Heat exchanger containing a component capable of discontinuous movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

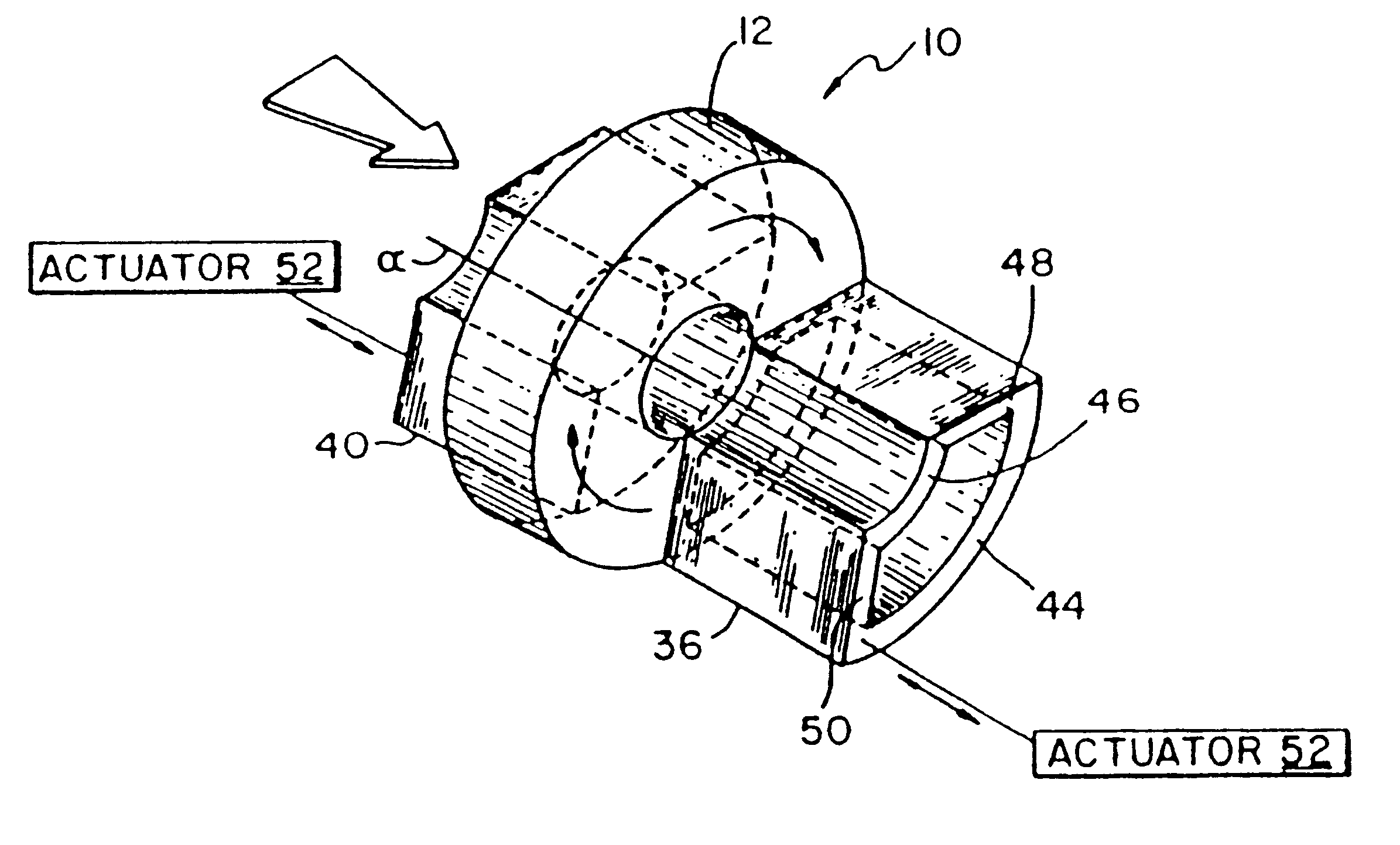

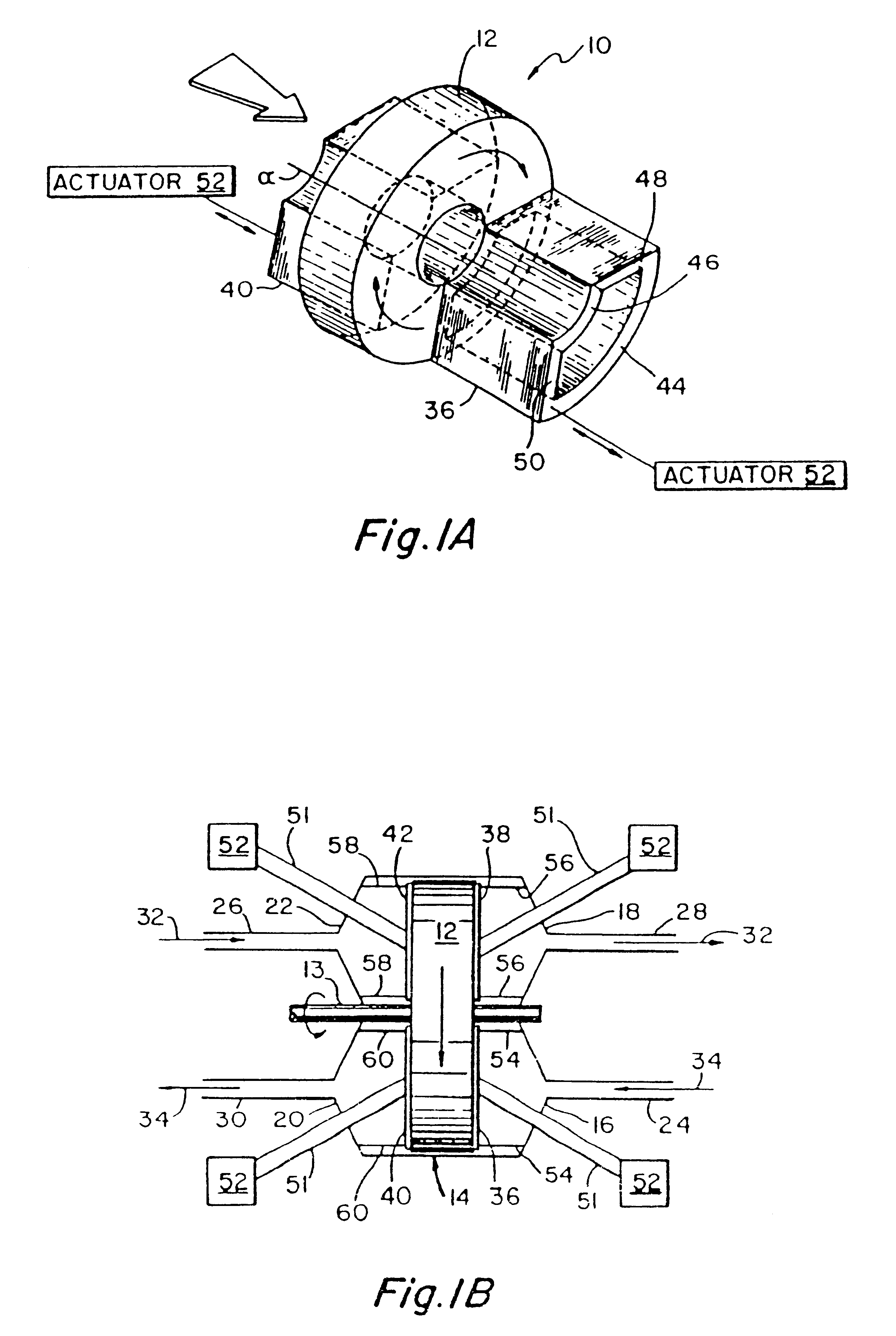

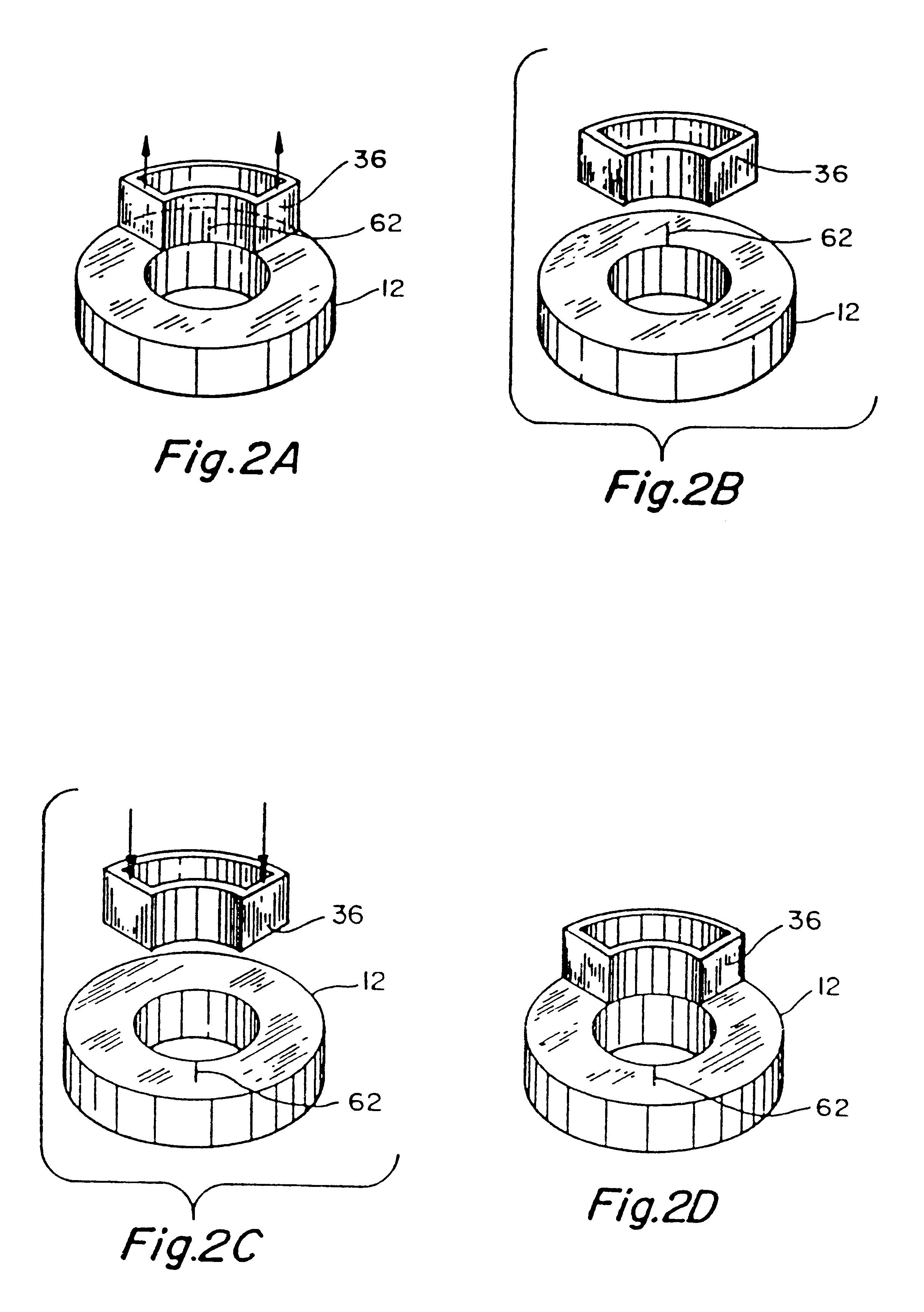

This invention pertains to regenerative heat exchangers for transferring heat between a hot fluid and a cold fluid. The heat exchangers are capable of providing discontinuous movement of a matrix relative to the hot and cold fluid streams. Sealing members are provided to isolate portions of the matrix when the components are stationary and released upon movement. By providing a system that isolates matrix portions only when the matrix is stationary, losses and wear associated with dynamic, sliding seals of conventional, continuously moving regenerative heat exchangers are significantly reduced. Additionally, by providing isolation of matrix portions only when the components are stationary, leakage across the seals that isolate the matrix portions and power losses resulting therefrom can be significantly reduced. The discontinuous movement of the matrix relative to the fluid streams is intended to encompass either discontinuous movement of the matrix or discontinuous movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com