Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190 results about "Metal sphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

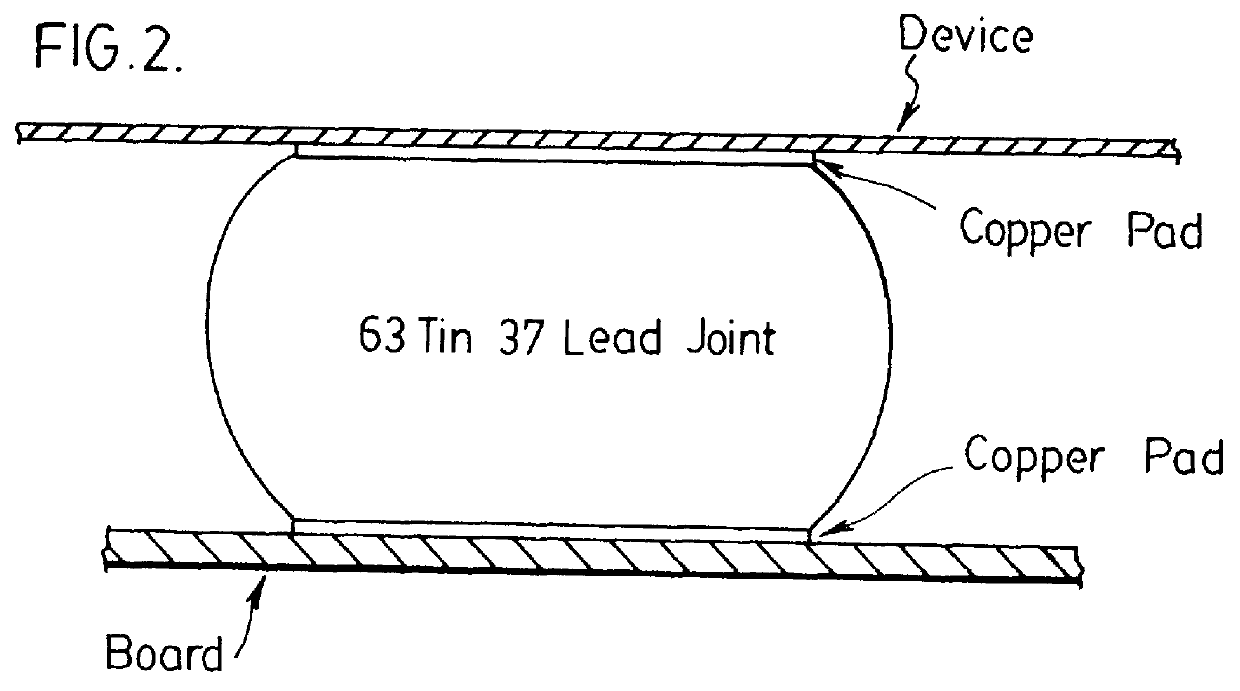

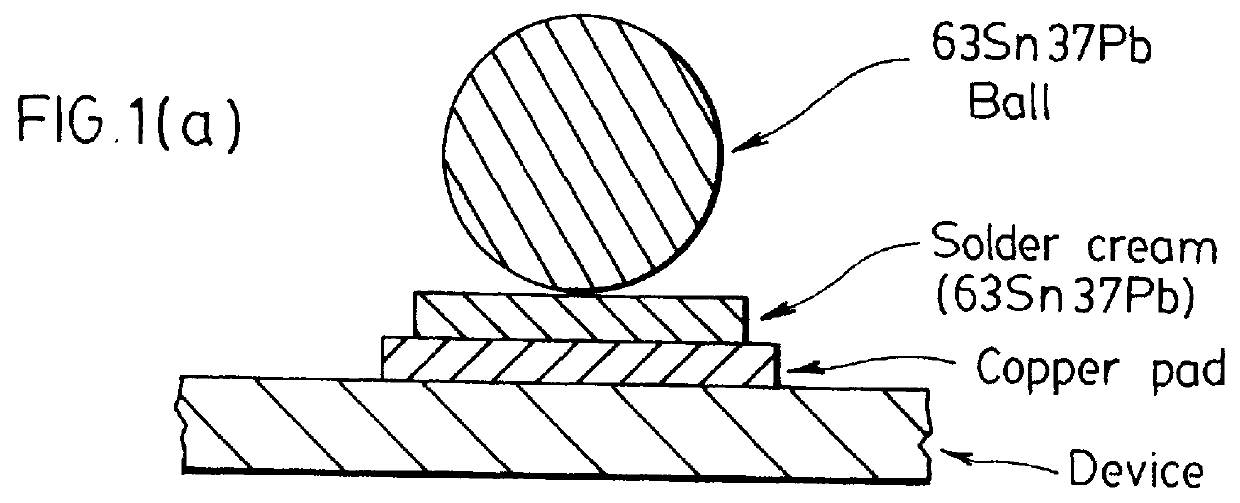

Spheres useful in a detachable connective medium for ball grid array assemblies

InactiveUS6037065AMinimal costEasy to manufactureFinal product manufactureSemiconductor/solid-state device detailsAlloyCopper

A connective medium is provided for use in ball grid assemblies for detachable connections between electronic devices and circuit boards. The medium includes novel, discrete spheres defining an inner metallic, spherical core and one or more outer, electrically conductive concentric, hard and non-deformable metallic layers of nickel, copper or alloys thereof and a coating of silver or gold thereon.

Owner:SULZER METCO CANADA INC

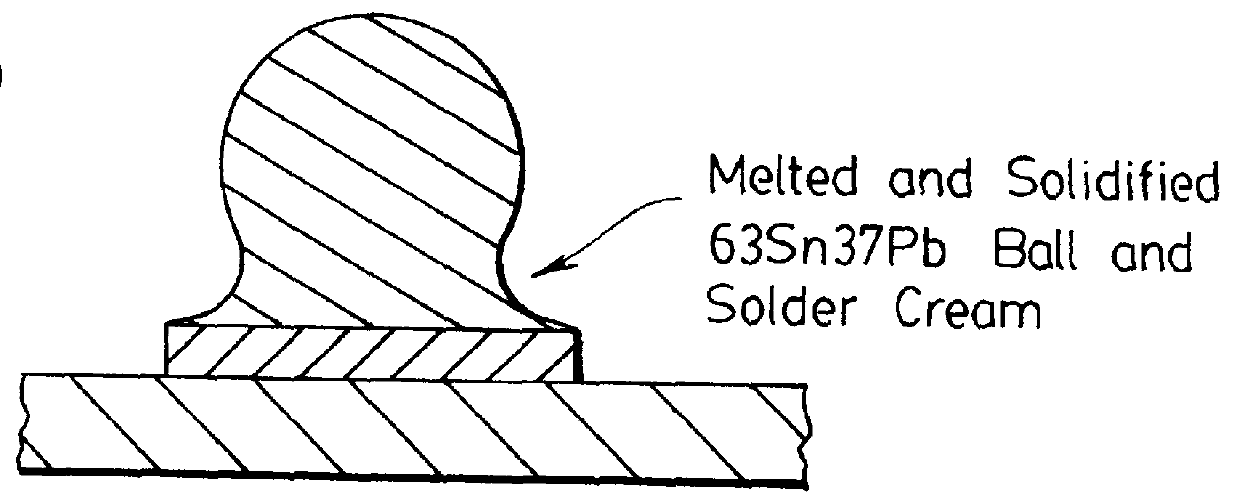

Formation of metal nanospheres and microspheres

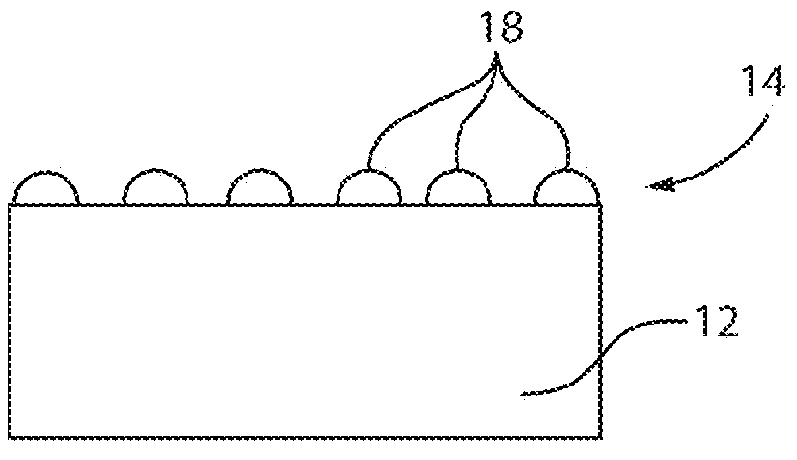

Hemispheres and spheres are formed and employed for a plurality of applications. Hemispheres are employed to form a substrate having an upper surface and a lower surface. The upper surface includes peaks of pillars which have a base attached to the lower surface. The peaks have a density defined at the upper surface by an array of hemispherical metal structures that act as a mask during an etch to remove substrate material down to the lower surface during formation of the pillars. The pillars are dense and uniform and include a microscale average diameter. The spheres are formed as independent metal spheres or nanoparticles for other applications.

Owner:GLOBALFOUNDRIES US INC

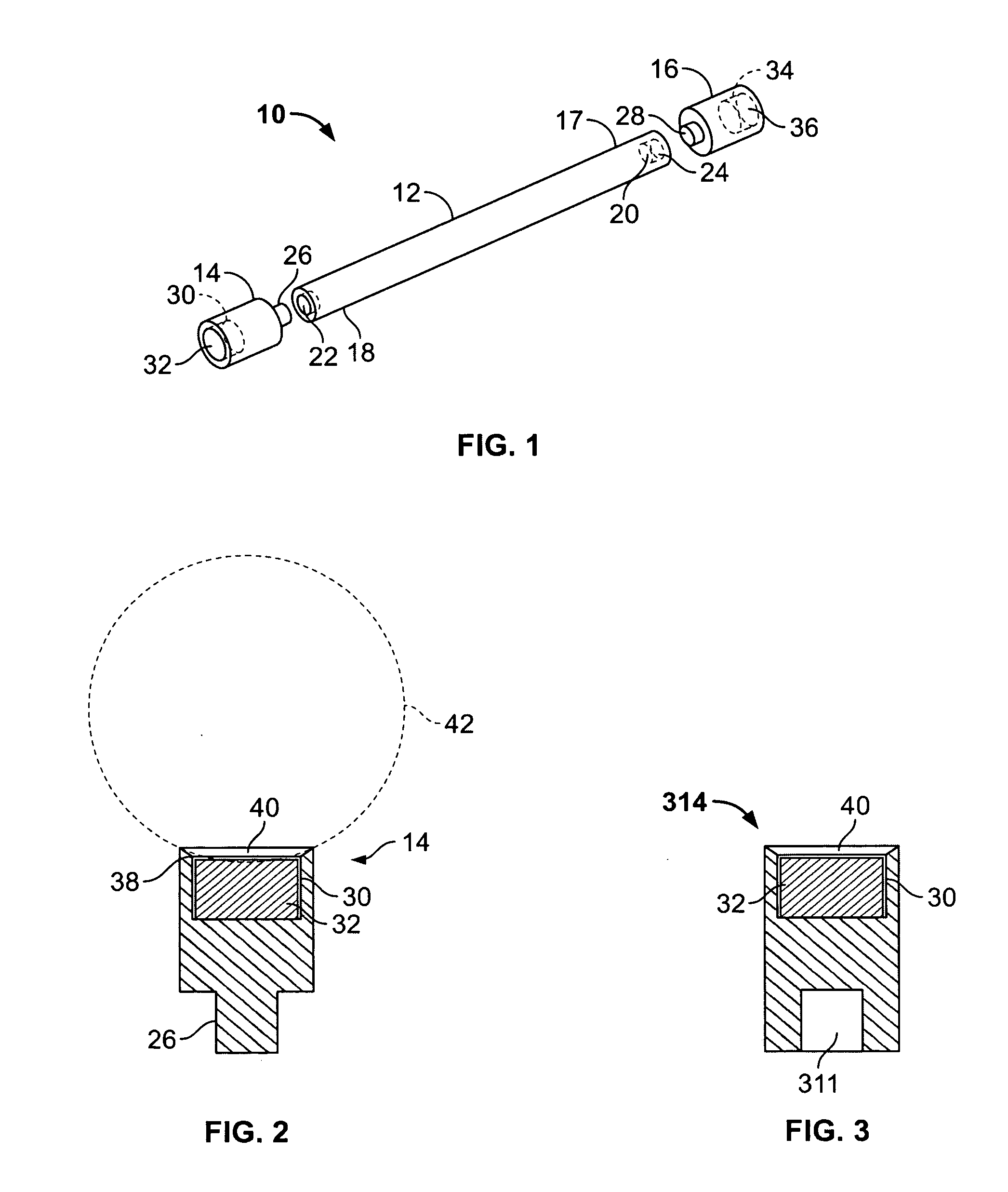

Magnetic construction module with interchangeable magnet holders

InactiveUS20050159076A1Improved structural profileImprove construction flexibilityRecord information storageToysArchitectural engineeringMetal sphere

A magnetic construction module that is suitable for creating a variety of different construction profiles and lengths and that permits the construction of modules where at least some of the members are adapted to be flexible. A rod is attachable to a holder adapted for retaining a magnet. The magnet is retained in a pocket of the holder. The holder can be attached in rods of various lengths, curves, rigidities to conform to the shape desired by the user. An outer surface of the magnet is adapted to provide a magnetic connection to a magnetizeable element such as a metal sphere with which the rod and holder can be operatively associated for a particular construction profile. Moreover, the holder may also be securely, selectively connected to the rod via a male-female connection in order to provide greater construction flexibility.

