Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "High shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

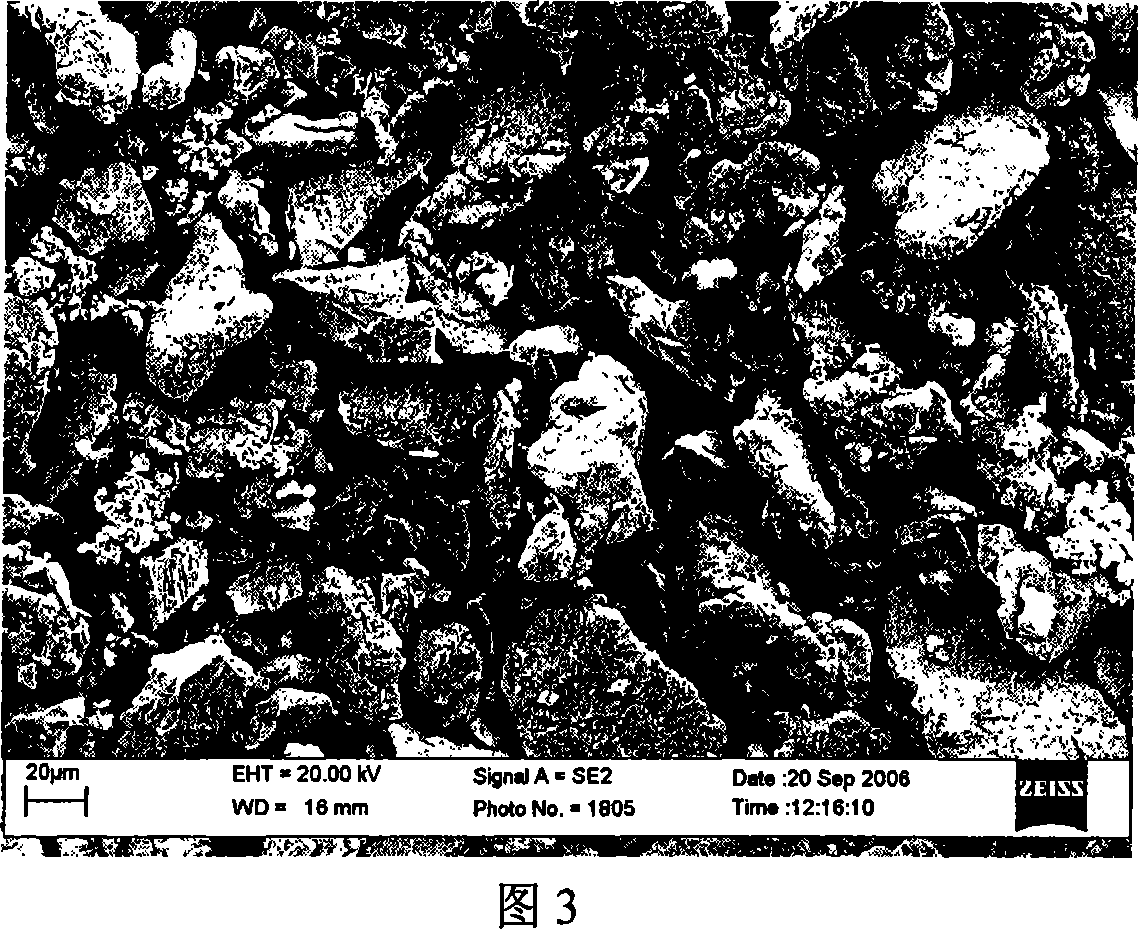

Method for rapid preparation of SiO2 aerogel micro-balloons

The utility model relates to a rapid preparation method of SiO2 aerogel sphere, belonging to a field of inorganic metallic materials, in particular to a method of rapidly preparing SiO2 aerogel sphere. Water glass is used as raw material that performs ion exchange to obtain the silicic acid PH=2-3, after added with alkaline catalyst, the silicic acid is added into the hydrophobic oil, and then is mixed to cut into micro liquid drops that are spherically suspended in the oil under the action of surface tension, the silicic acid is mixed until aerogel sphere is generated, afterwards, the oil and the sphere perform solid-liquid separation, and then are cleaned with water to obtain aerogel sphere, the aerogel sphere is soaked by the ethanol and absolute alcohol in sequence to perform solvent exchange to obtain alcohol gel sphere, after dried, aerogel sphere with micrometer or millimeter grade particles can be otained. The invention has low cost, easy and controllable process, mass production, good product quality and wide application prospect in the heat isolation and catalysis fields.

Owner:UNIV OF SCI & TECH BEIJING

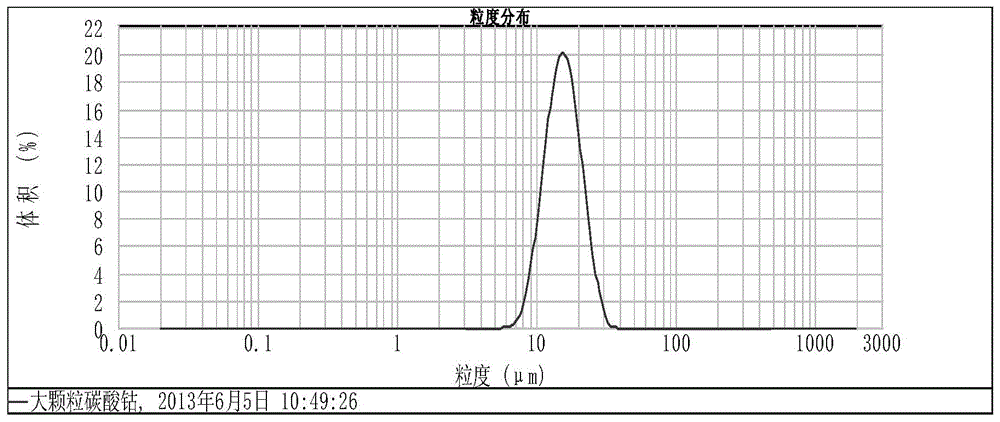

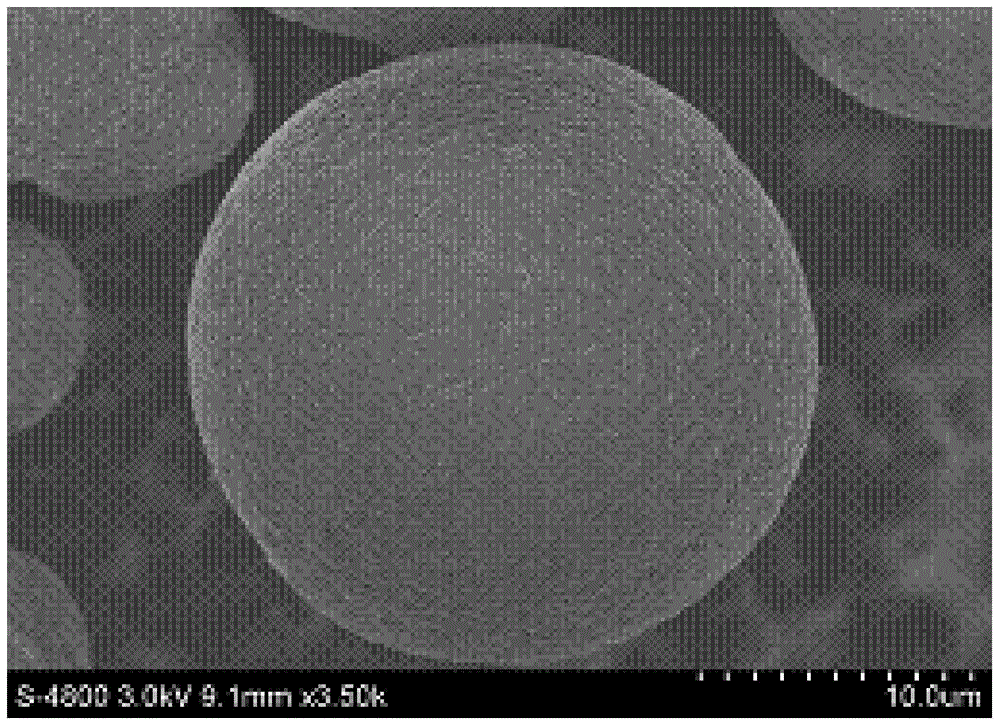

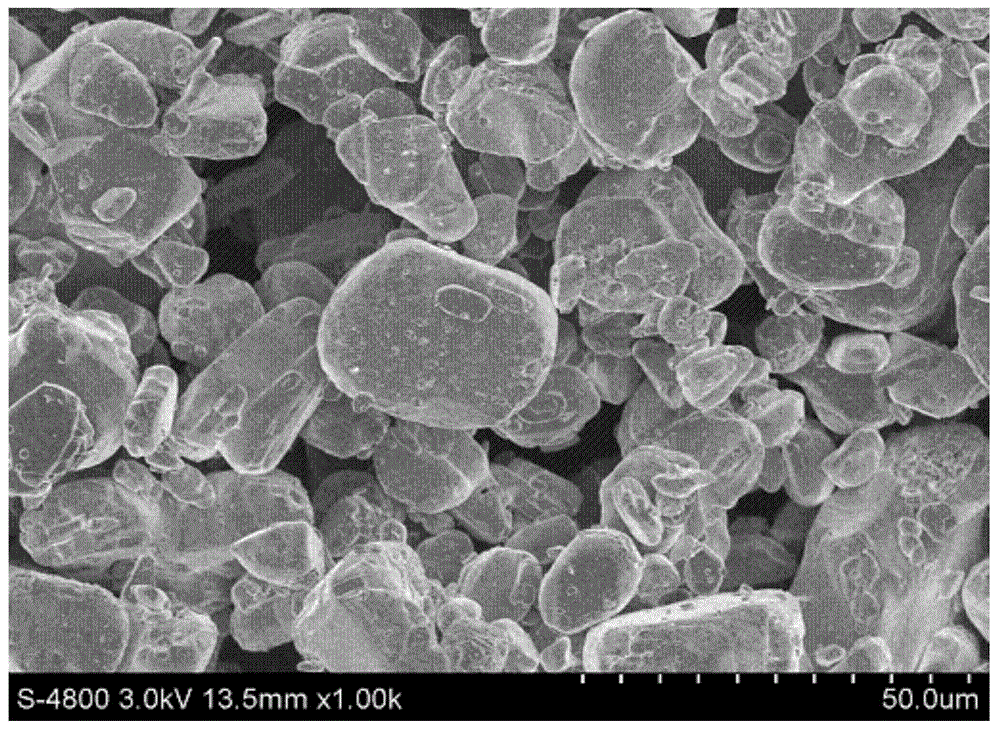

Method for continuously producing large-particle spherical cobalt carbonate

The invention relates to a method for continuously producing large-particle spherical cobalt carbonate. The method comprises the following steps: manufacturing a turbid liquid containing small-particle-size cobalt carbonate seed crystal and manufacturing a turbid liquid containing large-particle spherical cobalt carbonate, stirring the turbid liquid containing the small-particle-size cobalt carbonate seed crystal and the turbid liquid containing large-particle-size cobalt carbonate to form a mixed liquid, carrying out solid-liquid separation, washing and filter pressing to obtain a filter cake as a large-particle cobalt carbonate filter cake, drying the filter cake, and repeatedly operating to obtain the large-particle cobalt carbonate powder. According to the method disclosed by the invention, the small-particle-size cobalt carbonate seed crystal is adopted to control the particle size of the large-particle cobalt carbonate in reaction mother liquor, so that the degree of sphericity of cobalt carbonate produced by continuous production can be ensured to be high, the particle size can be stably controlled within the range of 15+ / -0.5 microns, and the consistency and the stability of the particle size of the large-particle spherical cobalt carbonate through large-scale continuous production can be realized; the method is simple in process, easy to operate and low in cost, and can provide the high-quality raw material for producing high-end lithium cobalt oxide; the carbonate is used as a precipitant, so that the environment can be optimized; the production efficiency can be improved, and the wide application prospect can be achieved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

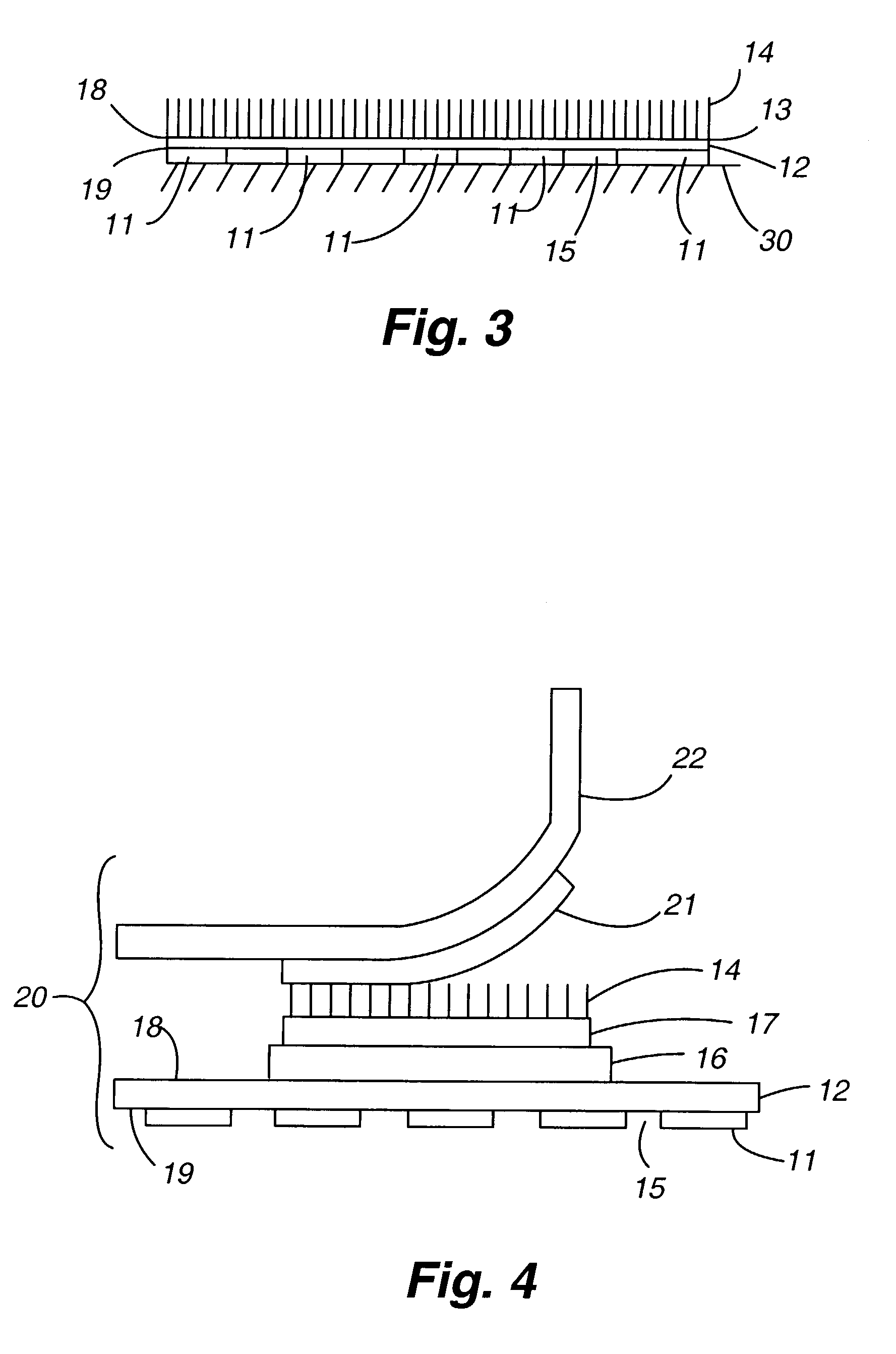

Flocked stretchable design or transfer

InactiveUS7410682B2Reduce the total massEffective adhesionLiquid surface applicatorsDecorative surface effectsFiberPolymer science

The present invention describes a flocked stretchable design and a process for producing a flocked stretchable design or transfer. The design, when configured as a transfer, includes a carrier layer, a release adhesive applied to the carrier layer, a plurality of flock fibers releasably attached to the release adhesive, an elastic film, and a first adhesive layer bonded to the flock fibers and the elastic film, and a second, discontinuously distributed, adhesive layer bonded to the other side of the elastic film. The design, when direct flocked, does not include the carrier and the release adhesive. The present invention also includes methods of producing both the designs.

Owner:HIGH VOLTAGE GRAPHICS

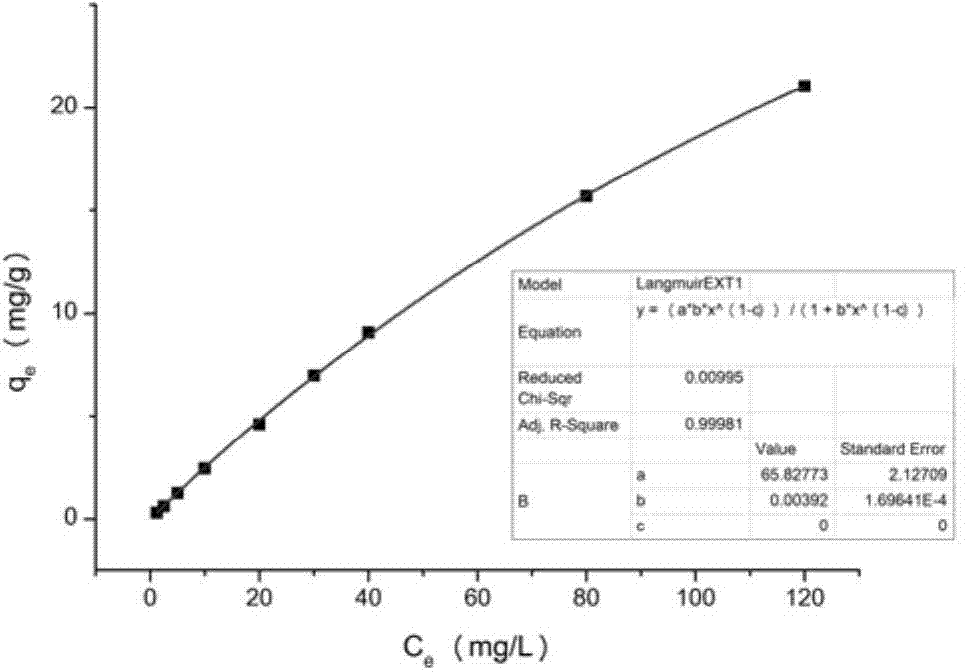

Method for preparing crosslinked-chitosan-system azo dye wastewater adsorbent

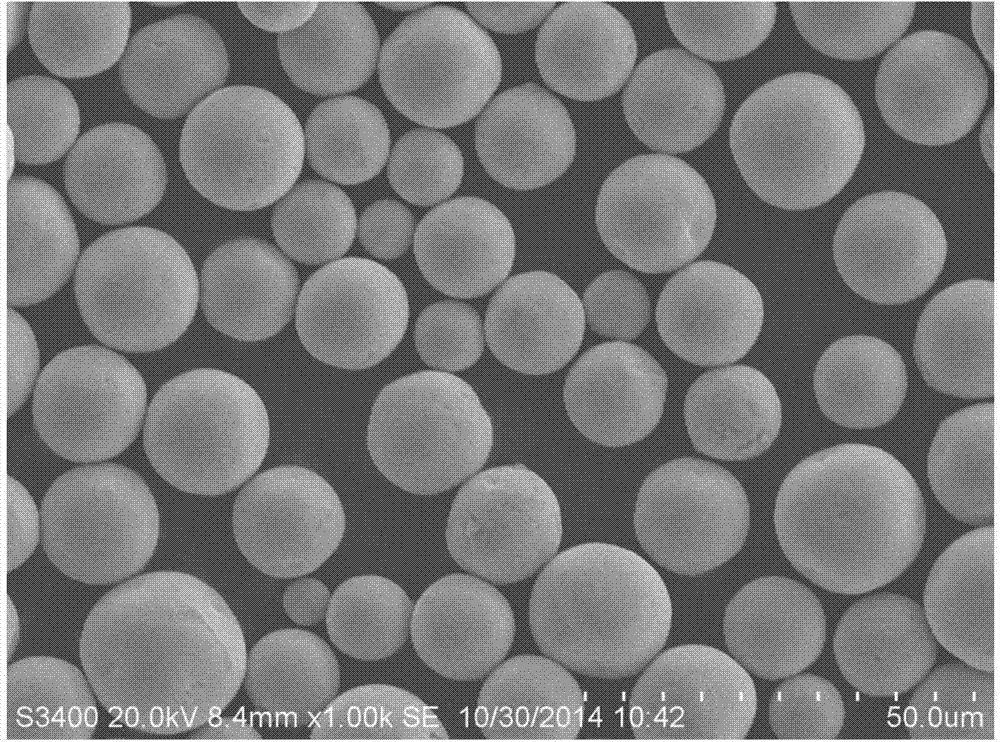

InactiveCN104741089ASimple structureHigh shapeOther chemical processesMicroballoon preparationCrosslinked chitosanMicron scale

The invention relates to a method for preparing a crosslinked-chitosan-system azo dye wastewater adsorbent. According to the method, the chitosan microsphere adsorbent aiming at azo dye wastewater treatment is prepared by carrying out reversed phase emulsification process and a cross-linking reaction on a microfluidic focusing type chip made from a laboratory-made polymethyl methacrylate (PMMA) material; the chitosan adsorbent prepared by virtue of the method belongs to a micron scale; compared with adsorbents at present, the chitosan adsorbent has the advantages that the specific surface area is larger, the degree of sphericity and the monodispersity are higher, the biocompatibility and the reproducibility of the chitosan adsorbent are guaranteed by virtue of a chitosan matrix, and the dissolving resistance and the swelling resistance of the chitosan adsorbent are improved under acid conditions when relatively high template dye adsorption capacity is guaranteed in a crosslinking process; by testing template dye wastewater methyl orange, the maximal adsorption capacity can reach 65.83mg / g.

