Industrial waste residue dry-mixed mortar

A technology for dry-mixing mortar and industrial waste residues, applied in the field of building materials, can solve problems such as limited utilization, and achieve the effects of rich material sources, high production costs, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

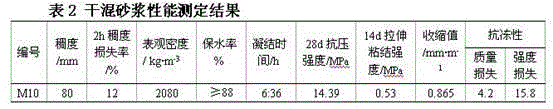

[0028] Example 1: A dry-mixed masonry mortar such as M10, which is mainly composed of cement, phosphorus slag powder, fly ash, composite activator, composite admixture and sand, and the ratio of the cementitious material is: cement 20 parts, 40 parts of phosphorus slag powder, 40 parts of fly ash, 0.5 parts of sodium sulfate, 3 parts of desulfurized gypsum, 5 parts of slaked lime powder, and 1 part of Nai series water reducer to prepare dry-mixed mortar, and the lime-sand ratio is controlled Between 1:1 and 1:6, the water consumption should be controlled at a consistency of 70 to 90 mm. The test uses a standard specimen size of 70.7mm×70.7mm×70.7mm. The test of time and shrinkage value is carried out according to JGJ / T 70-2009 "Standard for Test Methods of Basic Properties of Building Mortar". The test mix ratio and test results are shown in Table 1 and Table 2.

[0029]

[0030] It can be seen from the above table that the 2h consistency loss rate, apparent density, wate...

example 2

[0031] Example 2: A dry-mixed plastering mortar such as M10, on the basis of the formula of Example 1, 0.1 part of cellulose ether and 1 part of redispersible latex powder are added to prepare a dry-mixed plastering mortar, and the lime-sand ratio is controlled at Between 1:1 and 1:6, the water consumption should be controlled at a consistency of 90 to 110 mm. The standard specimen size used in the test is 70.7mm×70.7mm×70.7mm. The compressive strength, setting time, and shrinkage of the mortar The value test is carried out with reference to JGJ / T 70-2009 "Standard for Basic Performance Test Methods of Building Mortar". The test results are shown in Table 3.

[0032]

[0033] It can be seen from Table 3 that the 2h consistency loss rate, apparent density, setting time, water retention rate, strength and other properties of the above mix ratios all meet the requirements of GB / T25181-2010 "Ready Mixed Mortar".

[0034]

[0035] In the industrial waste slag dry-mixed mortar o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com