Underwater non-dispersive quick-setting and rapid-hardening cement-based composite material and preparation method and application thereof

A composite material and cement-based technology, applied in the field of composite materials, can solve problems such as cracks, scouring pits, honeycombs, bridge deck collapse, and cultural relic damage, and achieve the effects of promoting early response, improving concrete strength, and sufficient supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

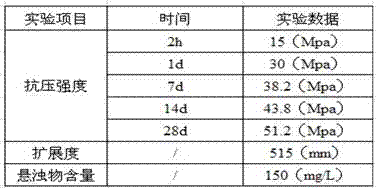

Examples

Embodiment 1

[0018] An underwater non-dispersible quick-setting quick-hardening repair cement-based composite material and a preparation method thereof, the materials used include calcium aluminate, ordinary Portland cement, magnesium oxide, sulfur trioxide, high-efficiency water reducer, and quick-setting agent Lithium carbonate, JM2000 new concrete air-entraining agent, calcium nitrite, acrylic flocculant, fine aggregate, coarse aggregate, water.

[0019] The proportioning and preparation method of various materials are as follows.

[0020] First mix 8.8% calcium aluminate, 32% ordinary Portland 42.5R cement, 5% magnesium oxide, 1.2% sulfur trioxide, 0.3% polycarboxylate high-performance water reducer, 0.2% carbonic acid Lithium, 0.7% acrylic flocculant UWB-Ⅱ, 0.2% JM2000 new concrete air-entraining agent, 0.3% calcium nitrite, 26% fine aggregate, 16.8% coarse aggregate; weighed and added to the mixing drum, Start the mixer to stir the materials evenly; then slowly add 8.5% water into t...

Embodiment 2

[0035] The underwater non-dispersible quick-setting and fast-hardening cement-based composite material is composed of the following raw materials in weight percentage: Portland cement 32.5%, calcium aluminate 9%, magnesium oxide 5%, sulfur trioxide 0.5%, polycarboxylic acid High-performance water reducing agent 0.2%, acrylic flocculant UWB-Ⅱ 0.3%, lithium carbonate 0.15%, JM2000 new concrete air-entraining agent 0.05%, calcium nitrite 0.3%, fine aggregate 28.5%, coarse aggregate 15% , 8.5% water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com