Preparation method of flexible self-supporting three-dimensional porous graphene film

A graphene membrane and three-dimensional porous technology, which is applied in the field of preparation of flexible self-supporting three-dimensional porous graphene membrane, can solve the problems of immaturity of flexible porous graphene membrane, and achieve uniform and controllable pore structure, simple preparation process and excellent pore structure. developed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare graphene oxide into 0.5 mg / mL graphene oxide aqueous solution;

[0025] (2) Add linear PVA with a molecular weight of 5000 into deionized water, stir and dissolve at a temperature of T=60°C, and prepare a PVA solution with a concentration of 5 mg / mL;

[0026] (3) Mix 100 mL graphene oxide aqueous solution with 1 mL PVA solution, stir and sonicate to disperse the two solutions evenly;

[0027] (4) Vacuum filter the mixed solution to form a film and dry to obtain a composite film of graphene oxide and PVP;

[0028] (5) The graphene oxide and PVP composite film was heated to 400 °C under the protection of nitrogen gas, and then heat-treated at constant temperature for 8 h to obtain a flexible self-supporting three-dimensional porous graphene film.

Embodiment 2

[0030] (1) Prepare graphene oxide into 1 mg / mL graphene oxide aqueous solution;

[0031] (2) Add spherical PS with a molecular weight of 10,000 into deionized water and disperse it ultrasonically to obtain a PS solution with a concentration of 50 mg / mL;

[0032] (3) Mix 100 mL of graphene oxide aqueous solution with 2 mL of PS solution, stir and sonicate to disperse the two solutions evenly;

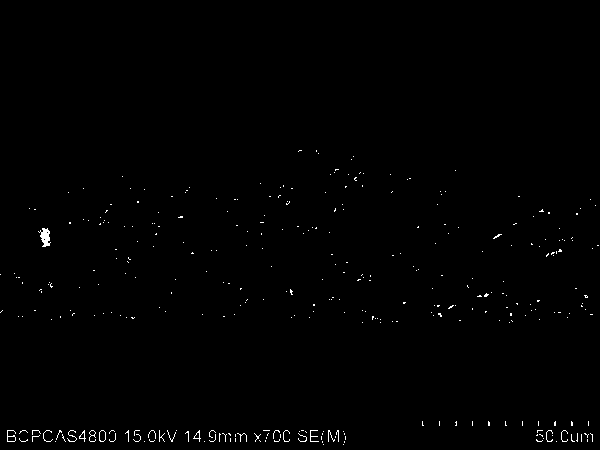

[0033] (4) Vacuum filter the mixed solution to form a film and dry to obtain a composite film of graphene oxide and PS (such as figure 1 , the SEM of graphene oxide and PS composite film shown in 2, figure 1 is the macroscopic topography, figure 2 for partial enlargement);

[0034] (5) The graphene oxide and PS composite film was heated to 800 °C under the protection of argon gas, and then heat-treated at constant temperature for 2 h to obtain a flexible self-supporting three-dimensional porous graphene film (such as image 3 , the SEM of the porous graphene membrane shown in 4, ...

Embodiment 3

[0036] (1) Prepare graphene oxide into 10 mg / mL graphene oxide aqueous solution;

[0037] (2) Add spherical PMMA with a molecular weight of 100,000 to deionized water and disperse it ultrasonically to obtain a PMMA solution with a concentration of 10 mg / mL;

[0038] (3) Mix 1 mL of graphene oxide aqueous solution with 10 mL of PMMA solution, stir and sonicate to disperse the two solutions evenly;

[0039] (4) vacuum filter the mixed solution to form a film, and dry to obtain a composite film of graphene oxide and PMMA;

[0040] (5) The composite membrane of graphene oxide and PMMA was heated to 500 °C under the protection of helium gas, and then heat-treated at constant temperature for 6 h to obtain a flexible self-supporting three-dimensional porous graphene membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com