Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

476 results about "Regenerative heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A regenerative heat exchanger, or more commonly a regenerator, is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid. To accomplish this the hot fluid is brought into contact with the heat storage medium, then the fluid is displaced with the cold fluid, which absorbs the heat.

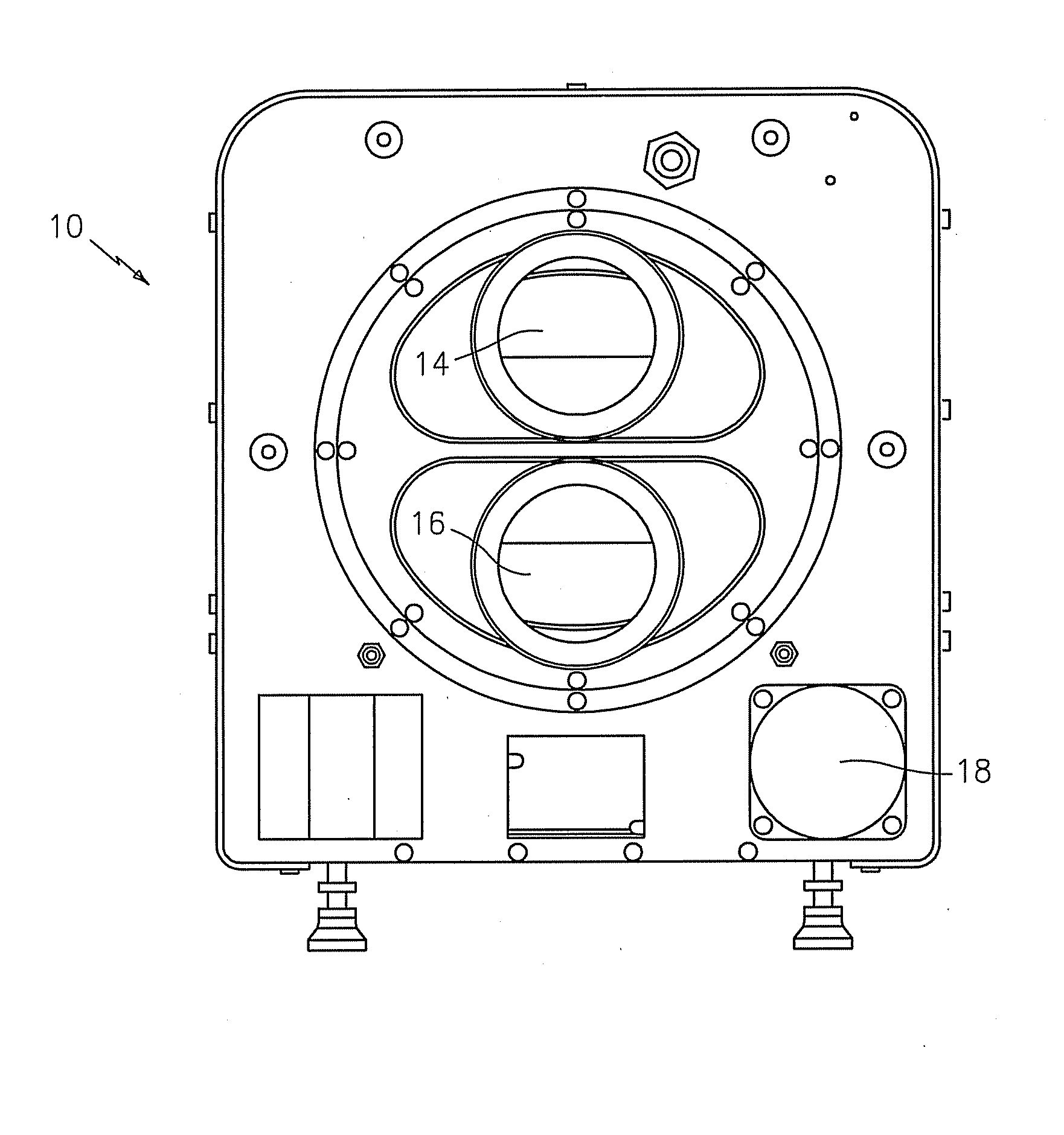

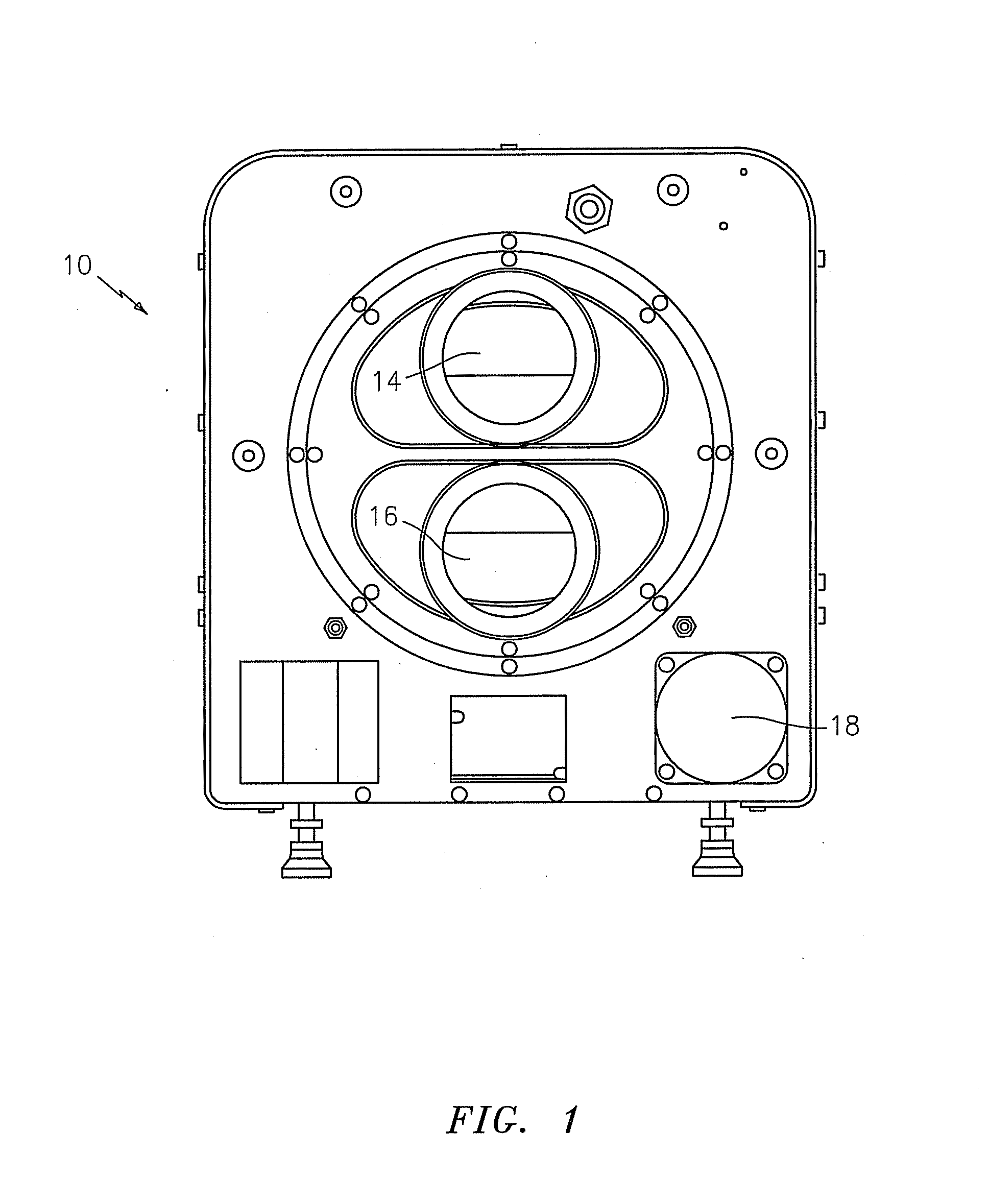

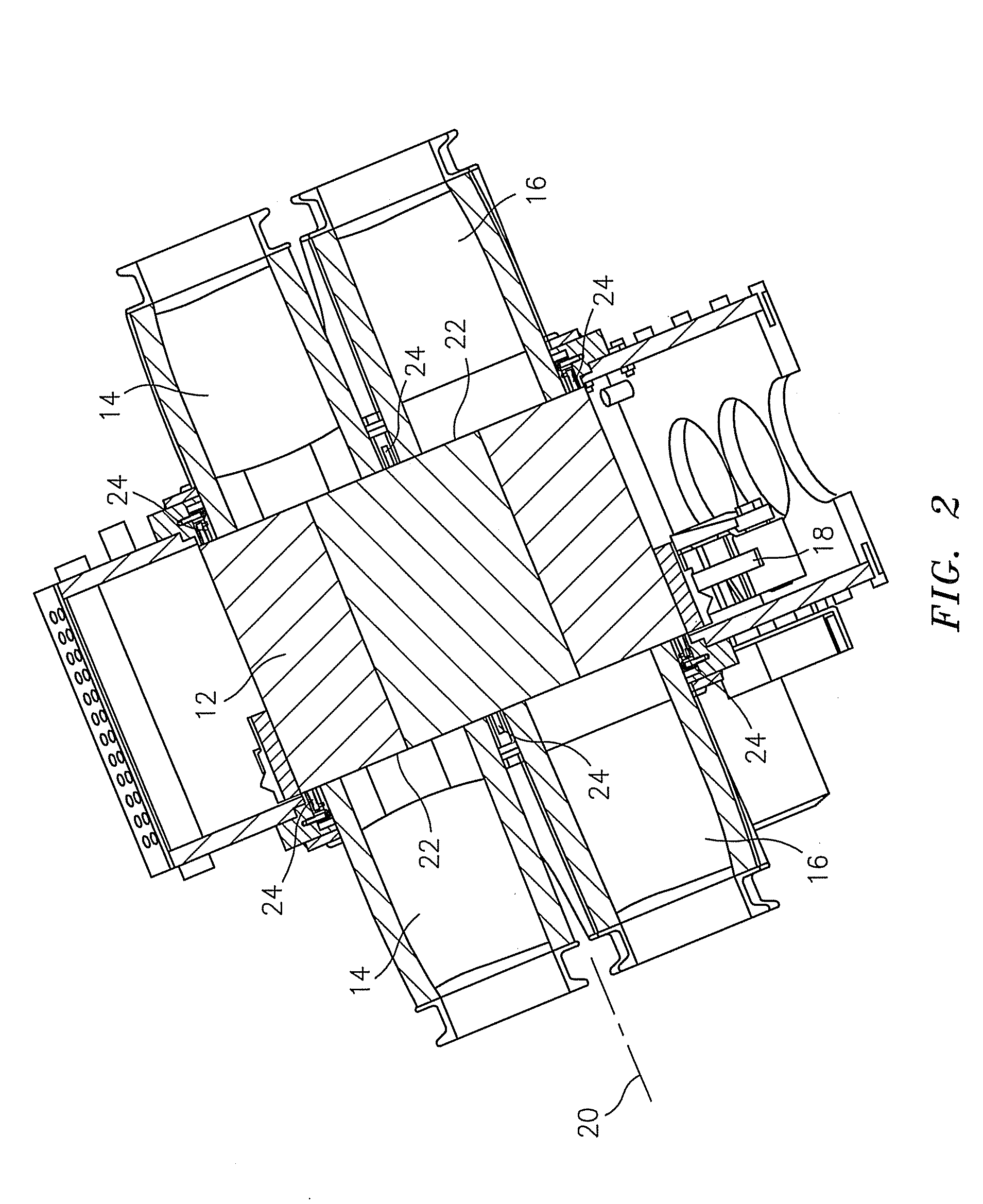

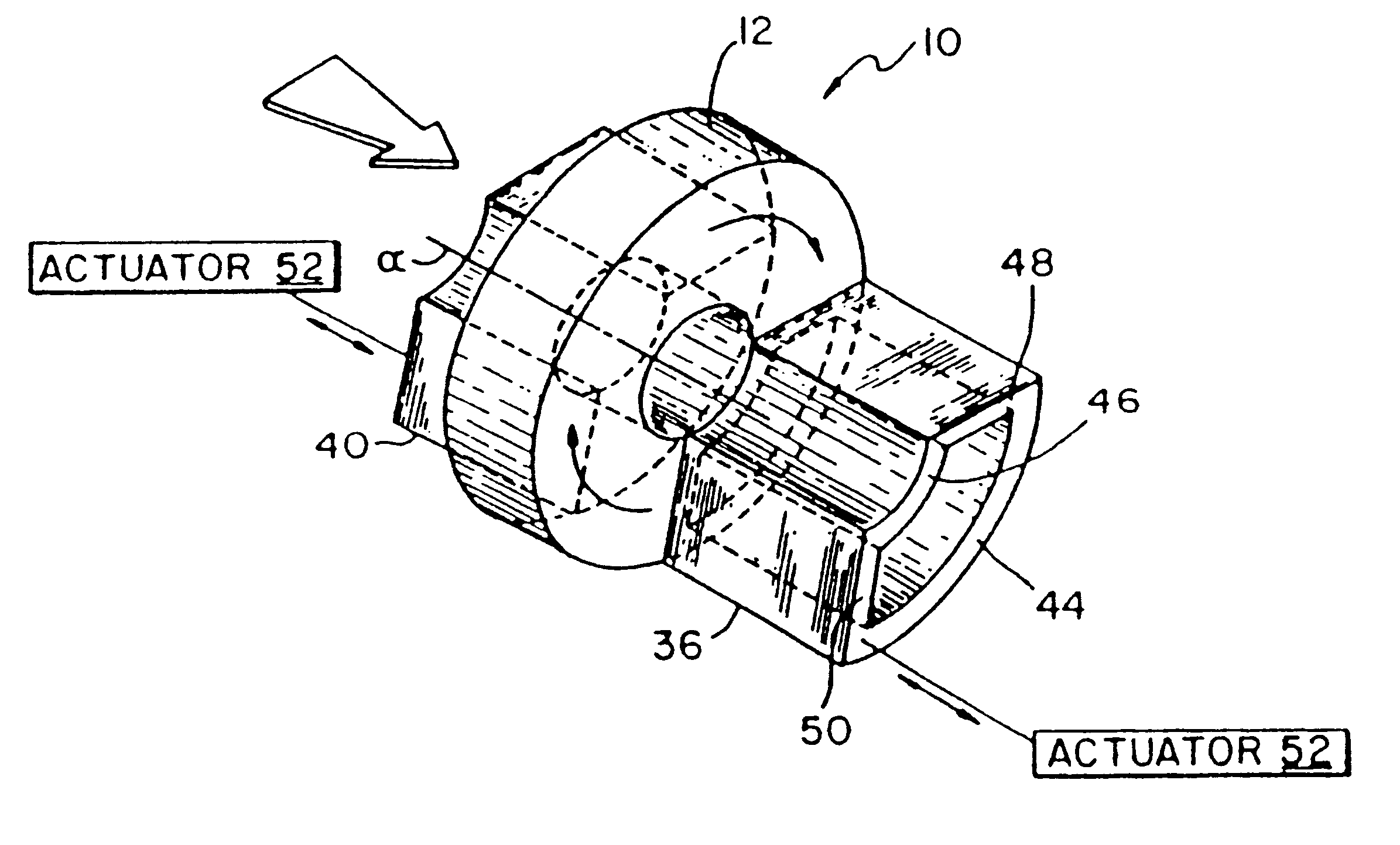

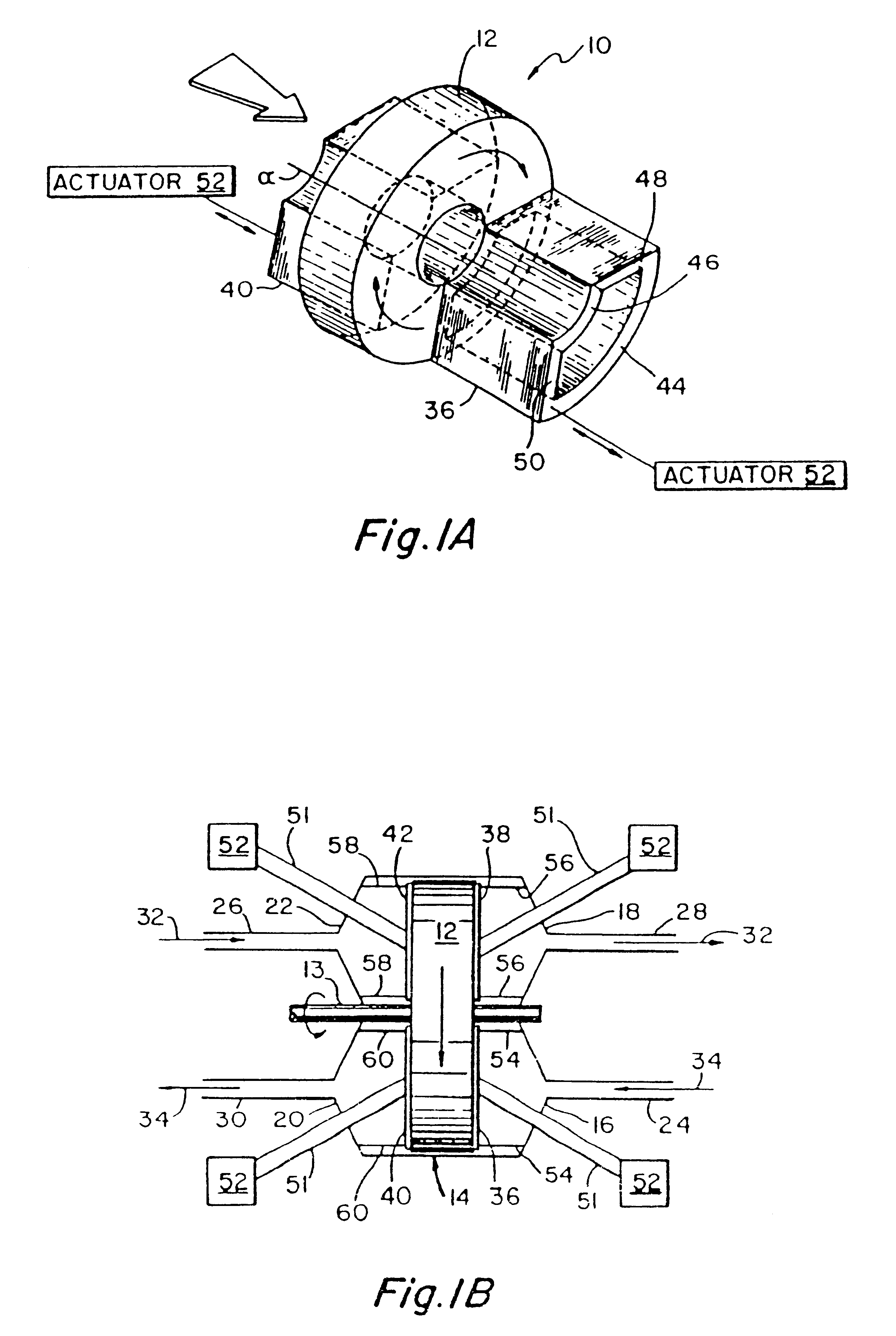

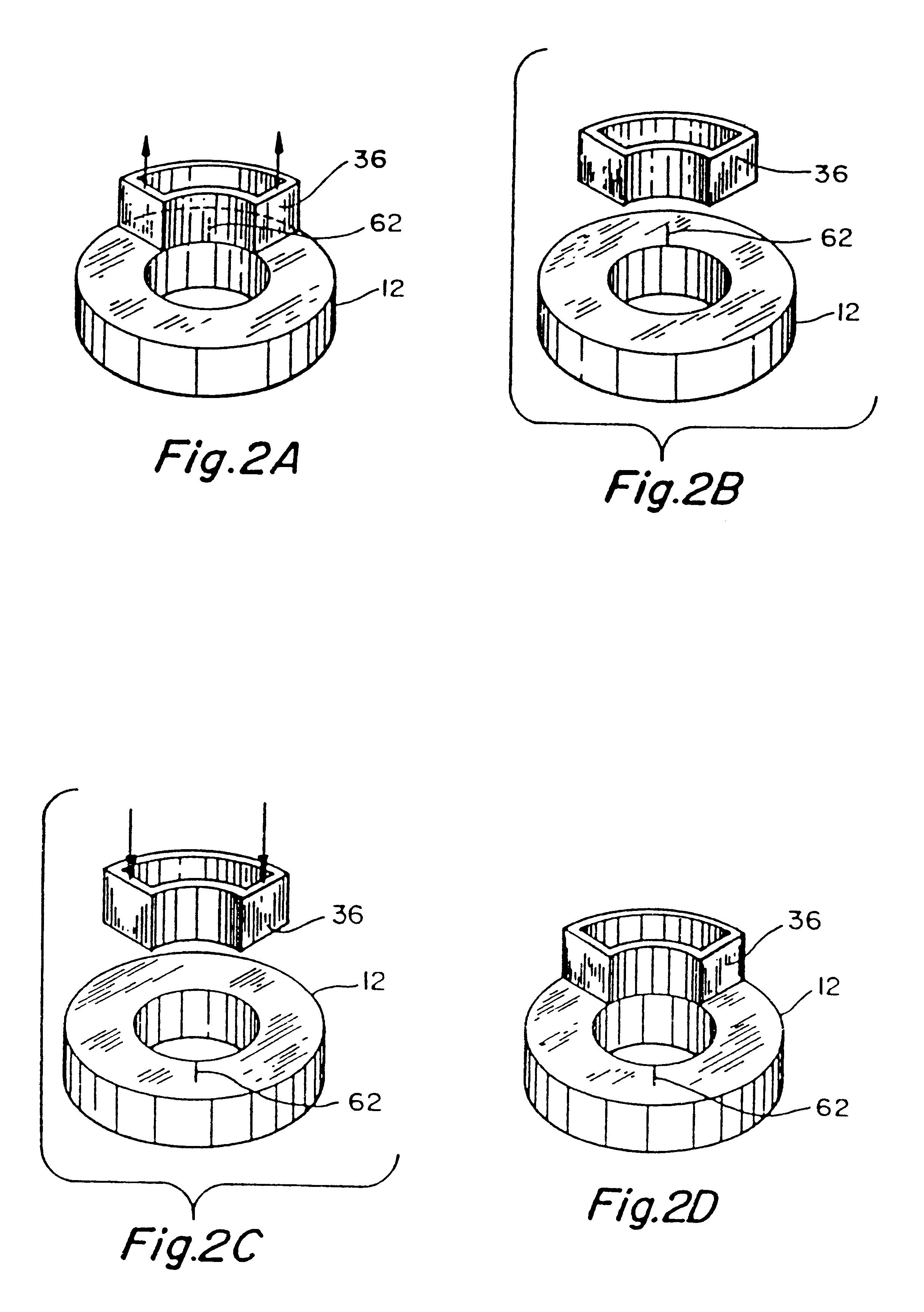

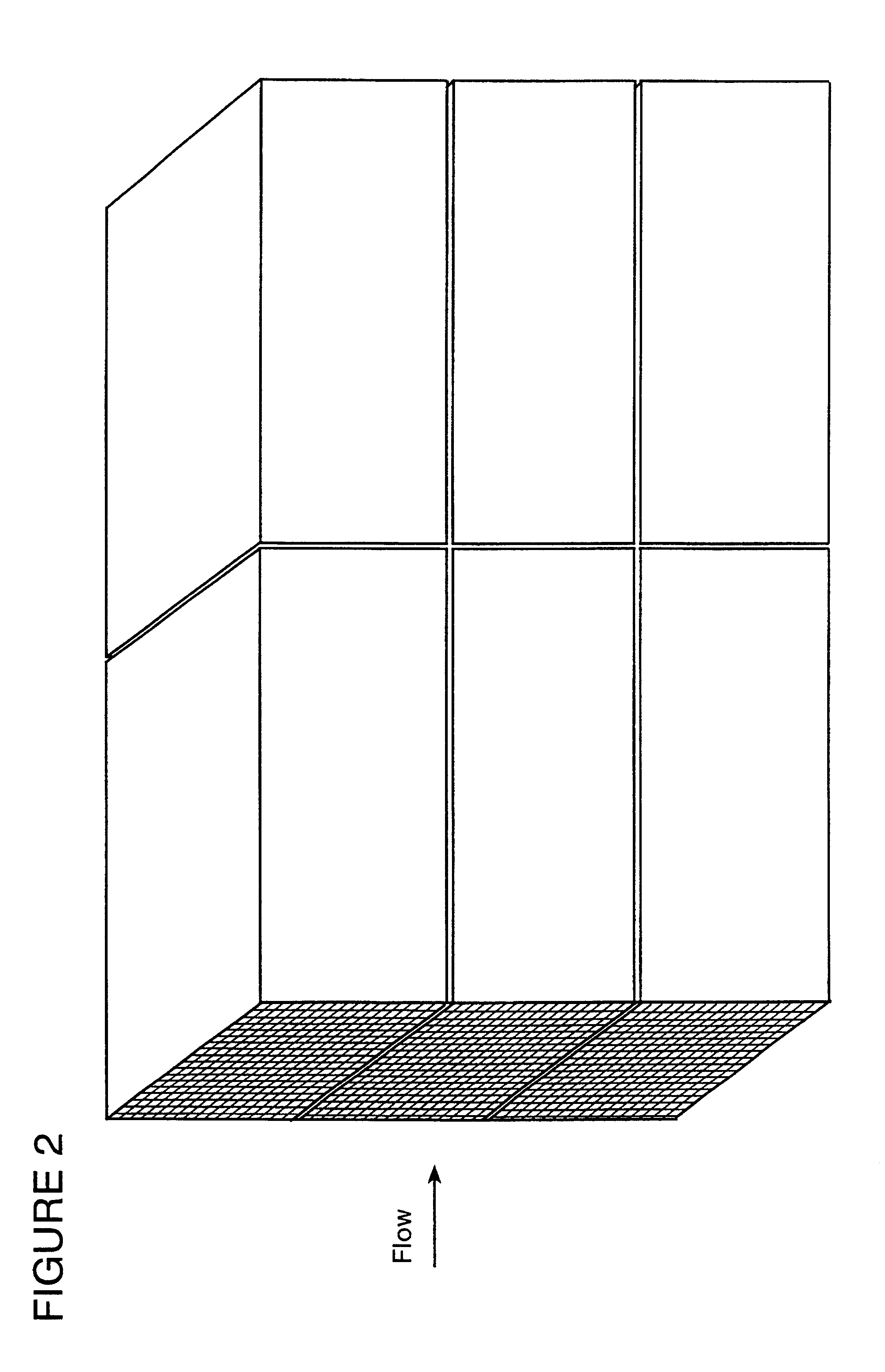

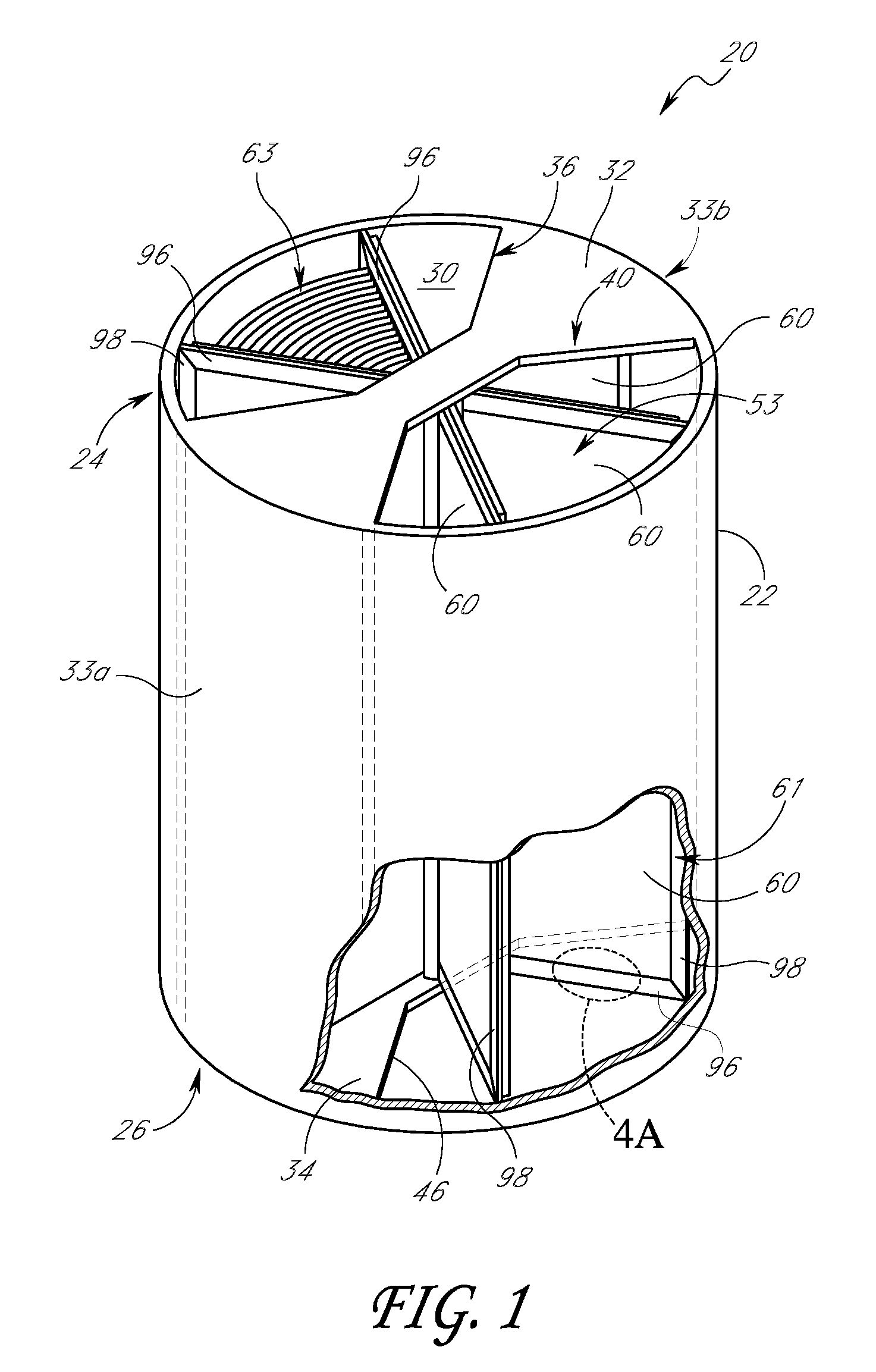

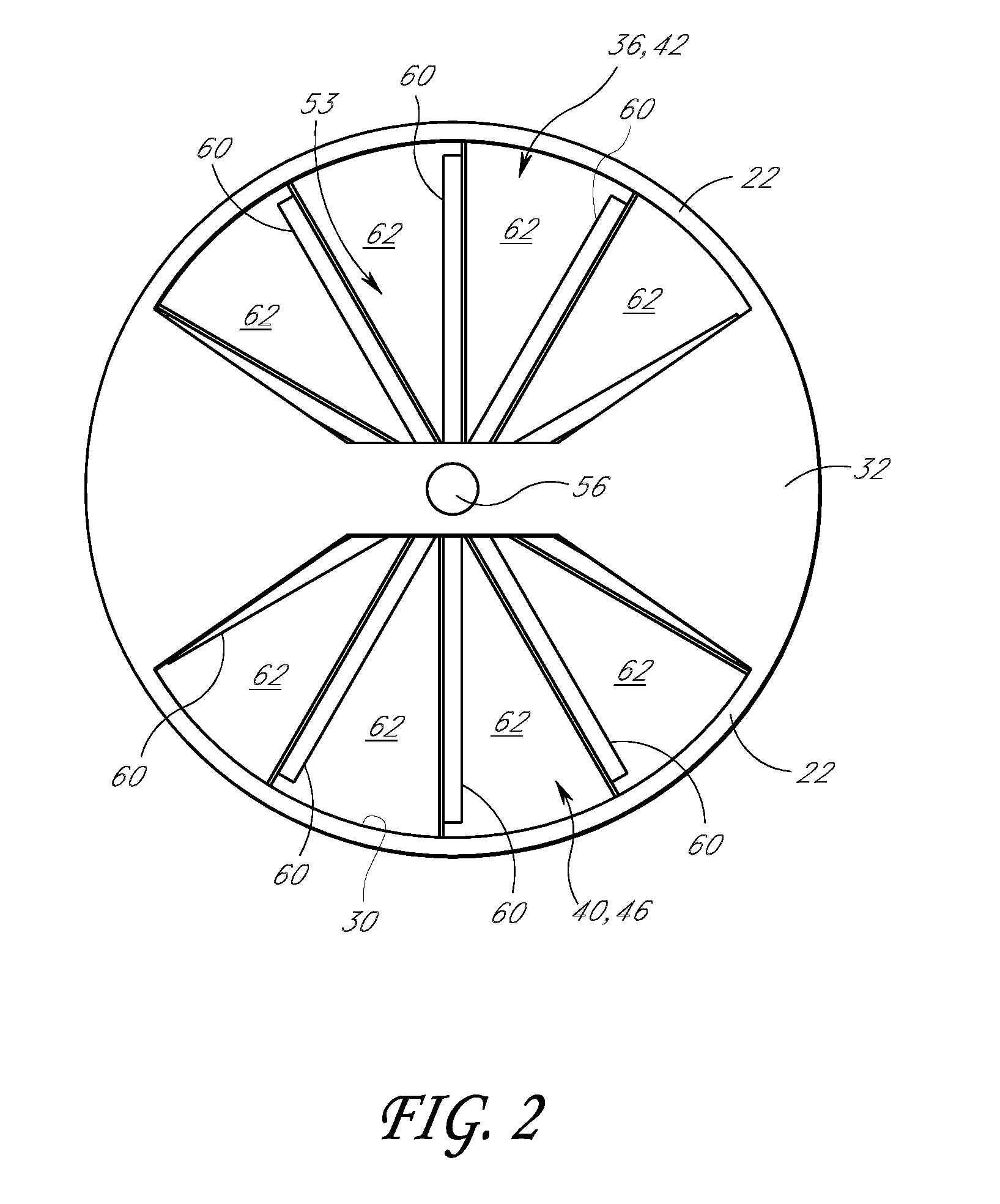

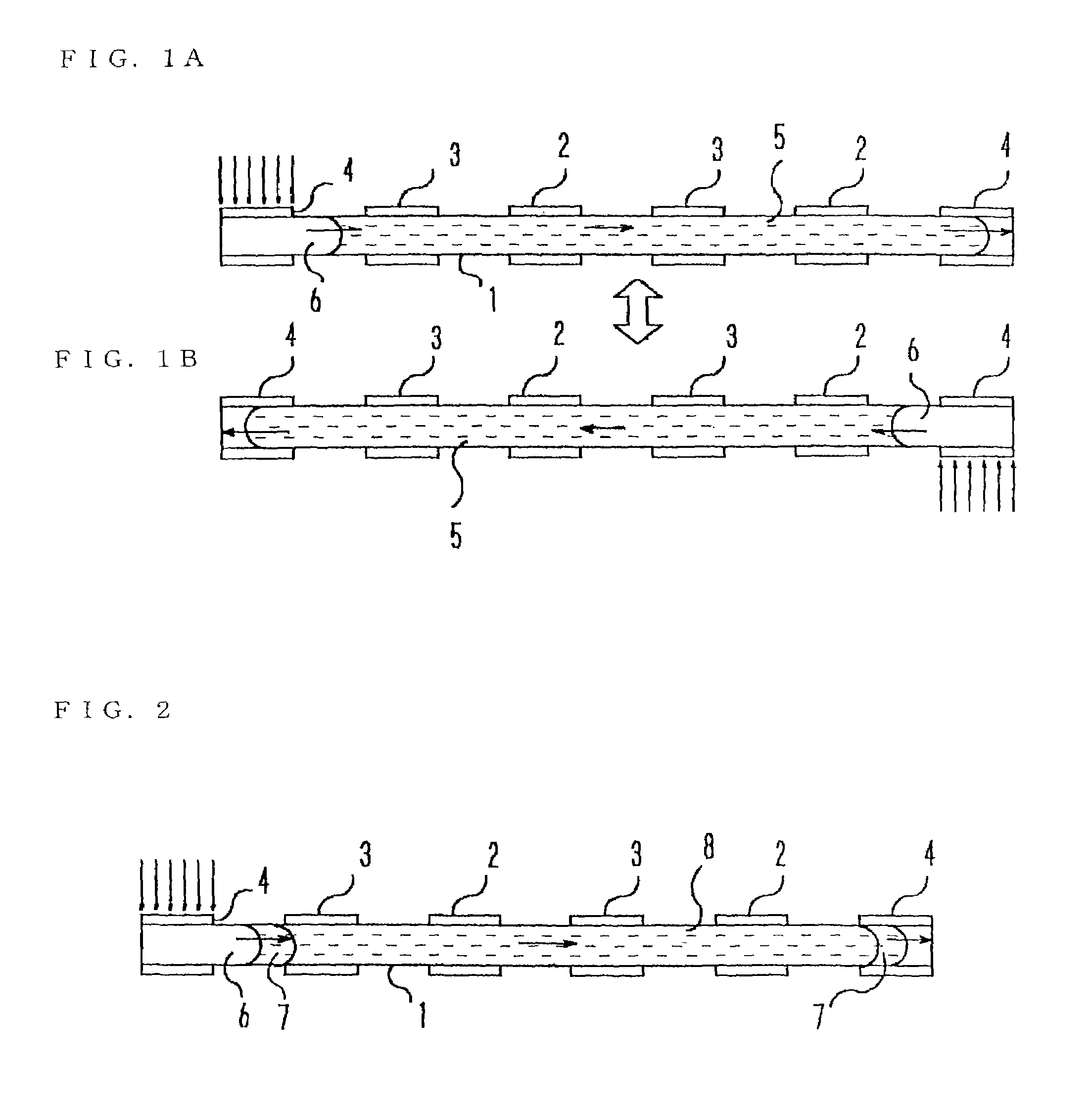

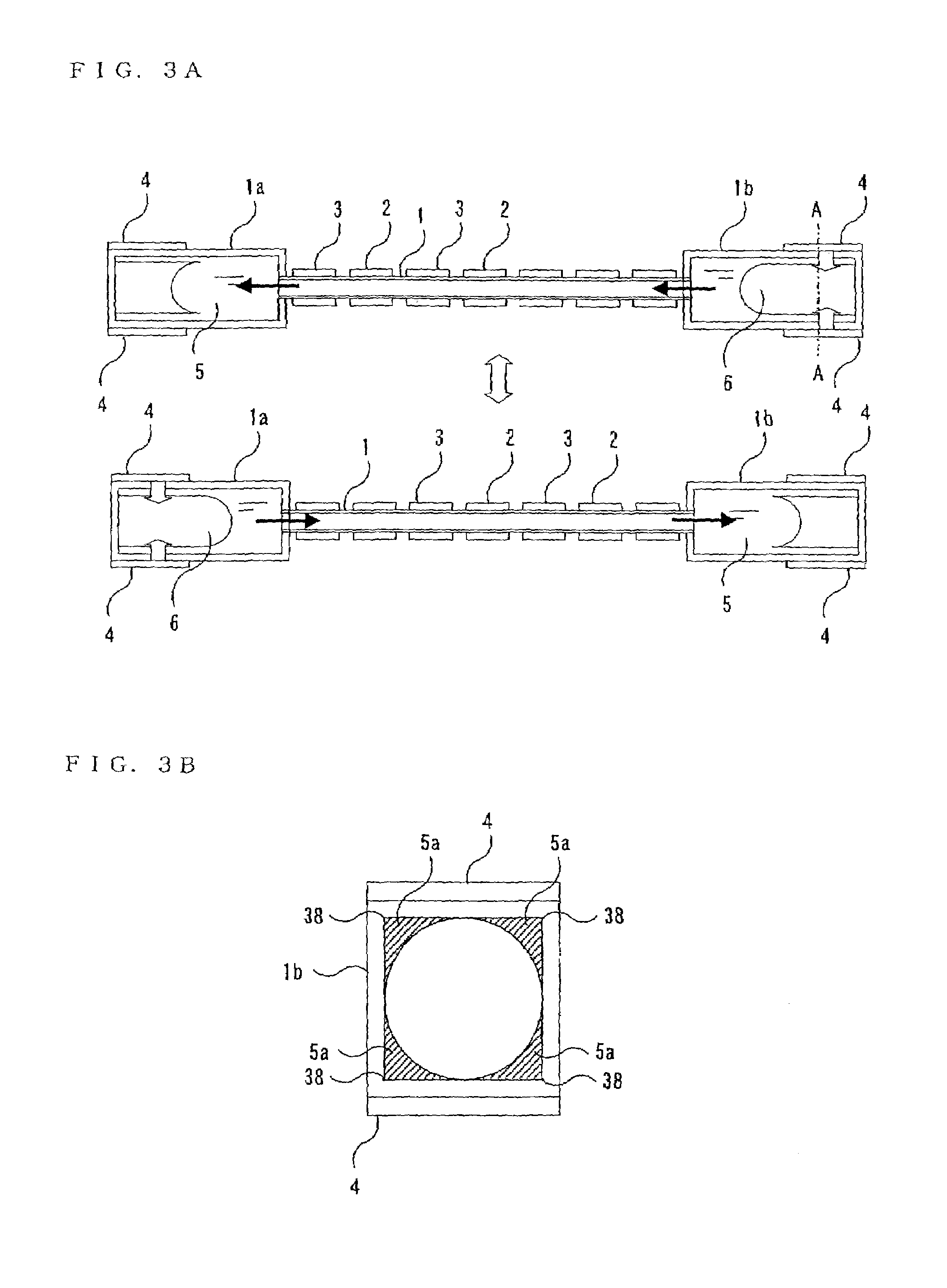

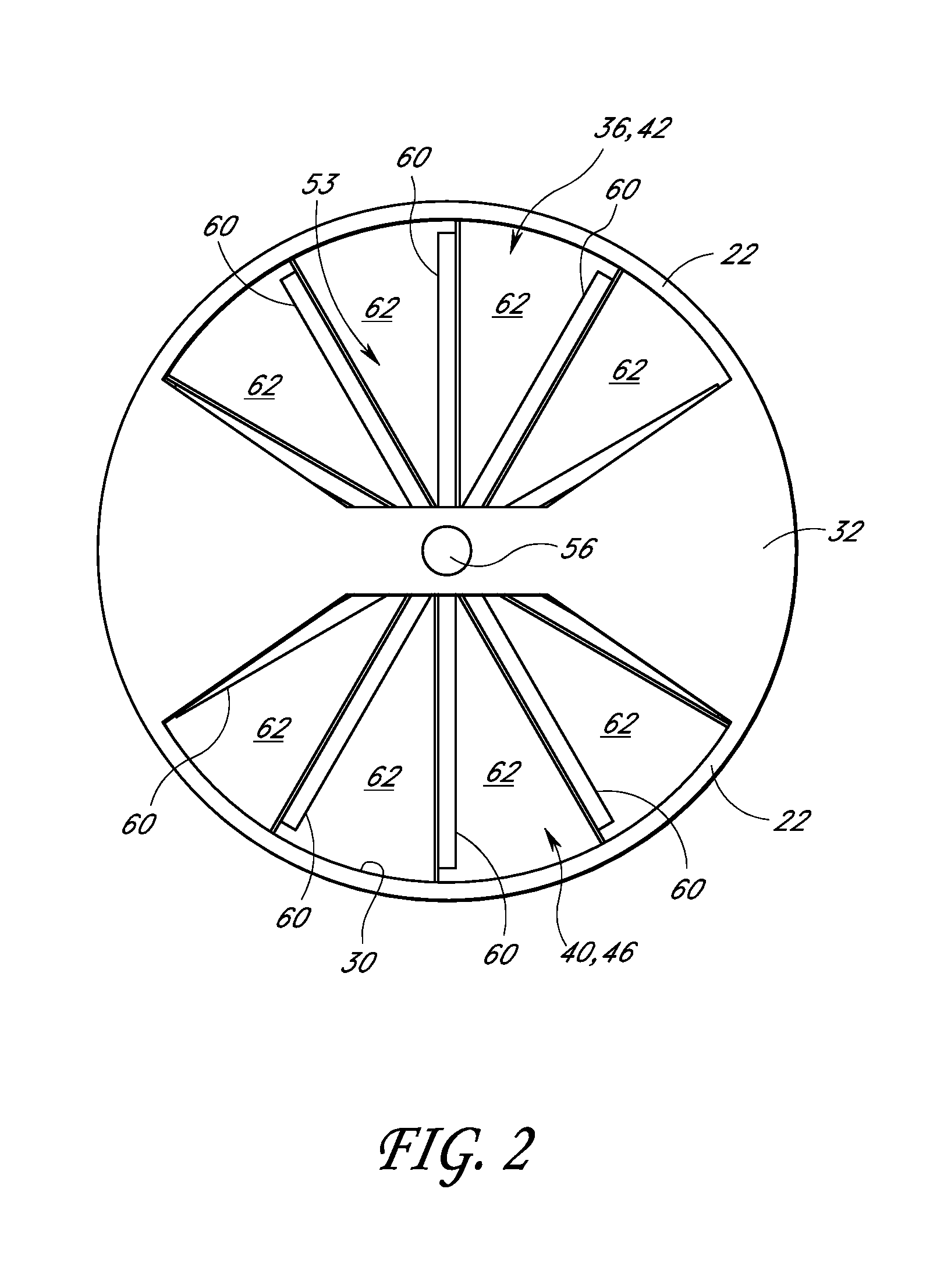

Brush-seal and matrix for regenerative heat exchanger, and method of adjusting same

InactiveUS20090000762A1Avoid mixingCombustion processIndirect carbon-dioxide mitigationEngineeringGuide tube

Disclosed is a regenerative heat exchanger including a brush-seal configuration to prevent mixing of fluid flows. The regenerative heat exchanger includes a regenerator, and at least two conduits, each conduit having a matrix end abutting a face of the regenerator matrix. The at least two conduits carrying at least two fluid flows, the fluid flows which pass through the regenerator matrix. The regenerative heat exchanger includes a plurality of brush-seals, each brush-seal located at a matrix end of each conduit without contacting the matrix, thereby sealing around a periphery of each conduit to prevent mixing of fluid flows. Also disclosed is a method for establishing a minimal gap between a regenerator matrix of a regenerative heat exchanger and a plurality of brush-seals.