Owner:ROSE ART INDS +1

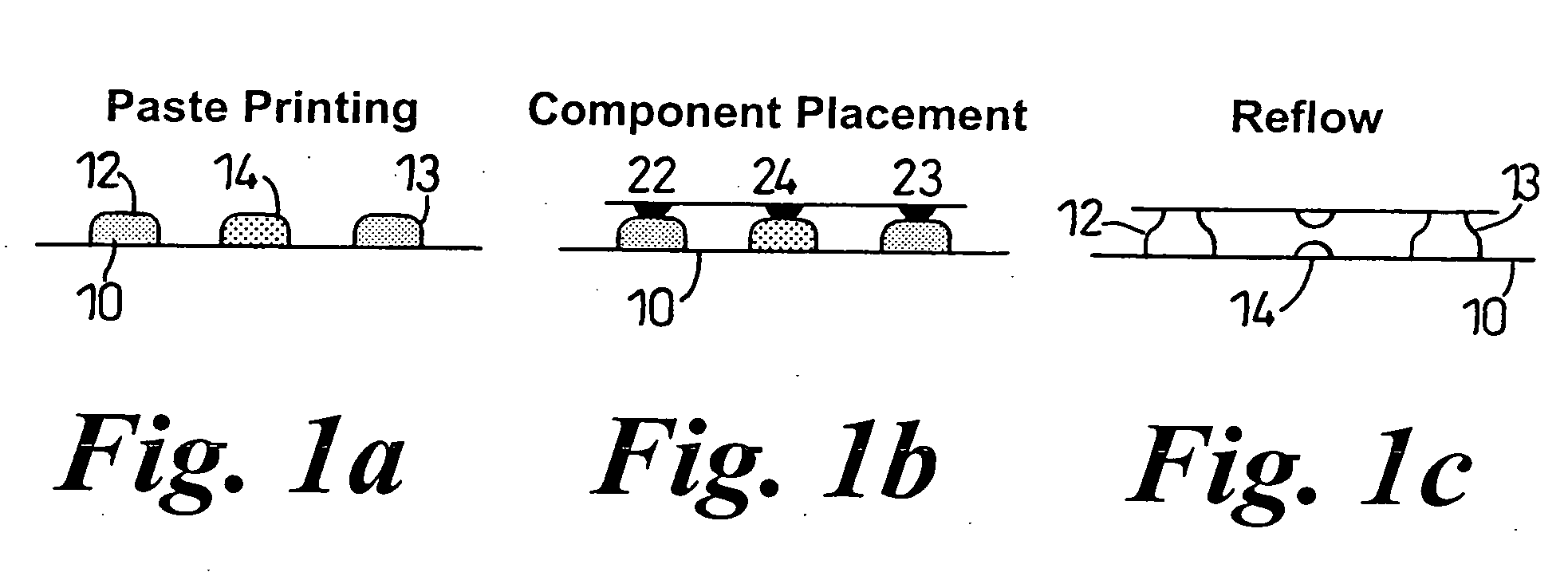

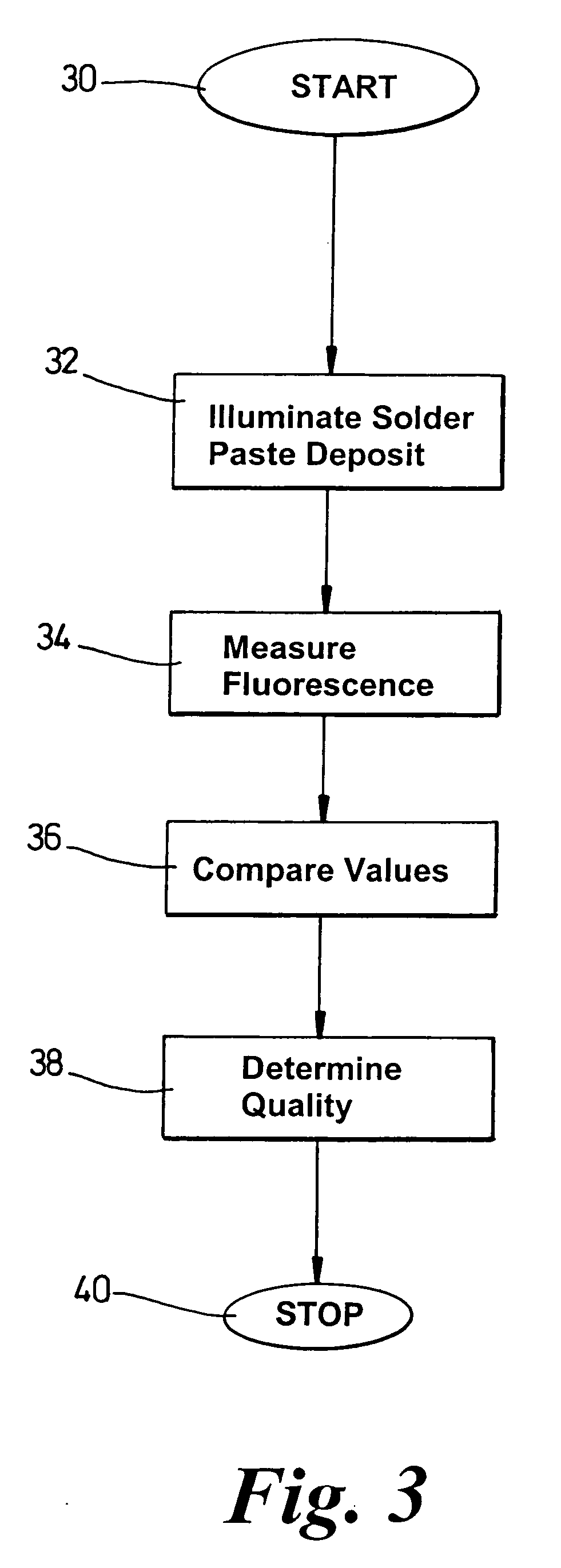

Method and apparatus for determining solder paste composition quality

InactiveUS20060071052A1Increase productionImprove circuit reliabilityPrinted circuit assemblingInspection/indentification of circuitsFluorescenceMetal sphere

Determining the quality of a solder paste deposit includes comparing the fluorescence from a solder paste deposit with that of a deposit having an ideal mixture of flux and metal spheres.

Owner:MV RES

Composite armor structure preventing blast waves

InactiveCN104792224AImprove explosion-proof performanceExplosion shock wave barrierSynthetic resin layered productsArmour platesMetal sphereEngineering

The invention relates to a composite armor structure preventing blast waves. The composite armor structure comprises a metamaterial layer, a combining layer and an energy-absorption buffering layer in sequence from outside to inside. The metamaterial layer and the energy-absorption buffering layer are combined in an optimized mode through the combining layer. The metamaterial layer is of a microstructure composed of a metal-nonmetal sphere system and can block shock waves in the area near the peak overpressure value in blast waves. The microstructure composed of the metal-nonmetal sphere system comprises metal balls, elastic materials and base body materials, and the metal balls wrapped by the metal materials are embedded into the base body materials. The blast resistant structure can effectively block explosion shock waves and more easily absorb explosion pressure waves, and therefore the explosion proofing ability of the structure is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

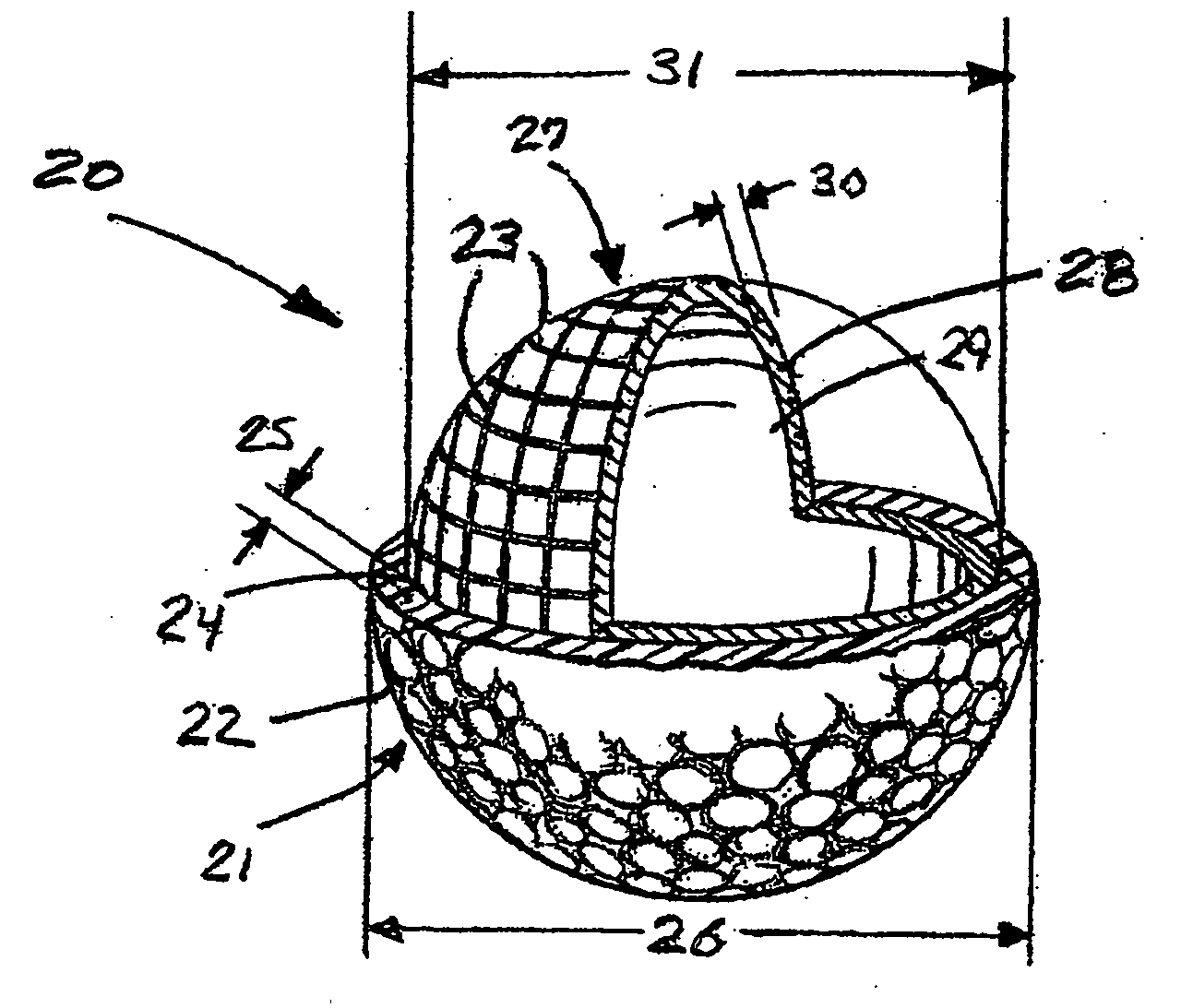

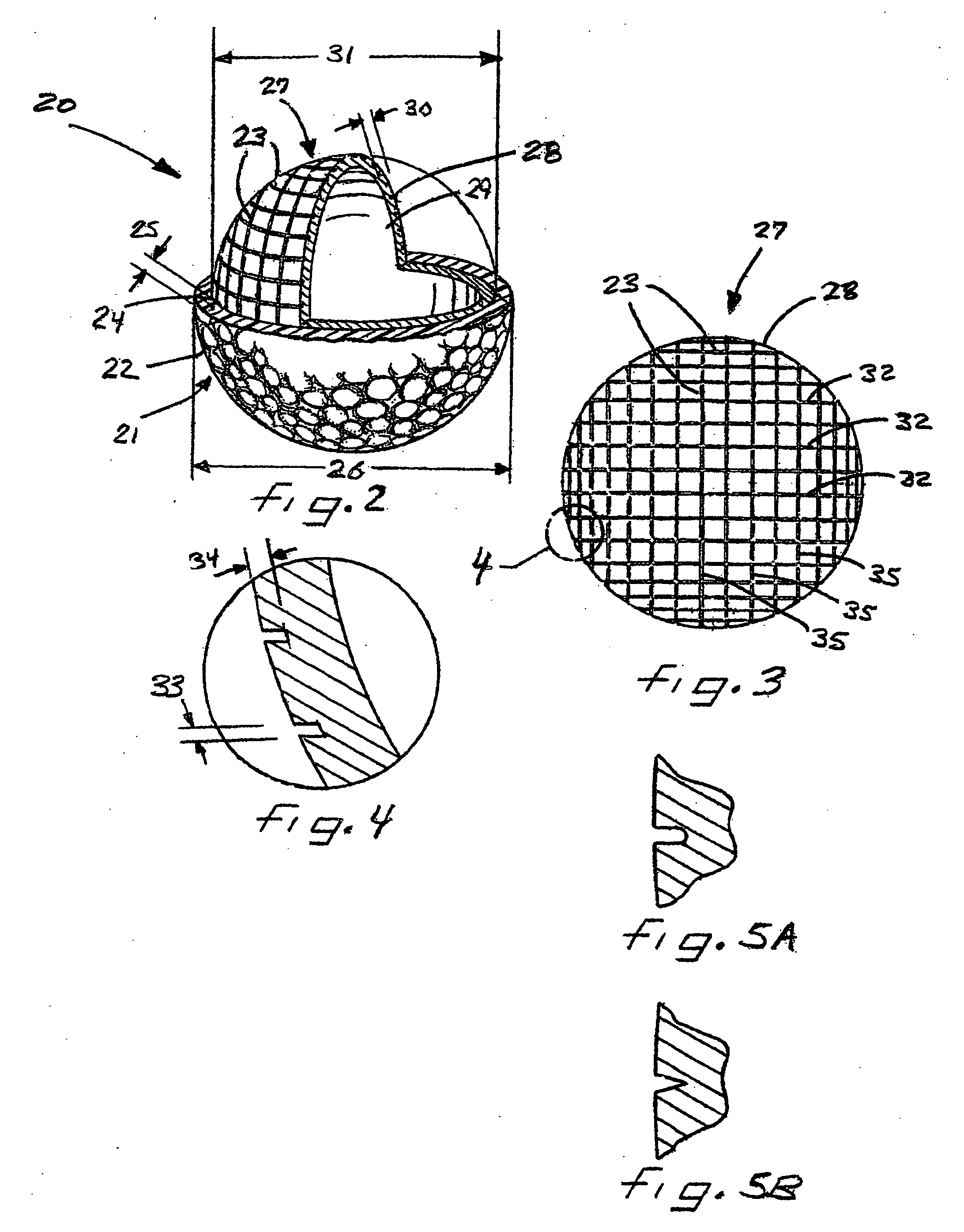

Golf ball

InactiveUS20070161434A1Limited stiffnessHigh overall moment of inertiaGolf ballsSolid ballsHard spheresMetal sphere

A golf ball is provided that has a hard sphere core or layer that exhibits a controlled vibrational response. The vibrational response may be controlled by tailoring the stiffness or damping of the sphere with at least one element, such as a groove(s) or any other type of indentation in the hard sphere core. The groove (or grooves) serves to locally reduce the wall thickness of the hollow metal sphere core, thereby reducing the stiffness of the core by allowing larger deformations under a load without significantly reducing the total mass of the core. This results in a golf ball that is legal for play and capable of drive distances essentially equivalent to those of currently available high performance golf balls, but that also maintains a high moment of inertia, allowing less hooks and slices during play.

