Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

762 results about "Bleed air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bleed air is compressed air taken from the compressor stage of a gas turbine upstream of its fuel-burning sections. Automatic air supply and cabin pressure controller (ASCPCs) valves bleed air from high or low stage engine compressor sections. Low stage air is used during high power setting operation, and high during descent and other low power setting operations. Bleed air from that system can be utilized for internal cooling of the engine, cross-starting another engine, engine and airframe anti-icing, cabin pressurization, pneumatic actuators, air-driven motors, pressurizing the hydraulic reservoir, and waste and water storage tanks. Some engine maintenance manuals refer to such systems as "customer bleed air". Bleed air is valuable in an aircraft for two properties: high temperature and high pressure (typical values are 200–250 °C and 275 kPa (40 PSI), for regulated bleed air exiting the engine pylon for use throughout the aircraft).

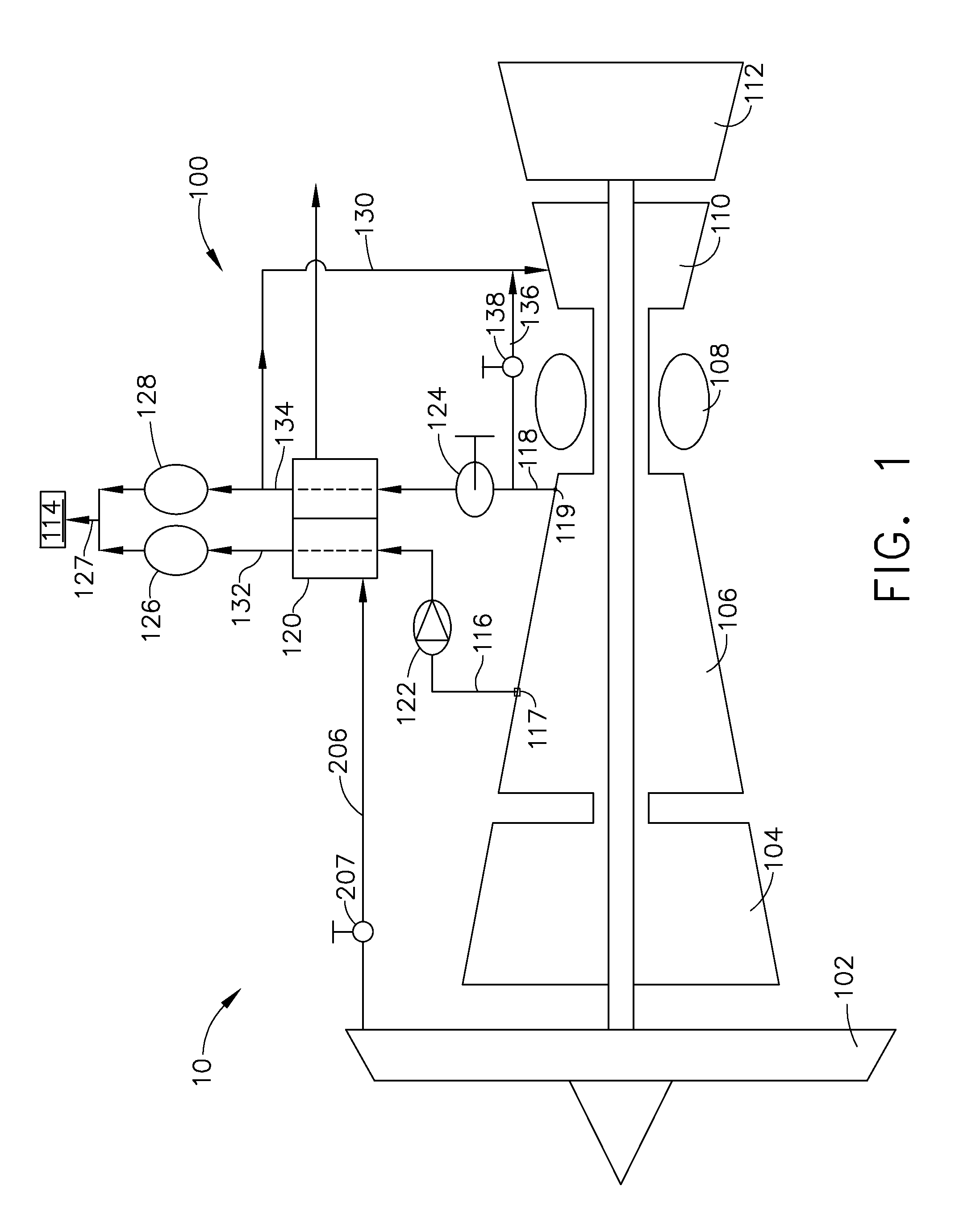

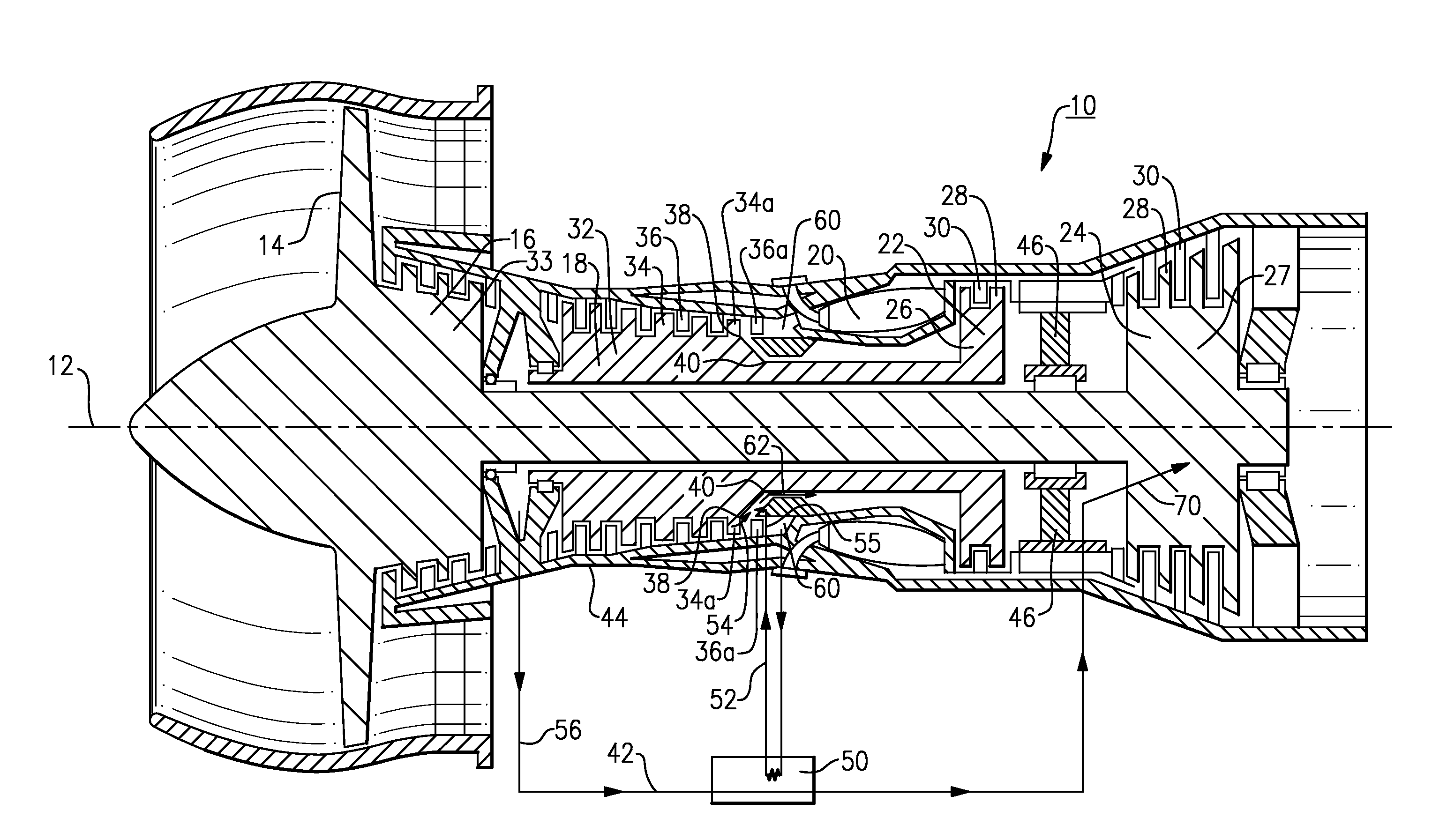

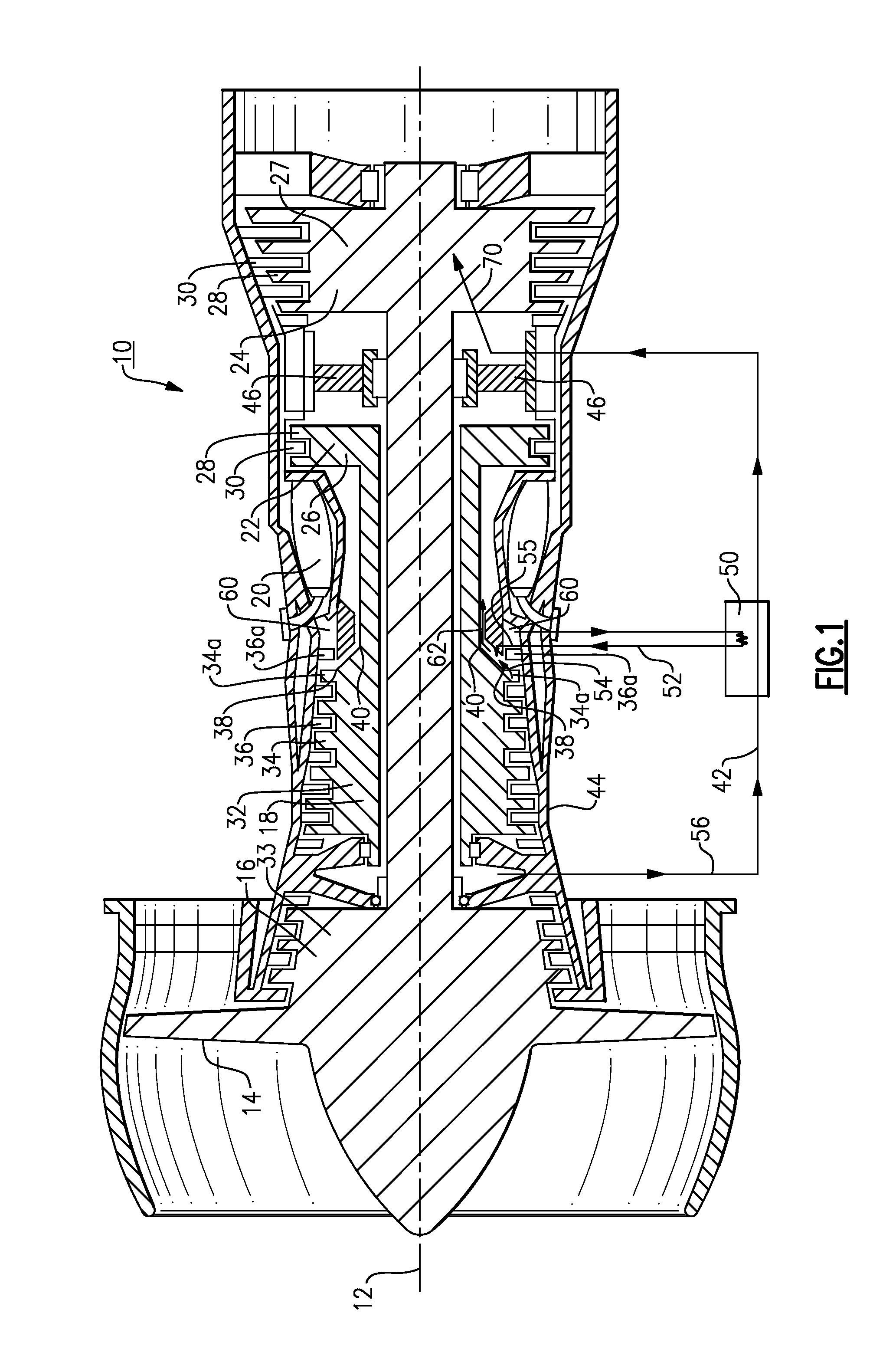

Gas turbine engine temperature modulated cooling flow

ActiveUS20110088405A1Improved blade cooling controlImprove efficiencyPump componentsTurbine/propulsion engine coolingPlate heat exchangerTurbine blade