Owner:WILSON SOLARPOWER CORP

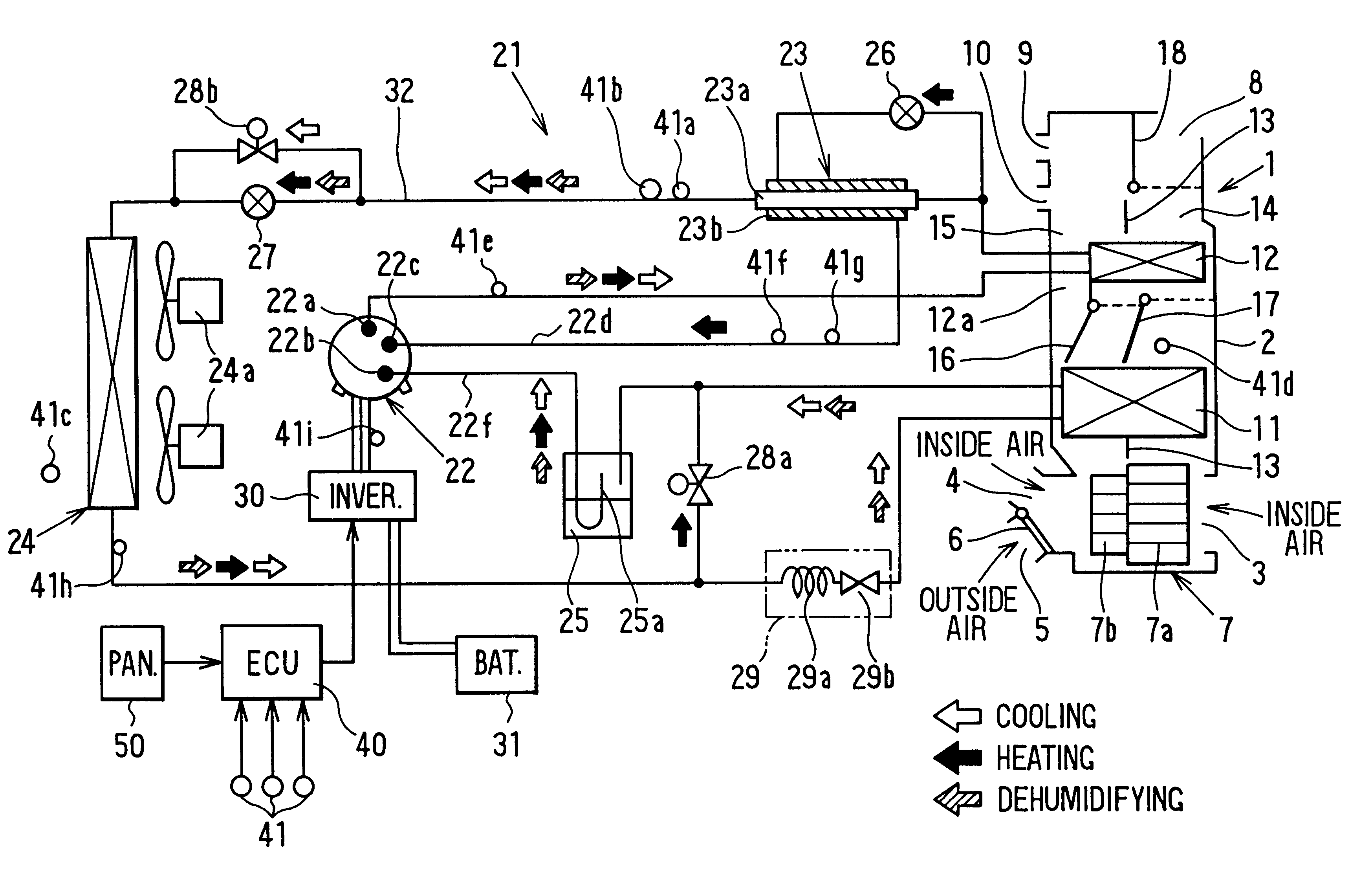

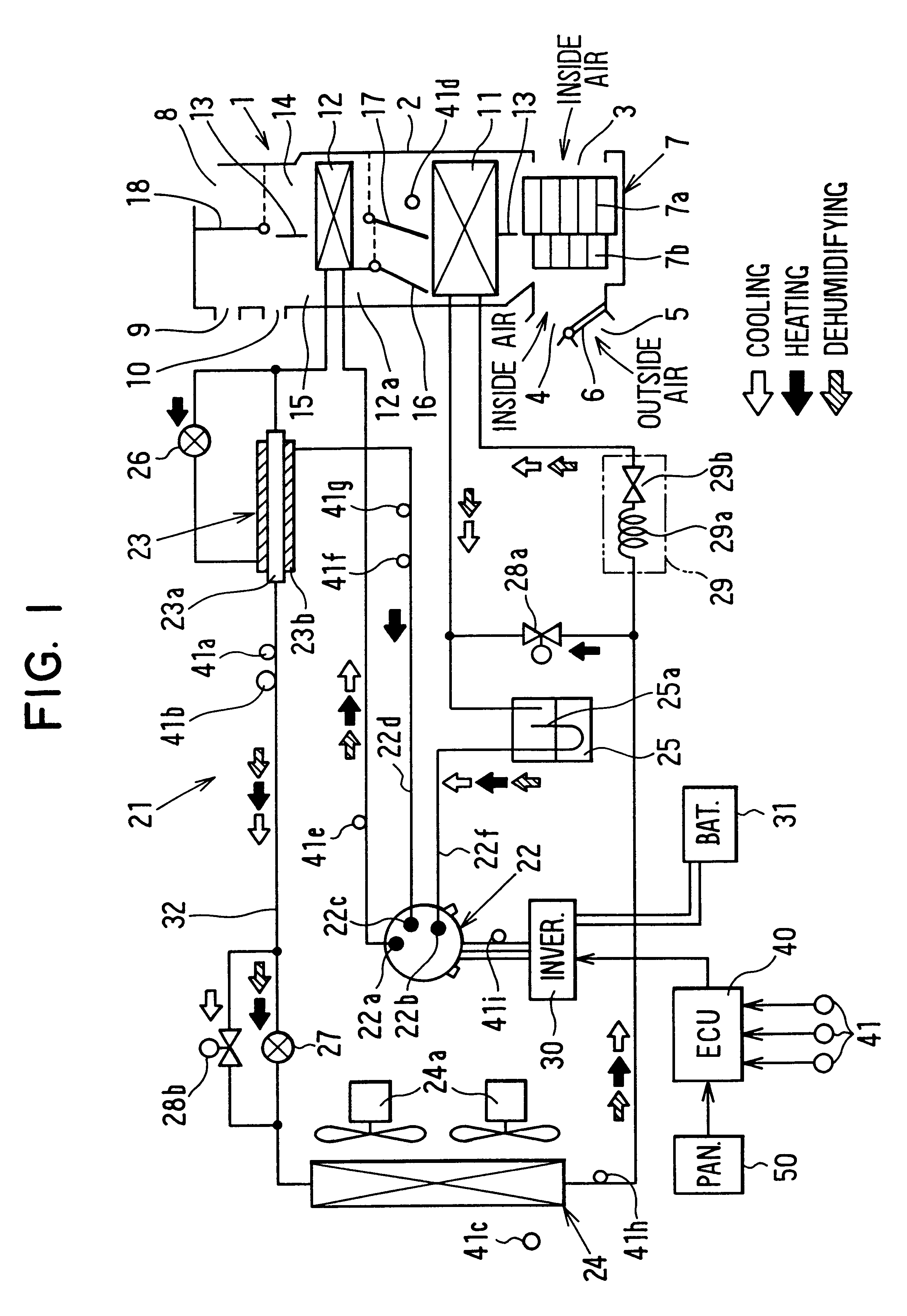

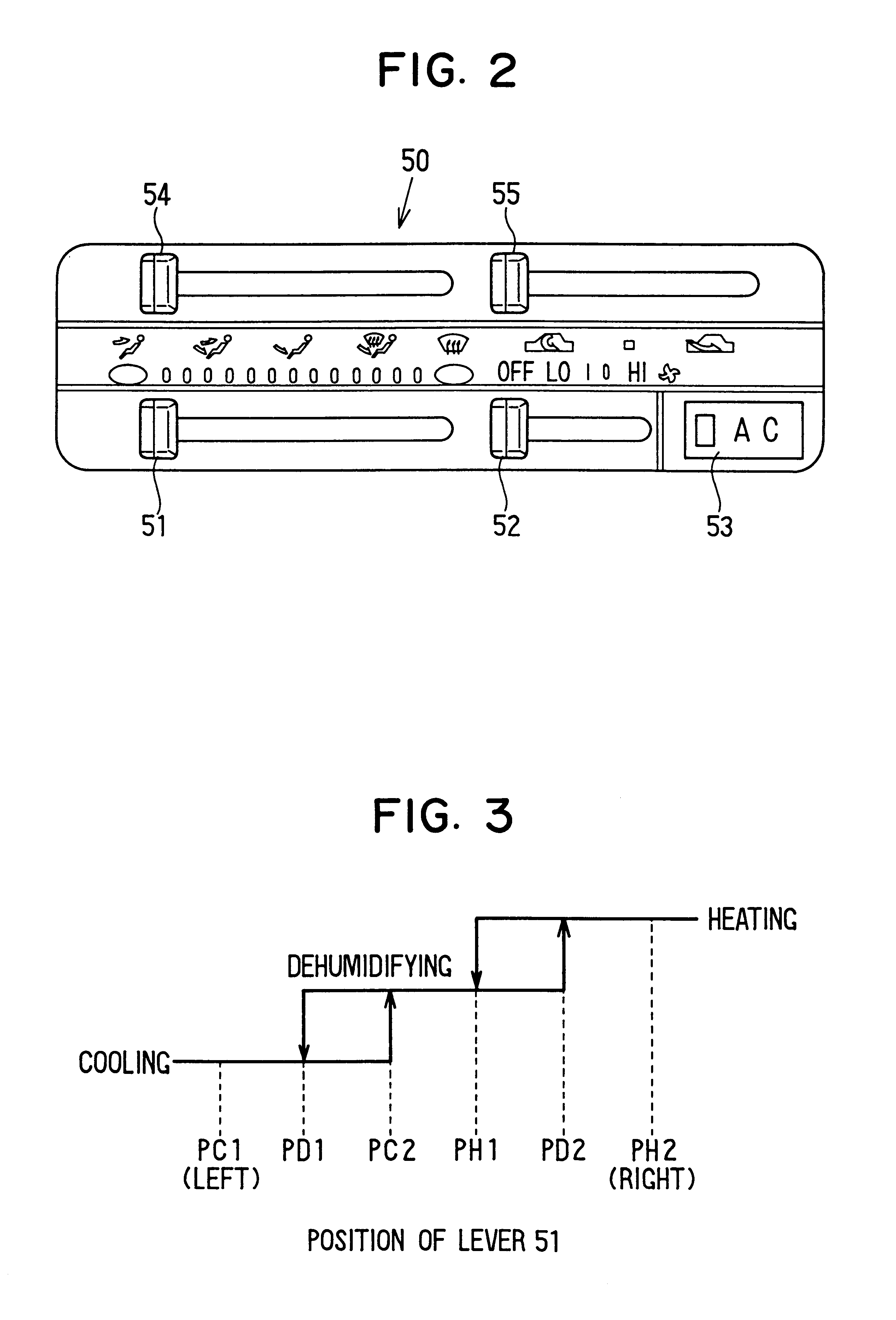

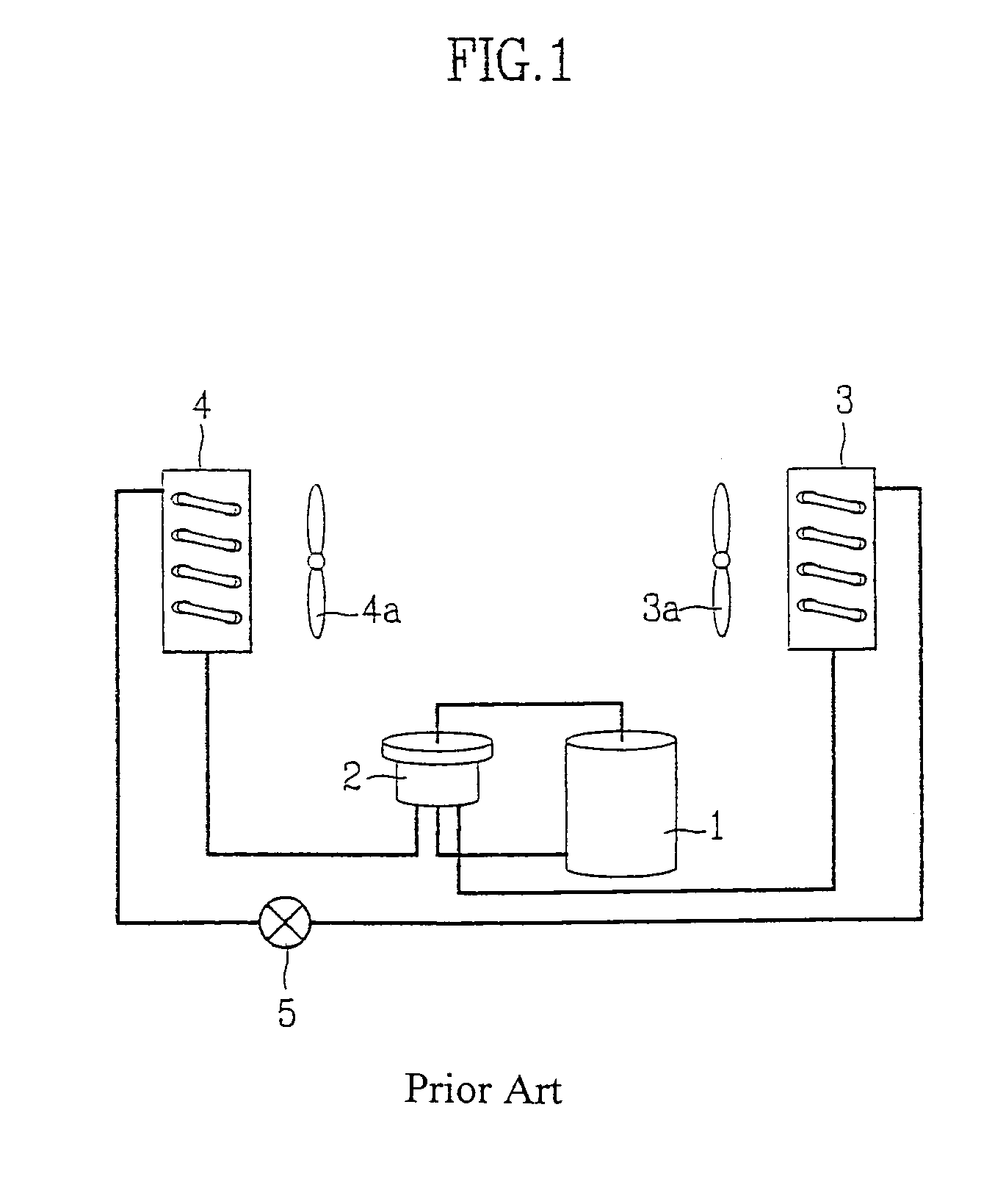

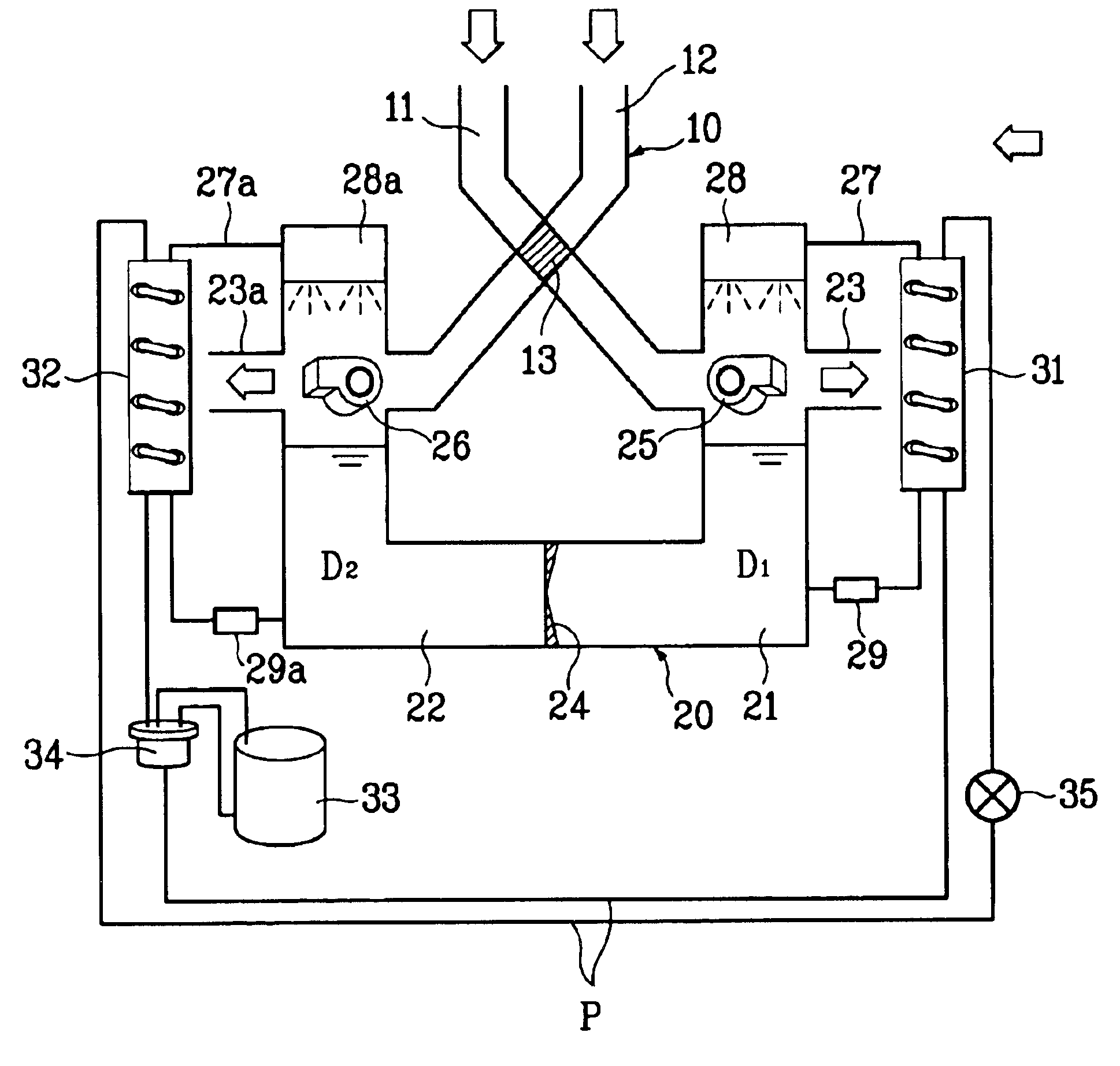

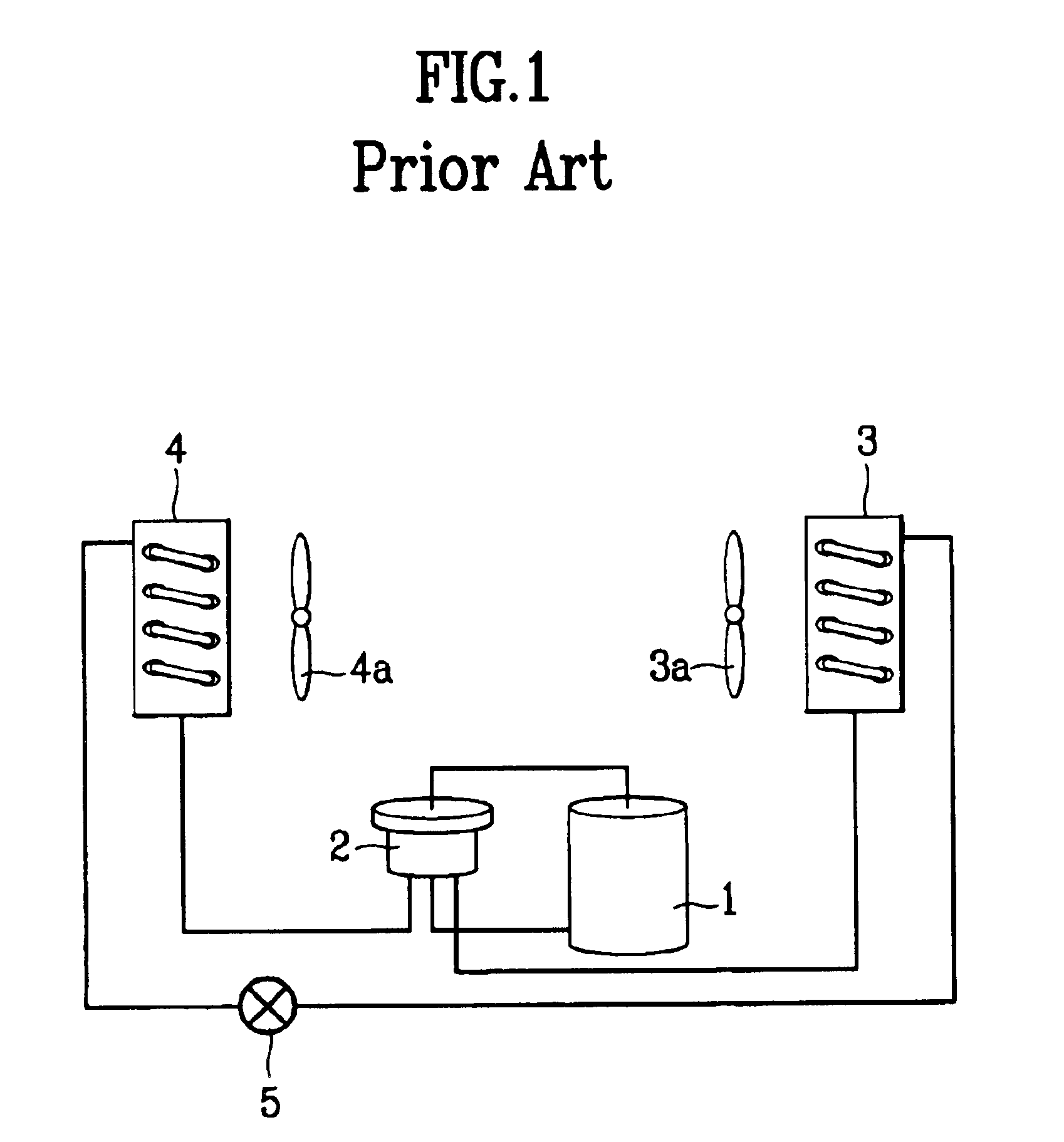

Heat pump type refrigerant cycle system

InactiveUS6237351B1Improve the heating effectAir-treating devicesCompression machines with several evaporatorsInjection portEngineering

When a heating mode is set in a refrigerant cycle system, air is heated in a condenser by condensing high-pressure gas refrigerant, a part of high-pressure refrigerant from the condenser is decompressed in a pressure reducing unit to a middle pressure, and the other part of high-pressure refrigerant from the condenser is heat-exchanged with the middle-pressure refrigerant having passed through the pressure reducing unit in a refrigerant-refrigerant heat exchanger. Therefore, middle-pressure refrigerant having passed through the pressure reducing unit is evaporated in the refrigerant-refrigerant heat exchanger and the evaporated middle-pressure refrigerant is introduced into a gas injection port of a compressor. Thus, in the refrigerant cycle system, heating capacity can be improved due to the gas refrigerant injection into the compressor.

