Alkali slag foamed concrete

A technology of foamed concrete and foamed concrete, which is applied in the field of foamed concrete and alkali slag foamed concrete, can solve the problems of long setting time, low compressive strength, and slow strength development, and achieve short setting speed, excellent weather resistance, and strength development fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

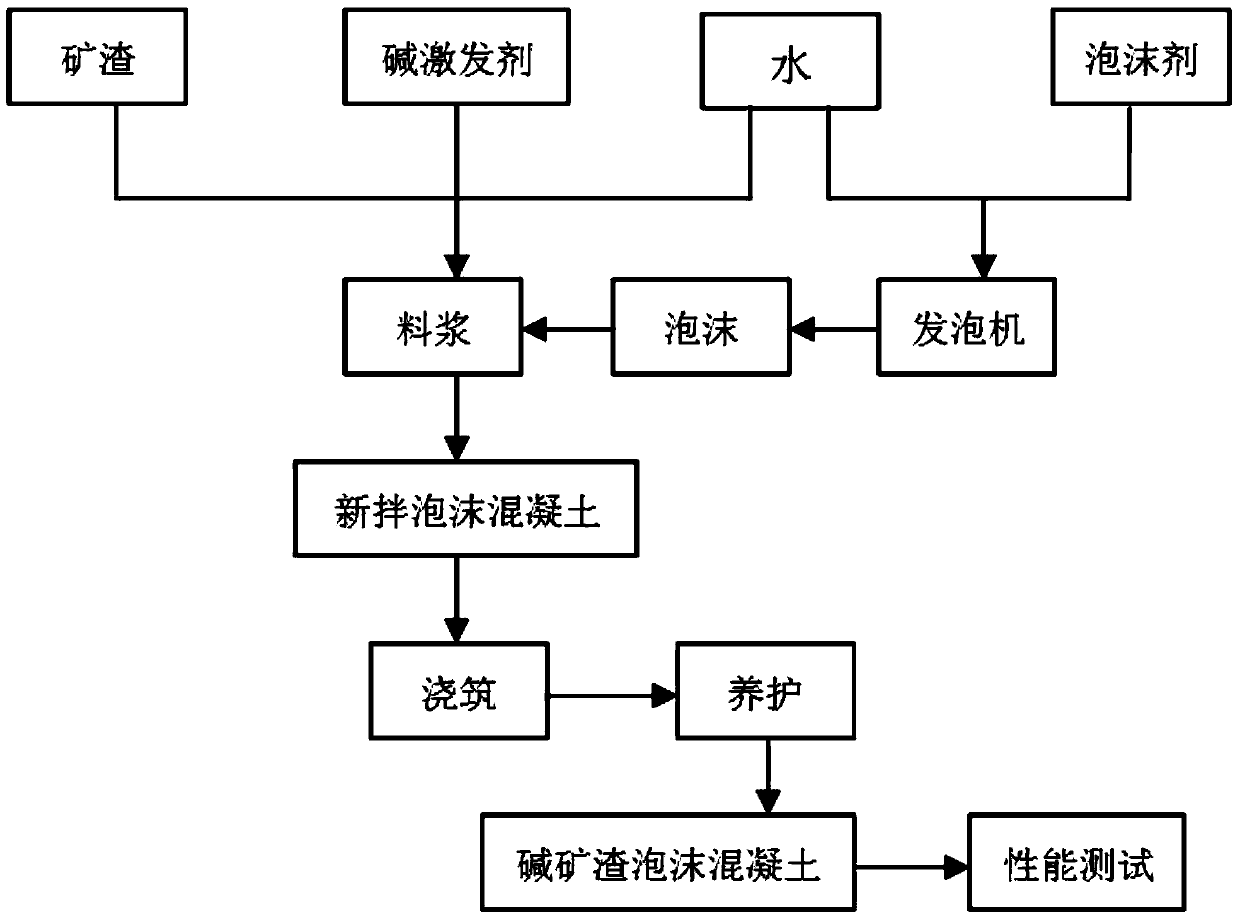

[0081] The method that present embodiment prepares alkali slag foamed concrete comprises the following steps:

[0082] 1), select raw materials according to the proportion, the selected raw materials in this embodiment are: slag: 63-65 parts; NaOH: 5-6 parts; water: 25-26 parts; foaming agent: 4.8-5.2 parts;

[0083] 2), mixing step 1) selected slag and alkali activator and add water and stir;

[0084] 3), add water to the foaming agent selected in step 1) and perform foaming treatment;

[0085] 4), the foam obtained in step 3) is added to the alkali slag slurry obtained in step 2), and the two are stirred until uniformly mixed;

[0086] 5), pouring and curing alkali slag foam concrete.

[0087] In this example:

[0088] The slag is water-quenched blast furnace slag, and its specific surface area is 440-460m 2 / kg, the density is 2.85-2.95g / cm 3 , Alkalinity coefficient M 0 =0.95~1.05, activity coefficient M a =0.42~0.48, quality factor M k =1.65~1.85;

[0089] The sl...

Embodiment 2

[0091] The method that present embodiment prepares alkali slag foamed concrete comprises the following steps:

[0092] 1), select raw material according to proportioning, the selected raw material of this embodiment is: slag: 60~61 parts; Water glass: 10~11 parts; Water: 24~25 parts; Foaming agent: 5.0~5.4 parts;

[0093] 2), mixing step 1) selected slag and alkali activator and add water and stir;

[0094] 3), add water to the foaming agent selected in step 1) and perform foaming treatment;

[0095] 4), the foam obtained in step 3) is added to the alkali slag slurry obtained in step 2), and the two are stirred until uniformly mixed;

[0096] 5), pouring and curing alkali slag foam concrete.

[0097] In this example:

[0098] The slag is water-quenched blast furnace slag, and its specific surface area is 440-460m 2 / kg, the density is 2.85-2.95g / cm 3 , Alkalinity coefficient M 0 =0.95~1.05, activity coefficient M a =0.42~0.48, quality factor M k =1.65~1.85;

[0099] T...

Embodiment 3

[0104] The difference between this example and Example 1 is that the raw materials selected in this example are: slag: 62-63 parts; NaOH: 5-6 parts; water: 25-26 parts; foaming agent: 6.3-6.7 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com