Method and device for preparing uniform-particle-diameter metal powder through quantitative centrifugal atomization method

A centrifugal atomization and metal powder technology, applied in the field of metal spherical powder preparation, can solve the problems of high manufacturing schedule requirements, difficult processing, affecting the performance of spherical metal powder, etc., and achieve the effect of high powder preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

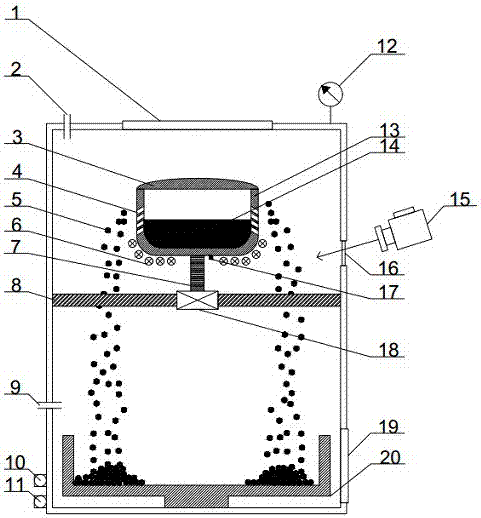

[0013] Embodiment 1: Prepare spherical powder of metal aluminum, the particle size of the powder is 100 μm, the diameter of the small hole of the crucible is 80 μm, and the rotation speed of the crucible is 3000 rpm, the specific steps are as follows:

[0014] Open the deflation valve (9), and after the deflation is completed, open the door (19), put the powder collector (20) directly under the crucible, close the door (19), open the door (1), and place the powder in the crucible Put metal aluminum into the crucible, the amount of metal aluminum put in does not exceed 2 / 3 of the volume of the crucible, cover the crucible cover (3) and fix it, close the door (1), close the air release valve (9), turn on the mechanical pump (10 ) to pump the pressure in the chamber to 1Pa, then use the diffusion pump (11) to further pump the pressure in the chamber to 0.01Pa, fill the chamber with high-purity inert gas through the intake pipe (2), so that the pressure inside and outside the chamb...

Embodiment 2

[0015] Example 2: Preparation of spherical powder of superalloy Inconel 718, the particle size of the powder is 50 μm, the diameter of the small hole of the crucible is 60 μm, and the rotation speed of the crucible is 1800 rpm. The specific steps are:

[0016] Open the deflation valve (9), and after the deflation is completed, open the door (19), put the powder collector (20) directly under the crucible, close the door (19), open the door (1), and place the powder in the crucible Put superalloy Inconel 718 into the crucible, the volume of which should not exceed 2 / 3 of the volume of the crucible, cover the crucible lid (3) and fix it, close the door (1), close the vent valve (9), and turn on the mechanical pump (10) Pump the pressure in the chamber to 1Pa, then use the diffusion pump (11) to further pump the pressure in the chamber to 0.01Pa, fill the chamber with high-purity inert gas through the intake pipe (2), so that the pressure inside and outside the chamber is balanced,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com