Owner:EAST CHINA UNIV OF SCI & TECH

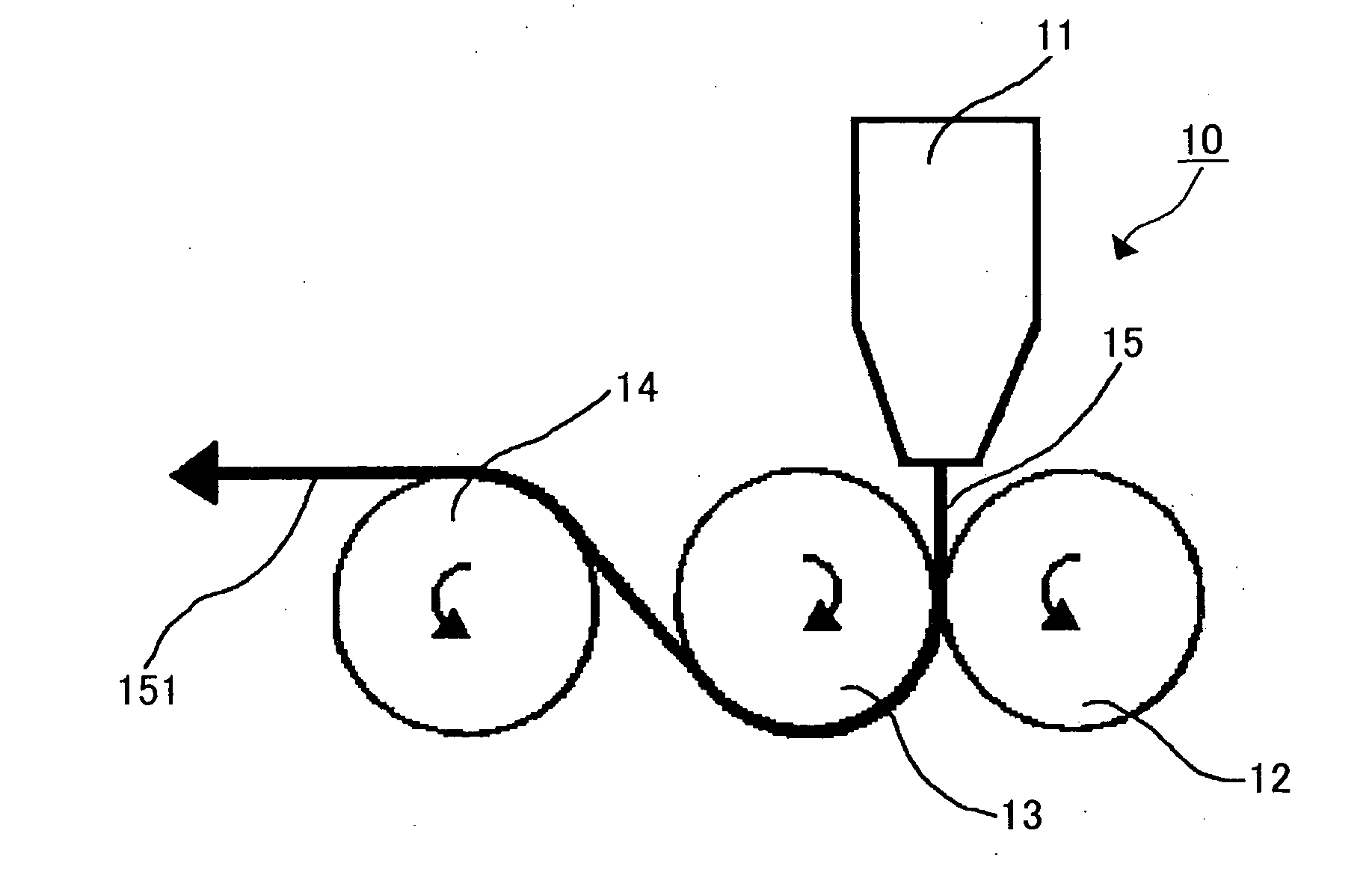

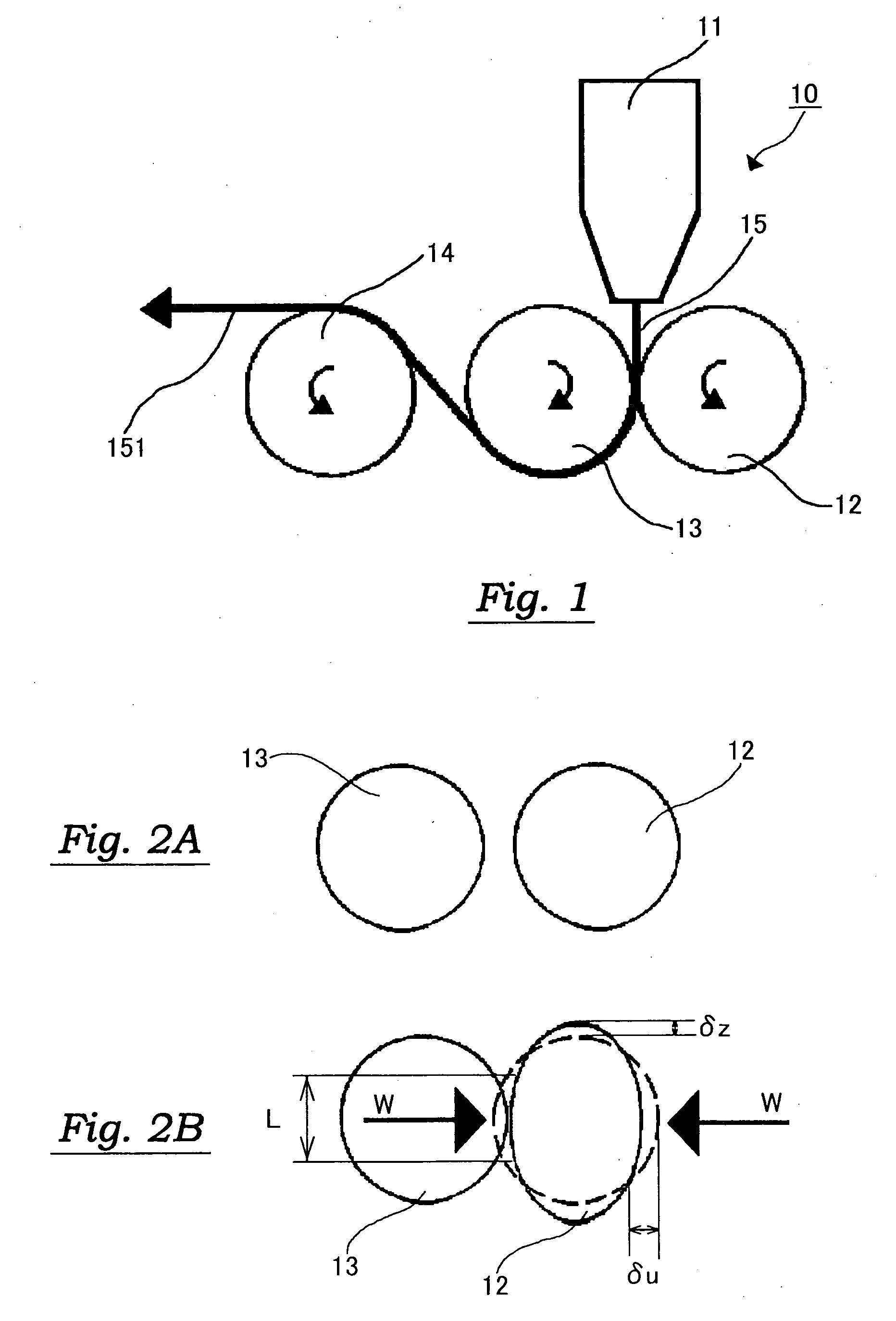

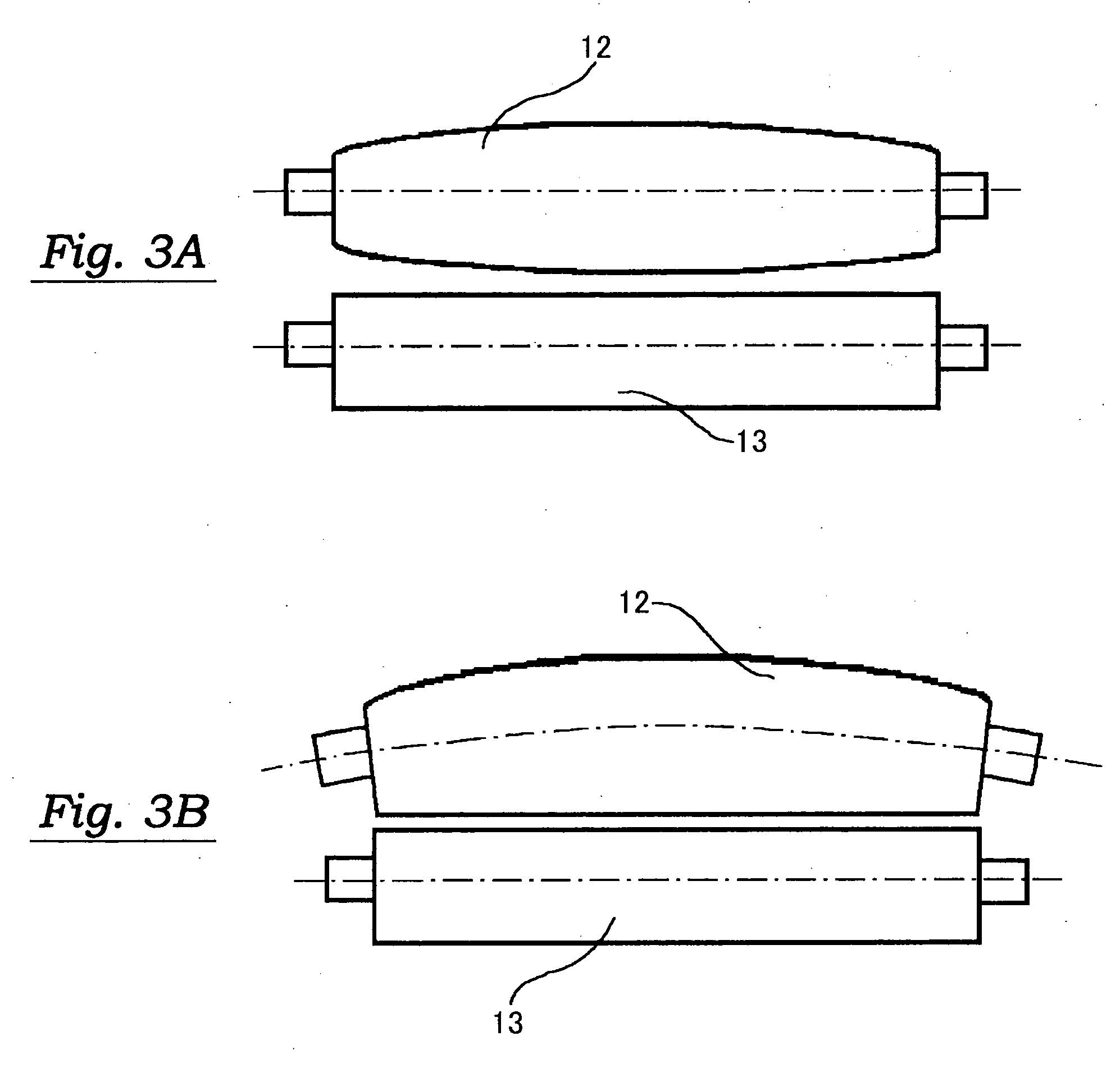

Method for producing optical sheet, optical sheet, and method for producing lenticular lens sheet

InactiveUS20060145374A1High thickness accuracyImprove performanceProjectorsOptical articlesLenticular lensEngineering

Owner:KURARAY CO LTD

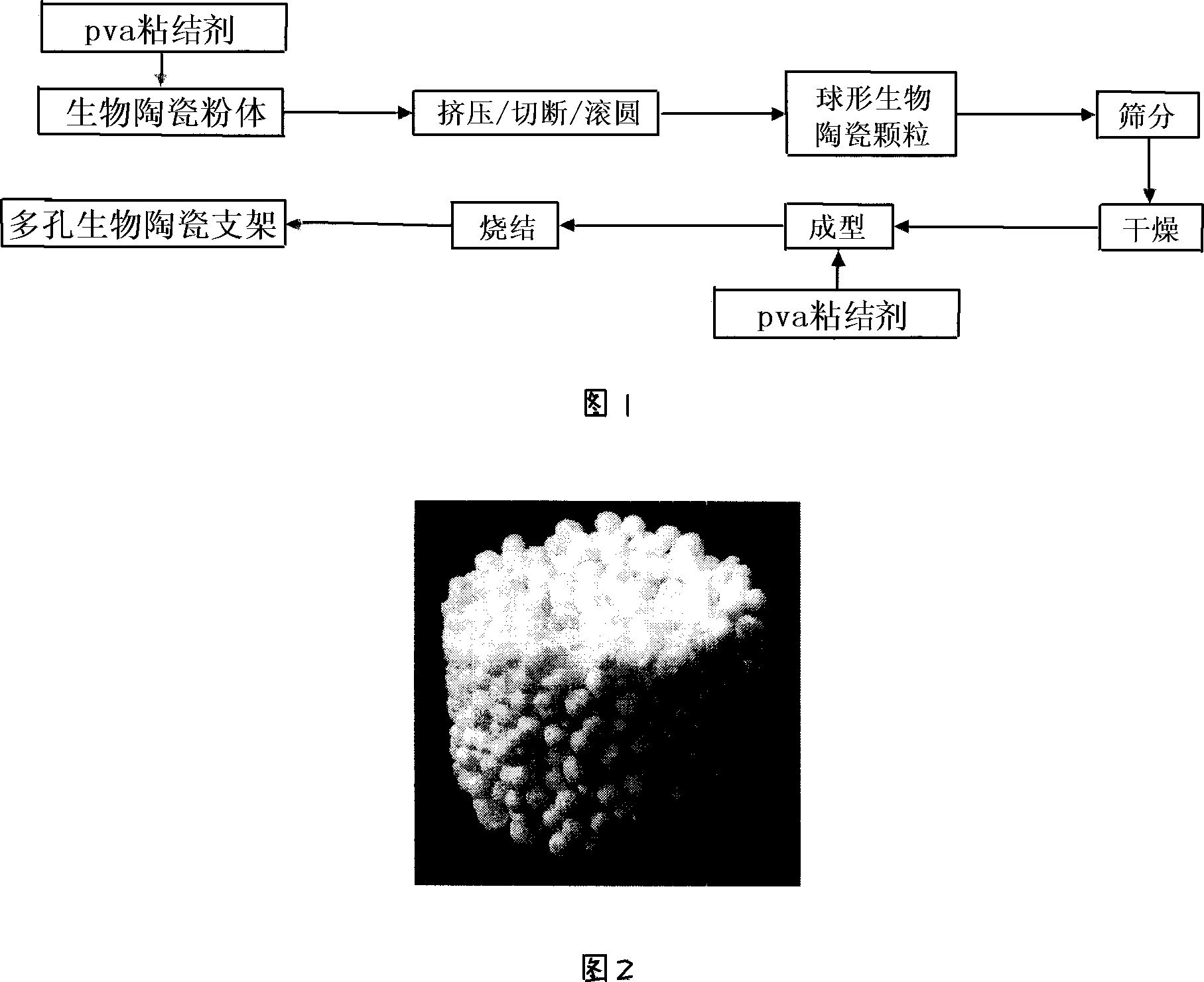

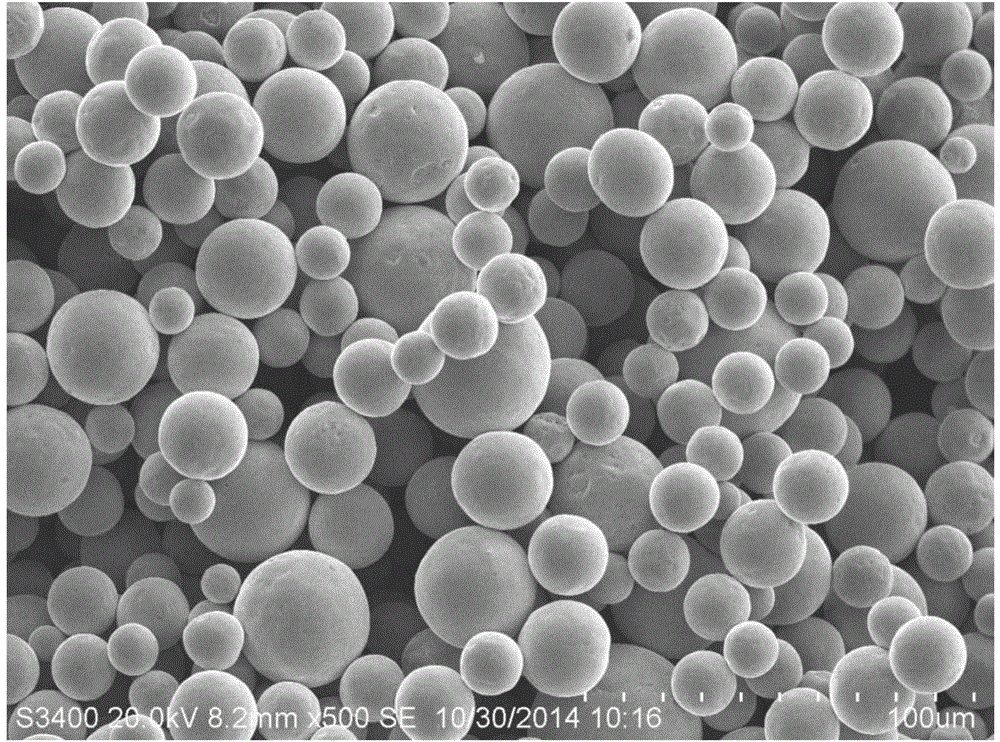

Process for preparing porous biological ceramics supporting frame

The invention relates to a method for preparing the porous biological ceramic support, used to repair the ill or hurt skeleton. The invention comprises that using polyvinyl alcohol water solution as adhesive to be mixed with biological ceramic powders, to be compressed via porous plate, cut and rolled, to obtain spherical particles, to be screened and dried; using the polyvinyl alcohol water solution as adhesive to be mixed with said spherical particles to be molded in mould, and sintered in sintering furnace. The invention uses the extruding rolling particle making method to prepare the biological ceramic spherical particles, with uniform diameter, while said particles are directly stacked into porous structure; therefore, the final support has non sealed porous structure, while the connecting diameter and the aperture is rationed higher than 1.0. And the polyvinyl alcohol is carbon hydrogen oxygen polymer which can be burnt out at high temperature, to avoid left material.

