A kind of ground rice husk ash-based composite admixture and its application

A composite admixture, rice husk ash technology, applied in the field of building materials, can solve the problem of not giving a guidance plan, reduce early hydration heat and other problems, and achieve the effects of improving work performance, reducing early hydration heat, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

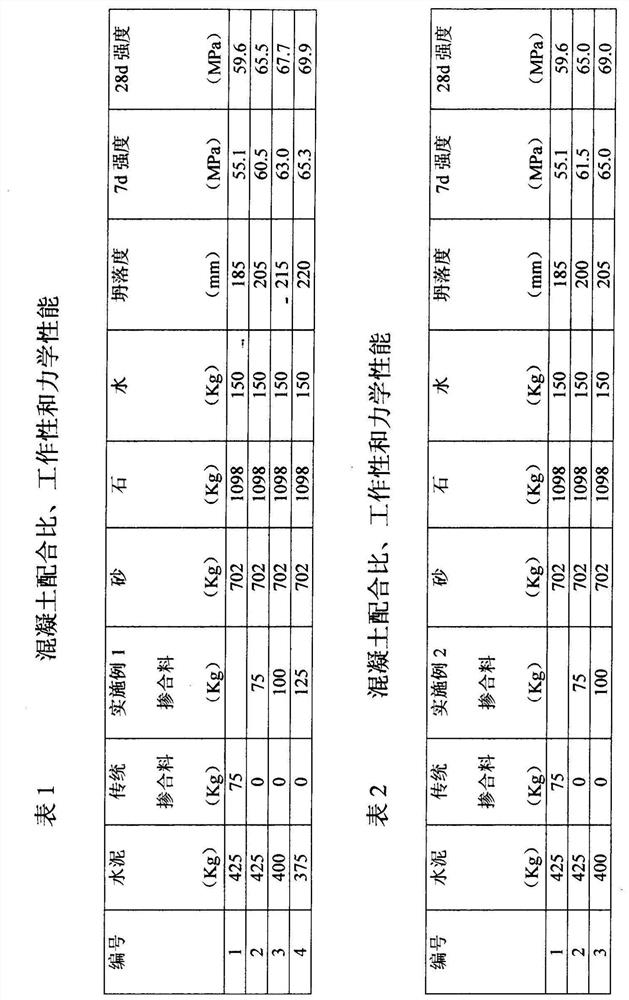

Embodiment 1

[0019] Embodiment 1: the ground rice husk ash-based composite admixture of the present invention is made of the following raw materials in mass percent: ground rice husk ash 30%, glass microspheres 30%, metakaolin 18%, Ultrafine silica fume 10%, steel slag 5%, limestone powder 5%, activator 1.0%, superplasticizer 0.5%, reinforcing agent 0.5%.

[0020] The above-mentioned ground rice husk ash is a powder with a loss on ignition ≤ 10% made of rice husk after being calcined at 600°C to 610°C for 2 hours, then naturally cooled and ground; the above-mentioned glass microspheres are a kind of continuous particle size distribution The ultra-fine glass sphere powder material is formed by sinking beads, and its particle size is D50, that is, the median diameter is ≤3.0um; the above-mentioned metakaolin is kaolin that is calcined at 800°C to 810°C for 2 hours and then finely ground. The particle size D50 is the median diameter D50≤10um; the silicon dioxide content in the above-mentioned...

Embodiment 2

[0022] Embodiment 2: The ground rice husk ash-based composite admixture of the present invention is made of the following raw materials in mass percent: ground rice husk ash 35%, glass microspheres 20%, metakaolin 20%, Ultrafine silica fume 15%, steel slag 5%, limestone powder 3%, activator 0.5%, superplasticizer 0.7%, reinforcing agent 0.8%.

[0023] The above-mentioned ground rice husk ash is a powder with a loss on ignition ≤ 10% made of rice husk after being calcined at a high temperature of 690°C to 700°C for 2 hours, then ground naturally; The ultra-fine glass sphere powder material is a composition formed of two raw materials, sinking beads and floating beads. The mass ratio of sinking beads and floating beads is 1:3. The particle size of glass beads is D50, that is, the median diameter is ≤ 3.0um; the above-mentioned metakaolin is made by kaolin calcined at 890°C to 900°C for 2 hours and then ground, and its particle size is D50, that is, the median diameter D50≤10um; ...

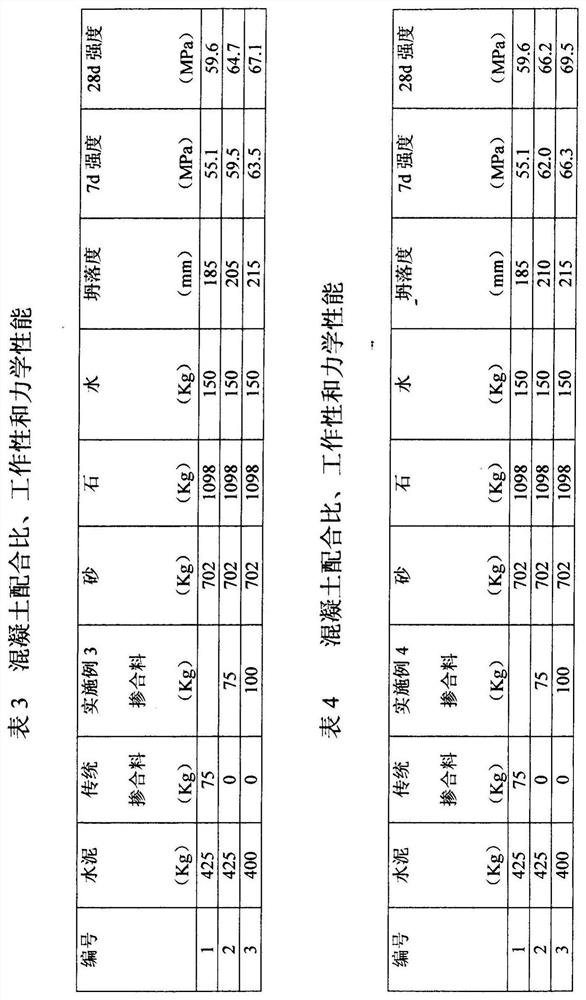

Embodiment 3

[0025] Embodiment 3: the ground rice husk ash-based composite admixture of the present invention is made of the following raw materials in mass percent: ground rice husk ash 40%, glass microspheres 22%, metakaolin 15%, Ultrafine silica fume 8%, steel slag 7%, limestone powder 5%, activator 0.5%, superplasticizer 0.5%, reinforcing agent 2.0%.

[0026] The above-mentioned ground rice husk ash is a powder with a loss on ignition ≤ 10% made of rice husk after being calcined at 630°C to 640°C for 2 hours and then ground naturally; The ultra-fine glass sphere powder material is a kind of raw material of floating beads, and its particle size is D50, that is, the median diameter is ≤3.0um; the above-mentioned metakaolin is made of kaolin after being calcined at 850°C to 860°C for 2 hours and then finely ground. , the particle size D50 is the median diameter D50≤10um; the silicon dioxide content in the above-mentioned ultrafine silica fume is 90%-98%, and the specific surface area is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com