A kind of anti-salt erosion concrete and preparation method thereof

A concrete and nano-clay technology, applied in the field of concrete, can solve problems such as wind erosion, freeze-thaw, increase of corrosion salt, concrete structure damage, etc., and achieve the effects of resisting erosion, prolonging service life, and eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the salt erosion-resistant concrete described in the above technical solution, comprising the following steps:

[0034] After mixing stones, sand, cement, nanoclay, water reducer, thickener, defoamer, air-entraining agent and water, molding, demoulding and curing are carried out in sequence to obtain salt erosion resistant concrete.

[0035] In the present invention, the mixing is preferably:

[0036] Mix the sand, stones and the first part of water, and then mix them with cement, so that the surface of the sand and stones is covered with a layer of cement slurry film to form a sand-cement mixture;

[0037] mixing the nanoclay with a second portion of water to form a nanoclay dispersion;

[0038] Mix sandstone cement mixture, nanoclay dispersion liquid, water reducer, thickener, defoamer, air entraining agent and remaining water to form a mixed material.

[0039] In the present invention, the first part of wa...

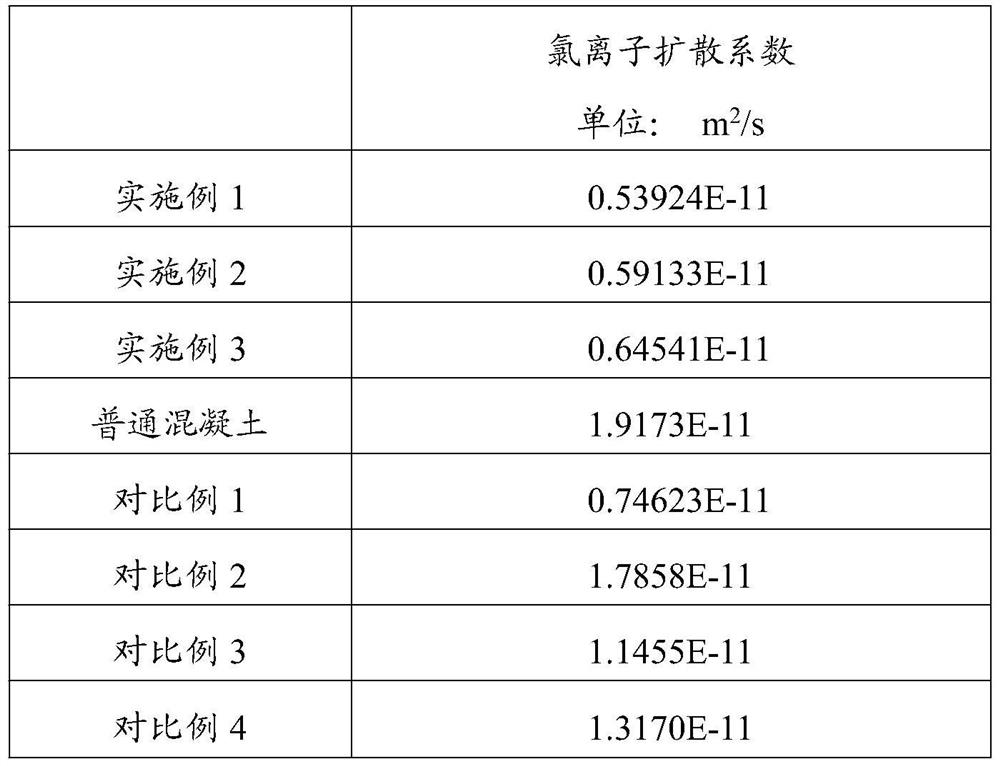

Embodiment 1

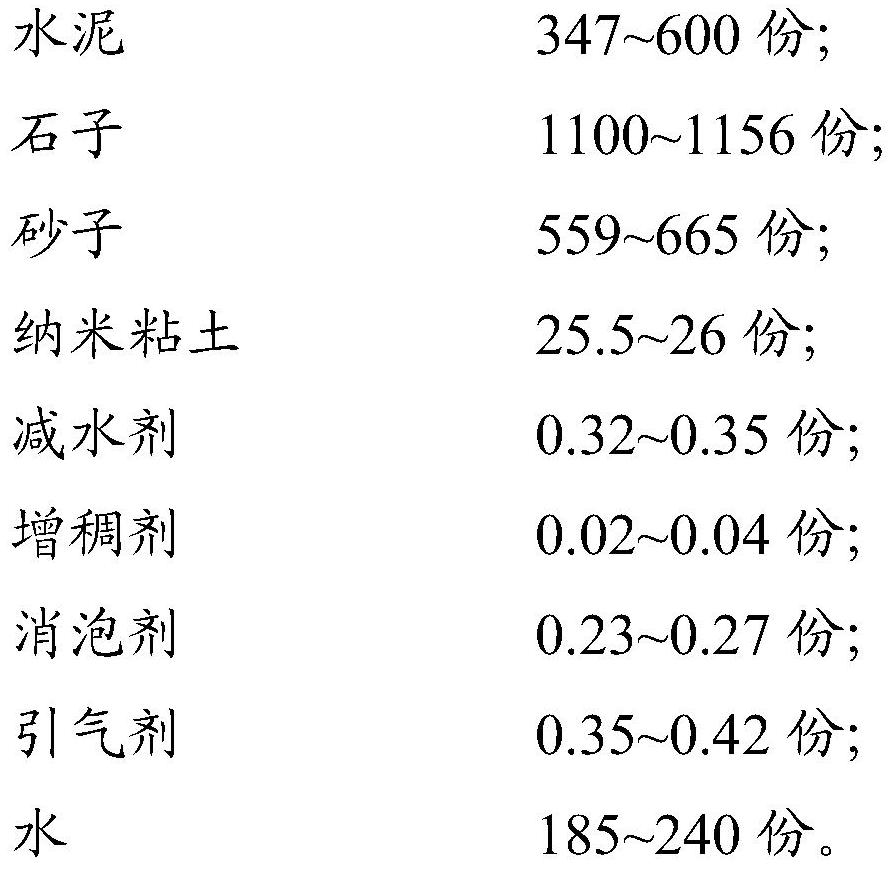

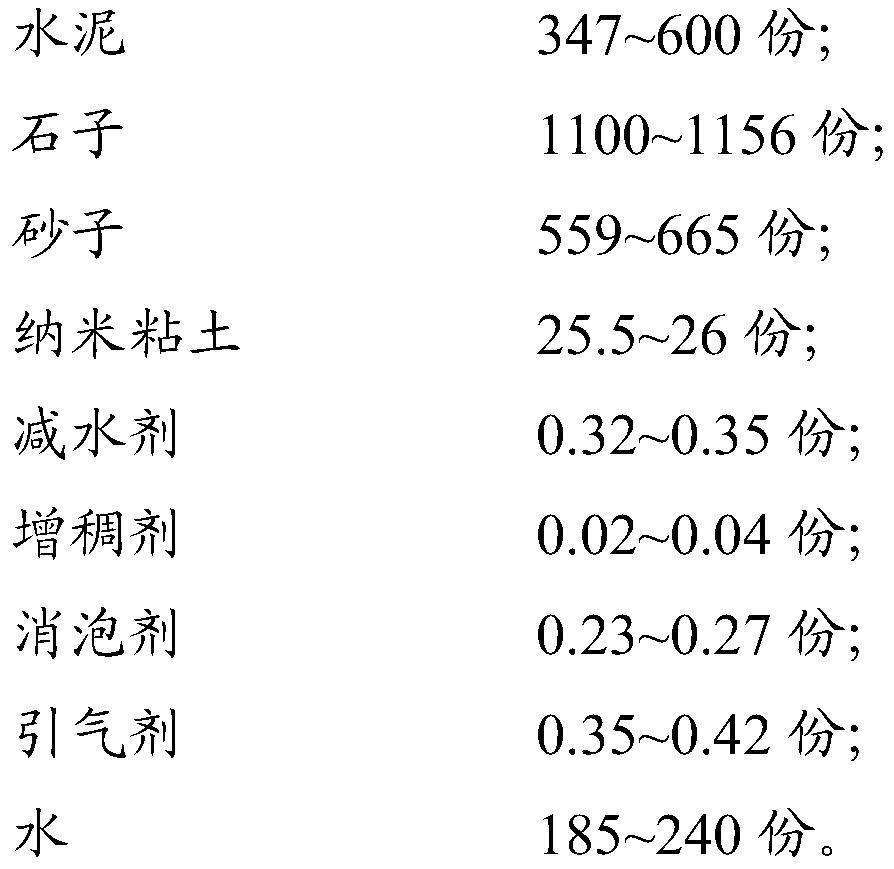

[0046] A kind of salt corrosion resistant concrete, the mix ratio of each component is as follows:

[0047] Cement 570kg / m 3 , P.O42.5R ordinary Portland cement, the strength grade is 42.5R;

[0048] Stone 1104kg / m 3 , produced in Tongliao, Inner Mongolia, high-quality crushed stone, with a particle size of 5-25mm;