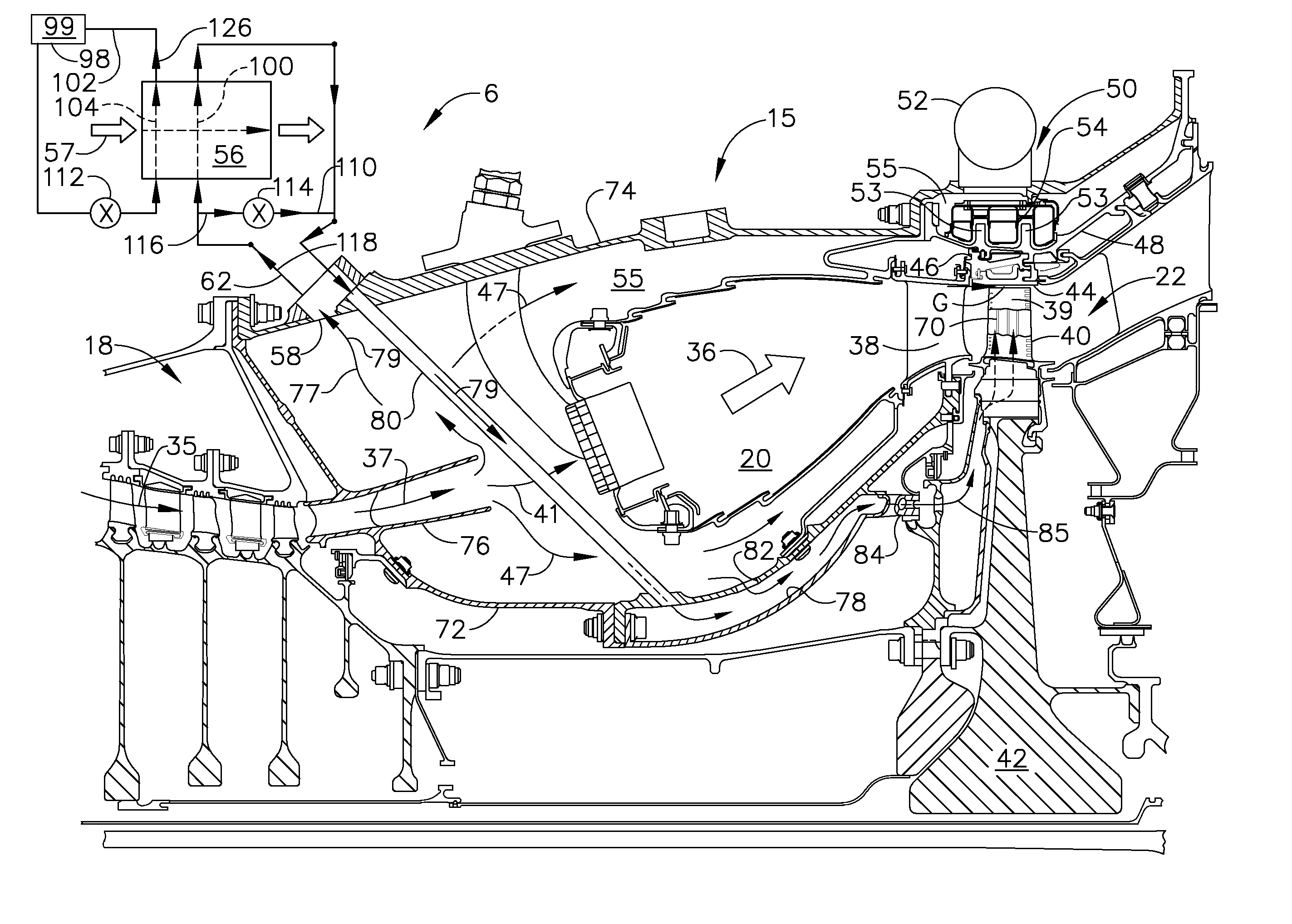

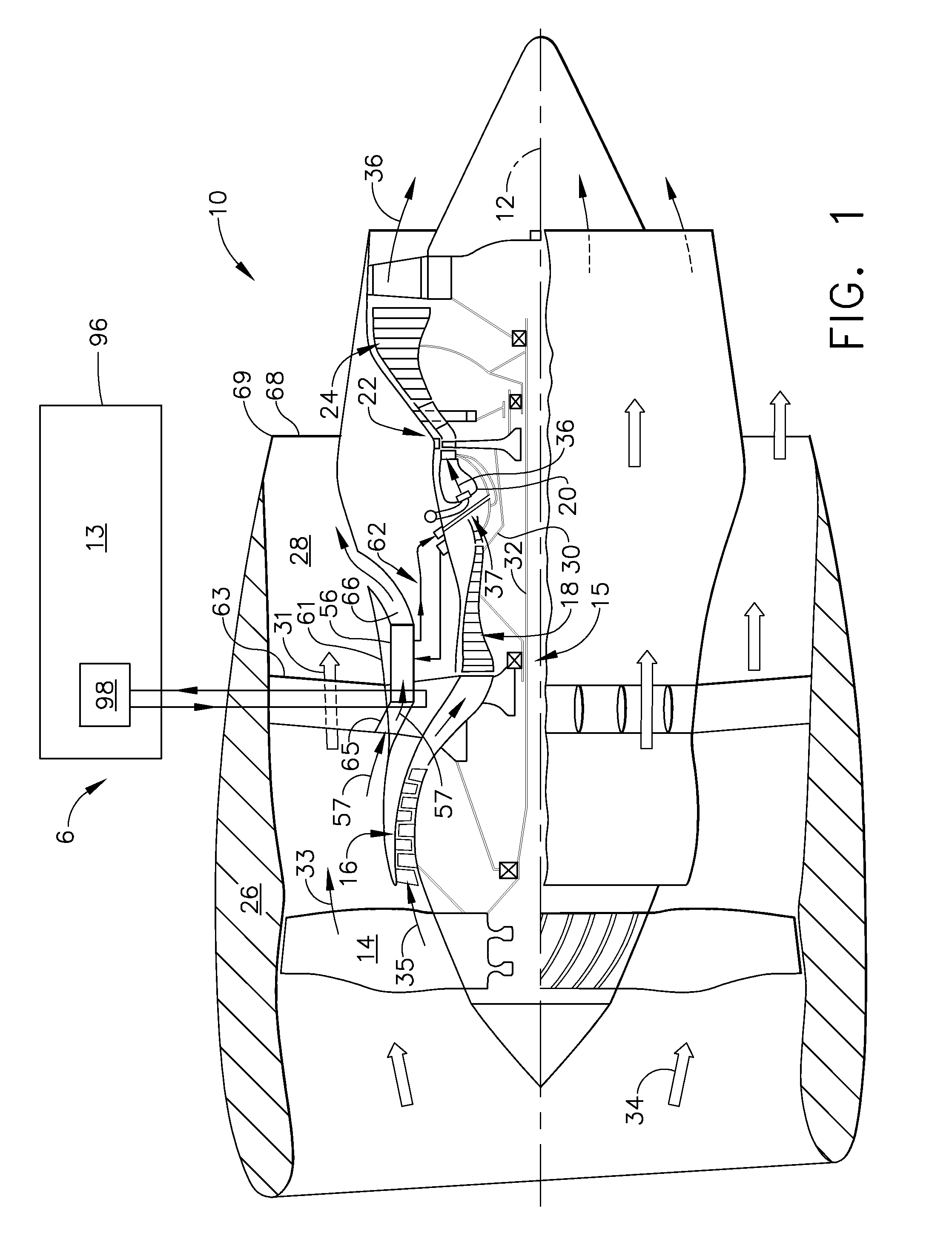

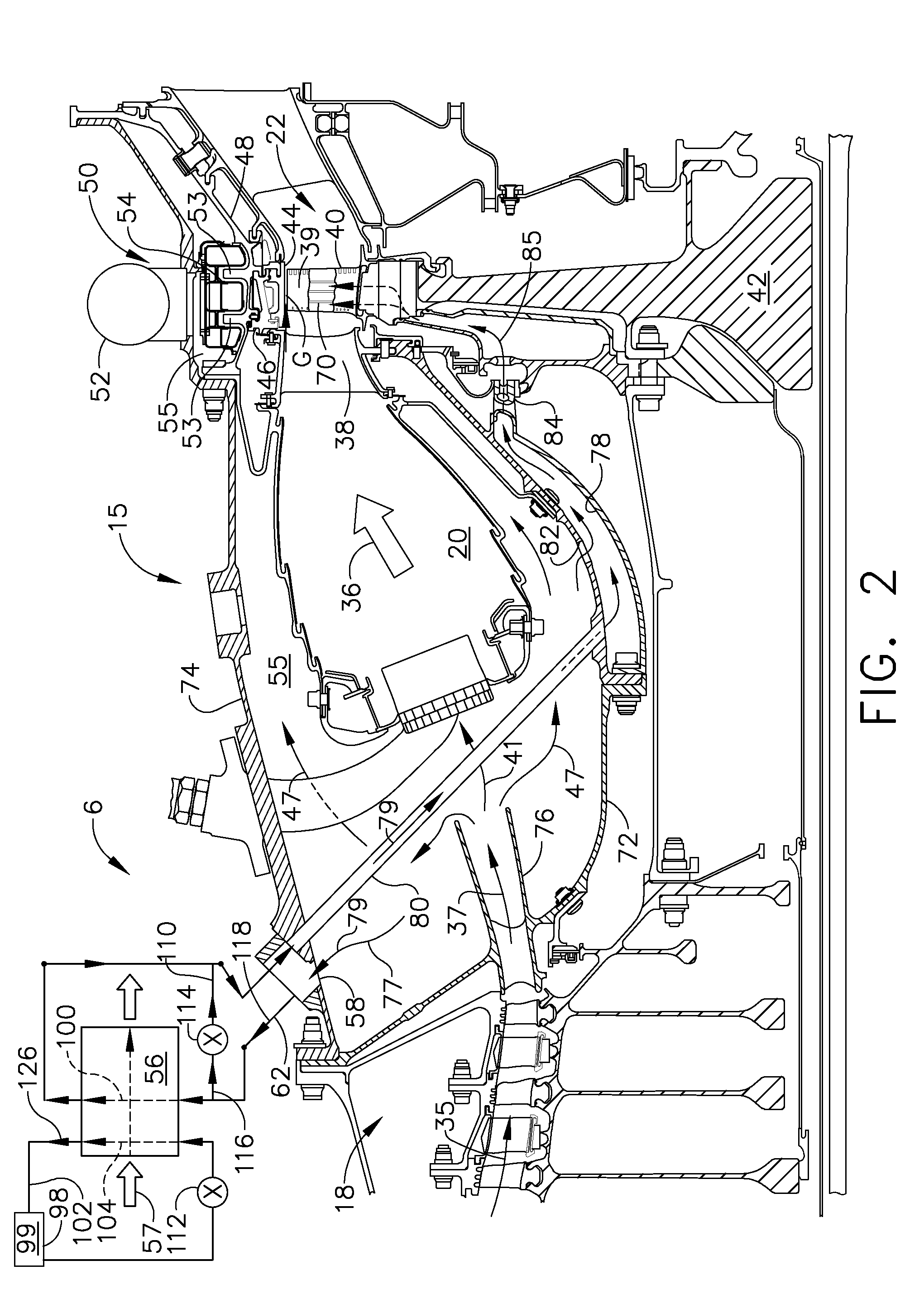

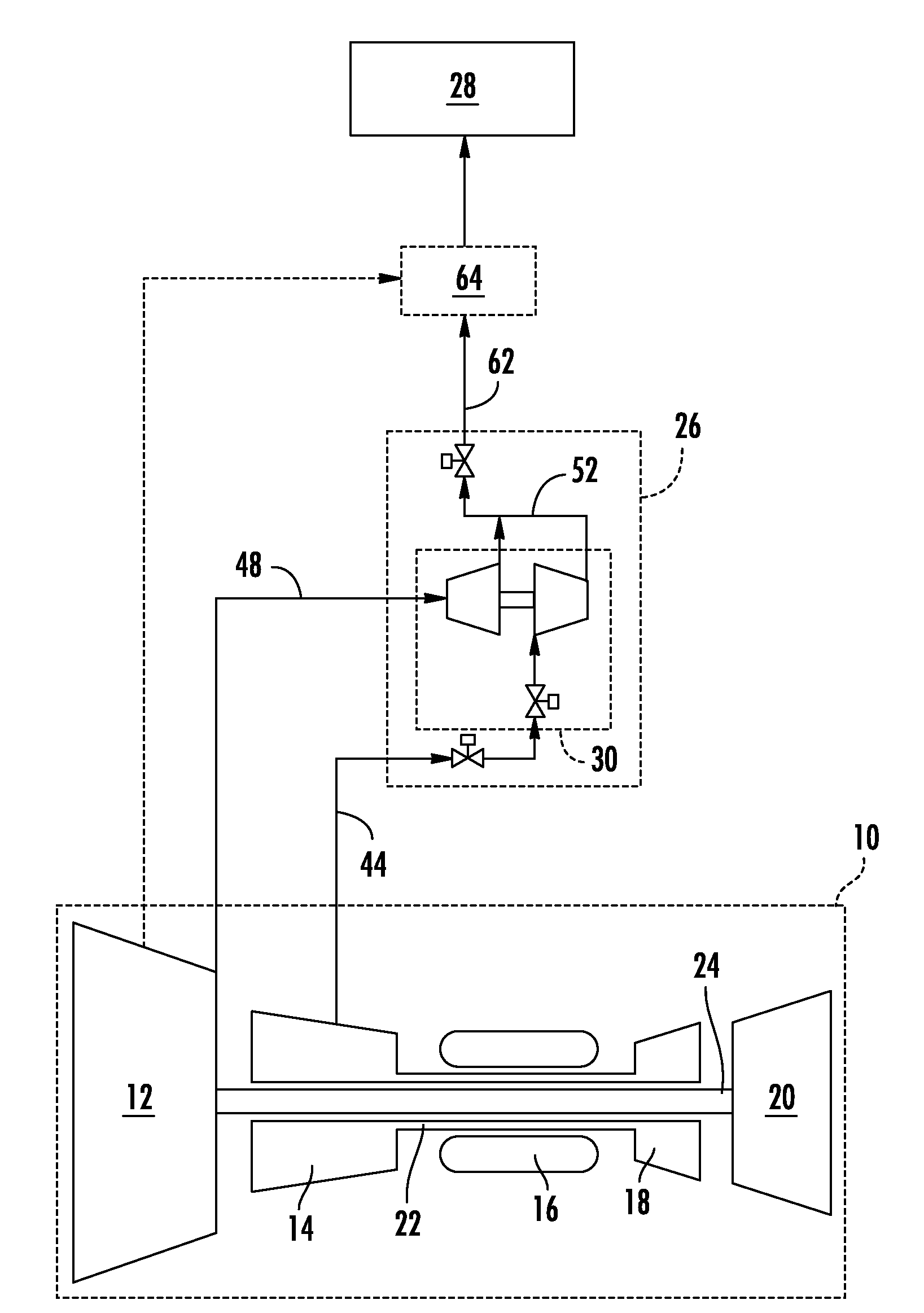

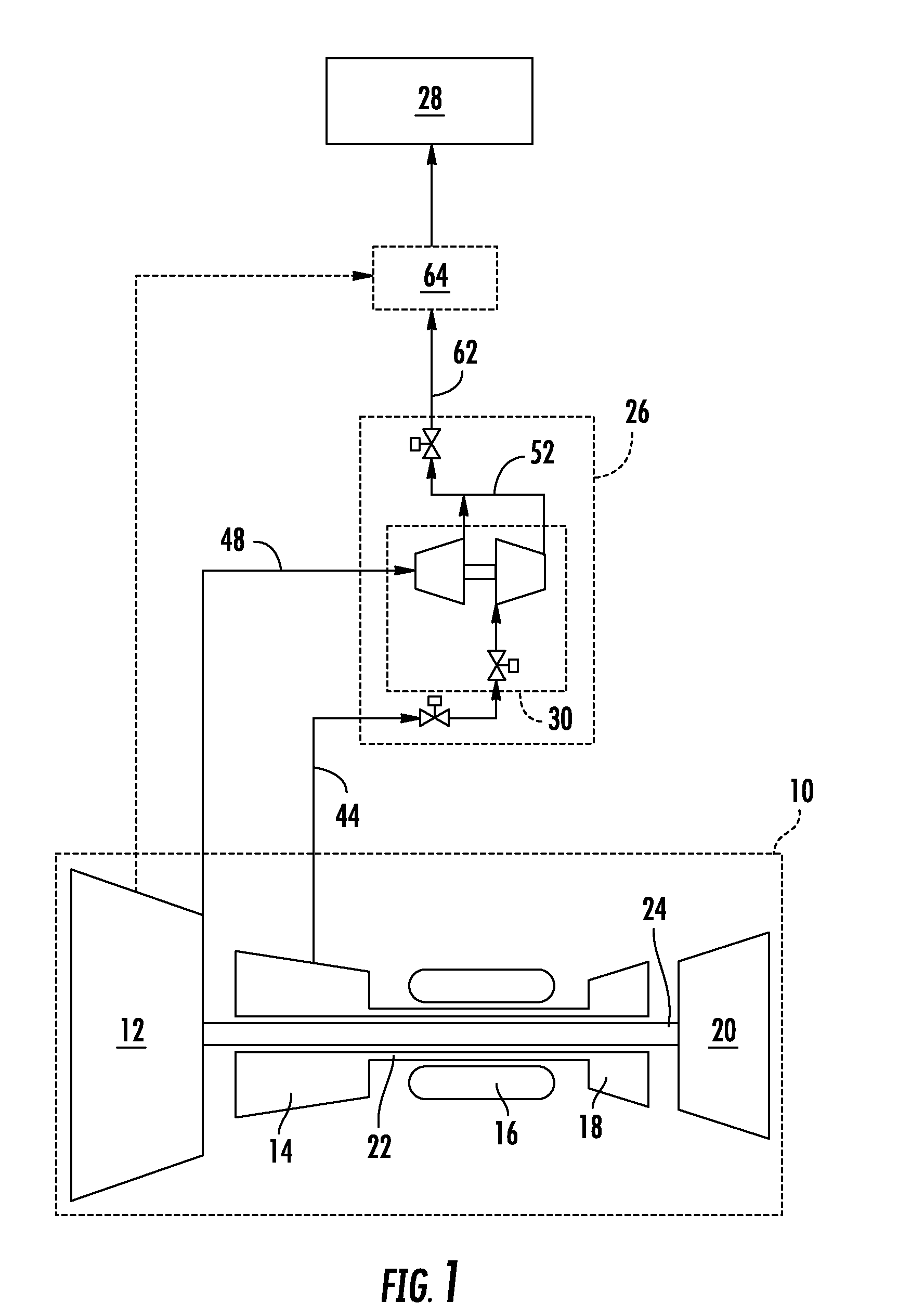

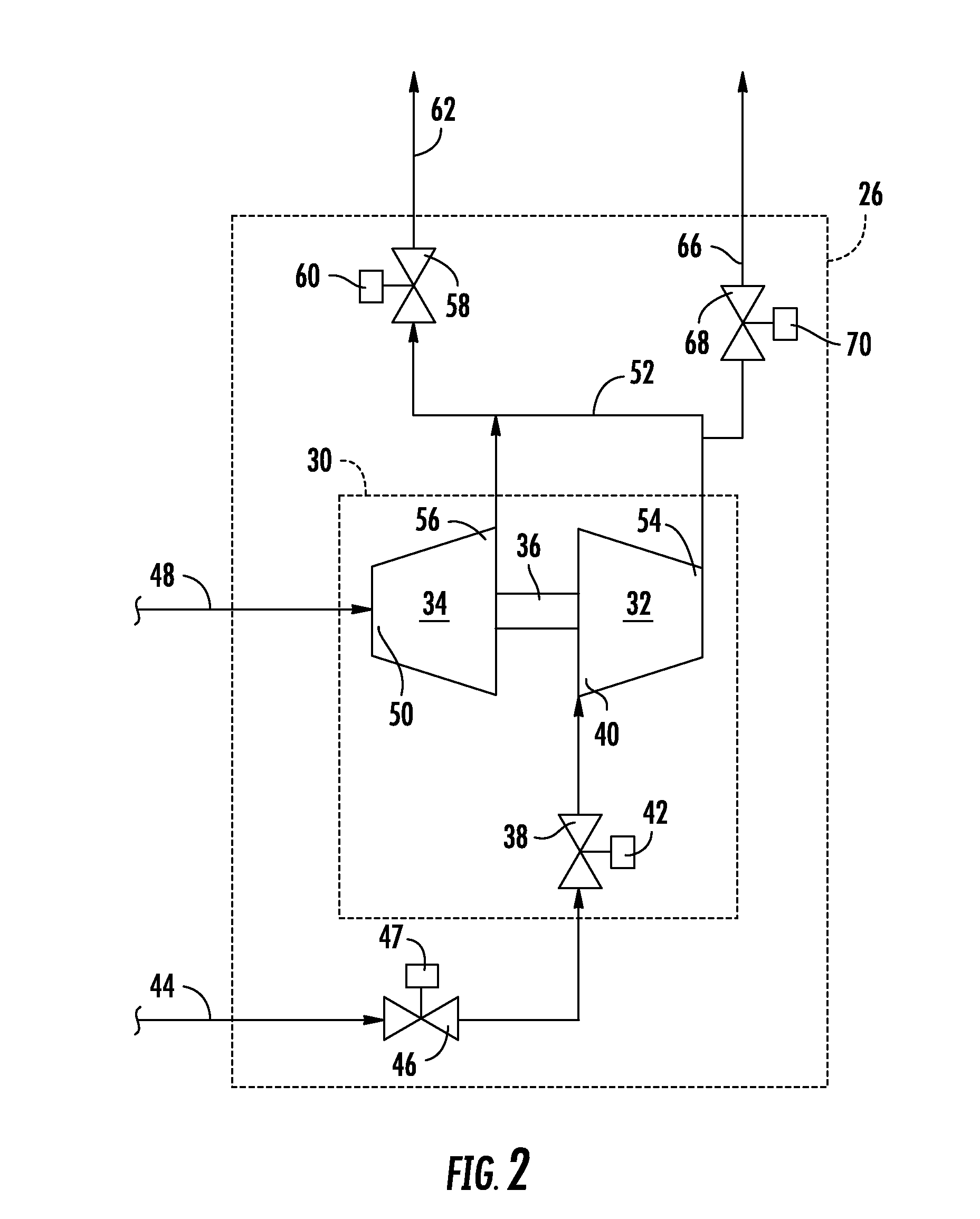

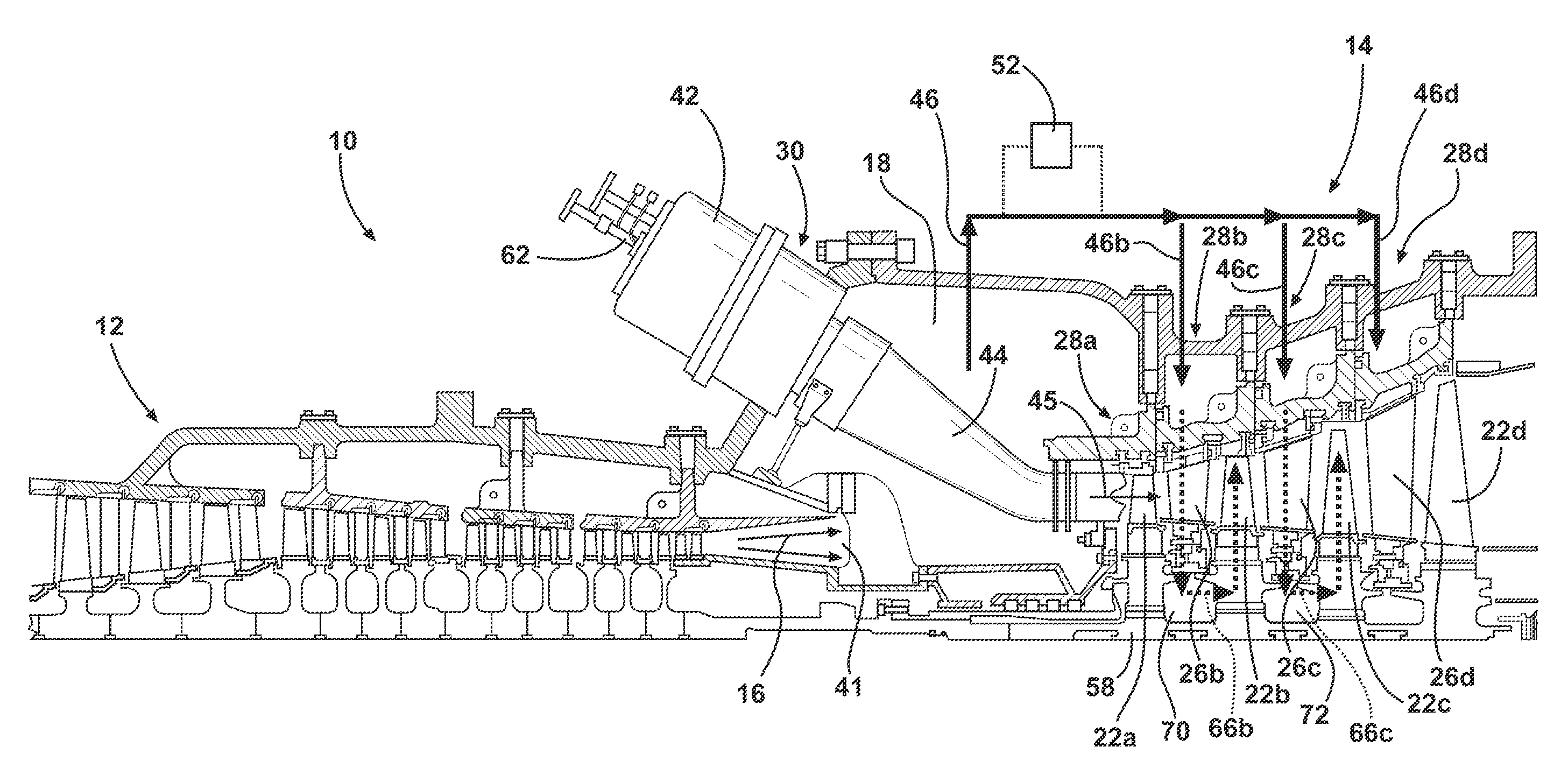

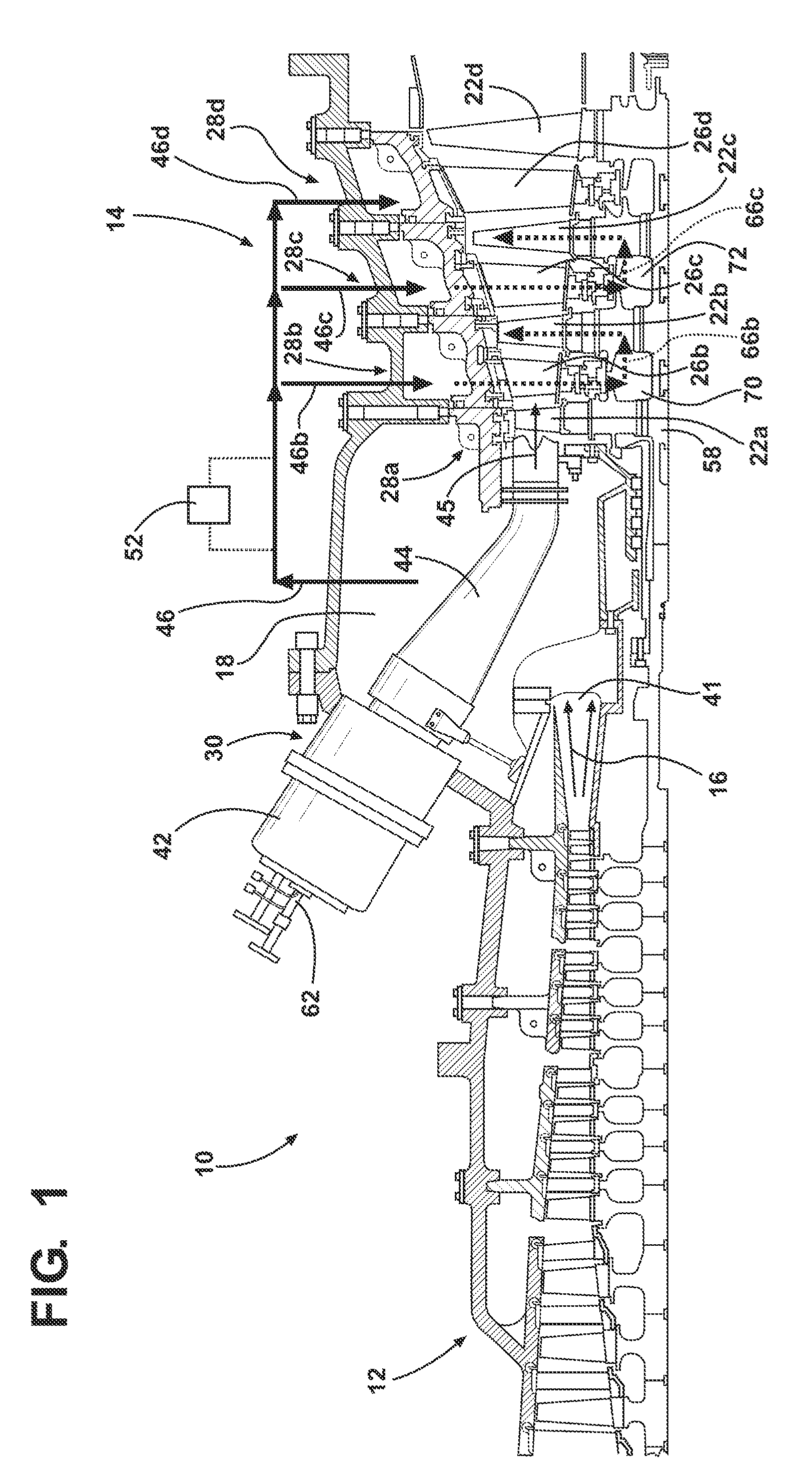

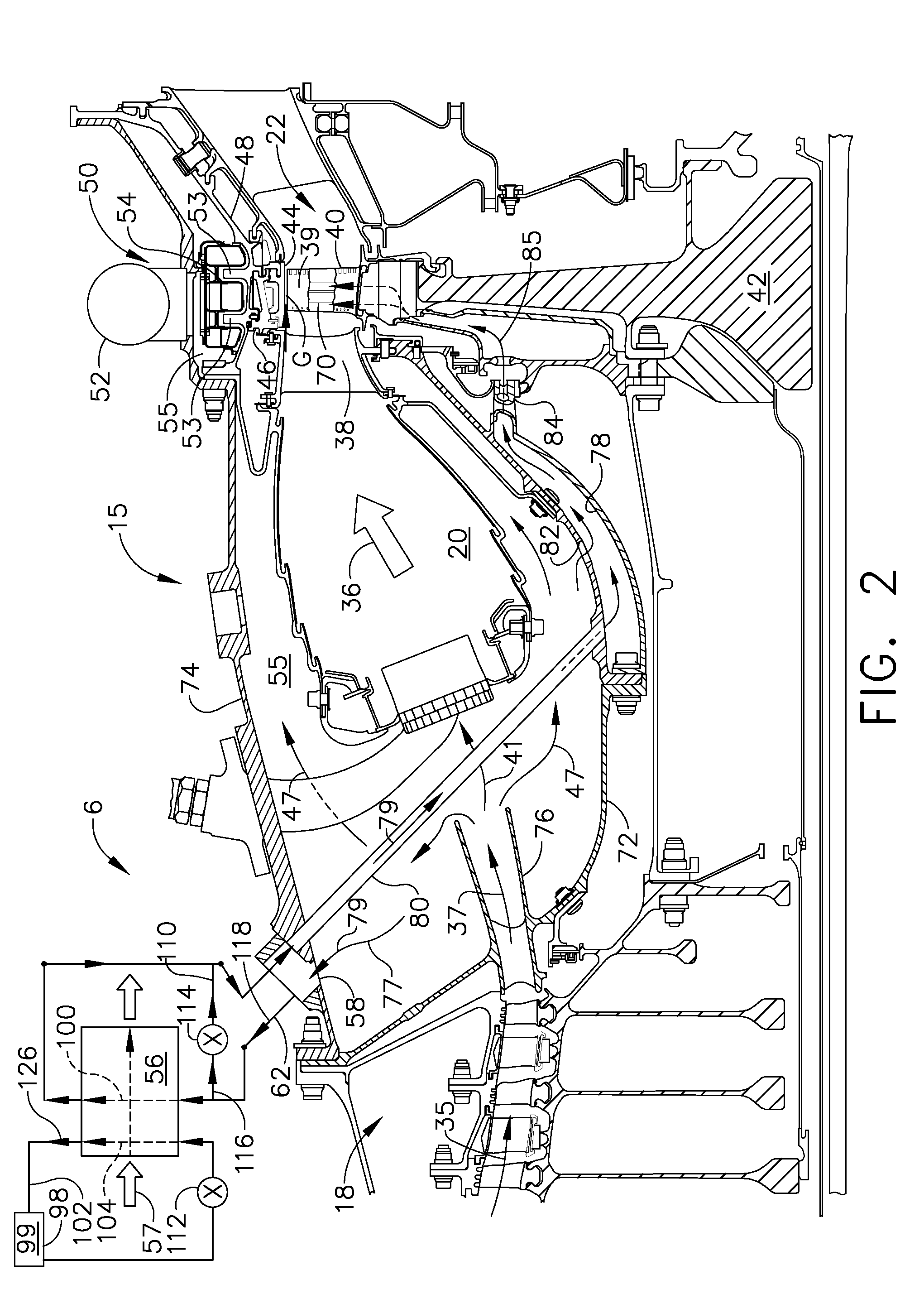

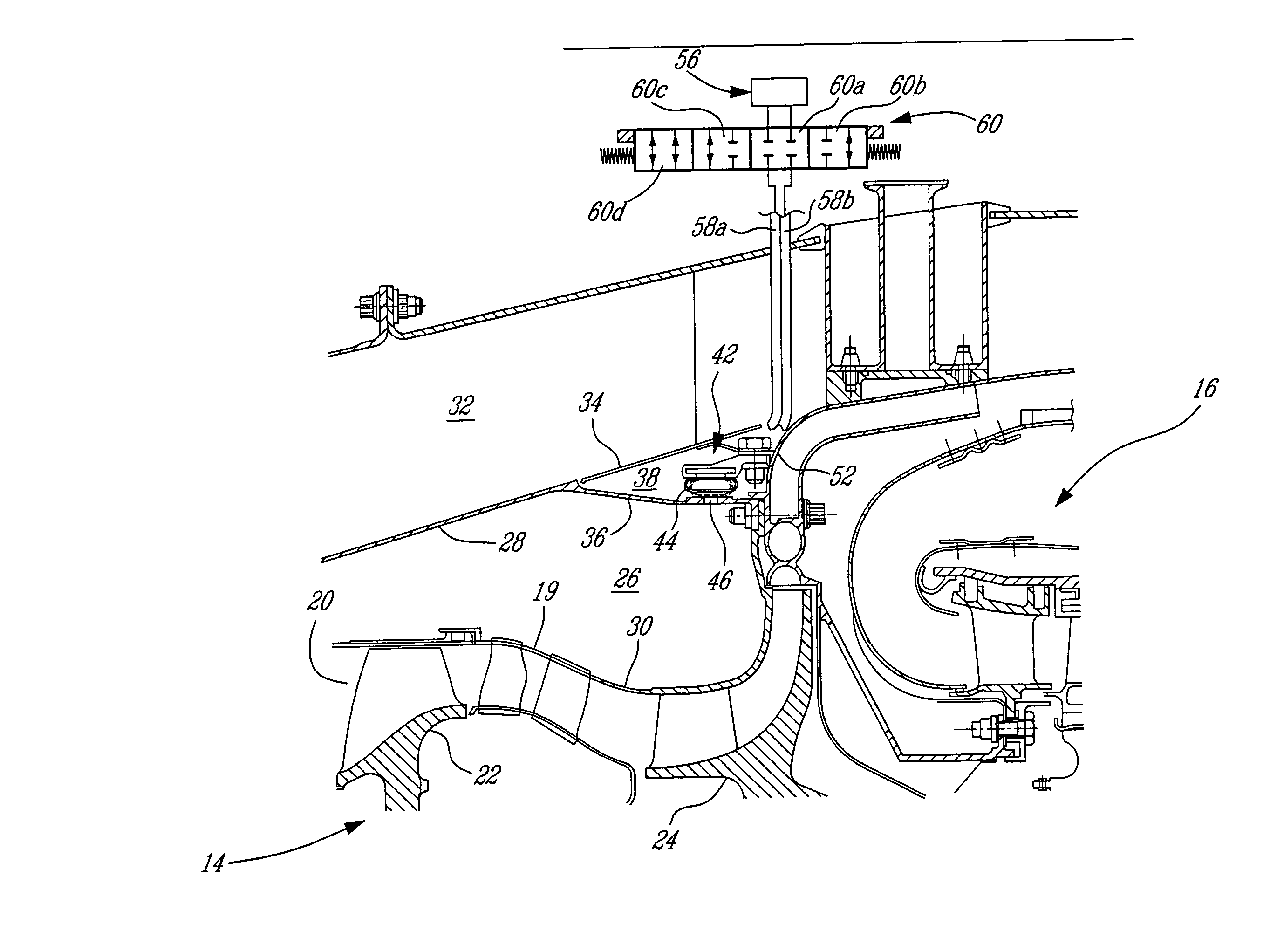

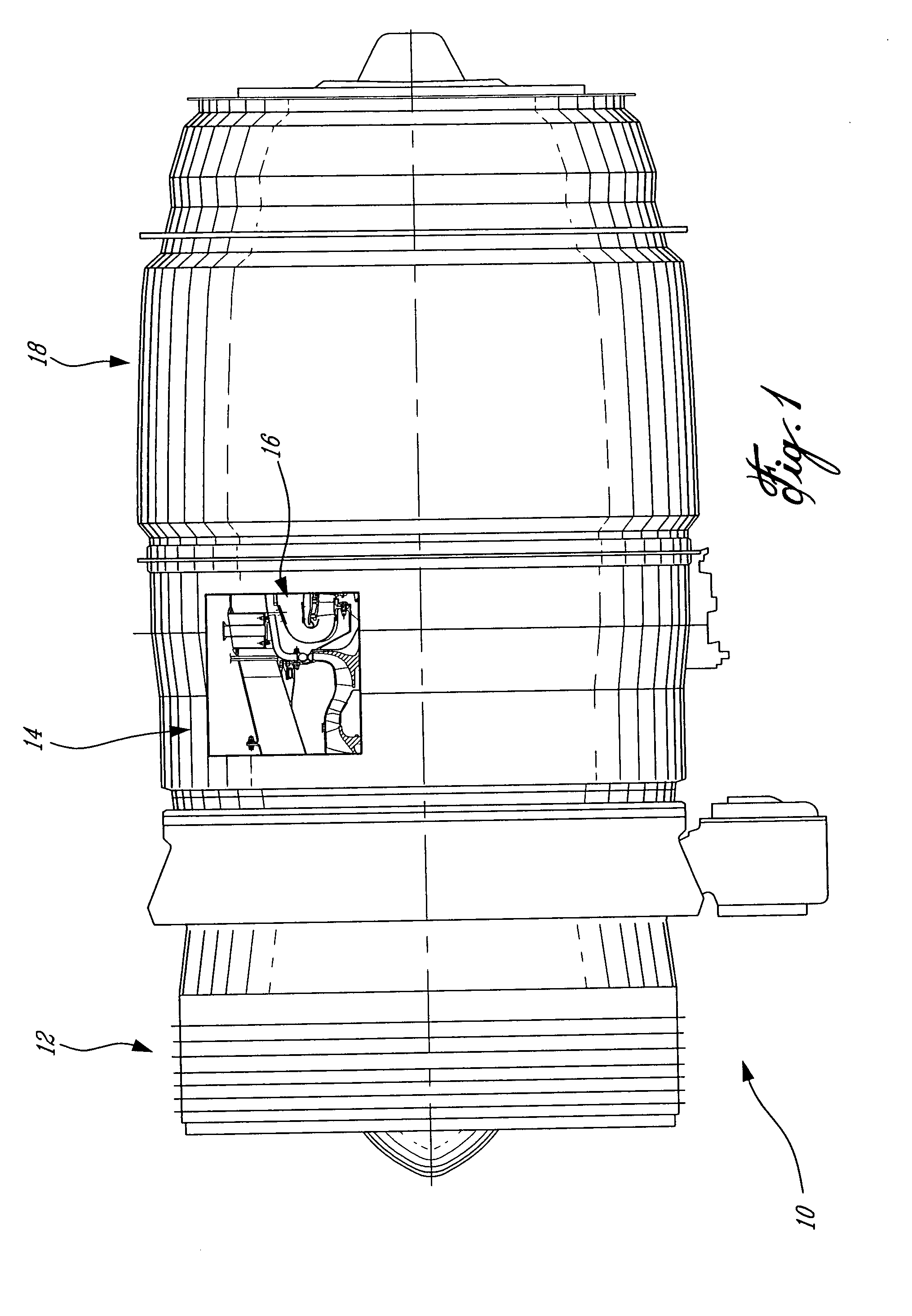

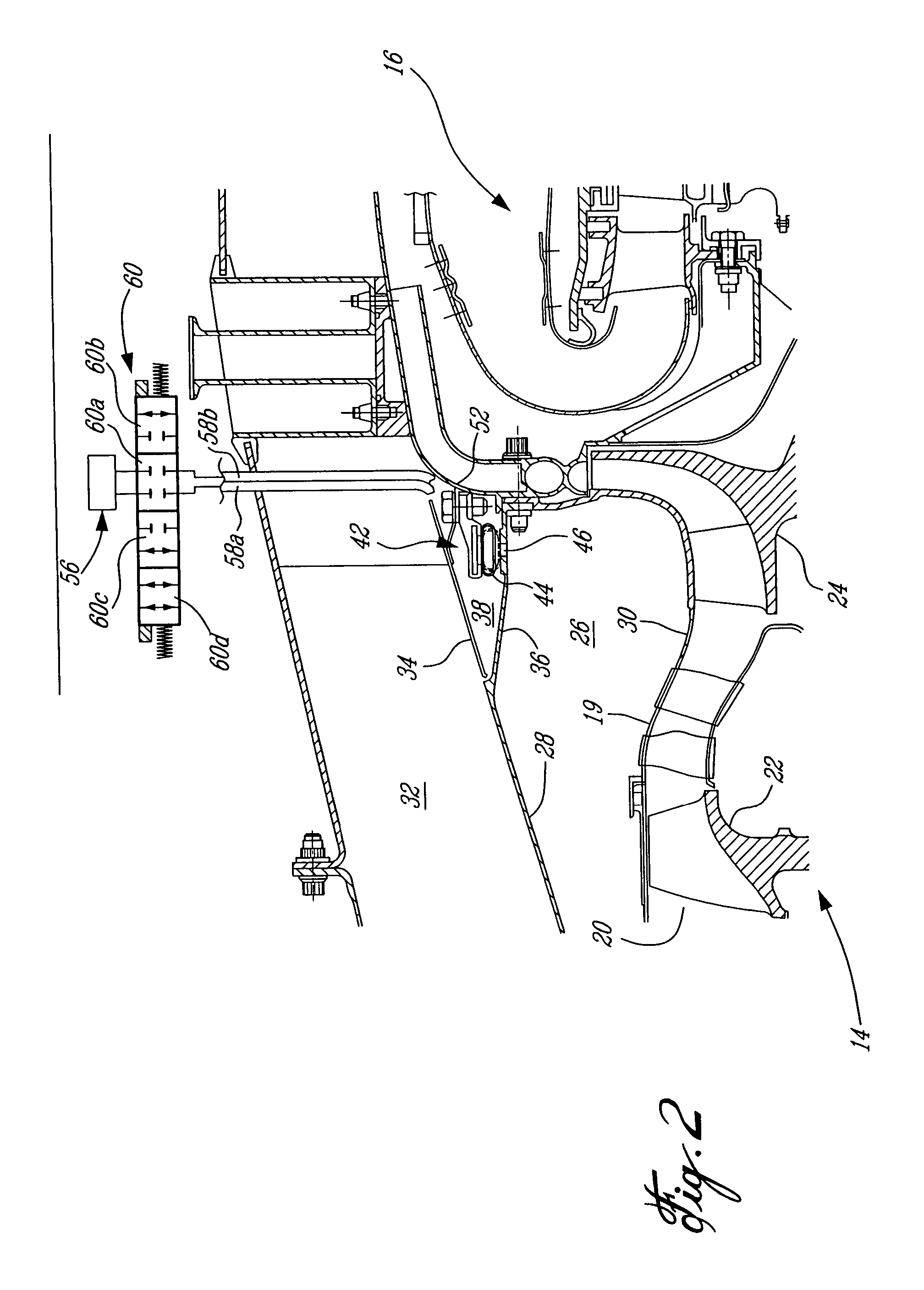

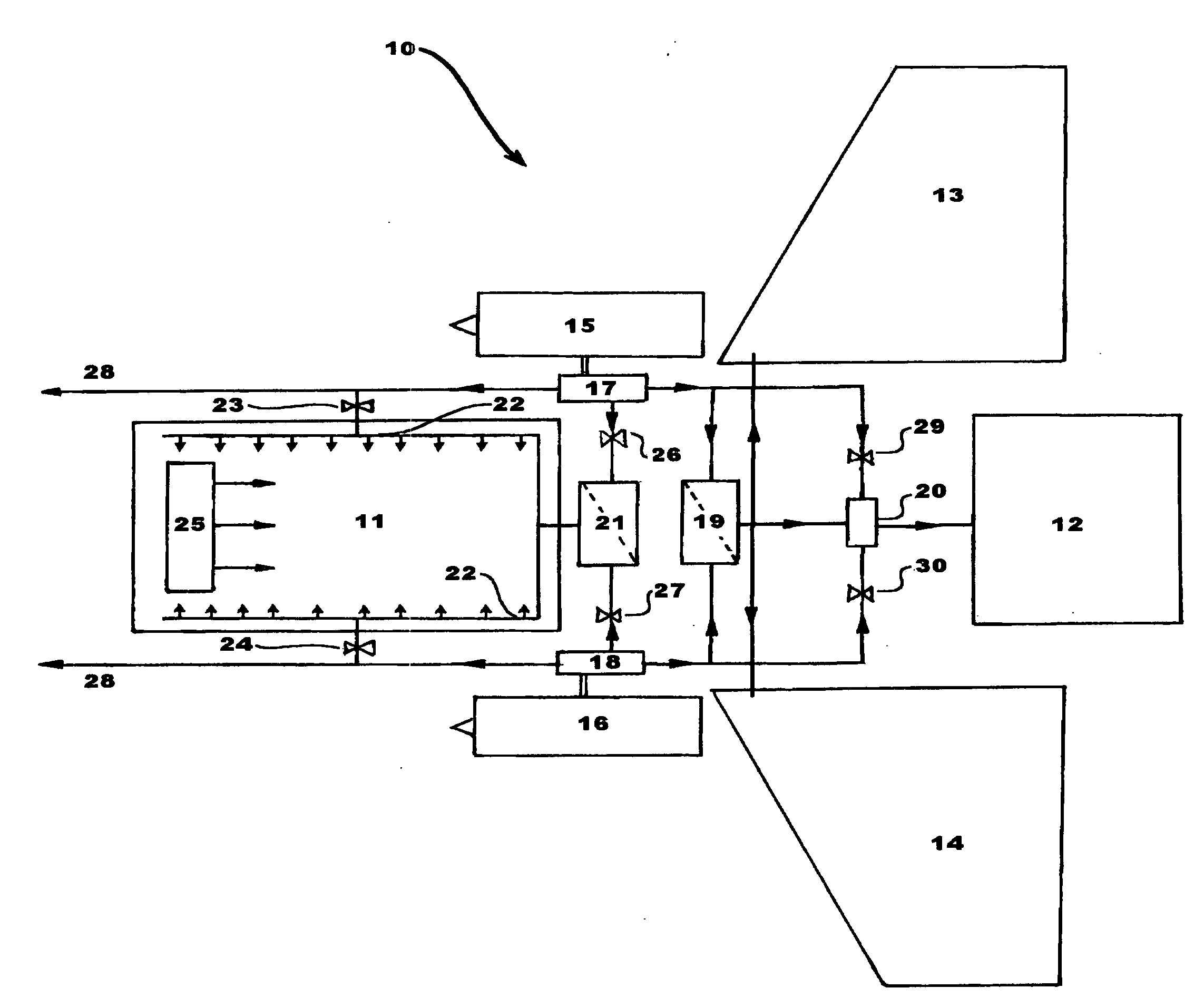

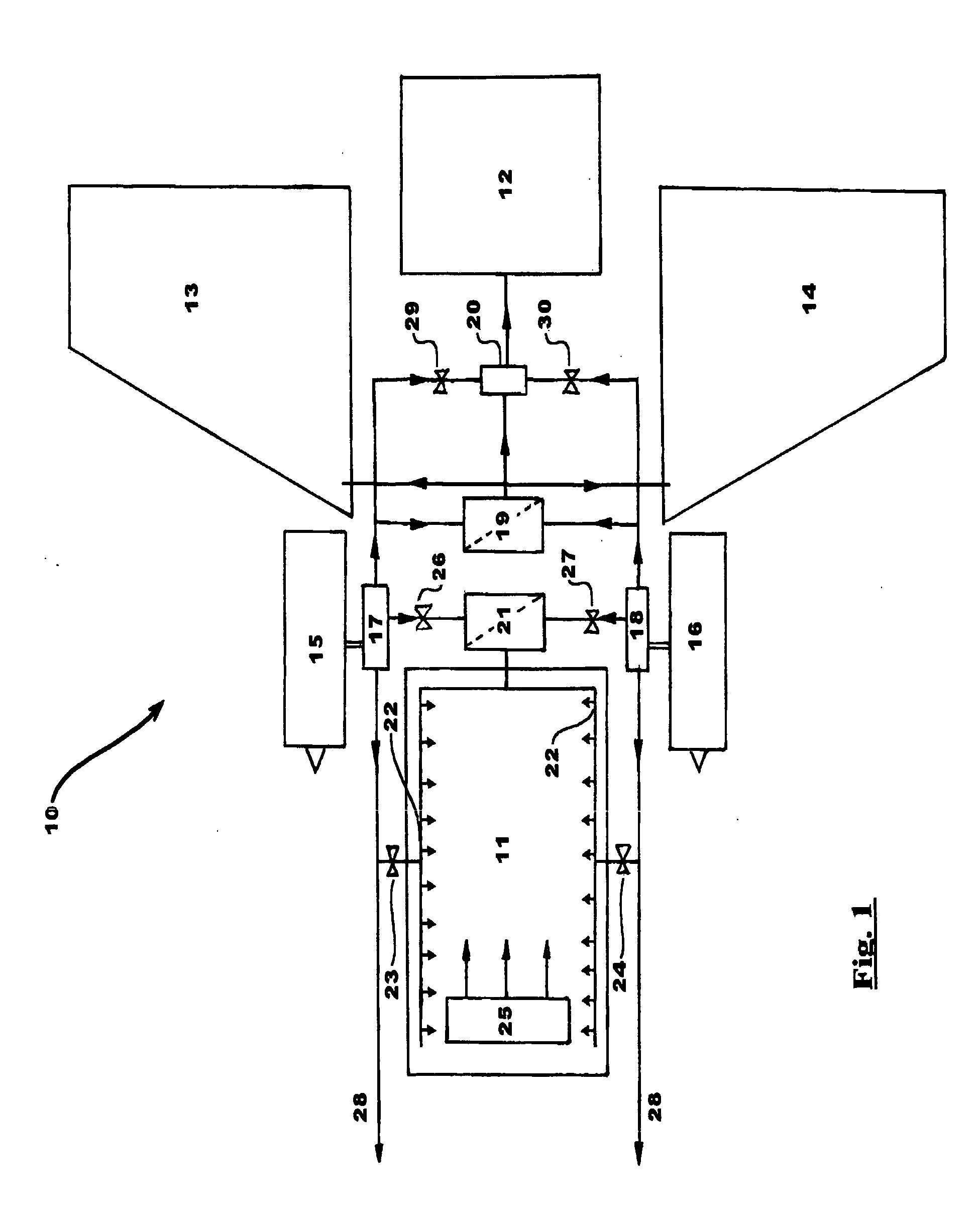

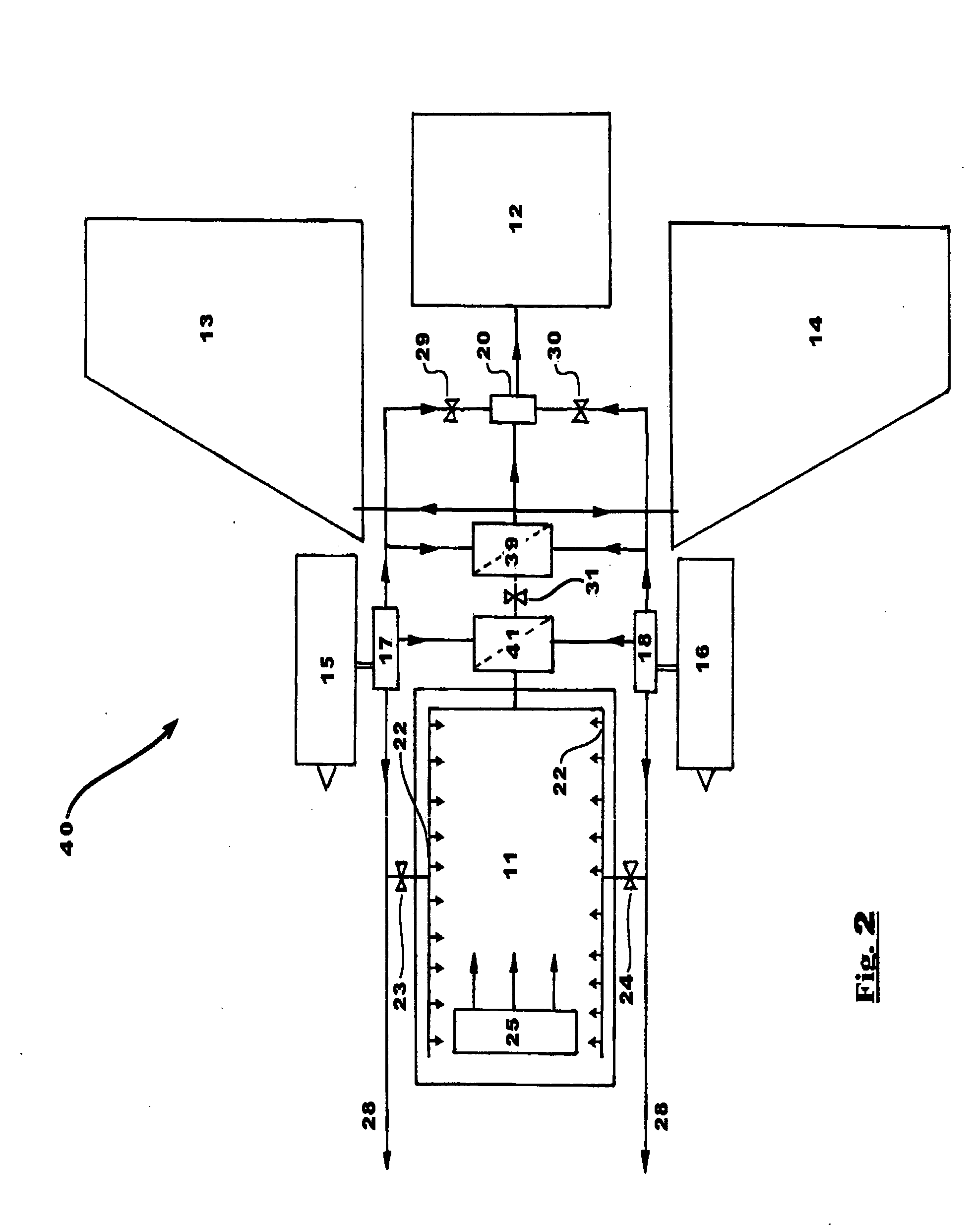

A gas turbine engine cooling system includes a heat exchanger in fluid communication with a source of cooling air, a first cooling circuit including a first heat exchanger circuit in the heat exchanger and a first bypass circuit with a first bypass valve for selectively bypassing at least a portion of first airflow around the first heat exchanger circuit. A second cooling circuit may be used having a second heat exchanger circuit in the heat exchanger and a shutoff control valve operably disposed in the second cooling circuit upstream of the second heat exchanger circuit and the heat exchanger. A circuit inlet of the first cooling circuit may be used to bleed a portion of compressor discharge bleed air for the first airflow to cool turbine blades mounted on a rotor disk using an annular flow inducer downstream of the first bypass valve and the heat exchanger.

Owner:GENERAL ELECTRIC CO

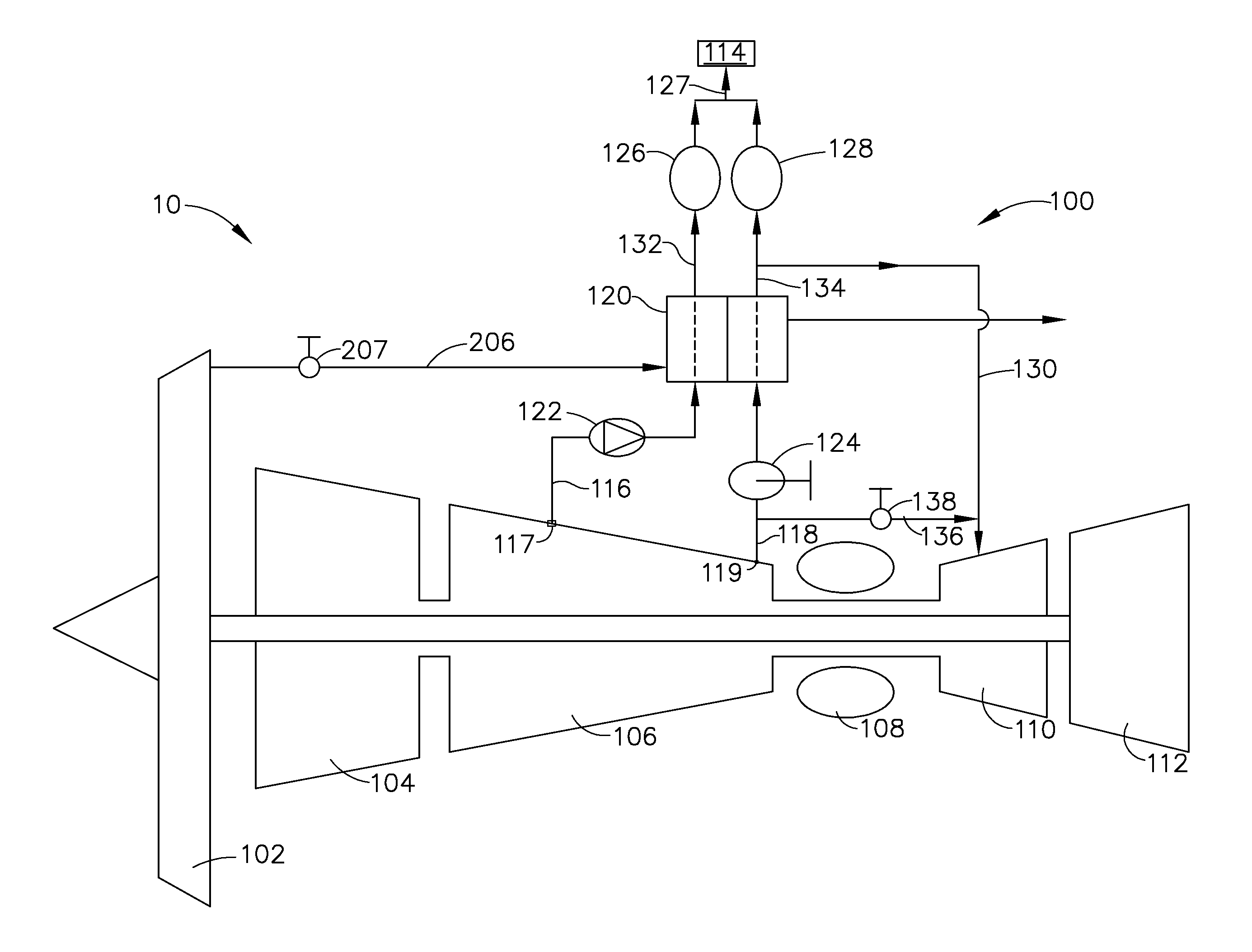

Turbine integrated bleed system and method for a gas turbine engine

InactiveUS20100107594A1Minimizing throttling inefficienciesEfficient extractionEfficient propulsion technologiesGas turbine plantsEngineeringBleed air

A bleed system for a gas turbine engine includes: (a) a bleed air turbine having a turbine inlet adapted to be coupled to a source of compressor bleed air at a first pressure; (b) a bleed air compressor mechanically coupled to the bleed air turbine, and having a compressor inlet adapted to be coupled to a source of fan discharge air at a second pressure substantially lower than the first pressure; and (c) a mixing duct coupled to a turbine exit of the bleed air turbine and to a compressor exit of the bleed air compressor.