Owner:DENSO CORP

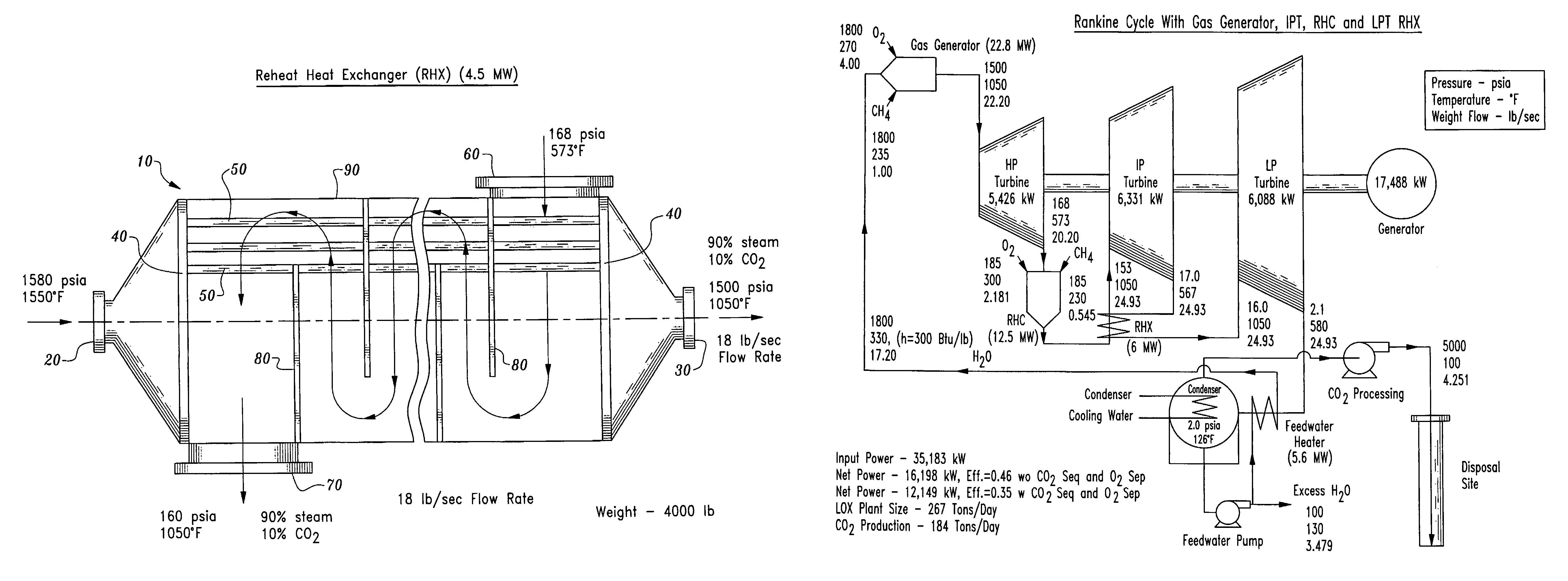

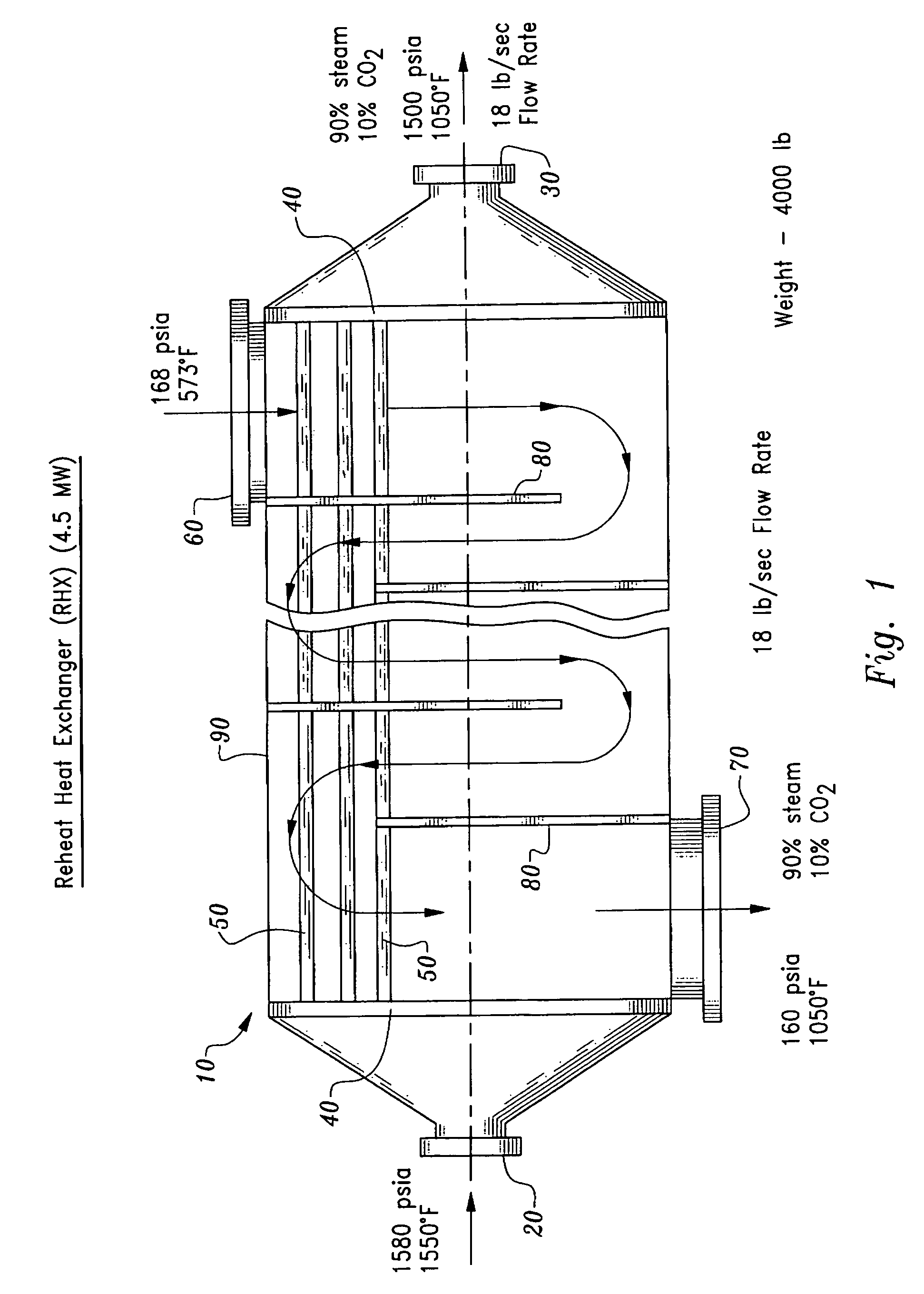

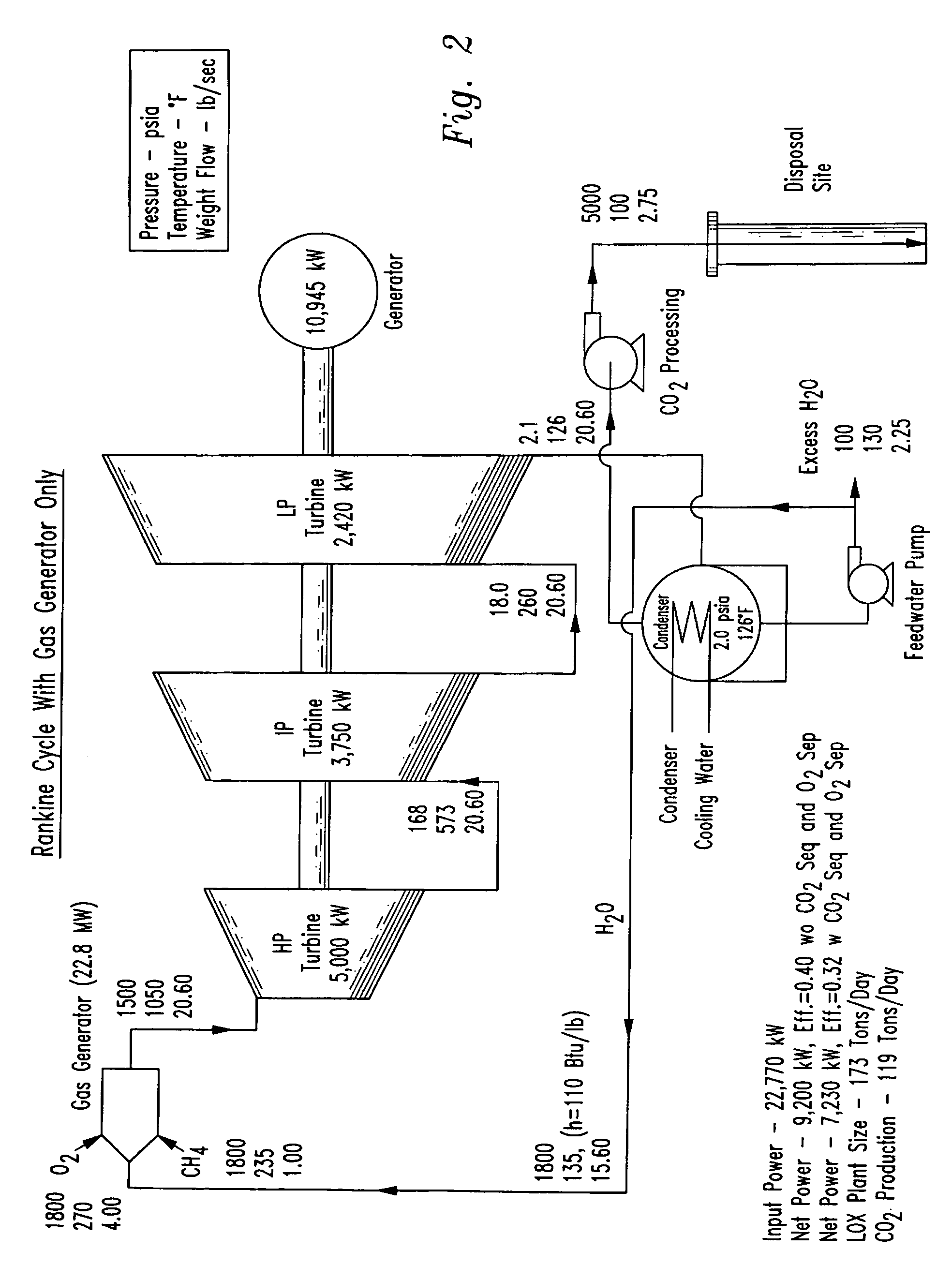

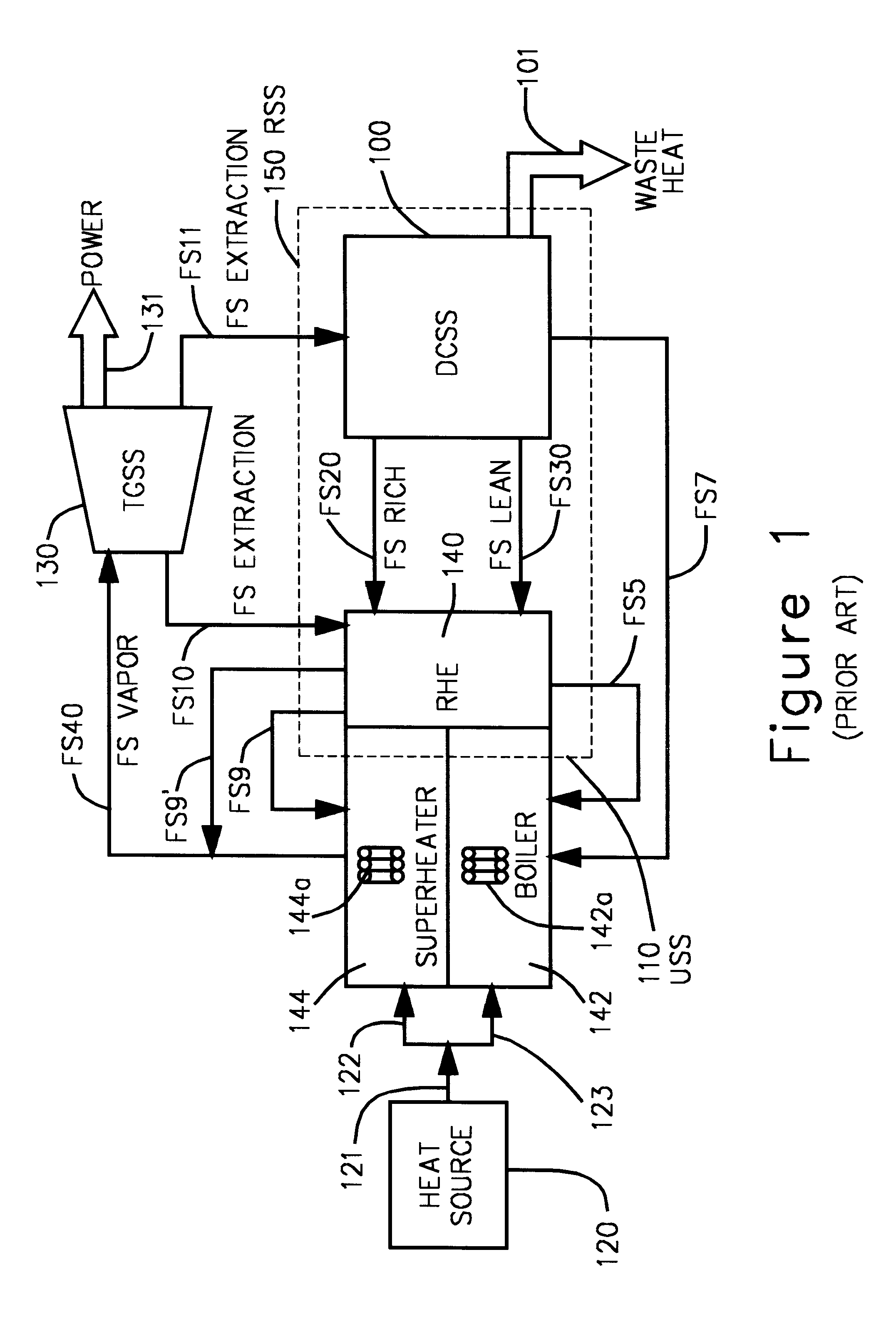

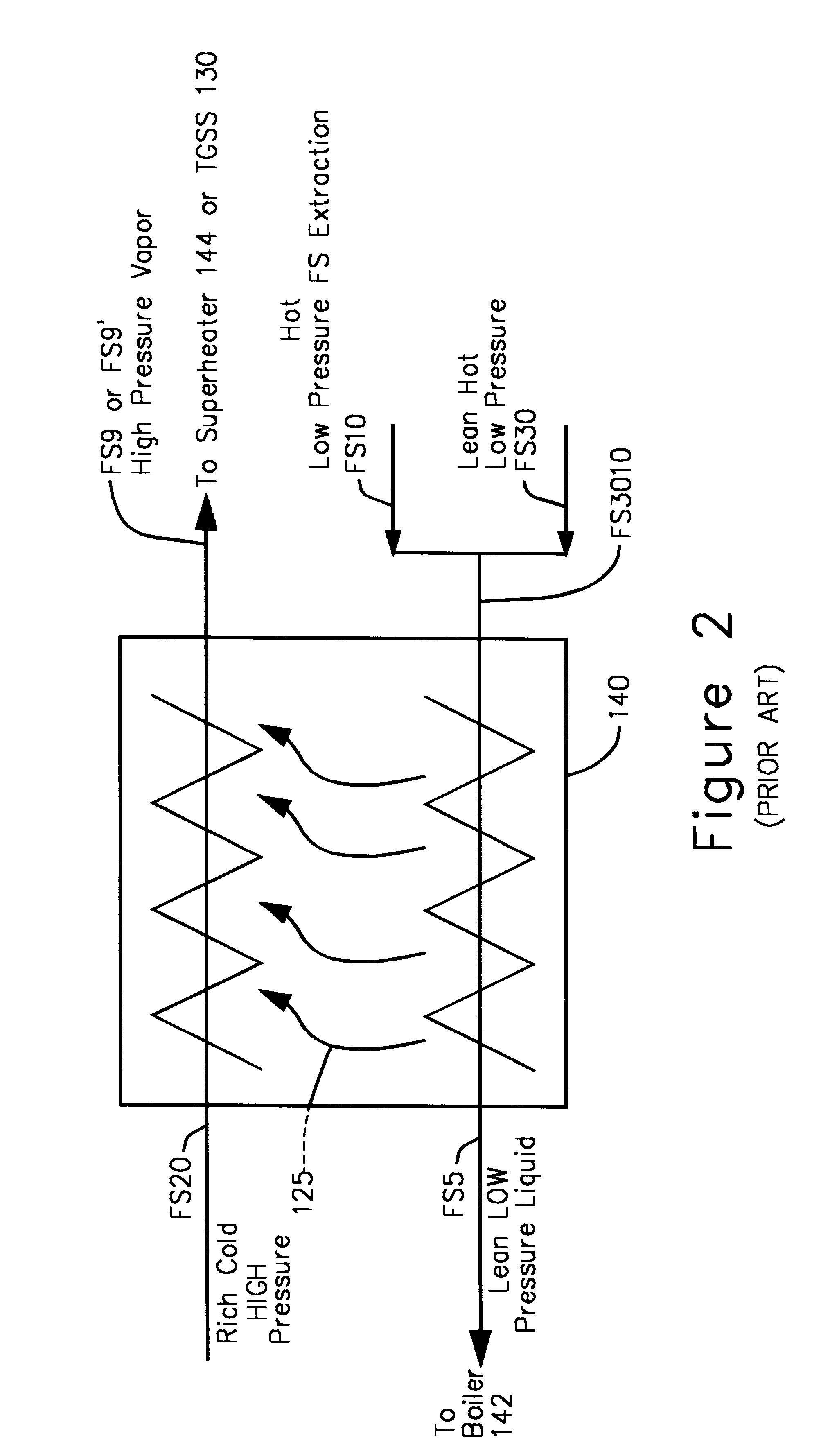

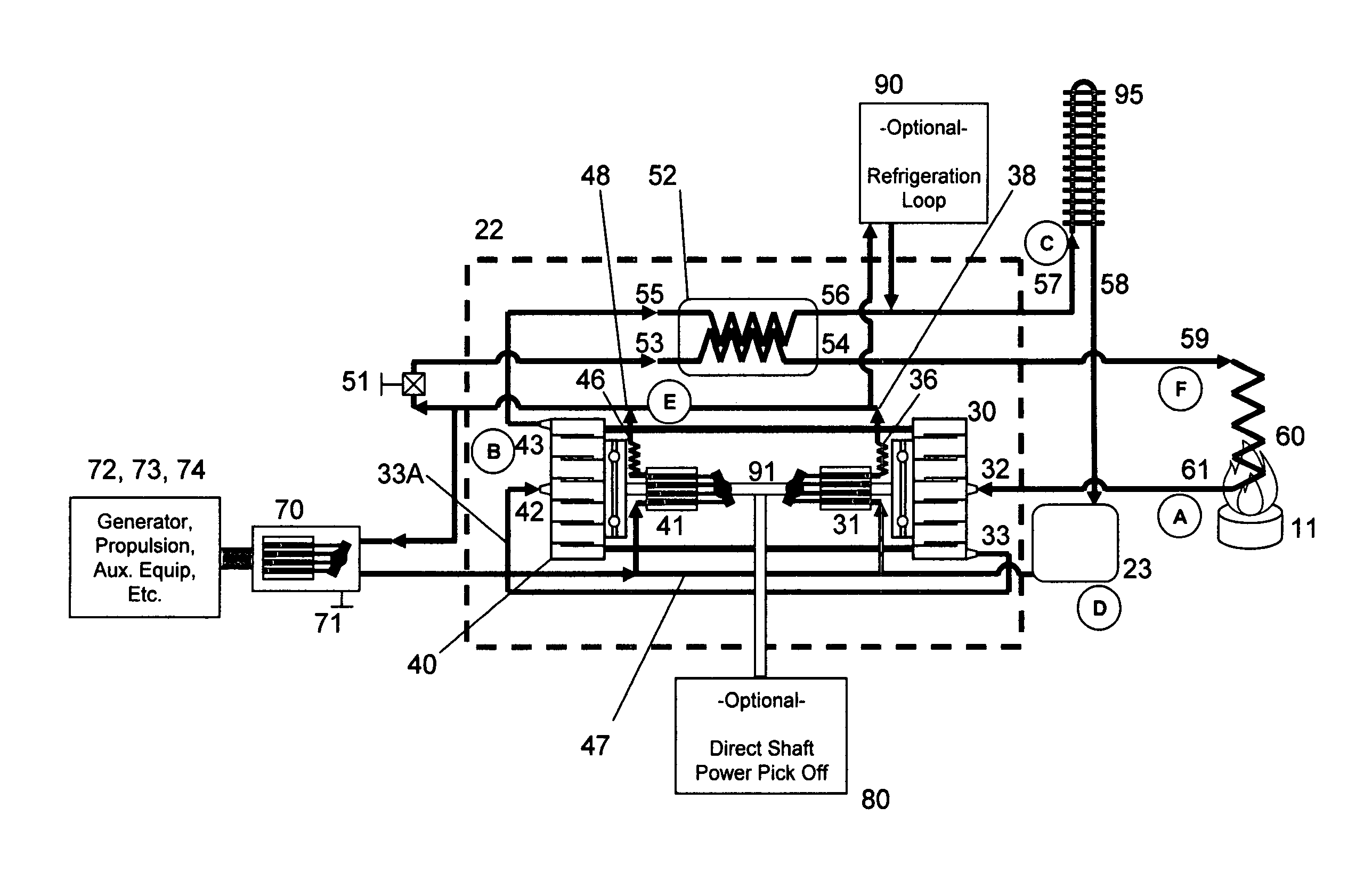

Reheat heat exchanger power generation systems

InactiveUS7021063B2High thermal efficiencyLow costGas turbine plantsDirect carbon-dioxide mitigationWorking fluidPlate heat exchanger

A reheat heat exchanger is provided particularly for use in Rankine cycle power generation systems. The reheat heat exchanger includes a high pressure path between a high pressure inlet and a high pressure outlet. The reheat heat exchanger also includes a low pressure path between a low pressure inlet and a low pressure outlet. The two paths are in heat transfer relationship. In a typical power generation system utilizing the reheat heat exchanger, the high pressure inlet is located downstream from a source of high temperature high pressure working fluid. An expander is located downstream from the high pressure outlet and upstream from the low pressure inlet. A second expander is typically provided downstream from the low pressure outlet. The reheat heat exchanger beneficially enhances the efficiency of power generation systems, particularly those which utilize expanders having inlet temperatures limited to below that produced by the source of working fluid.

Owner:CLEAN ENERGY SYST

Heat exchanger containing a component capable of discontinuous movement

InactiveUSRE37134E1Reduced Seal LeakageReduce leak rateCombustion processRegenerative heat exchangersEngineeringMicro heat exchanger

Owner:MASSACHUSETTS INST OF TECH

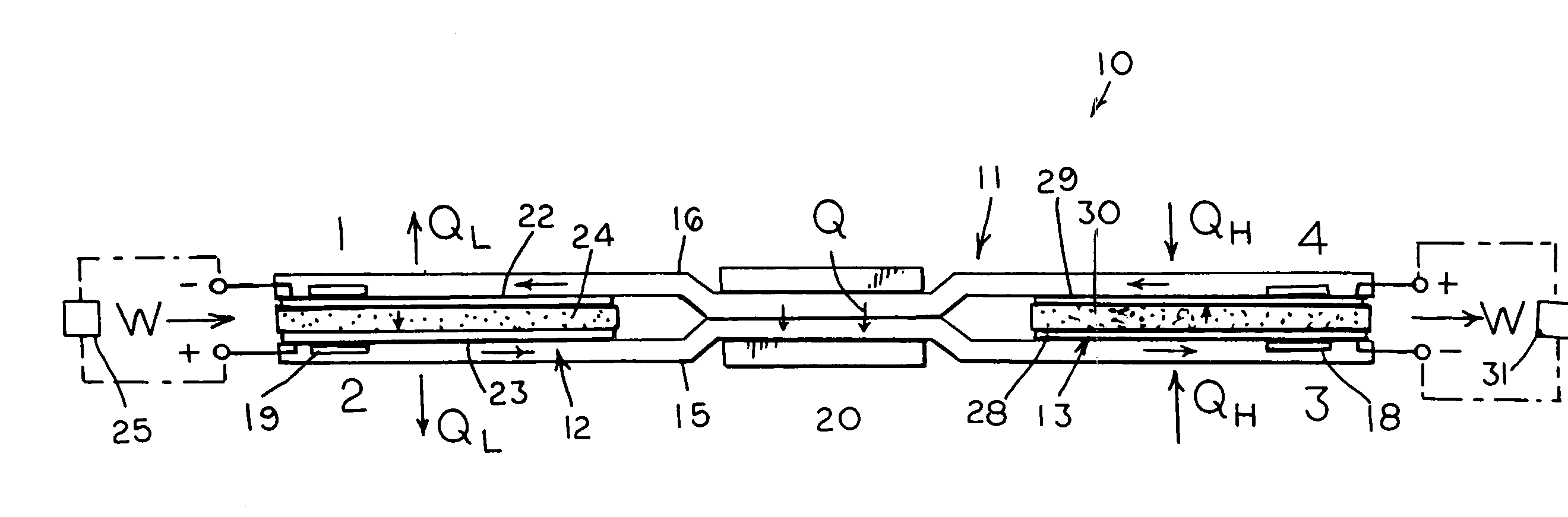

Johnson reversible engine

InactiveUS7160639B2Increase pressureReduce pressureHeat pumpsFuel cell heat exchangeEngineeringElectrochemical cell

An reversible engine (10) is disclosed having a conduit system (11), a first electrochemical cells (12), and a second electrochemical cell (13). The conduit system (11) includes a first conduit (15) extending from the first electrochemical cell (12) to the second electrochemical cell (13), and a second conduit (16) extending from the second electrochemical cell (13) to the first electrochemical cell (12). The heat engine (10) also includes a heater (18) mounted in thermal communication with the conduit system (11) adjacent the second electrochemical cell (13), a cooler (19) mounted in thermal communication with the conduit system (11) adjacent the first electrochemical cell (12), and a regenerative heat exchanger (20) thermally coupled to the first and second conduits (15) and (16) for the transfer of heat therebetween.

Owner:JTEC ENERGY INC

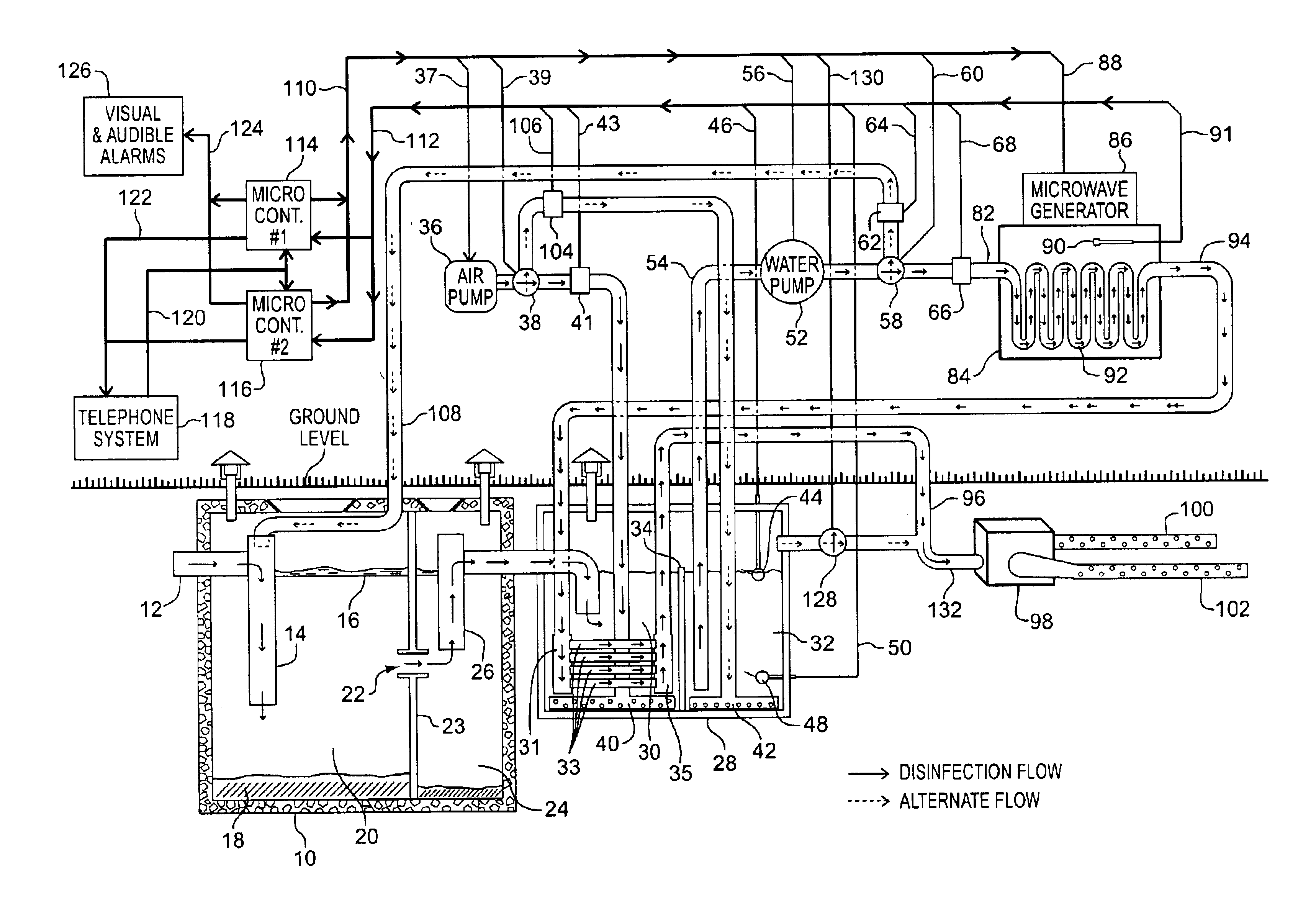

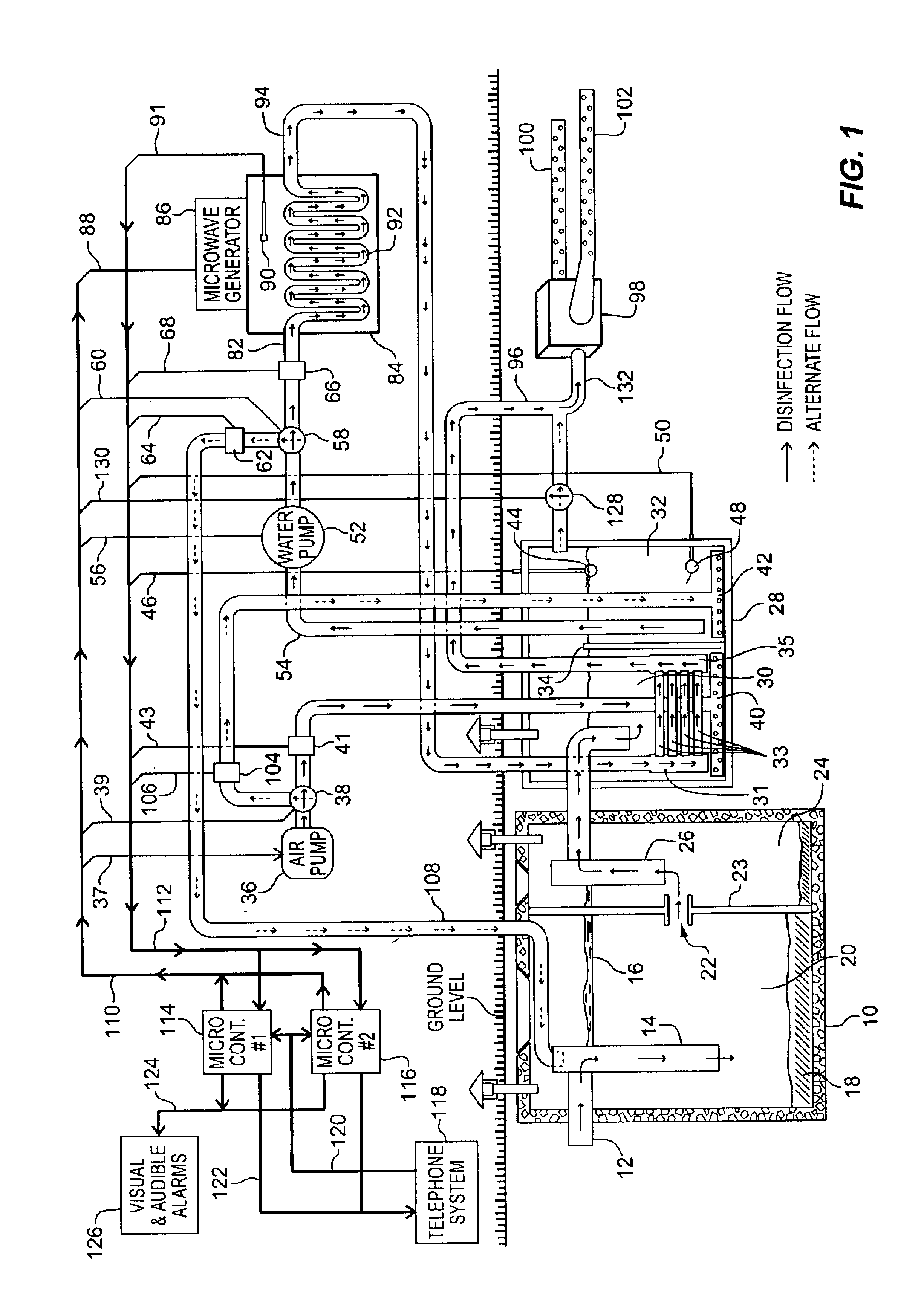

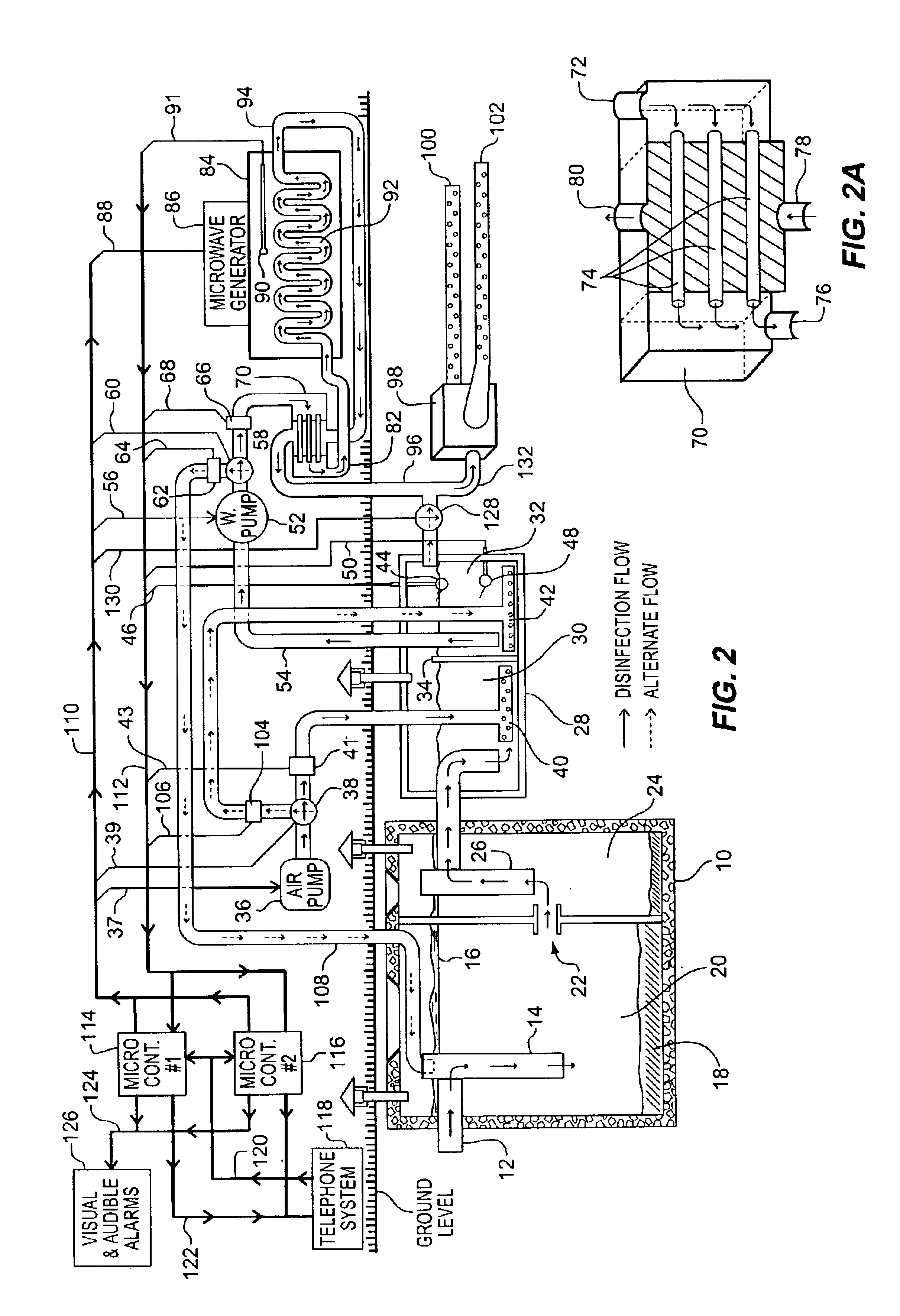

Automated, self-contained, home sewage treatment system

InactiveUS6863805B1Avoiding overflow conditionRaise the water levelGeneral water supply conservationLiquid displacementElectrical batterySolar cell

A small and cost effective sewage treatment system intended for unattended use in individual homes, small industries or businesses in locations where a central sewage treatment plant is not available. The sewage treatment system comprises a conventional septic tank which drains into a smaller aerated holding tank, a pump to transfer effluent from the holding tank into a disinfecting chamber, a regenerative heat exchanger used to raise the temperature of the effluent while being aerated in the holding tank, means for pumping the effluent at a controlled rate through a microwave field, and a conventional drain field used to release the disinfected water into the surrounding soil. Operation of this system is fully regulated by a micro-controller, thereby eliminating the need for human intervention during normal use. This invention also incorporates electronic means for detecting various fault conditions which may impede effective disinfection, means for diagnosing what part of the system is at fault, means for reporting the fault and diagnose to a central municipal location via a telephone or transponder system, an emergency battery backup system, and means for reverting system operation to that of a conventional septic tank and drain field system is case of a total power failure (both A / C and DIC) or water pump failure. Conventional household alternating current or a battery recharged via a wind generator or solar cells may power the sewage treatment system.

