Alpha-alumina micro-powder, preparation method and application thereof

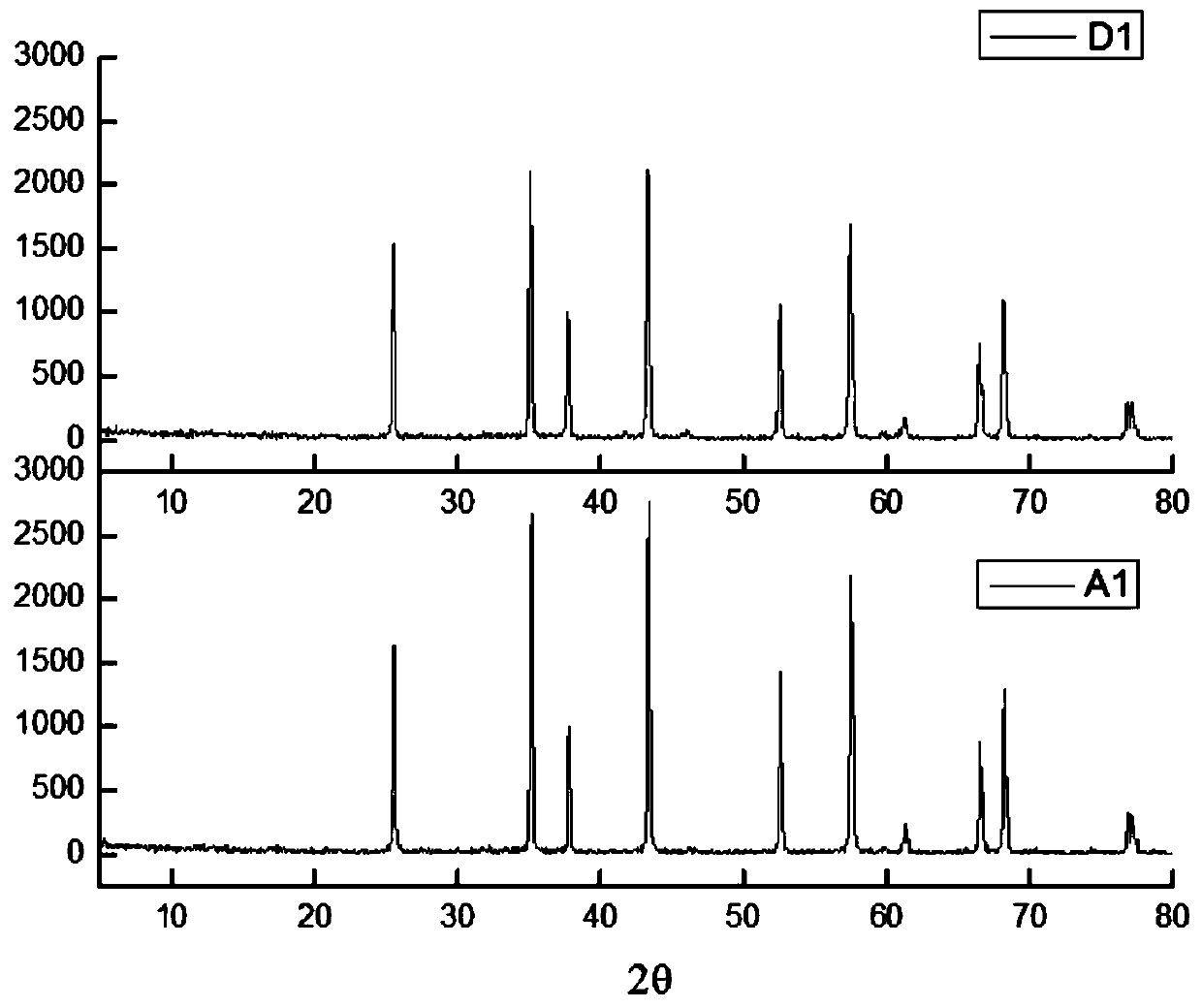

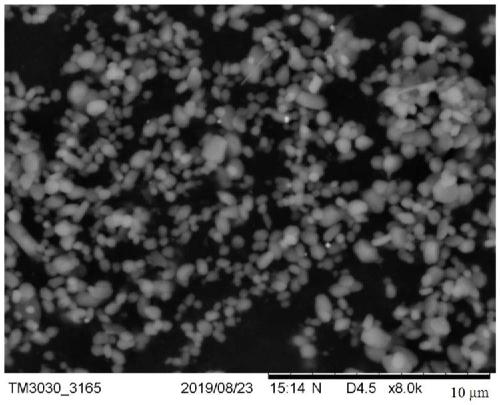

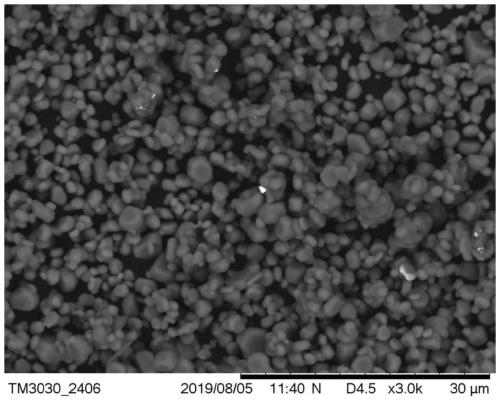

A technology of alumina micropowder and alumina, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve the problems of high impurity content, low sphericity, wide particle size distribution, etc., and achieve low impurity content , high sphericity and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] (1) Mix 1kg of industrial alumina (purity>99%), 4g of polyvinyl alcohol and 4L of deionized water to form a uniform slurry, and use nitric acid (1mol / L) to adjust the pH of the slurry to 5;

[0075] (2) The slurry obtained in step (1) is ball milled in a ball mill to obtain a liquid slurry containing intermediate particles (wherein, the D of the intermediate particles 50 = 1 μm, and (D 90 -D 10 ) / D 50 = 3.3; D of target alumina powder 50 -0=1.5 μm), the ball milling condition is: the mass ratio of grinding ball (alumina with a purity of 97%) to industrial alumina=15:1; the first grinding ball (diameter is 1mm) and the second grinding ball ( 3mm in diameter) mass ratio = 4:1;

[0076] (3) The slurry after ball milling is pressed into a filter cake in a filter press, evaporated to dryness quickly by flash evaporation, and crushed to obtain the first alumina powder;

[0077] (4) 3 g of boric acid and 3 g of aluminum fluoride were added to the first alumina powder, mix...

Embodiment 2

[0079] (1) Mix 1 kg of industrial alumina (same as Example 1), 2 g of polyacrylamide and 2.5 L of deionized water to form a uniform slurry, and use nitric acid (5 mol / L) to adjust the pH of the slurry to 6;