Owner:GENERAL ELECTRIC CO

Cooling of Turbine Components Using Combustor Shell Air

InactiveUS20100175387A1Continuous combustion chamberTurbine/propulsion engine coolingCombustion chamberCombustor

A turbine engine assembly for a generator including a turbine engine having a compressor section, a combustor section and a turbine section. An air bleed line is in communication with the combustor section for receiving combustor shell air from the combustor section and conveying the combustor shell air as bleed air to a plurality of stages of the turbine section. Bleed air is controlled to flow through the air bleed line when an operating load of the turbine engine assembly is less than a base load of the engine to bypass air exiting the compressor section around a combustor in the combustor section and effect a flow of high pressure combustor shell air to the stages of the turbine section.

Owner:SIEMENS ENERGY INC

System for actively controlling compressor clearances

InactiveUS20060225430A1Reduce the temperatureMinimize radial expansionPump componentsEngine fuctionsEngineeringBleed air

Aspects of the invention relate to a system and method for actively controlling compressor clearances in a turbine engine by passing a thermal fluid in heat exchanging relation through a compressor vane carrier. During some operational conditions, such as hot restart or spin cool, it may be desirable to heat the vane carrier to enlarge or at least prevent a decrease in compressor clearances. In such cases, a heated thermal fluid can be provided by reclaiming residual exhaust energy from a heat recovery steam generator. At any condition where improved performance is desired, such as at base load operation, the vane carrier can be cooled to minimize compressor clearances. A cooled thermal fluid can be bleed air from an upstream portion of the compressor, water-cooled high pressure bleed air from a downstream portion of the compressor, or feed water from the bottoming cycle in a combined cycle engine.

