Process for efficiently recovering afterheat generated in the process of producing sulfuric acid from pyritic

A technology of pyrite and waste heat, applied in the direction of preheating, chemical industry, sulfur compounds, etc., to achieve the effect of improving utilization rate, less heat release, and increasing heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

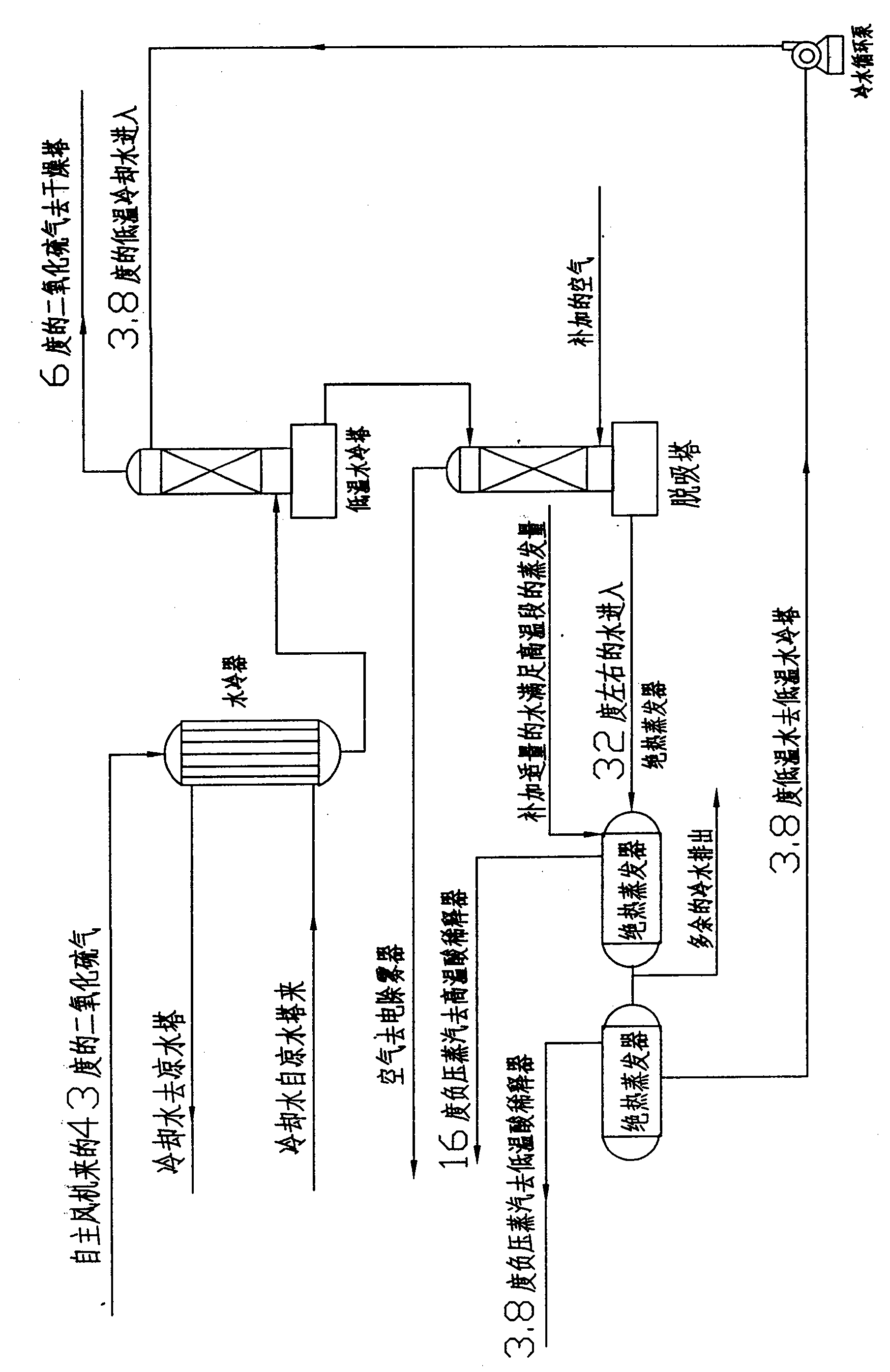

Image

Examples

Embodiment Construction

[0145] Take the sulfuric acid production line with an annual output of 300,000 tons of Hunan Xinhengguang Technology Co., Ltd. as an example.

[0146] The production of sulfuric acid is 37.5 tons per hour. The conversion gas concentration is 8.3%, and the 3+1 process of two rotations and two suctions is adopted.

[0147] 1. The temperature of the raw material gas coming out of the fluidized fluidized furnace is 980°C, the temperature drops to 350°C through the waste heat boiler, and then enters the electric dust collector through the cyclone separator.

[0148] 2. The temperature of the electrostatic precipitator is about 320°C, and the gas volume is 74330Nm 3 / h, the heat brought by the raw material gas is about 10.68*10 6 kcal / h, the moisture content of the raw material gas is generally 6.0% (volume content), the temperature drops to 100°C after passing through the three-chamber heat storage heat exchanger, and the air temperature in front of the furnace is 280°C. Process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com