Owner:西安点云生物科技有限公司

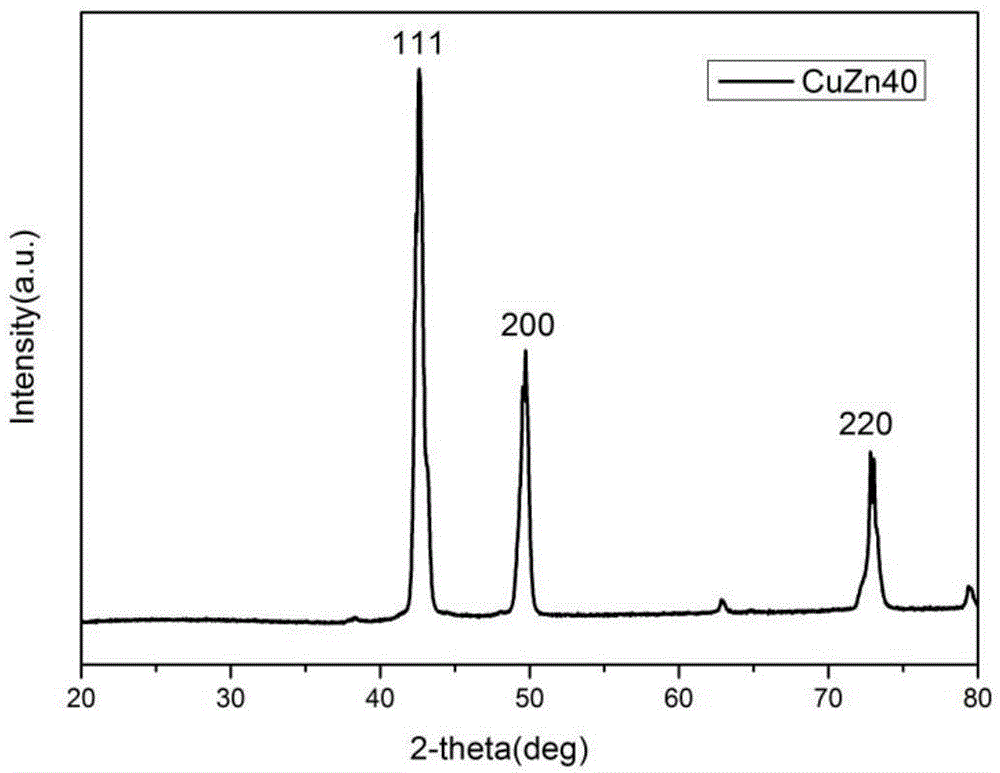

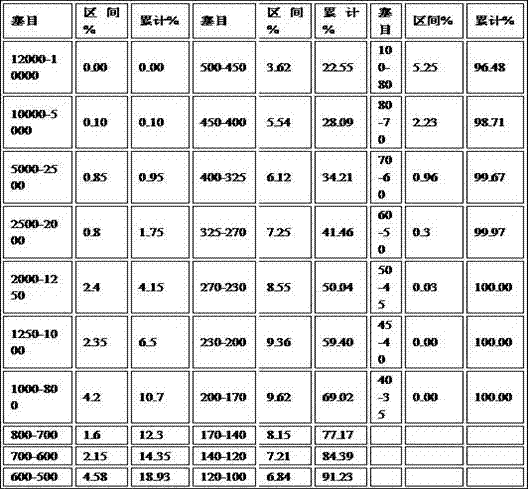

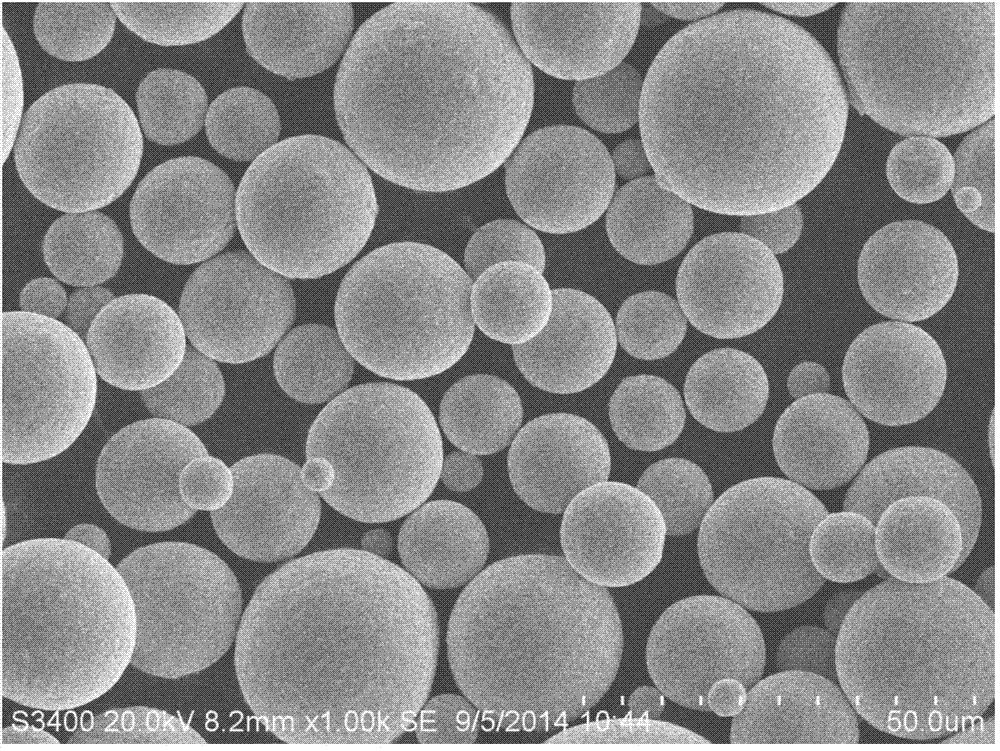

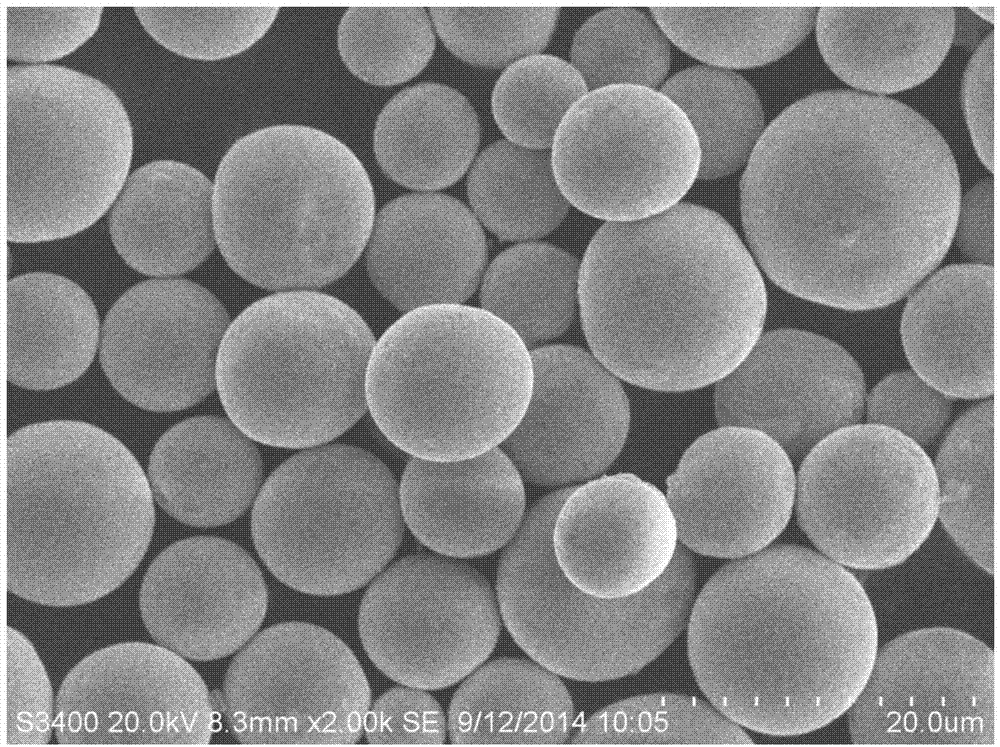

Spherical brass alloy powder manufacture method

The invention discloses a spherical brass alloy powder manufacture method. The method is characterized by including 1, preparing brass alloy powder; 2, preparing evenly-mixed powder of brass alloy powder and carbon material powder or ceramic material powder; 3, performing high temperature treatment, melting the brass alloy, solidifying, obtaining metal spheres, and cooling rapidly; 4, separating the carbon material powder or ceramic material powder, and obtaining micron or nano brass alloy spherical powder. The temperature of high temperature treatment is equal to or higher than that of metal melting, preferably, the temperature of high temperature treatment ranges from 10 to 80 DEG C higher than that of the brass alloy melting point. According to the method, process is simple, cost is low, and the method is adaptive to large scale production; the brass alloy powder is free of macro segregation, the surface metal sense is strong, and application of metal three-dimensional printing, print painting decoration, spraying (brazing) welding metal powder and metal filters can be met.

Owner:NANJING UNIV

Atomizing nozzle and method for producing powder

The invention relates to an atomizing nozzle for producing 3D printing powder. The atomizing nozzle comprises a nozzle body, wherein a flow guide pipe is arranged in the center of the nozzle body; a first annular atomizing chamber, a second annular atomizing chamber and a third annular atomizing chamber are arranged around a center line of the flow guide pipe in the nozzle body from inside to outside; air feeding tubes are arranged on the first annular atomizing chamber, the second annular atomizing chamber and the third annular atomizing chamber; the first annular atomizing chamber, the second annular atomizing chamber and the third annular atomizing chamber are correspondingly connected with a first injecting chamber, a second injecting chamber and a second injecting chamber; the area of air inlets of the injecting chambers is less than that of air outlets of the injecting chambers; the annular atomizing chambers and the injecting chambers form Laval tubes; the distance from the air inlets of the injecting chamber to the center line of the flow guide pipe sequentially increases from inside to outside. The atomizing nozzle is high in production efficiency; the powder is high in degree of sphericity; the particle size of a product is adjustable; a powder product with a certain particle size distribution can be produced as requirement, so that the workload of after-treatment in powder production can be decreased.

Owner:航天科工(长沙)新材料研究院有限公司

High-strength molybdenum nickel boron ternary boride material and manufacturing preparation method thereof

The invention discloses a high-strength molybdenum nickel boron ternary boride material and a preparation method thereof. The high-strength molybdenum nickel boron ternary boride material comprises the following elements by content percent: 3% to 6% of boron, 35% to 55% of molybdenum, 1% to 8% of chromium, 0.2% to 0.8% of carbon, 0.5% to 4% of vanadium, 1% to 4% of niobium, 0.5% to 5% of tungsten, 0.1% to 1% of cerium and 1% to 3% of manganese, and the balance being nickel. According to the preparation method provided by the invention, the manufacturing technology is simple, atomization powder forming replaces mechanical ball milling powder forming, segregation is reduced during follow-up forming, toughness of the material is improved, and a high-strength Mo2NiB2-based metal ceramic material with a dense structure is obtained through HIP hot isostatic pressure sintering. The high-strength molybdenum nickel boron ternary boride material provided by the invention is scientific and reasonable in formula design, has high melting point, high hardness and high abrasion resistance and corrosion resistance, can be utilized as a high-temperature resistant material, corrosion-resistant material, abrasion-resistant material and superhard material, and is good in comprehensive performance.

Owner:广东博杰特新材料科技有限公司

Ceramic color sand and preparation method thereof

The invention provides ceramic color sand and a preparation method thereof. The ceramic color sand comprises the following raw materials in parts by weight: 100 parts of solid wastes, 5 to 110 parts of plasticizer, 12 to 28 parts of silica fume, 0.1 to 10 parts of pigment, 0.5 to 2 parts of water reducer and 22 to 39 parts of water. The ceramic color sand has the advantages that the solid wastes are used as the main raw material, and are combined with other ceramic raw materials and pigment, so as to prepare the integral artificial color pottery sand through granulating, drying and sintering; the problem of pollution by the solid wastes is effectively relieved, and the problems of complicated artificial color sand preparation technology, destruction to ecological environment, poor degree of sphericity, easiness in stripping and separation of outer coating layer and inner core, short service life and the like are solved.

Owner:阳江清大环保科技有限公司

Manufacturing method of spherical bronze alloy powder

Disclosed is a manufacturing method of spherical bronze alloy powder. The manufacturing method includes steps of preparing bronze alloy powder; preparing uniform mixture of the alloy powder with carbon powder or ceramic powder; subjecting the uniform mixture to thermal treatment so as to melt bronze alloy and solidify to obtain metallic balls; separating the carbon powder or ceramic powder to obtain spherical alloy powder. The component of the bronze alloy includes CudSnaXbYc according to the weight percentage, wherein X indicates one or several kinds of Al, Be, Zn, Ni, Cr, Mn, Co, F3, Ag, Sb and Pb, Y indicates one or several kinds of Li, Ti, In, RE, P, Si and B, the weight percentage of a, b and c is 1-40, 0-30 and 0-2 respectively, and the balance is the weight percentage of d. The manufacturing method of the spherical bronze alloy powder is simple and applicable to bronze alloy added to multi-element intensified elements.

Owner:NANJING UNIV

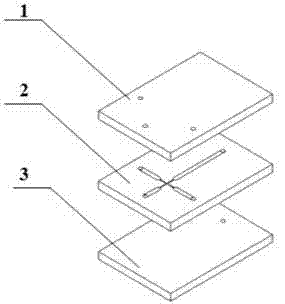

Microfluidic module for large-scale preparation of liquid drops

ActiveCN106215990AReduce pump consumptionImprove operational flexibilityBurettes/pipettesEmulsionParallel channel

The invention relates to a microfluidic module for large-scale preparation of liquid drops. A multi-stage modular amplification strategy is adopted; the module design comprises two parallel and stacked amplification processes; a plurality of modules operate in an integrated manner to realize an industrial production demand; N is the number of parallel channels in each chip group; M is the number of stacked chips of each module; the whole module comprises N * M channels; if Q is the number of integrated modules, the total yield is P= eta x (N * M * Q), and is respectively in positive correlation with N, M and Q; eta is the yield of the single channel. In actual application, three parameters can be reasonably weighed according to the demand for space utilization and yield, feature parameters of an obtained product and the like so as to achieve the optimal effect. The application of the microfluidic module for the large-scale preparation of the liquid drops or a microfluidic system based on the module realizes the large-scale production of the liquid drops or emulsion; when serving as a template, the microfluidic module can synthesize a functional particle material; the microfluidic module is widely applied to the field of biological medicines, chemistry and chemical engineering, material preparation and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

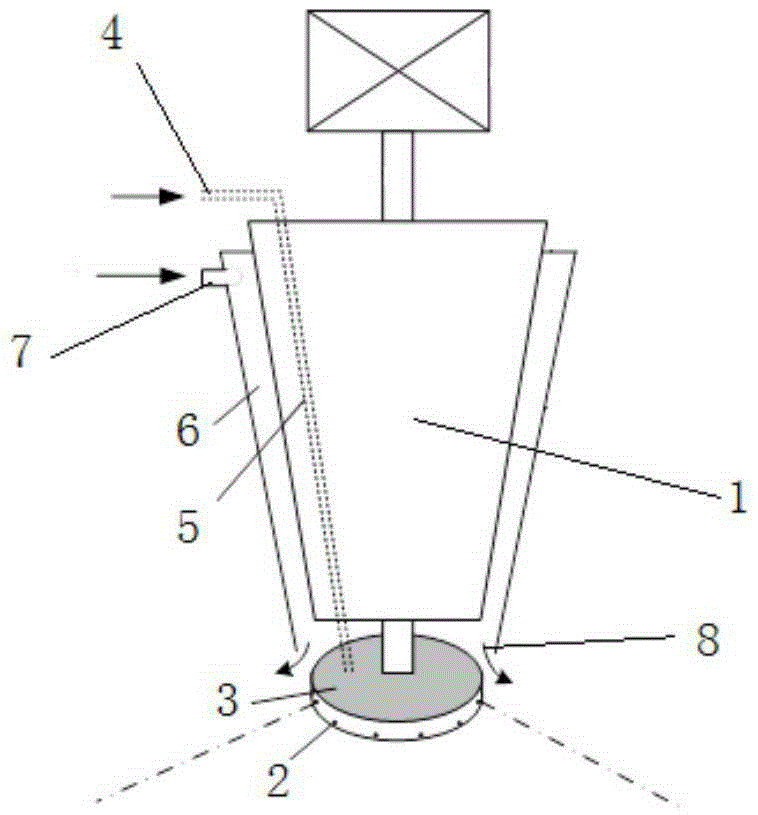

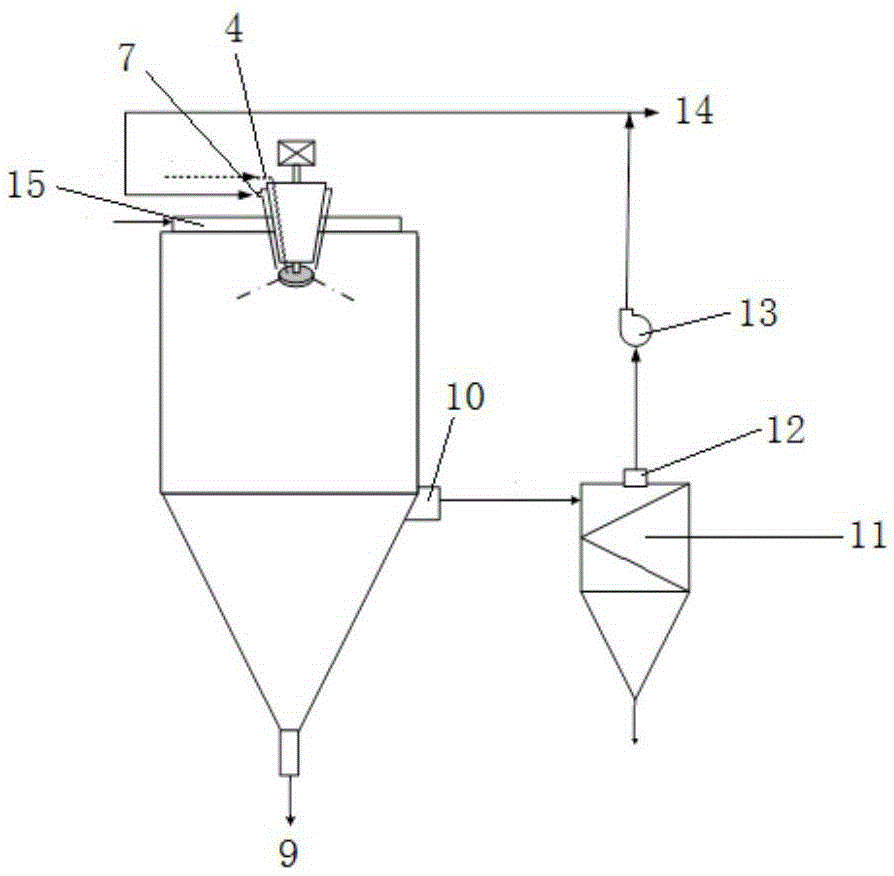

Centrifugal atomizing nozzle and spray dryer

InactiveCN106607197AReduce the chance of breakageAvoid direct contactSpray nozzlesEvaporation by sprayingNebulizerMicrosphere

The invention relates to the field of spray dryers and discloses a centrifugal atomizing nozzle and a spray dryer comprising the same. The centrifugal atomizing nozzle comprises a centrifugal atomizer and a protection wind guide pipe, wherein the centrifugal atomizer is internally provided with an atomizing disc which is used for spraying materials into fog drips and provided with atomizing holes, and a material guide pipe connected with the atomizing disc and a material inlet; and the protection wind guide pipe is provided with a protection wind inlet and a protection wind spraying opening. The protection wind guide pipe is arranged around the centrifugal atomizer, so that protection wind sprayed by the protection wind spraying opening surrounds the fog-drip-shaped materials sprayed by the atomizing holes. When spray drying is conducted by adopting the dryer comprising the centrifugal atomizing nozzle, the problems that microspheres are burst, abnormal shapes and fine powder are produced in the drying process can be solved, and the sphericity of obtained dried particles can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

