Modified calcium oxide expanding clinker as well as preparation method and application thereof

A technology of expanding clinker and calcium oxide, which is applied in the field of its preparation and modified calcium oxide expanding clinker, which can solve the problem of weak shrinkage compensation ability, fast hydration speed, poor weathering resistance and moisture resistance of calcium oxide expanding clinker and other issues, to achieve the effects of easy access, long shelf life, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of carbonation-coated modified calcium oxide expansion clinker (using commercially available calcium oxide expansion clinker as raw material)

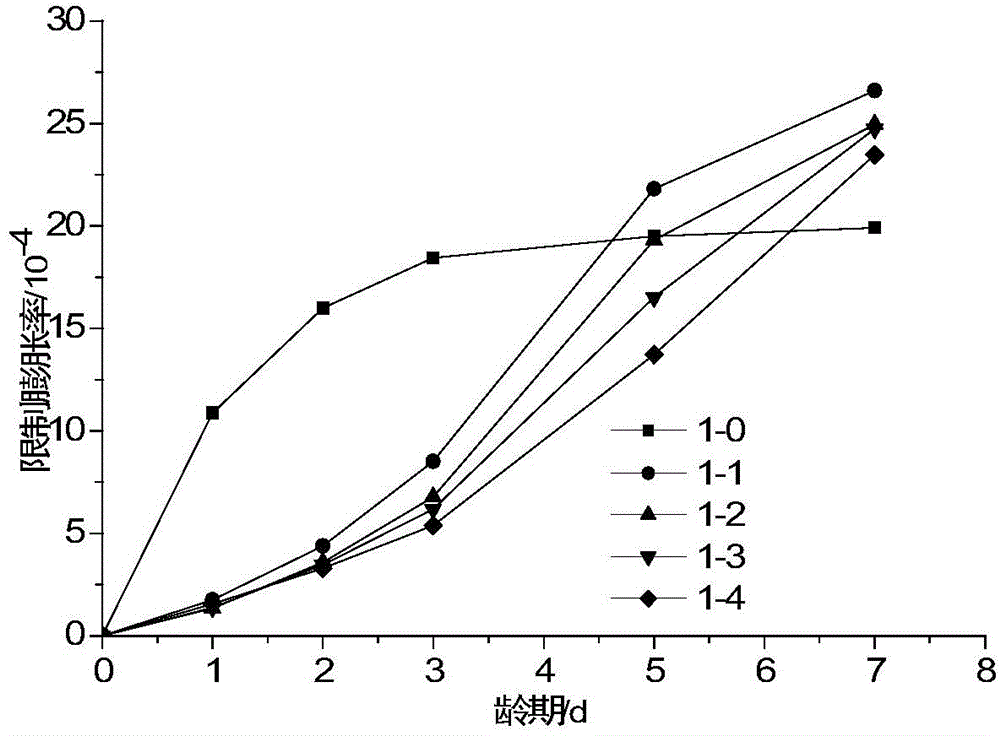

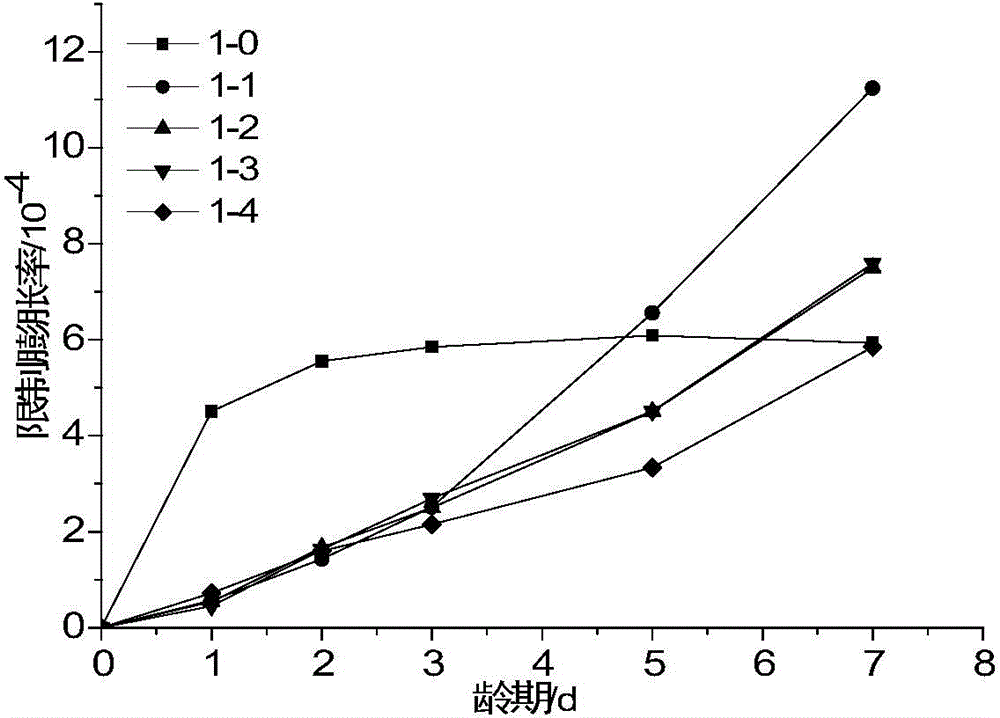

[0041] Commercially available calcium oxide expanded clinker is ground and crushed into a specific surface area of 350m 2 / kg of powder. Weigh 200g of clinker powder and put it into the reaction kettle and place it in the electric furnace; heat the furnace to the reaction temperature, and pass a certain humidity of CO 2 gas; when the temperature in the furnace drops to normal temperature, take out the reaction kettle filled with calcium oxide expansion clinker; weigh the quality of the modified calcium oxide expansion clinker to determine the degree of carbonation reaction and the amount of calcium carbonate generated. CO 2 The gas flow rate is 0.1L / min relative to the volume of 1L electric furnace, the reaction temperature is 110°C, the reaction time is 5min, 10min, 15min, and 30min, and the relative humidit...

Embodiment 2

[0058] (1) Preparation of carbonation-coated modified calcium oxide-based expanded clinker (mixed with limestone and composite mineralizer as raw material)

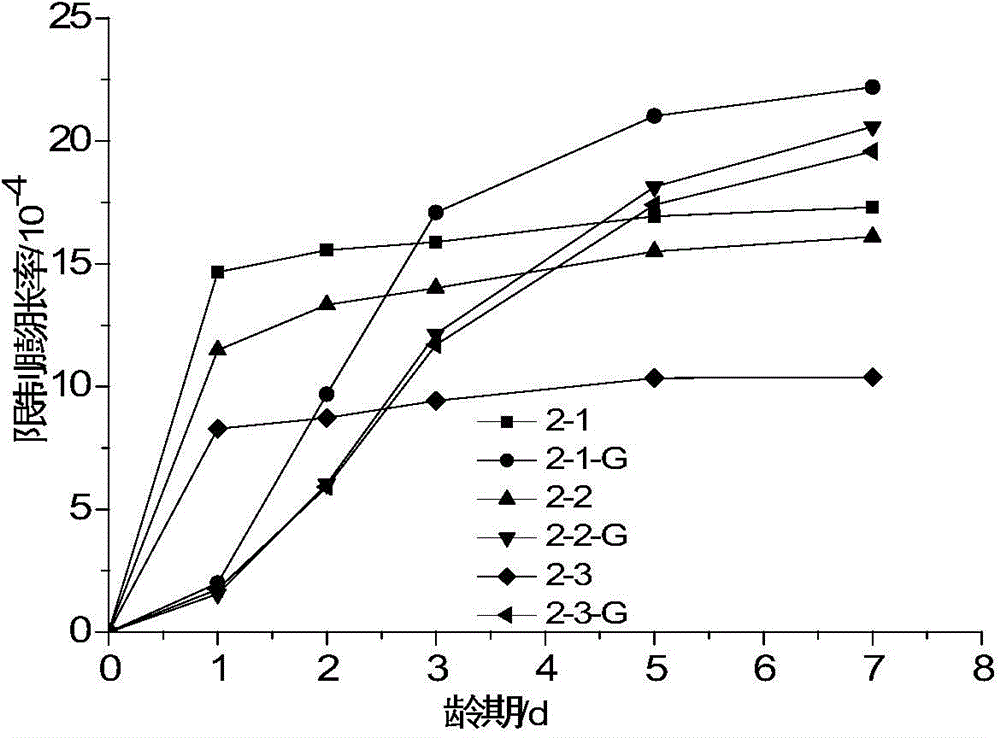