[0080] (2) The slurry obtained in step (1) is ball milled in a ball mill to obtain a liquid slurry containing intermediate particles (wherein, the D of the intermediate particles 50 = 1.8μm, and (D 90 -D 10 ) / D 50 = 3.7; D of the target alumina powder 50 -0=3μm), the ball milling conditions are: the mass ratio of grinding balls (alumina with a purity of 97%) to industrial alumina=10:1; the first grinding ball (2mm in diameter) and the second grinding ball (diameter 5mm) mass ratio = 2:1;

[0081] (3) The slurry after ball milling is pressed into a filter cake in a filter press, evaporated to dryness quickly by flash evaporation, and crushed to obtain the first alumina powder;

[0082] (4) 2.5 g of boric acid and 7.5 g of ammonium chloride were added to the first alum...

Embodiment 3

[0084] (1) 1 kg of industrial alumina (same as Example 1) was mixed with 2.5 L of deionized water to form a uniform slurry, and the pH of the slurry was adjusted to 3 using sulfuric acid (5 mol / L);

[0085] (2) The slurry obtained in step (1) is ball milled in a ball mill to obtain a liquid slurry containing intermediate particles (wherein, the D of the intermediate particles 50 = 0.8μm, and (D 90 - / D 10 ) / D 50 = 3; D of the target alumina powder 50 -0=3.5μm), the ball milling conditions are: the mass ratio of grinding balls (aluminum oxide with a purity of 97%) to aluminum oxide=20:1; the first grinding ball (diameter is 1mm) and the second grinding ball (diameter 2.5mm) mass ratio = 3:1;

[0086] (3) The slurry after ball milling is pressed into a filter cake in a filter press, evaporated to dryness quickly by flash evaporation, and crushed to obtain the first alumina powder;

[0087] (4) 5.8 g of boric acid and 4 g of ammonium fluoride were added to the first alumina p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com