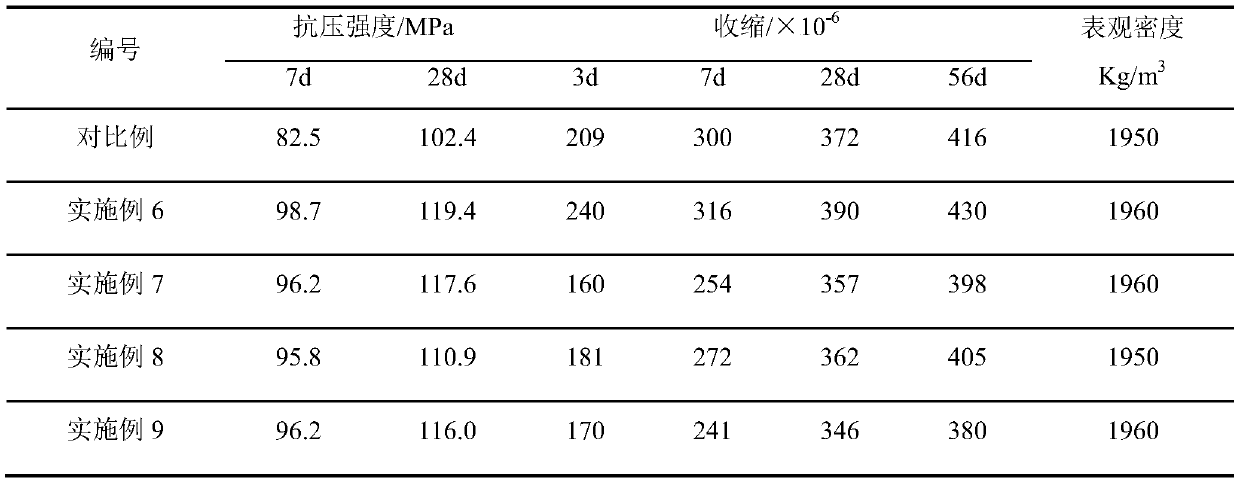

Autoclave curing-free, light and ultrahigh-strength concrete and preparation method thereof

ActiveCN110563409AReduce dosageHigh shapeCeramicwareClaywaresSuper absorbentUltimate tensile strength

Belonging to the field of building materials, the invention particularly relates to an autoclave curing-free, light and ultrahigh-strength concrete and a preparation method thereof. The concrete is composed of a cementing material, interface-modified high-strength porous microspheres, natural sand, a super absorbent slow-release internal curing material, a hyper-dispersion reducing admixture and water. Based on the particle close packing theory, the method provided by the invention adopts silica fume, fly ash microspheres and ultrafine limestone powder, designs and optimizes the cementing material particle composition, fires high-strength porous microspheres, researches and develops an interface improvement emulsion, and performs treatment on the surfaces of porous microspheres to obtain the interface-modified high-strength porous microspheres, and then optimizes the concrete interfacial transition zone; and the super absorbent slow-release internal curing material is prepared, and significantly lowers the early autogenous shrinkage of concrete. The prepared concrete has the characteristics of high strength, light weight, small shrinkage and the like, can obviously reduce the self-weight of the structure, and provides a new material choice for structural design and construction innovation.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

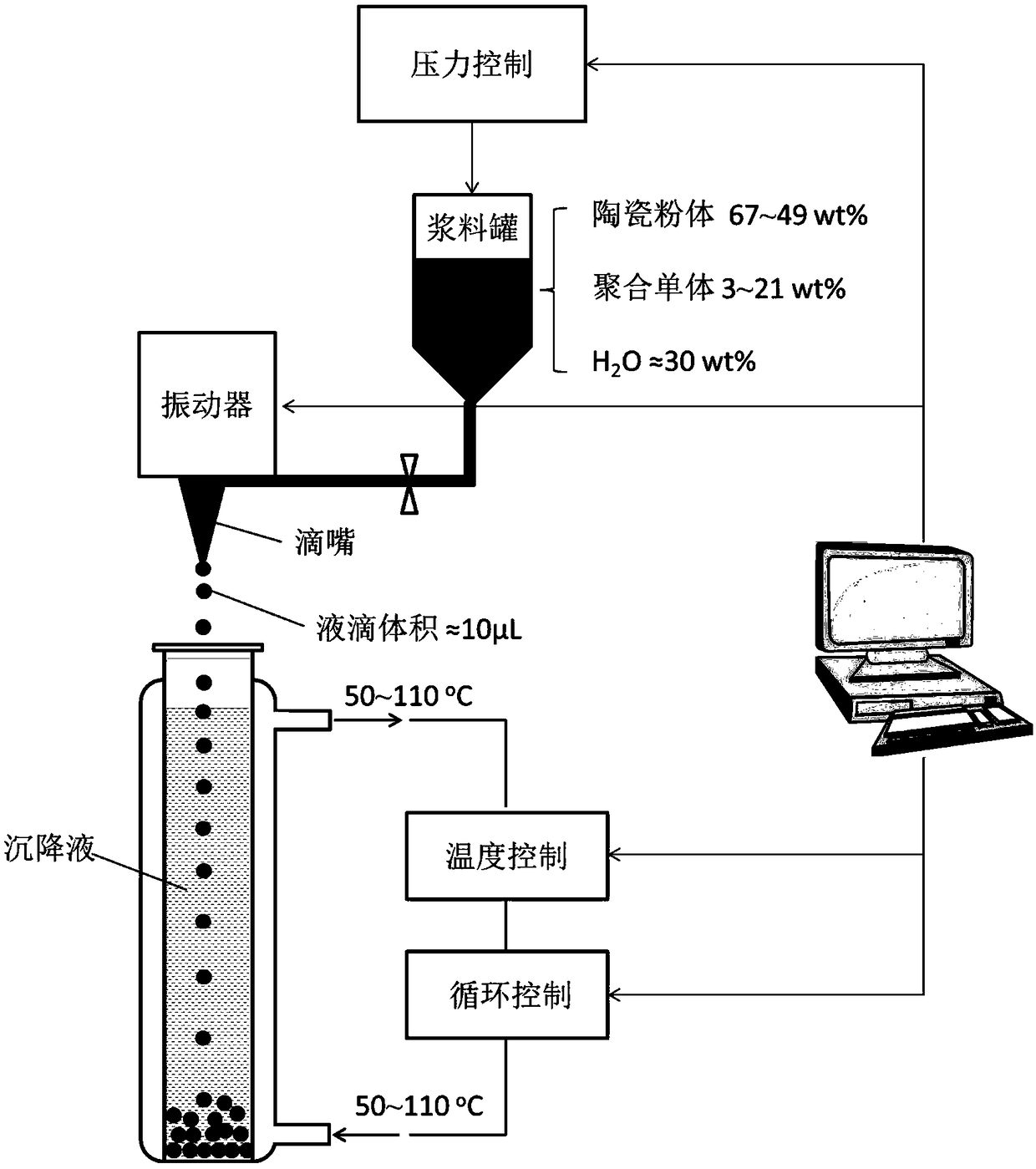

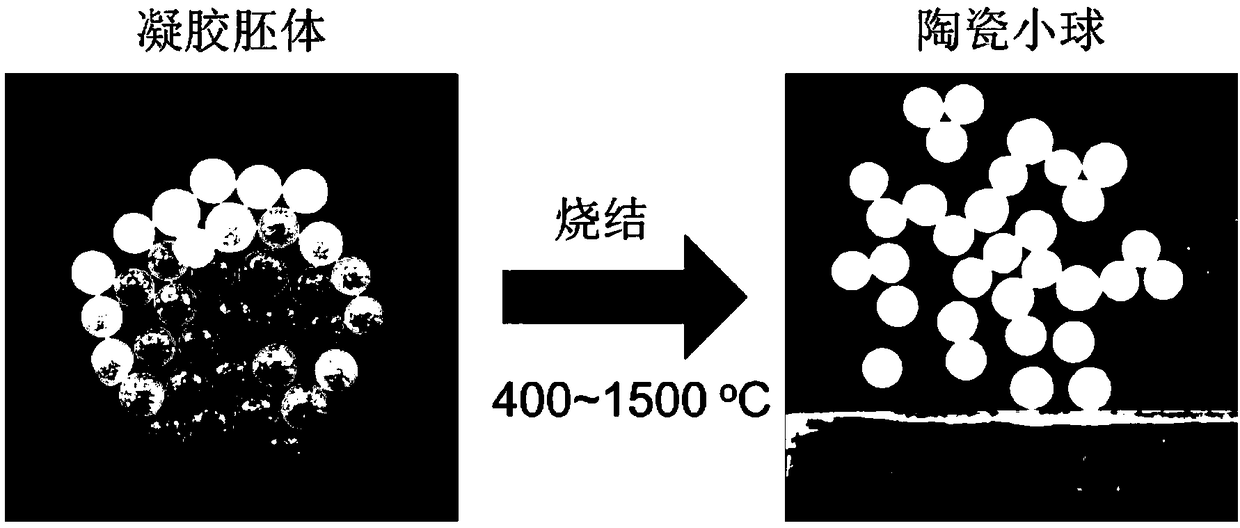

Preparation method of tritium multiplication ceramic pellet in fusion reactor solid blanket

InactiveCN108751975ASimple processHigh sphericityNuclear energy generationThermonuclear fusion reactorLithium oxideViscous liquid

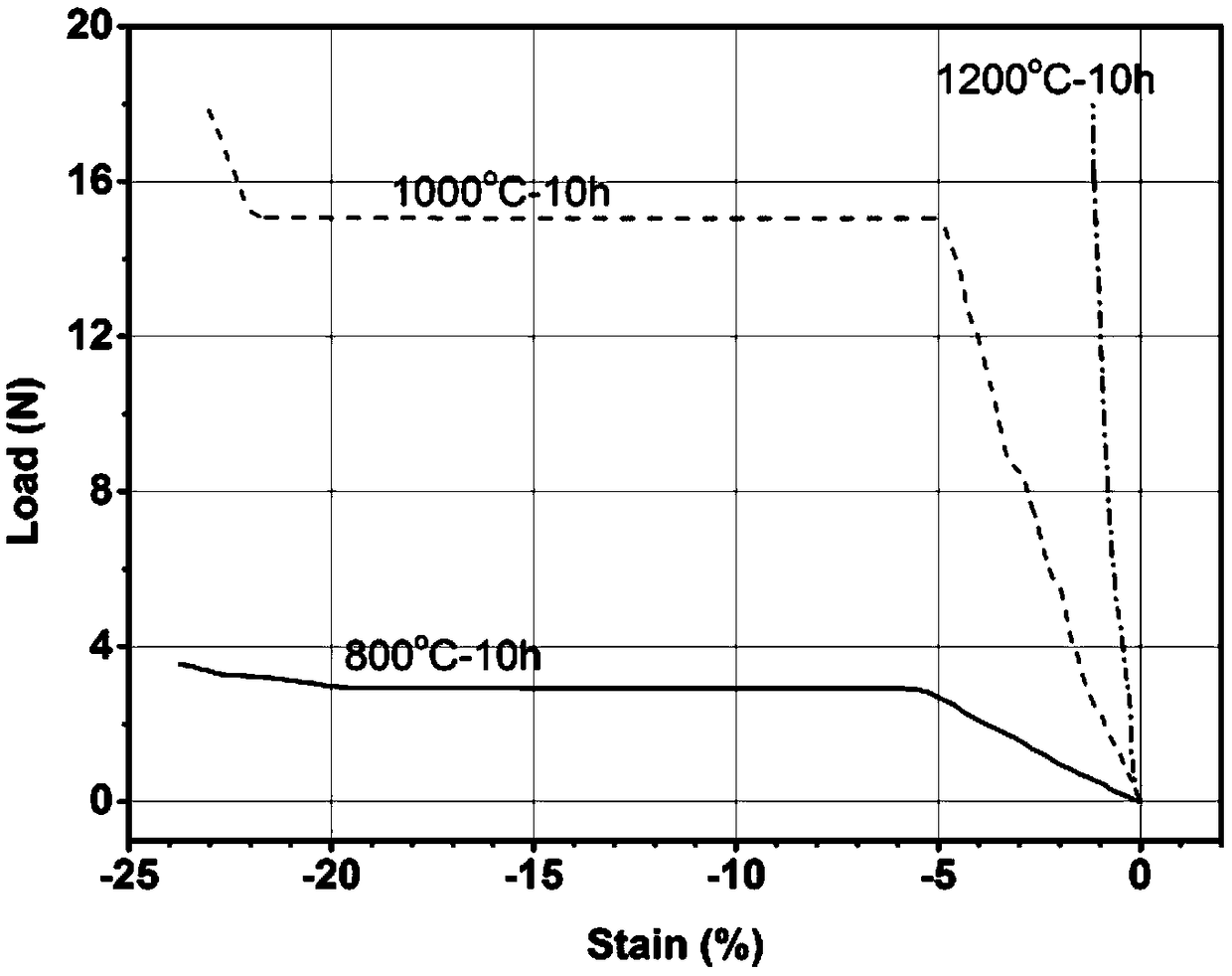

The invention discloses a preparation method of a tritium multiplication ceramic pellet in a fusion reactor solid blanket. A polymer auxiliary settling method is used; a micron order lithium oxide tritium multiplication ceramic powder is used as raw materials; during the ceramic slurry preparation, polymerizable organic monomers are added. When slurry liquid is dropped in viscous liquid and falls,the gravity, the liquid buoyancy and the viscous resistance are balanced, so that slurry liquid drops with high sphericity degree are obtained. Meanwhile, in the falling process, the spherical liquiddrops are polymerized to be cured into a pellet blank. In the sintering process, the pellet blank is subjected to ceramic treatment; the ceramic pellet with high sphericity degree is obtained. By optimizing the technological process and sintering schedule, the mechanical strength, the sphericility degree and the porosity of the pellet can be further improved. The preparation conditions of the pellet blank are mild; in the settling process, the two processes of palletization and curing are simultaneously completed; the purification and transfer processes of the ceramic pellet are simplified; the obtained product has high sphericility degree, particle diameter uniformity, high porosity and high mechanical strength; the industrial production is convenient.

Owner:ANHUI UNIVERSITY

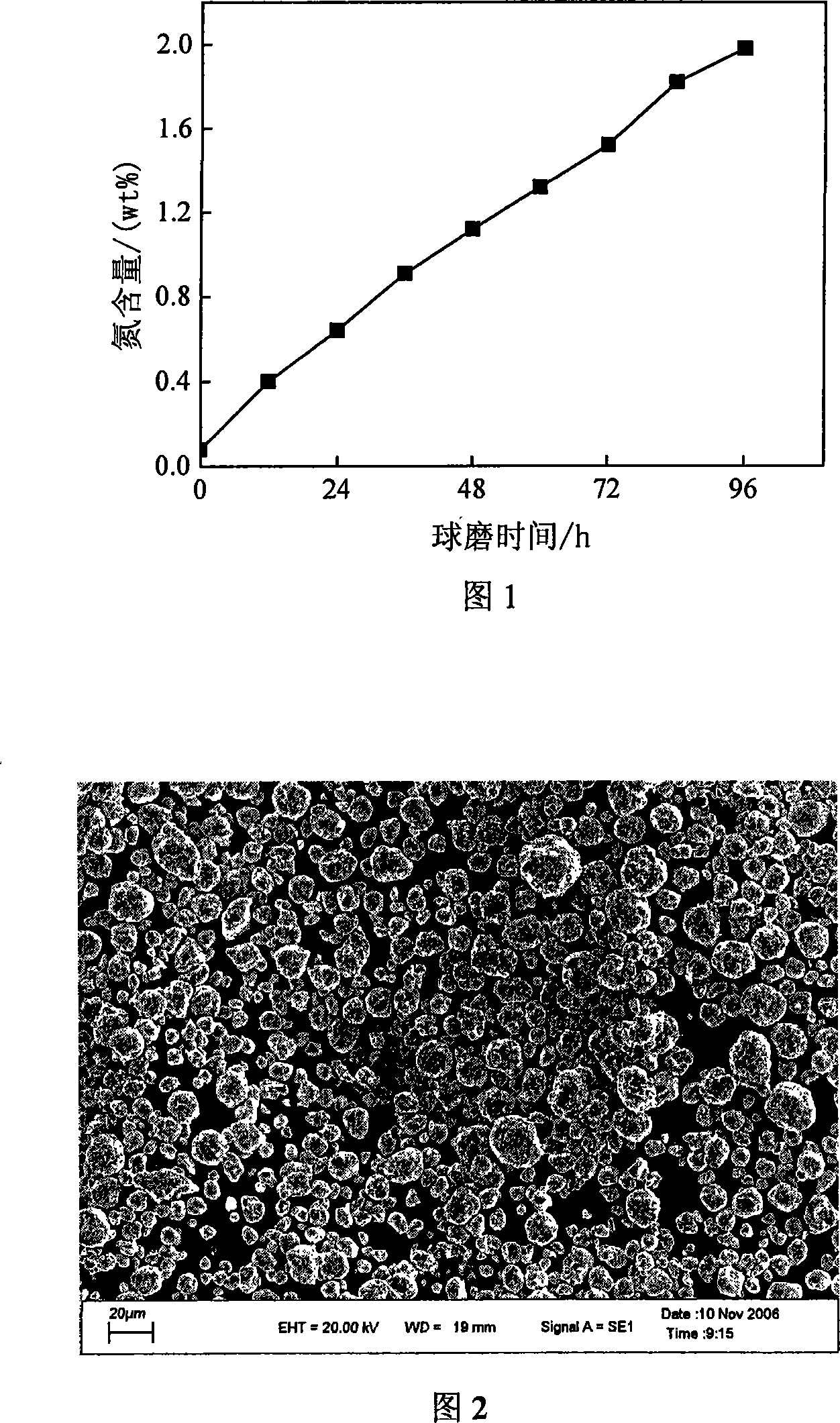

Method for preparing globular high-nitrogen stainless steel powder using with high-energy ball mill

The present invention relates to a method for producing the nearly-round high-nitrogen stainless steel powders, belonging to the alloy-powder fabrication technology field. The technical characteristics of the method are that: first, the powders composed of Fe, Cr, Mn, and Mo elementsare weighed in accordance with the mass fractions; wherein Cr: 16 to 17, Mn: 10 to11, Mo: 3.0 to 3.5, while the surplus belonged to Fe; then the powders are mixed evenly and are poured into a stirring-type high-energy ball mill to be grinded for 12 to 96 hours. During the period, the ball-grinding atmosphere is the flowing nitrogen high in purity, whereas every 12 hours the ball needs be stopped for 2 hours to cool down. The present invention has the advantages that the stainless steel powders rich in nitrogen and with fine particles and even components can be produced; moreover, the stainless steel powders have high sphericity and good fluidity, which are favorable for following process of injection molding. The present invention has simple facility, easy control of the process parameters and low cost.