[0049] Sand 660kg / m 3 , produced from high-quality medium sand in the Ordos area of Inner Mongolia, with a fineness modulus of 2.3-3.0;

[0050] Water 228kg / m 3 ;

[0051] Nano kaolin 5.7kg / m 3 , produced in the plateau mineral products processing plant, with a fineness of 50-80nm;

[0052] Nano montmorillonite 4.9kg / m 3 , nano-bentonite 6.8kg / m 3 , nano-montmorillonite and nano-bentonite are produced in plateau mineral product processing plants, with a fineness of 100-200nm;

[0053] Activated nano attapulgite 8.4kg / m 3 , using Changzhou Mineral Products Technology Co., Ltd. to produce raw ore and high-viscosity ore. The ore source is Xuyi County, Ji...

Embodiment 2

[0065] A kind of salt corrosion resistant concrete, the mix ratio of each component is as follows:

[0066] Cement 347kg / m 3 , P.O42.5R ordinary Portland cement, the strength grade is 42.5R;

[0067] Stone 1156kg / m 3 , produced in Tongliao, Inner Mongolia, high-quality crushed stone, with a particle size of 5-25mm;

[0068] Sand 580kg / m 3 , produced from high-quality medium sand in the Ordos area of Inner Mongolia, with a fineness modulus of 2.3-3.0;

[0069] Water 234kg / m 3 ;

[0070] Nano kaolin 5.7kg / m 3 , produced in the plateau mineral products processing plant, with a fineness of 50-80nm;

[0071] Nano montmorillonite 4.9kg / m 3 ,

[0072] Nano bentonite 6.8kg / m 3 , nano-montmorillonite and nano-bentonite are produced in plateau mineral product processing plants, with a fineness of 100-200nm;

[0073] Activated nano attapulgite 8.4kg / m 3 , using Changzhou Mineral Products Technology Co., Ltd. to produce raw ore and high-viscosity ore. The ore source is Xuyi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com