Owner:BARRERAS SR FRANCISCO J +1

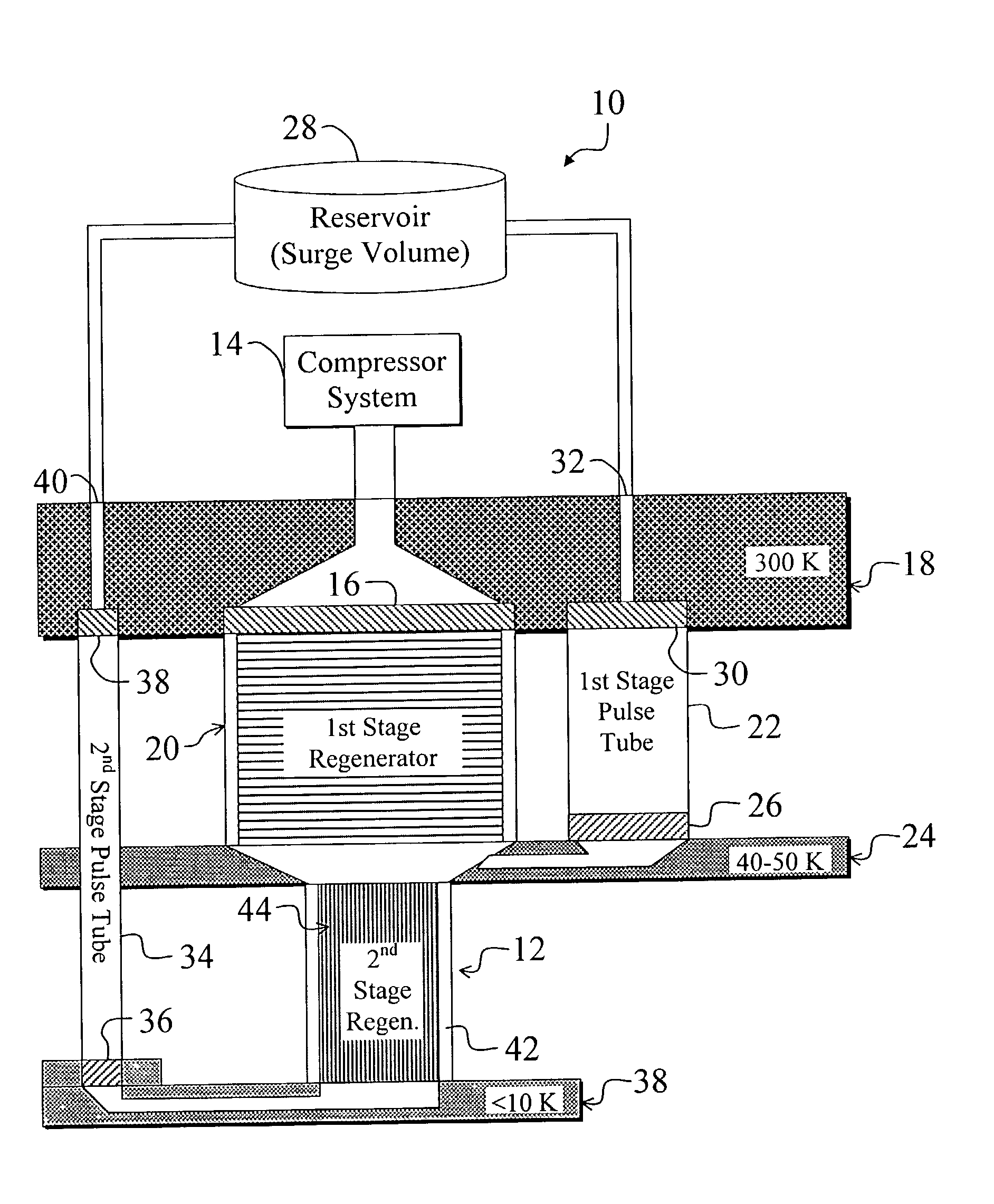

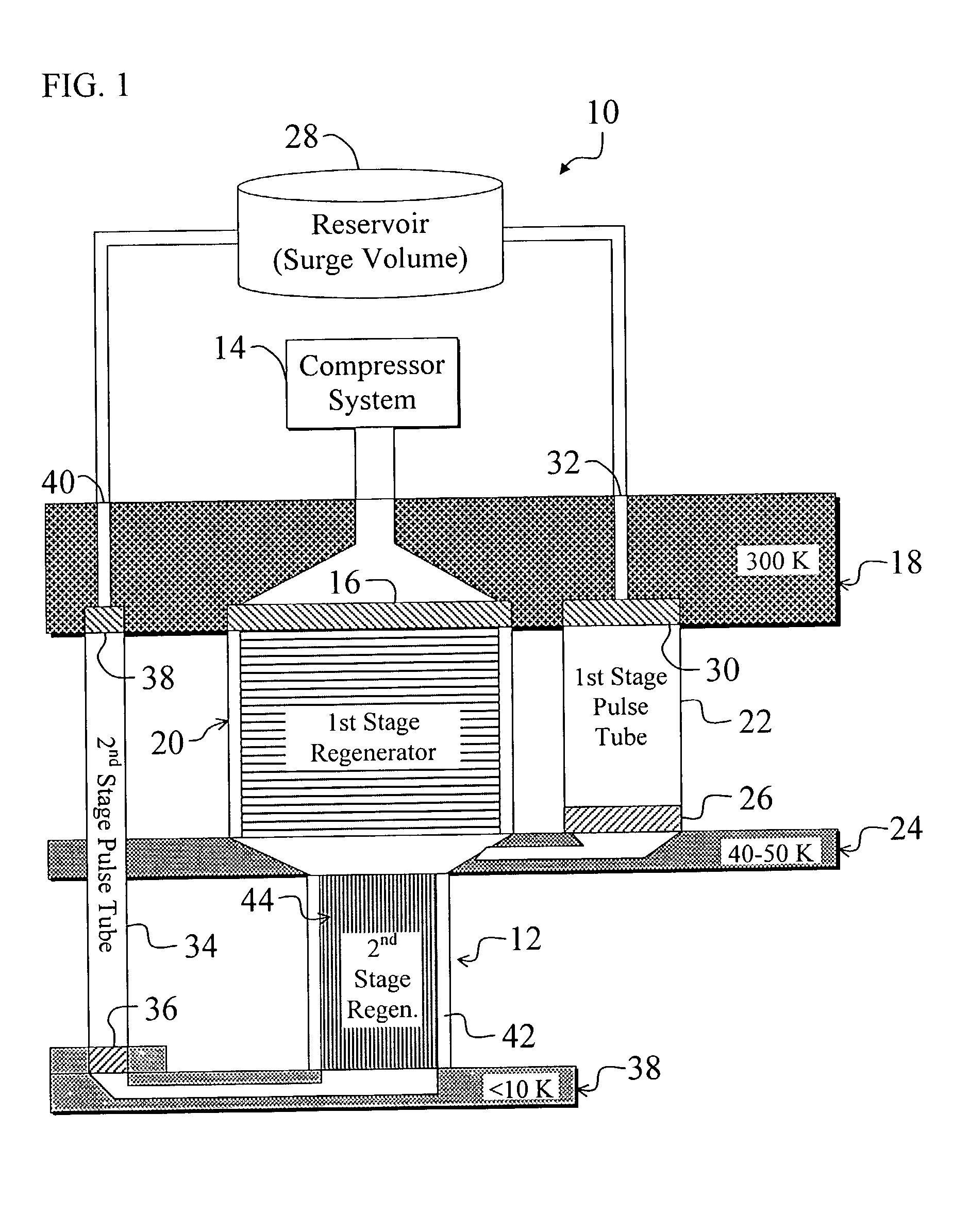

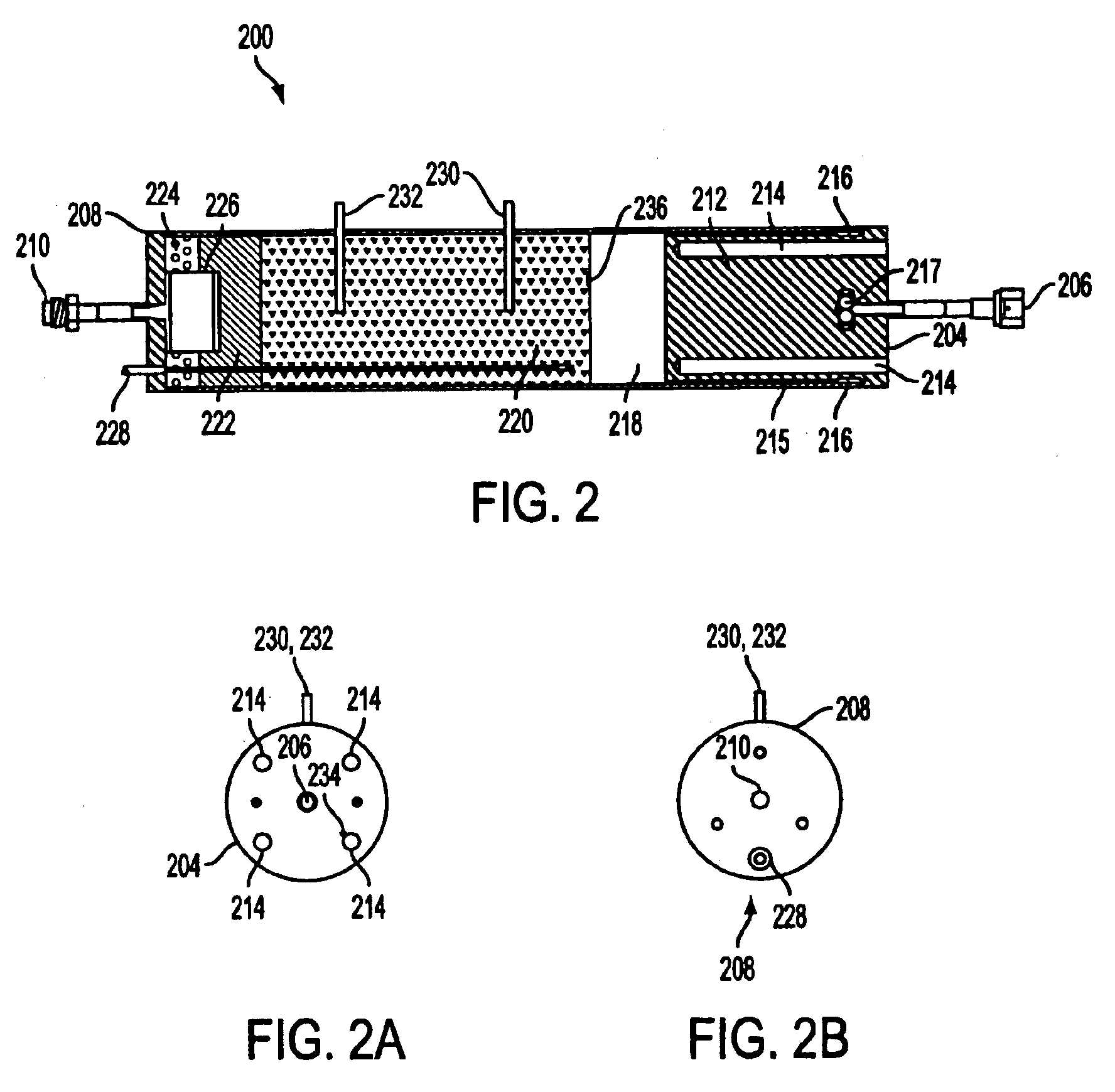

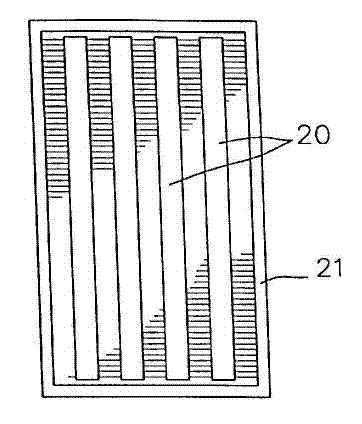

High-frequency, low-temperature regenerative heat exchanger

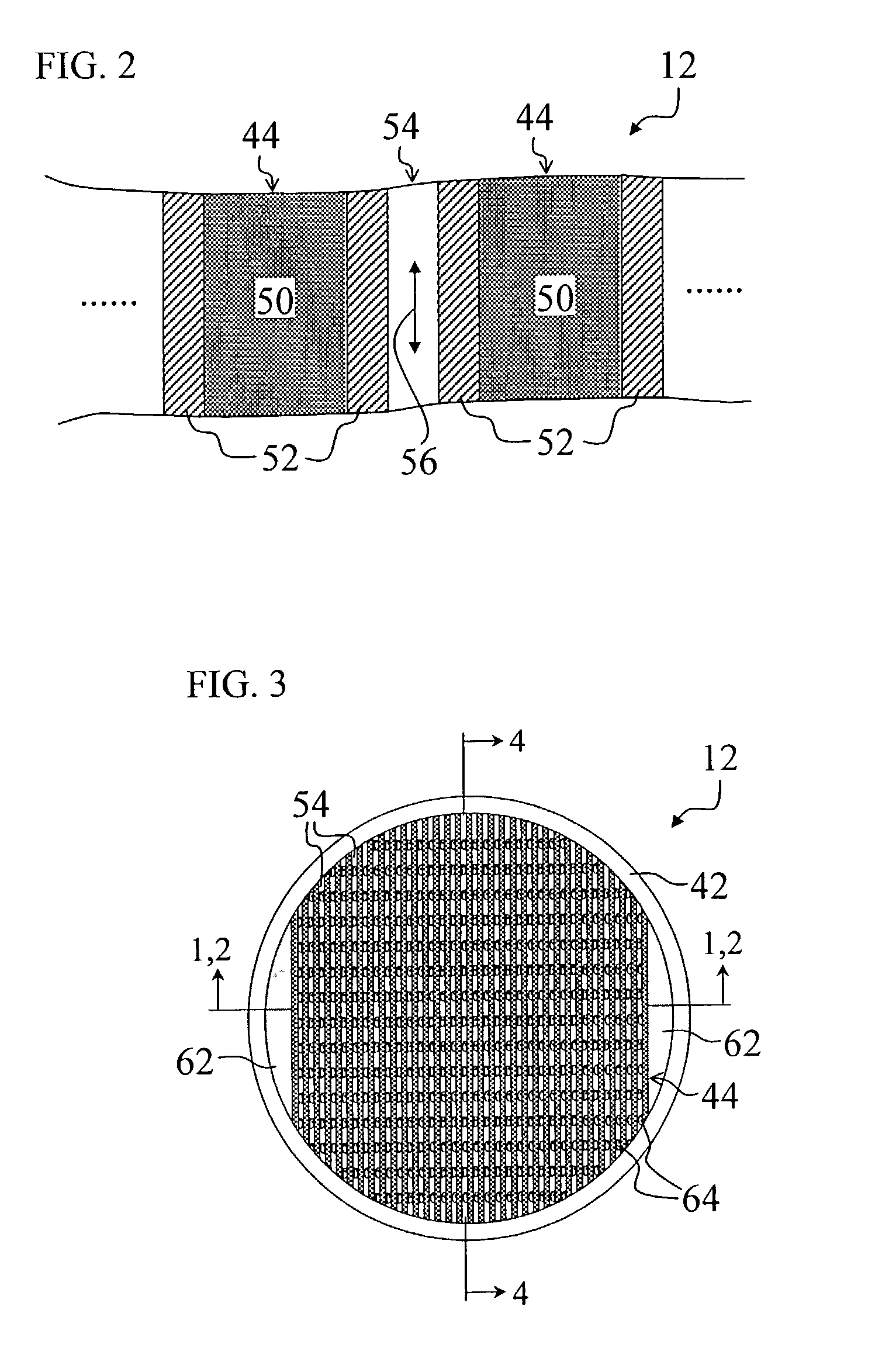

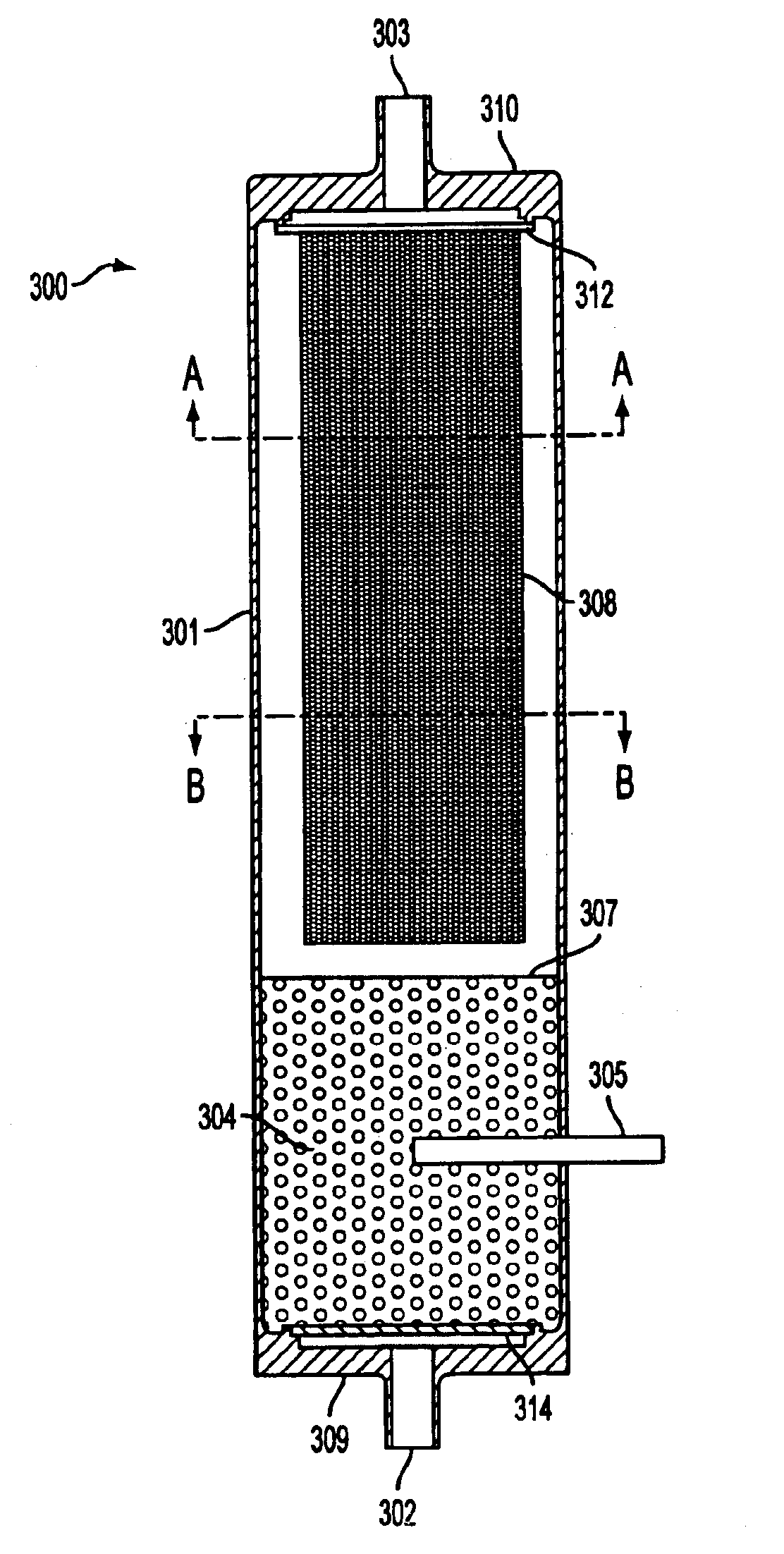

A high-frequency, low-temperature regenerator (12). The regenerator (12) includes a substrate (50) having rare earth material (52) disposed thereon. In a specific embodiment, the substrate (50) has channels or pores (54) therethrough or therein to facilitate gas flow through the regenerator (12). The substrate (50) is constructed from a material, such as polyimide, polyester, or stainless steel, which is sufficient to define the geometry of the regenerator (12). The rare earth material (52) is selected and deposited on the substrate (50) in a layer (52) having thermal penetration depth that is greater than the thickness of the layer (52). The thermal penetration depth is sufficiently high to enable all of the rare earth material (52) to contribute to thermal regeneration at an operating frequency of 30 Hz. In the illustrative embodiment, the thickness of the substrate (50) is less than or equal to approximately 0.001 inches. The layer of rare earth material (52) is approximately 0.0002 inches thick. The substrate (44, 50) includes a stack of plated substrates (44) that are stacked so that spaces (54) exist between the plated substrates (44), which result in a porosity of approximately 15 percent. Dimples, pleats, or other mechanisms in the plated substrates (44) preserve the spaces (54) between the plated substrates (44). In the specific embodiment, the spaces (54) are approximately 0.00025 inches wide, and the working gas is helium.

Owner:RAYTHEON CO

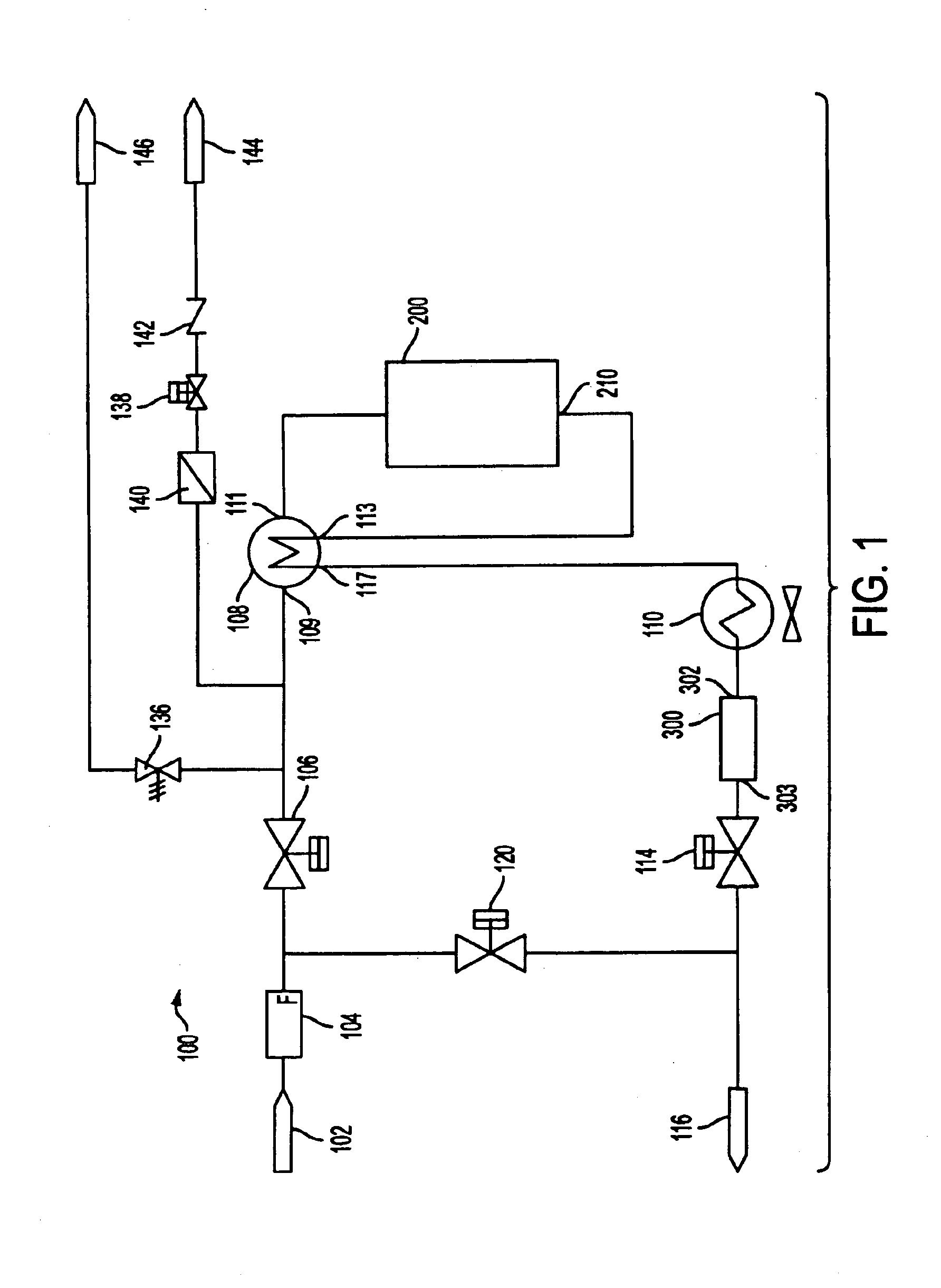

Gas purification system with an integrated hydrogen sorption and filter assembly

InactiveUS6890376B2Easy maintenanceManufacturing EaseCombination devicesNitrogen purification/separationThermal energyHydrogen

The present invention provides a gas purification system with improved efficiency, simpler construction, cost reductions, form factor improvements, and increased durability. The present invention provides cost and form factor improvements through fewer components overall and through utilizing multiple integrated components. Prior art gas purification systems are more bulky and complicated. The present invention achieves increased thermal efficiency through utilization of a regenerative heat exchanger to recapture a portion of the heat energy transferred to the gas during the purification process. Prior art purifiers lacked a regenerative heat exchanger. The present invention integrates the two components into one integrated heater and purification vessel assembly. The present invention integrates the two discrete components into one integrated hydrogen sorption and particle filter assembly. The integrated hydrogen sorption and particle filter assembly is also capable of operating at higher temperatures. This eases maintenance and manufacture. The resulting gas purification system is simpler through utilizing fewer components, smaller by utilizing fewer and integrated components, and reduced cost through fewer components, smaller components and through reduced manufacture labor requirements.

Owner:ENTEGRIS GP INC

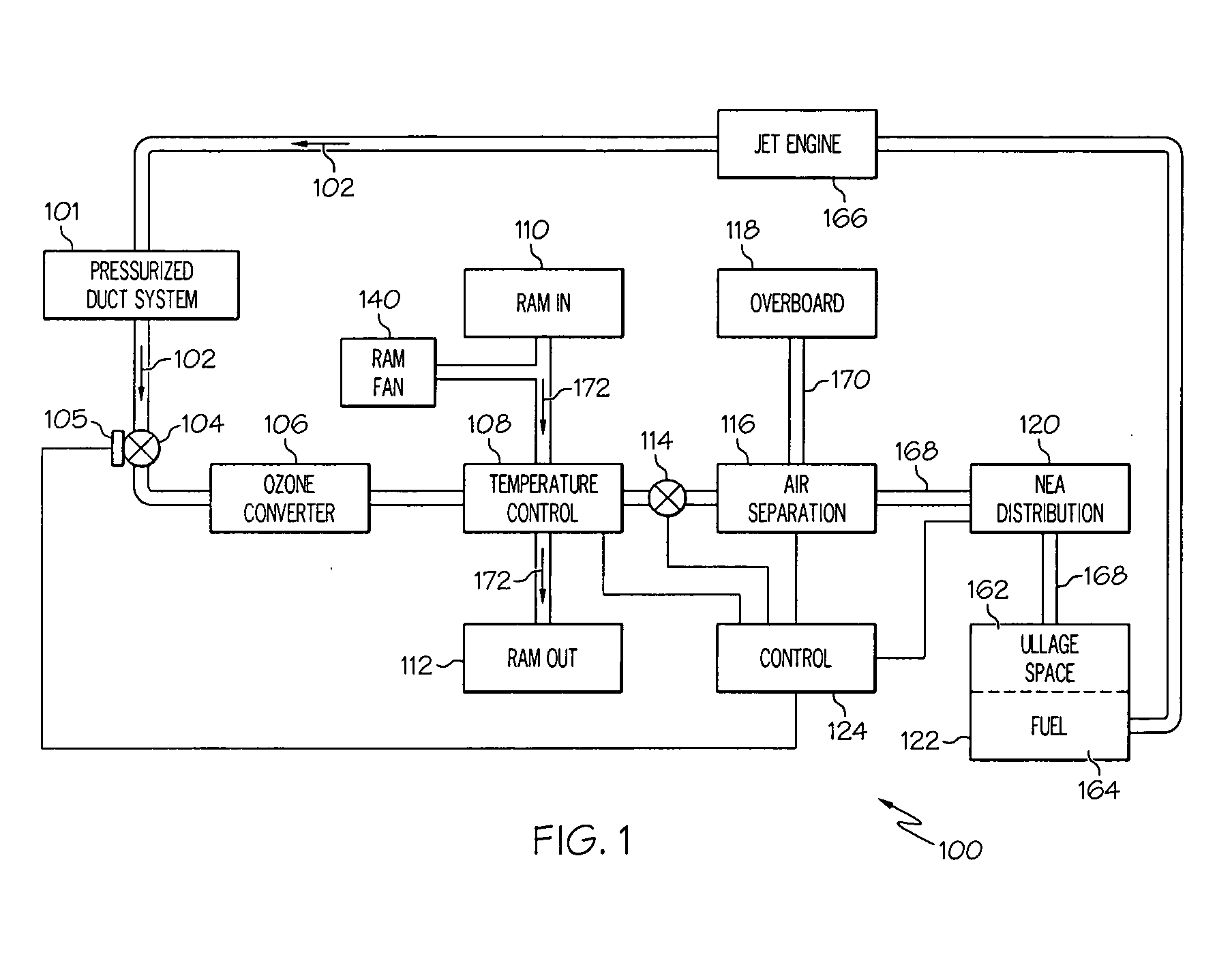

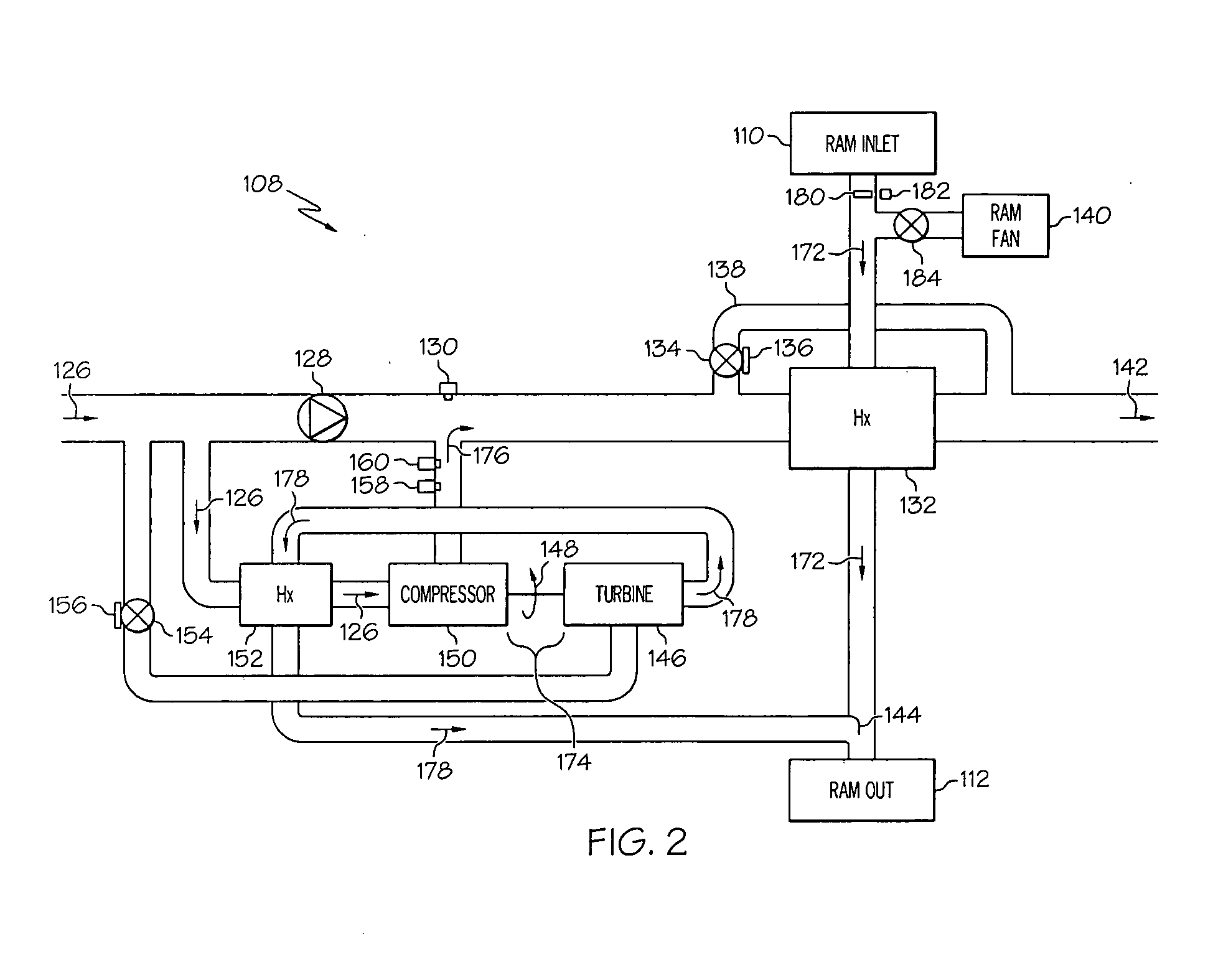

On-board inert gas generation turbocompressor systems and methods

The present invention provides a system and method for cooling the bleed air supply in an on-board inert gas generation system. The gas generation system cools the bleed air using a turbocompressor in conjunction with heat exchangers. Exhaust from a regenerative heat exchanger providing air to the turbocompressor is ported to a ram air outlet using a flow-restriction / ejector unit.

Owner:HONEYWELL INT INC

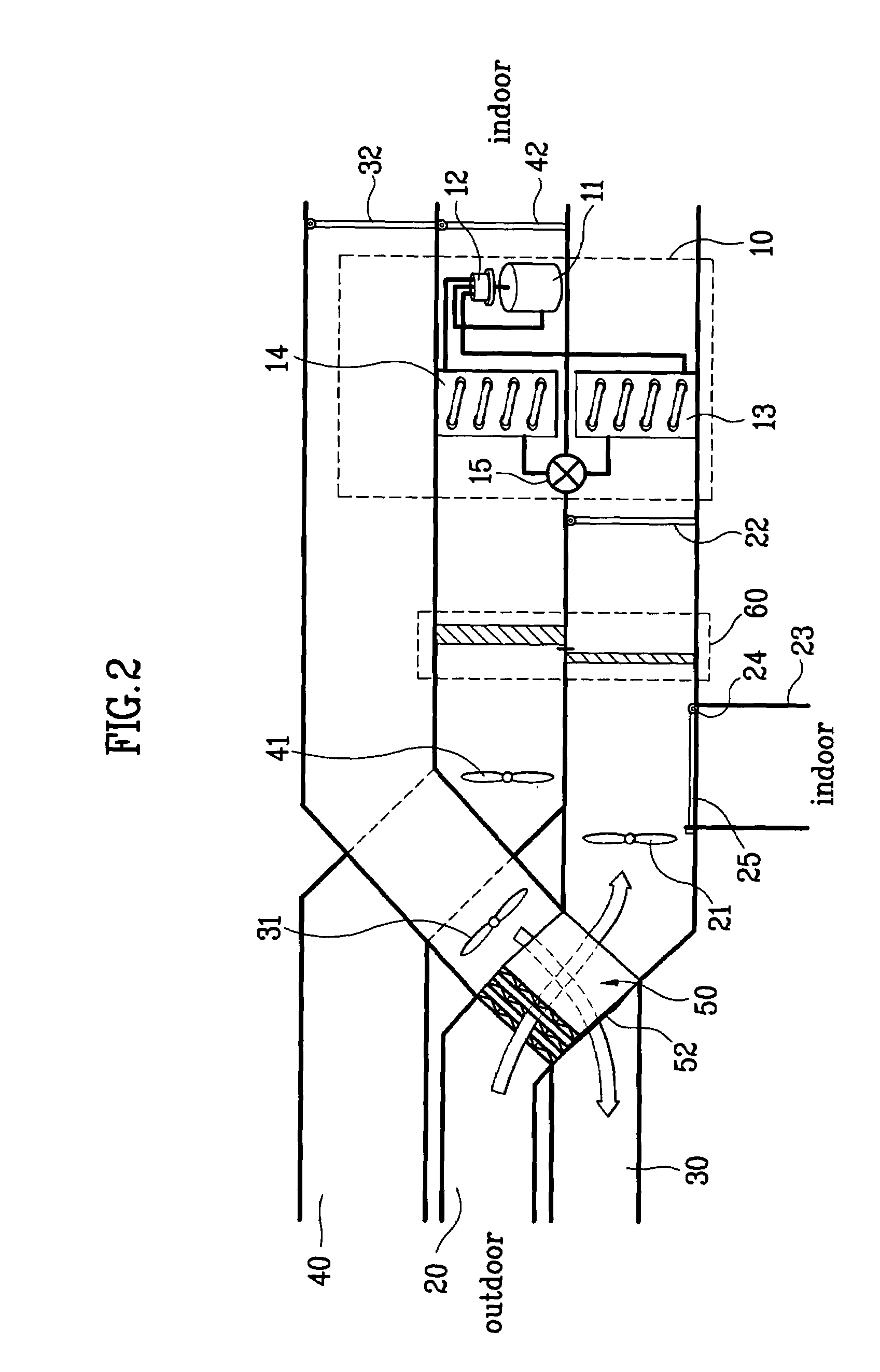

Combined ventilating and air conditioning system

InactiveUS7007495B2Reduce heat lossImprove efficiencyMechanical apparatusHeat pumpsEngineeringAir conditioning

Disclosed is a combined ventilating and air conditioning system, comprising: a first air duct for guiding outdoor air to the indoor spaces, the first air duct being capable of opening and closing; a second air duct for guiding indoor air to outdoors, wherein the second air duct is capable of opening and closing and installed in such a manner that part of the second air duct intersects with the first air duct; a third air duct for guiding the indoor air to the outdoors, the third air duct being capable of opening and closing; a regenerative heat exchanger, being provided in an intersection between the first and second air ducts, for exchanging heat between the indoor air and the outdoor air passing through the intersection; and blowing fans for controlling airflows, being provided in the first air duct, in the second air duct, and in the third air duct, respectively. The compressor mounted on the air conditioner is provided in the third air duct. The second heat exchanger is provided nearby the third air duct through which the indoor air is intaken, and the first heat exchanger is provided nearby the first air duct through which the outdoor air is emitted from the first air duct to the indoor spaces.

