Proportioning method for novel C25 concrete applied to downhole floor pouring

A new type of concrete technology, which is applied in the field of concrete preparation and concrete proportioning, can solve the problems of high compressive strength of concrete, affecting concrete compressive strength, and uneven floor potholes, so as to improve durability, prevent cracks, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

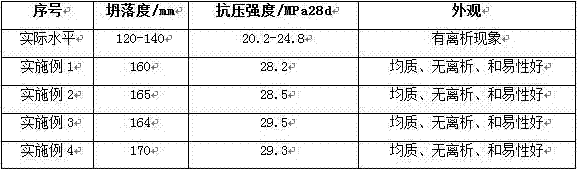

Embodiment 1

[0042] A new type of C25 concrete proportioning method for underground floor pouring. The mass ratio of cement, gravity-selected iron tailings, yellow sand, stones, water, high-efficiency water reducer, and steel fiber in the concrete is 396:411:380:793:221 :5:56, the sand is medium-coarse sand, the sand is medium-coarse sand without deducting the water content, the water is the water content without adding sand, the cement is P.042.5 grade cement, and the particle size of the stone is 15mm-20mm. The superplasticizer is Star build HP350 (star standard HP350) high-efficiency concrete superplasticizer (PH value 11.2, density 1.220 / ml, solid content 31.5%, chloride ion content ≦ 1.0%, alkali content ≦ 8.0%, net slurry fluidity ≧ 120mm, mortar water-reducing rate≧18%, product inspection standard conforms to GB / T 8077-2000), steel fiber is long straight steel fiber with circular cross section, length is 40~60mm, diameter is 0.2~0.6mm, long diameter The ratio is 40~100. The slump o...

Embodiment 2

[0044] A new type of C25 concrete proportioning method for underground floor pouring. The mass ratio of cement, gravity-selected iron tailings, yellow sand, stones, water, high-efficiency water reducer and steel fiber in the concrete is 394:412:383:794:222 :4.5:58, the sand is medium-coarse sand, the sand is medium-coarse sand without deducting the water content, the water is the water content without sand, the cement is P.042.5 grade cement, and the particle size of the stone is 15mm-20mm. The superplasticizer is Star build HP350 (star standard HP350) high-efficiency concrete superplasticizer (PH value 11.5, density 1.190 / ml, solid content 31.7%, chloride ion content ≦ 1.0%, alkali content ≦ 8.0%, net slurry fluidity ≧ 120mm, mortar water-reducing rate≧18%, product inspection standard conforms to GB / T 8077-2000), steel fiber is long straight steel fiber with circular cross section, length is 40~60mm, diameter is 0.2~0.6mm, long diameter The ratio is 40~100. The slump of the ...

Embodiment 3

[0046] A new type of C25 concrete proportioning method for underground floor pouring. The mass ratio of cement, gravity-selected iron tailings, yellow sand, stones, water, high-efficiency water reducer and steel fiber in the concrete is 396:414:385:796:220 :4.8:60, the sand is medium-coarse sand, the sand is medium-coarse sand without water content deducted, the water is the water content without sand, the cement is P.042.5 grade cement, and the particle size of the stone is 15mm-20mm. The superplasticizer is Star build HP350 (star standard HP350) high-efficiency concrete superplasticizer (PH value 11.8, density 1.180 / ml, solid content 32.0%, chloride ion content ≦ 1.0%, alkali content ≦ 8.0%, net slurry fluidity ≧ 120mm, mortar water-reducing rate≧18%, product inspection standard conforms to GB / T 8077-2000), steel fiber is long straight steel fiber with circular cross section, length is 40~60mm, diameter is 0.2~0.6mm, long diameter The ratio is 40~100. The slump of the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com