Owner:NOONAN TECH +1

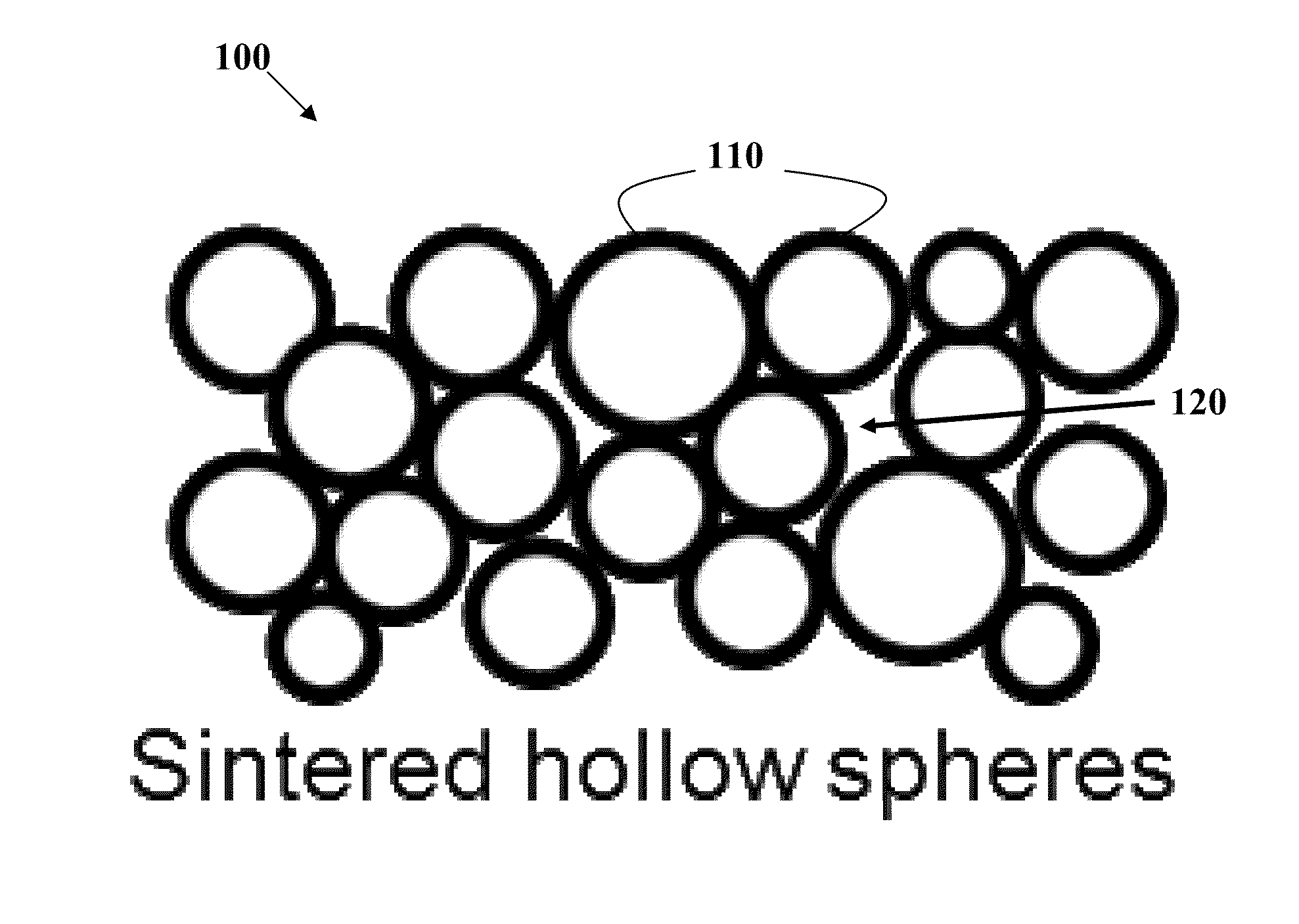

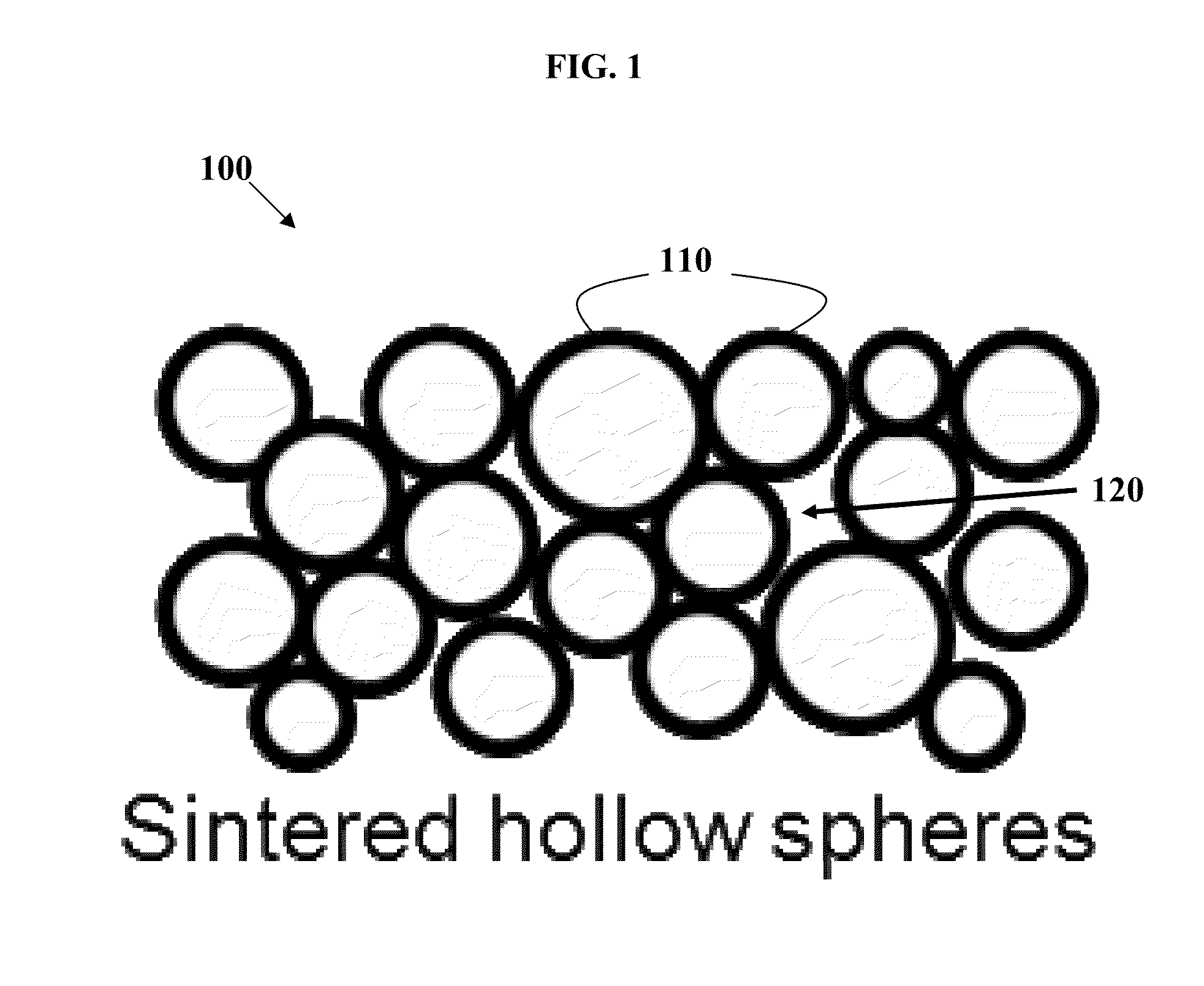

Thermal barrier materials and coatings with low heat capacity and low thermal conductivity

Thermal barrier materials are provided that possess low heat capacity and low thermal conductivity, while at the same time, high structural integrity and robustness. In some embodiments, the disclosed coating comprises metal-containing spheres that are sintered or glued together and / or embedded in a matrix. The coating has at least 60% void volume fraction and closed porosity. The coating thickness is from 50 microns to 500 microns, and the metal spheres have an average diameter that is from about 5% to about 30% of the coating thickness. In some embodiments, the metal spheres have an average diameter that is 4-10 times smaller than the coating thickness. Thermal barrier materials with these coatings can be beneficial in engine applications, for example.

Owner:HRL LAB

Hollow metal sphere with mesoporous structure and method for manufacturing the same

ActiveUS20120321897A1Simple processUniform particle sizeMaterial nanotechnologySynthetic resin layered productsMetal sphereMesoporous silica

A method for manufacturing a hollow metal sphere with a mesoporous structure is disclosed, which comprises the following steps: (A) providing a hollow sphere template with a mesoporous structure, wherein the hollow sphere template comprises: a first shell with plural channels penetrating the first shell, the material of the first shell comprises a mesoporous silica material, and the mesoporous silica material has a cubic Ia3d symmetry pore structure; (B) mixing the hollow sphere template with a metal precursor; (C) reducing the metal precursor; and (D) removing the hollow sphere template to obtain a hollow metal sphere with a mesoporous structure. In addition, the present invention also provides a hollow metal sphere with a mesoporous structure prepared by the aforementioned method.

Owner:NATIONAL TSING HUA UNIVERSITY

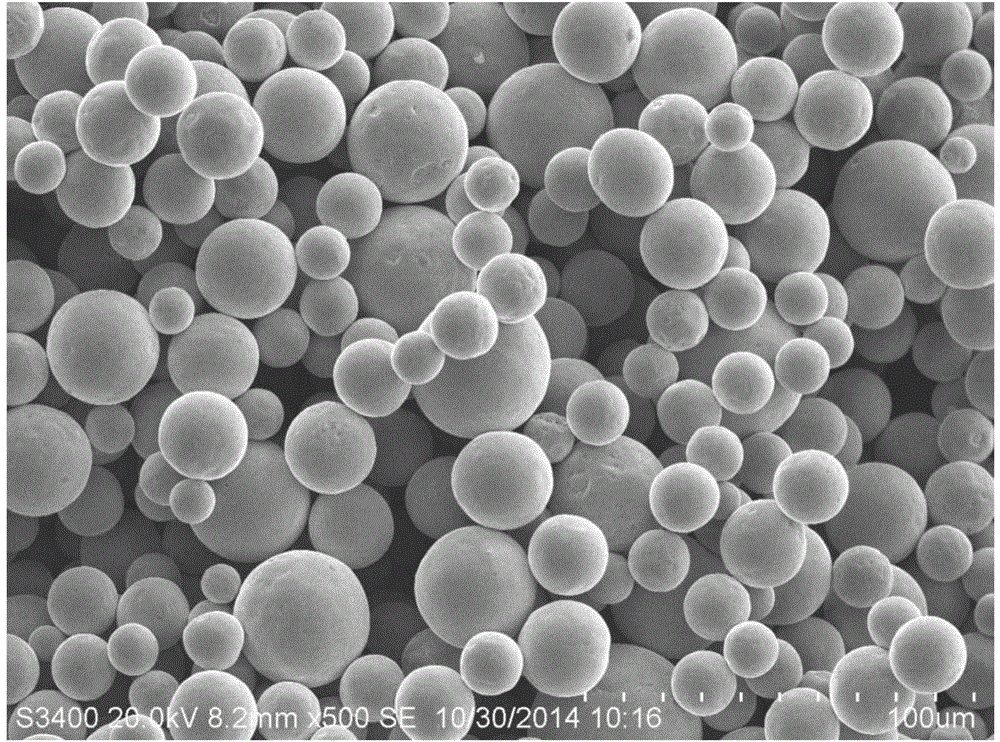

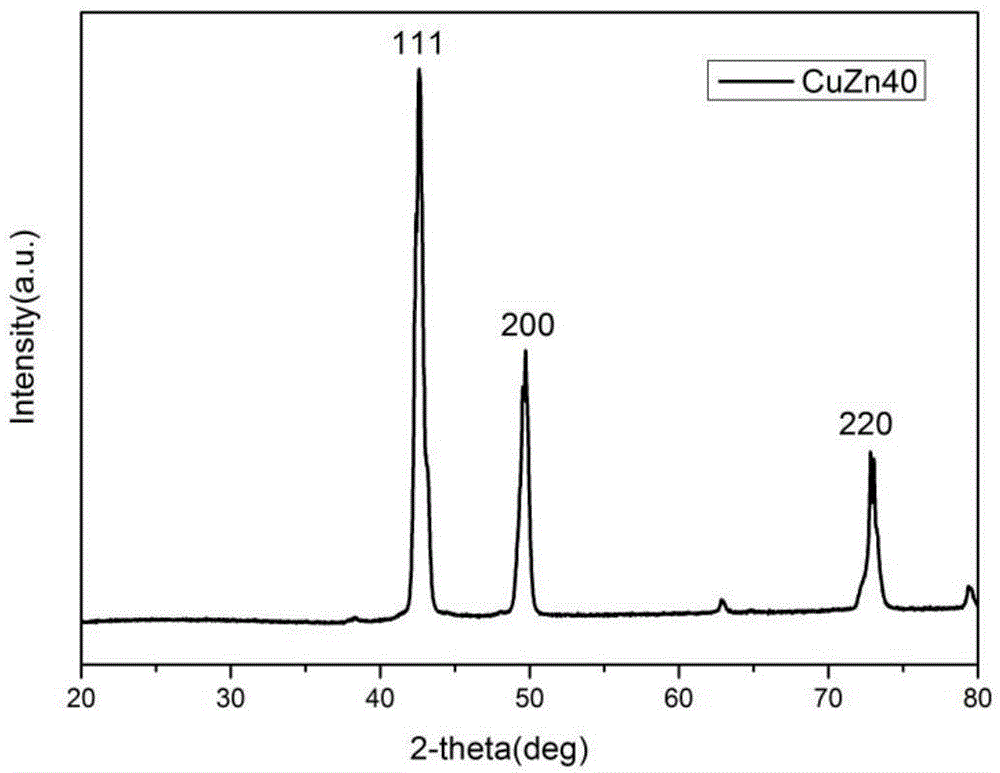

Spherical brass alloy powder manufacture method

The invention discloses a spherical brass alloy powder manufacture method. The method is characterized by including 1, preparing brass alloy powder; 2, preparing evenly-mixed powder of brass alloy powder and carbon material powder or ceramic material powder; 3, performing high temperature treatment, melting the brass alloy, solidifying, obtaining metal spheres, and cooling rapidly; 4, separating the carbon material powder or ceramic material powder, and obtaining micron or nano brass alloy spherical powder. The temperature of high temperature treatment is equal to or higher than that of metal melting, preferably, the temperature of high temperature treatment ranges from 10 to 80 DEG C higher than that of the brass alloy melting point. According to the method, process is simple, cost is low, and the method is adaptive to large scale production; the brass alloy powder is free of macro segregation, the surface metal sense is strong, and application of metal three-dimensional printing, print painting decoration, spraying (brazing) welding metal powder and metal filters can be met.