Owner:UNIV OF SCI & TECH BEIJING

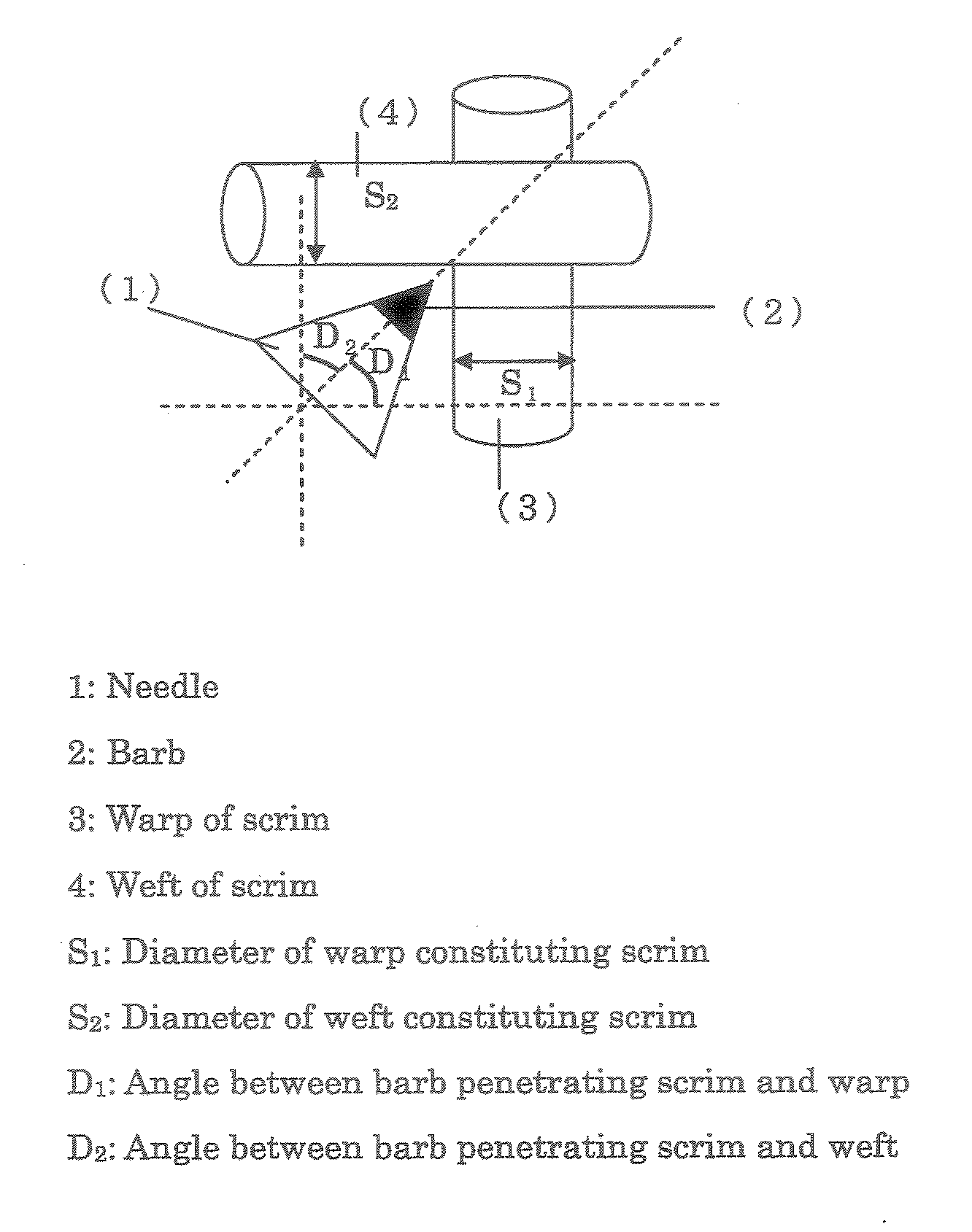

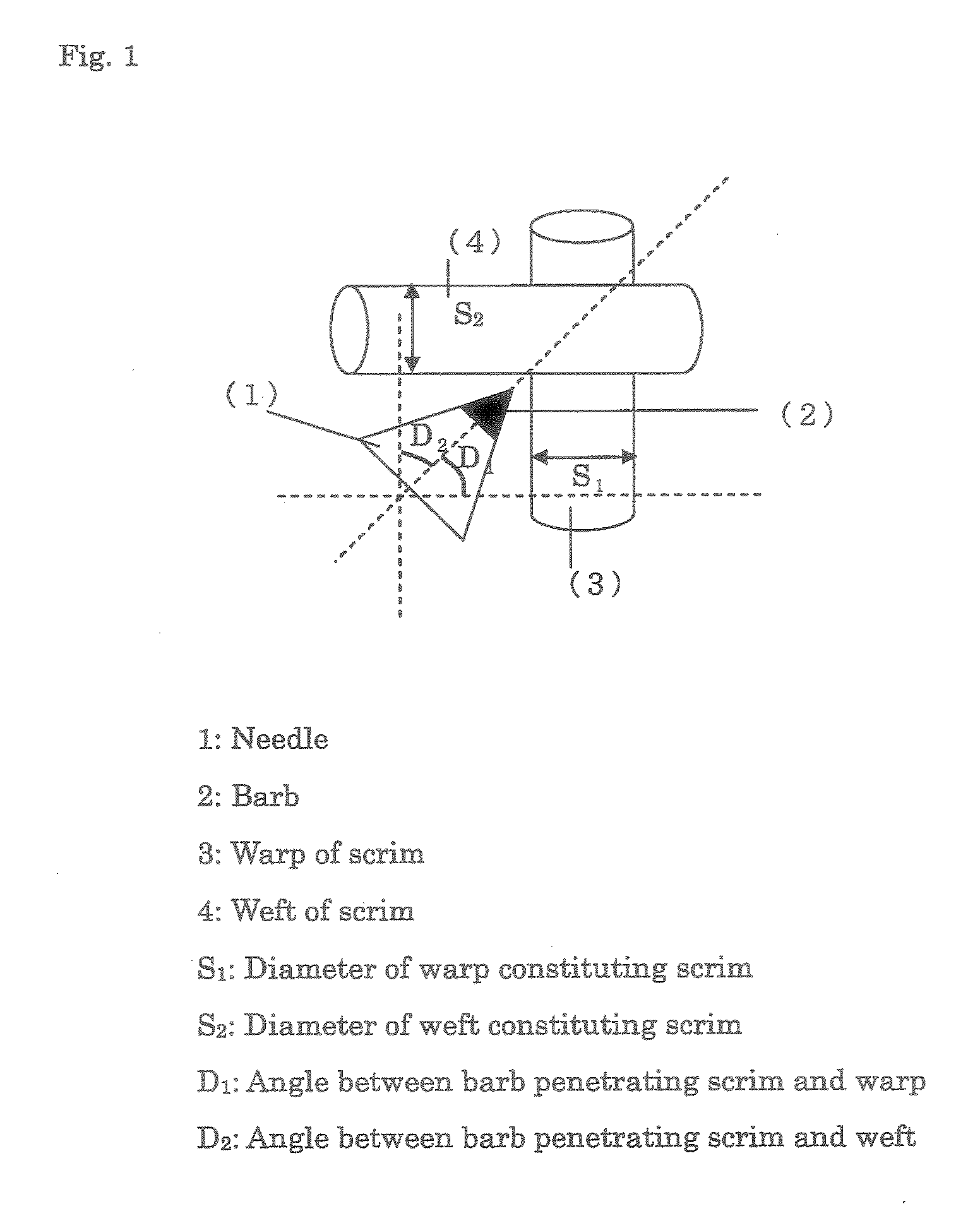

Nonwoven Fabric For Artificial Leather And Process For Producing Artificial Leather Substrate

ActiveUS20080163469A1Avoid damageImproved shape stabilityDomestic upholsteryPattern makingPunchingNonwoven fabric

Problem to be Solved To provide a method of producing a nonwoven fabric for artificial leather and substrate for artificial leather which is capable of providing the substrate for artificial leather having a sufficient shape stability by producing the nonwoven fabric for artificial leather without causing serious damages to the scrim.Means for Solving Problem A method of producing a nonwoven fabric for artificial leather, including a step of entanglement for uniting superposed fiber web and scrim by a needle punching, wherein the needle punching is performed in a manner satisfying the following formulae 1 and 2;S1<2P≦S1 / cos(D1×(π / 180)) (1)S2<2P≦S2 / cos(D2×(π / 180)) (2)wherein S1 is a diameter of warps constituting the scrim, S2 is a diameter of wefts constituting the scrim, D1 is an angle between the warps and barbs which penetrate the scrim, D2 is an angle between the wefts and barbs which penetrate the scrim, and P is a total barb depth of the barbs.

Owner:KURARAY CO LTD

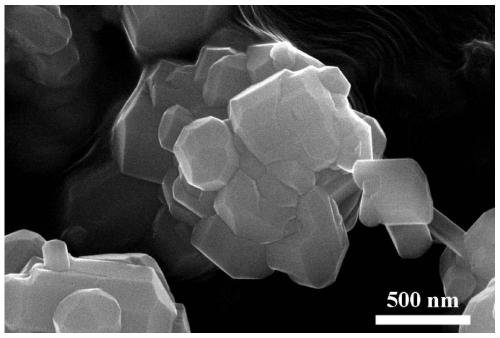

Large-size silicon nitride ceramic ball and preparation method thereof

The invention provides a silicon nitride ceramic ball and a preparation method thereof, and belongs to the technical field of ceramic materials. According to the invention, a vacuum injection-coagulation forming method is adopted, so that the forming of large-size and oversized silicon nitride ceramic balls with high sphericity degree and uniform density can be realized. Microwave drying is adopted, the drying speed is high, and deformation of a green body is small. According to the invention, the cold isostatic pressing treatment is carried out on the degummed ceramic balls, so that the compactness of the sintered ceramic balls is improved. A two-step air pressure sintering process is adopted, so that internal air holes of the ceramic ball can be removed, and the density can be further improved. According to the invention, the surfaces and the core parts of the large-size and oversized silicon nitride ceramic balls prepared by adopting the method of combining injection coagulation forming with cold isostatic pressing forming and two-step air pressure sintering have no obvious difference in properties such as relative density, Vickers hardness and fracture toughness. Homogenization of density and mechanical properties of large-size and oversized silicon nitride ceramic balls can be realized.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD +1

Preparation method of steel slag aggregate

The invention discloses a preparation method of a steel slag aggregate. The preparation method comprises the following steps: screening steel slag particles with sizes being 18-25mm, and drying the steel slag particles after washing; maintaining the dried particles in a carbonization reaction of which the pressure is 2-4MPa and the temperature is 35-55 DEG C for 3-5 hours to obtain carbonized steel slag particles; mixing 30-60% of papermaking sludge, 20-30% of lime and 10-40% of oil shale residues uniformly in percentage by weight, adding water according to a mass ratio of the mixture to water of 1:(0. 05-0.15), performing stirring for 10-60 seconds, then adding 10-25wt% of emulsified asphalt, and performing stirring for 10 to 60 seconds to obtain a uniformly mixed material; and preparing gravels into balls by taking carbide steel slag particles as cores, and the mixed material as a wrapping layer, and performing maintenance for 20-50 minutes under the conditions that the pressure is 4-6MPa, the temperature is 40-60 DEG C and the relative humidity is 60-95%, so as to obtain the steel slag aggregate. The obtained steel slag aggregate has a low water absorption rate, a low crushing index and a stable volume, and the preparation method is simple and low in cost.

