Method for preparing silicon carbide granulation powder for reflecting mirror

A manufacturing method and technology of silicon carbide powder, which are applied in the field of ceramic materials, can solve problems such as affecting the surface processing quality of mirrors, and achieve the effect of avoiding hollow spherical particles and improving processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

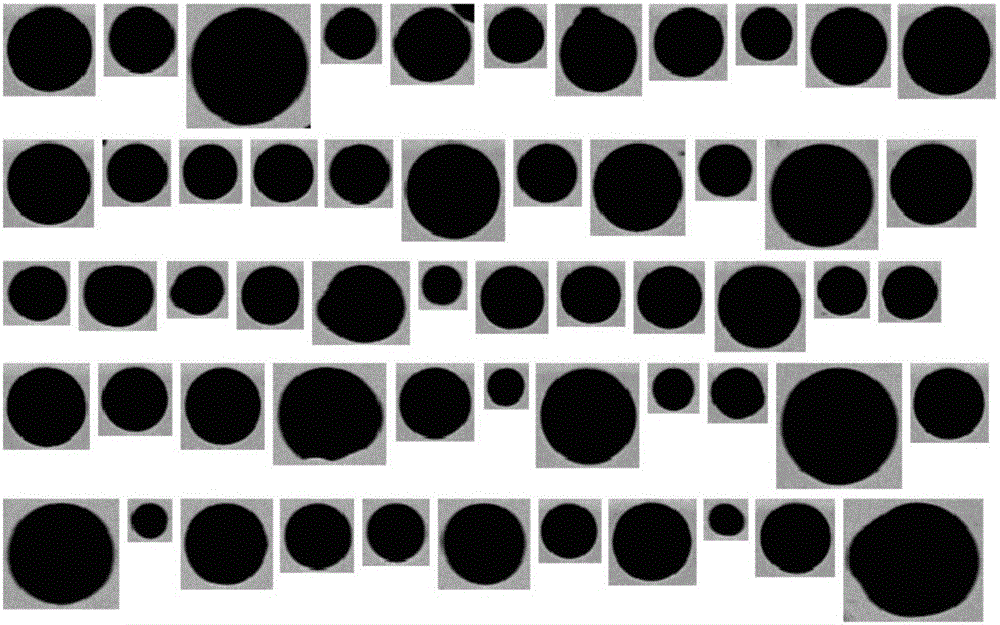

Image

Examples

Embodiment 1

[0023] A method for preparing silicon carbide granulated powder for reflectors, comprising the following steps:

[0024] 1) Mixing: Add appropriate amount of silicon carbide ceramic grinding medium to the vertical stirring mill, the mass ratio of silicon carbide ceramic grinding medium to ceramic slurry is 2:1; add deionized water to silicon carbide powder according to the mass ratio of 1.6:1 Ionized water and silicon carbide powder; based on silicon carbide powder, add B 4 C, 5% mixture of B and C, 1% tetramethylammonium hydride, 0.1% n-octanol, start stirring after mixing. After stirring for 1 hour, add 6% diethylhexyl phthalate, continue stirring for 0.5 hour, then add 10% polyethylene glycol, and stir for another 1 hour to extract the slurry.

[0025] 2) Vacuum defoaming: put the uniformly stirred ceramic slurry in a vacuum defoaming machine, the vacuum degree is controlled at 20 Pa, keep it for 1 hour, and then take it out.

[0026] 3) Spray drying: adjust the inlet tem...

Embodiment 2

[0029] A method for preparing silicon carbide granulated powder for reflectors, comprising the following steps:

[0030] 1) Mixing: Add appropriate amount of silicon carbide ceramic grinding medium to the vertical stirring mill, the mass ratio of silicon carbide ceramic grinding medium to ceramic slurry is 2.5:1; add deionized water to silicon carbide powder according to the mass ratio of 1.8:1 Ionized water and silicon carbide powder; based on silicon carbide powder, add B 4 C, 6.8% mixture of B and C, 1.1% aminoethanol, 0.25% polyoxyethylene polyoxypropylene pentaerythritol ether, start stirring after mixing. After stirring for 1 hour, add dioctyl phthalate 12%, continue stirring for 0.5 hour, add polyvinyl butyral 13.5%, and stir for 1 hour, then take out the slurry.

[0031] 2) Vacuum defoaming: put the uniformly stirred ceramic slurry in a vacuum defoaming machine, the vacuum degree is controlled at 10 Pa, keep it for 2 hours, and then take it out.

[0032] 3) Spray dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com