Owner:NANJING UNIV

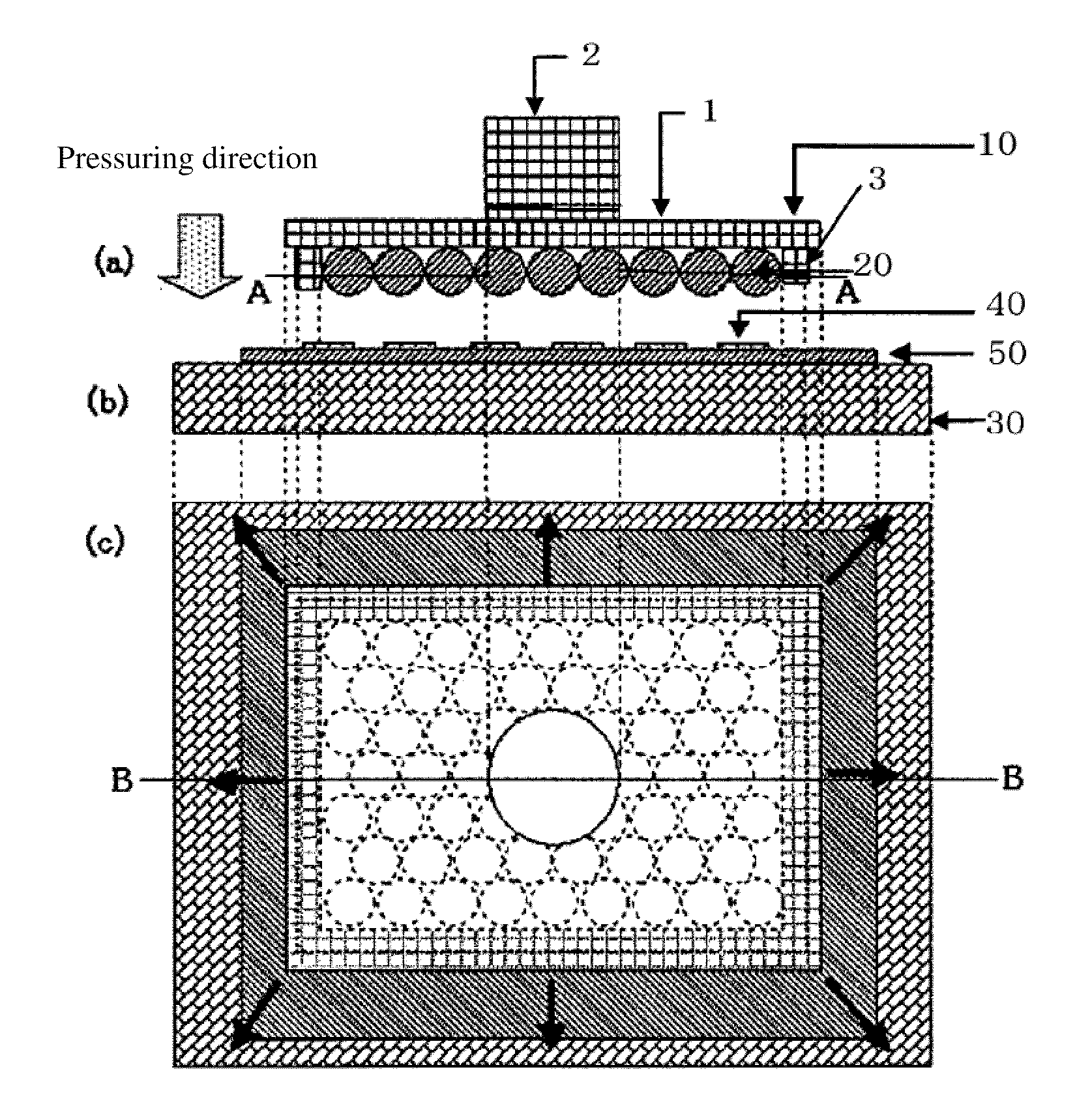

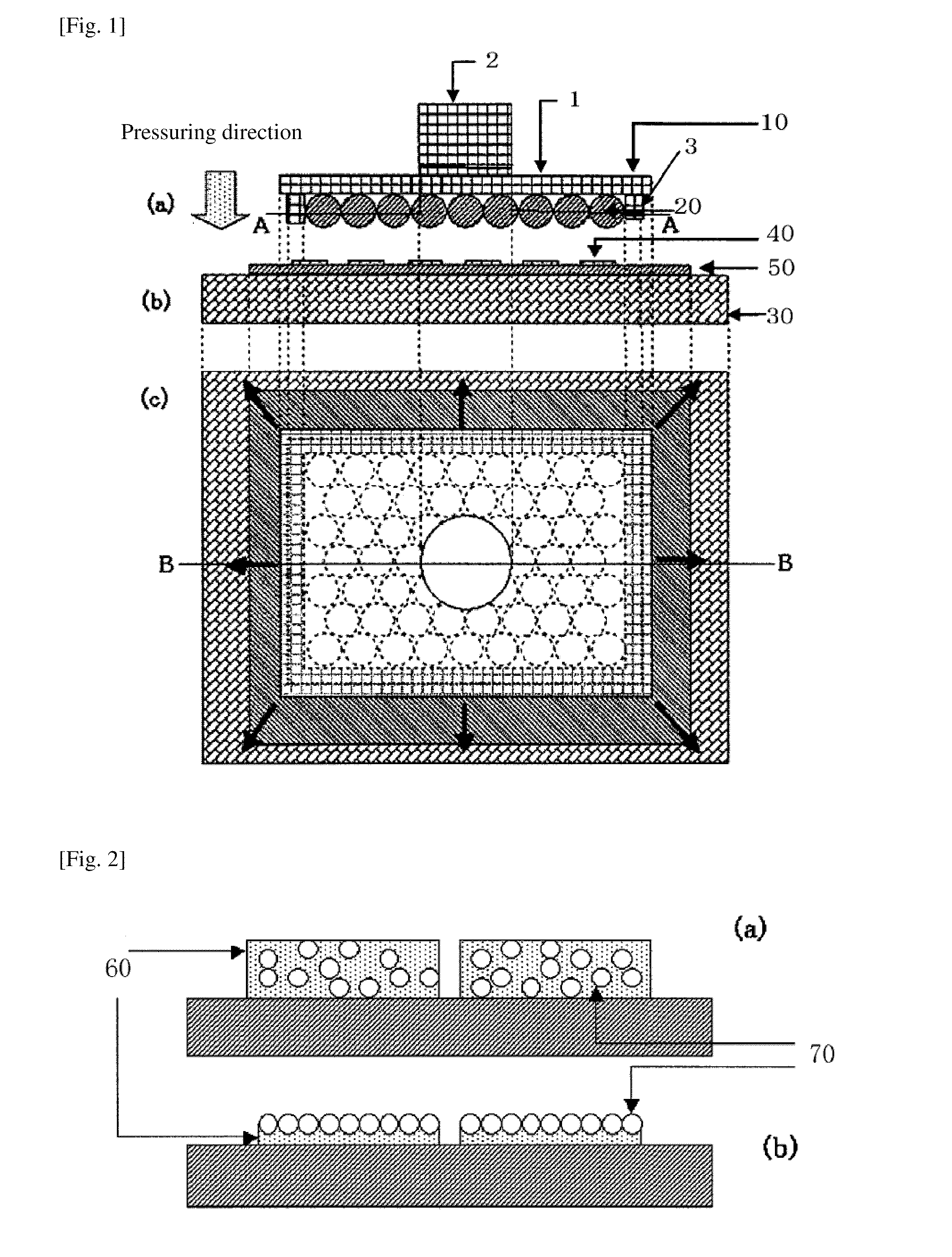

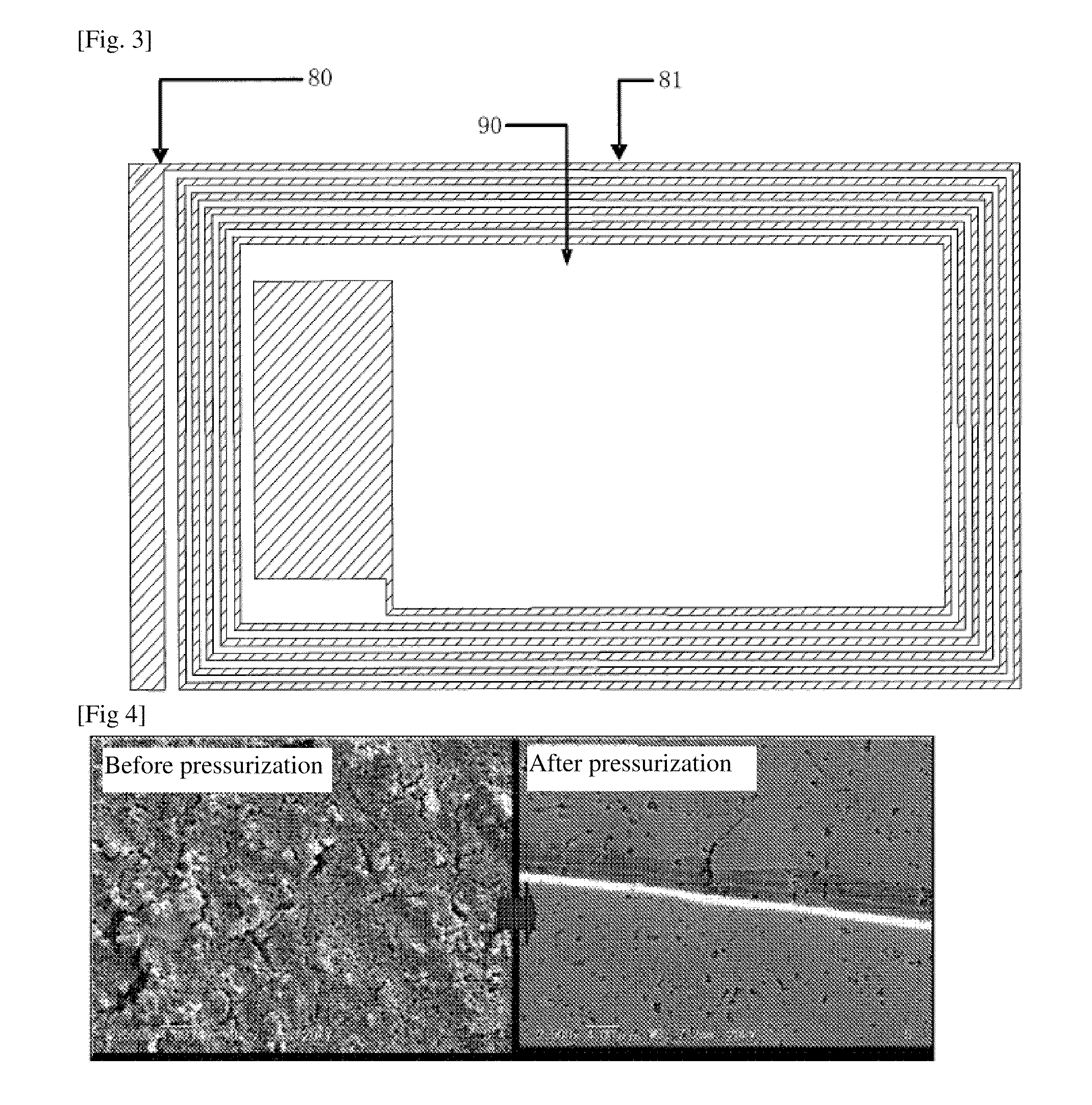

Conductive pattern forming film, and conductive pattern forming method and conductive pattern forming apparatus for the conductive pattern forming film

InactiveUS20100025088A1Simple structureEasy to operateApparatus for heat treatmentConfectioneryConductive pasteMetal sphere

The present invention forms a conductive pattern using a simple process on a general plastic substrate having flexibility, and also provides a conductive pattern forming film that allows for easy formation of a conductive pattern using an apparatus that performs a simple process of oriented pressurization at low temperature, as well as a method for forming conductive pattern and a conductive pattern forming apparatus for the same.The conductive pattern forming film provides a pattern formed on a film substrate having flexibility by pressurizing, under heating, a conductive paste in which powder or fine particles of metal or semiconductor are dispersed and filled. The conductive pattern forming apparatus comprises a sample installation table having a flat placement surface, and a driving body for pressure application which is placed in a manner facing the placement surface and movable, wherein the driving body for pressure application is equipped with a support which is constituted by a flat metal panel having metal spheres along its bottom face.

Owner:NAT INST OF ADVANCED IND SCI & TECH

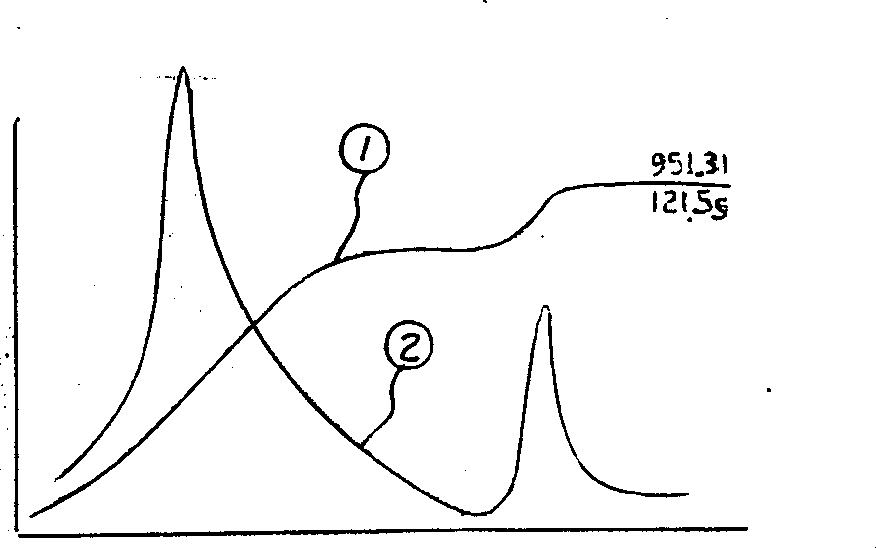

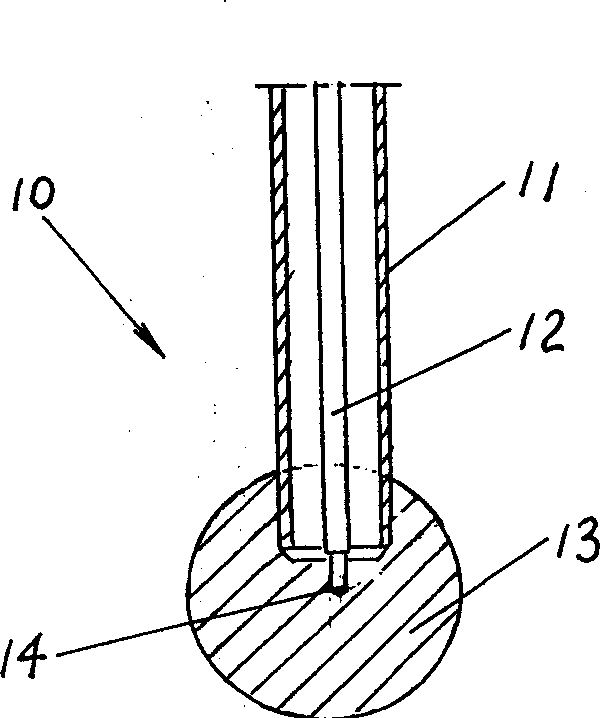

On-line real time measuring method and measurer for aluminium electrolyzing parameters

An on-line real-time aluminium electrolyzing parameters measuring process includes the steps of detecting the primary crystal temperature by inserting the measurer probe into electrolyzer and sendingout the primary crystal temperature signal; and processing the signal and calculating other electrolysis parameters according to the set mathematical model. The probe of the present invention includes thermocouple, metal ball and protecting tube, and the thermocouple inside the protection tube has its end inserted to the geometric center of the metal ball. The present invention can measure and find out important aluminium electrolyzing parameters timely and precisely, and this makes it possible to realize the autocontrol of aluminium electrolyzer for raising its current efficiency, reducing the power consumption and raising the yield.

Owner:程留恩 +1

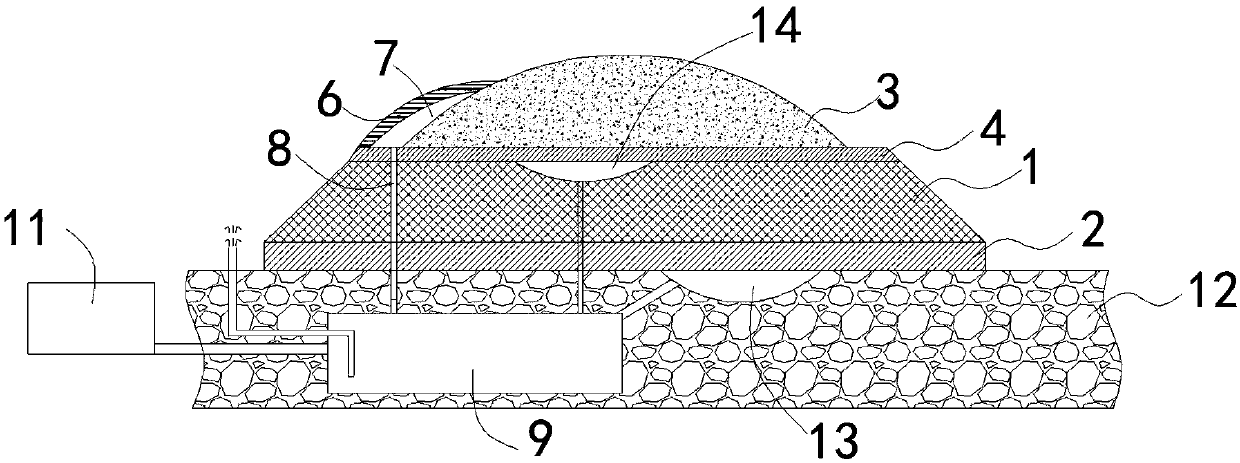

Speed bump system with jet-wet function

InactiveCN107724275ASolve the single functionFill up sharp cornersRoad cleaningTraffic signalsSpeed bumpMetal sphere

The invention discloses a speed bump system with a wet spraying function, which includes a speed bump body and a water spray module; the speed bump body includes: a base fixed on the road surface; a first elastic layer arranged between the base and the road surface; A second elastic layer arranged on a plane on the base, a plurality of metal spheres are wrapped in the second elastic layer; a top block arranged above the second elastic layer, the width of the bottom of the top block is smaller than that of the plane on the base Width so that the top block forms an angle with the outside of the base; the sprinkler module includes: a water storage chamber arranged in the road structure layer and located below the base; multiple sprinkler pipes located on both sides of the base, with the sprinkler pipes facing downward extending and communicating with the water storage chamber; the first extruding unit arranged in the included angle, the first extruding unit includes an extruding block and an air pipe, the extruding block fits into the included angle and is formed by closing the included angle Air cavity; a water supply pool arranged on both sides of the road or under the road.