Owner:永城市磊鑫建材有限公司

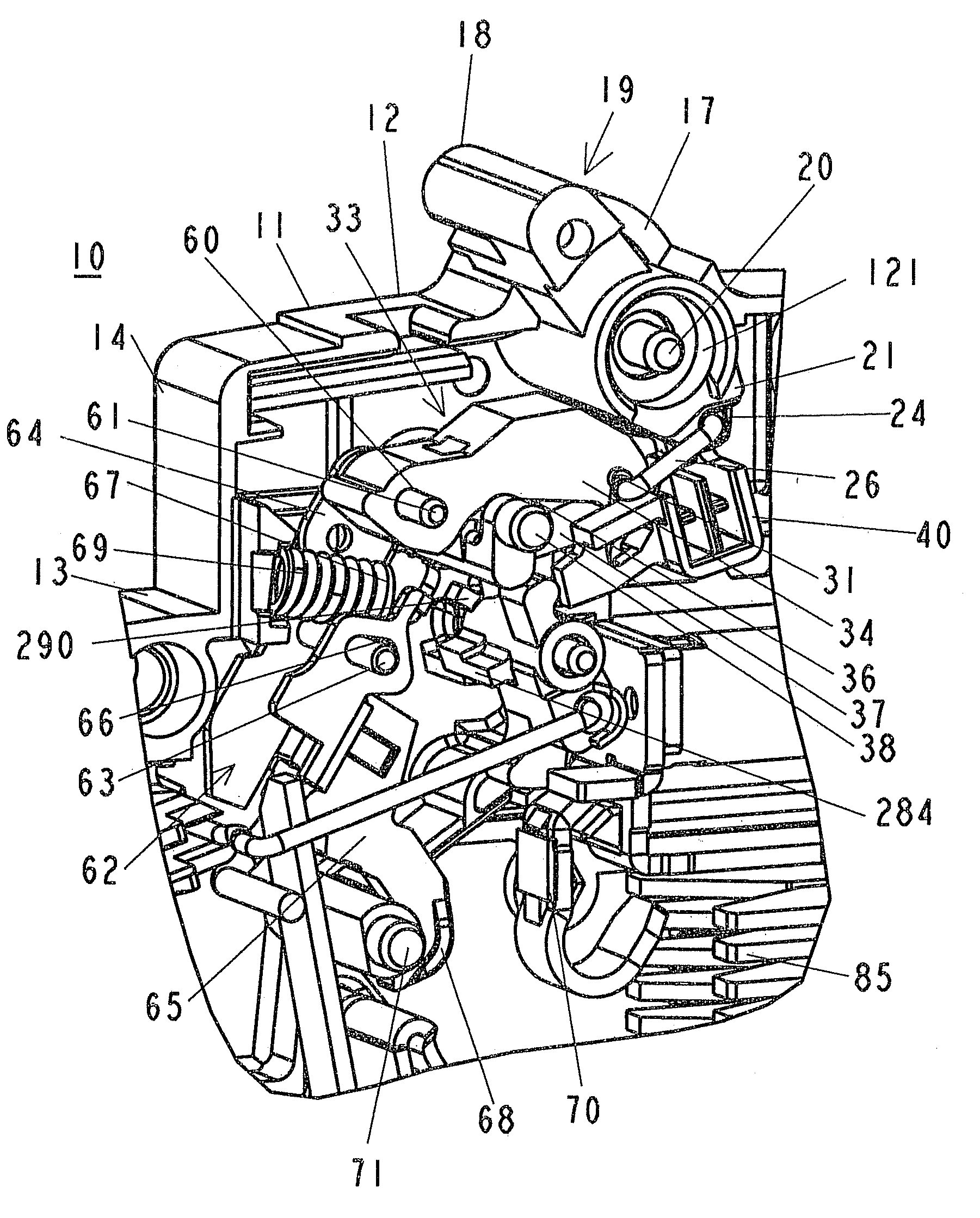

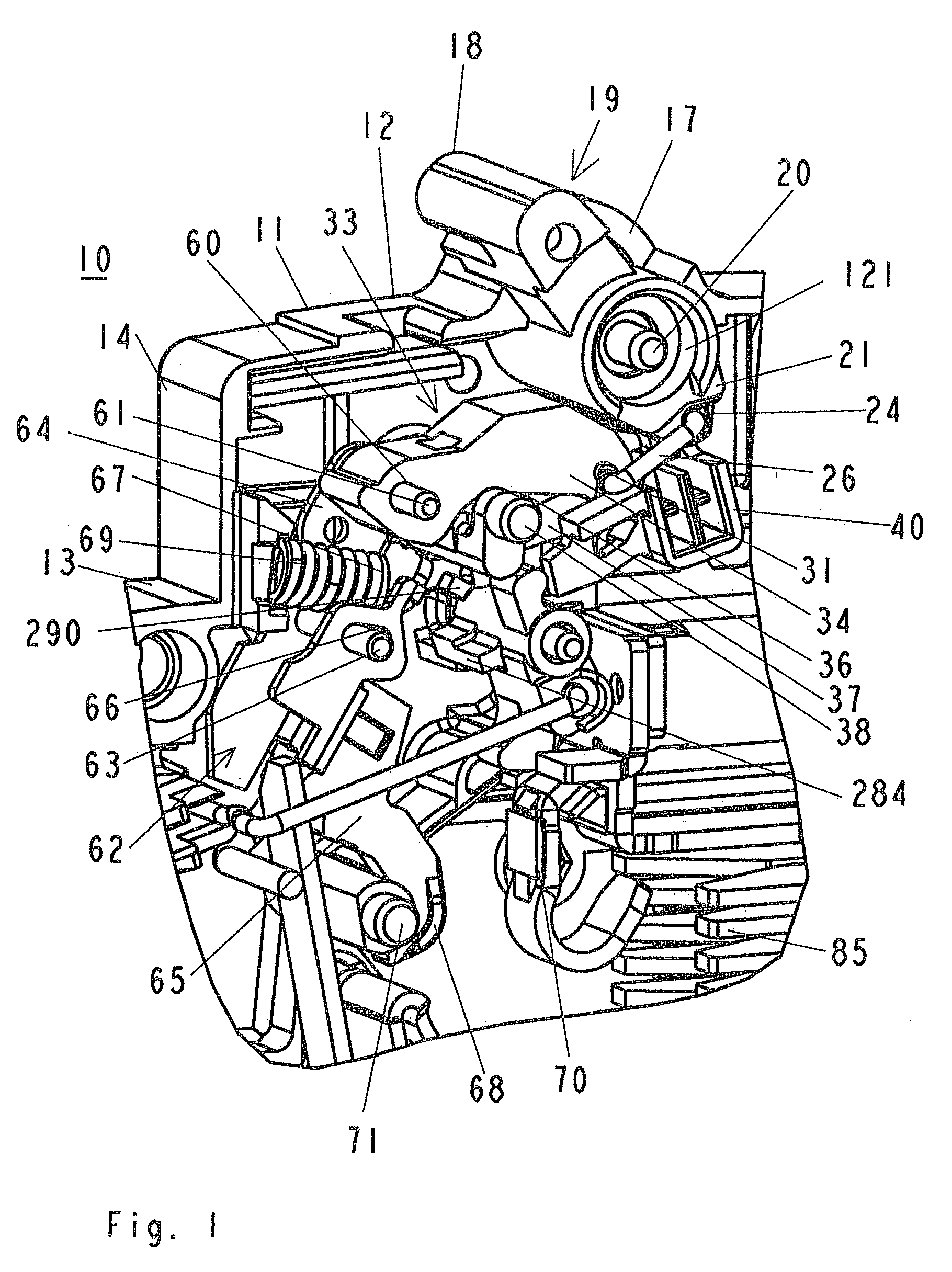

Electrical service switching device

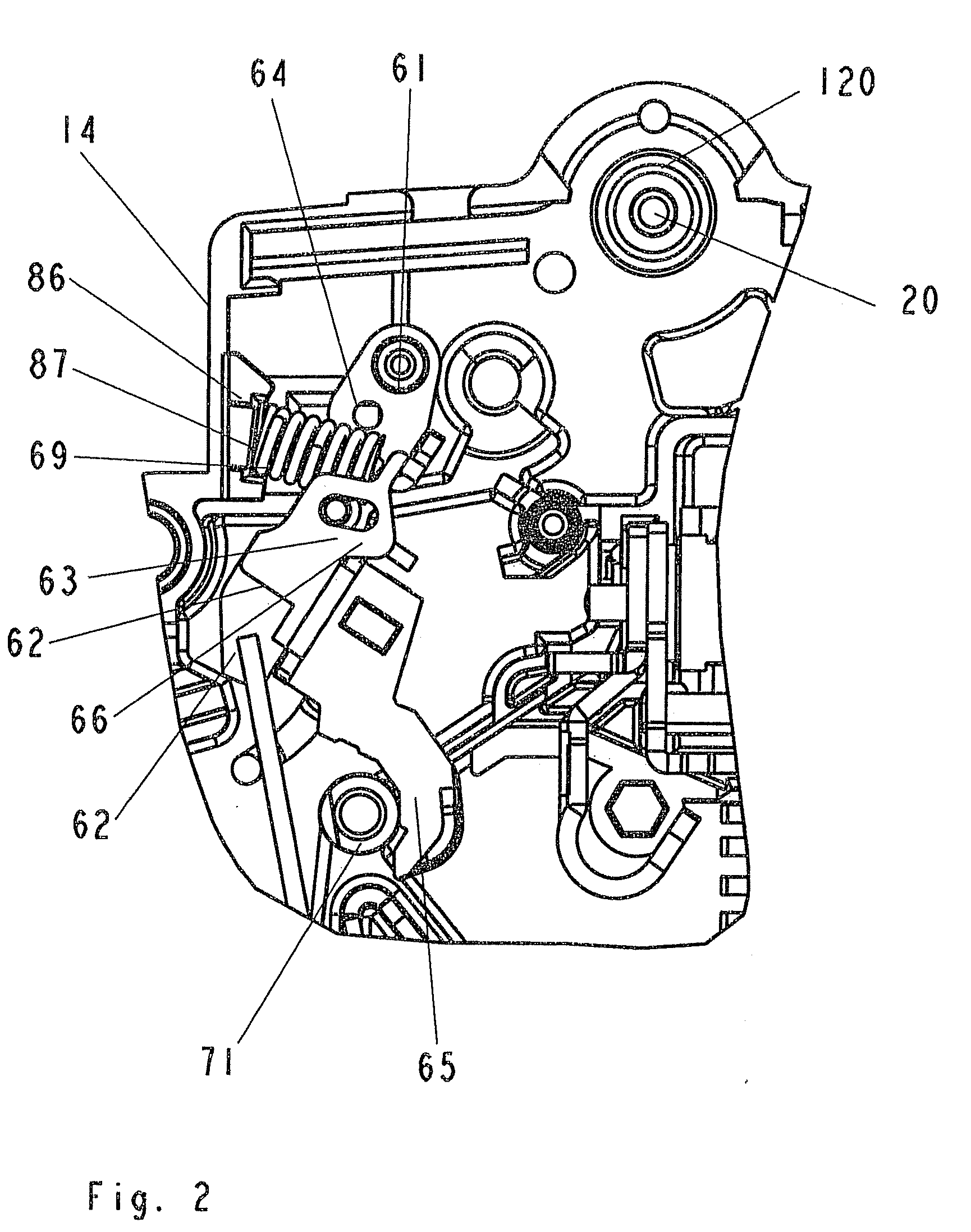

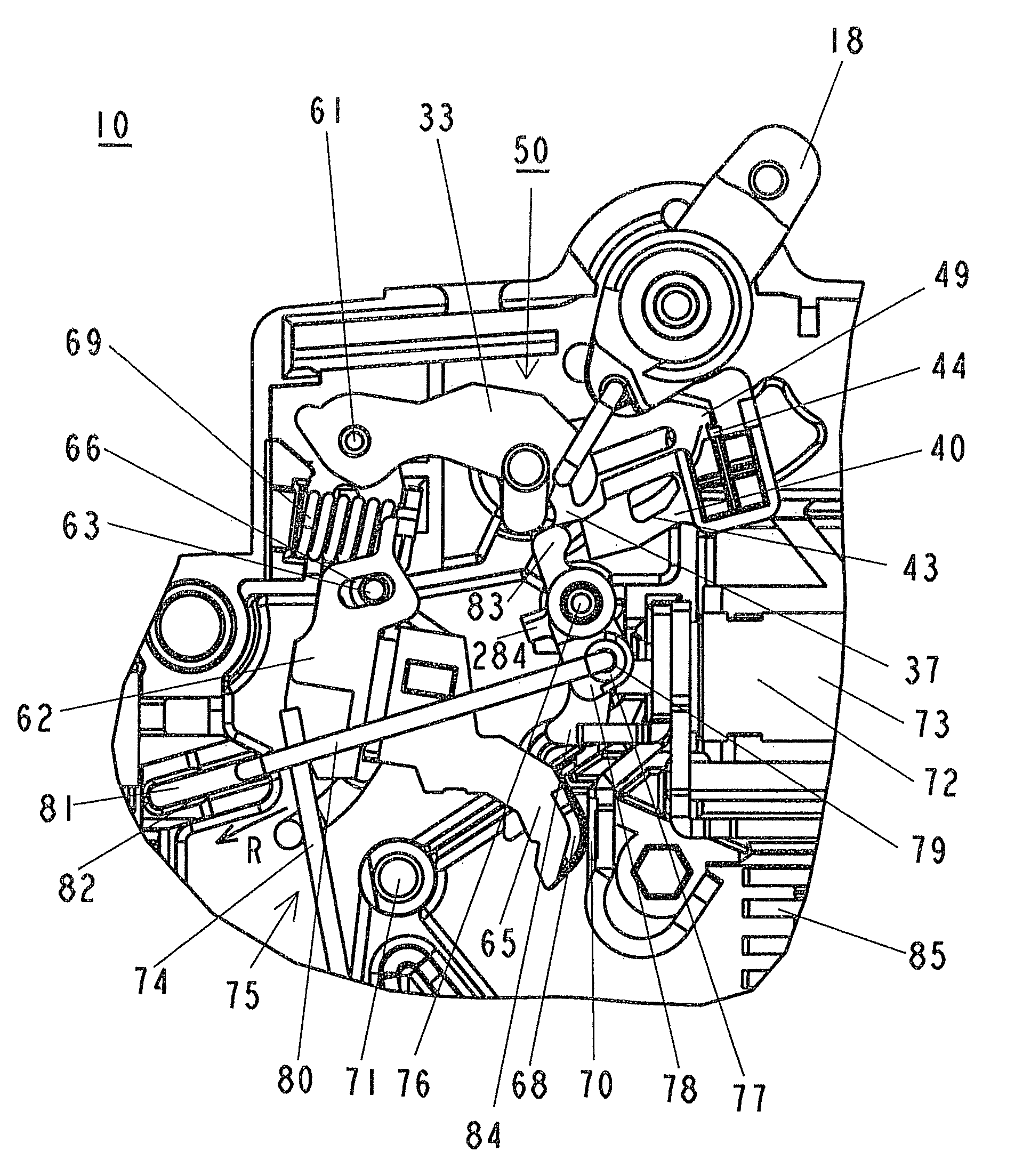

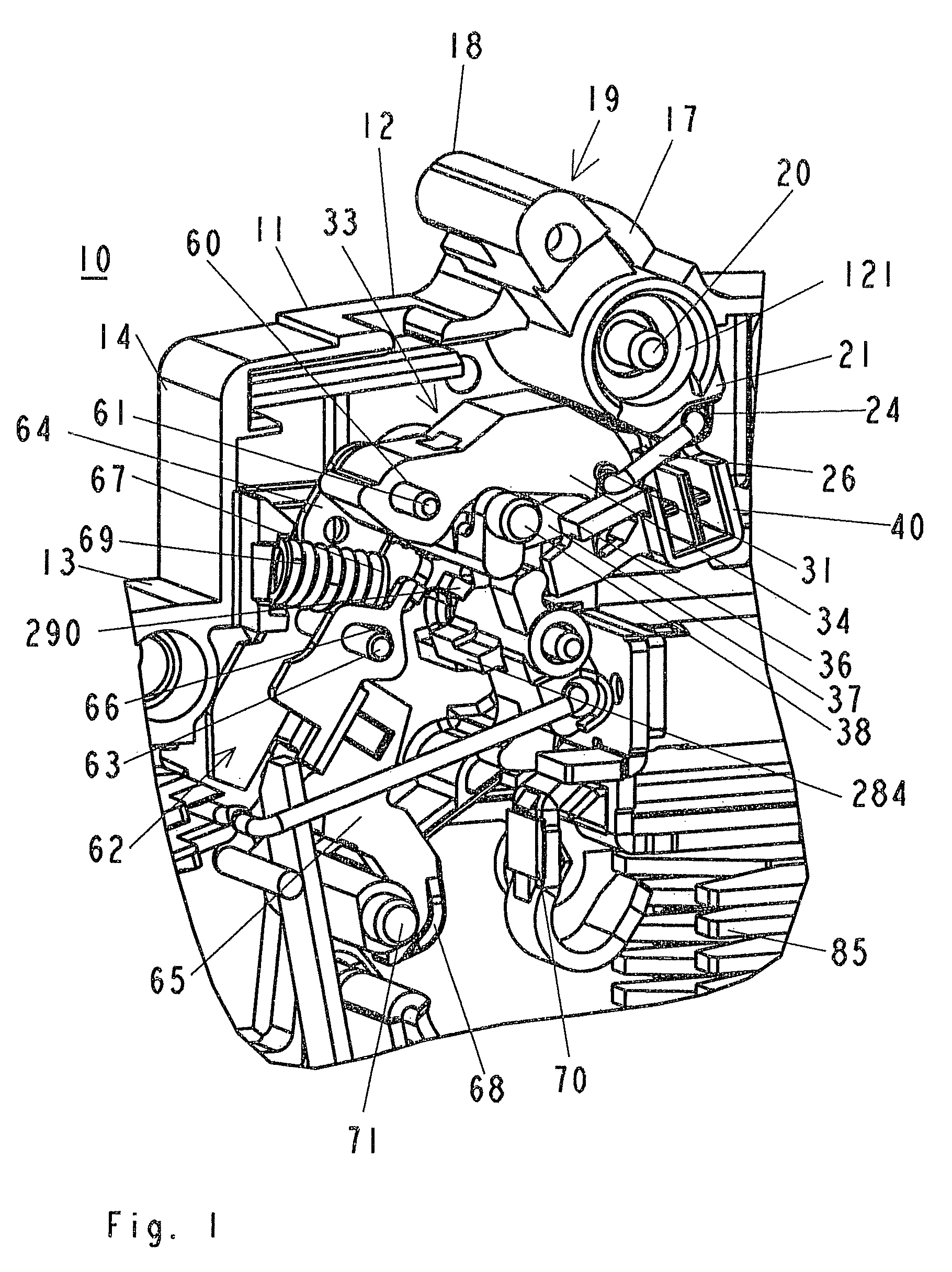

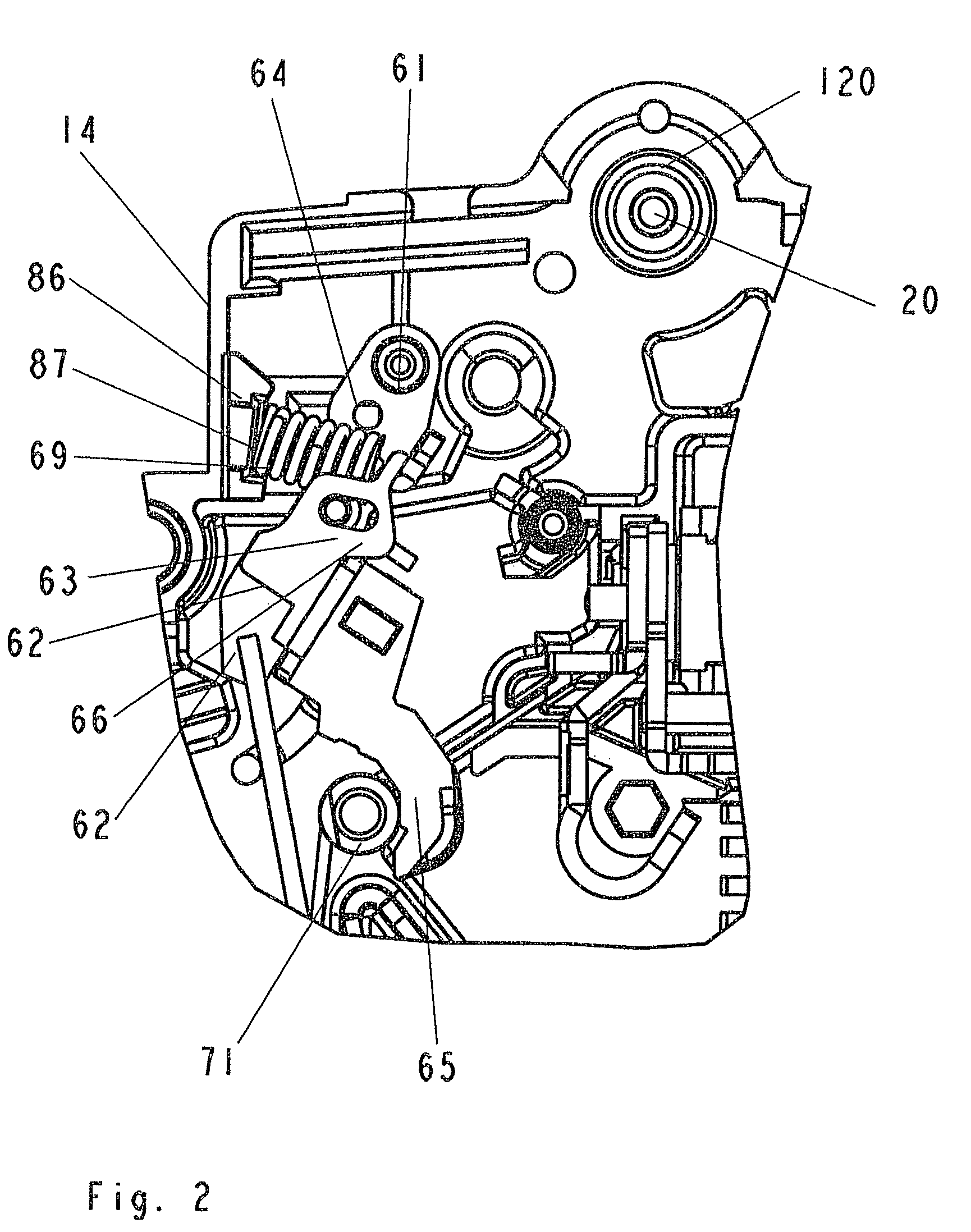

ActiveUS20080290971A1High positionHigh shapeSwitches with electrothermal and electromagnetic releaseProtective switch operating/release mechanismsEngineeringFixed position

The disclosure relates to an electrical service switching device, e.g., a circuit breaker, having a magnetic release with a magnet armature, a thermal release, a fixed and moving contact piece, a switching mechanism which can be tripped by the thermal and magnetic release and has a latching point which is formed by a tripping lever and a catch lever which is mounted in a fixed position such that it can rotate and has an elongated hole in order to guide a clip, wherein the magnet armature can act on the contact lever, to which the moving contact piece is fitted, in order to open the contact point in the event of a short, and the switching mechanism can hold the contact lever permanently in the open position, having a switching toggle for manual operation of the switching mechanism, and having an intermediate lever which is articulated at one of its ends with the contact lever and at its other end on the clip, wherein the clip is articulated with at least one limb on the switching toggle.

Owner:ABB (SCHWEIZ) AG

Electrical service switching device

ActiveUS7839241B2High positionHigh shapeSwitches with electrothermal and electromagnetic releaseProtective switch operating/release mechanismsFixed positionCircuit breaker

The disclosure relates to an electrical service switching device, e.g., a circuit breaker, having a magnetic release with a magnet armature, a thermal release, a fixed and moving contact piece, a switching mechanism which can be tripped by the thermal and magnetic release and has a latching point which is formed by a tripping lever and a catch lever which is mounted in a fixed position such that it can rotate and has an elongated hole in order to guide a clip, wherein the magnet armature can act on the contact lever, to which the moving contact piece is fitted, in order to open the contact point in the event of a short, and the switching mechanism can hold the contact lever permanently in the open position, having a switching toggle for manual operation of the switching mechanism, and having an intermediate lever which is articulated at one of its ends with the contact lever and at its other end on the clip, wherein the clip is articulated with at least one limb on the switching toggle.

Owner:ABB (SCHWEIZ) AG

Preparation method of low-cost medium carbon steel spherical powder for 3D printing

PendingCN111570814AHigh sphericityGood surface morphologyTransportation and packagingMetal-working apparatusCarbon steelVacuum induction melting

The invention discloses a preparation method of low-cost medium carbon steel spherical powder for 3D printing. The preparation method comprises the following steps: proportioning medium carbon steel from the following components: 0.43% of C, 0.58% of Mn, 0.18% of Si, 0.25% of Cr, 0.24% of Ni and the balance of Fe, adopting vacuum induction melting to prepare a carbon steel bar, removing the oxidescale on the surface of the alloy bar through machining to process an electrode bar size meeting the requirement of a plasma rotating electrode atomization powder manufacturing apparatus, placing theelectrode bar in a flour mill, adopting a plasma gun to melt the end part of the electrode bar to obtain spherical powder under the action of the centrifugal force, and later, adopting supersonic vibration to screen the collected powder according to different particle sizes. According to the preparation method, plasma rotating electrode atomization is adopted to prepare medium carbon steel spherical metal powder, and the prepared powder has the characteristics of being high in degree of sphericity, less in satellite powder, high in powder density and low in impurity content, can meet the demand of metal powder for 3D printing and is suitable for wide popularization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

