Cement-based material carbon sequestration internal curing agent as well as preparation and application thereof

A technology of cement-based materials and curing agents, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as high cost, insufficient maintenance effect, and few types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of a cement-based material carbon-fixing internal curing agent, the specific steps are as follows:

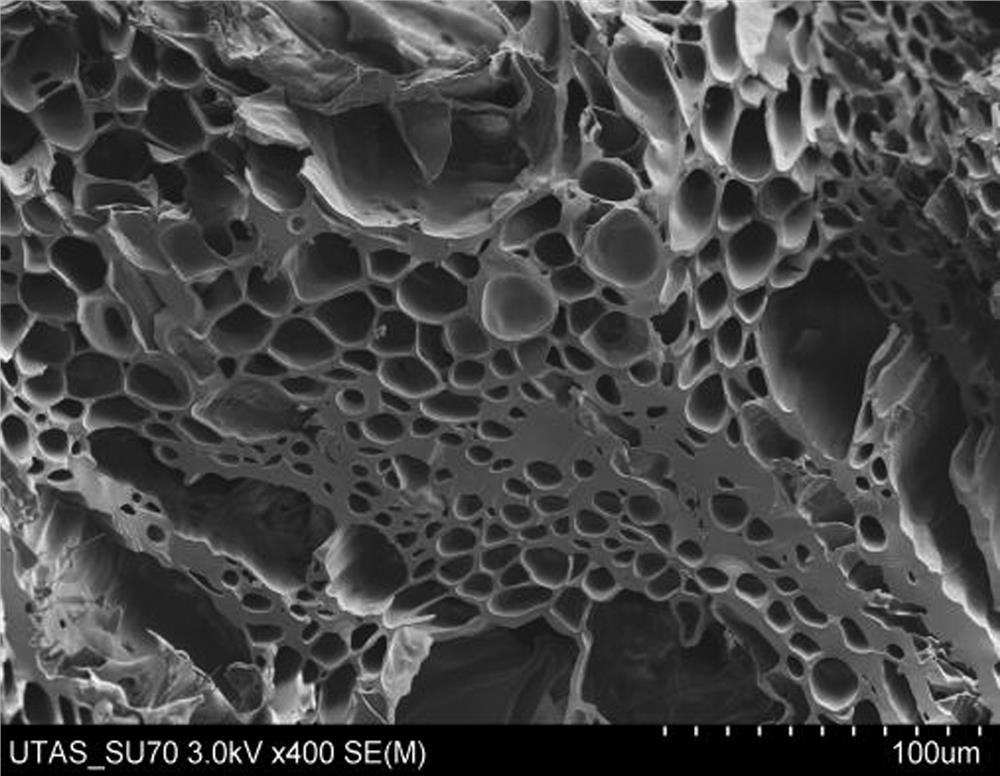

[0025] (1) Preparation of biochar: Using waste wood as raw material, the wood was cut into cubes, pre-dried in a room with a temperature of 22 °C and a relative humidity of 65%, and then placed in a temperature-controlled muffle furnace for heating. Then, the temperature was raised to 500°C at 10°C / min and then kept for 2 hours to completely carbonize it into biochar, and it was taken out after cooling.

[0026] (2) Biochar modification: block biochar was soaked in saturated lime aqueous solution for 24 h, dried in an oven at 95 °C, and then ground with a flying knife mill for 4 min to obtain modified biochar powder particles.

[0027] The modified biochar powder particles obtained above were mixed into cement mortar with a water-cement ratio of 0.4 instead of 1% cement by mass. Compared with pure cement mortar without internal curing agent, the comp...

Embodiment 2

[0029] A preparation method of a cement-based material carbon-fixing internal curing agent, the specific steps are as follows:

[0030] (1) Preparation of biochar: Using waste wood as raw material, the wood was cut into cubes, pre-dried in a room with a temperature of 22 °C and a relative humidity of 65%, and then placed in a temperature-controlled muffle furnace for heating. Then, the temperature was raised to 700°C at 10°C / min and then kept for 2 hours to completely carbonize it into biochar, and it was taken out after cooling.

[0031] (2) Biochar modification: block biochar was soaked in saturated lime aqueous solution for 48 h, dried in an oven at 95 °C, and then ground with a flying knife mill for 4 min to obtain modified biochar powder particles.

[0032] The modified biochar powder particles obtained above were mixed into cement mortar with a water-cement ratio of 0.5 instead of 5% cement by mass. The flexural strength is increased by 2%, and the autogenous shrinkage ...

Embodiment 3

[0034] A preparation method of a cement-based material carbon-fixing internal curing agent, the specific steps are as follows:

[0035] (1) Preparation of biochar: Using waste wood as raw material, the wood was cut into cubes, pre-dried in a room with a temperature of 22 °C and a relative humidity of 65%, and then placed in a temperature-controlled muffle furnace for heating. Then, the temperature was raised to 500°C at 10°C / min and then kept for 2 hours to completely carbonize it into biochar, and it was taken out after cooling.

[0036] (2) Biochar modification: block biochar was soaked in NaOH solution with a mass concentration of 1% for 24 hours, dried in an oven at a temperature of 95°C, and then ground with a flying knife mill for 4 minutes to obtain a modified biochar. Charcoal powder particles.

[0037] The modified biochar powder particles obtained above were mixed into cement mortar with a water-cement ratio of 0.5 instead of 3% cement by mass. Compared with pure ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com