Owner:SIEMENS ENERGY INC

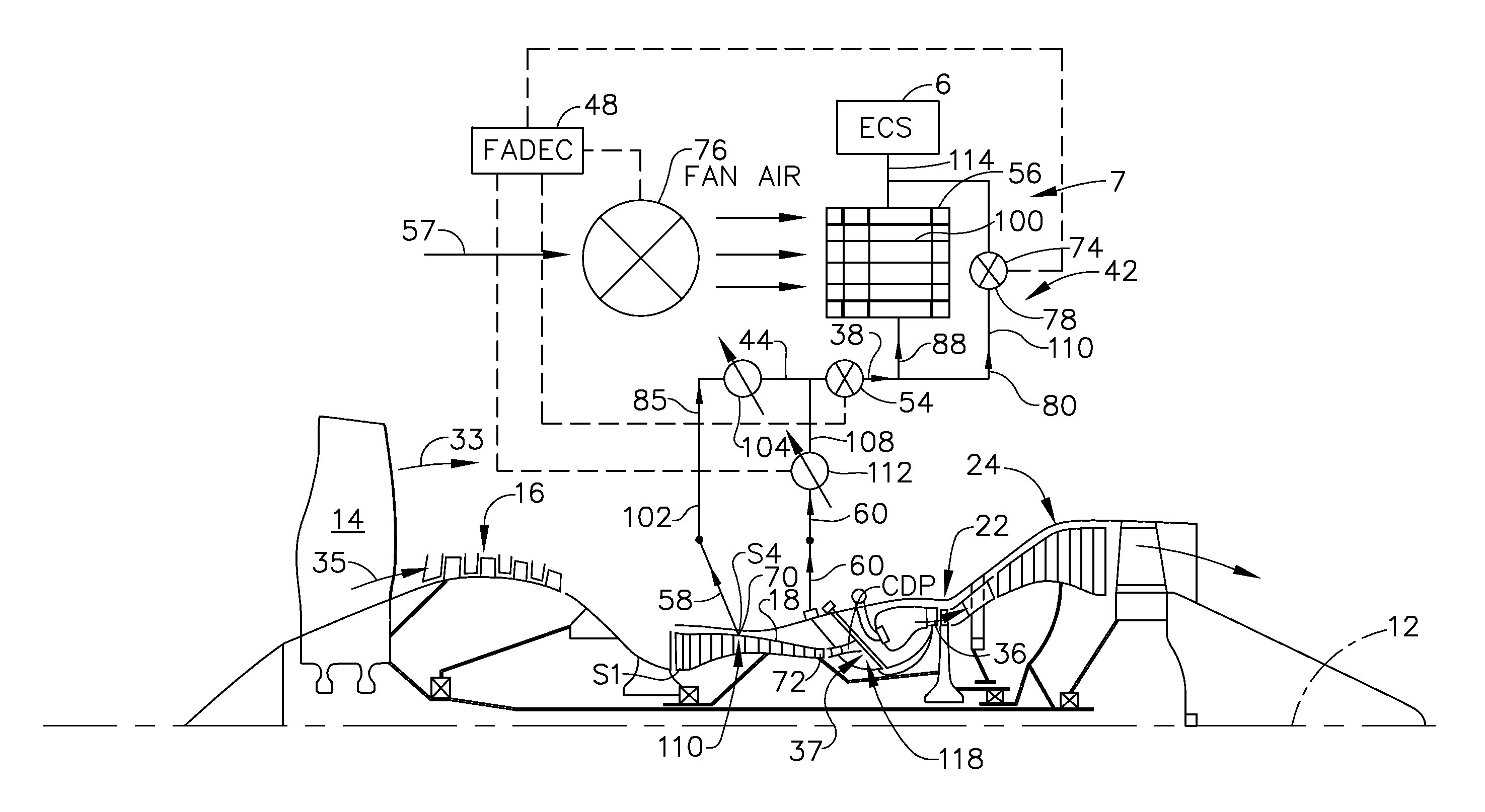

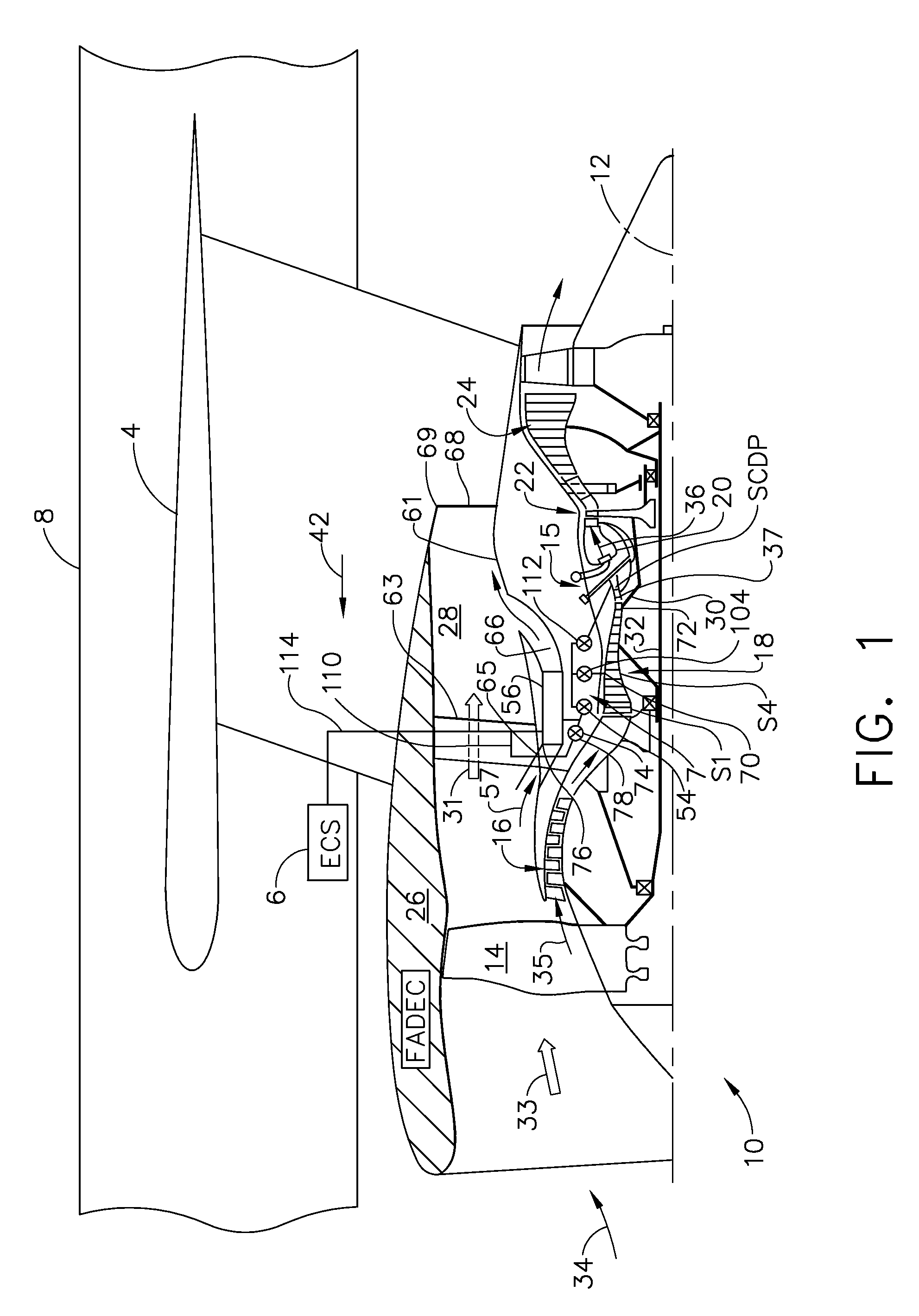

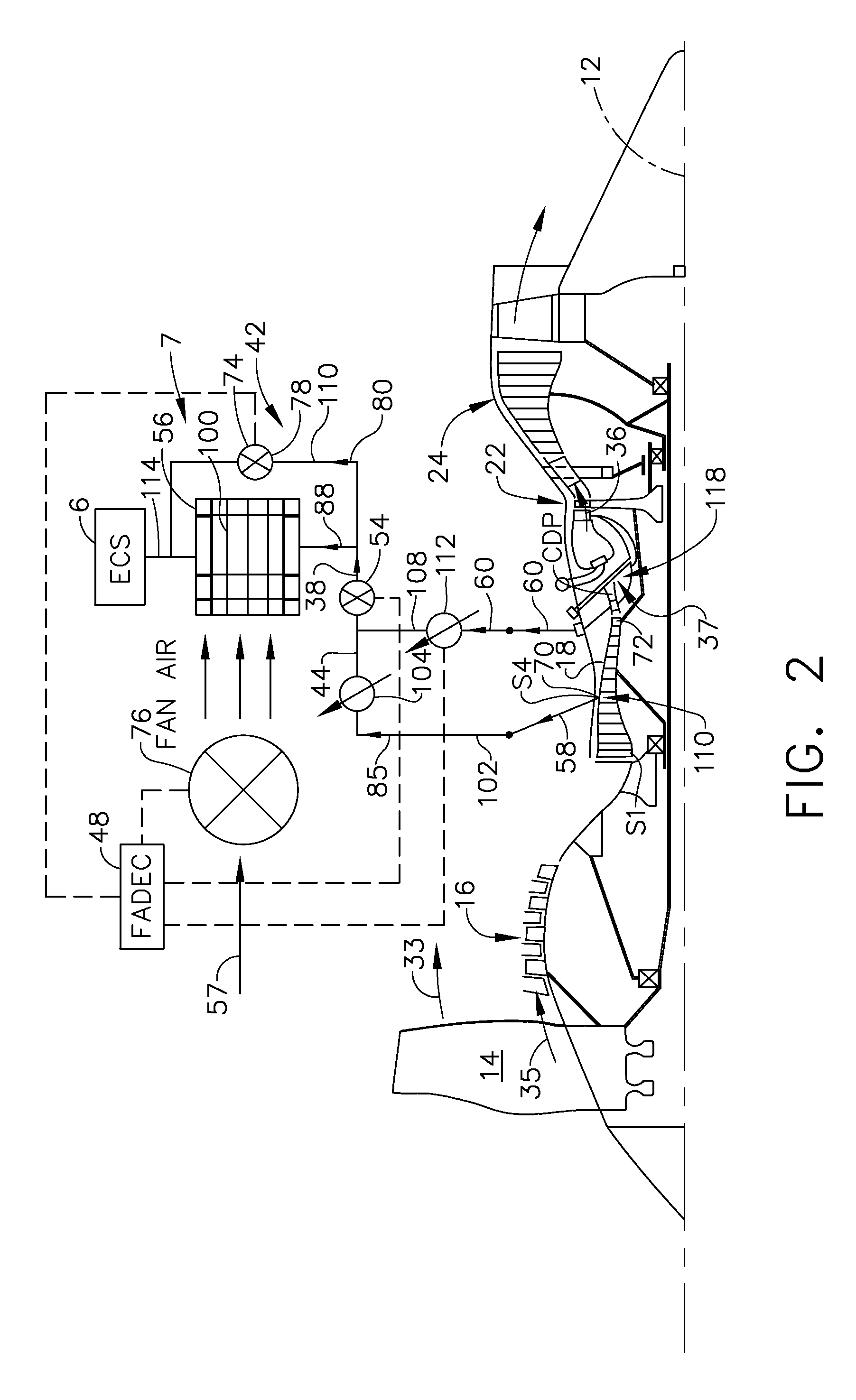

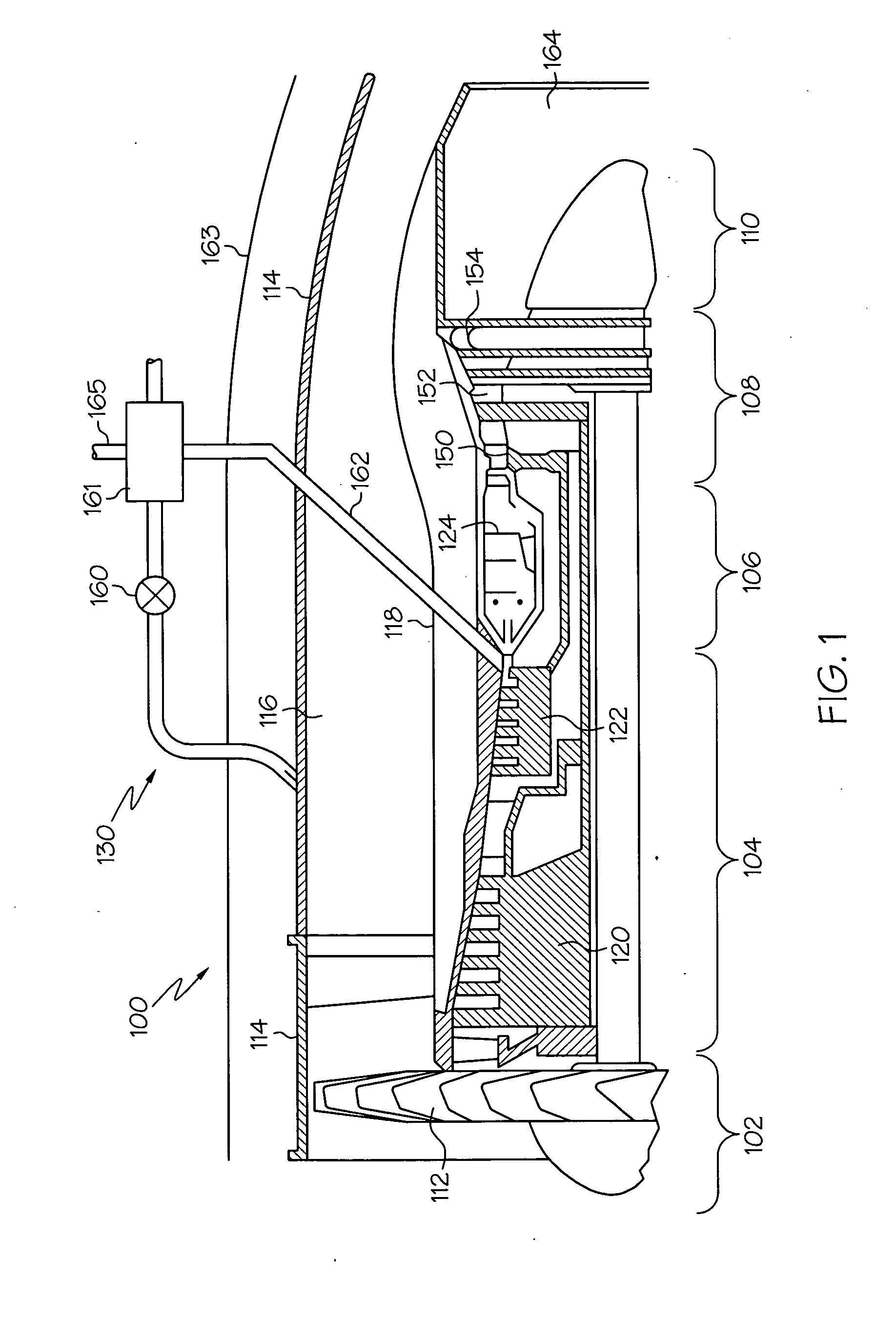

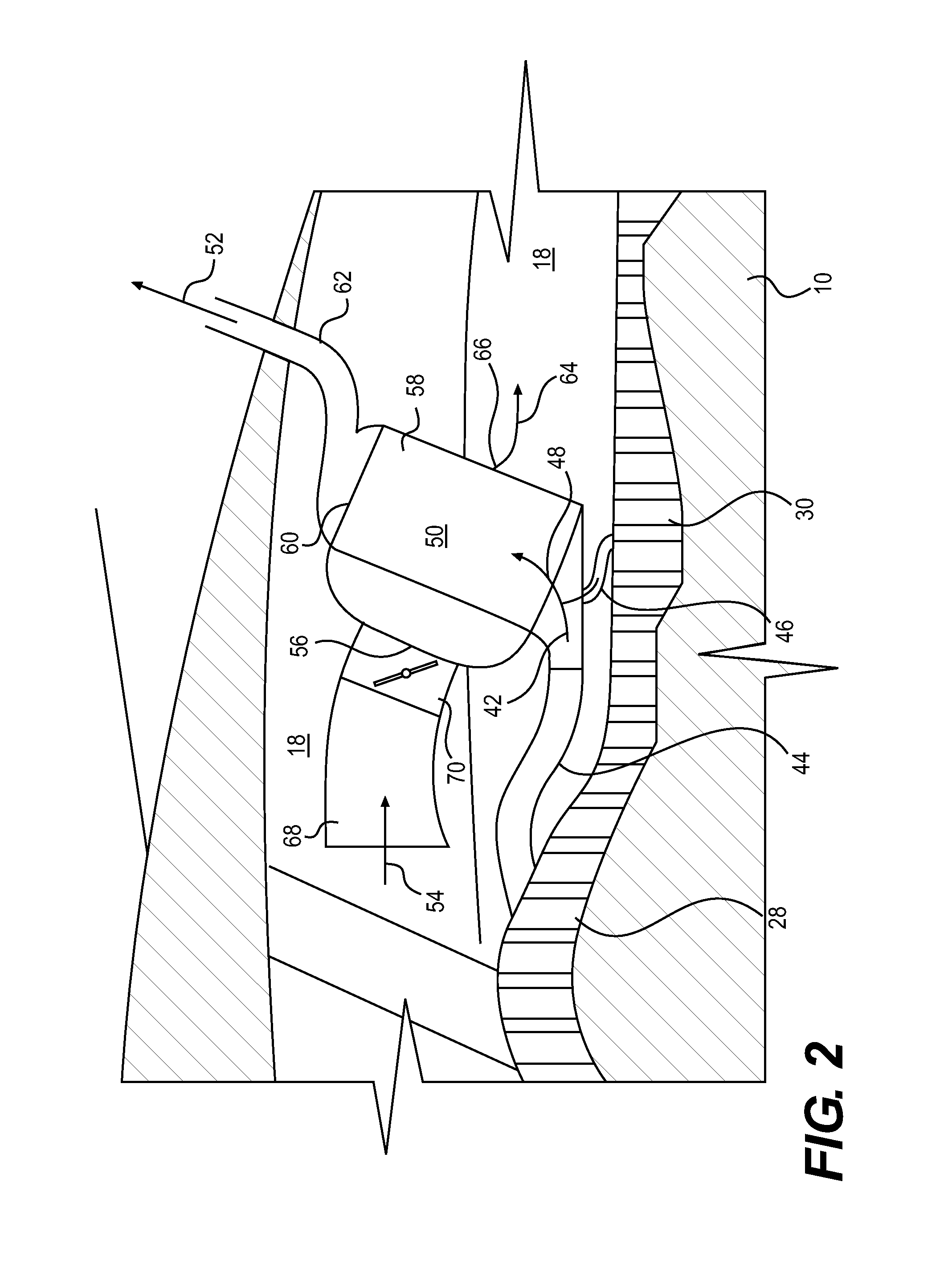

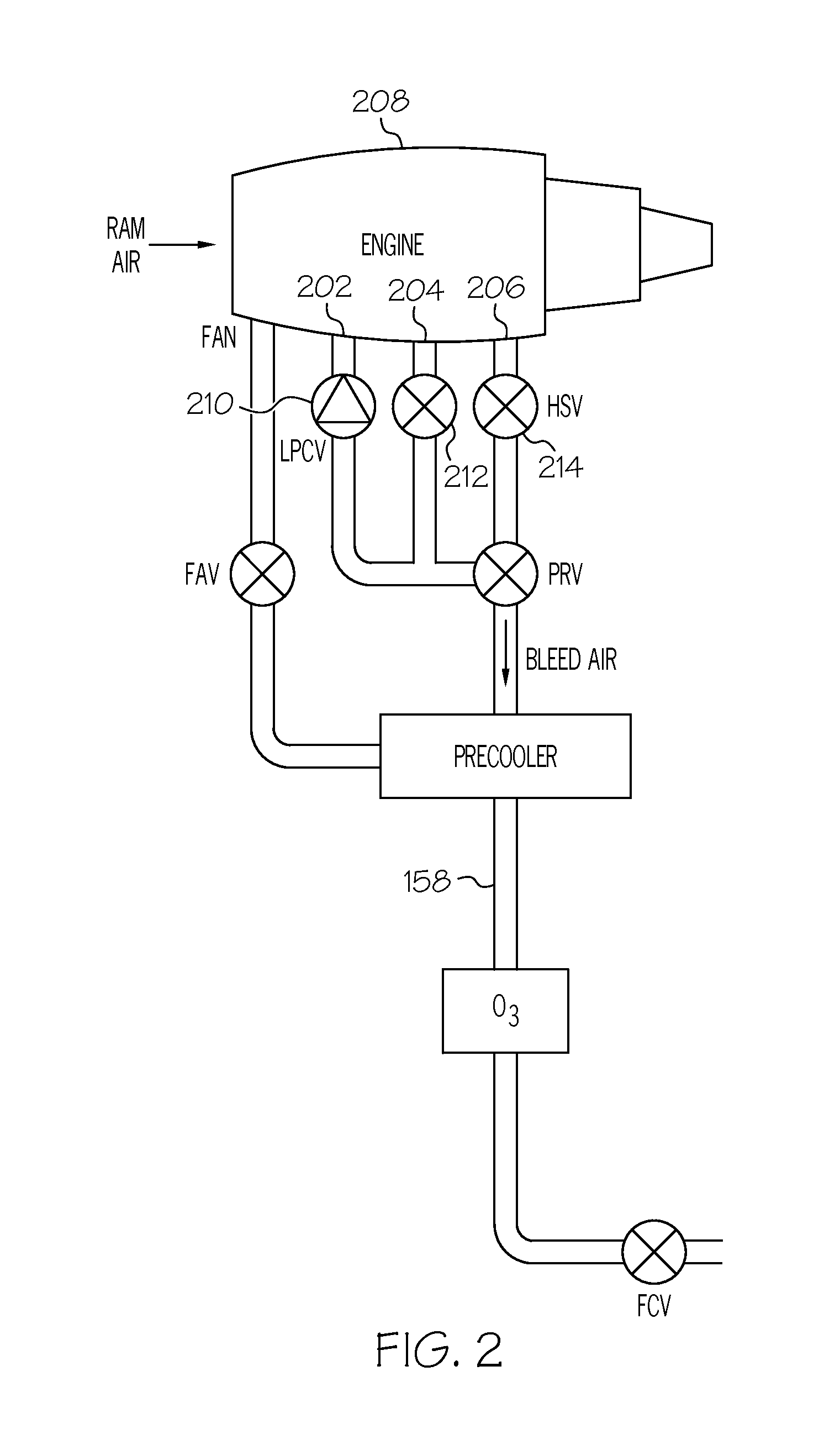

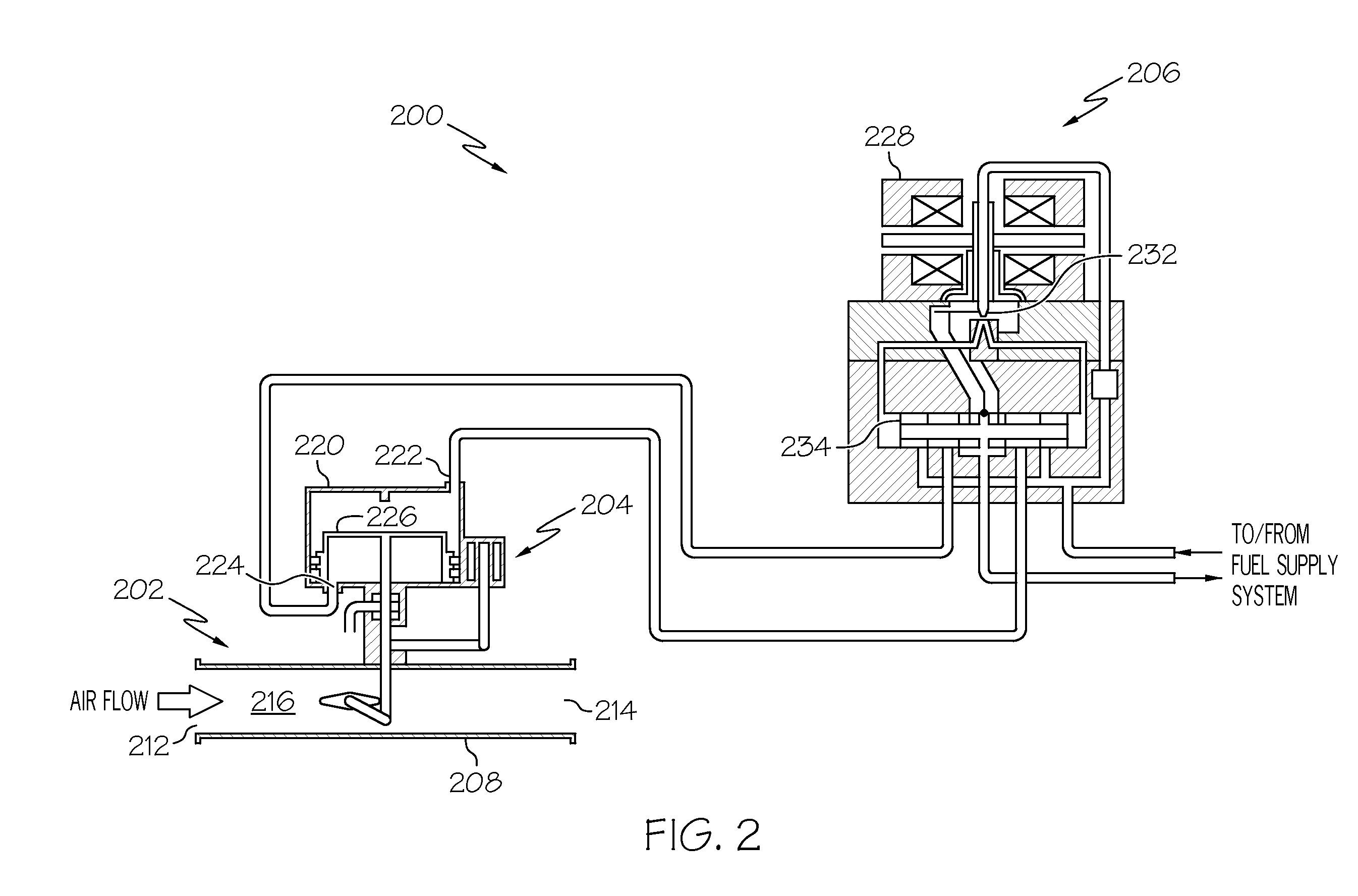

Environmental control system supply precooler bypass

ActiveUS8397487B2Air-treatment apparatus arrangementsEnergy efficient board measuresControl systemEnvironmental control system

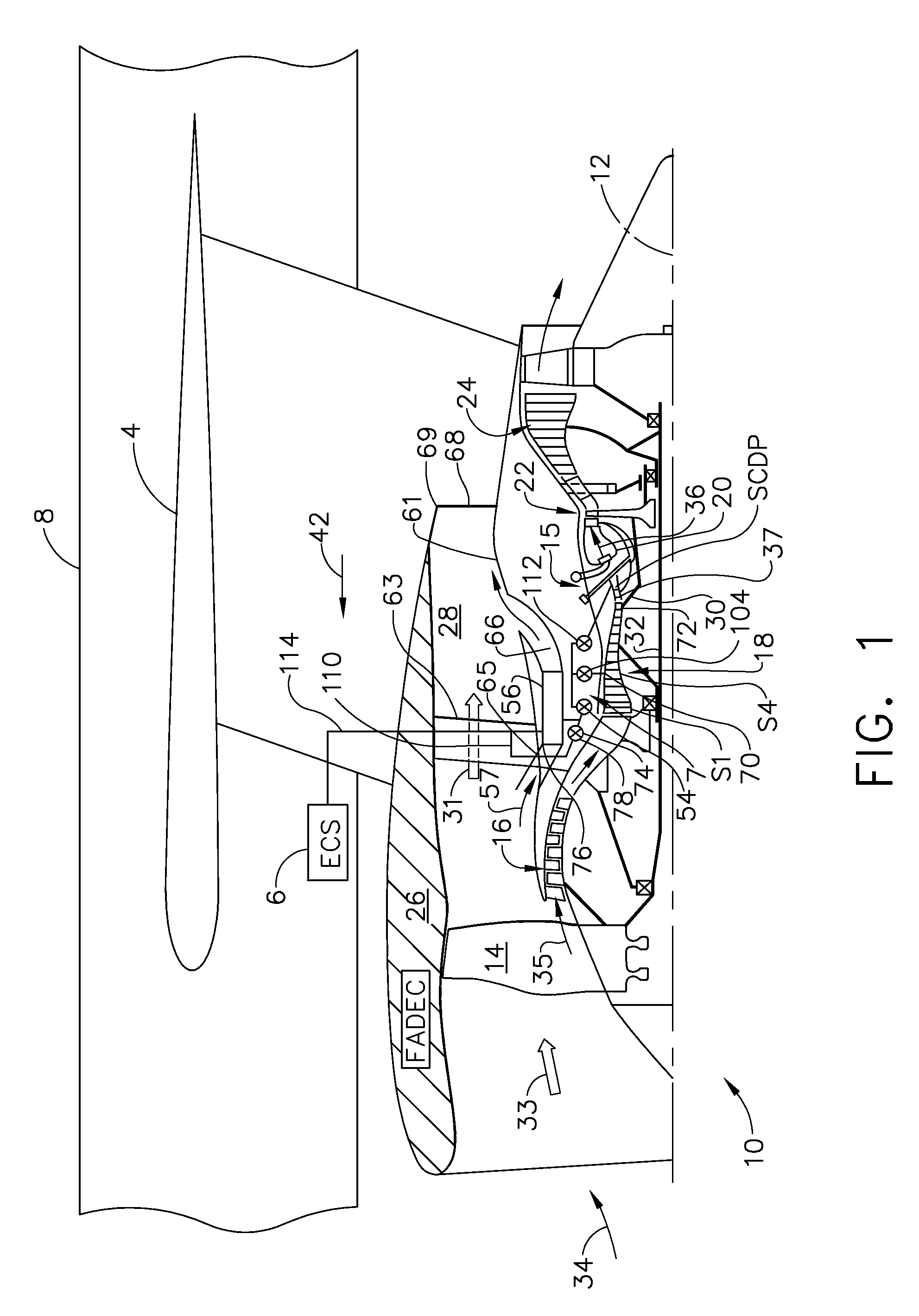

A precooler for cooling compressor bleed air for an environmental control system includes a heat exchanger in fluid communication with a source of cooling air and operable for cooling the bleed air. A variable bypass valve between a bleed air source and environmental control system is operable for bypassing at least a portion of the compressor bleed air around the heat exchanger. The cooling air may be a portion of fan air modulated by a variable fan air valve. The bleed air source may be selectable between the low pressure bleed air source and a high pressure bleed air source. One method includes flowing the compressor bleed air from a single low pressure source only and increasing thrust sufficiently to meet a minimum level of pressure of the bleed air during one engine out aircraft operating condition during approach or loitering.

Owner:GENERAL ELECTRIC CO

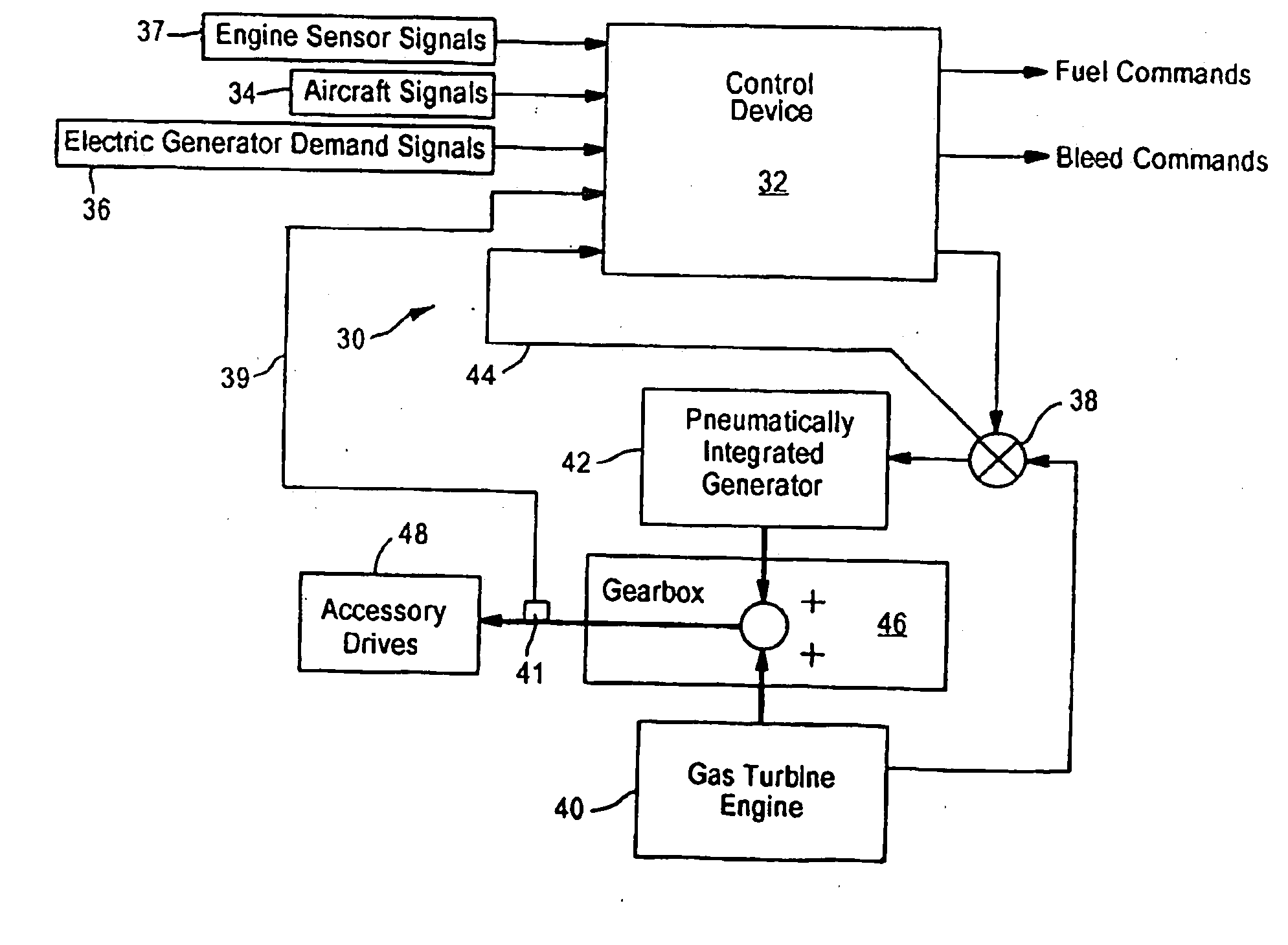

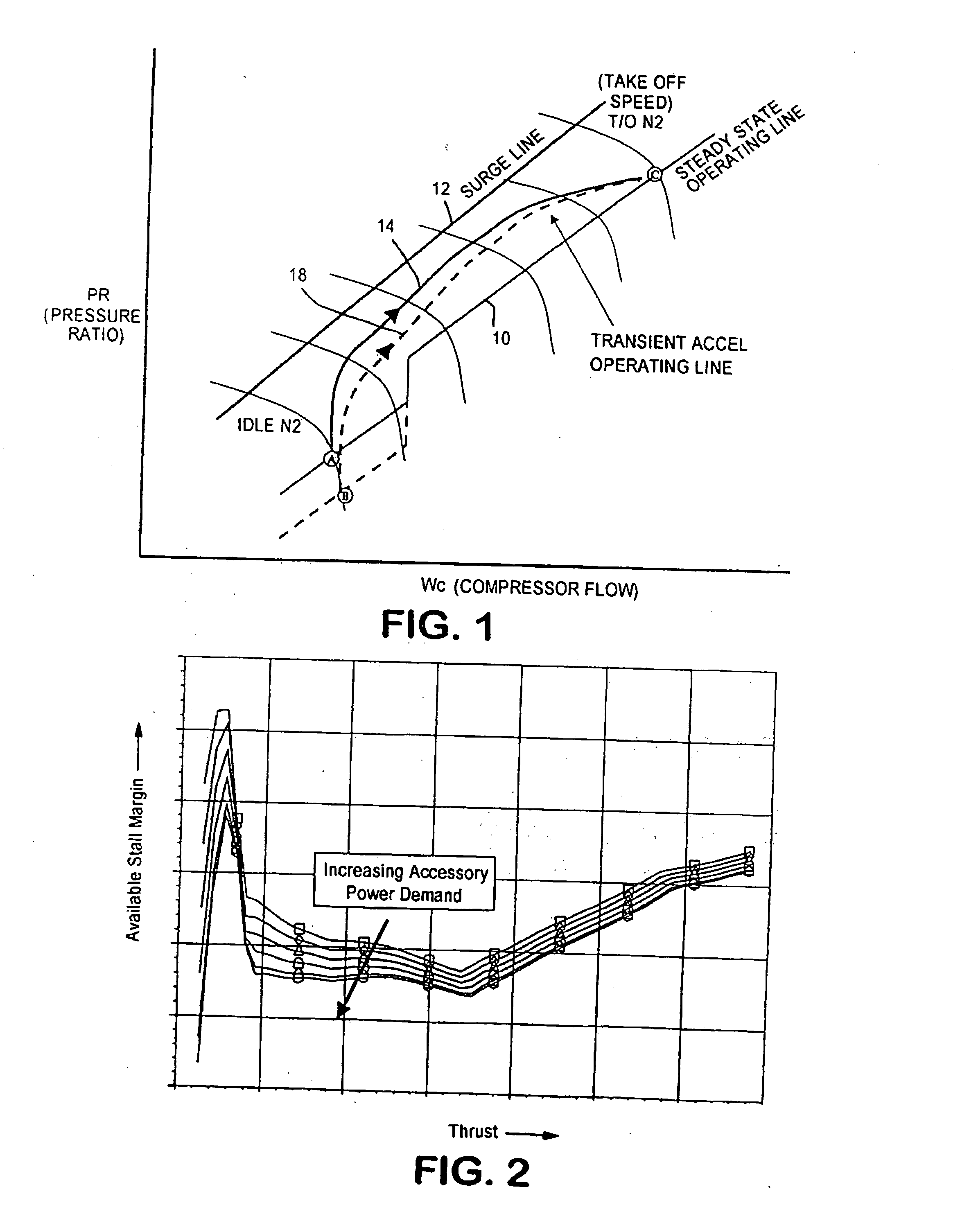

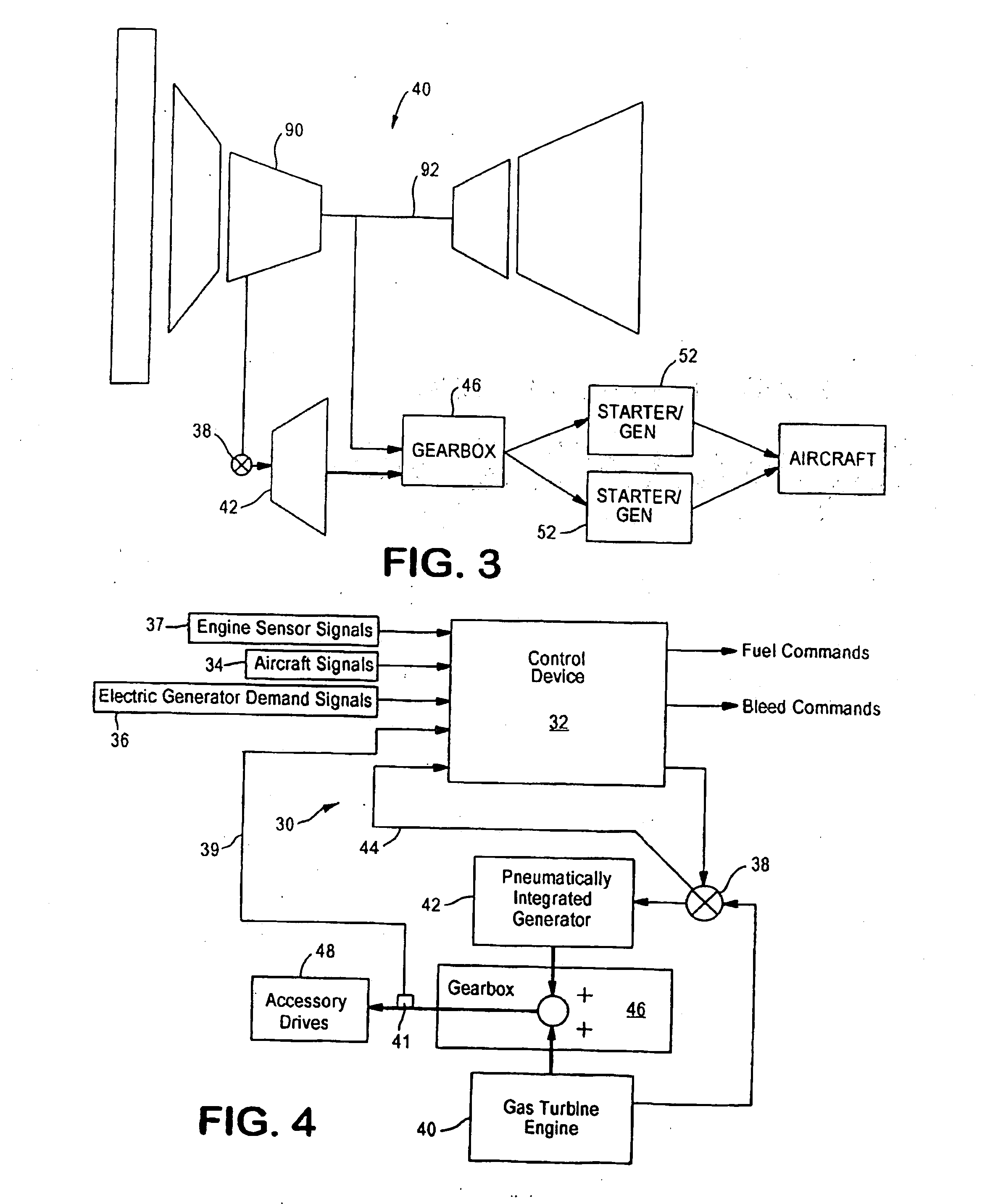

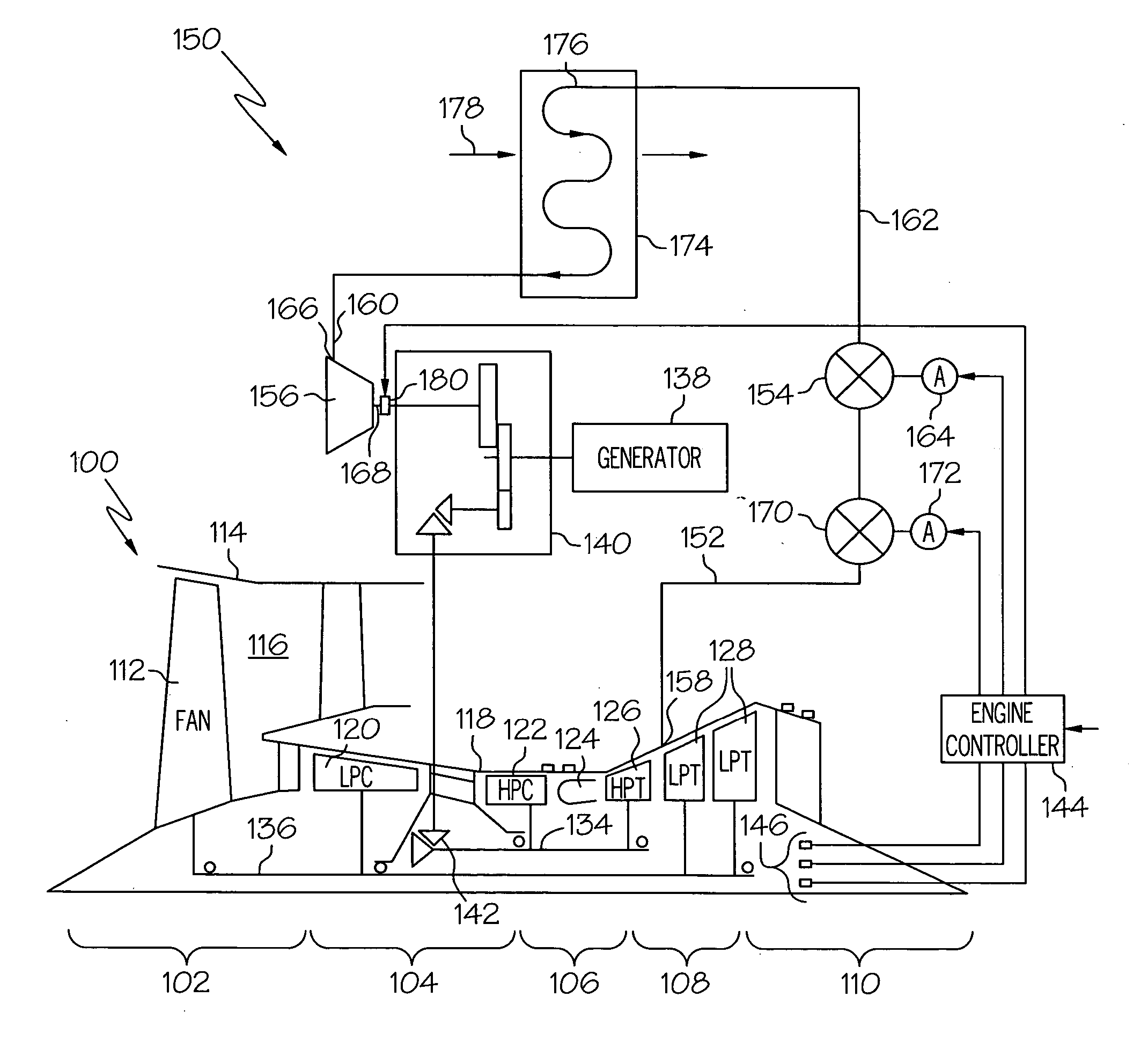

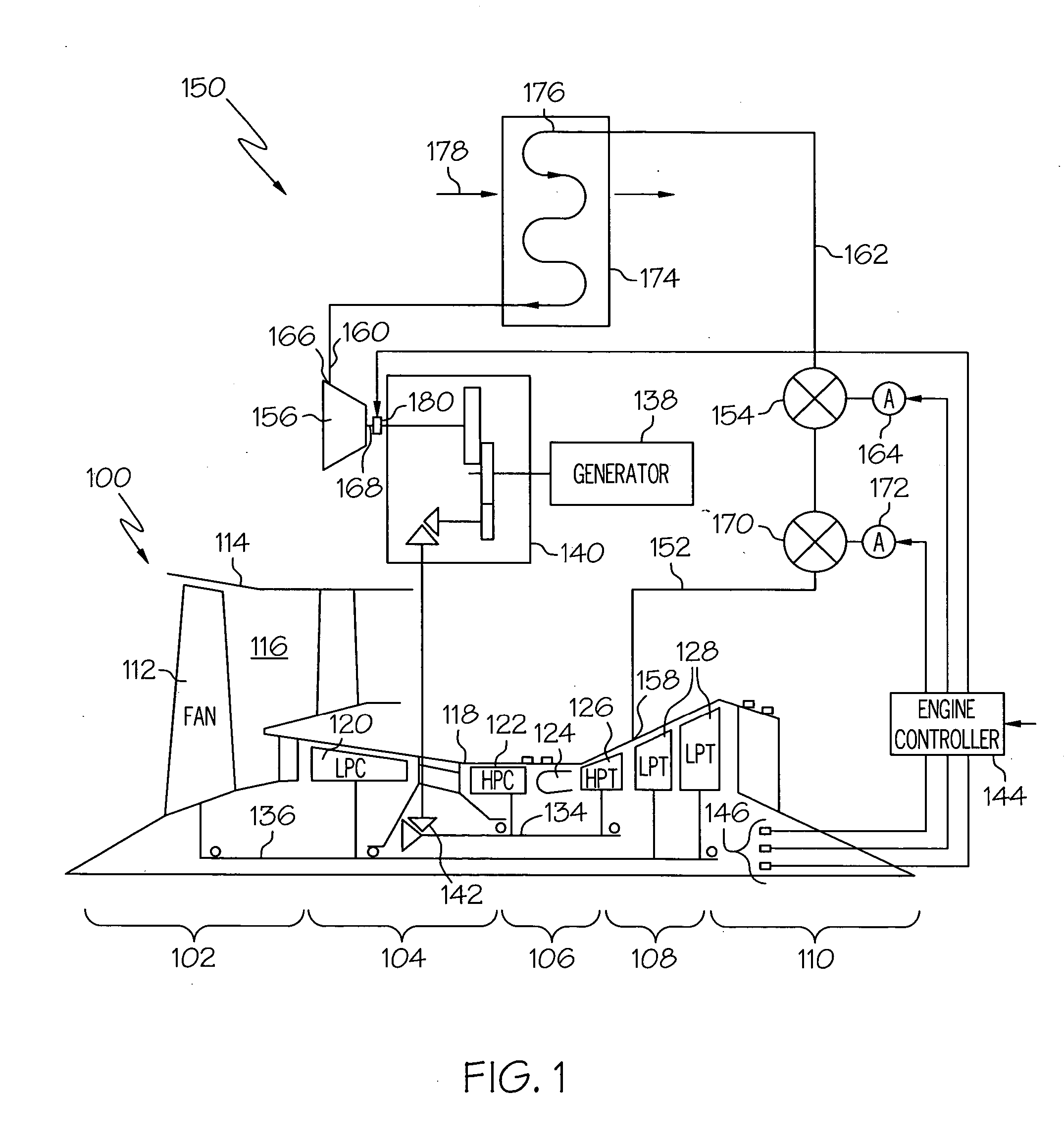

Hybrid engine accessory power system

InactiveUS20050103931A1Easy to operatePower installationsEfficient propulsion technologiesTransient stateBleed air

A system for generating accessory power from a gas turbine engine is provided by the present invention. The system includes an electronic control device for monitoring at least one parameter which provides information about an incipient change in power demand, a control valve operated by the control device for supplying bleed air from the engine during a transient state in response to the at least one monitored parameter, and a pneumatically operated device for receiving the bleed air and for generating power to operate equipment onboard an aircraft. The pneumatically operated device may be an air turbine or a pneumatically integrated generator.

