Safe static breaking agent for coal mines

A static breaking agent and a safe technology, applied in blasting barrels, discharge machinery, attacking equipment, etc., can solve problems such as the first condensation of the breaking agent, the inability to use the mixer, and the long construction distance, etc., to achieve the effect of slowing down the hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the special safe static crushing agent for coal mines, firstly, mix heavy calcium powder and silicon oxide evenly, add appropriate amount of water to make a cake, put it into a sintering furnace and burn it, and then grind the medicine cake into a powder of about 200 meshes, and The powder is packed into a prefabricated packaging cylinder and packaged into a drug column, weighed and packaged in a plastic bag for moisture-proof storage.

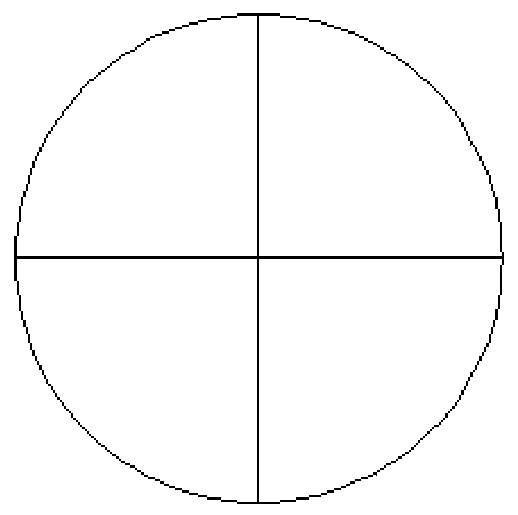

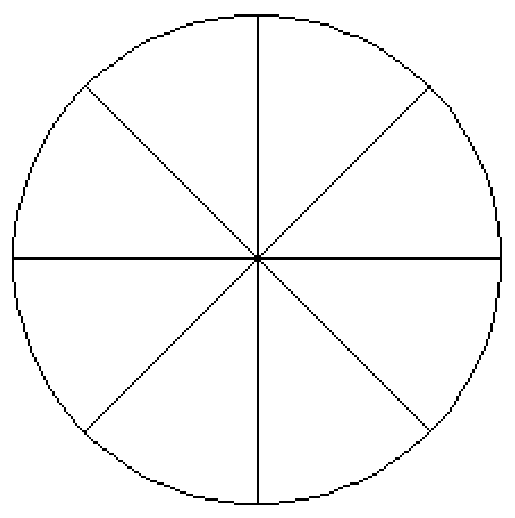

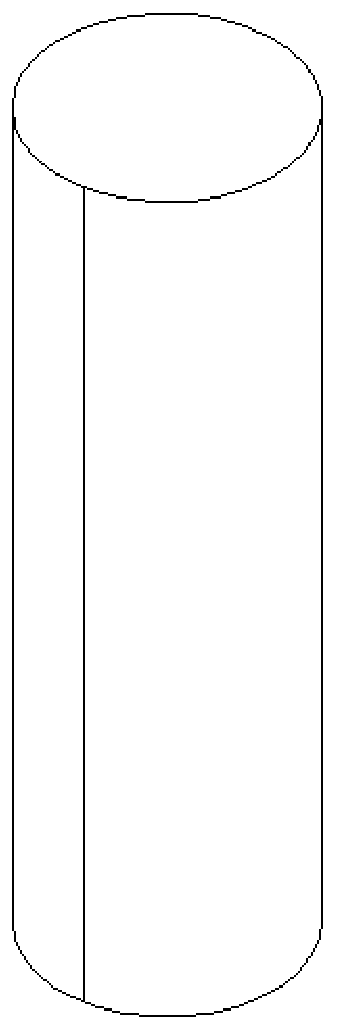

[0029] The packing column mainly includes a paper body, a base, a paper cover, and a grid, and the material is a paper product that has water permeability and is not soft when soaked in water. The length of the paper body is determined by the length of the hole, generally 10mm to 20mm. The grid is placed inside the grain. The structure adopts eight or four petals, which is determined by the diameter of the grain. The diameter of the grain is related to the actual hole size.

[0030] The method of using the spec...

Embodiment 1

[0033] The special safe static breaker for coal mines of this implementation example, its sintering raw materials are made of the following raw materials in parts by weight: heavy calcium powder 1.74Kg, silicon oxide 0.06Kg, iron oxide 0.08Kg, aluminum oxide 0.13Kg. The packing diameter of the powder column is 38mm.

[0034] The preparation method steps of the safety static crushing agent special for coal mine of this embodiment example are as follows: First, mix the heavy calcium powder and silicon oxide together and add an appropriate amount of water to make a cake, put it into a sintering furnace and burn it, and then grind the medicine cake into 200 Pack the powder into a prefabricated packaging cylinder to form a powder, weigh it and put it in a plastic bag, and store it away from moisture.

[0035] In this example, the method of using the special safe static crushing agent for coal mines is firstly to mix heavy calcium powder and additives evenly, add appropriate amount ...

Embodiment 2

[0037] The special safe static breaking agent for coal mines of this embodiment, its sintering raw material is to be made by the raw material of following parts by weight: heavy calcium powder 13.05Kg, silicon oxide 0.45Kg, iron oxide 0.6Kg, aluminum oxide 0.9Kg. The packing diameter of the powder column is 34mm.

[0038] The steps of preparation and use of the safe static crushing agent for coal mines in this implementation example are as follows: First, mix the heavy calcium powder and additives evenly, add an appropriate amount of water to make a cake, put it into a sintering furnace and burn it at 1400 ° C to 1500 ° C , and then grind the medicine cake into a powder of about 200 meshes, pack the powder into a prefabricated packaging cylinder to form a medicine column, weigh it and put it in a plastic bag, and store it away from moisture. When in use, soak the powder column with an appropriate amount of water, pound it into the drilled hole after reaching the required water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com