Hydrangea flower-cluster-shaped bismuth tungstate/biocarbon composite photocatalytic material, preparation method and application thereof

A technology of composite photocatalysis and biochar, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of limiting the industrialization process of materials, expensive raw materials, and complicated preparation processes, etc. Effects of catalytic activity, simplified process, and wide light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention comprises the following steps:

[0033] (1) Peel off the white floc layer of the inner layer of pomelo peel and put it in a vacuum tube furnace with Ar gas, and calcine it at 500°C to 800°C for 60min to 90min to carbonize grapefruit peel to obtain grapefruit peel biological carbon material.

[0034] (2) biochar, analysis of pure bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) and sodium tungstate (Na 2 WO 4 2H 2 O), dissolved in a beaker of deionized water with magnetic stirring to make it fully dissolve, then add the surfactant cetyltrimethylammonium bromide (CTAB), and continue to dissolve with ultrasonic stirring; the precursor raw material Bi(NO 3 ) 3 ·5H 2 O, Na 2 WO 4 2H 2 The ratio between O, biochar and CTAB is (3~5)mmol: (1~3)mmol: (0.1~0.3)g: (1.2~1.8)mmol; Bi(NO 3 ) 3 ·5H 2 The ratio of O and water is (3-5) mmol: 40ml.

[0035] (3) Finally, adjust the pH range of the reaction precursor solution to 1-3 with ...

Embodiment 1

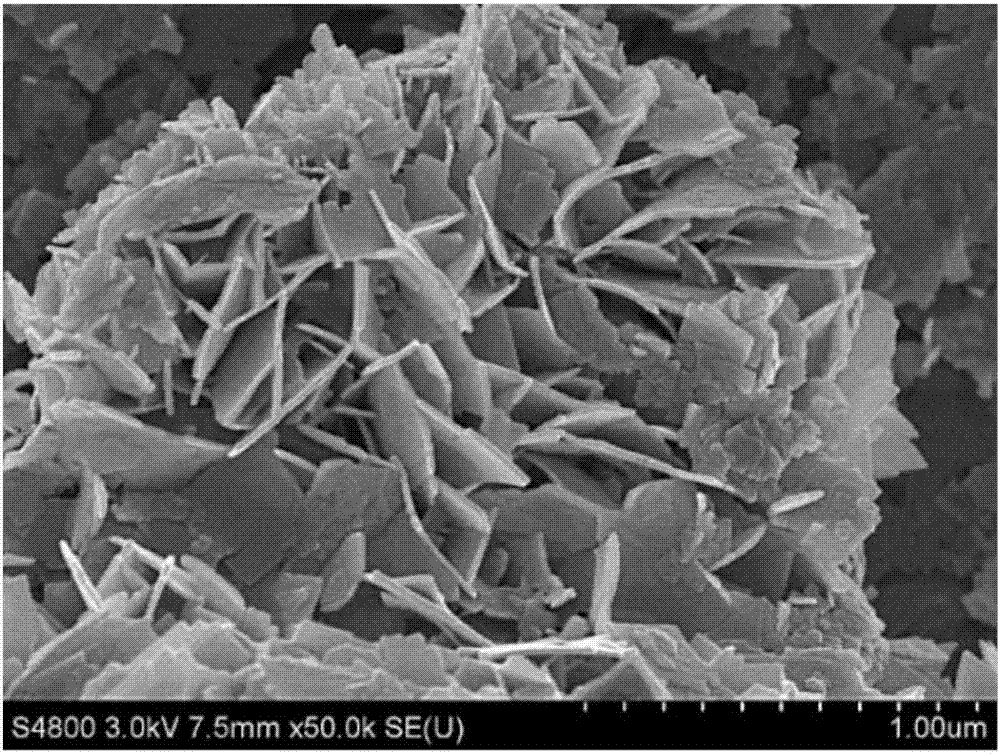

[0042] Hydrangea cluster Bi of the present invention 2 WO 6 / Biological charcoal composite photocatalytic material is based on pomelo peel as the raw material of biochar, with cationic surfactant cetyltrimethylammonium bromide (CTAB) as carrier or template agent, and bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) and sodium tungstate (Na 2 WO 4 2H 2 O) interactions between self-assembled to form a hydrangea cluster Bi with rich porous structure characteristics 2 WO 6 / biochar composite photocatalytic material.

[0043] Wherein, the ratio between bismuth nitrate, sodium tungstate, biochar and CTAB is 4mmol:2mmol:0.2g:1.6mmol.

[0044] A kind of hydrangea cluster Bi 2 WO 6 The preparation method of biochar composite photocatalytic material comprises the following steps:

[0045] (1) Peel off the white flocculent layer of the inner layer of pomelo peel, that is, the inner white fiber, and put it in a vacuum tube furnace with Ar gas for calcination at 800 °C for 60 min. After c...

Embodiment 2

[0071] (1) Peel off the white floc layer of the inner layer of pomelo peel, that is, the inner white fiber, put it in a vacuum tube furnace with Ar gas and calcinate at 500 °C for 90 minutes, and obtain grapefruit peel biochar material after cooling.

[0072] (2) Weigh 0.1g of biochar, 3mmol of bismuth nitrate and 1mmol of sodium tungstate respectively, and dissolve them in a beaker of 40ml of deionized water with magnetic stirring to fully dissolve to obtain a brown-black solution, and then add 1.2mmol of surfactant to it Cetyltrimethylammonium bromide, continue ultrasonic stirring to fully dissolve.

[0073] (3) Finally, adjust the pH value of the precursor solution to 1 with 0.2mol / L NaOH solution.

[0074] (4) Put the above-mentioned reaction precursor solution into a polytetrafluoroethylene liner, seal the reaction hydrothermal kettle, and put it into a magnetic stirring microwave reactor MDS-10 for microwave hydrothermal reaction under the condition of 180°C for 90 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com