Owner:UNITED TECH CORP

Gas turbine engine temperature modulated cooling flow

A gas turbine engine cooling system includes a heat exchanger in fluid communication with a source of cooling air, a first cooling circuit including a first heat exchanger circuit in the heat exchanger and a first bypass circuit with a first bypass valve for selectively bypassing at least a portion of first airflow around the first heat exchanger circuit. A second cooling circuit may be used having a second heat exchanger circuit in the heat exchanger and a shutoff control valve operably disposed in the second cooling circuit upstream of the second heat exchanger circuit and the heat exchanger. A circuit inlet of the first cooling circuit may be used to bleed a portion of compressor discharge bleed air for the first airflow to cool turbine blades mounted on a rotor disk using an annular flow inducer downstream of the first bypass valve and the heat exchanger.

Owner:GENERAL ELECTRIC CO

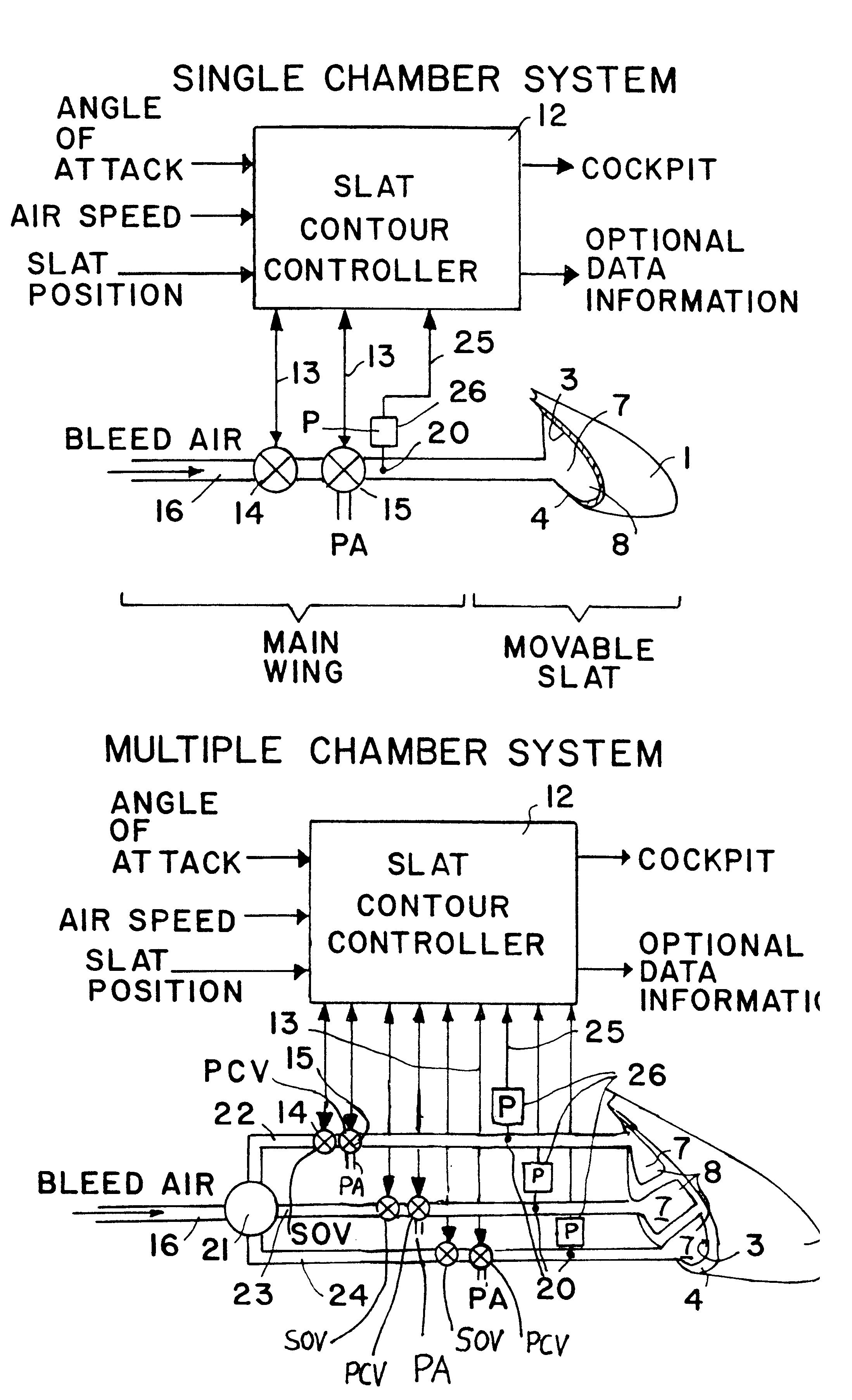

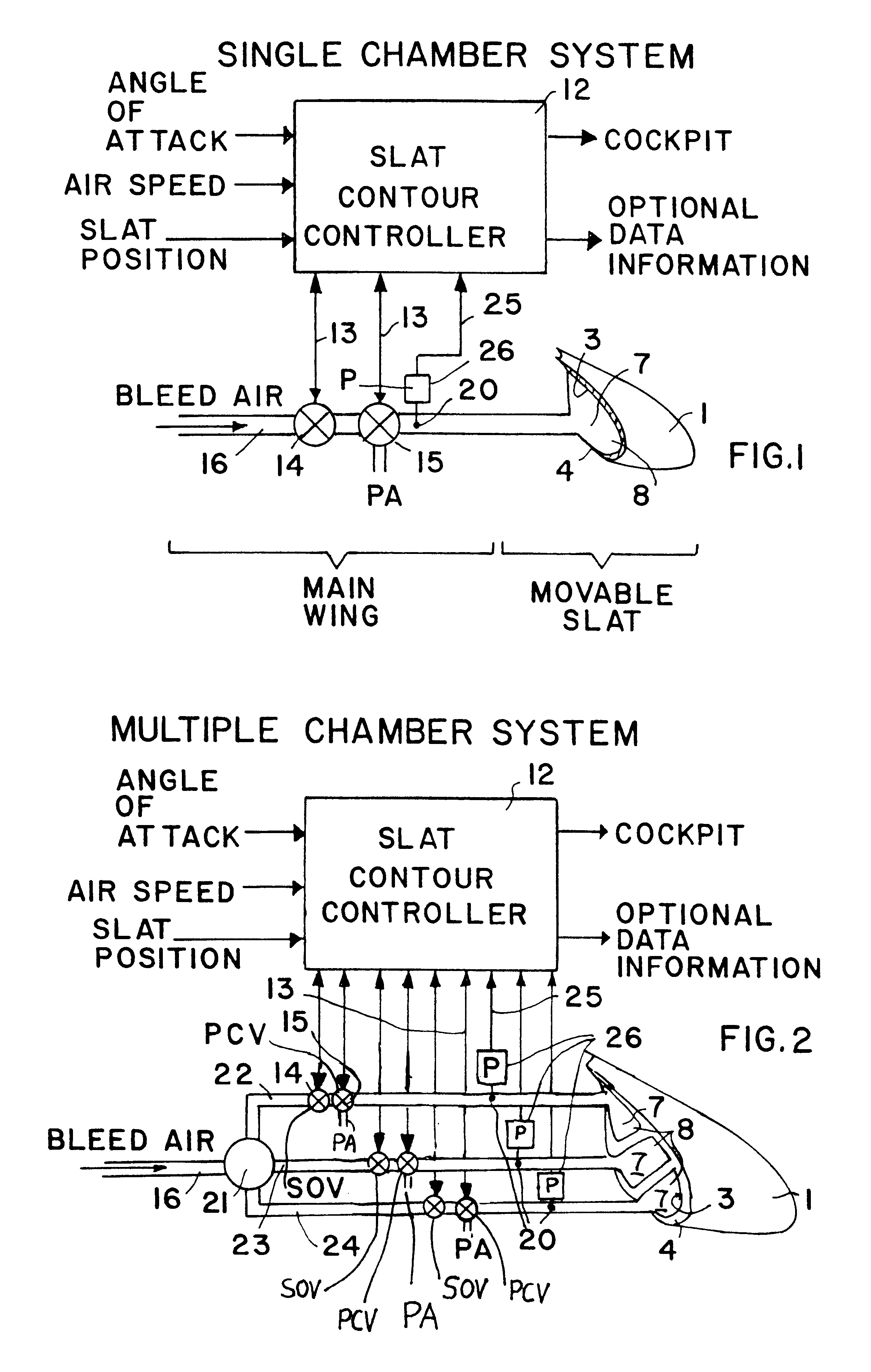

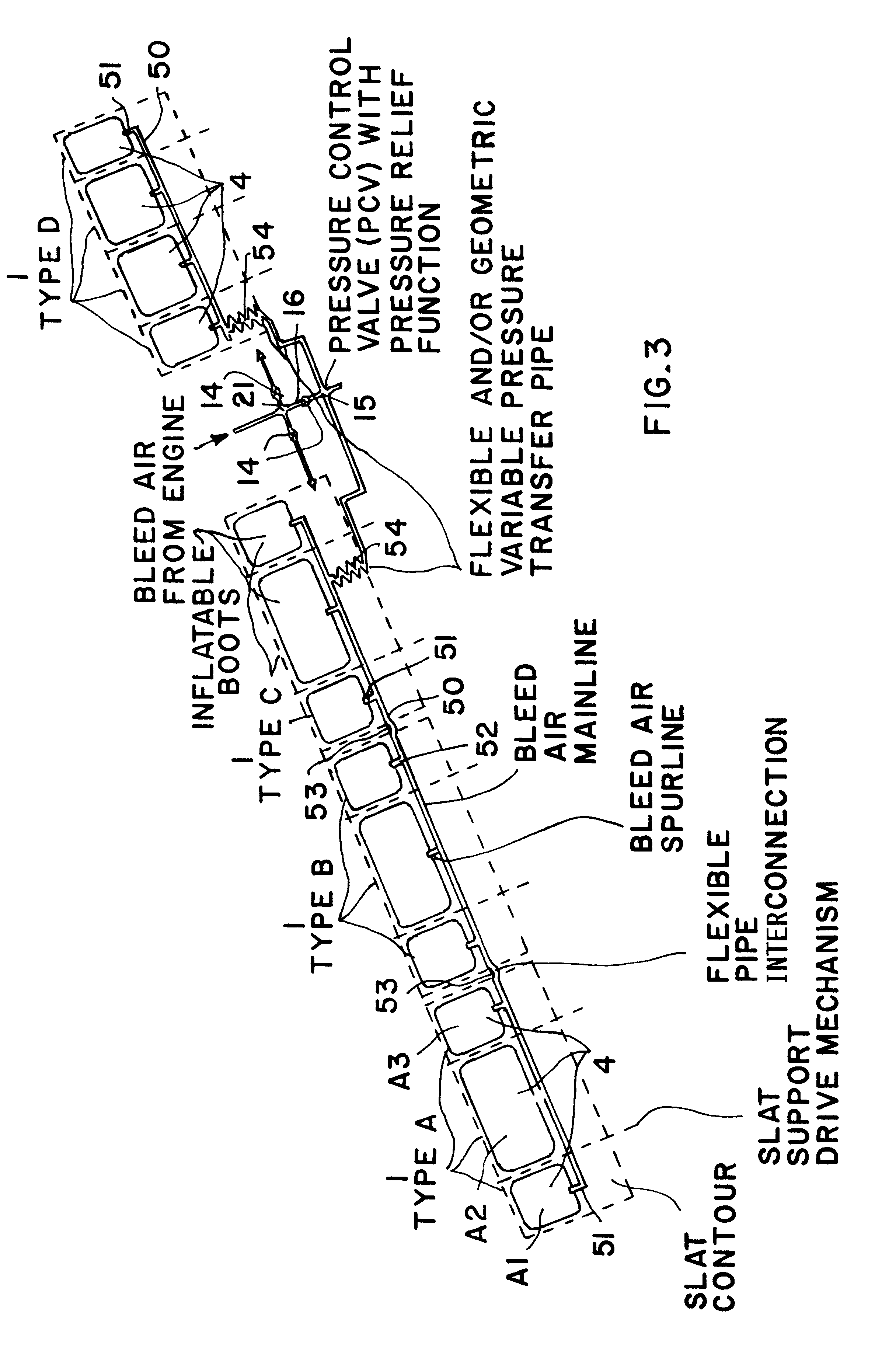

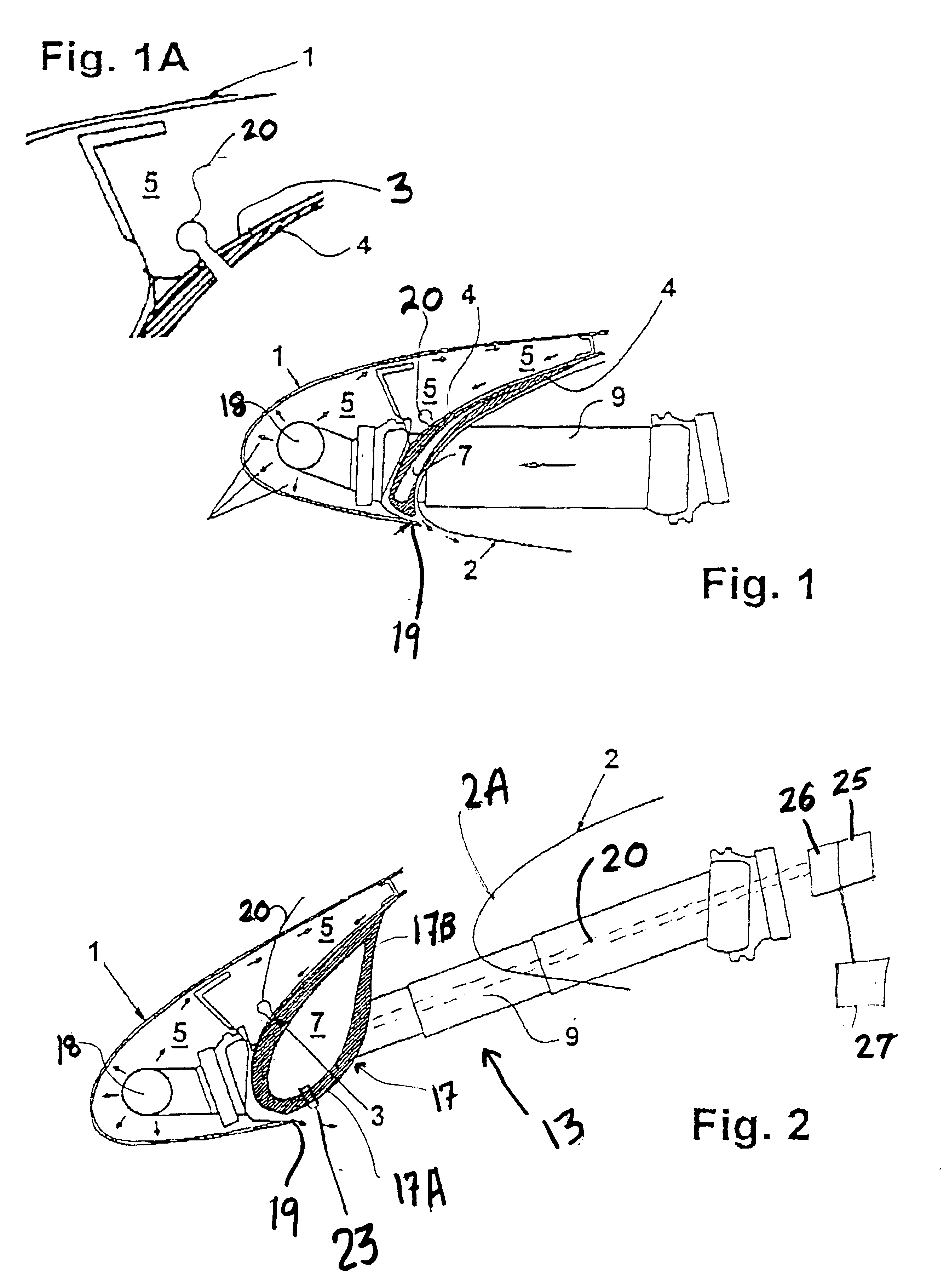

Pressure control system for a pressure-expandable displacement element

An elastically expandable hollow displacement element is secured to the rear surface of an aircraft wing slat. When the displacement element is contracted, the slat may be retracted onto the wing's leading edge. When the slat is extended, the displacement element is expanded to protrude convexly from the slat, thereby preventing vortex formation in the slat air gap and reducing aero-acoustic noise. A pressure control system for inflating and deflating the displacement element includes a bleed air line connected from the aircraft engine bleed air system to the displacement element, a shut-off valve and a pressure control valve interposed in series in the bleed air line, and a slat contour controller connected by respective signal lines to the valves, which control the quantity and the pressure of the bleed air supplied into the displacement element, for properly inflating the same.

Owner:AIRBUS OPERATIONS GMBH

Inflatable compressor bleed valve system

InactiveUS20050008476A1Simplified compressor bleed valve systemReduce in quantityPump componentsWind motor controlEngineeringBleed air

A compressor bleed valve system for bleeding air from a gas turbine engine compressor comprises a bladder inflatable between at least a collapsed position and an expanded position for selectively opening and closing a compressor airbleed passage.

Owner:PRATT & WHITNEY CANADA CORP

Environmental control system supply precooler bypass

ActiveUS20120216545A1Air-treatment apparatus arrangementsEnergy efficient board measuresControl systemBleed air

A precooler for cooling compressor bleed air for an environmental control system includes a heat exchanger in fluid communication with a source of cooling air and operable for cooling the bleed air. A variable bypass valve between a bleed air source and environmental control system is operable for bypassing at least a portion of the compressor bleed air around the heat exchanger. The cooling air may be a portion of fan air modulated by a variable fan air valve. The bleed air source may be selectable between the low pressure bleed air source and a high pressure bleed air source. One method includes flowing the compressor bleed air from a single low pressure source only and increasing thrust sufficiently to meet a minimum level of pressure of the bleed air during one engine out aircraft operating condition during approach or loitering.

Owner:GENERAL ELECTRIC CO

Turbo-Compressor System and Method for Extracting Energy from an Aircraft Engine

ActiveUS20150251766A1Easy to optimizeSatisfies needCompressorAir-treating devicesBleed airControl valves

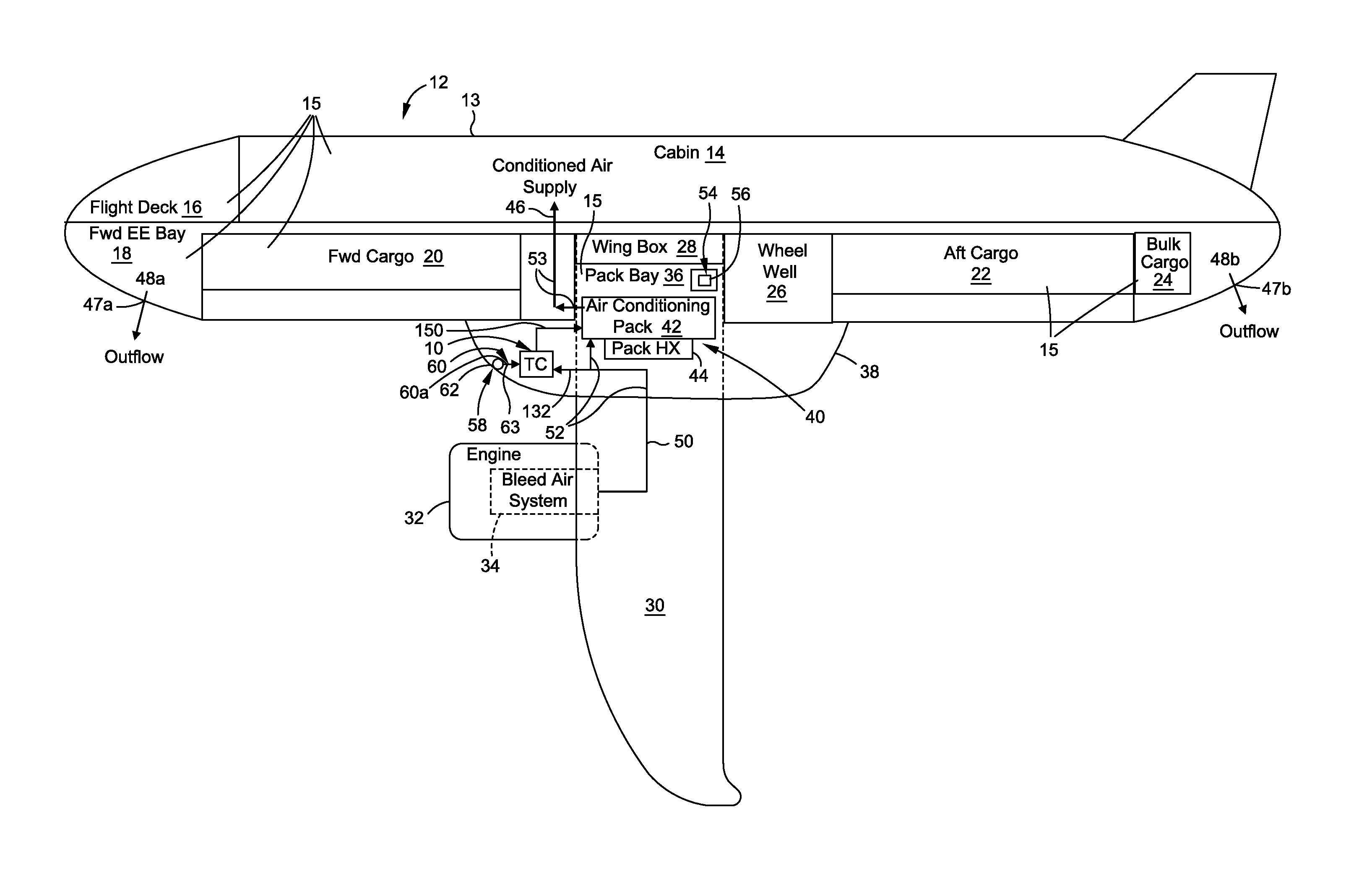

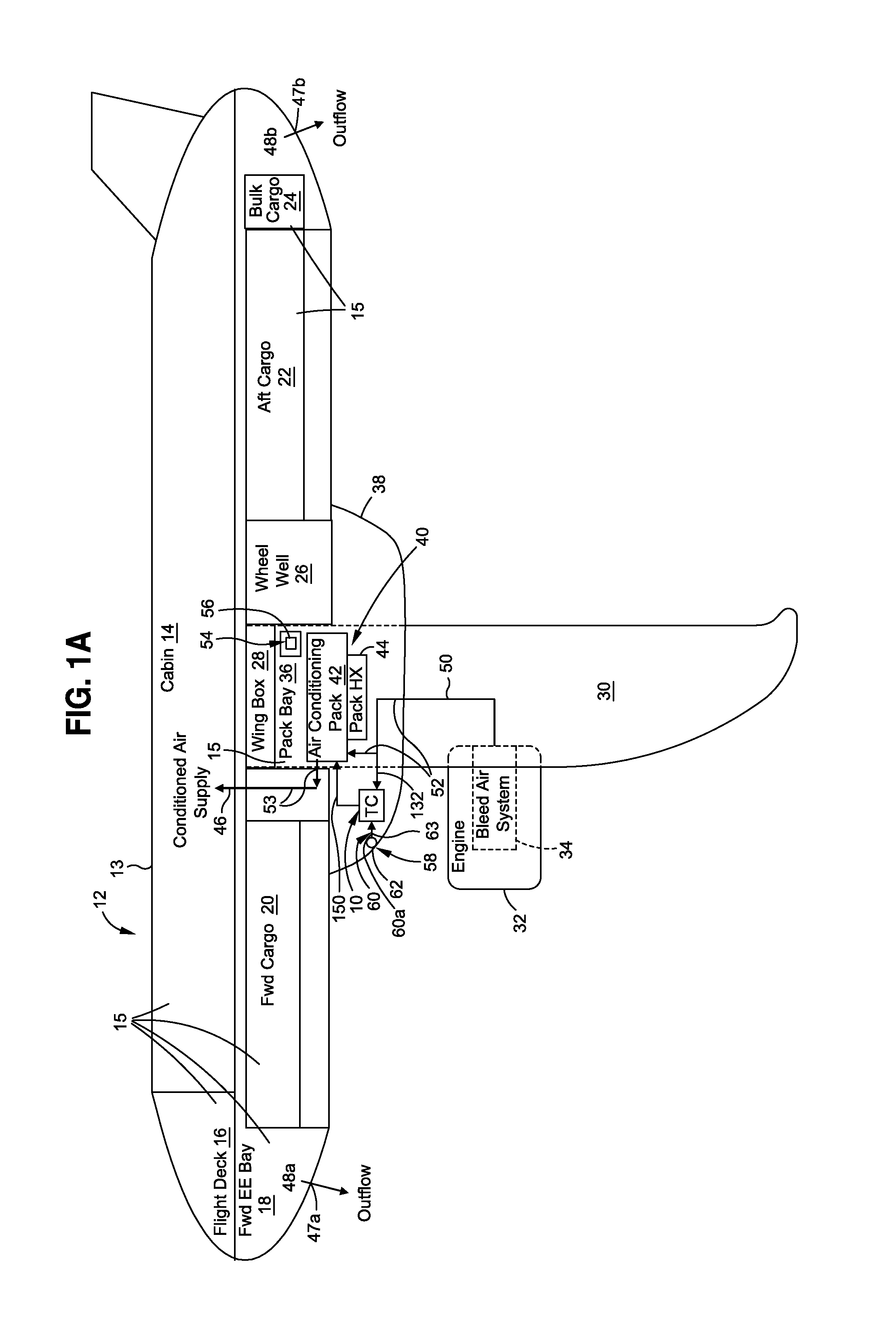

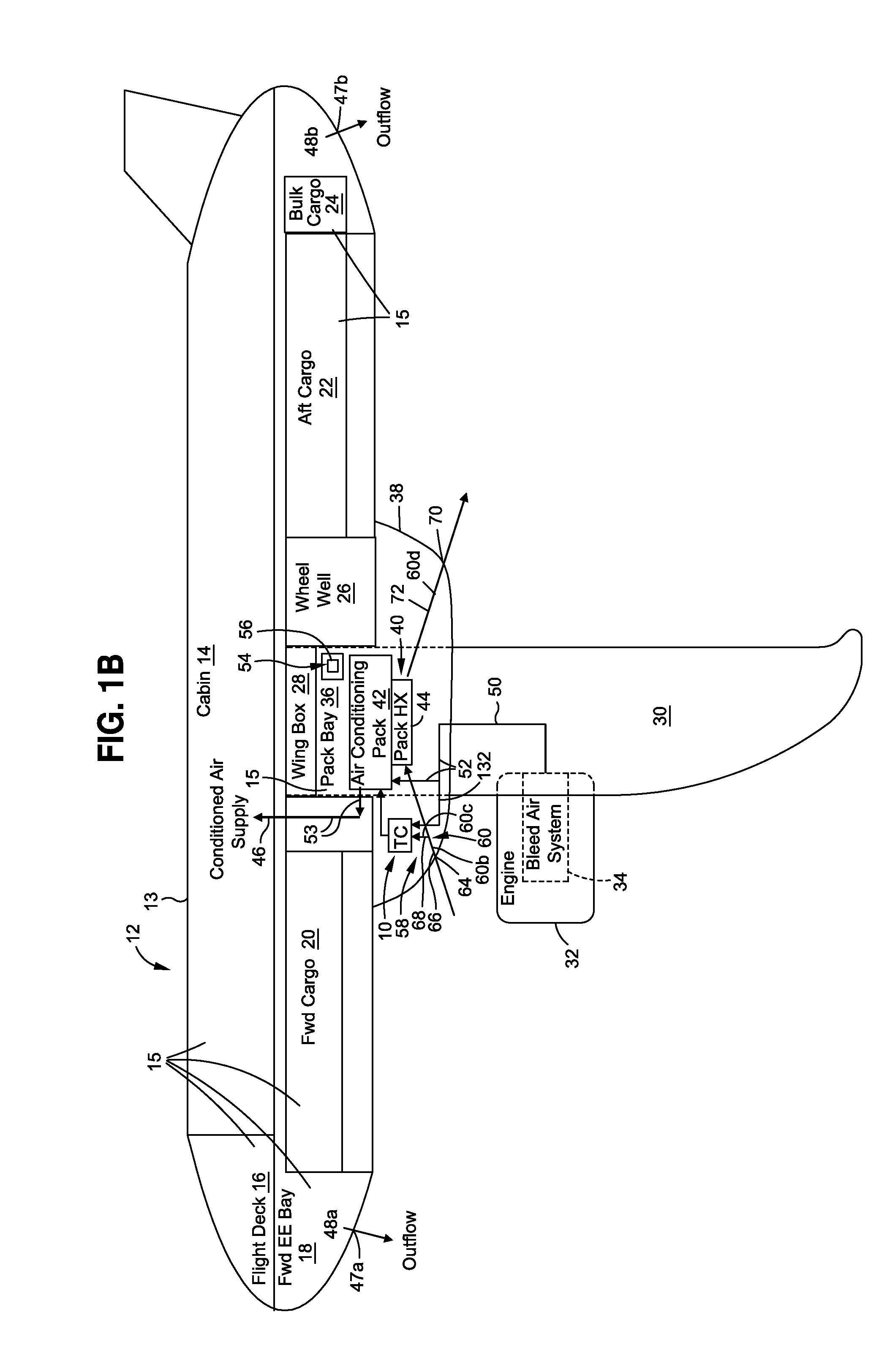

A turbo-compressor (TC) system for extracting energy from an aircraft engine. The TC system has a TC assembly with a turbine mechanically coupled to at least one compressor. The TC system has a TC inlet in fluid communication with a bleed air system in the aircraft engine and a TC outlet in fluid communication with an air conditioning (AC) pack of an aircraft air conditioning system and configured to extract reduced temperature pack inlet air from the TC assembly into the air conditioning pack. The TC system has a ram air inlet coupled to the at least one compressor. The TC system has a TC control valve, and a TC check valve or a TC shutoff valve, both coupled to the TC assembly via a plurality of connective ducts. The TC system extracts energy from the bleed air to reduce bleed air flow and AC pack ram air usage.