Owner:LG ELECTRONICS INC

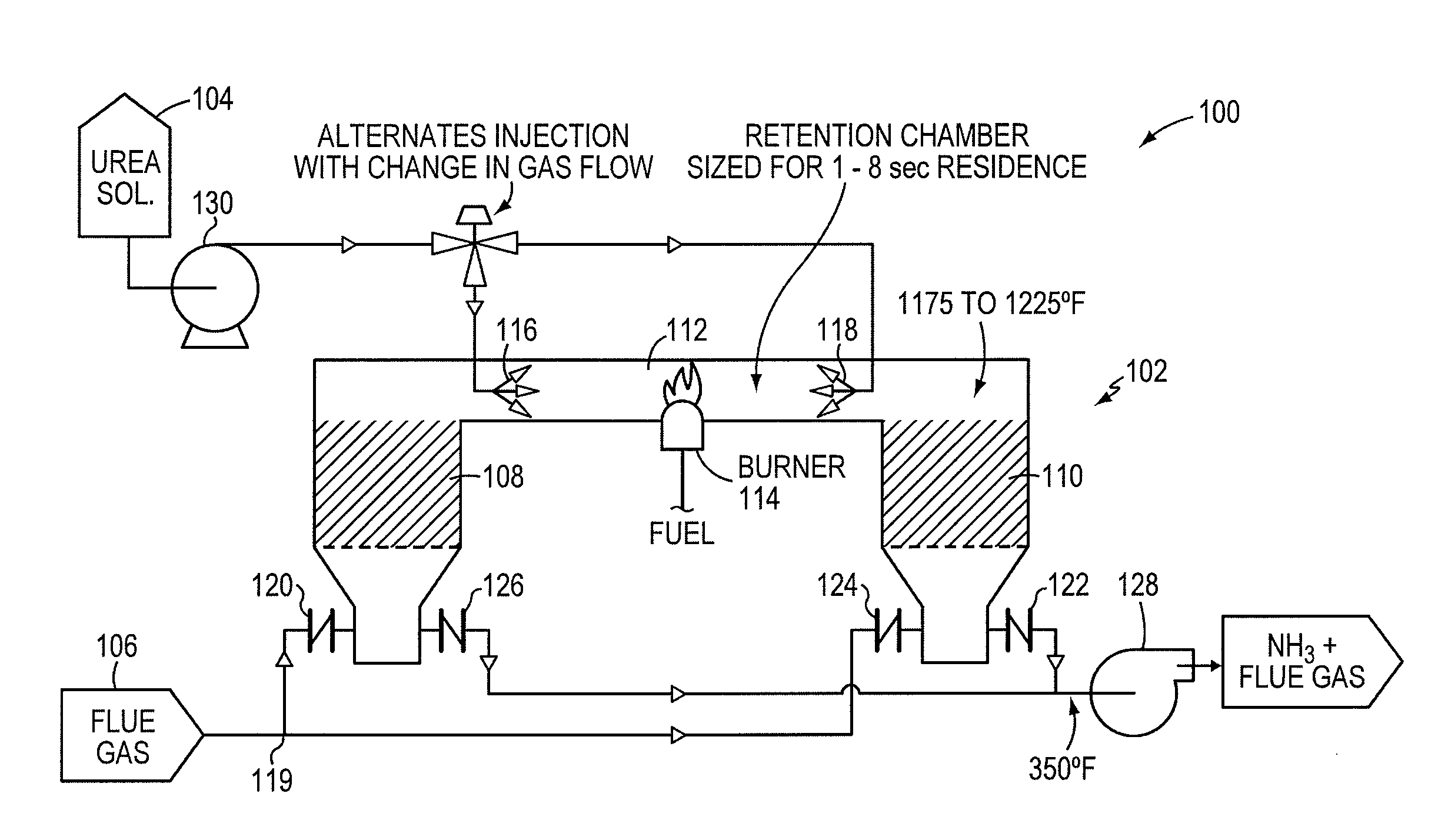

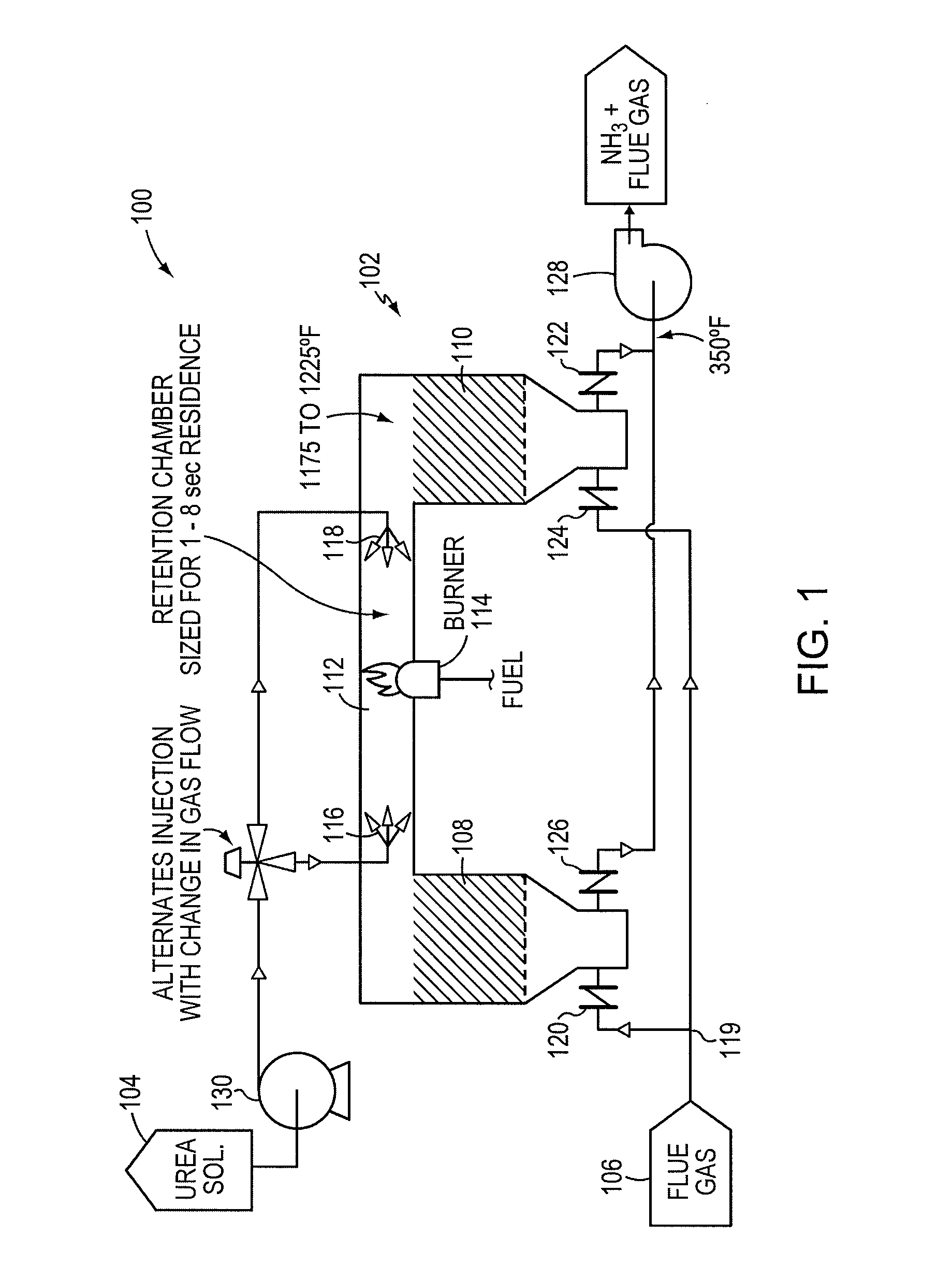

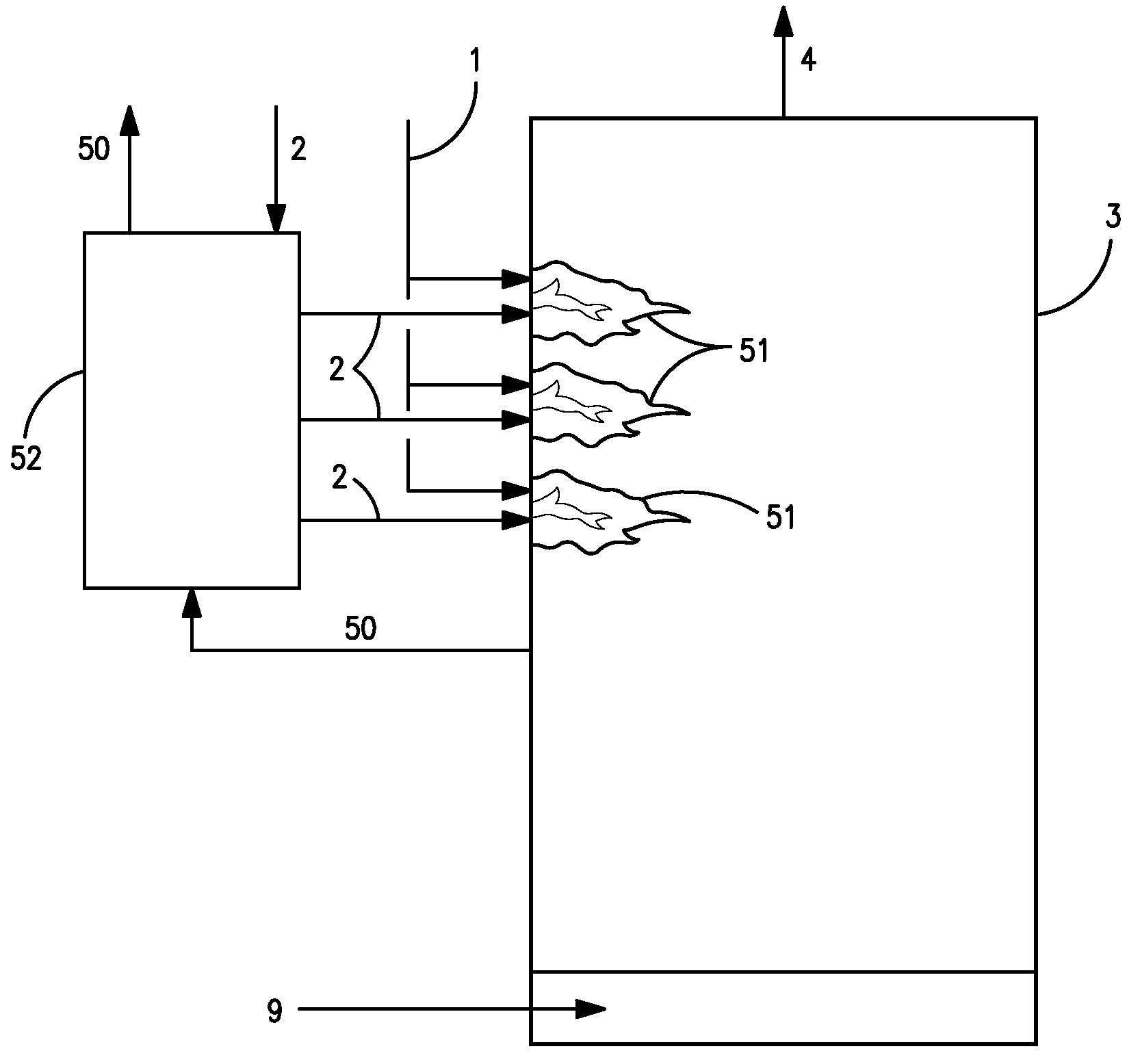

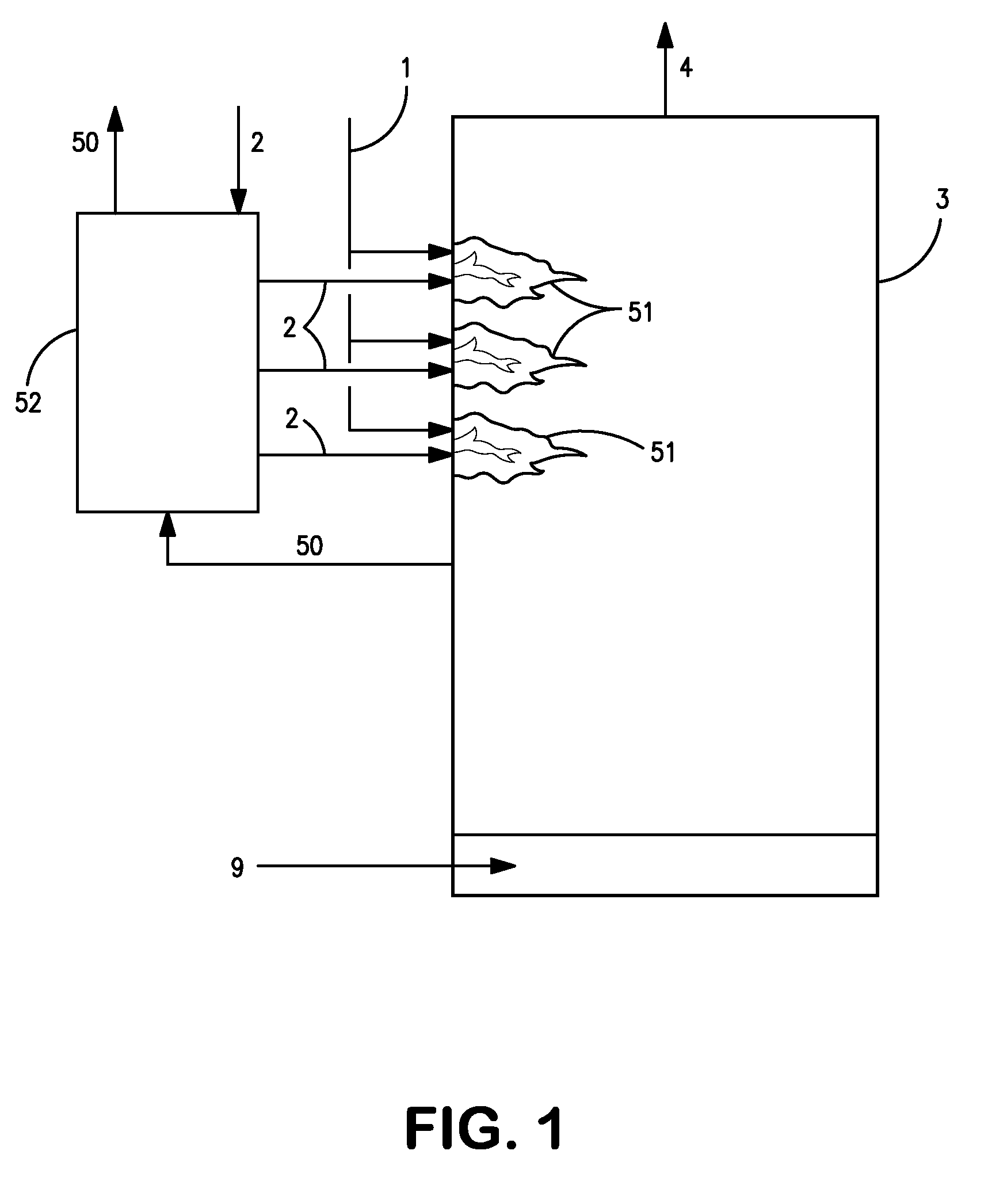

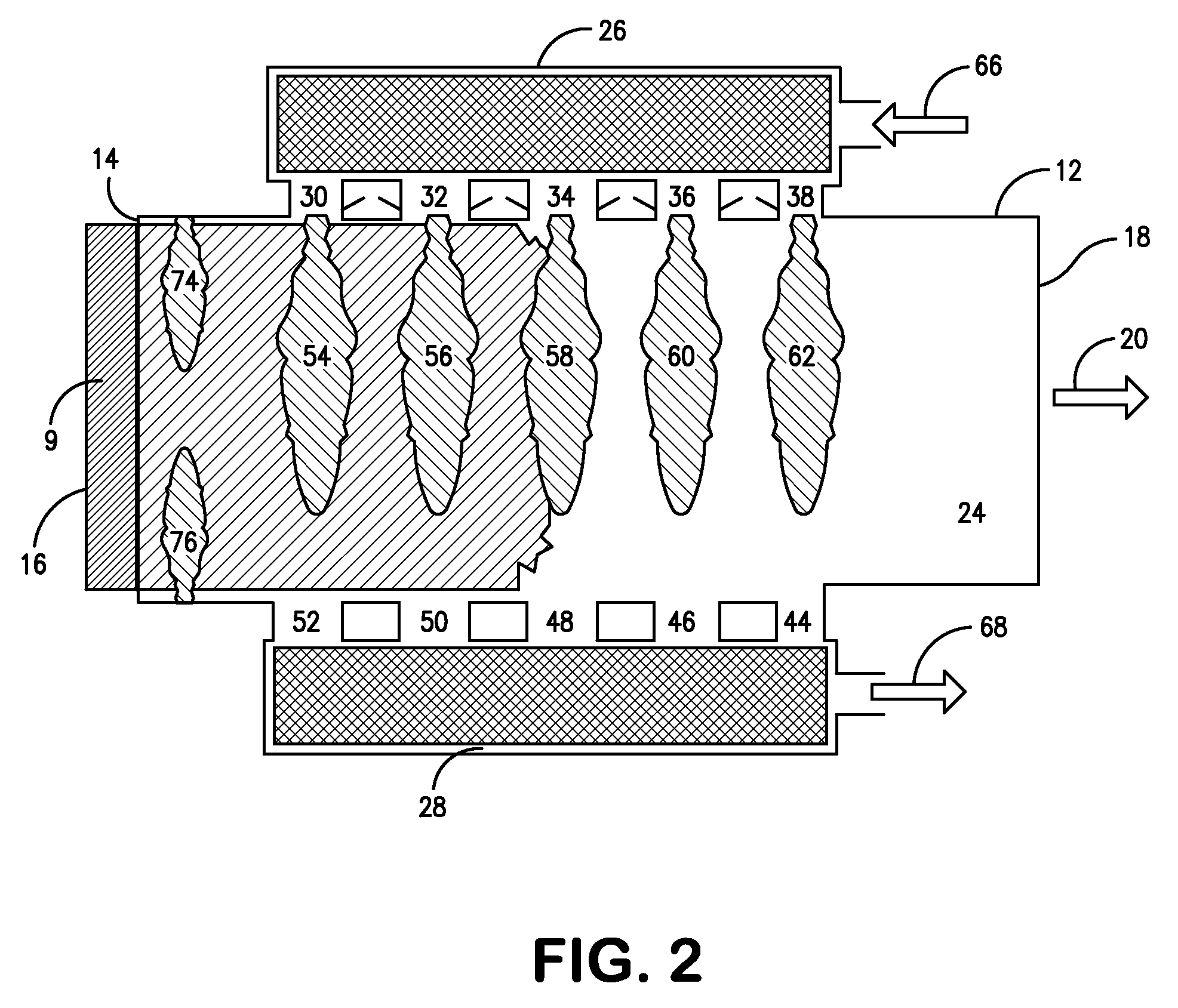

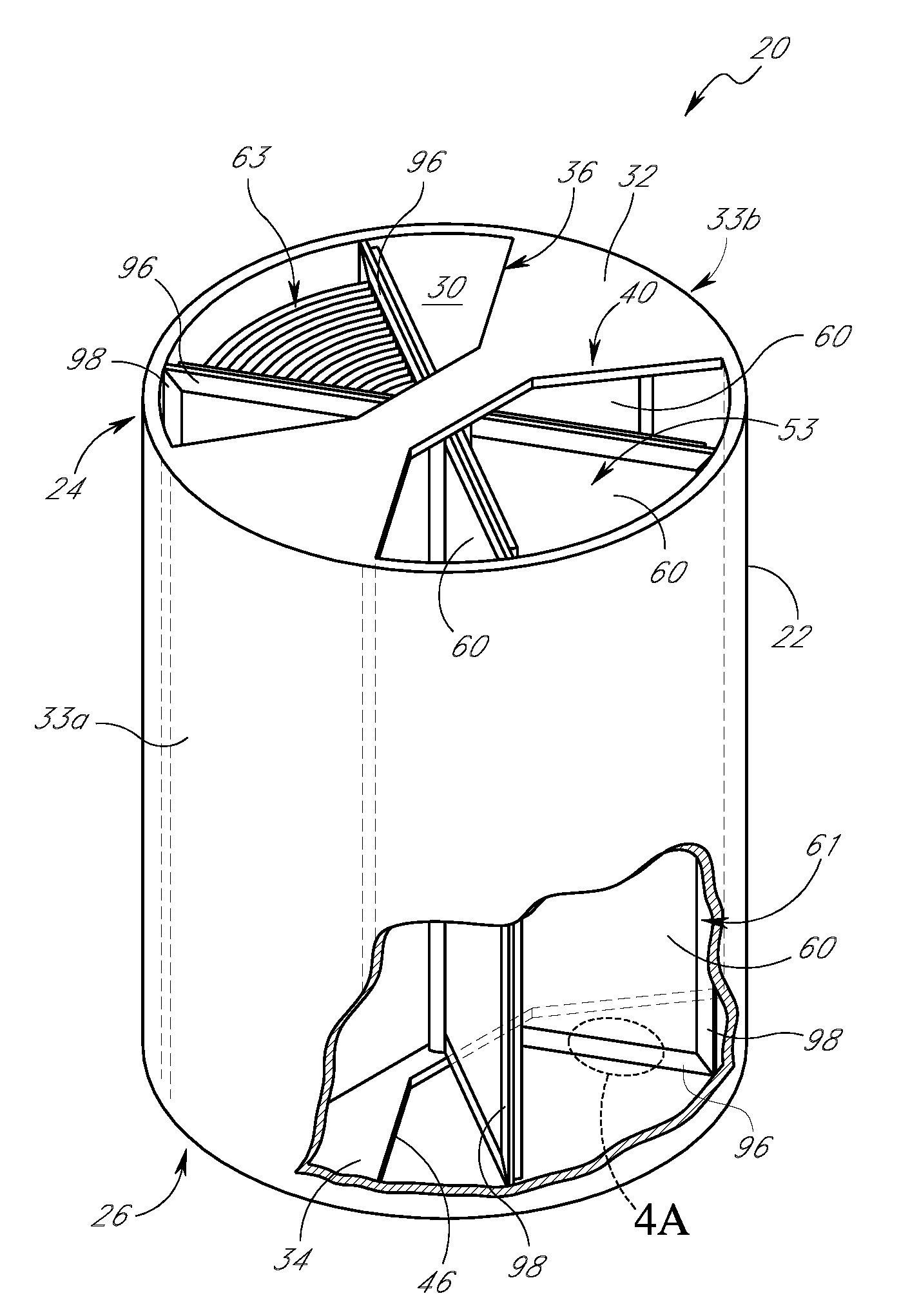

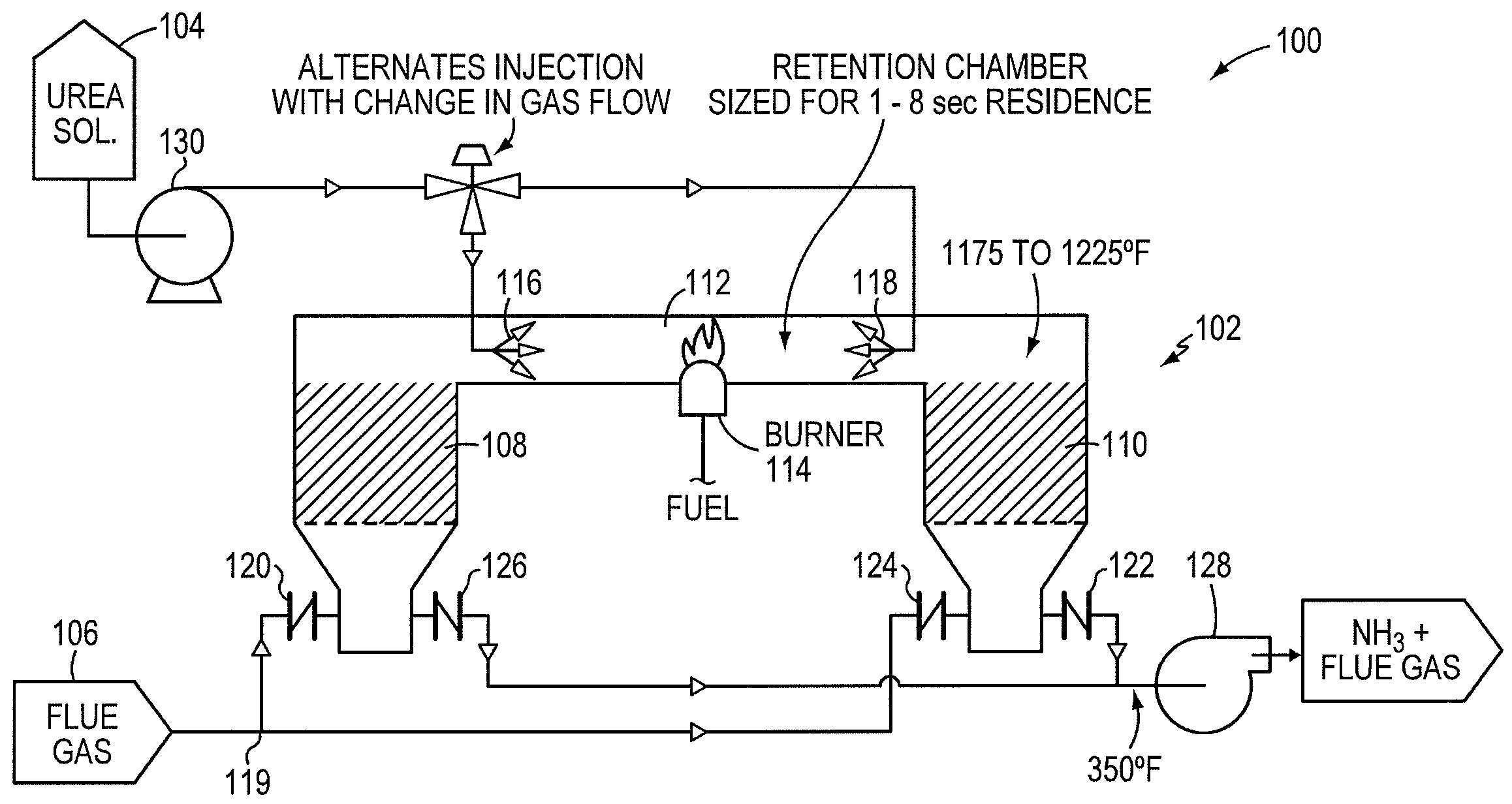

Thermal Decomposition of Urea in a Side Stream of Combustion Flue Gas Using a Regenerative Heat Exchanger

InactiveUS20080050297A1Avoid insufficient temperatureImprove thermal efficiencyNitrogen compoundsExhaust apparatusFlue gasThermal efficiency

This invention relates generally to the treatment of NOx in combustion flue gas. In certain embodiments, the invention relates to the use of a regenerative heat exchanger (RHE) to convert urea to ammonia in a side stream of flue gas. Ammonia and / or other urea decomposition products exit the heat exchanger, are mixed with the rest of the flue gas, and enter a selective catalytic reduction (SCR) unit for reduction of NOx in the flue gas. The use of an RHE significantly improves the thermal efficiency of the overall process. More particularly, in certain embodiments, the regenerative heat exchanger is a dual chamber RHE.

