir evenly for 120 seconds to obtain concrete.

Embodiment 2

[0030] The low-temperature-difference large-volume concrete suitable for chute construction in this embodiment is prepared from the following components by mass: 200 parts of cement, 300 parts of mineral powder, 80 parts of fly ash, 150 parts of water, and 1200 parts of gravel , 700 parts of sand, 15 parts of pumping agent.

[0031] The preparation process of the low-temperature-difference mass concrete applicable to the slide pipe construction of the present embodiment comprises the following steps:

[0032] Step 1. Uniformly mix 700 parts of sand, 1200 parts of gravel and 150 parts of water to obtain a mixture; the temperature of the water is 0°C to 10°C;

[0033] Step 2: Add 200 parts of cement, 80 parts of fly ash, 300 parts of mineral powder and 15 parts of pumping agent to the mixture obtained in step 1 and stir evenly for 120 seconds to obtain concrete.

Embodiment 3

[0035] The low-temperature-difference large-volume concrete suitable for slide pipe construction in this embodiment is prepared from the following components by mass: 150 parts of cement, 260 parts of mineral powder, 110 parts of fly ash, 110 parts of water, and 900 parts of gravel , 800 parts of sand, 14 parts of pumping agent.

[0036]The preparation process of the low-temperature-difference mass concrete applicable to the slide pipe construction of the present embodiment comprises the following steps:

[0037] Step 1, uniformly mix 800 parts of sand, 900 parts of crushed stone and 110 parts of water to obtain a mixture; the temperature of the water is 0°C to 10°C;

[0038] Step 2: Add 150 parts of cement, 110 parts of fly ash, 260 parts of mineral powder and 14 parts of pumping agent to the mixture obtained in step 1 and stir evenly for 120 seconds to obtain concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com