Owner:THE BOEING CO

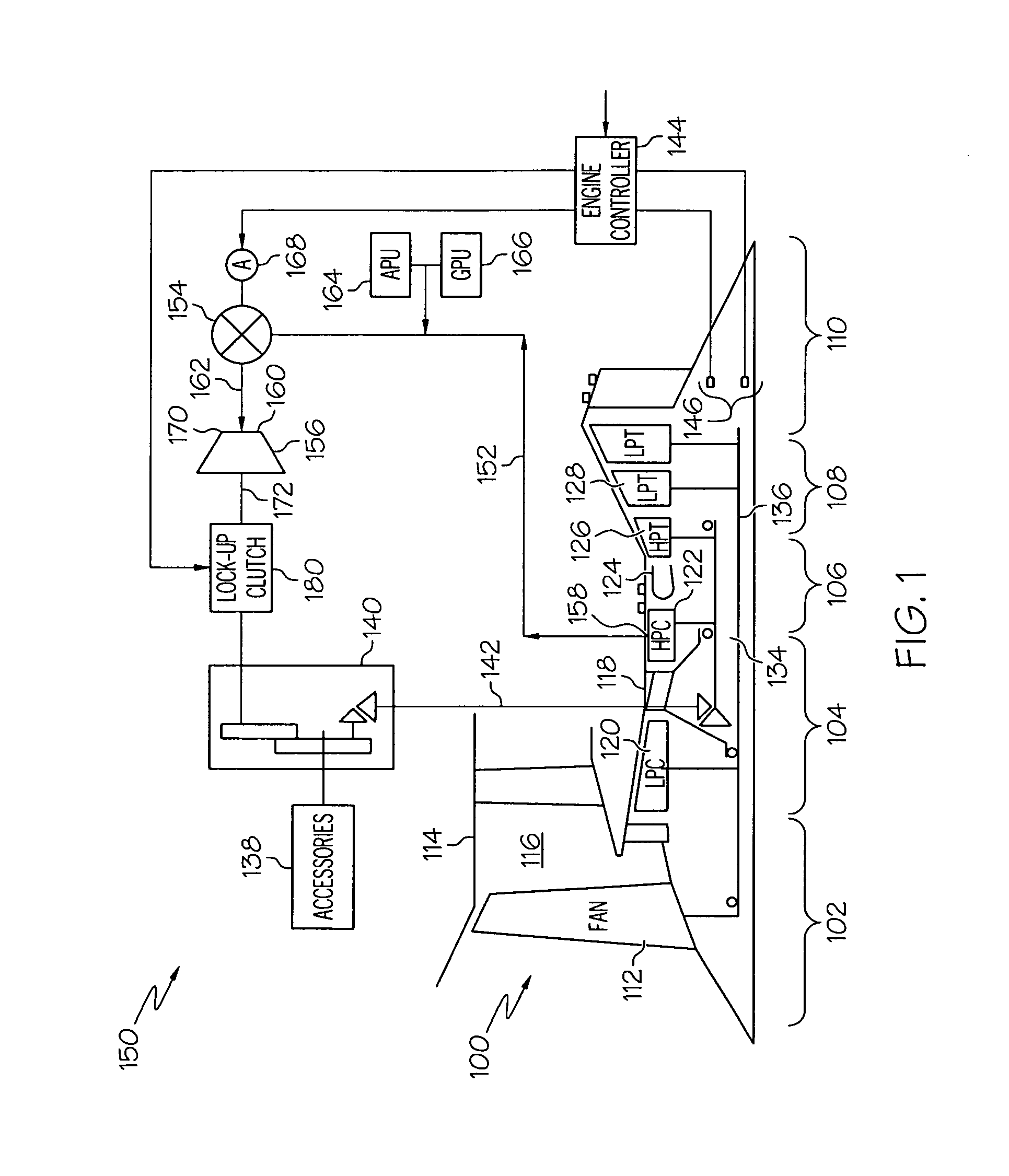

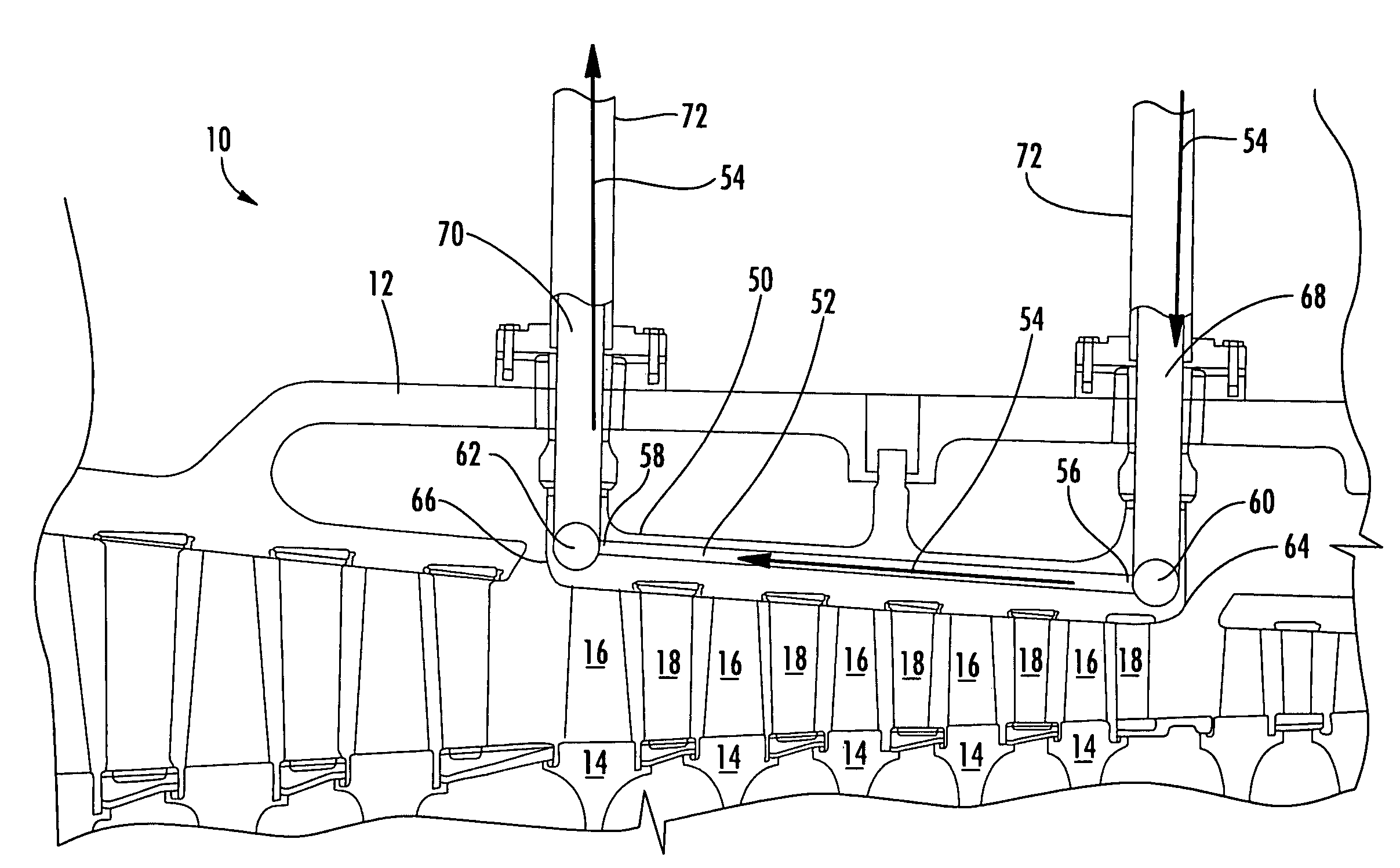

Turbine drive system with lock-up clutch and method

InactiveUS20090288421A1Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionLow speedBleed air

A pneumatically driven turbine drive system is coupled to a gas turbine engine that includes low and high pressure compressors, low and high pressure turbines, a lock-up clutch, and at least one engine accessory driven by the high pressure compressor. The pneumatically driven turbine drive system selectively bleeds air discharged from the high pressure compressor and supplies it to an air turbine that is coupled to the at least one engine accessory. Thus, the system selectively reduces the power extracted from the high pressure compressor and is capable of supplying power back to the engine core. This, coupled with the bleed air that is diverted from the high pressure turbine and the low pressure turbine, allows the high pressure spool and the low pressure spool to run at lower speeds when high engine thrust is not needed or desired, but when the at least one engine accessory is still needed.

Owner:HONEYWELL INT INC

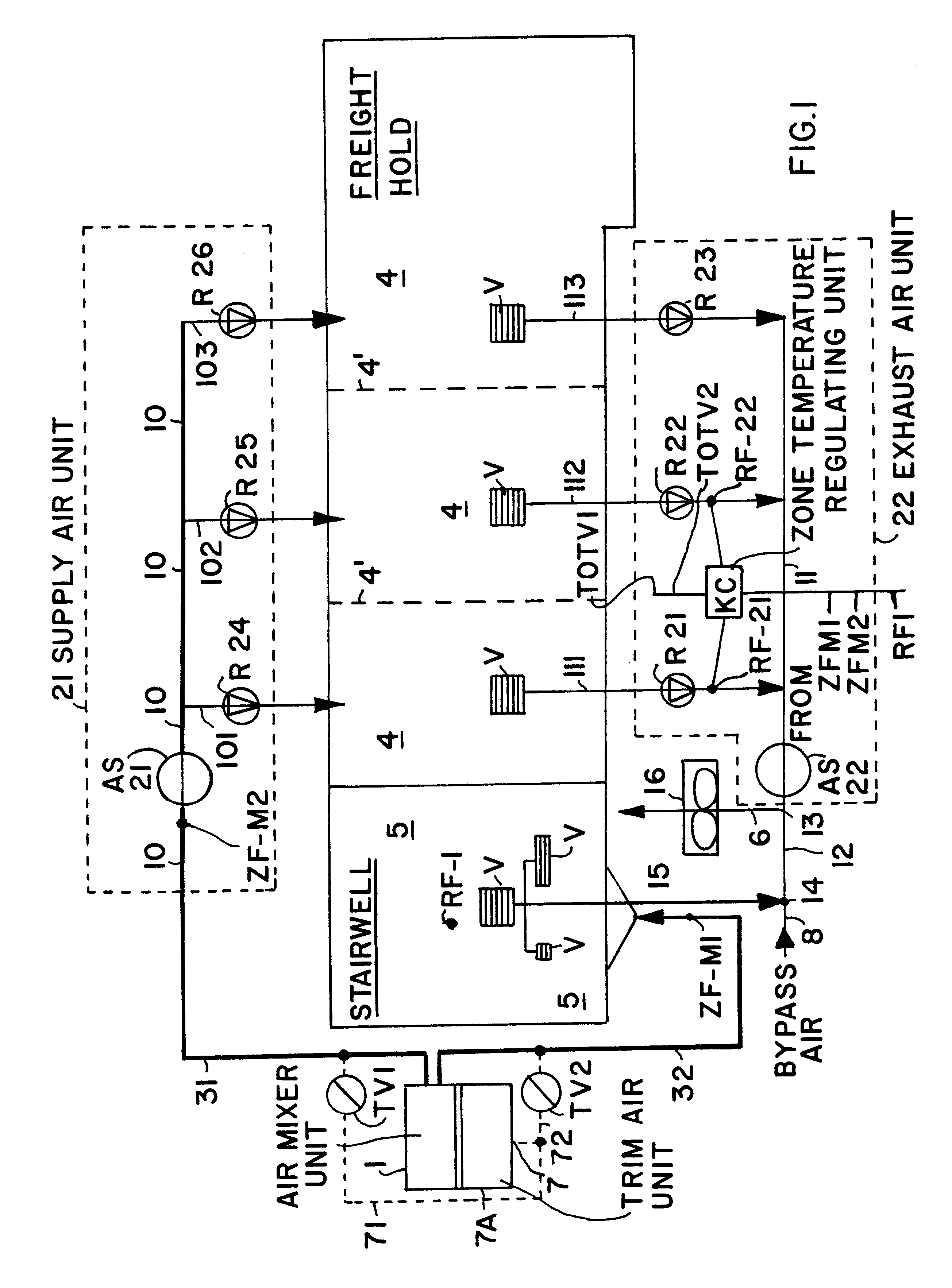

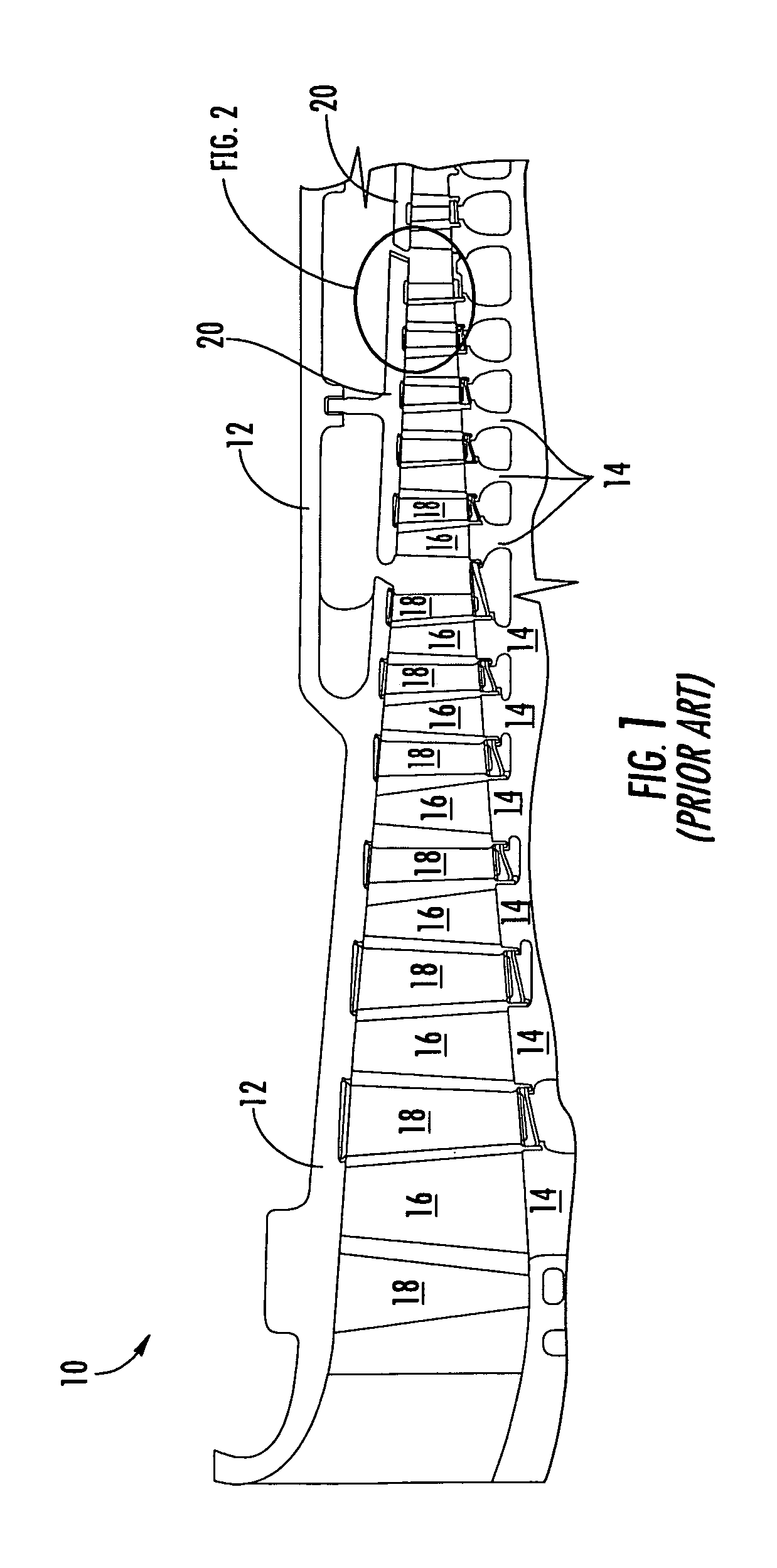

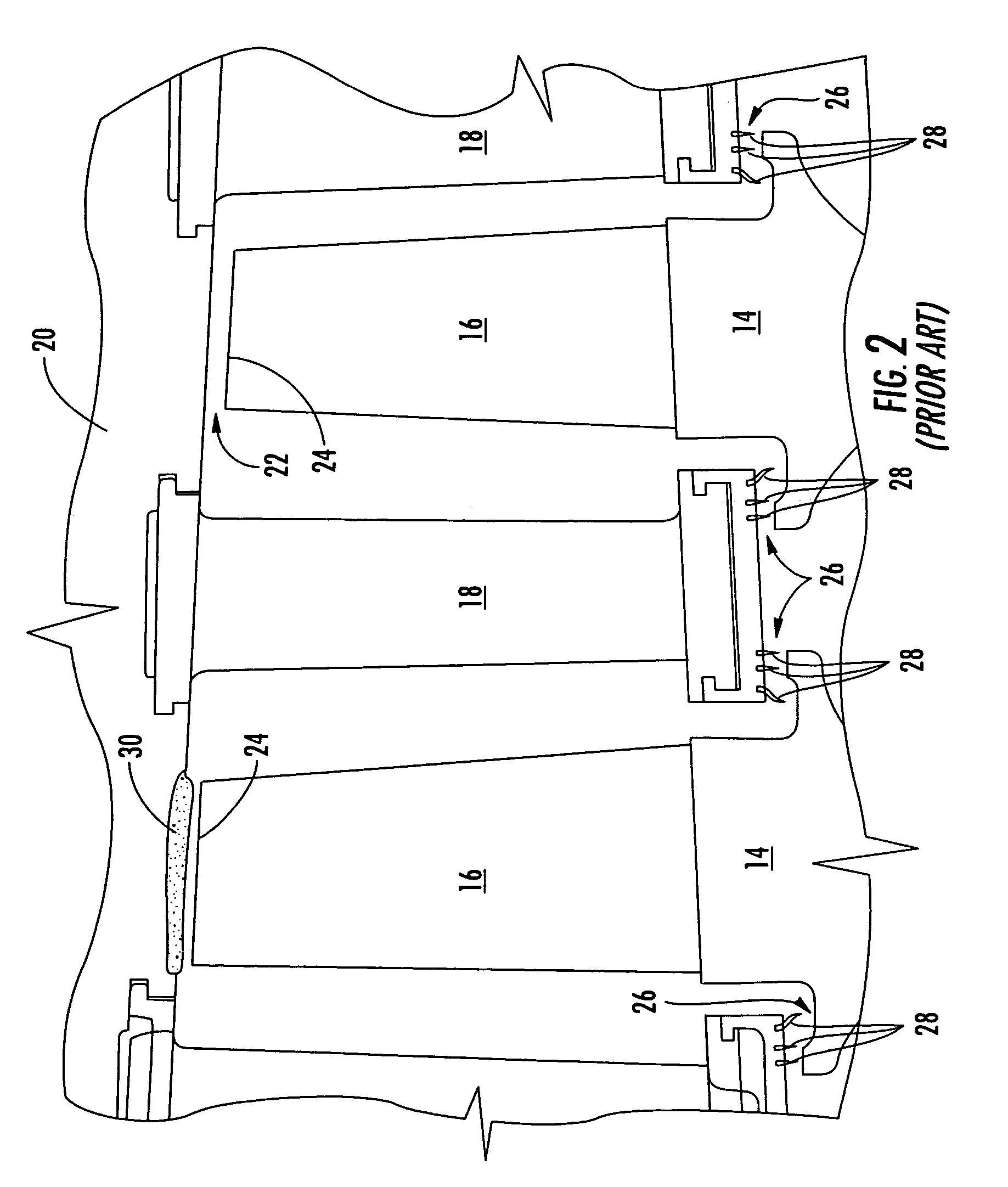

Air-conditioning system for below-deck areas of a passenger aircraft

InactiveUS6306032B1Air-treatment apparatus arrangementsEnergy efficient board measuresFire protectionFresh air

An aircraft air-conditioning system provides ventilation, air-conditioning and fire protection for a below-deck stairwell and cargo hold that may be equipped with passenger sleeping compartment containers. An air mixing unit mixes fresh air and recycled air to supply mixed air through a first supply air main line (31) and a supply air unit (21) into the freight hold (4), and through a second supply air main line (32) into the stairwell (5). A trimming air unit (7A) provides hot bleed air from the aircraft engines into the mixed air supplied through the first and second supply air main lines (31, 32). An exhaust air line (11) extracts exhaust air from the freight hold (4), while an exhaust air supplemental line (15) extracts exhaust air from the stairwell (5), both of which are connected to an exhaust air main line with an exhaust air ventilator (16) that blows the exhaust air overboard. A bypass line (8) provides bypass air if needed for the demands of the ventilator (16). Regulating valves and non-return flap valves in the supply air line and in the exhaust air line regulate the flow of air and prevent back-flow. Temperature sensors are connected to a controller that regulates the temperature of the mixed supply air to achieve a comfortable temperature in the freight hold and in the stairwell. In the event of fire, the air valves are closed, to seal-off the freight hold (4) and prevent the spread of smoke into the stairwell or other ventilated areas.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