Owner:BABCOCK POWER ENVIRONMENTAL INC (US)

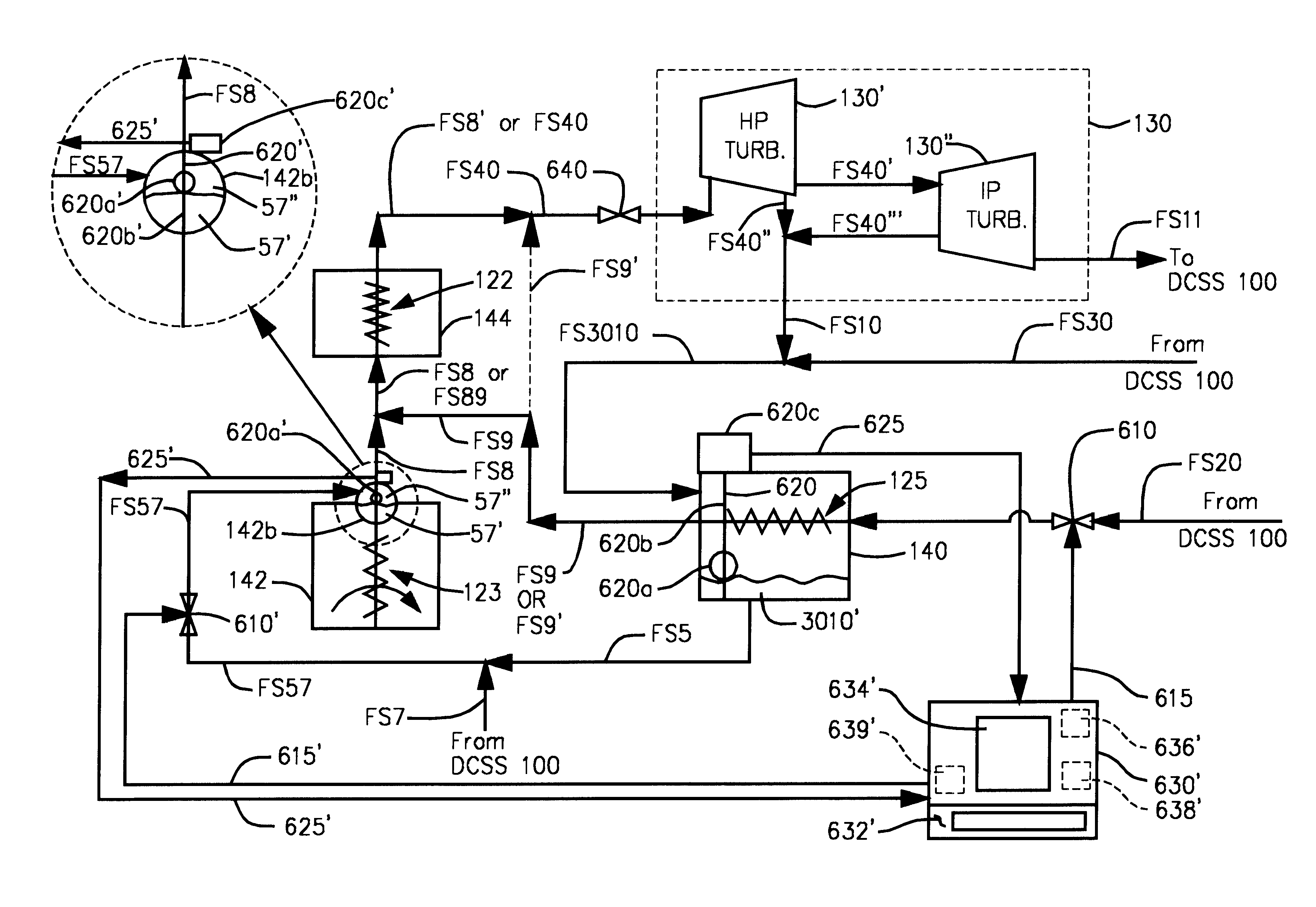

Regenerative subsystem control in a kalina cycle power generation system

A method of operating a Kalina cycle power generation system includes directing a stream of vaporized binary working fluid to a turbine where it is expanded to produce power. At least a portion of the expanded binary working fluid is directed to a regenerative heat exchanger where it is transformed into a feed binary working fluid. The feed binary working fluid is directed to a vapor generator where it is vaporized. The binary working fluid flow within the regenerative heat exchanger is actively regulated to balance the expanded binary working fluid and the feed working fluid.

Owner:ABB ALSTOM POWER INC

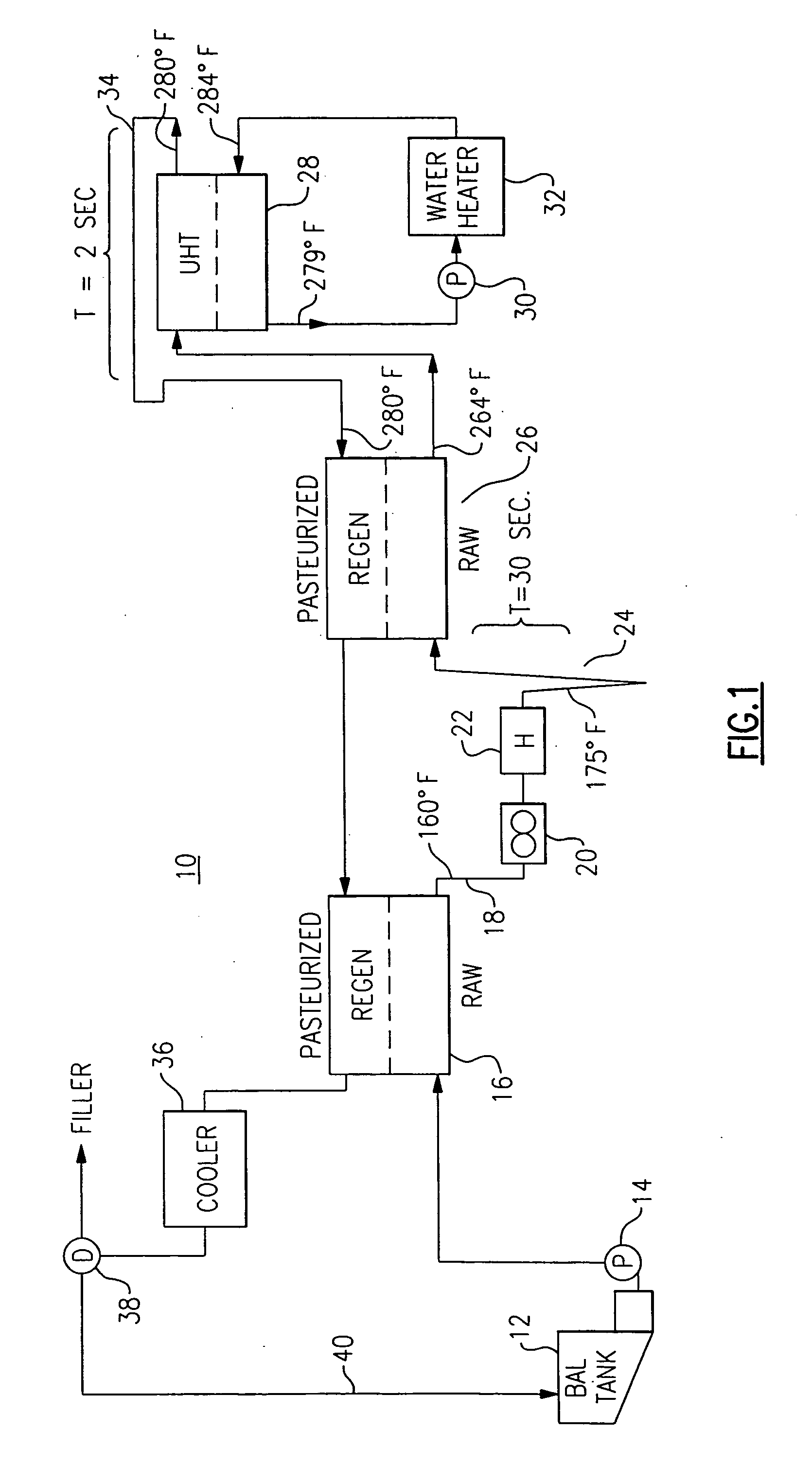

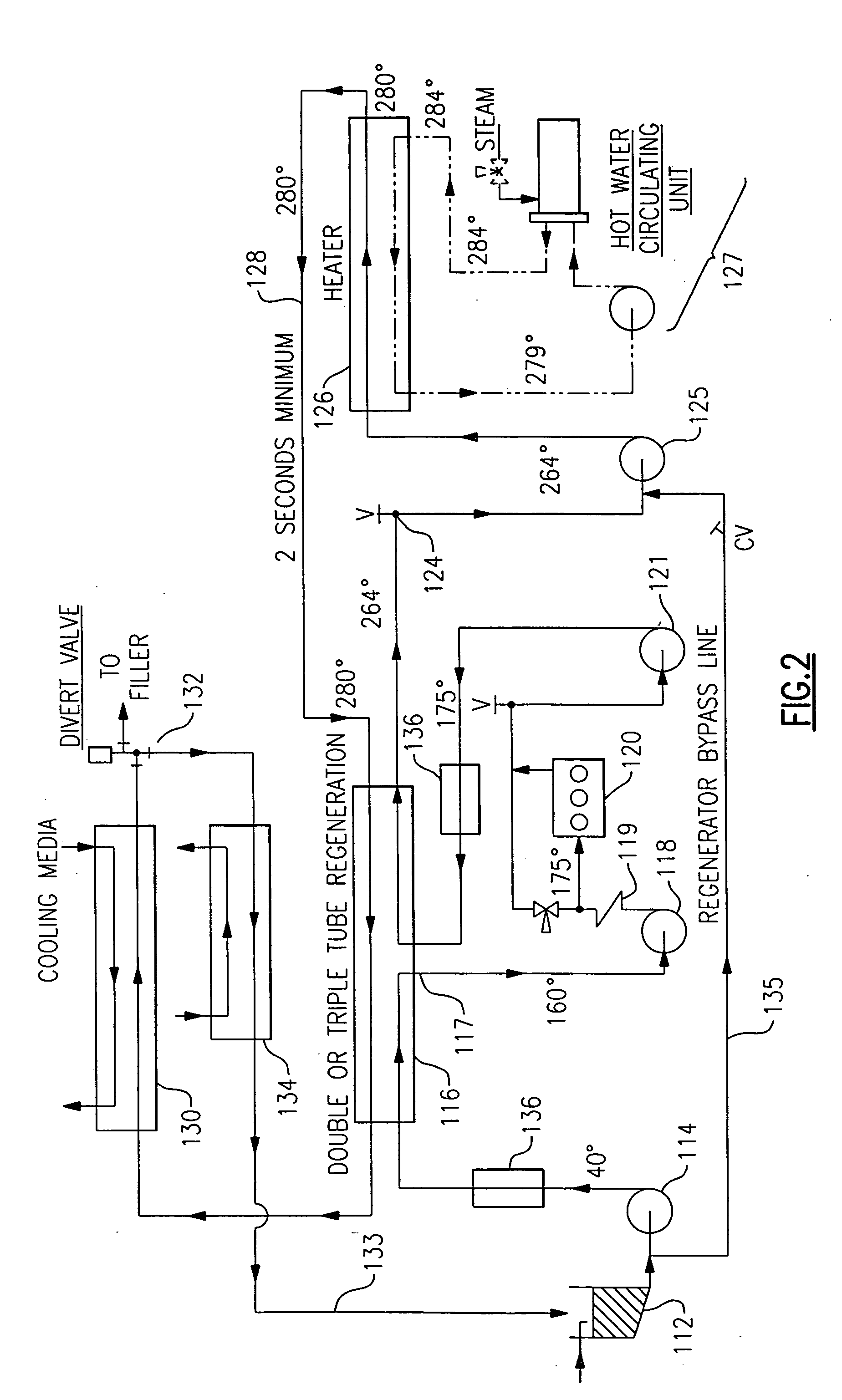

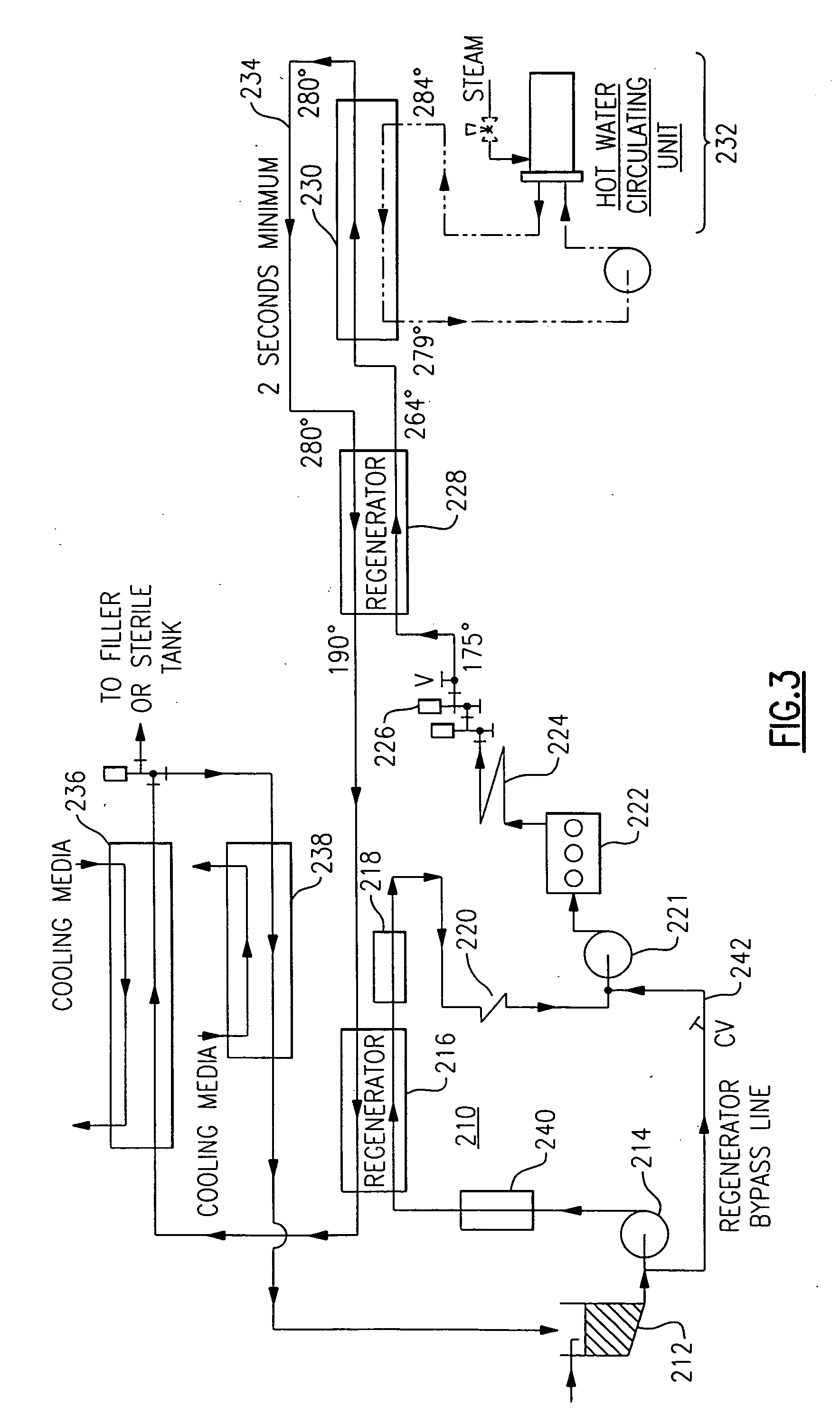

UHT pasteurizer with regeneration

ActiveUS20050112257A1Maximize efficiencyAvoid the tasteMilk preservationWort preparationWater flowProcess engineering

A pasteurization arrangement employs regeneration to bring raw milk or other liquid food product up to a few degrees below a UHT pasteurizing temperature. The product is first heated up by regeneration to about 175° F., and held at this temperature for about sixty seconds to denaturize proteins so that they do not deposit on the heat exchange walls of following stages. Then the product proceeds through a product-product regenerative heat exchanger where it emerges at about 264° and proceeds to a water-product heater to heat the product to 280° F. The water flows in counter current to the product. The temperature differential at any reference point in the heater and the regenerative heat exchanger is below 20°, and the ratio of rate of water flow to product flow in the heater is below about 3:1.

Owner:FELDMEIER EQUIP

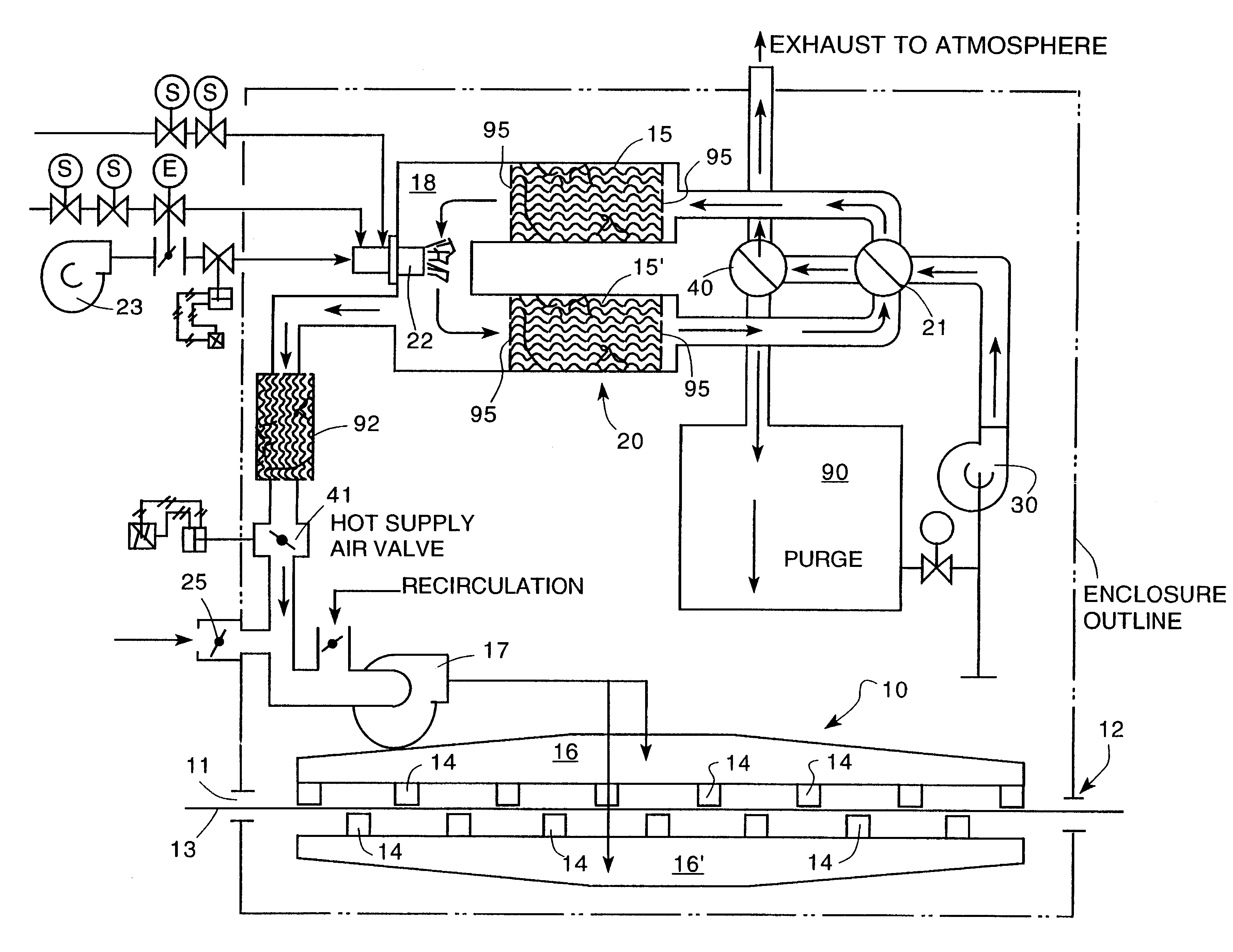

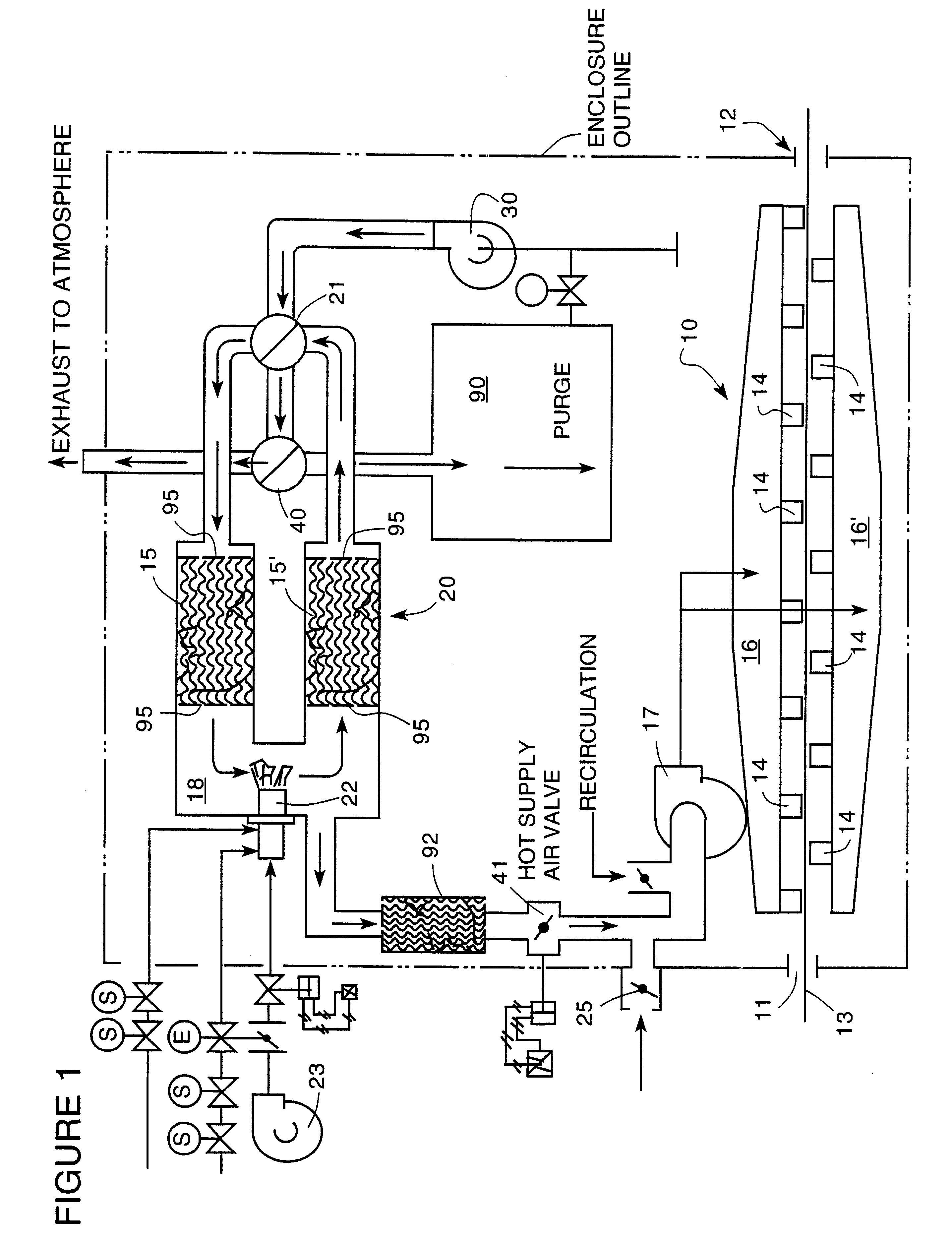

Web dryer with fully integrated regenerative heat source

Integrated web dryer (10) and regenerative heat exchanger (20), as well as a method of drying a web of material using the same. The apparatus and method of the present invention provides for the heating (22) of air and the converting of VOC's to harmless gases in a fully integrated manner via the inclusion of a regenerative combustion device as an integral element of the drying apparatus.

Owner:MEGTEC SYST INC

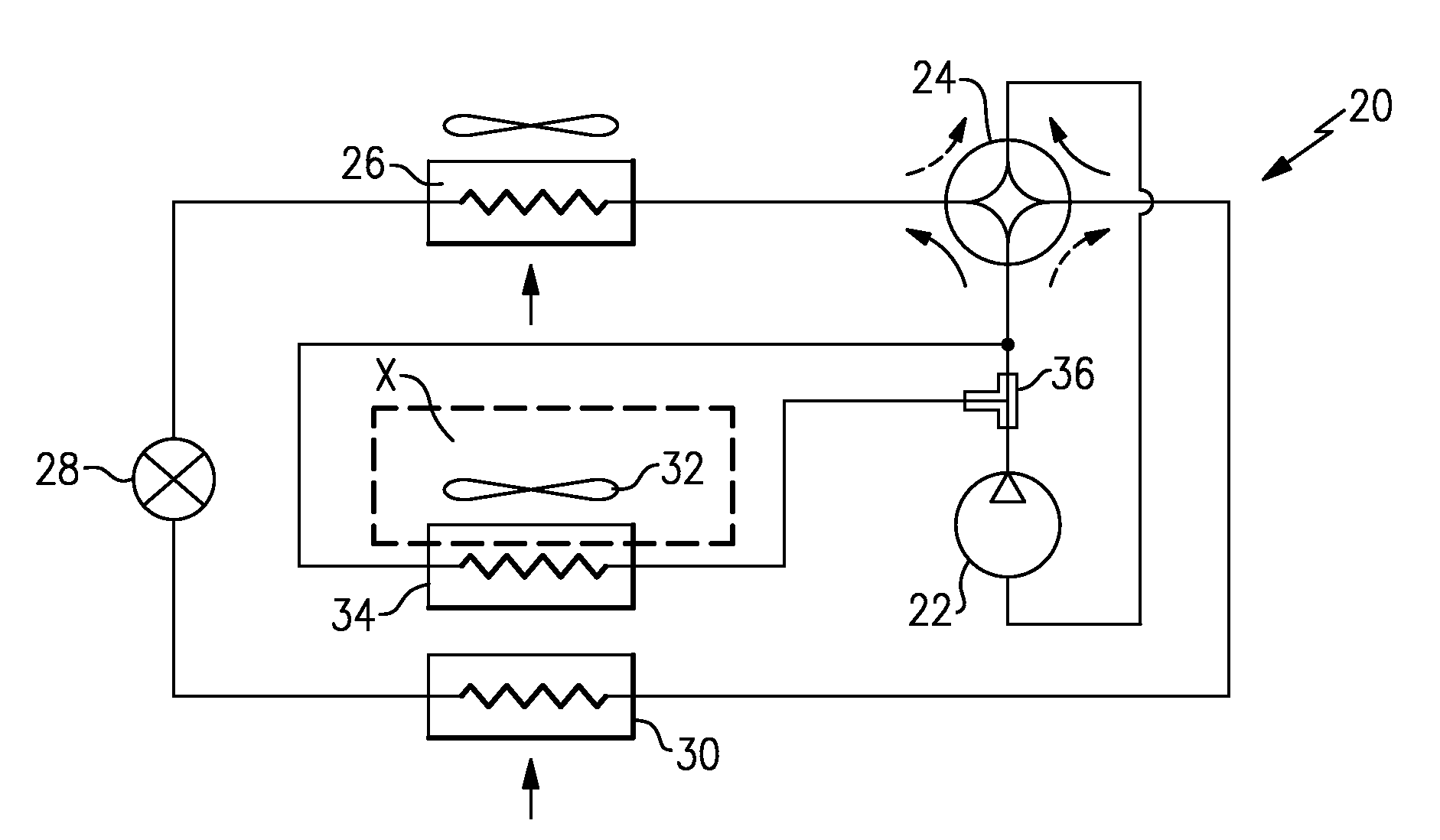

Heat pump with microchannel heat exchangers as both outdoor and reheat exchangers

InactiveUS20110079032A1Stationary conduit assembliesFluid circulation arrangementPlate heat exchangerEngineering

A heat pump refrigerant system has a compressor for delivering a compressed refrigerant to a reversing refrigerant flow control device. The reversing refrigerant flow control device selectively delivers refrigerant to an outdoor heat exchanger in a cooling mode of operation, and to an indoor heat exchanger in a heating mode of operation. Refrigerant from an outdoor heat exchanger passes through an expansion device to an indoor heat exchanger in a cooling mode, and from the indoor heat exchanger through an expansion device and to the outdoor heat exchanger in a heating mode. A reheat circuit includes a reheat heat exchanger positioned to be in the path of air delivered over the indoor heat exchanger and into an environment to be conditioned. The reheat heat exchanger and outdoor heat exchanger both are provided by microchannel heat exchangers. The reheat circuit is utilized to minimize or prevent refrigerant charge migration while operating at a wide spectrum of environmental conditions or switching between modes of operation.