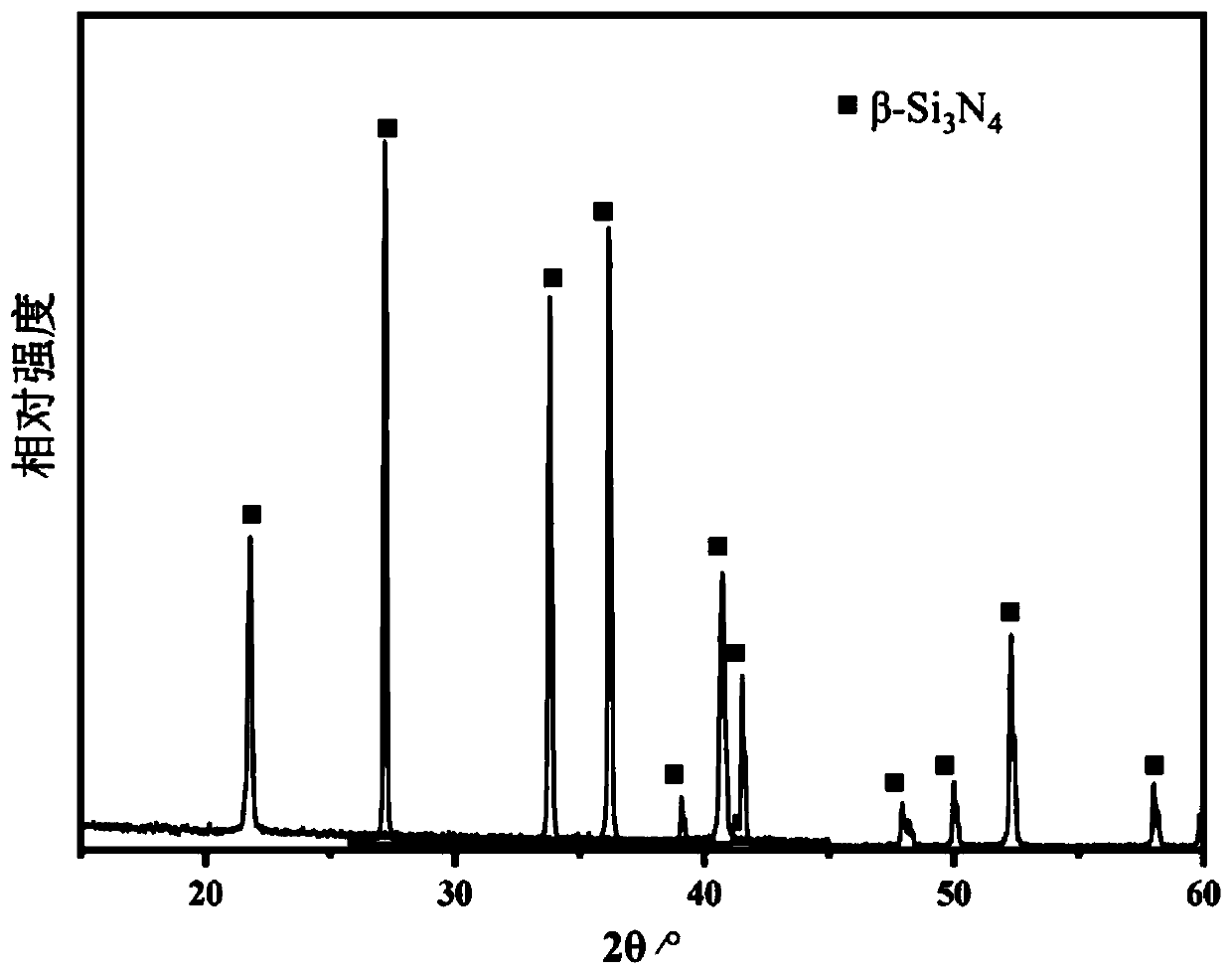

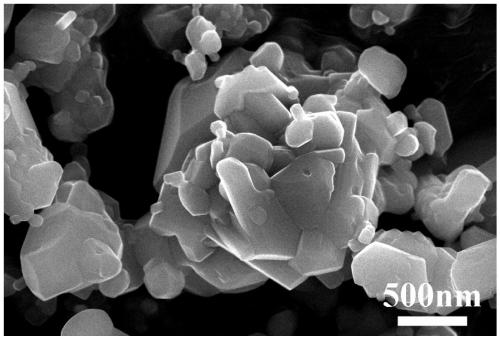

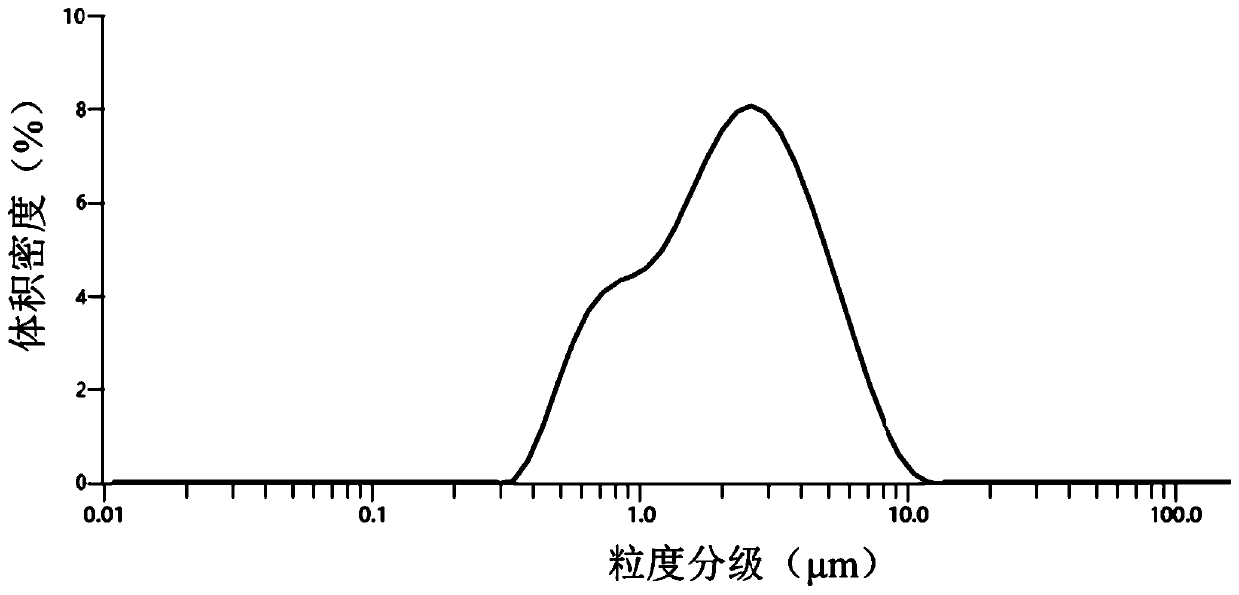

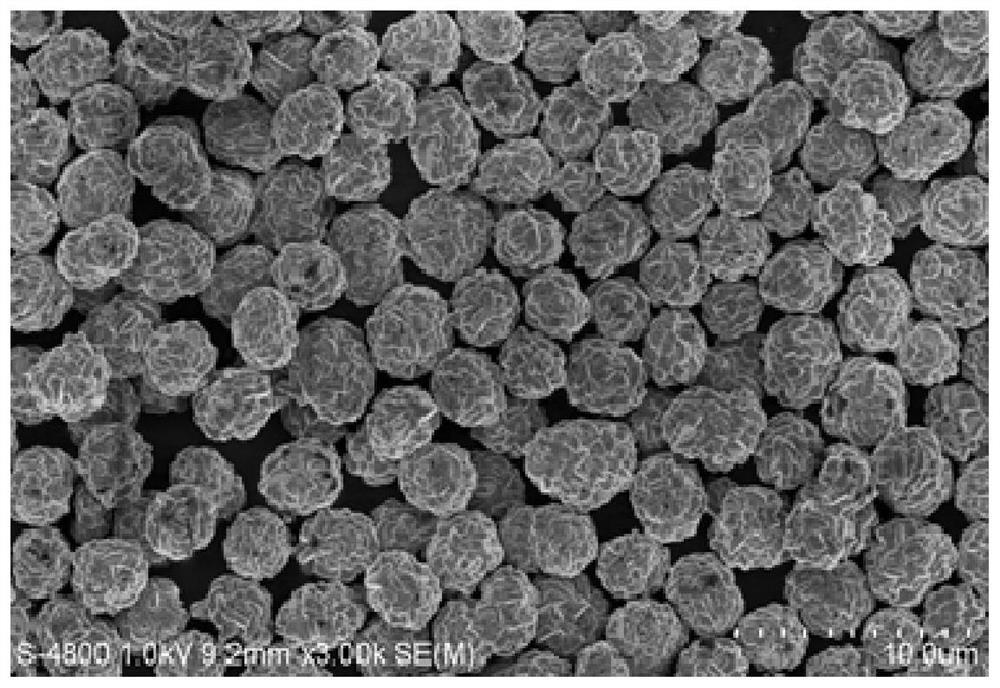

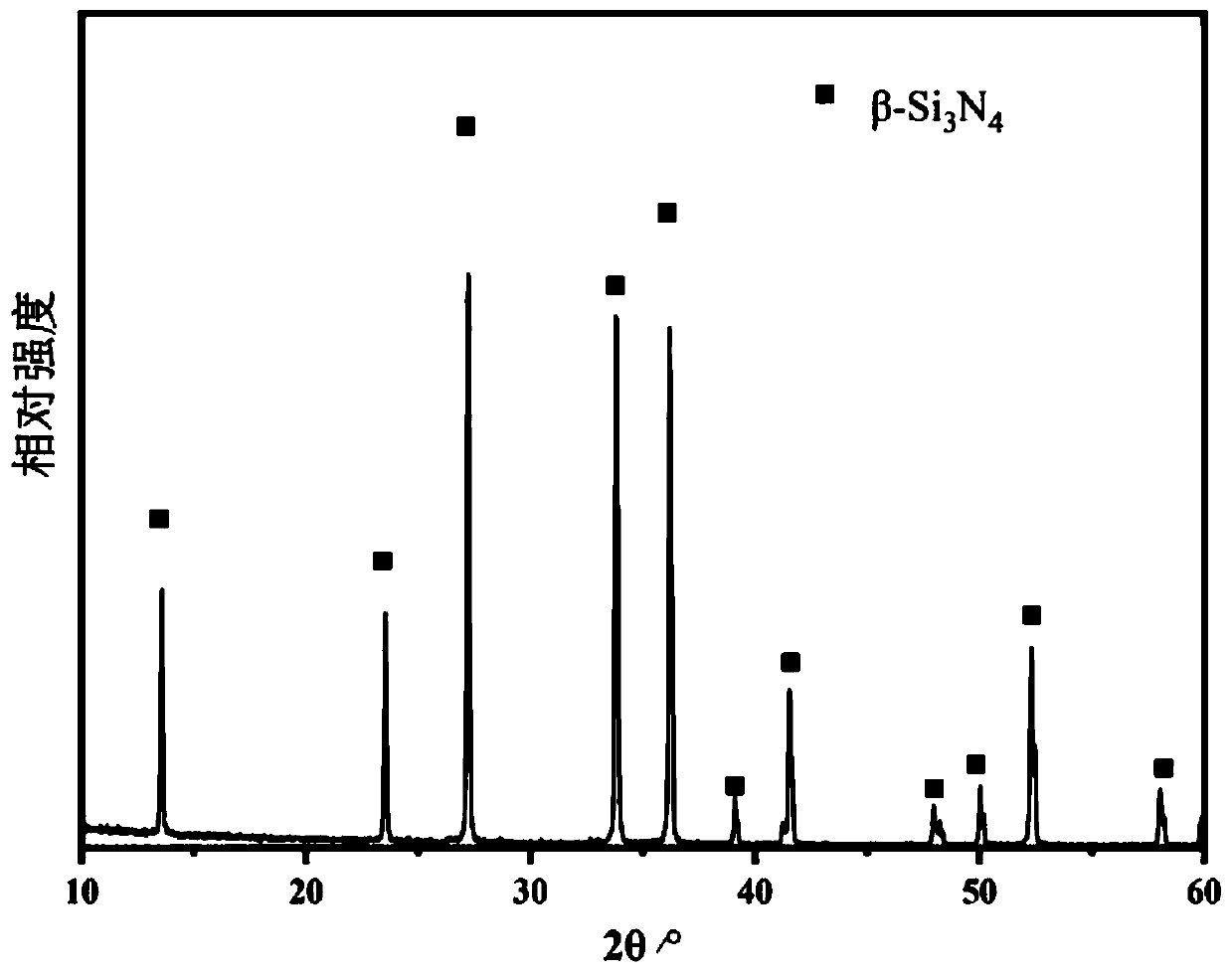

High-purity low-aluminum type spherical beta silicon nitride powder as well as manufacturing method and application thereof

PendingCN109761206AHigh sphericityLow impurity contentNitrogen compoundsHeat-exchange elementsGranularityMetallurgy

The invention provides high-purity low-aluminum type spherical beta silicon nitride powder. The sphericity degree of the silicon nitride powder is between 0.5 and 0.99; Al impurity content is less than 500 ppm; granularity range is between 0.5 mum and 50 mum; the beta silicon nitride powder can be used as a filling material of an electronic encapsulation material, and is particularly applicable tohigh-heat-conductivity ultra-high-frequency and extreme-high-frequency electronic encapsulation materials, such as the field of burgeoning 5G communication.

Owner:QINGDAO CUP NEW MATERIALS CO LTD

Single-crystal type multi-element positive electrode material as well as preparation method and application thereof

ActiveCN114703544ARound shapeUniform particle sizePolycrystalline material growthElectrode thermal treatmentPhysical chemistrySingle crystal

The invention relates to the technical field of lithium ion batteries, and discloses a single crystal type multi-element positive electrode material and a preparation method and application thereof. The positive electrode material meets the following conditions: the single crystal sizes DPS90, DPS10 and DPS50 of the positive electrode material measured by SEM meet the following relation: 0.1 < = B90 = (DPS90-DPS10) / DPS50 < = 1.5; the agglomeration rate of the positive electrode material is less than or equal to 20%; wherein 90% of the single crystal size of the DPS90 positive electrode material is smaller than that of DPS90; the single crystal size of the DPS50 positive electrode material is 50% smaller than that of DPS50; the single crystal size of the DPS10 positive electrode material is 10% smaller than that of DPS10. The single crystal type multi-element positive electrode material is round and full in morphology, uniform in particle size, less in agglomeration, less in adhesion, high in compaction density and good in structural stability, and when the single crystal type multi-element positive electrode material is applied to the lithium ion battery, the energy density, the rate capability, the cycling stability and the safety of the lithium ion battery can be improved.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

