Method and device for preparation of micron-sized iron-based hollow sphere material

A hollow sphere and micron-scale technology, which is applied in the field of building decoration materials, can solve the problems of few hollow spheres made of iron-based materials with high melting point, few researches on hollow powders, and many hollow powders, etc., to achieve fine structure and low oxygen content , the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

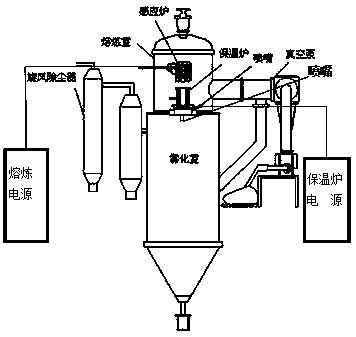

[0016] 1. Put 5kg of pure iron and pure manganese (99.7%) in the induction melting chamber according to the mass ratio of 87:13 ( figure 1 ) in the dry pot, adjust the protruding length of the nozzle guide tube to 3.5-9.5mm, and the inner diameter to 3.0-5.5mm.

[0017] 2. Turn on the power supply and air source of the electric cabinet ( figure 1 ), water cooling system, adjust the water pressure to 0.3-0.4MPa, turn on the power of the holding furnace to preheat the holding crucible, the preheating temperature is 1100°C-1550°C.

[0018] 3. Turn on the smelting power switch, adjust the water pressure, turn on the inverter switch, adjust the intermediate frequency to make it vibrate, and then slowly adjust the power to 30kW. After the alloy is melted, control the superheat to 220°C-420°C (infrared temperature measurement). When shutting down, slowly lower the power, reduce the intermediate frequency to 0, turn off the inverter, and finally turn off the smelting power switch ( ...

Embodiment 2

[0022] 1. Put 5kg of pure iron and pure manganese in the induction melting chamber according to the mass ratio of 83:17 ( figure 1 ) in the dry pot, adjust the protruding length of the nozzle guide tube to 3.0-9.0mm, and the inner diameter to 3.5-5.5mm.

[0023] 2. Turn on the power supply and air source of the electric cabinet ( figure 1 ), water cooling system, the water pressure is adjusted to 0.3-0.4MPa, turn on the power of the holding furnace to preheat the holding crucible, the preheating temperature is 1150°C-1550°C.

[0024] 3. Turn on the smelting power switch, adjust the water pressure, turn on the inverter switch, adjust the intermediate frequency to make it vibrate, and then slowly adjust the power to 30kW. After the alloy is melted, control the superheat to 250°C-420°C (infrared temperature measurement). When shutting down, slowly lower the power, reduce the intermediate frequency to 0, turn off the inverter, and finally turn off the smelting power switch ( fi...

Embodiment 3

[0028] 1. Put the high molybdenum cast iron in the induction melting chamber ( figure 1 ) in the dry pot, adjust the protruding length of the nozzle guide tube to 3.2-9.0mm, and the inner diameter to 3.5-6.5mm.

[0029] 2. Turn on the power supply and air source of the electric cabinet ( figure 1 ), vacuum, water cooling system, the water pressure is adjusted to 0.3-0.4MPa,

[0030] 3. Close all valves, and when the vacuum is within 10Pa, turn on the power of the holding furnace to preheat the holding crucible, the preheating temperature is 1150°C-1450°C.

[0031] 4. Turn on the smelting power switch, adjust the water pressure, turn on the inverter switch, adjust the intermediate frequency to make it vibrate, and then slowly adjust the power to 30kW. After the alloy is melted, control the superheat to 260°C-400°C (infrared temperature measurement). When shutting down, slowly lower the power, reduce the intermediate frequency to 0, turn off the inverter, and finally turn off...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com