Owner:CARRIER CORP

Cooling/heating system of air conditioner

InactiveCN1517610AAvoid dirtyPrevent drynessEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringHeat losses

Owner:LG ELECTRONICS INC

Furnace with multiple heat recovery systems

InactiveUS20100081103A1Glass drawing apparatusGlass forming apparatusProcess engineeringHeat capacity rate

In a furnace such as a glassmelting furnace, a portion of the combustion products formed by combustion of fuel with gaseous oxidant within the furnace are passed through a recuperative or regenerative heat exchanger system to heat a portion of the incoming gaseous oxidant, and a portion of the combustion products are passed instead through a secondary heat exchanger system, wherein the hot combustion products and oxidant which are passed through said first heat exchanger are passed at a heat capacity rate ratio of combustion products to oxidant of less than 1.3.

Owner:PRAXAIR TECH INC

Self-adjusting seal for a heat exchanger

InactiveUS20090145574A1Prevent leakageCombustion processMetal-working apparatusDistortionMicro heat exchanger

Disclosed is an improved sealing element for a regenerative heat exchanging apparatus, such as a Ljungstrom™-type or other suitable regenerative heat exchangers. The sealing element can be mounted to a wall of the rotor of the heat exchanger to provide a secure seal between the wall and a housing of the heat exchanger, thereby inhibiting the leakage of gas between the hot gas conduit and cool air conduit of the regenerative heat exchanger. In one embodiment, the sealing element includes a base plate that is used to mount the sealing element to the wall. The sealing element also includes a contact shoe that maintains a sealing contact between the wall and housing. A flexible portion is coupled between the base plate and contact shoe to provide the sealing element with flexibility and resiliency so that the sealing element maintains contact with the sealing surface even when the heat exchanging apparatus experiences warping and / or distortion from thermal stress. The stress from the deflection of the seal during operation of the heat exchanger is substantially concentrated in the flexible portion of the seal.

Owner:PARAGON AIRHEATER TECH

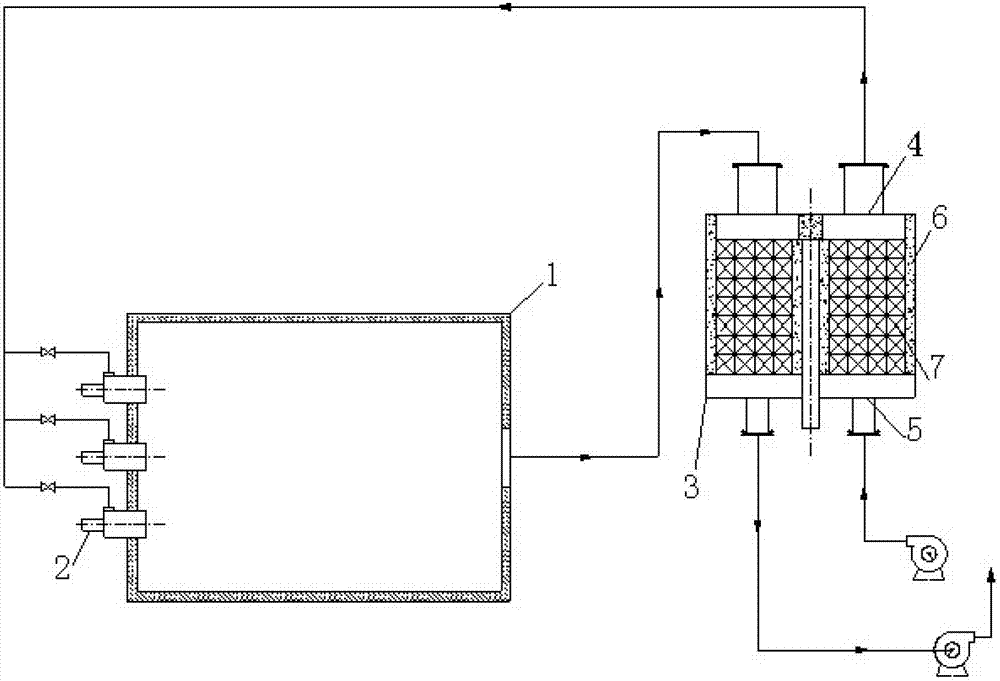

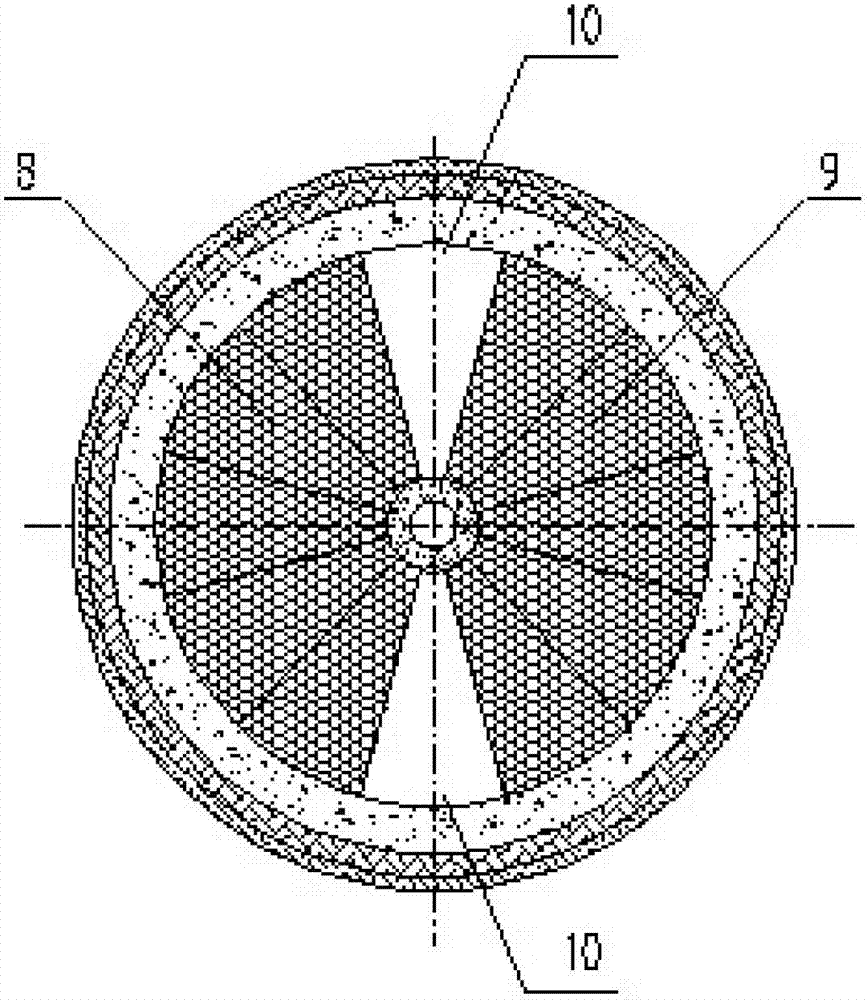

Continuous combusting regenerative industrial furnace

InactiveCN102878817AOptimize layoutStable combustionCombustion processIndirect carbon-dioxide mitigationCombustorProcess engineering

The invention discloses a continuous combusting regenerative industrial furnace, which includes a rotary regenerative heat exchanger, wherein the rotary regenerative heat exchanger includes a rotary cylinder, an upper cover and a lower cover, and the rotary cylinder is internally provided with a regenerator; the high-temperature smoke outlet on the furnace body is connected with an induced draft fan through the high-temperature smoke inlet and the low-temperature smoke outlet of the rotary regenerative heat exchanger in sequence; an air blower is connected with an combustor on the furnace body through the normal temperature air inlet and the preheated air outlet of the rotary regenerative heat exchanger in sequence; and the rotary cylinder is connected with a rotary driving device. The regenerator in the rotary regenerative heat exchanger rotates to continuously preheat the air, the preheated air can be continuously fed into the furnace, the whole combusting process needs no reversing, the pipeline arrangement is simple, the continuous regenerative heat exchange between the high-temperature smoke and the normal temperature air can be realized, and the whole combusting process needs no reversing and is stable.

Owner:SHENWU TECH GRP CO LTD

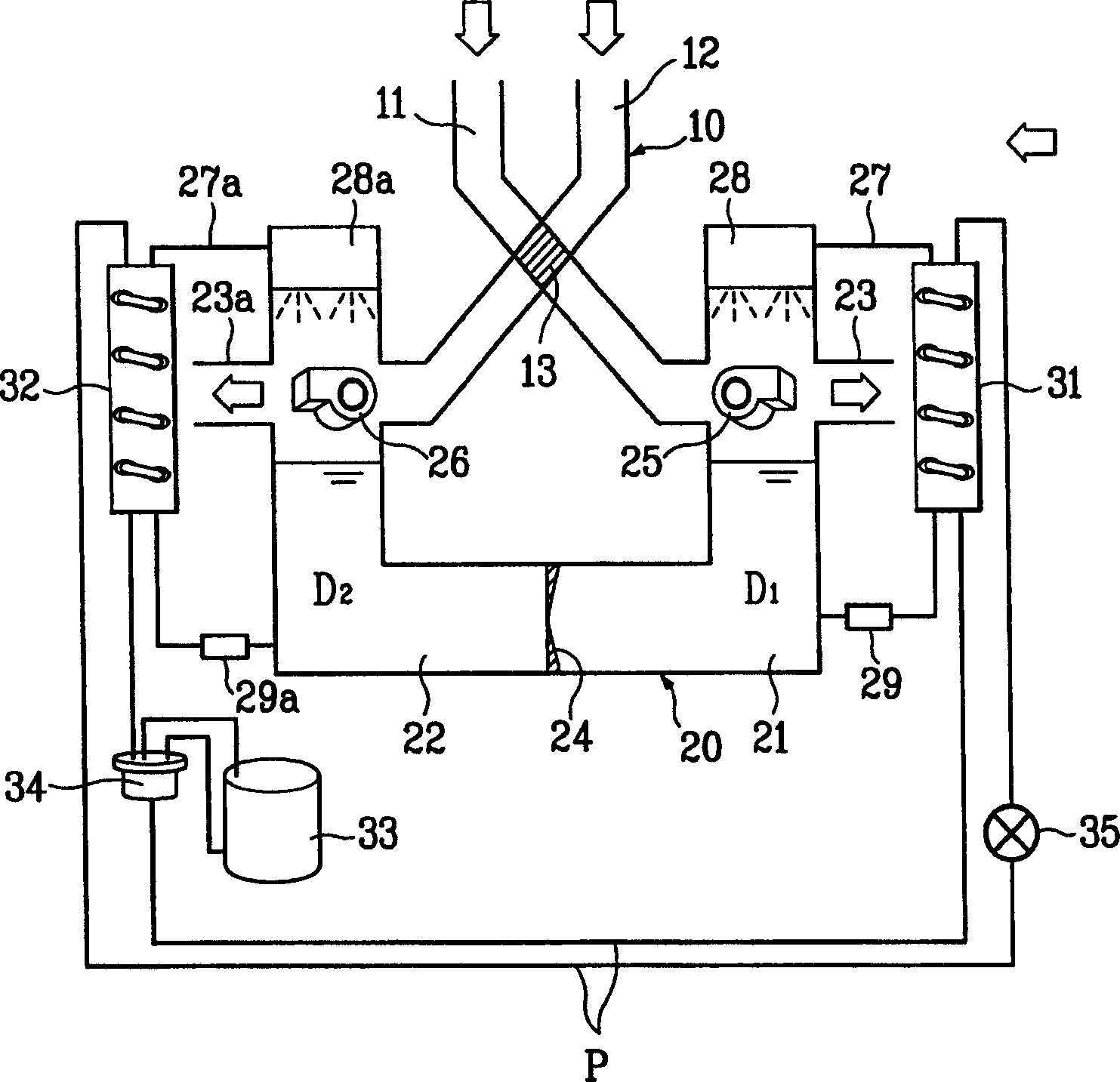

Air conditioning system

InactiveUS6915655B2Energy recovery in ventilation and heatingAir treatment detailsAir conditioningHeat pump

Air conditioning system including a duct having a suction passage for drawing external air and a discharge passage for discharging room air, the suction passage and the discharge passage being split with a split plate, a suction fan and a discharge fan in the suction passage and the discharge passage, respectively, a dehumidifier having a desiccant wheel rotatably mounted in an opening in a split plate of the duct to cross, and exposed to the suction passage and the discharge passage, a regenerative heater in the discharge passage of the duct adjacent to air inlet of the dehumidifier for heating the air introduced into the dehumidifier, a regenerative heat exchanger mounted both in the suction passage and the discharge passage on a room side with reference to the dehumidifier for making heat exchange of the air flowing in the suction passage and the air flowing in the discharge passage, and a heat pump having a first heat exchanger in the discharge passage between the dehumidifier and the regenerative heat exchanger, and a second heat exchanger in the suction passage on the air outlet of the regenerative heat exchanger.

Owner:LG ELECTRONICS INC

Heat treating plant, installation method for porous regenerative element, production method for heat treated substance, selection method for porous regenerative element, and spent porous regenerative element component member

InactiveUS6880619B1Extension of timeLarge apertureHeat storage plantsFurnace typesCombustorPore diameter

A heat treatment equipment having a heating chamber having a plurality of regenerative combustors provided with direct-fired burner having a built-in porous regenerator, for applying a heat treatment to an object in the heating chamber, wherein the substantial average surface pore diameter is not uniform for porous regenerators in a plurality of direct-fired burners or a plurality of regenerative combustors. By making contrivances in the shape of porous regenerators of the direct-fired burners or the regenerative heat exchangers arranged in an area where substances causing choking tend to easily adhere to make it difficult for such substances to adhere or prevent choking phenomenon from becoming apparent.

Owner:NIPPON KOKAN KK +2

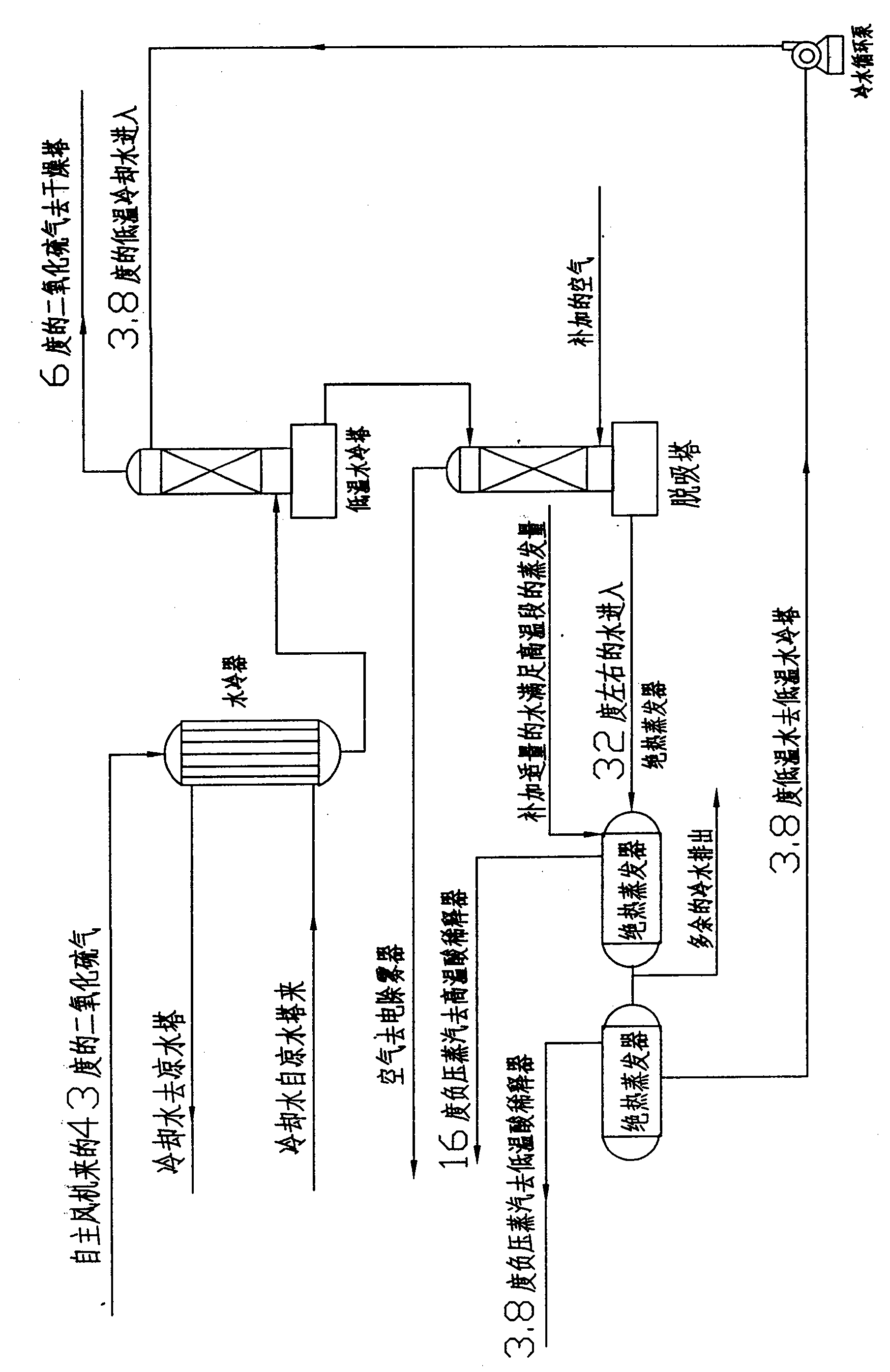

Process for efficiently recovering afterheat generated in the process of producing sulfuric acid from pyritic

ActiveCN102070128AImprove quality and quantityImprove waste heat utilizationSulfur compoundsEnergy inputProcess engineeringRefrigeration

The invention discloses process technology for comprehensively and efficiently recovering the afterheat generated in the process of producing sulfuric acid from pyritic. According to characteristics of the afterheat on different parts in the production process, different novel process technologies are applied, the recovery rate of the afterheat is improved to the maximum, a three-chamber regenerative heat exchanger is adopted to fully recover the afterheat generated by roasting raw gas, and the utilization rate of the roasting afterheat is improved; and a key process technology that low-temperature cooling water generated through spontaneous heat-insulating vacuum evaporating refrigeration in the process cools the SO2 gas to reduce the vapor content in the SO2 gas entering a drying tower is adopted to fulfill the aim of fully and efficiently recovering the afterheat in the absorption process and the conversion process. At present, the utilization rate of the afterheat recovered in the process of producing acid from the pyritic at home is only 43.4 percent. After the afterheat recovery technology is adopted, the afterheat utilization rate is 83.9 percent, and a way of comprehensively, fully and efficiently recovering and utilizing medium or high pressure overheat vapor generated by the afterheat in the process of producing the acid from the pyritic is opened up.

Owner:HUNAN HENGGUANG TECH

Thermal decomposition of urea in a side stream of combustion flue gas using a regenerative heat exchanger

InactiveUS7682586B2Avoid insufficient temperatureHeat produced by the burner is conservedNitrogen compoundsExhaust apparatusFlue gasThermal efficiency

This invention relates generally to the treatment of NOx in combustion flue gas. In certain embodiments, the invention relates to the use of a regenerative heat exchanger (RHE) to convert urea to ammonia in a side stream of flue gas. Ammonia and / or other urea decomposition products exit the heat exchanger, are mixed with the rest of the flue gas, and enter a selective catalytic reduction (SCR) unit for reduction of NOx in the flue gas. The use of an RHE significantly improves the thermal efficiency of the overall process. More particularly, in certain embodiments, the regenerative heat exchanger is a dual chamber RHE.

Owner:BABCOCK POWER ENVIRONMENTAL INC (US)

Heat transport device, semiconductor apparatus using the heat transport device and extra-atmospheric mobile unit using the heat transport device

InactiveUS6983790B2Low noise performanceImprove heat transfer and cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal radiation

Owner:MITSUBISHI ELECTRIC CORP

Closed loop scroll expander engine

ActiveUS8006496B2Reduce weightEasy maintenancePump componentsCombination enginesWorking fluidClosed loop

Apparatuses and methods related to an engine for converting heat into mechanical output using a working fluid in a closed circulating system are disclosed. In some embodiments, the engine includes a pump to pressurize the working fluid, a regenerative heat exchanger to transfer heat from a first portion of the working fluid to a second portion, a heating device to heat the working fluid, and first and second scroll expanders to expand the working fluid and generate the mechanical output. Other embodiments may be described and claimed.

Owner:SECCO2 ENGINES

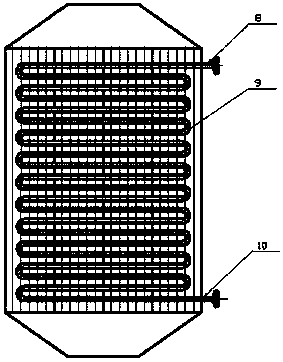

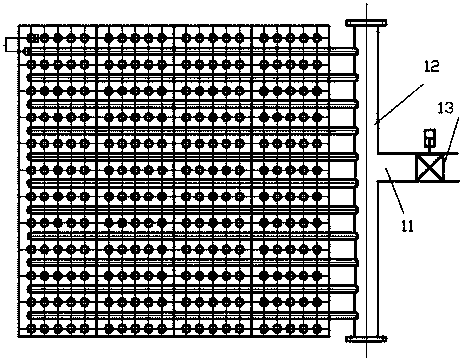

Three-dimensional heat-pipe heat exchanger and production method thereof

The invention discloses a three-dimensional heat-pipe heat exchanger. A plurality of pipes are combined into an S-shaped heat pipe by a U-shaped elbow, and the heat-pipe heat exchanger connected by the U-shaped elbow can form a completely continuous coiled pipe. The S-shaped heat pipe and the heat exchanger can be configured into an integrative heat exchanger, wherein a condensing end and an evaporating end are isolated by a heat insulation section, or can be configured into a split type heat exchanger, wherein the evaporating end and the condensing end are connected by an evaporating pipe and a reflowing pipe. The three-dimensional heat-pipe heat exchanger can form a continuous closed loop, in this way, the heat exchanger works no matter whether the reflowing is implemented with the aid of gravity. A plurality of U-shaped pipes are needed to interconnect in the production of the S-shaped pipe to form one S-shaped heat pipe loop, wherein one pipe has an opening end, each of all the pipes can work as one independent heat pipe only by injecting enough refrigerant from the opening end at one time. The three-dimensional heat-pipe heat exchanger can be used for the aspects of enhancement of dehumidification effect of the air conditioner, energy recovering, heat radiation of partial space, and the like.

Owner:苏州浩佳节能科技有限公司

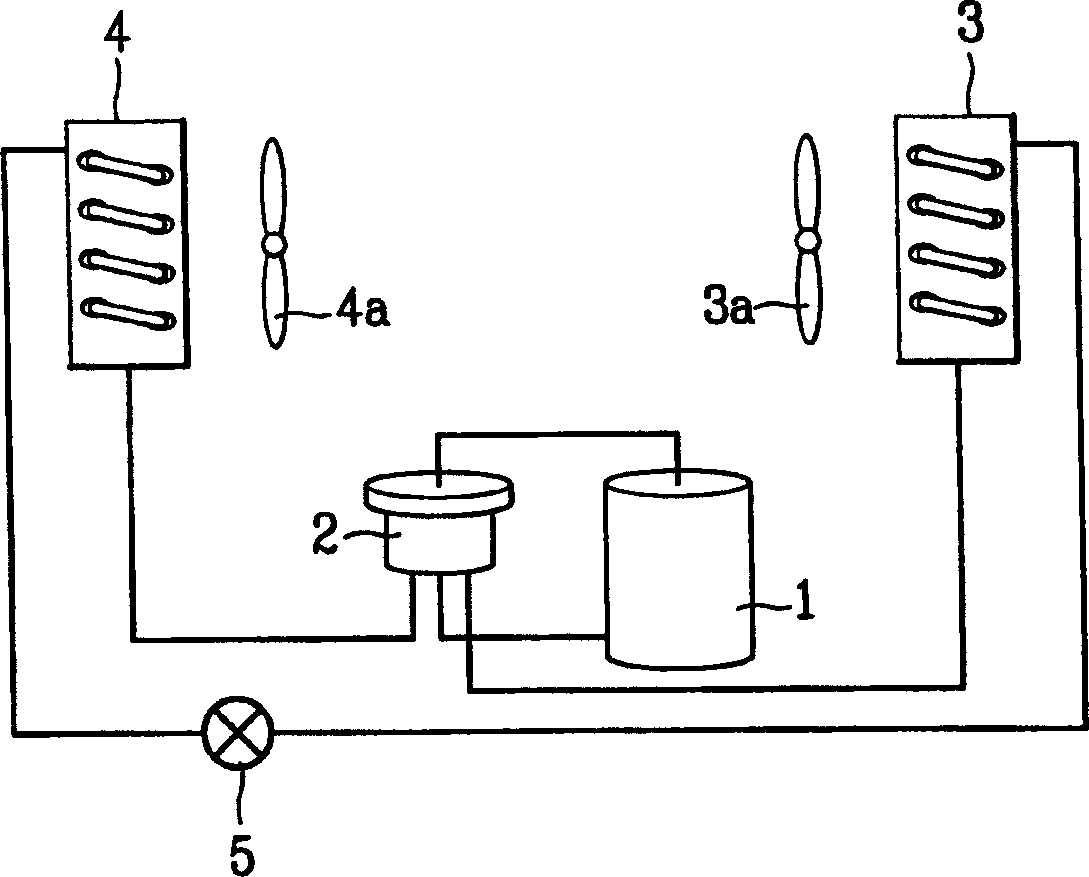

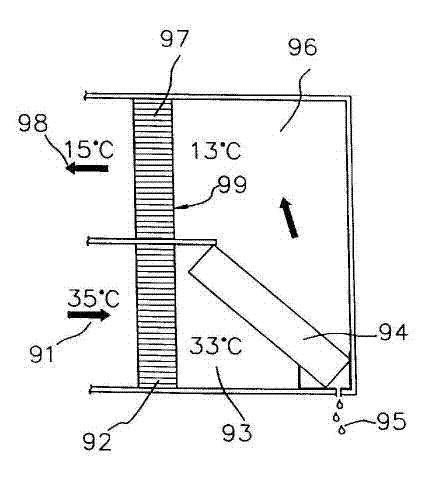

Cooling/heating system of air conditioner

InactiveUS6945065B2Reduce heat lossKeep energy smallEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringHeat losses

Cooling / heating system of air conditioner including a duct having a first passage for drawing external air, and a second passage for drawing room air, the second passage having a part crossed with the first passage, a regenerative heat exchanger having first and second flow passages in the crossed part of the first and second passages for indirect heat exchange between the external air and the room air, a case connected to the first and second passages of the duct having first and second outlets for drawing / discharging external and room air, first and second fans for drawing in the external air and the room air into the case through the first and second passages, and discharging the external air and the room air through the first and second outlets, and first and second heat exchangers for heat exchange with the external air and the room air discharge through the first and second outlets, thereby preventing contamination and dried room air and reducing heat loss to permit cooling / heating even with small amount of energy.

Owner:LG ELECTRONICS INC

Full contact flexible seal assembly for heat exchanger

ActiveUS20110036536A1Combustion processIndirect carbon-dioxide mitigationPlate heat exchangerEngineering

A seal assembly for a regenerative heat exchanger can include a primary sealing member with a mounting base and a flexible contact portion that defines a first distance between a proximal edge of the mounting base and a contact edge of the flexible contact portion, the first distance being generally constant along the length of the primary sealing member. The seal assembly can also include a second member with a mounting portion and a cantilevered portion that defines a second distance between a proximal edge of the mounting portion and a distal edge of the cantilevered portion, the second distance being generally constant along the length of the second member. The first distance is greater than the second distance by a predetermined amount so as to limit the preload flexure of the flexible contact portion against a sector plate of the heat exchanger when the seal assembly is installed in the regenerative heat exchanger.

Owner:PARAGON TECH

Control of heat exchanger operation

ActiveUS7310958B2Minimizing energyMeet needsEfficient regulation technologiesStationary conduit assembliesPlate heat exchangerEngineering

A method of controlling the operation of a heat exchanger with evaporative and non-evaporative sections. The method includes the following steps: providing desired values of temperature or pressure; comparing present values of temperature or pressure to the desired values of temperature and pressure; and manipulating an air flowrate to the heat exchanger and load to the evaporative heat exchanger to optimize total energy and water costs while maintaining an outlet fluid at the desired temperature or pressure.

Owner:BALTIMORE AIRCOIL CO INC +1

Waste heat utilization heat exchanger and multilevel heat accumulation system thereof

InactiveCN103925823AIncrease profitImprove stabilityHeat storage plantsHeat exchange apparatusProcess engineeringThermal efficiency

The invention provides a multilevel heat accumulation system. The multilevel heat accumulation system comprises a heat accumulation type heat exchanger and which are connected through connection fragements. According to the heat accumulation type heat exchanger, waste heat in cement production is fully utilized, the heat exchange efficiency of the heat accumulation type heat exchanger can be maximized, so that energy is saved, and the purposes of protecting the environment and saving energy are achieved.

Owner:山东中和热工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com