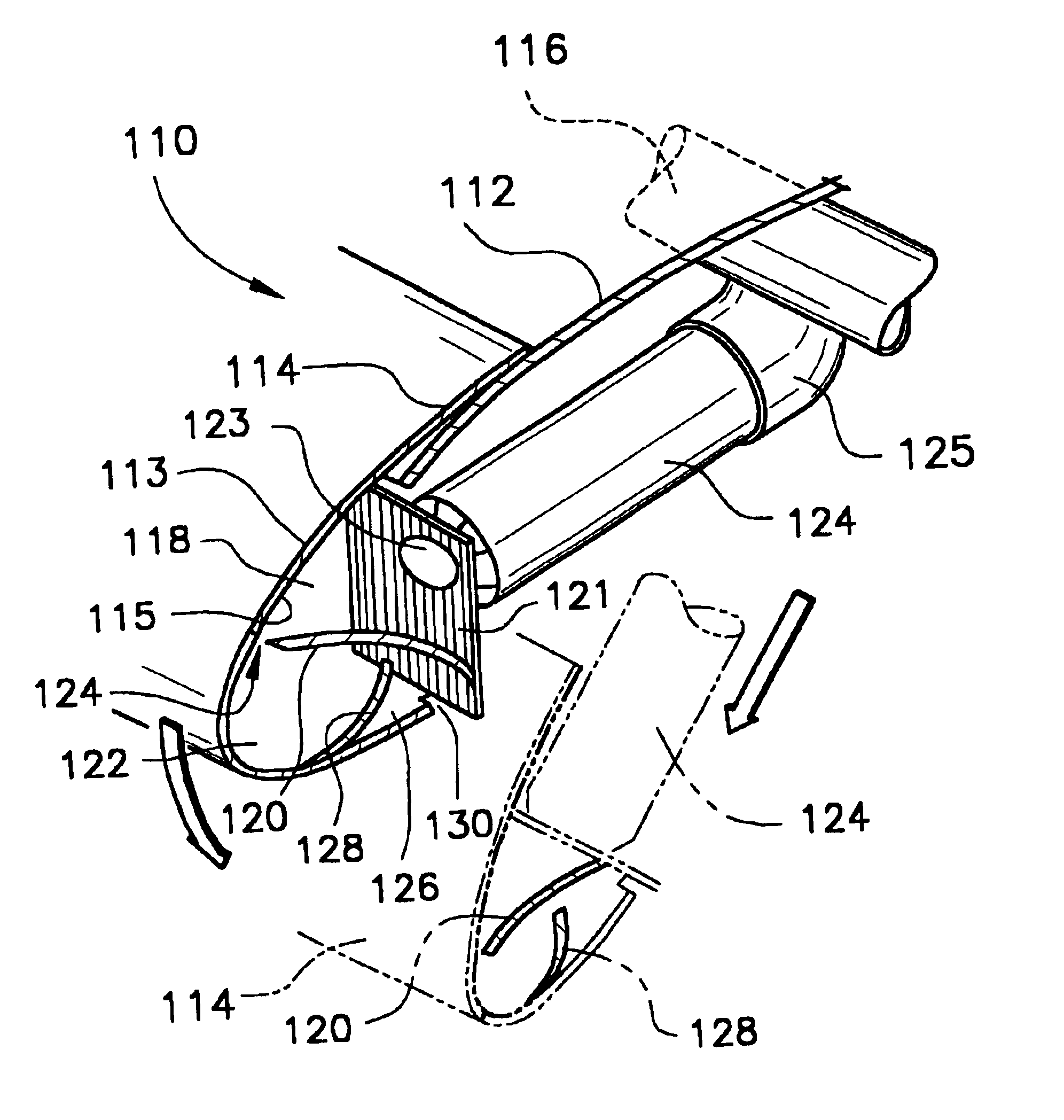

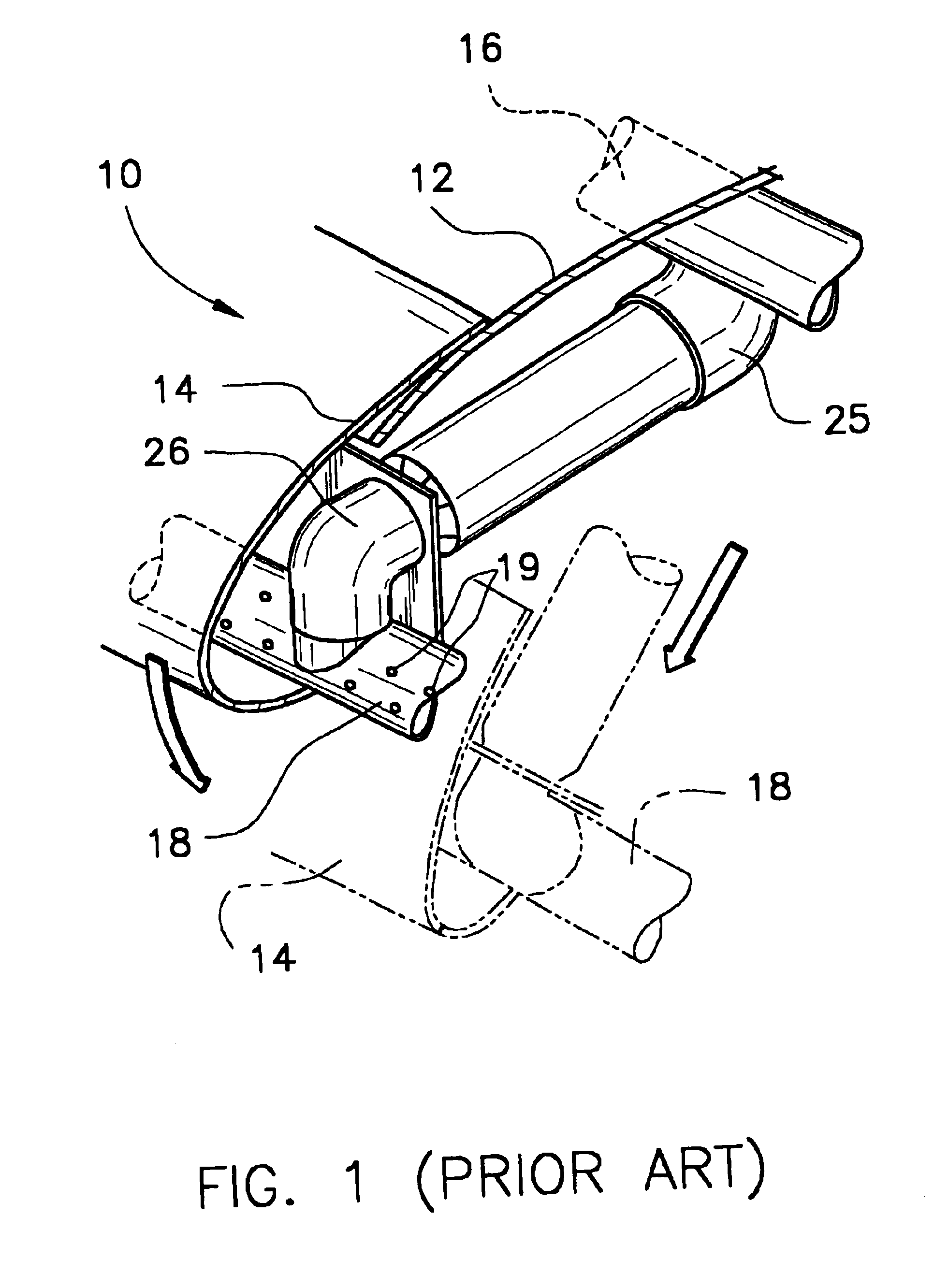

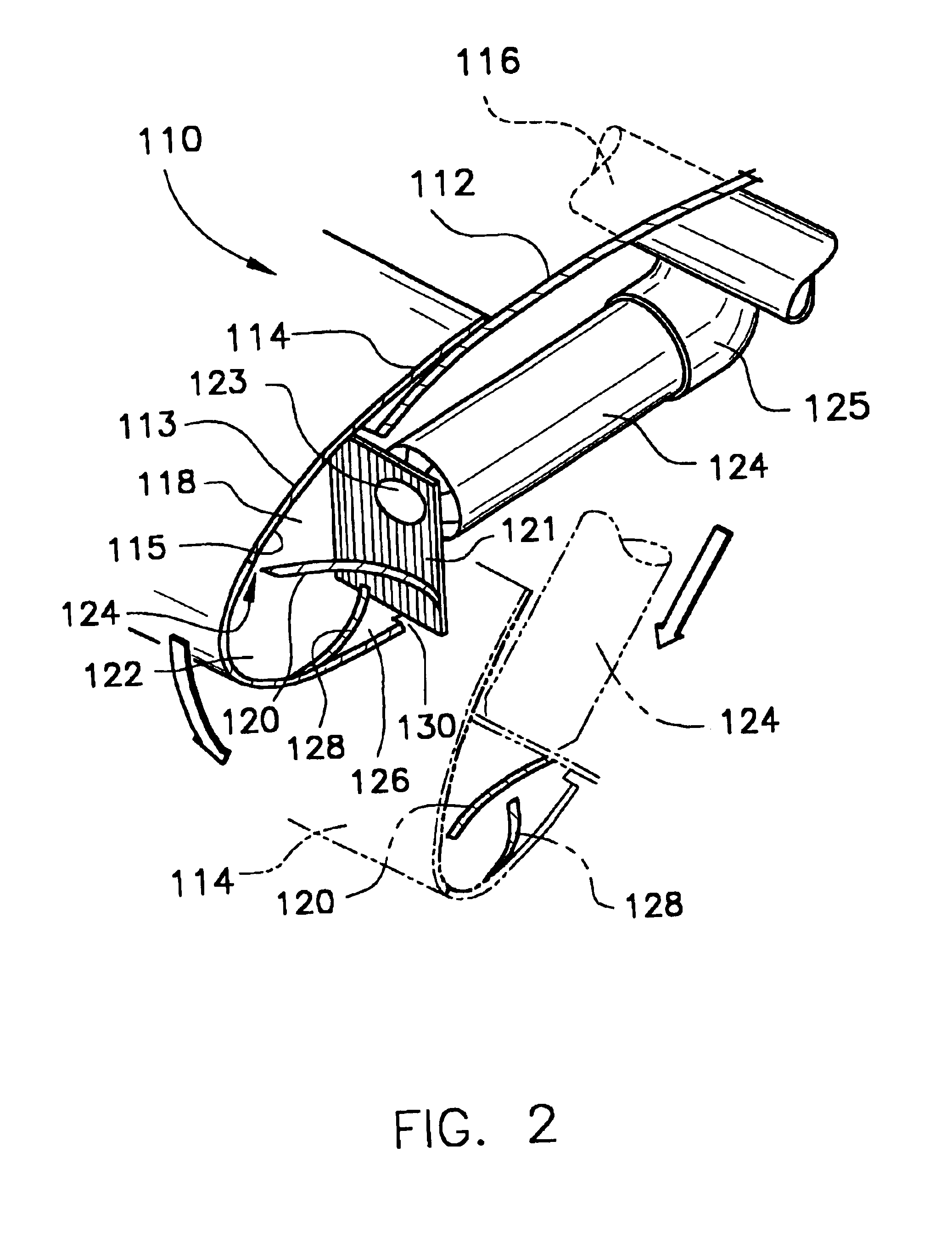

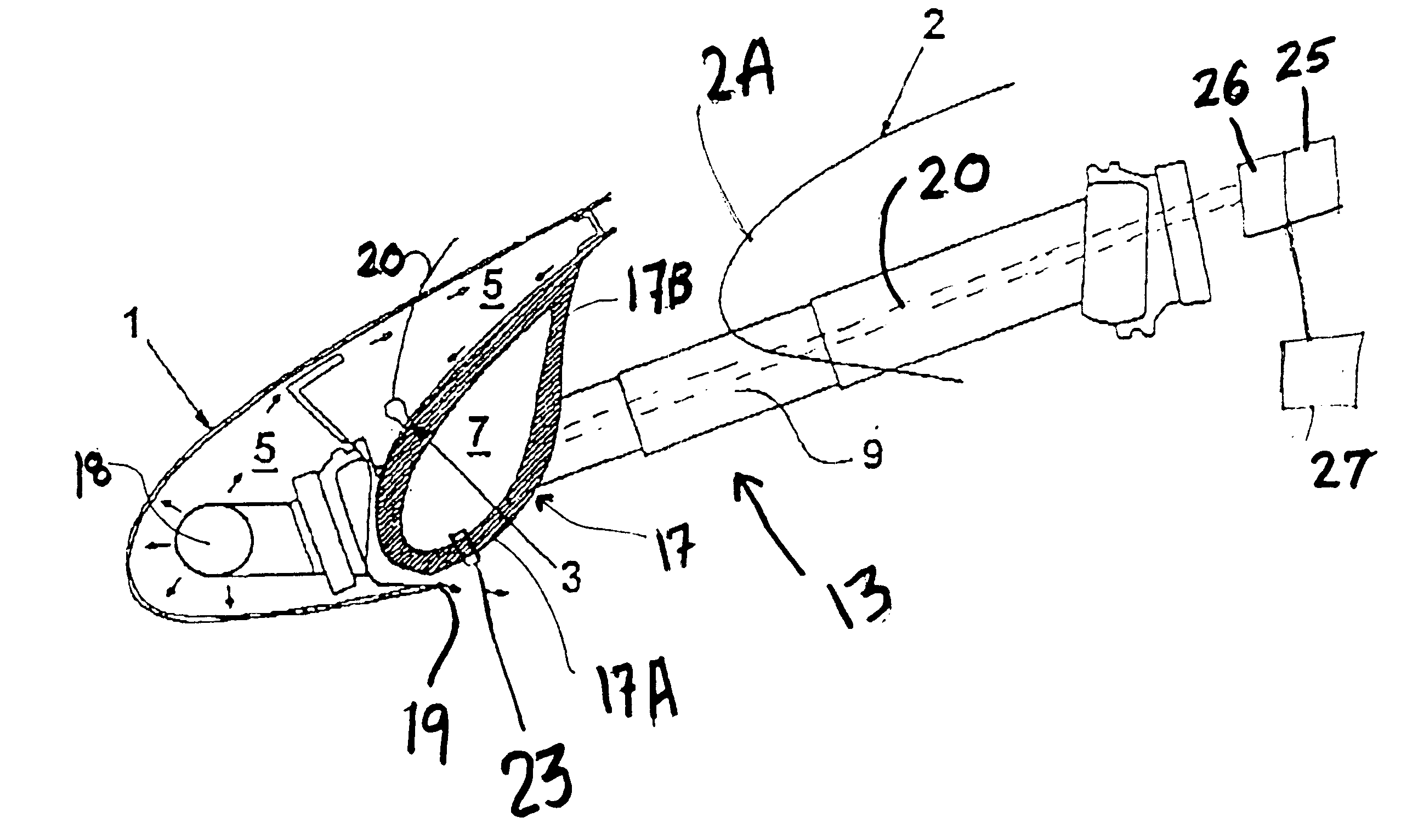

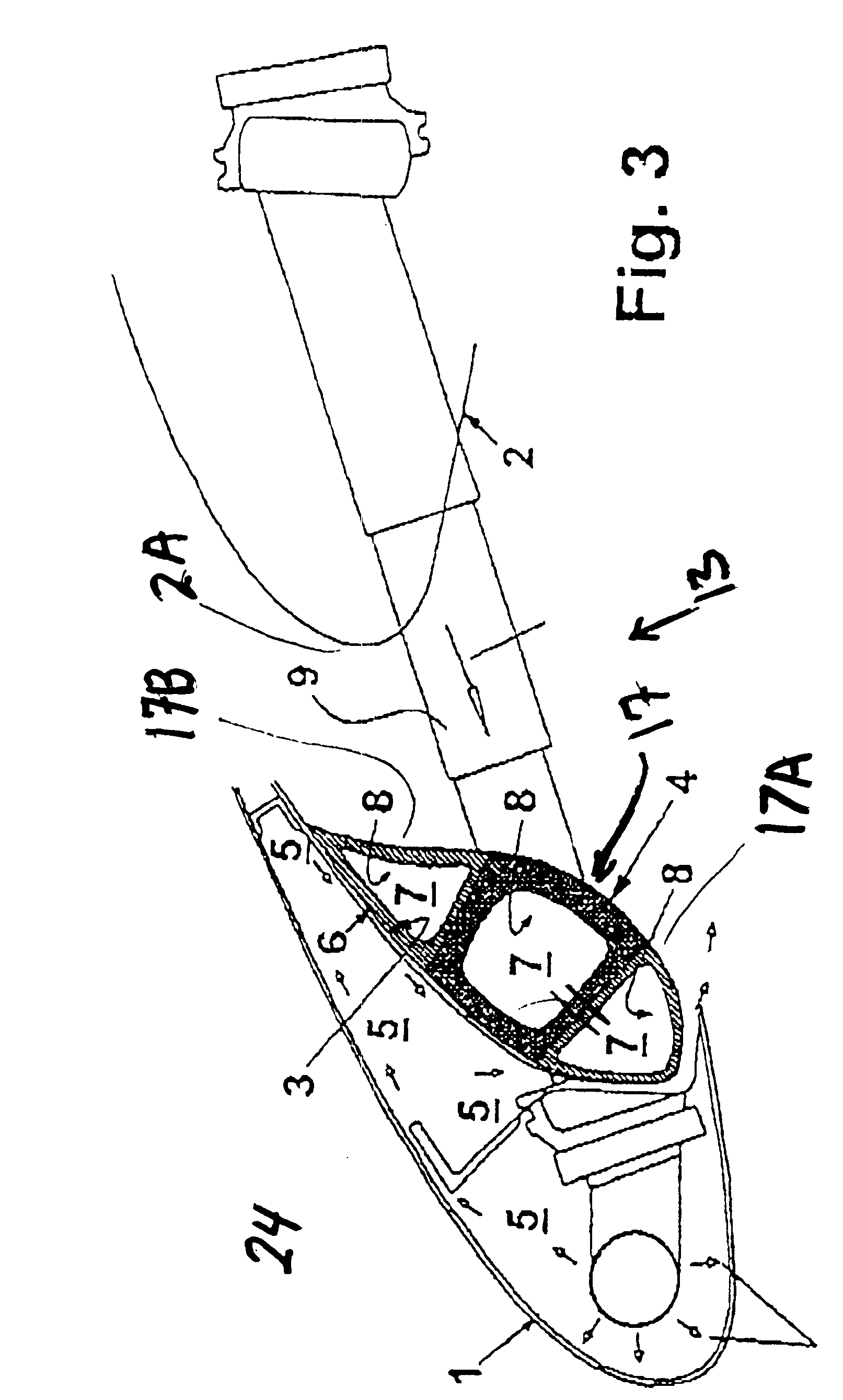

Airfoil anti-icing assembly and method

InactiveUS6702233B1De-icing equipmentsHot gas positive displacement engine plantsJet engineEngineering

An anti-icing assembly for an airfoil such as an aircraft wing or slat comprises: (a) an airfoil having an exterior surface and interior wall defining an interior cavity, and bottom, middle and side portions all adjacent to the interior cavity; (b) an inlet plenum integral to the airfoil, wherein the inlet plenum comprises (i) an inlet baffle capable of directing hot gases into the airfoil interior cavity and (ii) a throat section interfacing the inlet plenum and airfoil interior cavity; and (c) an outlet plenum integral to the airfoil, wherein the outlet plenum comprises an outlet baffle capable of directing hot gases from the airfoil interior cavity. The airfoil anti-icing method of this invention comprises providing hot gases such as jet engine bleed air to the airfoil assembly of this invention, swirling the hot gases within the airfoil interior cavity, and discharging the hot gases from the airfoil interior cavity through the airfoil outlet end. The system of this invention comprises a source of hot gases, typically jet engine bleed air, and the airfoil assembly of this invention.

Owner:ROHR INC

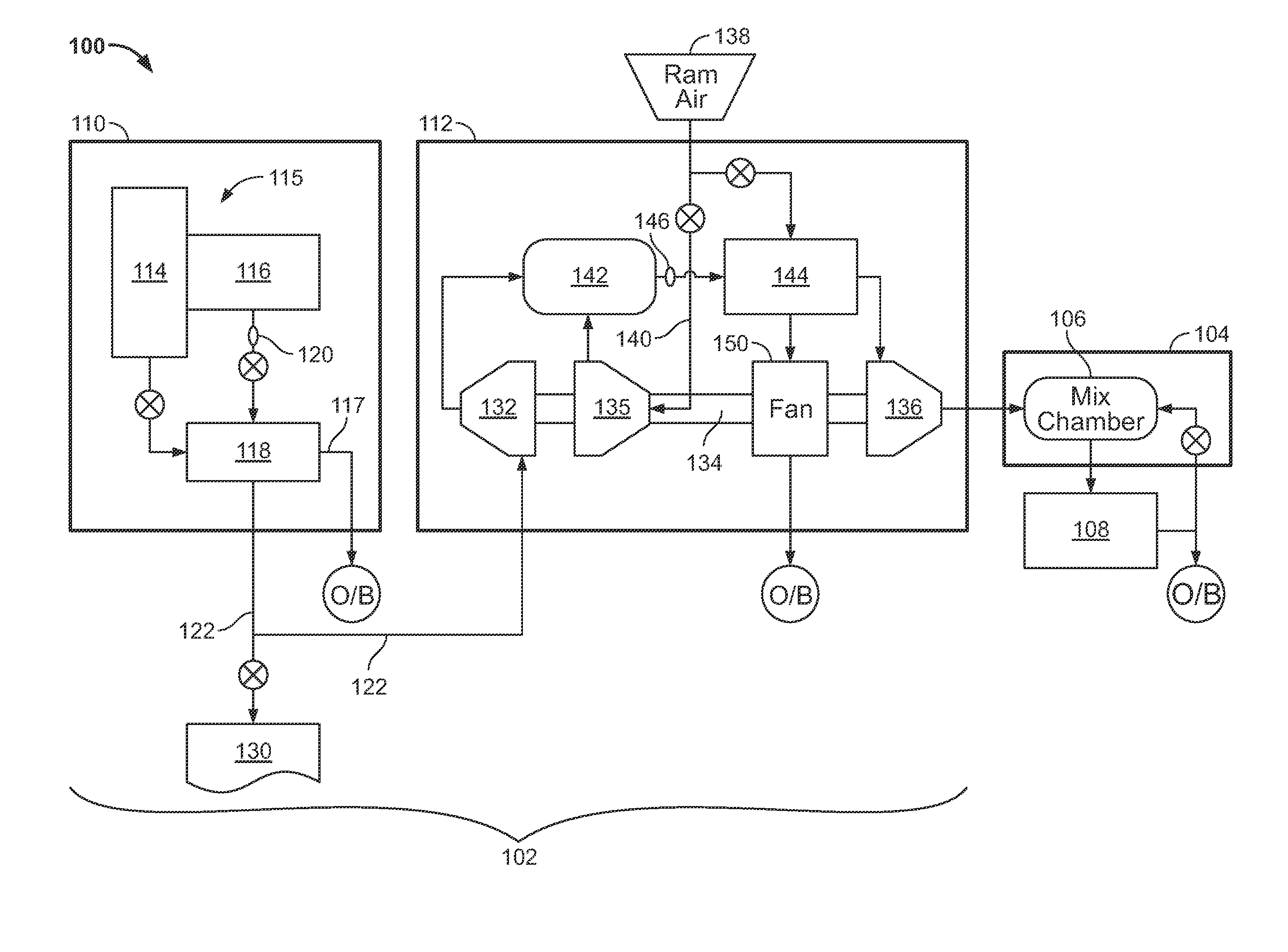

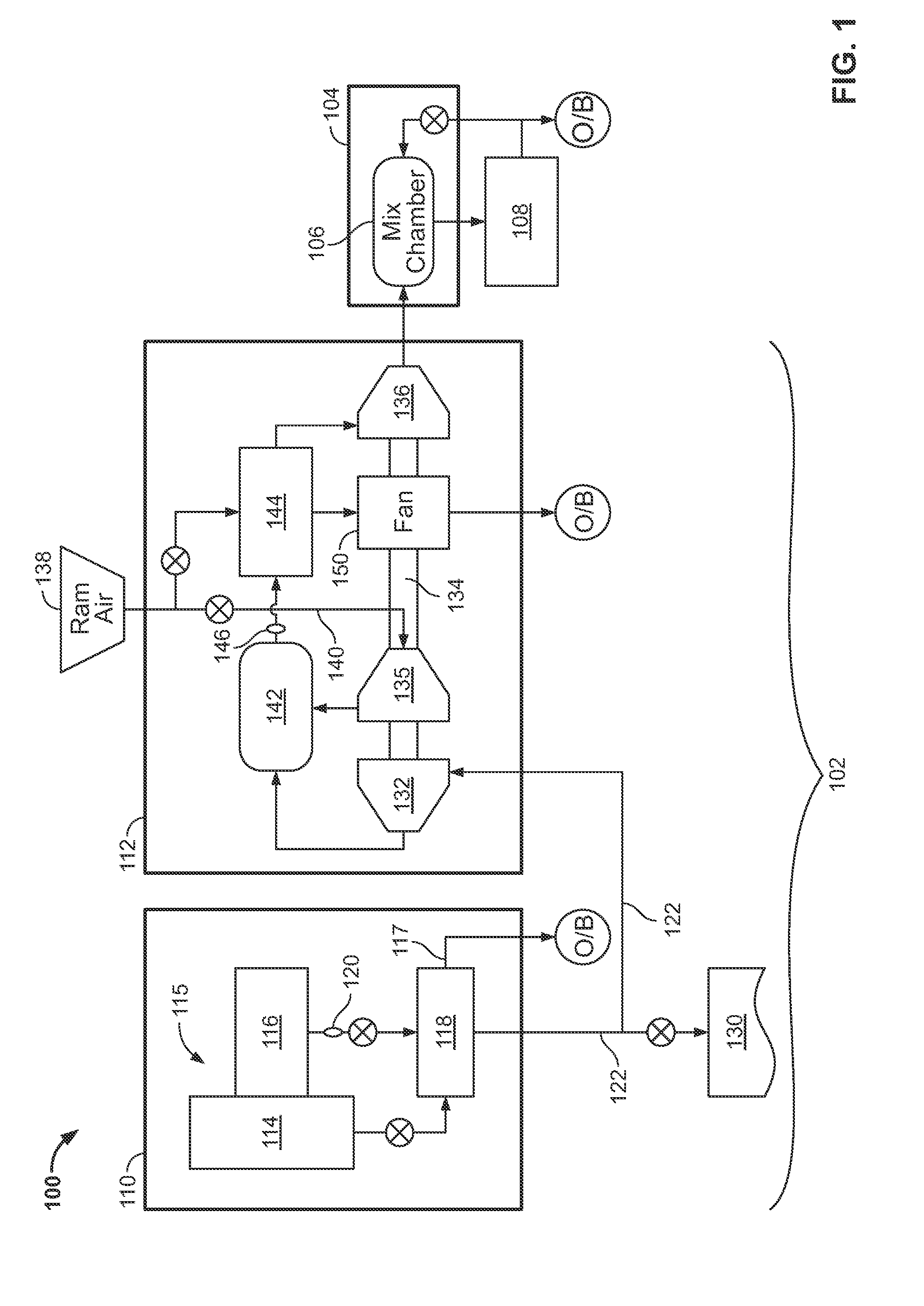

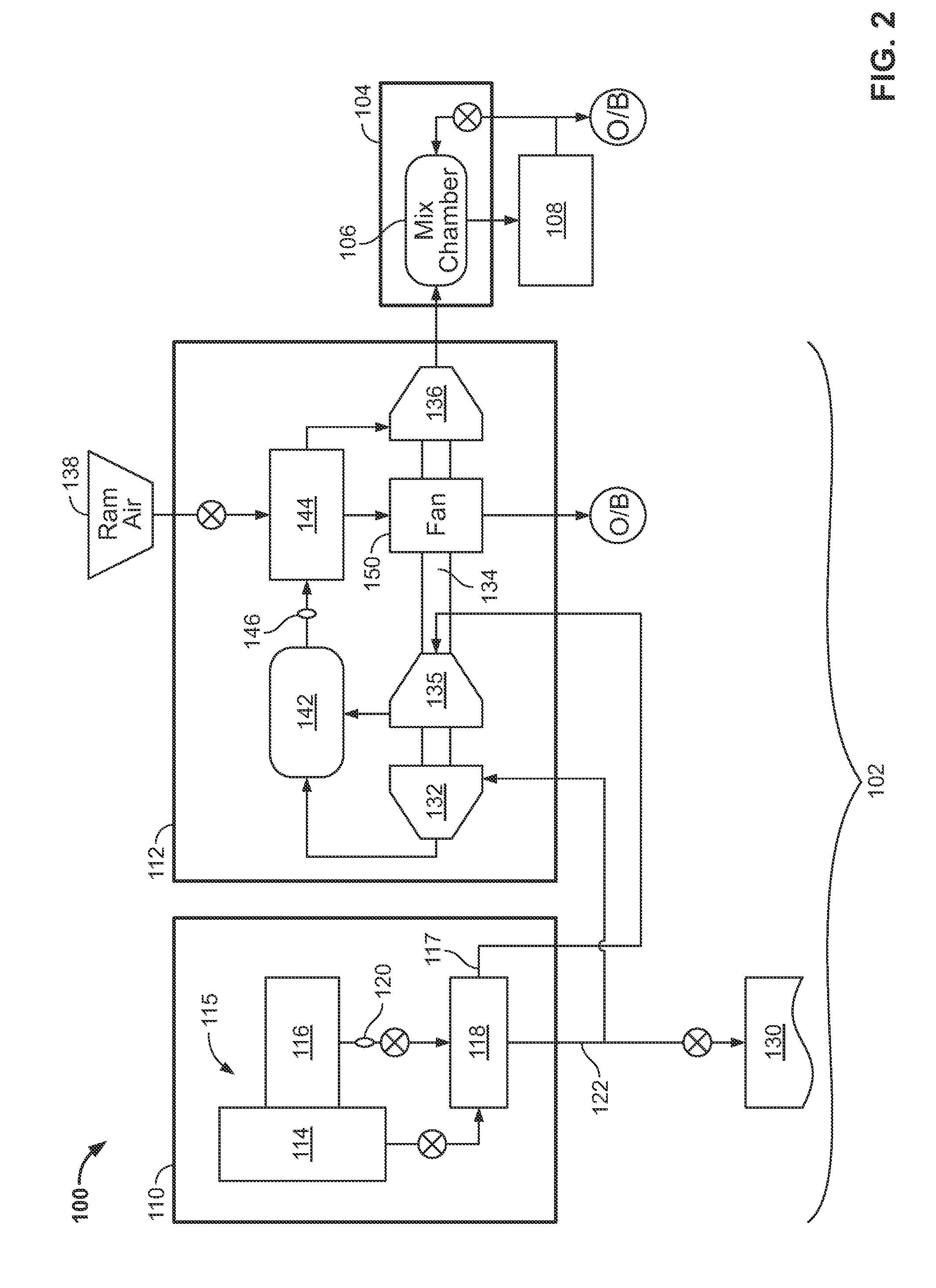

Blended flow air cycle system for environmental control

ActiveUS20130133348A1Domestic cooling apparatusAir-treatment apparatus arrangementsAir cycleBleed air

Owner:HAMILTON SUNDSTRAND CORP

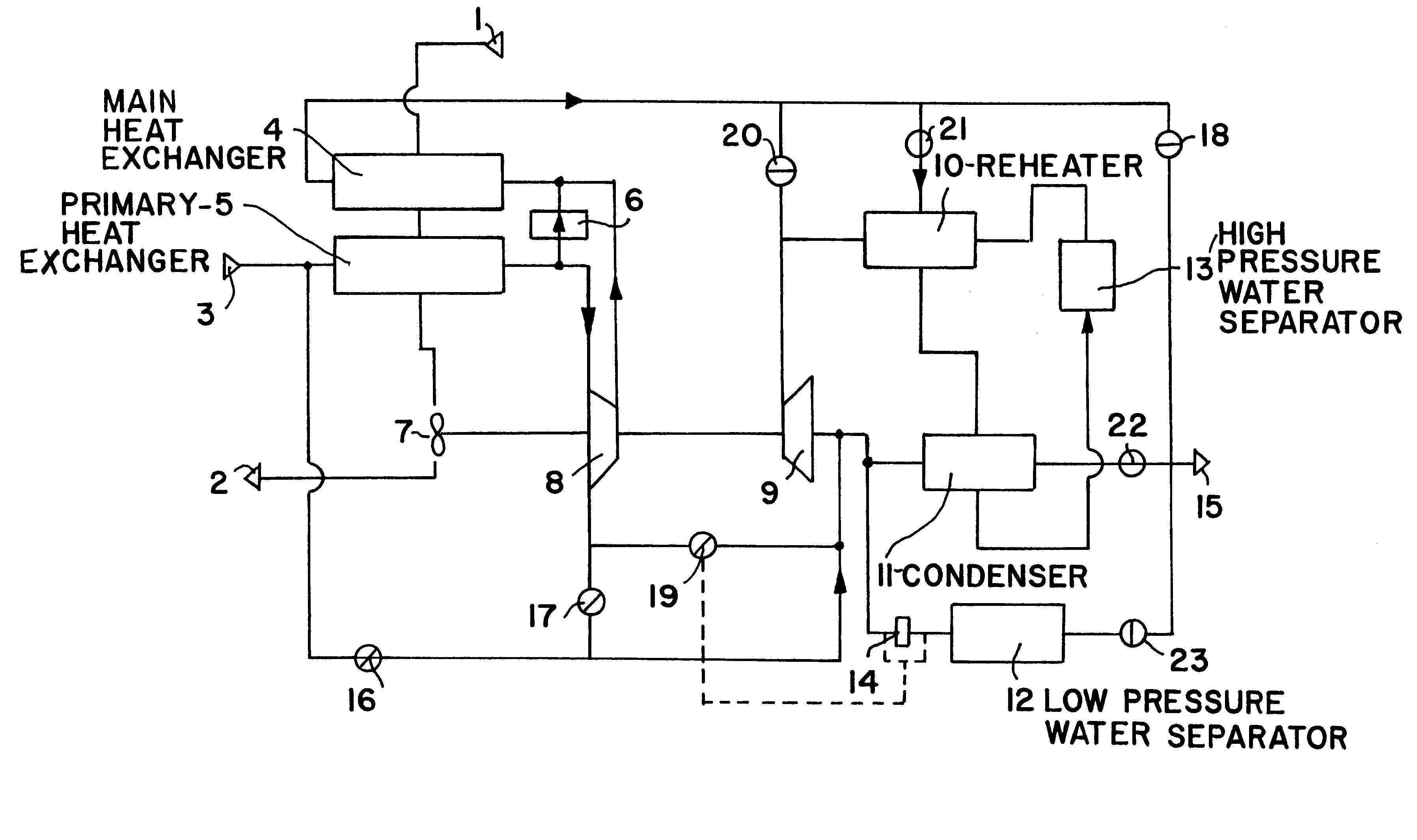

Aircraft air-conditioning apparatus with water separators

InactiveUS6295822B1Efficiently usMinimize the numberDomestic cooling apparatusAir-treatment apparatus arrangementsNacelleFlight vehicle

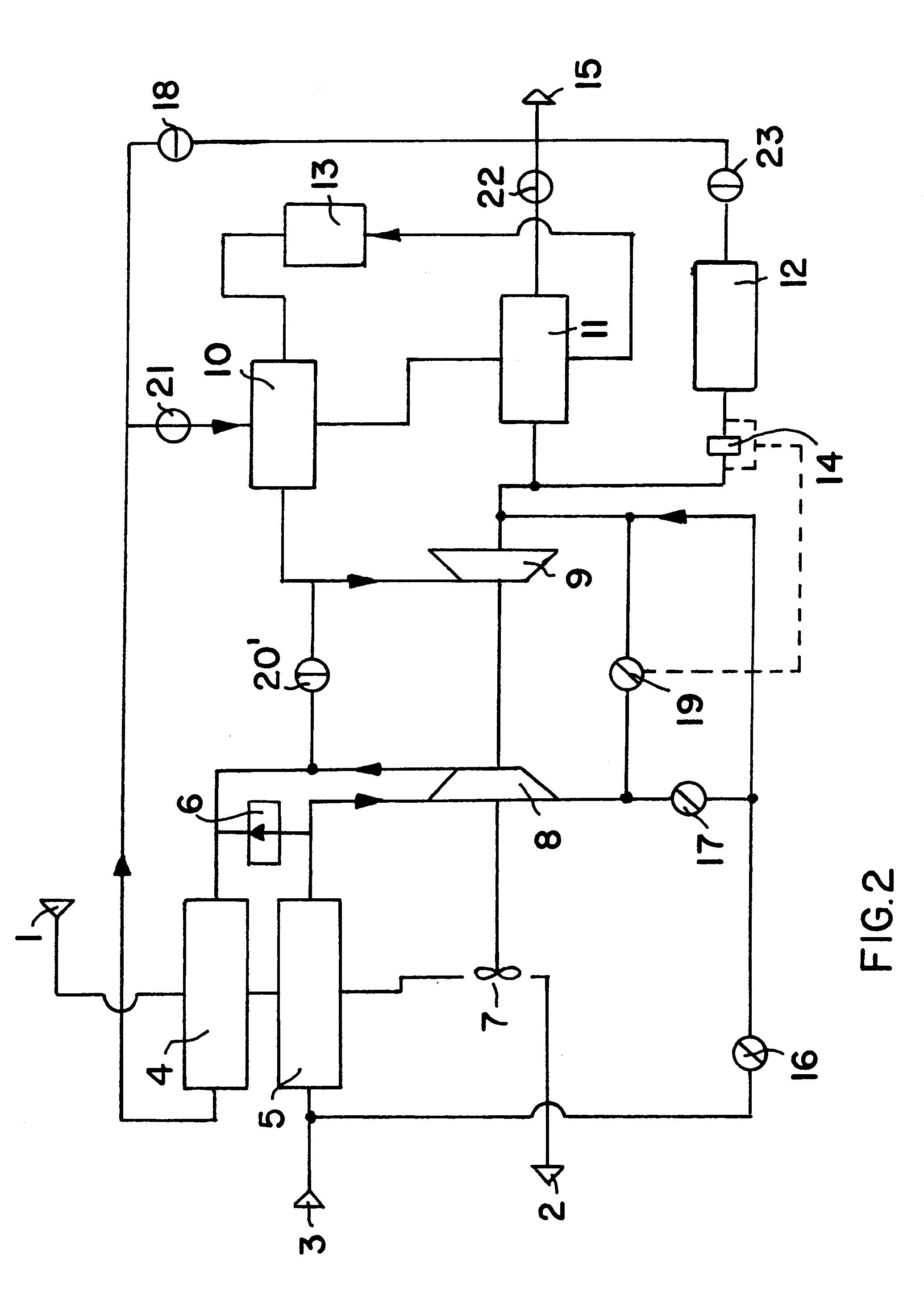

A system for air-conditioning the cabin of a passenger aircraft using externally provided fresh air as well as bleed air tapped from the engine of the aircraft includes at least one heat exchanger (4, 5), a blower (7), a compressor (8), an expansion turbine (9), a condenser (11), a reheater (10), a first high pressure water separator (13), and a second low pressure water separator (12). The several components are connected to each other by air lines such as air ducts, with control valves interposed therein. Two separate air-flow paths representing two different sub-systems are formed. A first air-flow path uses the high pressure water separator while a second air-flow path uses the low pressure water separator. These two air-flow paths or sub-systems can be operated separately and independently of each other by appropriately switching respective shut-off valves. In this manner, the operation of the air-conditioning system can be adaptively switched to achieve an optimal operation under different operating conditions of the aircraft and different air-conditioning requirements.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