Owner:蒋星

Manufacturing method of iron-based amorphous soft magnetic alloy spherical powder

The invention provides a manufacturing method of iron-based amorphous soft magnetic alloy spherical powder. The manufacturing method includes the steps of 1, preparing soft magnetic alloy powder; 2, well mixing the soft magnetic alloy power with carbon powder or ceramic powder; 3, melting soft magnetic alloy which quickly solidifies into metal spheres, by high-temperature heat treatment at a temperature reaching to a melting temperature of the soft magnetic alloy, especially a temperature in a range 40 to 100 DEG C greater than the melting temperature of the soft magnetic alloy; 4, separating the carbon powder or the ceramic powder to acquire micron and nano amorphous soft magnetic alloy spherical powder. The manufacturing method has the advantages that the process is simple, manufacturing cost is low, and the method is environment friendly and suitable for large-scale production of the amorphous soft magnetic alloy spherical powder.

Owner:NANJING UNIV

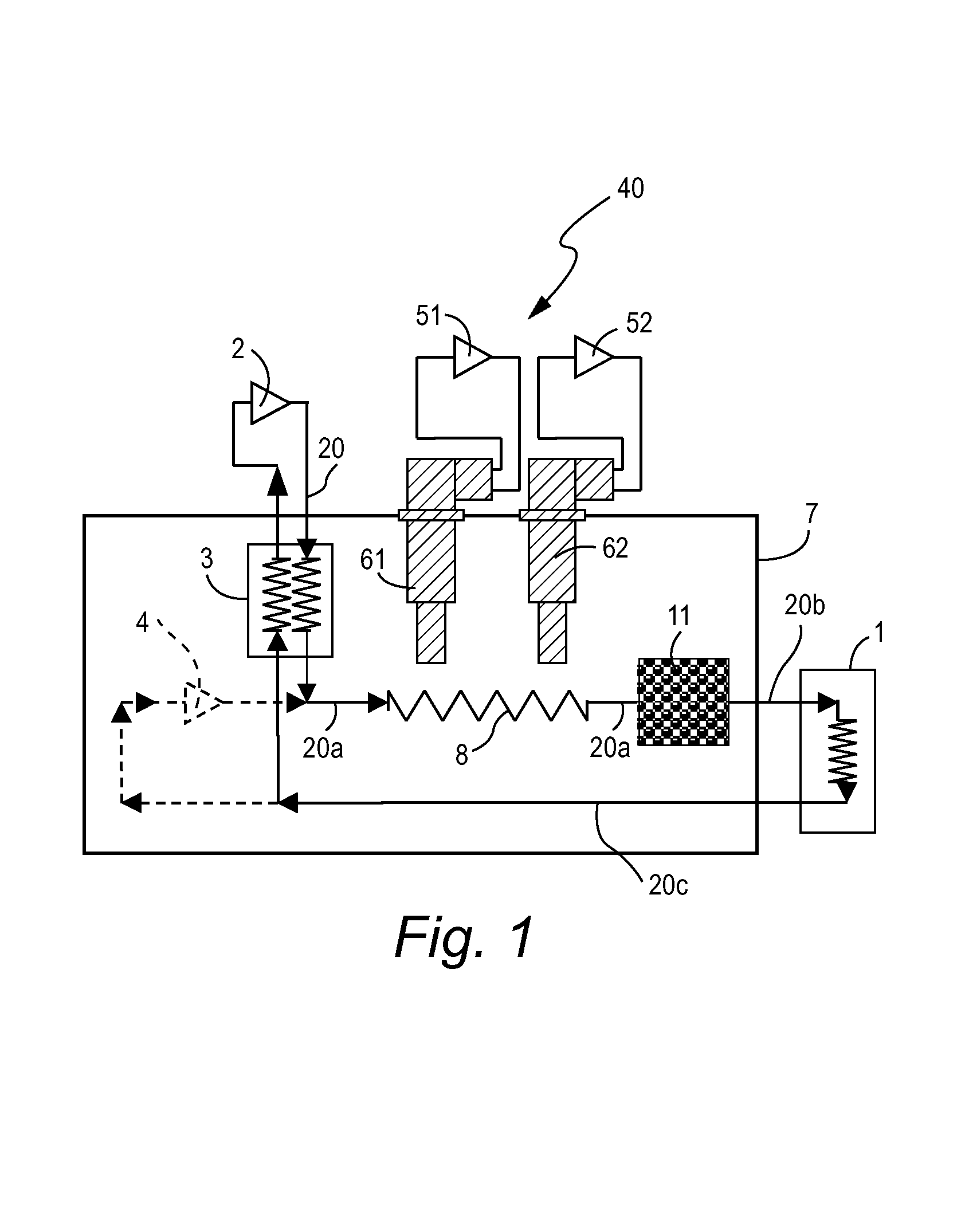

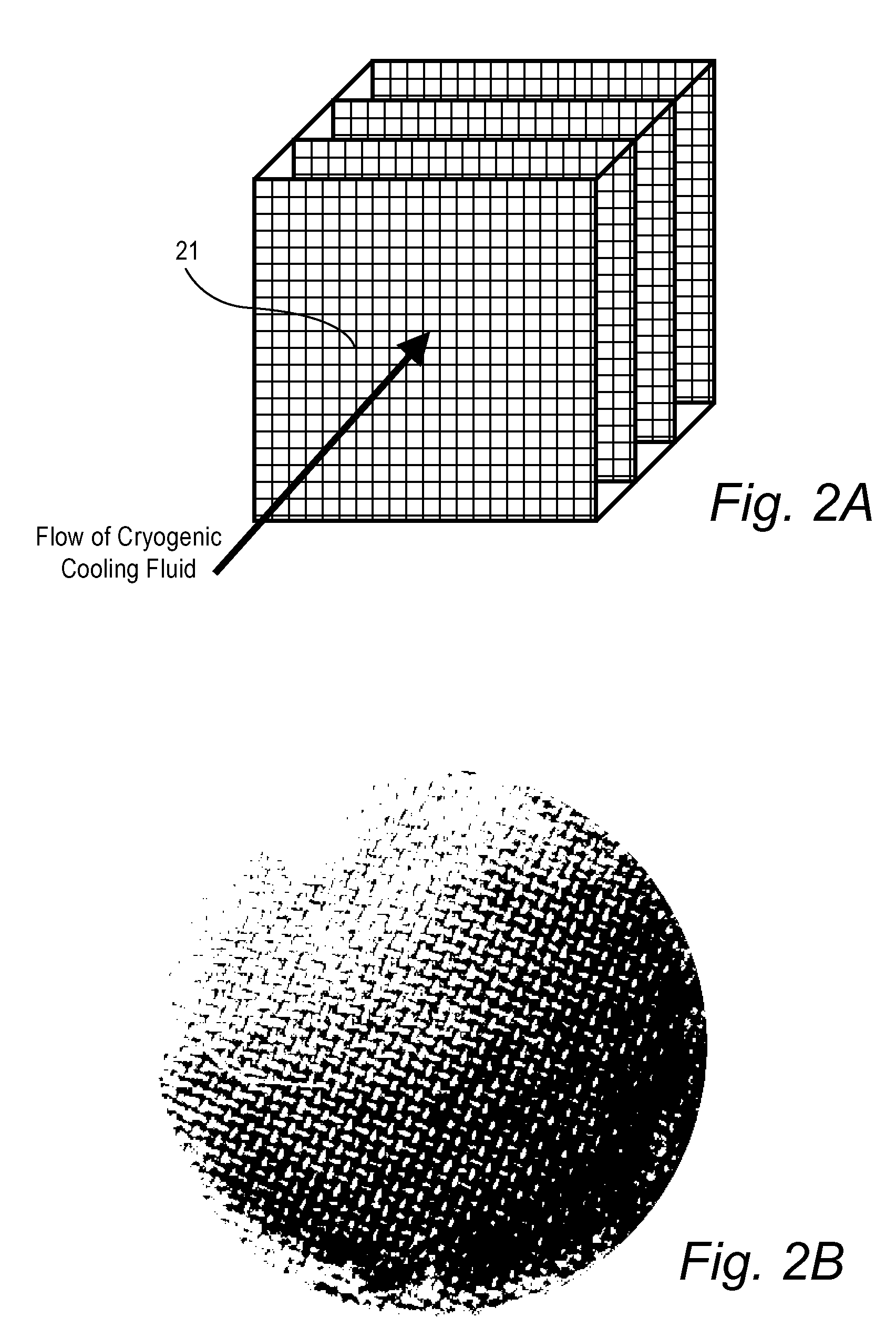

Cryogenic cooling system and method with cold storage device

InactiveUS7003977B2Increase in costAvoid temperatureCompression machinesDomestic refrigeratorsLine tubingMetal sphere

A cooling system for providing cryogenic cooling fluid to an apparatus comprises a re-circulation device, a passive cold storage device having a porous matrix of material which directly contacts the cryogenic cooling fluid as the cryogenic cooling fluid passes through the passive cold storage device, a first portion of a fluid communication feed line fluidly connecting the re-circulation device to the passive cold storage device, a second portion of a fluid communication feed line fluidly connecting the passive cold storage device to the apparatus for communicating cryogenic cooling fluid to the apparatus, and a fluid communication return line fluidly connecting the apparatus to the re-circulation device. The passive cold storage device may comprise a regenerative heat exchanger including a porous matrix of metal wire mesh, metal spheres or ceramic spheres.

Owner:GENERAL ELECTRIC CO

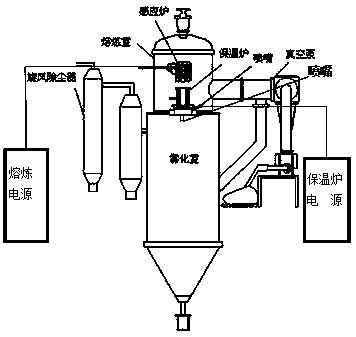

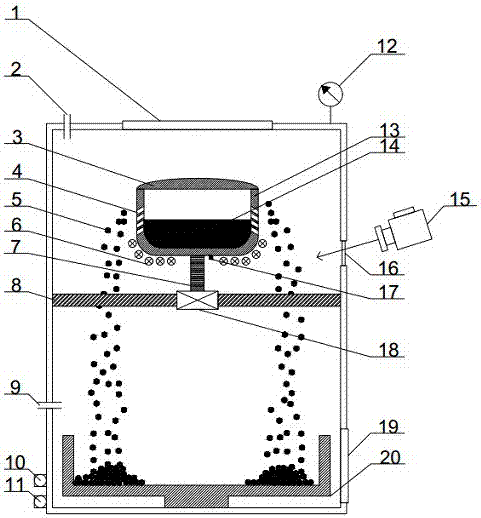

Method and device for preparation of micron-sized iron-based hollow sphere material

The invention relates to a method and a device for preparation of micron-sized iron-based hollow sphere material, and belongs to the technical field of novel functional building decoration materials. The metal hollow sphere material is prepared by a gas atomization method; pressure of nitrogen gas is controlled within a certain range, so that superheated melt with dissolved gas and gas-forming property substance is atomized into micro-liquid-drops. The atomized liquid drops are cooled by an atomizing medium quickly, and the surfaces of the liquid drops are solidified to form solidified casings to prevent gas from separating out of the surfaces of the liquid drops; during temperature reduction of the liquid drops, gas solubility is decreased so that the dissolved gas is separated out to enter the insides of the liquid drops to form cavities therein; during solidifying, volume of the liquid drops is reduced quickly due to the liquid-solid volume change, and the liquid drops contract to form hollow metal spheres. By the method and the device, micron-sized and even millimeter-sized hollow spheres with high sphericity can be manufactured, particle size of the spheres ranges from several microns to hundreds of microns in normal distribution, and the spheres have small tissues, low oxygen content and high rigidity due to high cooling speed.

Owner:SHANGHAI UNIV

Method for Incorporating an Anti-Counterfeiting Device into a Multi-Walled Container and the Multi-Walled Container Containing Such Device

A method of incorporating an anti-counterfeiting device into a multi-walled container is provided. The multi-walled container includes an inner wall having an outer surface, an outer wall adjacent to the inner wall, and an anti-counterfeiting device sandwiched between the inner and outer walls. The method includes forming the inner wall from a polymeric composition, adhering the anti-counterfeiting device to the outer surface of the inner wall either during, or after formation of the inner wall, and then over molding the outer wall about the inner wall to form the multi-walled container. Suitable anti-counterfeiting devices for incorporation into the multi-walled container include RFID, printed or foil antennae, conductive inks, metal spheres, and x-ray readable foils.

Owner:CSP TECH INC

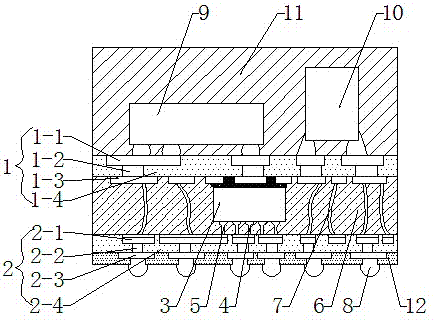

3D connected fan-out type packaging structure and process method therefor

PendingCN106876363AReduce manufacturing costImprove wire bonding efficiencySemiconductor/solid-state device detailsSolid-state devicesMetal sphereElectronic component

The invention relates to a 3D connected fan-out type packaging structure and a process method therefor. The packaging structure comprises a circuit layer (1), wherein a chip (3) is arranged on the back surface of the circuit layer (1); a re-wiring circuit layer (2) is arranged on the front surface of the chip (3); the chip (3) and the re-wiring circuit layer (2) are connected through metal sphere cylinders (4) and first bonding wires (5); the peripheries of the circuit layer (1), the re-wiring circuit layer (2) and the chip (3) are all encapsulated with a first plastic sealing material (6) separately; an electronic element (9) or a packaging element (10) is arranged on the front surface of the circuit layer (1); and the periphery of the electronic element (9) or the packaging element (10) is encapsulated with a second plastic sealing material (11). According to the 3D connected fan-out type packaging structure and the process method therefor, a conventional two-end routing method is adopted to realize wire bonding on the chip and the metal circuit layer or the metal circuit layer of the adjacent packaging element, so that height and stability can be improved, and routing efficiency can be improved.

