A low-shrinkage and low-creep concrete composite additive suitable for early-age prestressed tension

A composite additive and prestressing technology, which is used in the field of low shrinkage and low creep concrete composite additives and functional additive materials for building concrete, can solve the problems of easy cracking and seepage, tension and creep, complex stress, etc., and enhance the anti-settling ability. , Improve the compactness and ease the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

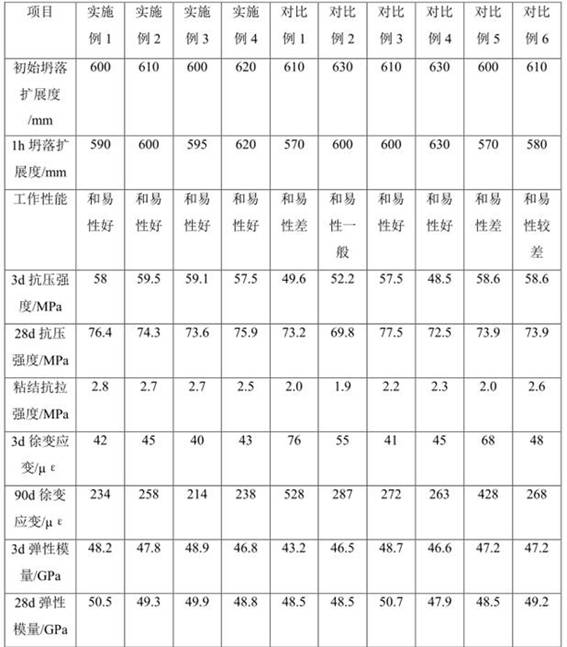

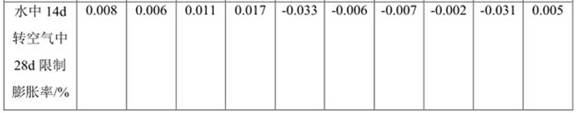

Examples

Embodiment 1

[0018] Example 1: Preparation of low-shrinkage and low-creep concrete composite additives suitable for early-age prestressed tension: 80 parts of anhydrous calcium sulfoaluminate clinker (80% content of anhydrous calcium sulfoaluminate), 5 parts of calcium sulfate 10 parts of silica fume (particle size 0.2 μm), 1 part of lithium carbonate, 1 part of triisopropanolamine, 0.1 part of anti-settling agent (D-glucose:D-galactose=4:6), styrene-butylene Diene copolymer (AXILAT PSB 150 from Hexion, USA) 3 parts, mixed and ground to a specific surface area of 2000cm 2 / g of powder.

[0019] Preparation of C60 low shrinkage and low creep wet joint concrete: P·O52.5 ordinary portland cement 280kg / m 3 , Class I fly ash 65 kg / m 3 、S95 mineral powder 65 kg / m 3 , Low shrinkage and low creep concrete composite additive suitable for early prestressed tension 80kg / m 3 , medium sand 720kg / m 3 , 4.75~9.5mm gravel 226kg / m 3 , 9.5-20mm gravel 903kg / m 3 , slow-release polycarboxylate superp...

Embodiment 2

[0020] Example 2: Preparation of low-shrinkage and low-creep concrete composite additives suitable for early-age prestressed tension: 60 parts of anhydrous calcium sulfoaluminate clinker (80% content of anhydrous calcium sulfoaluminate), 20 parts of calcium sulfate 10 parts of silica fume (particle size 0.2 μm), 2 parts of lithium carbonate, 3 parts of triisopropanolamine, 0.1 part of anti-settling agent (D-glucose:D-galactose=6:4), styrene-butylene Diene copolymer (AXILAT PSB 150 from Hexion, USA) 5 parts, mixed and ground to a specific surface area of 2000cm 2 / g of powder.

[0021] Preparation of C60 low shrinkage and low creep wet joint concrete: P·O52.5 ordinary portland cement 280kg / m 3 , Class I fly ash 65 kg / m 3 、S95 mineral powder 65 kg / m 3 , Low shrinkage and low creep concrete composite additive suitable for early prestressed tension 80kg / m 3 , medium sand 720kg / m 3 , 4.75-9.5mm gravel 226kg / m 3 , 9.5~20mm gravel 903kg / m 3 , slow-release polycarboxylate super...

Embodiment 3

[0022] Example 3: Preparation of low-shrinkage and low-creep concrete composite additives suitable for early-age prestressed tension: 70 parts of anhydrous calcium sulfoaluminate clinker (content of anhydrous calcium sulfoaluminate 70%), 10 parts of calcium sulfate 12 parts of silica fume (particle size 0.1 μm), 1 part of lithium carbonate, 2 parts of triisopropanolamine, 0.2 parts of anti-sedimentation agent (D-glucose:D-galactose=4:6), styrene-butylene 5 parts of diene copolymer (AXILAT PSB 150 from Hexion, USA), mixed and ground to a specific surface area of 2200cm 2 / g of powder.

[0023] Preparation of C60 low shrinkage and low creep wet joint concrete: P·O52.5 ordinary portland cement 280kg / m 3 , Class I fly ash 65 kg / m 3 、S95 mineral powder 65 kg / m 3 , Low shrinkage and low creep concrete composite additive suitable for early prestressed tension 80kg / m 3 , medium sand 720kg / m 3 , 4.75-9.5mm gravel 226kg / m 3 , 9.5~20mm gravel 903kg / m 3 , slow-release polycarboxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com