High-performance sulfur concrete and preparation method thereof

A sulfur concrete, high-performance technology, applied in the field of building materials, can solve the problems of high storage and processing costs, reduced concrete performance, toxic and harmful gases, etc., to reduce early hydration heat, improve cohesive force, and improve hydration degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

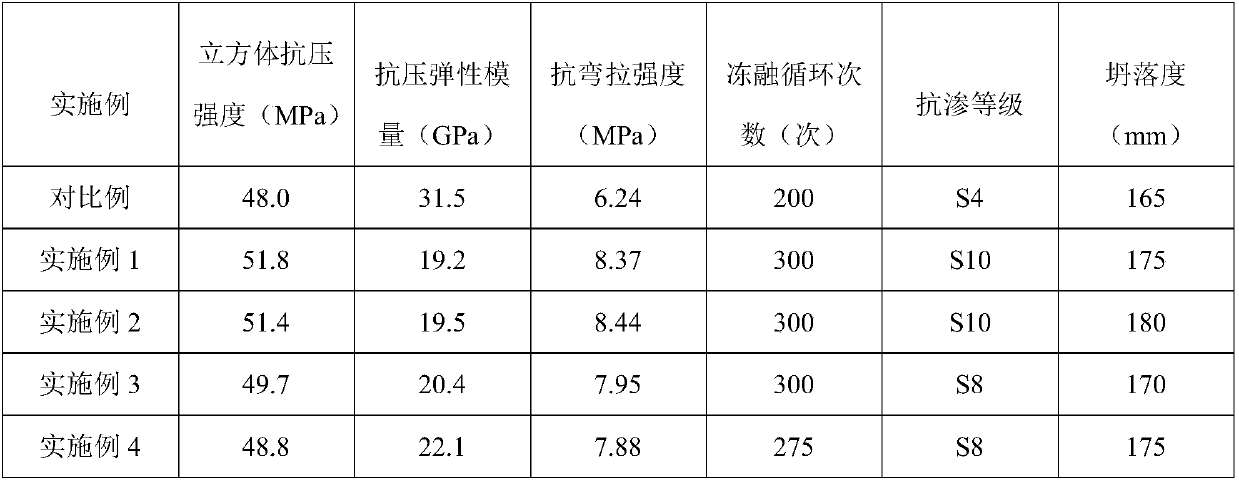

Examples

preparation example Construction

[0031] A preparation method of high-performance sulfur concrete, comprising the following steps:

[0032] 1) Weigh each raw material respectively according to the mass ratio of the above-mentioned raw materials;

[0033] 2) Sodium dodecylbenzenesulfonate and sodium carboxymethyl cellulose are prepared into a 2% aqueous solution, which is denoted as a and set aside;

[0034]3) Add sulfur into solution a, stir evenly with a magnetic stirrer, keep stirring and slowly add triglyceride fatty acid ester, let stand for 30min, record as b, and set aside.

[0035] 4) Stir and mix components A and B of the resin emulsion at room temperature, record as c, and set aside.

[0036] 5) Mix the remaining water and water reducer evenly, record it as d, and set aside.

[0037] 6) Mix the cement and river sand evenly, and add d, b, and c successively to stir and mix evenly and form it to obtain a high-performance sulfur concrete.

Embodiment 1

[0040] A kind of high-performance sulfur concrete given in this embodiment is composed of the following raw materials in terms of weight percentage: 34% cement; 41% river sand; 13.1% water; 0.6% water reducer; 10% sulfur powder; emulsifying dispersant 0.3%; resin emulsion 1%. The sum of the weight percentages of raw materials is 100%.

[0041] Among them, the sodium dodecylbenzenesulfonate in the emulsifying dispersant is 25%, the sodium carboxymethylcellulose is 25%, and the triglyceride fatty acid ester is 50%; the contents of components A and B in the resin emulsion are 35% and 65% respectively .

[0042] The preparation method of the above-mentioned high-performance sulfur concrete is carried out according to the following steps:

[0043] Step 1, weigh each raw material respectively according to the mass ratio of the above-mentioned raw materials, and set aside;

[0044] Step 2, preparing sodium dodecylbenzenesulfonate and sodium carboxymethylcellulose into a 2% aqueous...

Embodiment 2

[0050] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The high-performance sulfur concrete is composed of the following raw materials in terms of weight percentage: 30% cement; 41.5% river sand; 11% water; 0.8% water reducing agent; 15% sulfur powder; 0.5% emulsifying and dispersing agent; resin emulsion 1.2%. The sum of the weight percentages of raw materials is 100%.

[0051] Among them, the sodium dodecylbenzenesulfonate in the emulsifying dispersant is 20%, the sodium carboxymethylcellulose is 25%, and the triglyceride fatty acid ester is 55%; the contents of components A and B in the resin emulsion are 40% and 60% respectively .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com