Owner:JCET GROUP CO LTD

Powder metallurgy fabrication method of hollow metal sphere

The invention discloses a powder metallurgy fabrication method of a hollow metal sphere, which comprises the following steps of placing a polystyrene sphere in a centrifugal mold, preparing slurry 1 with metal powder, adhesive solution and a defoaming agent, pouring the slurry 1 into the centrifugal mold, centrifuging, putting the centrifuged polystyrene sphere in an oven for drying together with the centrifugal mold, preparing slurry 2 with the metal powder, the adhesive solution and the defoaming agent, pouring the slurry 2 into the dried centrifugal mold, centrifuging, putting the centrifuged polystyrene sphere in the oven for drying together with the centrifugal mold, taking out the dried polystyrene sphere from the centrifugal mold, embedding the polystyrene sphere into alumina packing, and then putting in a vacuum furnace for pyrolysis and sintering, thereby obtaining the hollow metal sphere. The method is reasonable in design, simple in process and low in cost. The hollow metal sphere fabricated by the fabrication method has the advantages of uniform, smooth and complete spherical shell wall thickness, facilitation of sphere dimension selection, easiness in overall structure control and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

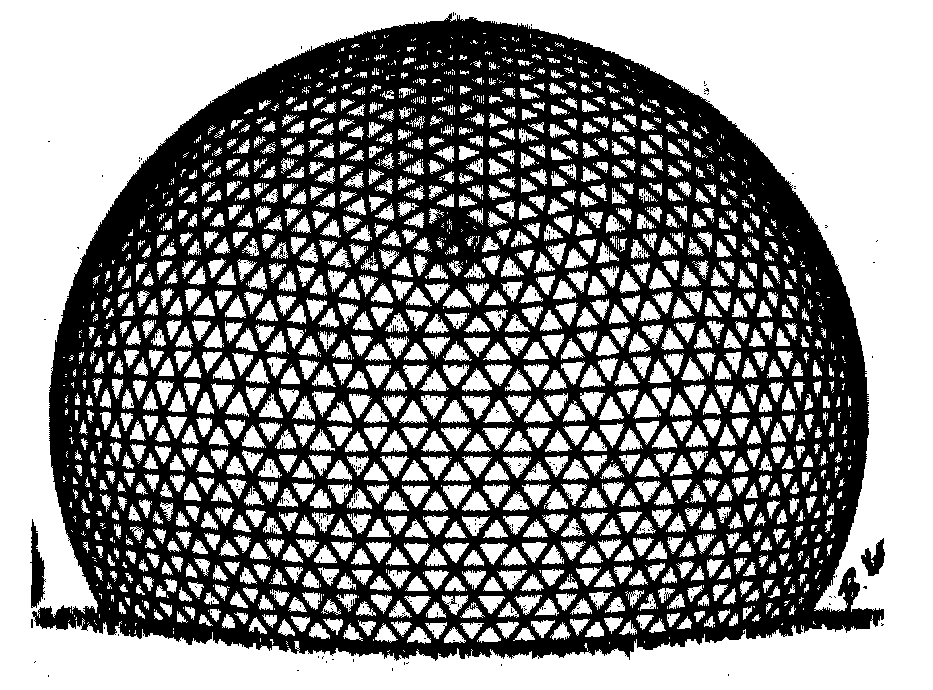

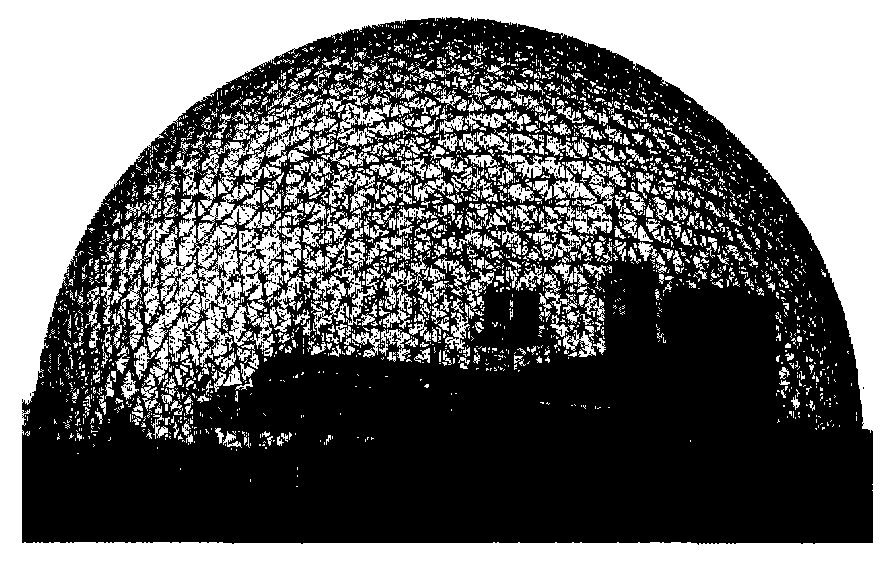

Large-space metal spherical lattice shell structure used for device storage and transportation, and construction method

ActiveCN103938720AEasy to installImprove the performance of strong wind and snow resistanceBuilding roofsArched structuresTopology mappingStructure of the Earth

The invention relates to a large-space metal spherical roof plate lattice shell structure suitable for device storage and transportation, and belongs to the field of civil engineering mechanics and mechanical engineering. According to the metal spherical roof plate lattice shell structure, a 32-face body variant plane base element serves as a foundation, and topology mapping conversion is conducted on the spherical face so that the positions of space spherical surface nodes can be obtained. A spherical lattice shell roof plate is structurally composed of body node bases, base node bases, hinge joint connecting rod pieces and foam metal thin roof plate bodies, the node bases and the hinge joint connecting rod pieces are connected through threads, and rapid and accurate installation is achieved. The whole lattice shell structure is fastened to a base beam and a ground foundation by means of base beam foundation bolts through anchor hole plates of the base node bases, and therefore the performance for bearing all outward loads is improved for the spherical lattice shell. Field installation can start from ground erecting, connection is sequentially conducted upward, a hydraulic jacking machine supports the top of the lattice shell, external expansion installation is sequentially conducted from top to bottom, construction is quite convenient, and the large-space metal spherical roof plate lattice shell structure can be used for large-scale engineering construction, device storage and transportation, and emergency rescue and relief work centers.

Owner:INST OF DEFENSE ENG ACADEMY OF MILITARY SCI PLA CHINA

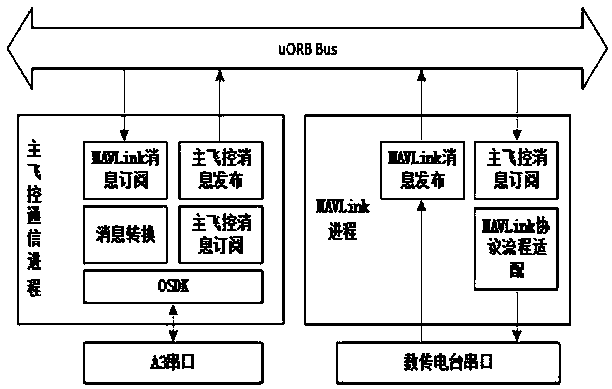

Weather radar calibration method and system based on unmanned aerial vehicle

ActiveCN111537965AImprove accuracyEasy to operateWave based measurement systemsRemote controlled aircraftWeather radarUncrewed vehicle

The embodiment of the invention provides a weather radar calibration method and system based on an unmanned aerial vehicle. The method is characterized in that the method comprises the steps: controlling an unmanned aerial vehicle provided with an airborne calibration device to fly to a predetermined spatial position in a wireless communication mode through a ground console; and controlling the airborne calibration device to calibrate a weather radar at the predetermined spatial position in a wireless communication mode through the ground console. Through the method, problems that an existingsignal source method is high in erection cost and cannot work under the special terrain condition can be solved; meanwhile, a problem that an existing metal ball calibration method is inaccurate in calibration result is solved.

Owner:CMA METEOROLOGICAL OBSERVATION CENT

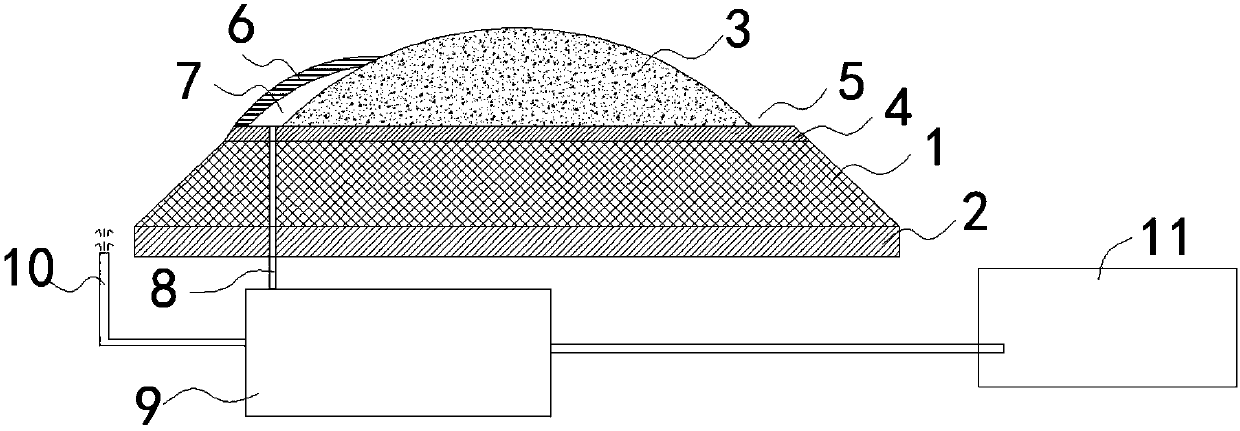

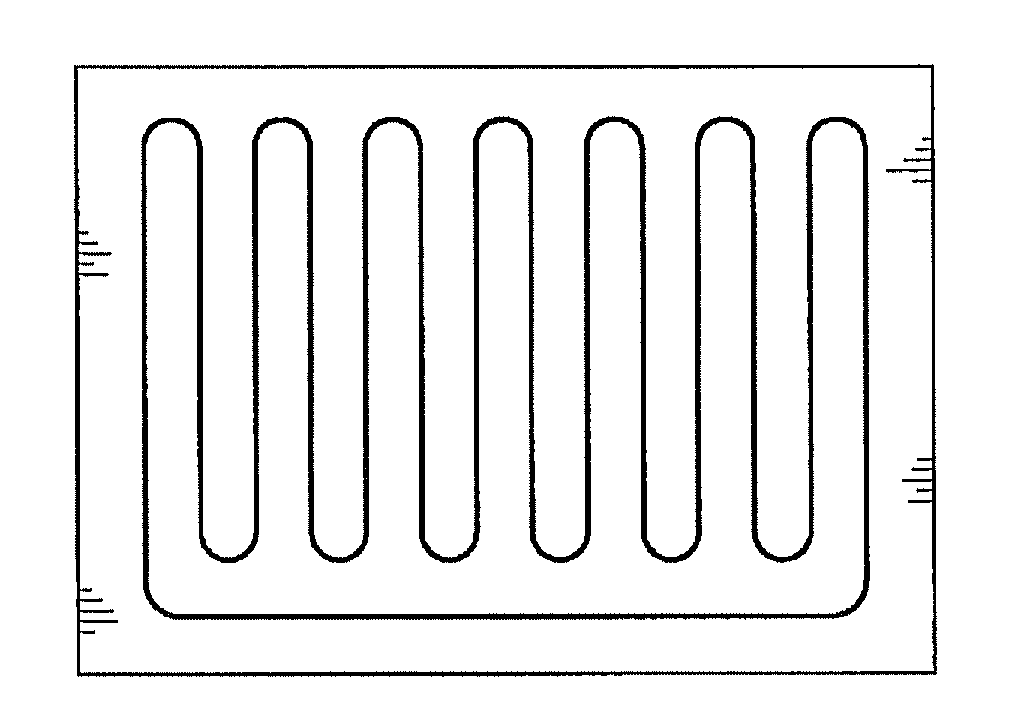

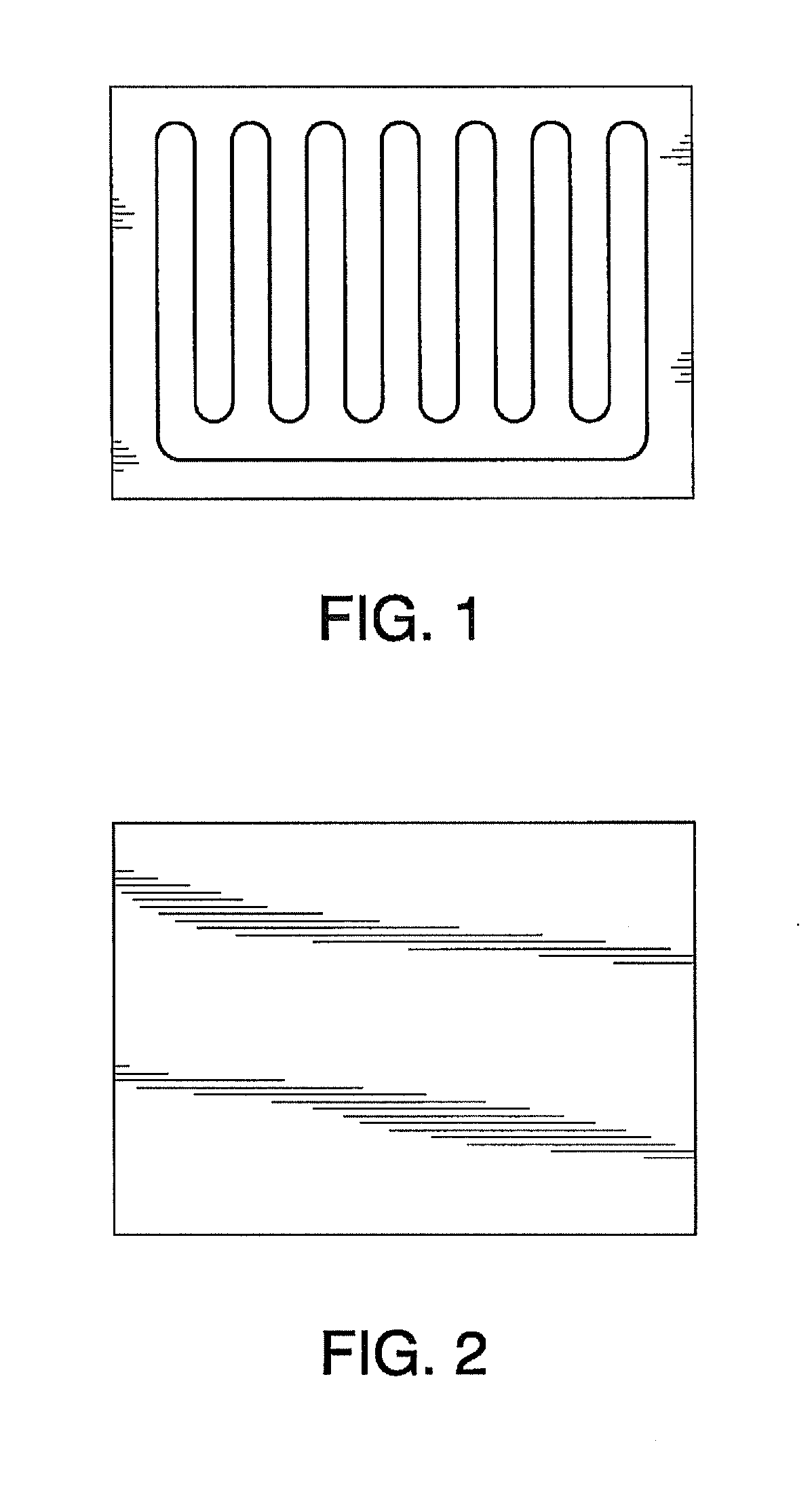

Selective laser melting preparation method of porous structure variable-density-gradient metal material

PendingCN111570793AImprove production efficiencySimple and fast operationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingPorosity

The invention belongs to the field of additive manufacturing, and relates to a selective laser melting preparation method of a porous structure variable-density-gradient metal material. The method includes the steps that (1) metal spherical powder suitable for selective laser melting is selected as a raw material; (2) a required variable-density porous structure model is constructed by using three-dimensional modeling software, and it is noted that the structural model can be simplified as an entity without designing an extra hole structure; (3) the three-dimensional model is sliced through special software and then is guided into a selective laser melting forming device; (4) proper selective laser melting forming process parameters are set, wherein the laser scanning rate is increased along with the forming height; and (5) forming is completed, the porous structure and a substrate are subjected to annealing treatment together, and after annealing, the metal material is obtained through linear cutting, surface cleaning and sand blasting. The variable-density-gradient porous structure with the porosity gradiently ranging from over 99.9% to about 50% can be obtained only by adjustingthe laser scanning speed, a structural member has good surface quality and strength as a whole, and the light weight requirement of the structure can be met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method and device for detecting current-carrying capacity of overhead transmission line

PendingCN112345864AAccurate ampacityReduce the difficulty of implementationMaterial heat developmentEnvironmental/reliability testsThermal coefficientMetal sphere

The invention discloses a method and a device for detecting the current-carrying capacity of an overhead transmission line. The method comprises the following steps: setting a metal ball body at a position in the same air environment as the overhead transmission line, enabling the metal ball body to be in a temperature steady state when the overhead transmission line operates normally, and obtaining the temperature of the metal ball body, wherein the metal ball is made of the same material as an overhead transmission line; based on the heat balance equation of the metal ball, calculating the heat exchange coefficient of the metal ball according to the temperature of the metal ball; obtaining the Reynolds number of the metal ball according to the relationship between the Nusselt number andthe heat transfer coefficient, substituting the Reynolds number of the metal ball into a Reynolds number relationship formula, and calculating to obtain the Reynolds number of the overhead transmission line; and calculating the current-carrying capacity of the overhead power transmission line according to the Reynolds number of the overhead power transmission line based on the thermal balance equation current-carrying capacity calculation formula of the overhead power transmission line. The technical problem that the current-carrying capacity detection error of the overhead power transmissionline is relatively large due to relatively low measurement precision of the environmental parameters of the overhead power transmission line in the prior art is solved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