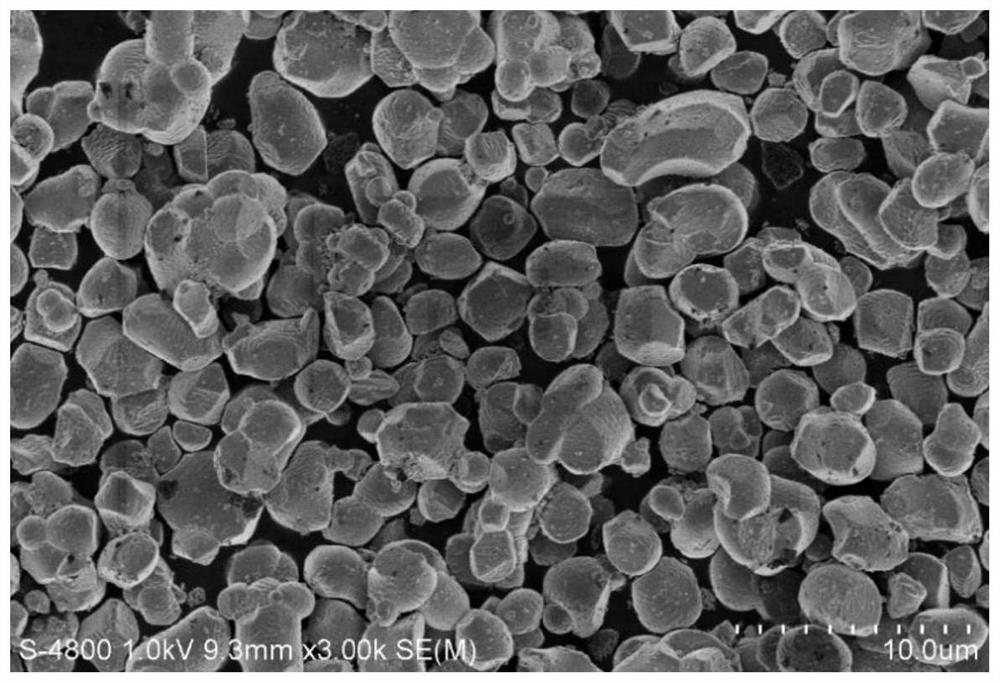

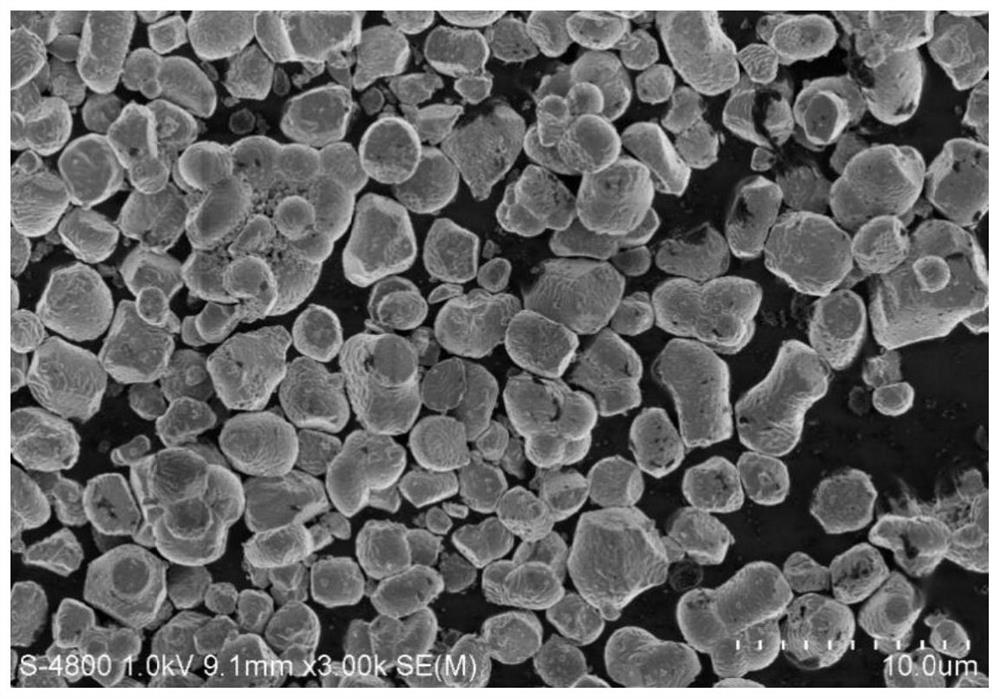

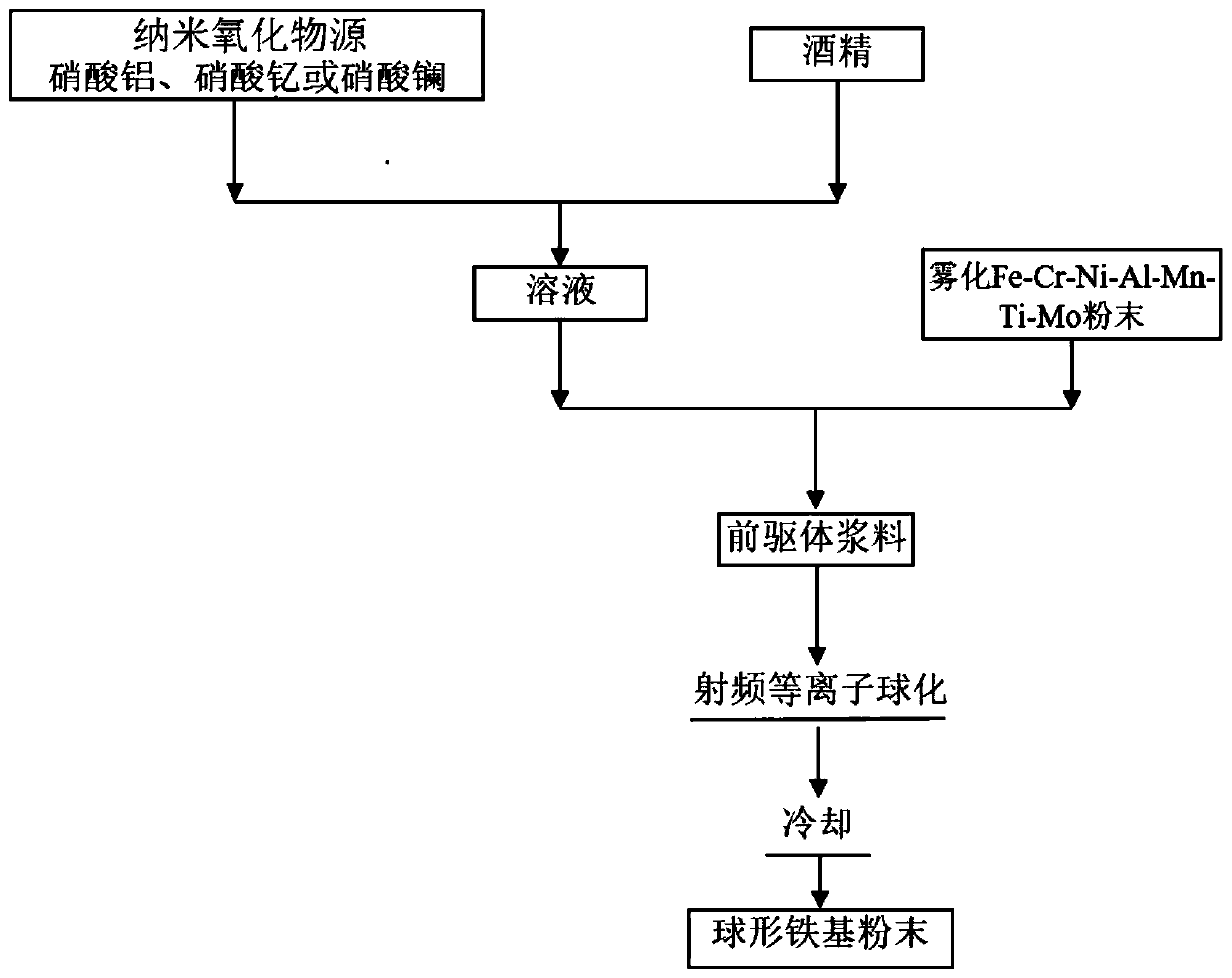

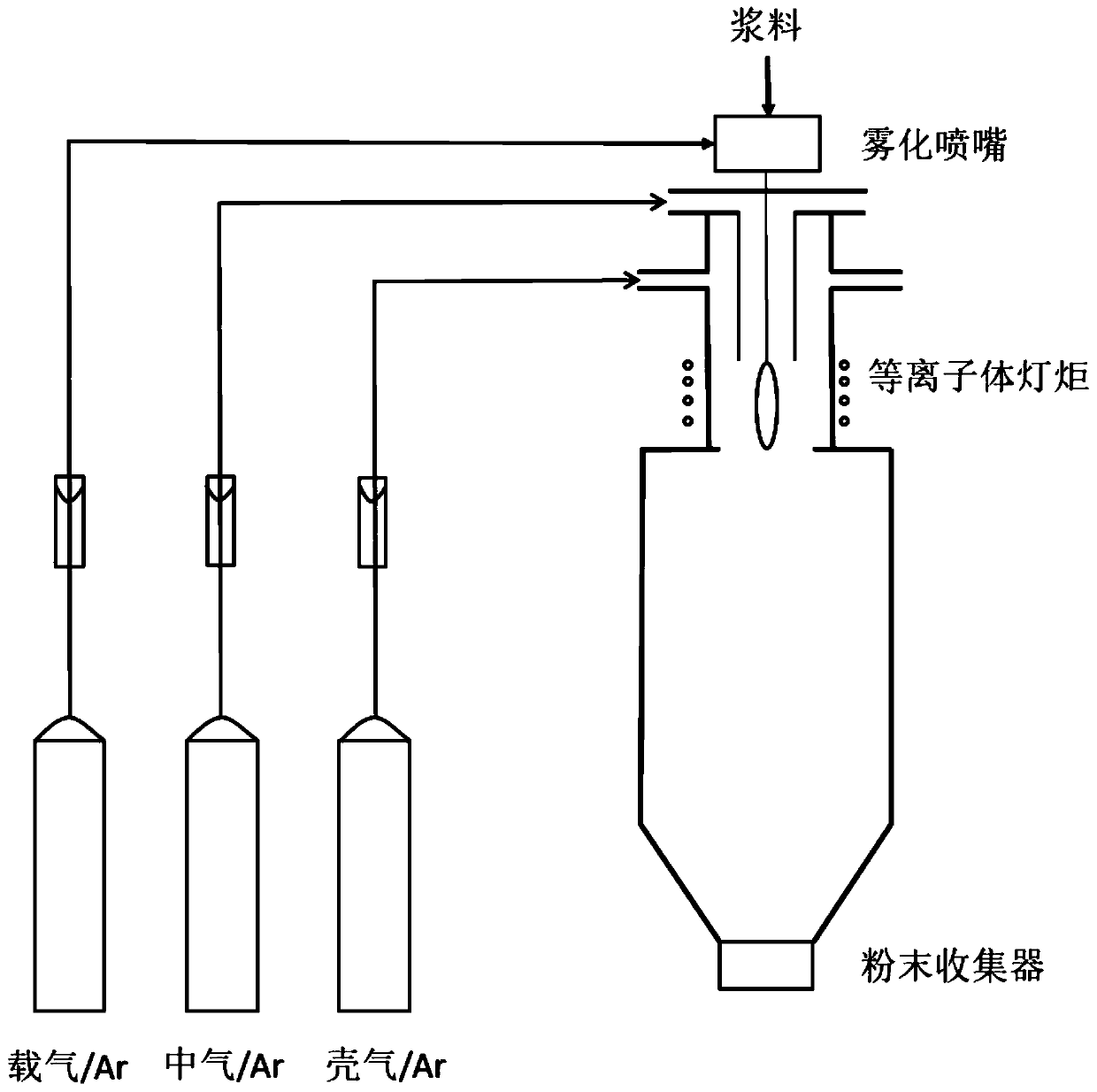

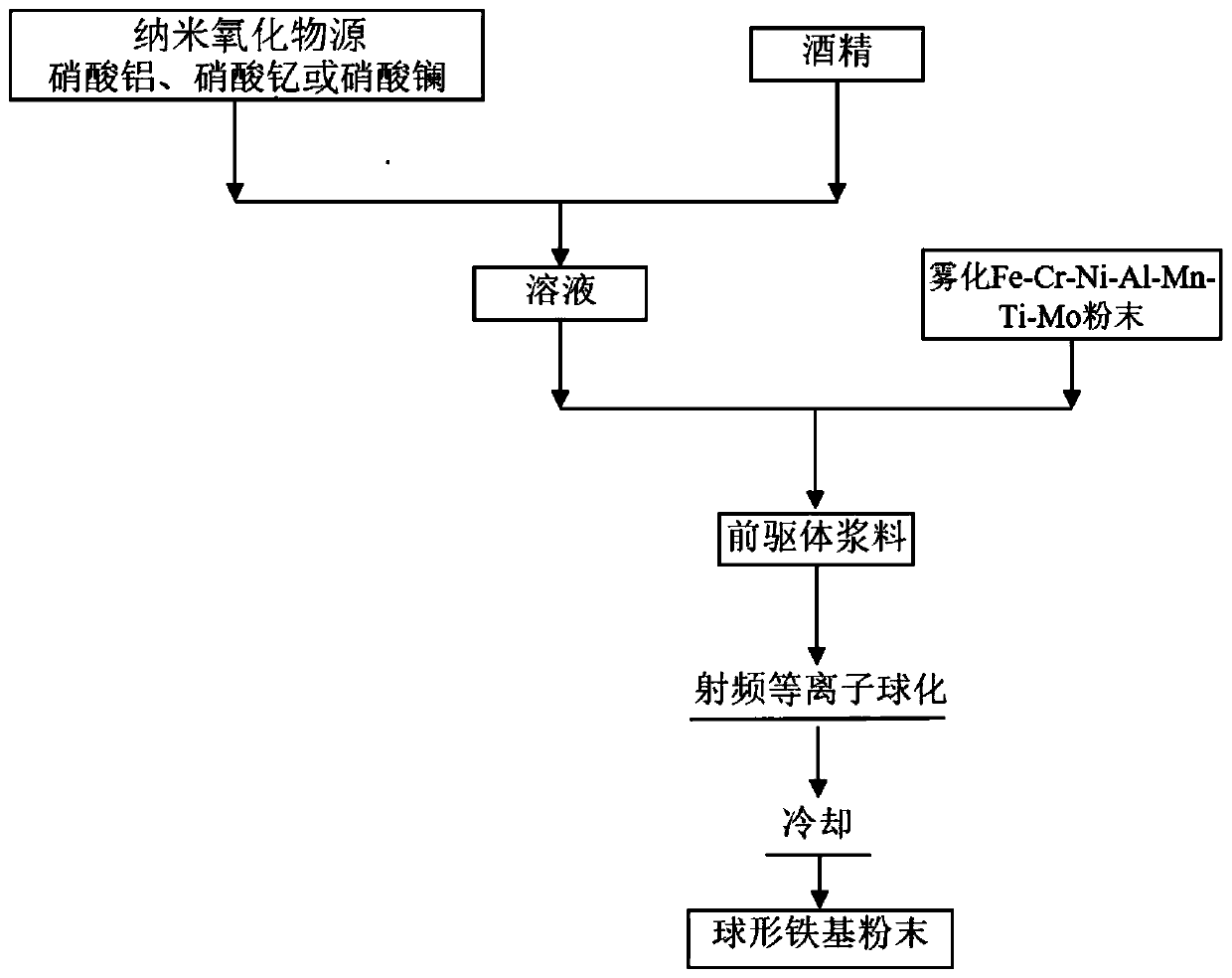

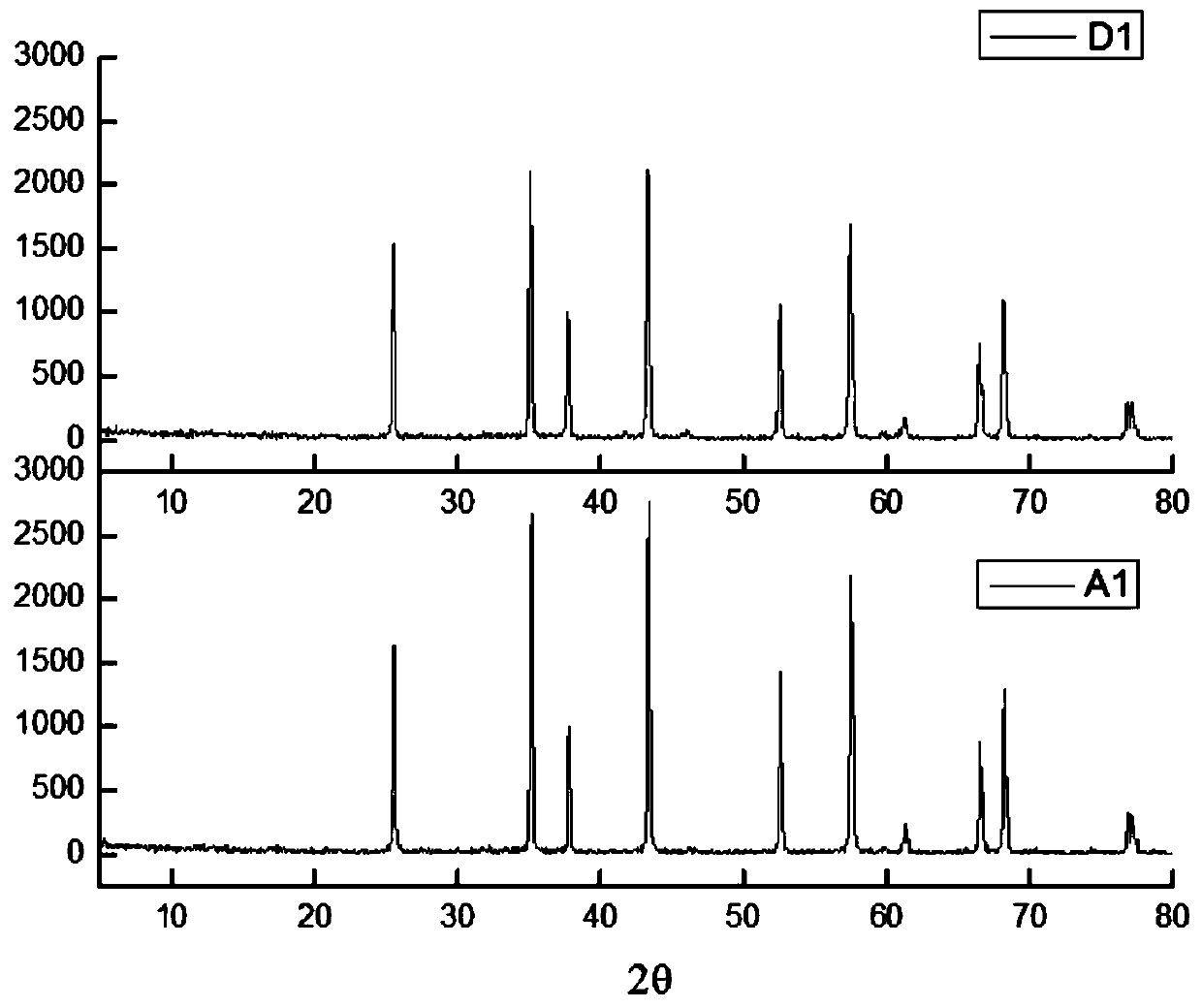

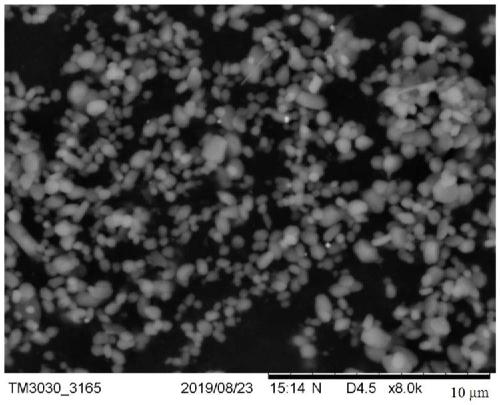

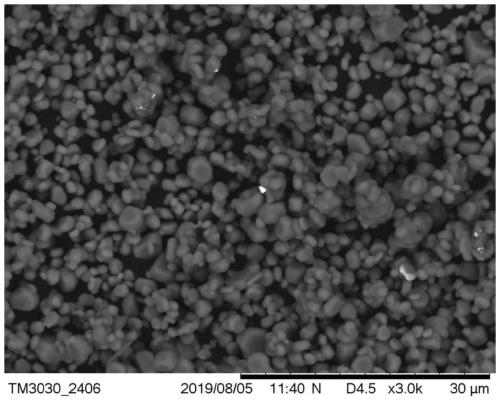

Preparation method of spherical iron-based powder

ActiveCN110014145AHigh sphericityStrong designabilityAdditive manufacturing apparatusTransportation and packagingRadio frequency plasmaOxide

The invention belongs to the field of study on preparation of spherical metal-based powder, and particularly provides a preparation method of intermetallic compound and nano oxide co-reinforced spherical ferrite-based powder. The preparation method comprises the steps that precursor slurry is prepared; and the intermetallic compound and nano oxide co-reinforced spherical ferrite-based powder is prepared, and specifically, radio-frequency plasma spheroidization is conducted on the obtained precursor slurry, the precursor slurry is delivered into an anatomization nozzle through a carrier gas, isatomized, and then reaches a high-temperature region for radio-frequency plasma heating, nitrate is decomposed first to obtain corresponding oxide nano particles, and then atomized powder and the oxide nano particles are heated by radio-frequency plasma to be molten and finally turn into the spherical ferrite-based powder under the effect of surface tension. The preparation method provides a novel idea for preparation of the intermetallic compound and nano oxide co-reinforced spherical ferrite-based powder and has the advantage of short production cycle, low cost, convenient operation, and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

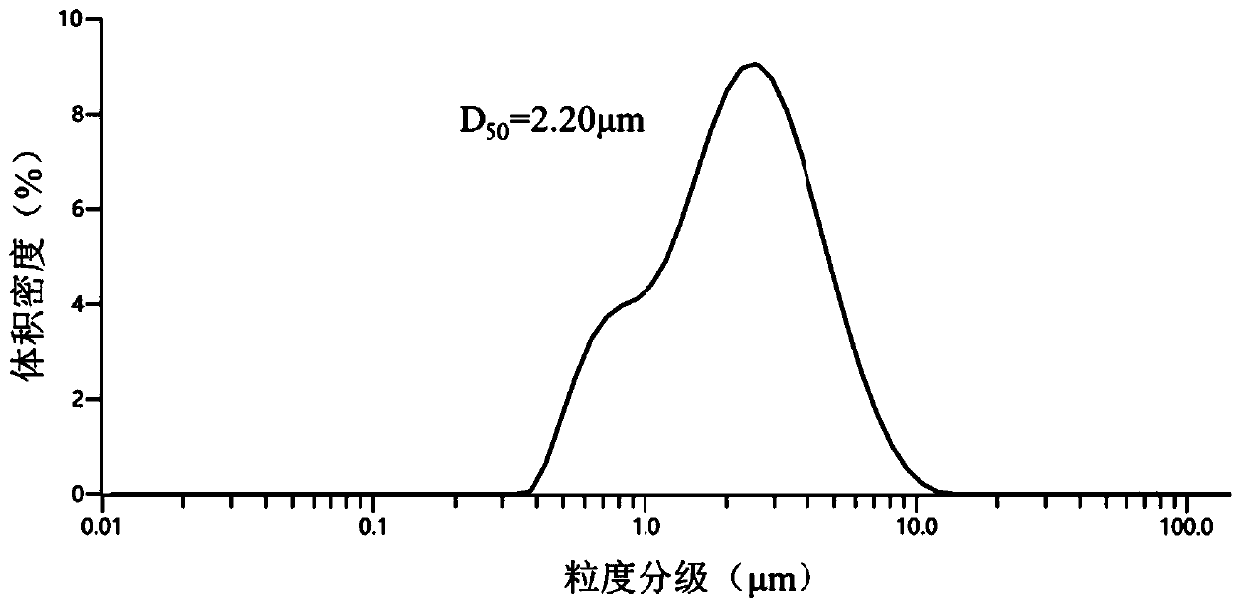

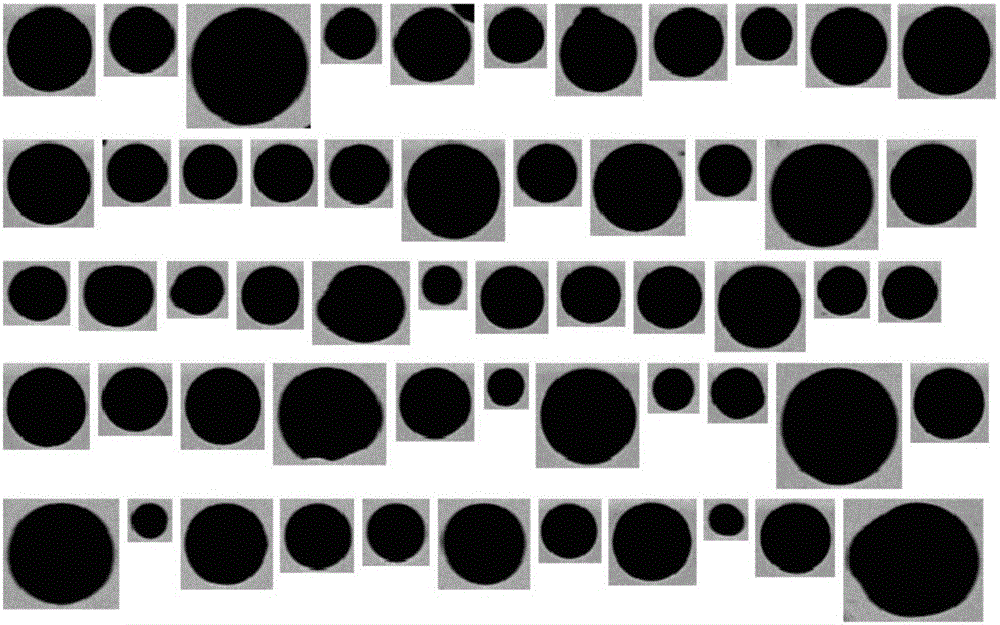

Alpha-alumina micro-powder, preparation method and application thereof

InactiveCN111302368AHigh shapeNarrow particle size distributionAluminium oxides/hydroxidesSlurrySolvent

The invention relates to alpha-aluminum oxide micro-powder, a preparation method and application thereof, wherein the sphericity of the alpha-alumina micro-powder is 0.5-1, and the particle size D50-0of the alpha-alumina micro-powder is 0.5-8 [mu]m. The method comprises the following steps: (1) pulping: mixing an aluminum oxide raw material and a solvent to prepare slurry, and adjusting the pH value of the slurry to 3-6 by using an acid; (2) ball milling: carrying out ball milling on the slurry obtained in the step (1), and controlling the granularity of intermediate particles in the slurry according to the target granularity of an end product; (3) removing of the solvent in the ball-milled slurry obtained in the step (2) to obtain first aluminum oxide powder; and (4) calcining: mixing the first aluminum oxide powder with a mineralizing agent, and calcining to obtain the alpha-aluminum oxide micro-powder with the target particle size. The alpha-alumina micro-powder provided by the invention is high in sphericity and narrow in particle size distribution, particularly the target particle size of a final product can be modulated according to requirements, the modulation range is 0.5-8 [mu]m, the impurity content is low, and the alpha-alumina micro-powder is particularly suitable for the fields of heat conduction, insulating fillers and the like.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

3D-printing metal powder material preparation method capable of reducing hollow powder

InactiveCN106735268AReduce oxygen contentRaise the outlet temperatureAdditive manufacturing apparatusMaterials preparationNitrogen

The invention discloses a 3D-printing metal powder material preparation method capable of reducing hollow powder. The 3D-printing metal powder material preparation method includes A, melting stainless steel or aluminum alloy under protection of micro-positive pressure nitrogen into stainless steel or aluminum alloy liquid; B, taking nitrogen as an atomizing gas, controlling the atomizing pressure as 1.5-2MPa when the aluminum alloy serves as a raw material, controlling the atomizing pressure as 3-4MPa when the stainless steel serves as the raw material, and atomizing the melted stainless steel or aluminum alloy liquid to crush and cool the liquid into spherical or near-spherical stainless steel or aluminum alloy particles; C, collecting the spherical or near-spherical particles obtained in the step B, and treating the spherical or near-spherical particles to obtain 3D-printing metal powder. By the 3D-printing metal powder material preparation method, quantity of the hollow powder is reduced greatly, and 3D printing quality and mechanical property are improved.

Owner:NANTONG JINYUAN INTELLIGENT TECH CO LTD

Preparation technology of superfine spherical nickel, cobalt and iron ternary alloy powder

The invention relates to a preparation technology of superfine spherical nickel, cobalt and iron ternary alloy powder and belongs to the field of powder metallurgy. The preparation technology includes the four steps of burdening, liquid phase reduction, high energy ball milling and post-processing. Nickel, cobalt and iron salt materials are added in a liquid phase reduction agent to be reduced. Ethyl alcohol is added in obtained reduced products, and mixtures are ball-milled in a high-energy ball mill. Then products are obtained through vacuum drying and packaging. The preparation technology of the superfine spherical nickel, cobalt and iron ternary alloy powder is provided. The technological process is short; production efficiency is high; waste water containing ammonia and nitrogen is not generated; cost is low; particle size distribution of obtained nickel, cobalt and iron is uniform; the Fsss particle size is small; and the nickel, cobalt and iron ternary alloy powder is spherical.

Owner:兰云科

Ultrapure low radioactive spheroid beta silicon nitride powder as well as manufacturing method and application thereof

PendingCN109761205AHigh sphericityLow radioactive impurity contentNitrogen compoundsHeat-exchange elementsSemiconductor packageElectron

The invention relates to ultrapure low radioactive spheroid beta silicon nitride powder. The sphericity degree is high; the purity is high; the uranium and thorium impurity content reaches 5ppb or below. The beta silicon nitride powder can be used as a filling material of an electronic encapsulating material, and is particularly applicable to a high-heat-conduction memory semiconductor encapsulating material.

Owner:QINGDAO CUP NEW MATERIALS CO LTD

Method for preparing silicon carbide granulation powder for reflecting mirror

The invention provides a method for preparing silicon carbide granulation powder for a reflecting mirror. The carbide granulation powder contains silicon carbide powder, an organic binder, a sintering aid and the like and is formed by binding a plurality of silicon carbide particles with the binder. The method comprises the steps as follows: the silicon carbide powder, the sintering aid, a dispersant, a plasticizer, the binder and a defoamer are added in sequence to deionized water as a solvent, and are stirred and then subjected to vacuum defoaming and spray drying after being stirred uniformly, and the silicon carbide granulation powder is obtained. The granulation powder with good sphericity and good fluidity can be prepared with the addition of the binder, the dispersant and the plasticizer in a proper proportion; hollow spherical particles are prevented from being prepared by the aid of the defoamer and a vacuum defoaming process, and the surface processing quality of the silicon carbide reflecting mirror is effectively improved.

Owner:北京钢研新冶精特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com