[0059] Mix limestone and compound mineralizer with a mass ratio of 90:10 (sample 2-1), 92:8 (sample 2-2) and 95:5 (sample 2-3) and grind them together with a ball mill to a fineness of 200m 2 / kg of raw meal powder, in which the composite mineralizer is composed of 50% gypsum and 50% copper slag. The ground raw meal powder was calcined at 1300°C, and kept at this temperature for 1 hour. After the heat preservation was completed, the fired sample was immediately taken out and quenched in the air, and the specific surface area was 250m2 after grinding. 2 / kg of calcium oxide expanded clinker powder. The reaction temperature of carbon dioxide gas and calcium oxide expanded clinker powder is 190° C., and the reaction time is 10 minutes. Except for the above, the carbonation surface treatment process is carried out in the sa...

Embodiment 3

[0074] (1) Preparation of carbonation-coated modified calcium oxide expansion clinker (using 6 types of calcium oxide expansion clinker as raw materials)

[0075] Six commercially available calcium oxide-based expanded clinkers were subjected to carbonation surface treatment. CO 2 The flow rate of gas is 0.05L / min relative to the volume of 1L electric furnace, the reaction temperature is 50°C, the reaction time is 15min, and the relative humidity of the gas is controlled at RH85%-90%. Except the above, the carbonation surface treatment process was carried out in the same manner as in Example 1.

[0076] Table 7 shows the chemical composition (wt.%) of the commercially available calcium oxide expanded clinker.

[0077]

[0078]

[0079] Table 8 shows the effect of carbonation modification on the coating amount of calcium carbonate on the surface of six commercially available calcium oxide-based expanded clinker powders (500g).

[0080]

[0081] Note: The amount of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com