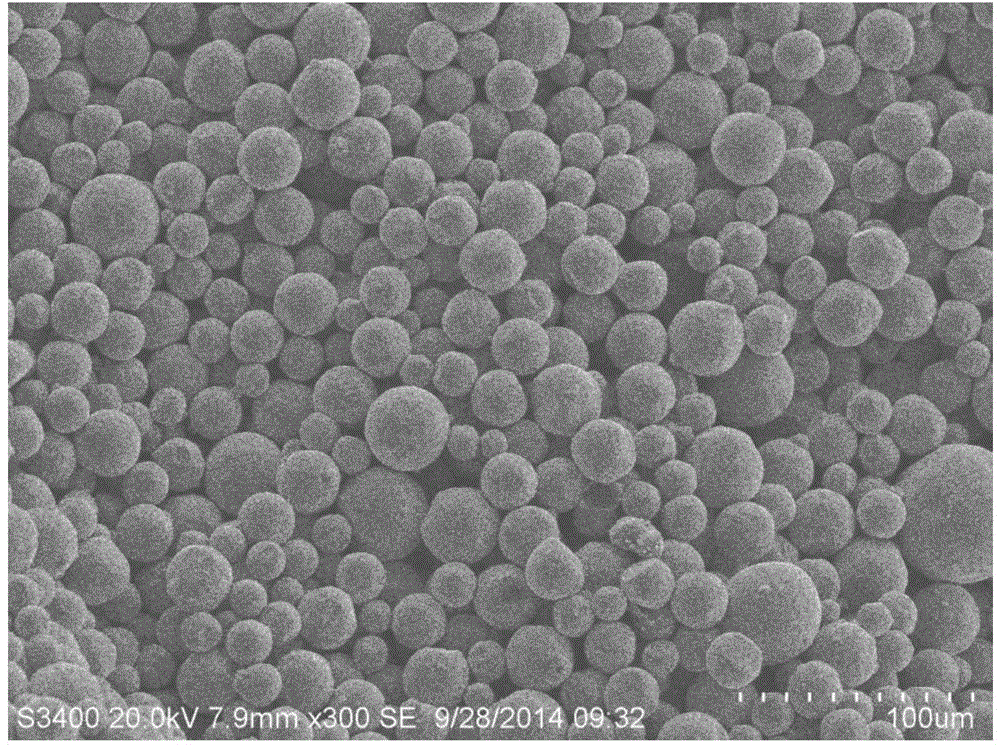

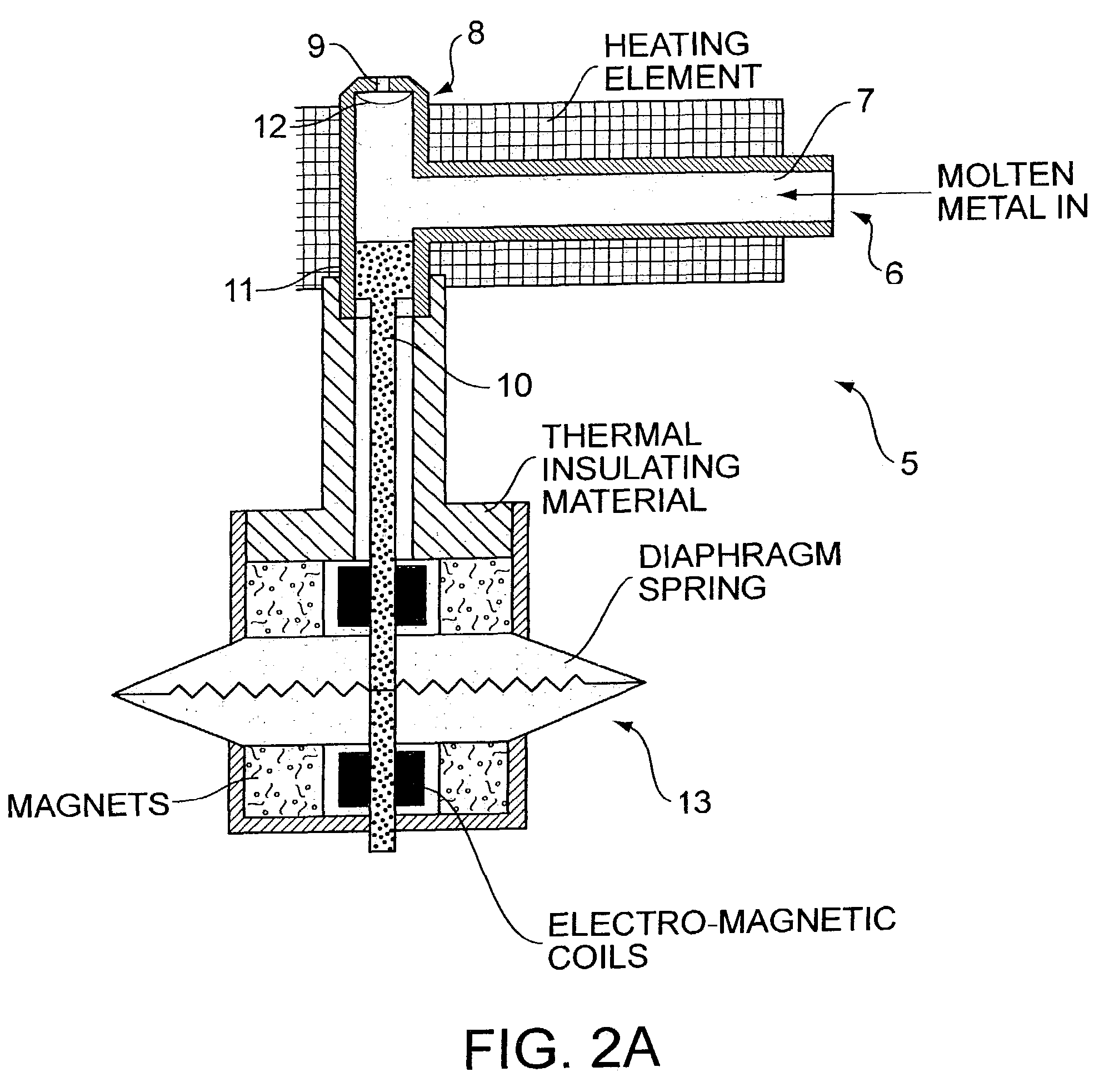

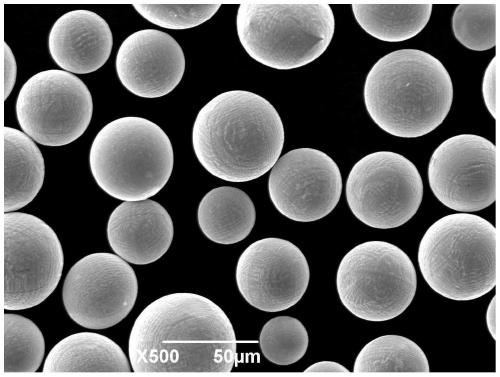

Method and device for preparing uniform-particle-diameter metal powder through quantitative centrifugal atomization method

InactiveCN107570720AQuantitative control sizeQuantitative control of particle sizeCrucibleMetal sphere

The invention discloses a method and a device for preparing uniform-particle-diameter metal powder through a quantitative centrifugal atomization method. According to the method, a perforated crucibleis driven by a motor to rotate, and then a molten metal liquid in the crucible is jetted from tiny holes in the crucible under the action of centrifugal force; after being jetted from the tiny holes,the metal liquid is atomized into metal liquid drops under the action of centrifugal force; under the action of gravity and surface tension, spherical metal liquid drops are formed; and during the falling process, uniform-particle-diameter metal spheres are formed. The method is matched with different crucible tiny-hole diameters and crucible rotation speeds, so that metal powder of different types can be prepared; the particle diameters are controllable; and the metal powder prepared according to the method has the characteristics being controllable in particle diameter, high in sphericity and uniform in particle size.

Owner:张家港创博金属科技有限公司

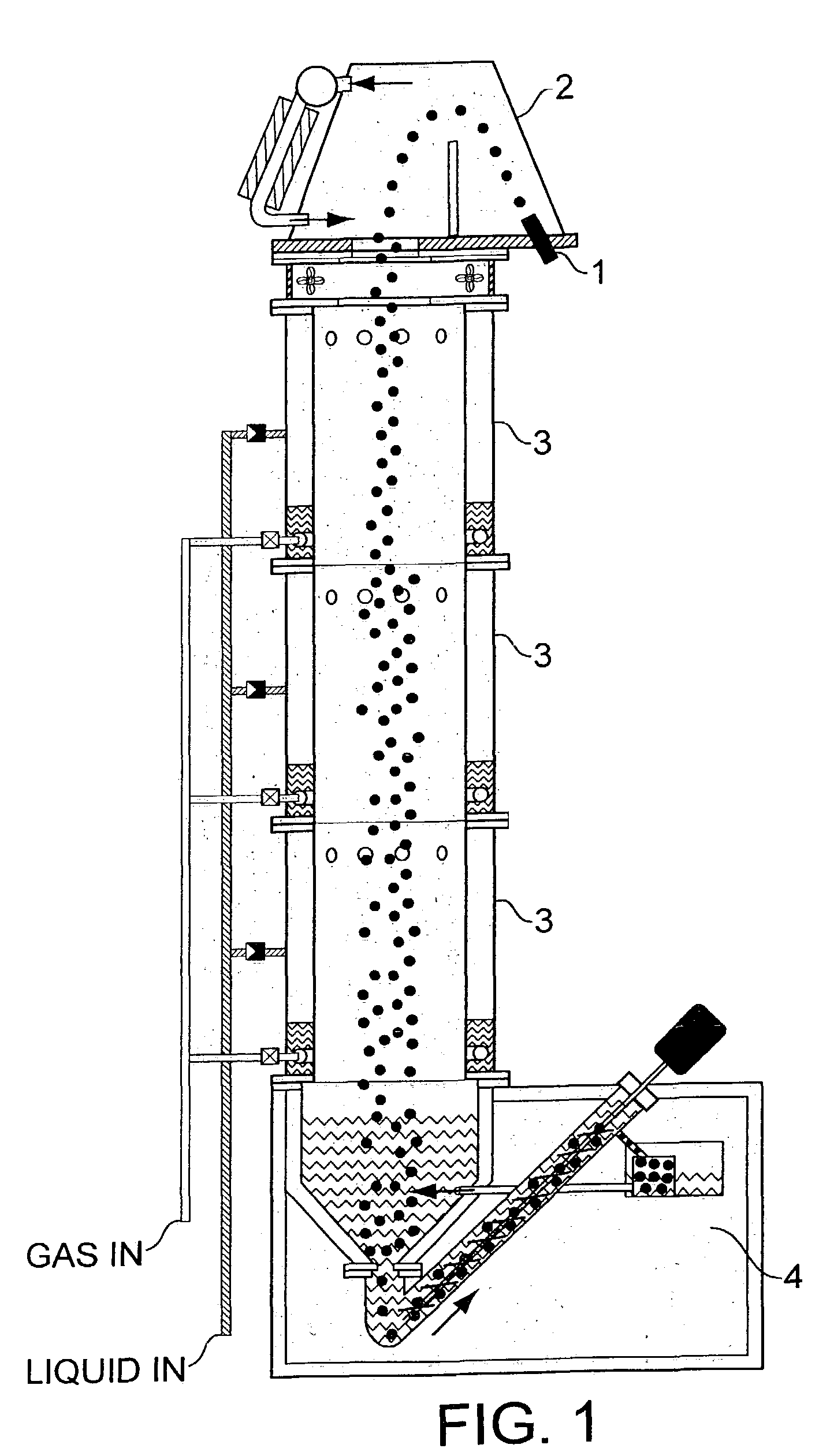

Process for fabricating metal spheres

InactiveUS7097687B2Small toleranceEasy to processTransportation and packagingMetal-working apparatusMetallurgyMetal sphere

A method of forming metal spheres includes ejecting a precisely measured droplet of molten metal from a molten metal mass, buffering the molten metal droplet to reduce the internal kinetic energy of the droplet without solidifying the droplet and cooling the buffered droplet until the droplet solidifies in the form of a metal sphere. An apparatus for fabricating metal spheres includes a droplet generator that generates a droplet from a molten metal mass, a buffering chamber that receives the droplet from the droplet generator, and diminishes internal kinetic energy of the droplet without solidifying the droplet, and a cooling drum that receives the droplet from the buffering chamber, and cools the droplet to the extent that the droplet solidifies into a metal sphere. The apparatus may further include a collector arrangement that receives the metal spheres from the cooling drum and makes the metal sphere available for collection.

Owner:ACCURUS SCI

Safe type lightning rod grounding device

ActiveCN108233183AIngenious design structureImprove practicalityCorona dischargeLightning rodProtection mechanism

The invention relates to a safe type lightning rod grounding device. The safe type lightning rod grounding device comprises a lightning protection mechanism and a detection mechanism, wherein the lightning protection mechanism comprises a lightning rod, a voltage stabilizing ring, a connection post, a metal sphere, a support rod, a first lead wire and a rib plate assembly; a connection assembly comprises a box body and also comprises a power connection socket, a first electromagnet, a spring, a second electromagnet, a second lead wire, a moving block, a lifting block, an indication lamp and afixed block which are arranged on the box body; a power supply assembly comprises a shell and also comprises a storage battery, a control box, a motor, a round gear, a strip gear and a power connection post which are arranged on the shell. According to the safe lightning rod grounding device, PLC in the control box is used for controlling the motor to be started; the power supply assembly is connected with the connection assembly; the moving block can move up; the second lead wire connected onto the connection post is connected onto the voltage stabilizing ring, so that electric signals are sent to the PLC; when the PLC does not receive the electric signals, the PLC is capable of controlling a wireless communication module to send alarm signals to intelligent terminals such as mobile phones and then make a request for repair.

Owner:江苏金合益复合新材料有限公司

Anti-static device

PendingCN107825373AFacilitated releaseEasy to adjustWork benchesCoupling protective earth/shielding arrangementsMetal sphereOrganic glass

The invention discloses a height adjustable anti-static device which can release static. The anti-static device comprises a workbench, a tool storage frame, an anti-static organic glass plate, a static releasing unit, an anti-static socket structure, an adjustable pedal structure, adjustable supporting legs, adjusting nuts and supporting feet. The tool storage frame is welded to the lower portionof the workbench. The anti-static organic glass plate is arranged on the upper portion of the tool storage frame. The static releasing unit is mounted on the right side of the tool storage frame through bolts. The anti-static socket structure is mounted on the left side of the lower portion of the workbench. According to the anti-static device, a metal ball is connected to the upper portion of anadjusting rod through glue and connected with a ground lead, statics are released from human bodies conveniently through the metal ball, and thus the effect of static releasing is achieved; the adjusting nuts are connected to the joints of the adjustable supporting legs and a supporting frame through threads, and the height of the anti-static device can be adjusted conveniently; and an anti-staticpedal specifically adopts an anti-static nylon pedal, and the anti-static effect is advantageously improved when a user steps on the pedal.

Owner:张家港市得道电子有限公司

Preparation method of ferronickel-based alloy spherical powder for 3D printing

ActiveCN111570812AReduced propensity to formDrop high temperature stretchAdditive manufacturing apparatusTransportation and packagingChemical compositionMetal sphere

The invention discloses a preparation method of ferronickel-based alloy spherical powder for 3D printing. The preparation method comprises the following steps that 1) burdening is conducted by using the following chemical composition proportion of, in percentage by mass, 44.77%-51.5% of Ni, 18%-20% of Fe, 21.0%-22.5% of Cr, 1.0%-2.0% of Co, 8.0%-9.5% of Mo, 0.5%-1.0% of W, 0%-0.02% of C, 0%-0.01%of Mn and 0%-0.2% of Si; 2) the ingredients in the step 1) are prepared into an alloy ingot by adopting a vacuum induction melting horizontal continuous casting process, a shrinkage cavity defect at the head of the alloy ingot is removed, and then the alloy ingot is machined into an electrode bar; 3) the electrode bar in the step 2) is placed in a plasma rotating electrode powder making machine toform metal spherical powder; and 4) the prepared metal spherical powder is screened by adopting an ultrasonic vibrating screen under the protection of high-purity argon to obtain the ferronickel-based alloy spherical powder for the 3D printing.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

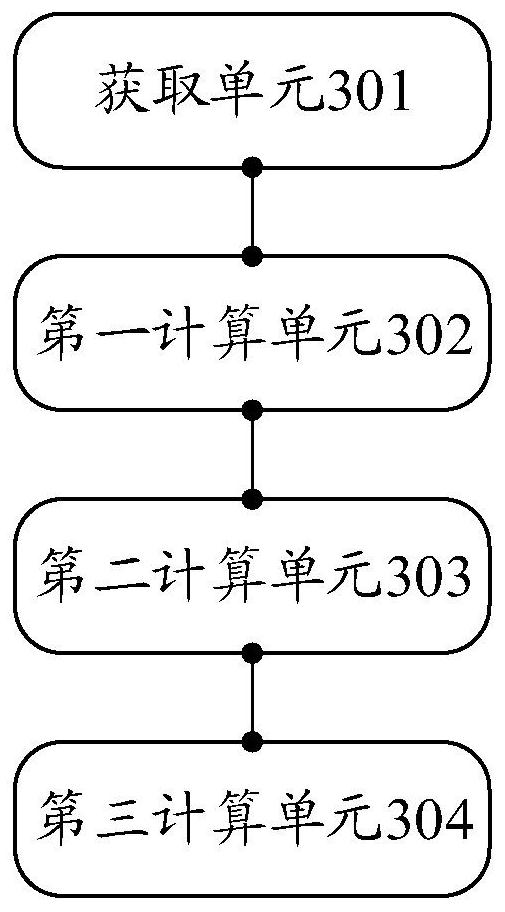

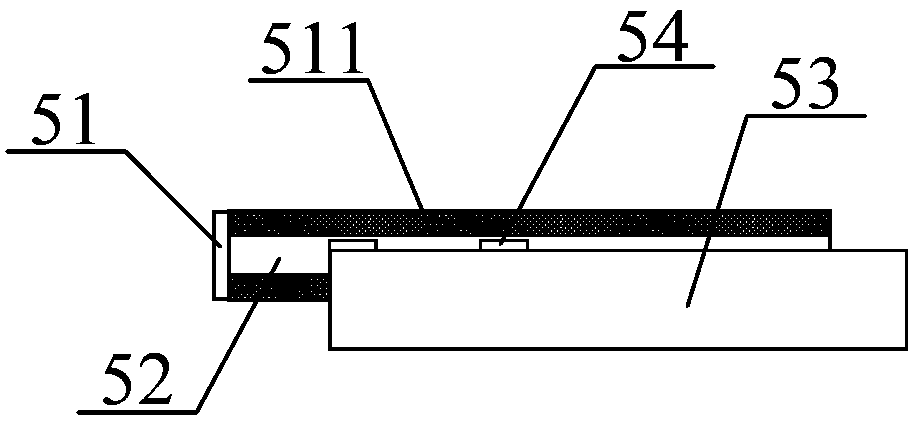

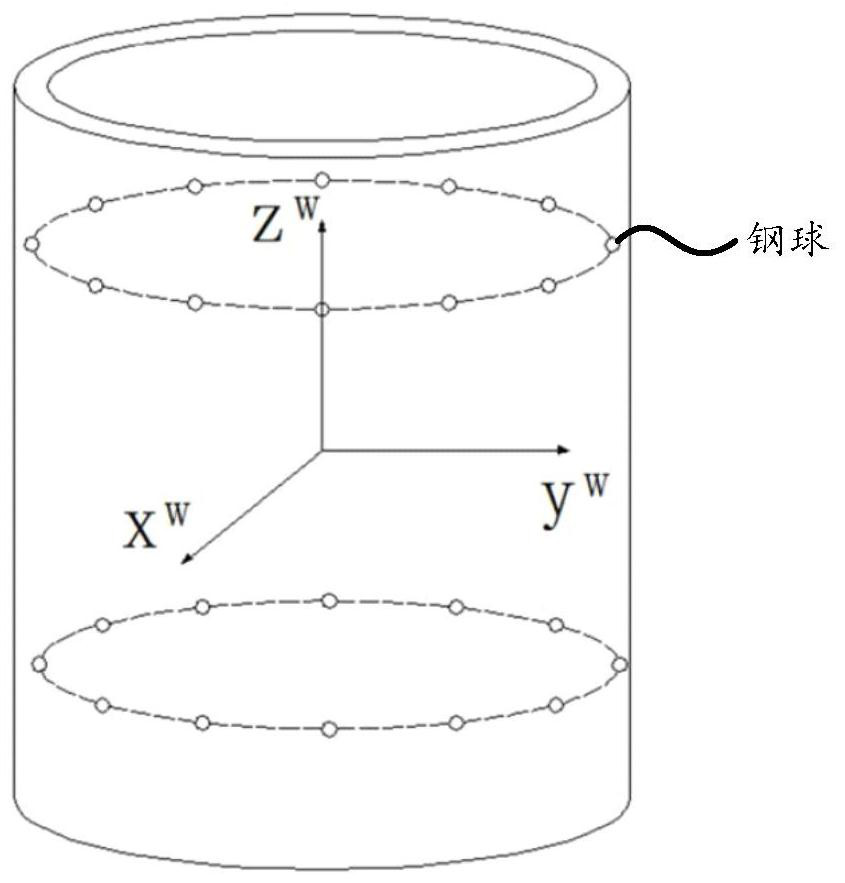

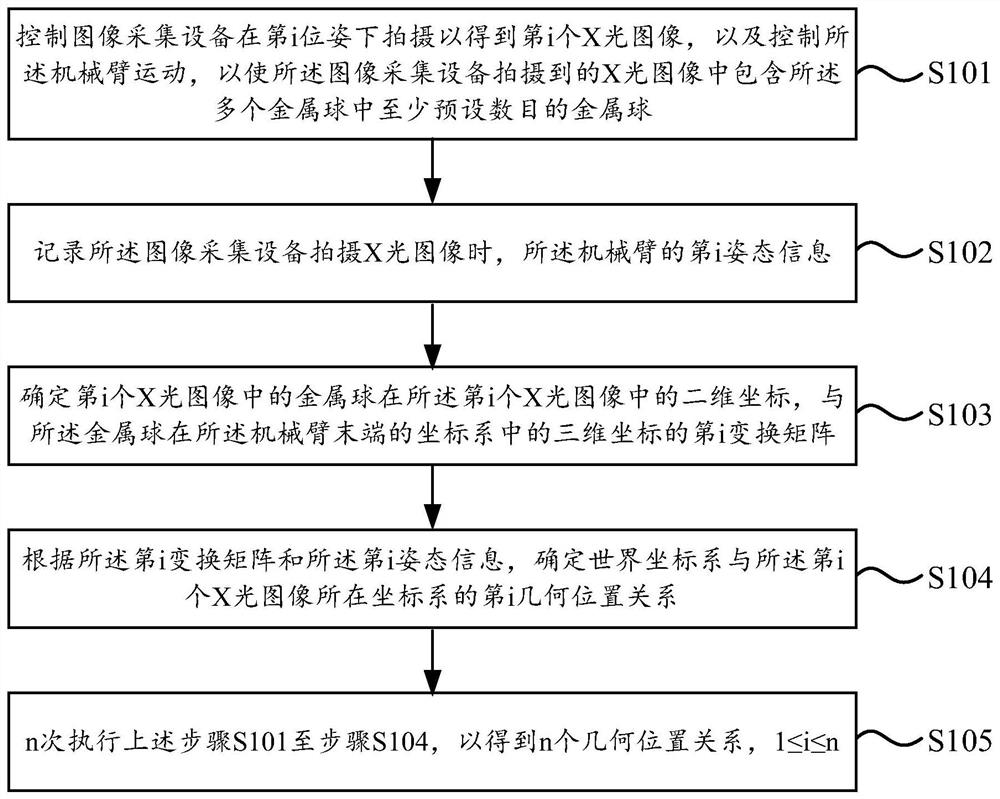

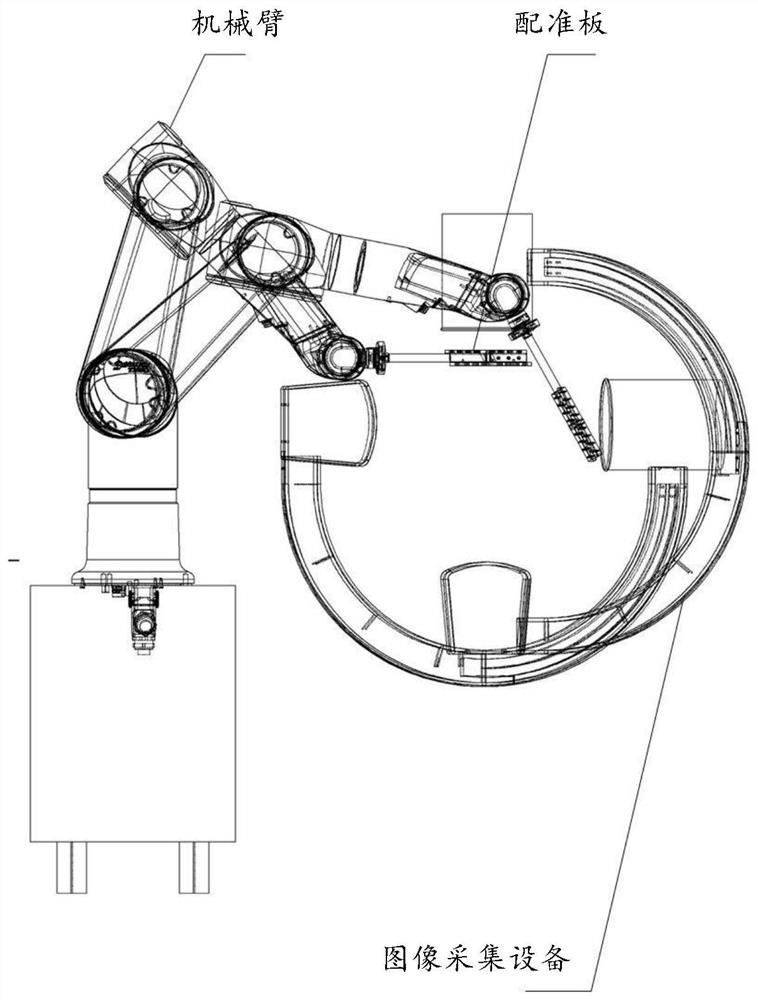

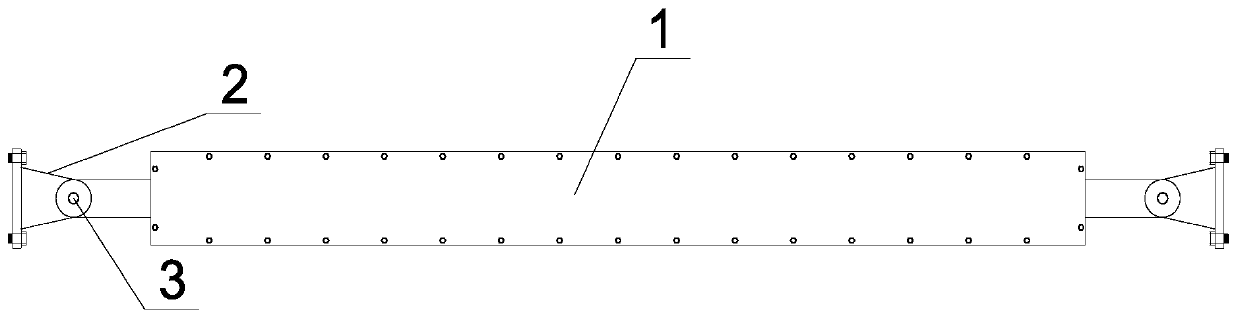

Parameter calibration method and parameter calibration device

ActiveCN111973212AAttitude information is accurateSure easyComputerised tomographsTomographyAcquisition apparatusClassical mechanics

The invention relates to a parameter calibration method. The method comprises steps as follows: controlling image acquisition equipment to perform shooting in an ith pose to obtain an X-ray image, andcontrolling a mechanical arm to move to realize that the X-ray image shot by the image acquisition equipment contains at least the preset number of metal balls in multiple metal balls; recording ithpose information of the mechanical arm; determining two-dimensional coordinates of the metal balls in the X-ray image and an ith transformation matrix of three-dimensional coordinates of the metal balls in a coordinate system at the tail end of the mechanical arm; and determining a geometric position relation of a world coordinate system and the coordinate system where the X-ray image is located according to the ith transformation matrix and the ith pose information. According to the parameter calibration method, the process of determining the geometric position relation of the world coordinate system and the coordinate system where the X-ray image is located does not need a specific die body, the process is relatively simple, and besides, the pose information of the mechanical arm is relatively accurate and easy to determine, so that a result with higher accuracy can be obtained through the relatively simple process.

Owner:HANGZHOU SANTAN MEDICAL TECH

Anti-buckling support and installation method of multi-stage energy dissipation foam metal sphere composite inner plate

InactiveCN109868912AImprove self-healing abilityIncreased durabilityBridge structural detailsProtective buildings/sheltersSheet steelSelf recovery

The invention discloses an anti-buckling support and installation method of a multi-stage energy dissipation foam metal sphere composite inner plate. A multi-stage energy dissipation foam and metal sphere composite inner plate comprises a composite energy dissipation restraint rod body 1 and a hinged shoe 2, wherein the hinge shoe 2 comprises a bottom plate and an ear plate; installation holes areformed in the periphery of the bottom plate and are connected through high-strength bolts and end-column reserve anchor part bolt holes in a bolted mode; a hole opening is formed in the middle of theear plate, and the diameter of the hole opening is the same as the diameter of a high strength bolt pin 3; rod arms of loading connection rods 5 at the two ends of the hinge shoe 2 and the compositeenergy dissipation restraint rod body 1 are connected through the high strength bolt pin 3; the composite energy dissipation restraint rod body 1 comprises a restraint steel sleeve 4, a sealing rubberring 10, and a sleeve cover plate 11; and the resistant steel sleeve 4 is a rectangular steel sleeve, a groove channel in the sleeve is provided with the loading connection rods 5, a foam metal sphere 6, a memory alloy spring 7, a high-damping curved-surface rubber 8, and an arc tensile steel plate 9. The multi-stage energy dissipation foam metal sphere composite inner plate can be widely used inthe technical fields of building structures, bridges, non-structural components and the like, and has the characteristics of environmental protection, uniform distribution of energy dissipation, multi-stage energy dissipation, and strong self-recovery ability.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

Formation of metal nanospheres and microspheres

Hemispheres and spheres are formed and employed for a plurality of applications. Hemispheres are employed to form a substrate having an upper surface and a lower surface. The upper surface includes peaks of pillars which have a base attached to the lower surface. The peaks have a density defined at the upper surface by an array of hemispherical metal structures that act as a mask during an etch to remove substrate material down to the lower surface during formation of the pillars. The pillars are dense and uniform and include a microscale average diameter. The spheres are formed as independent metal spheres or nanoparticles for other applications.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com