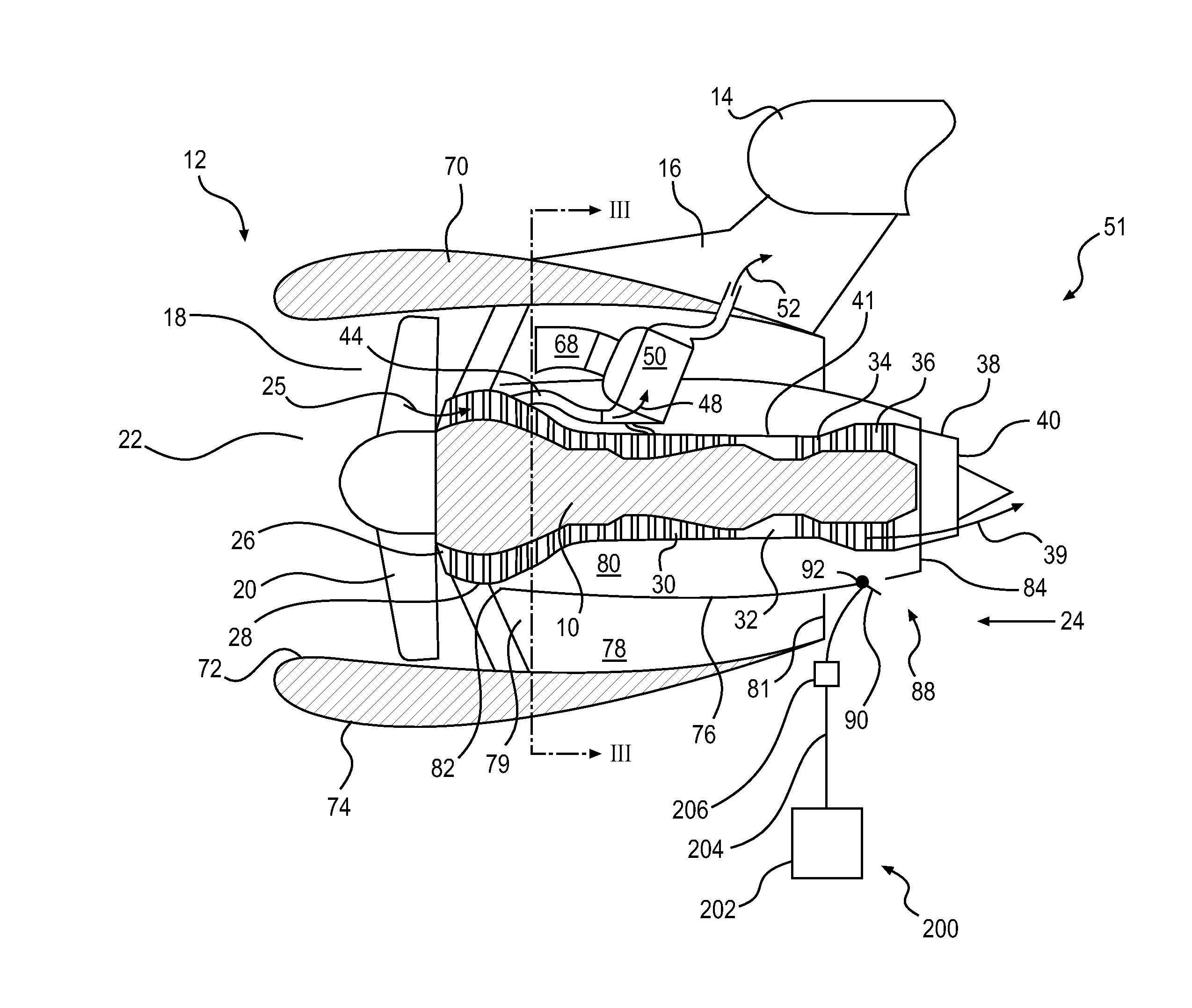

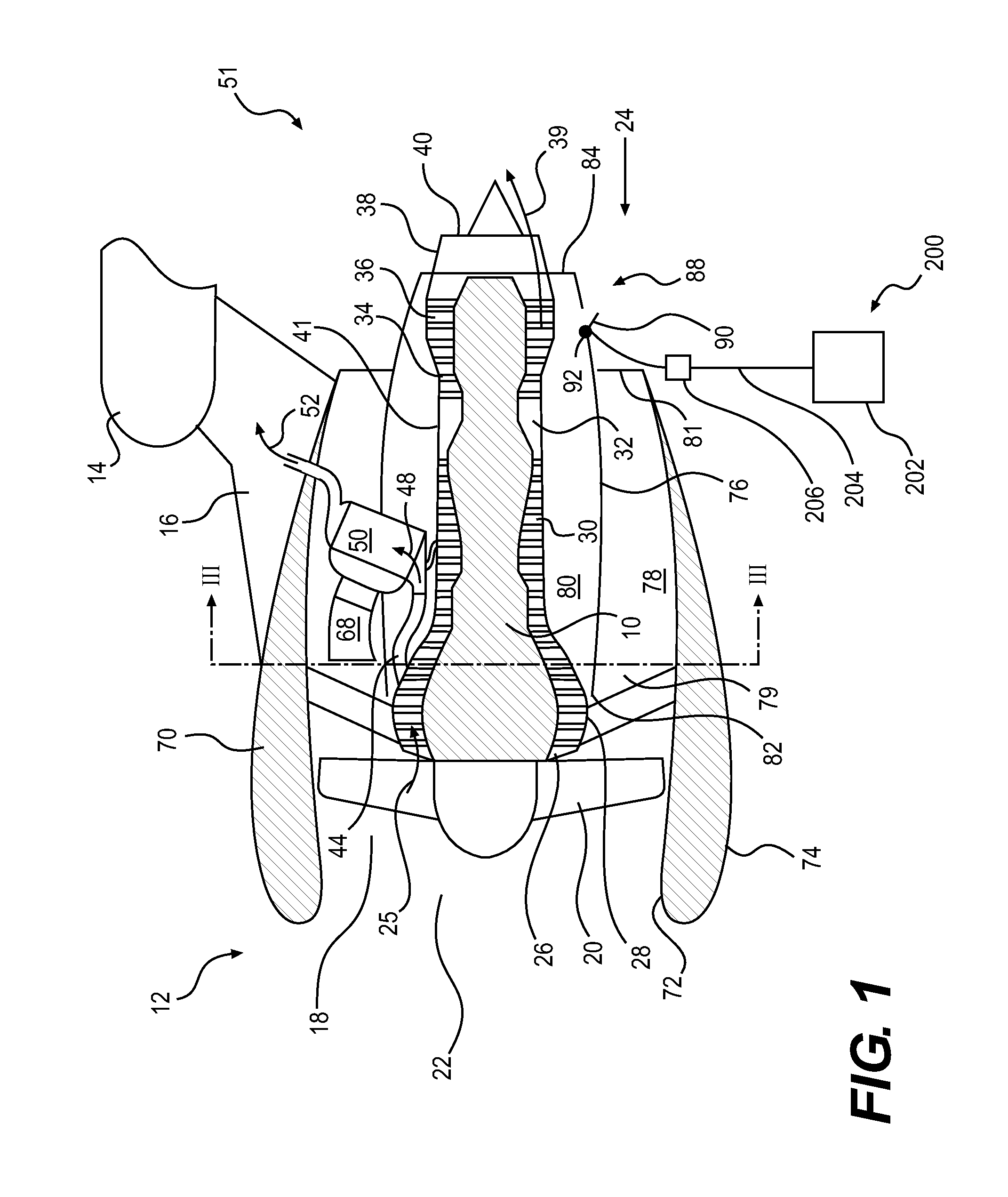

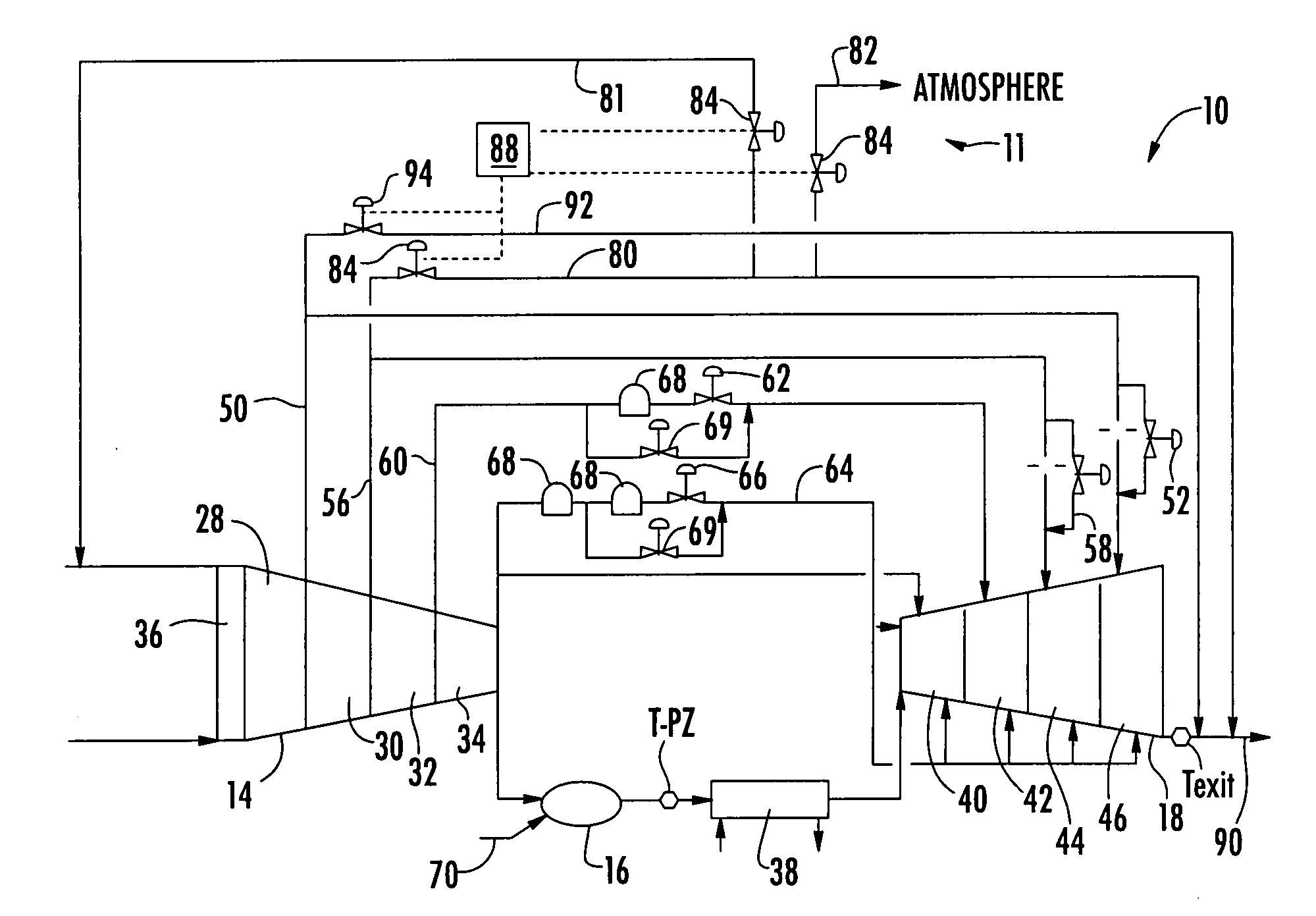

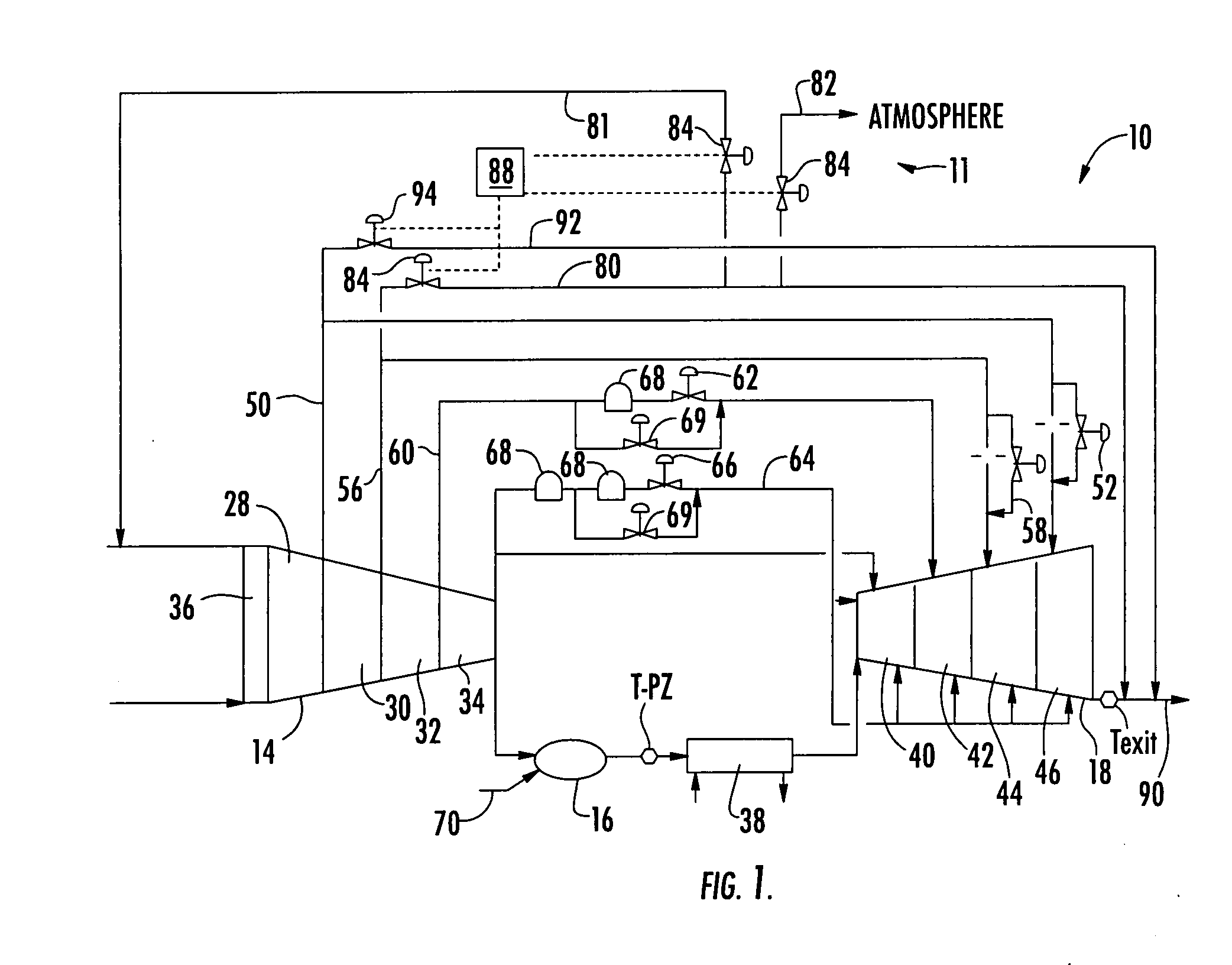

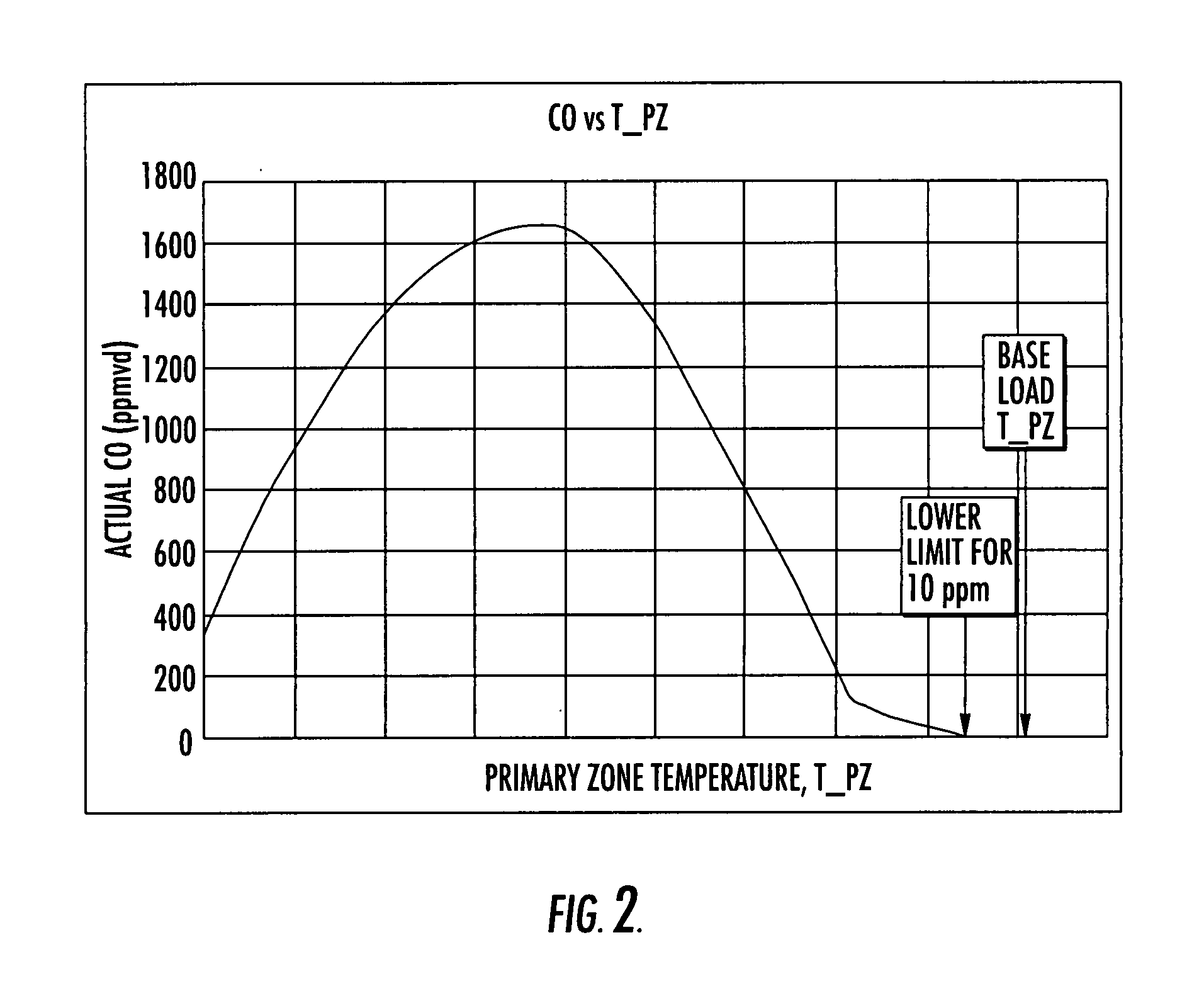

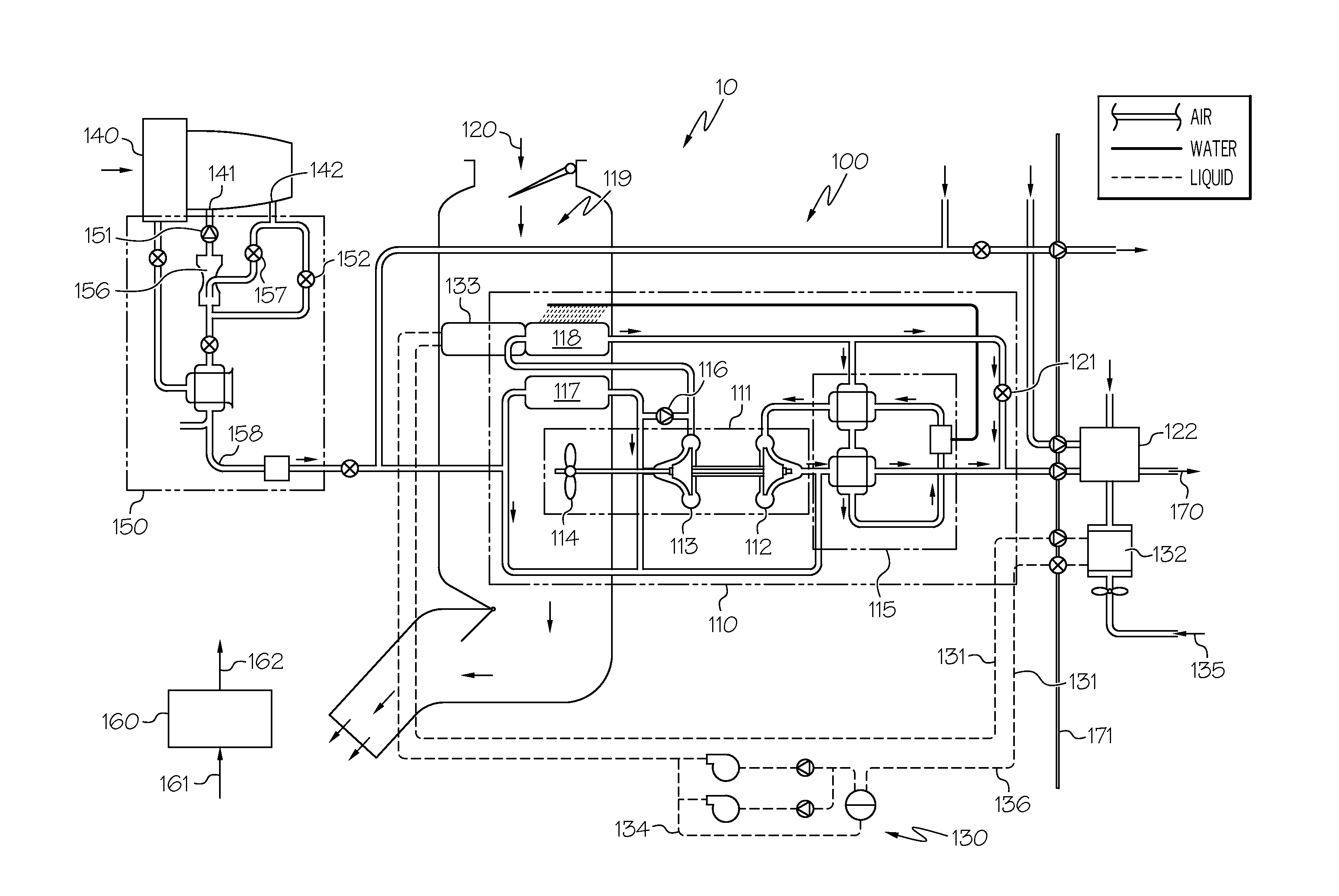

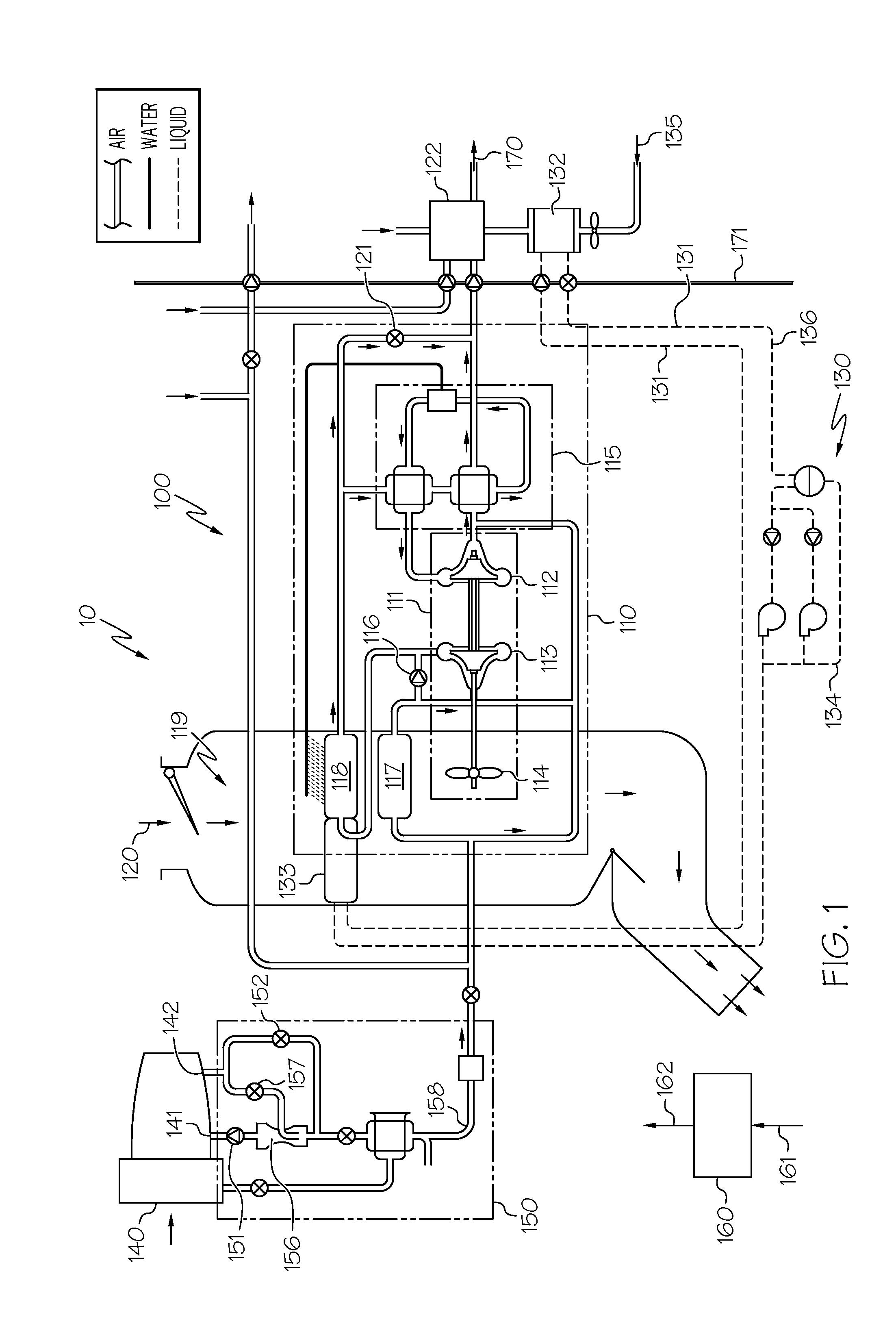

Engine brake for part load CO reduction

ActiveUS8015826B2Increase flow rateReduce operating loadGas turbine plantsEngine controlCombustorBleed air

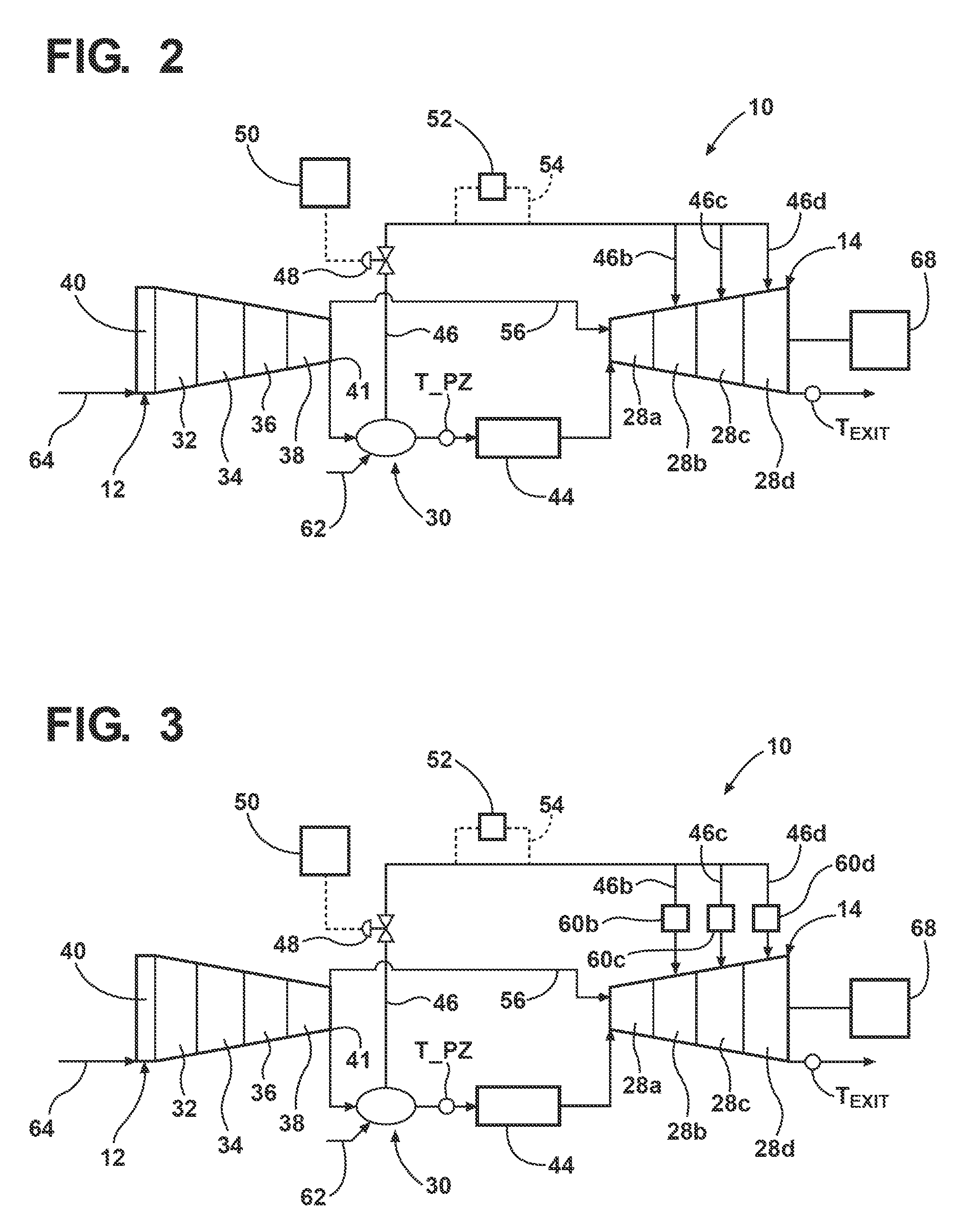

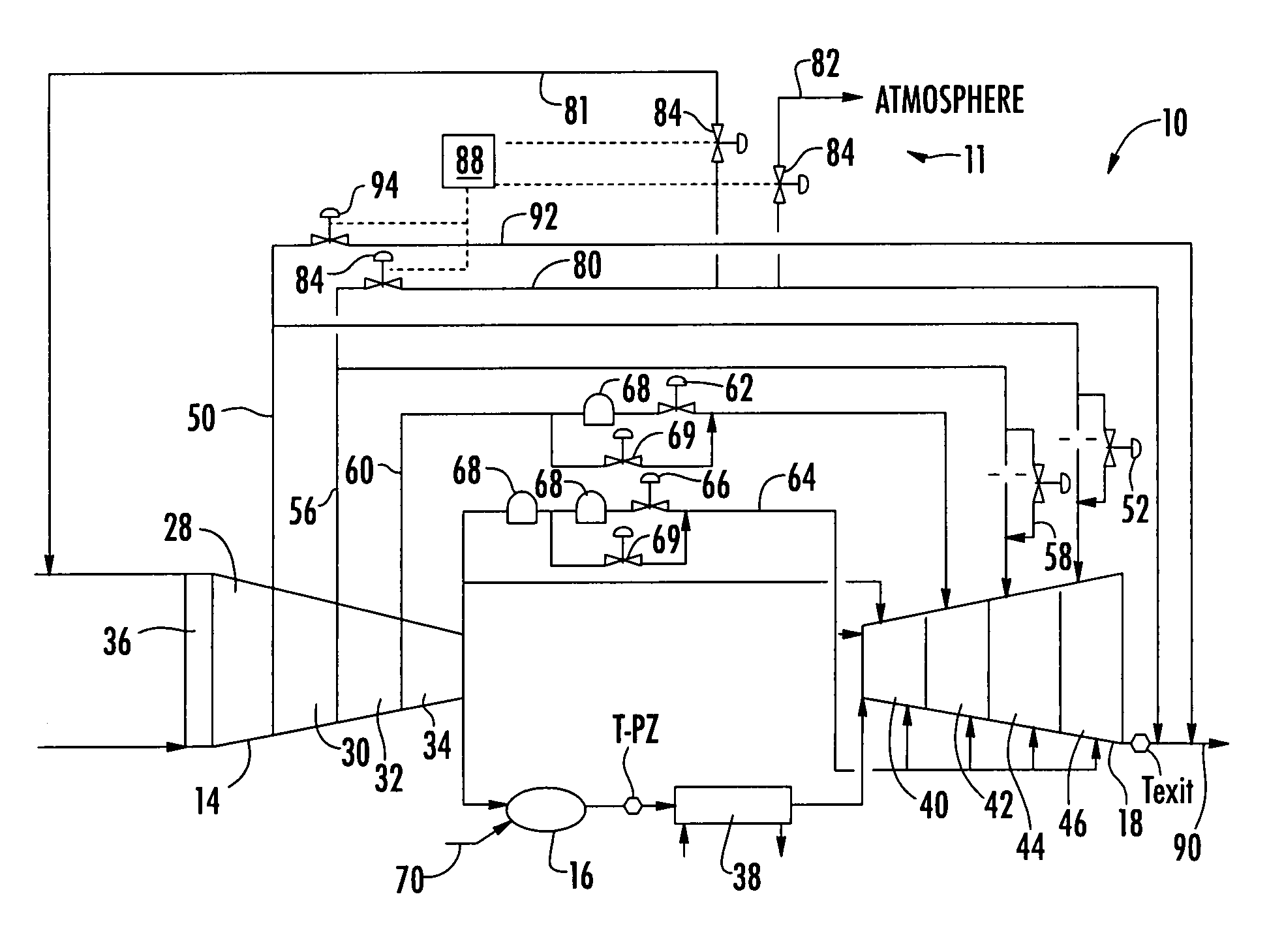

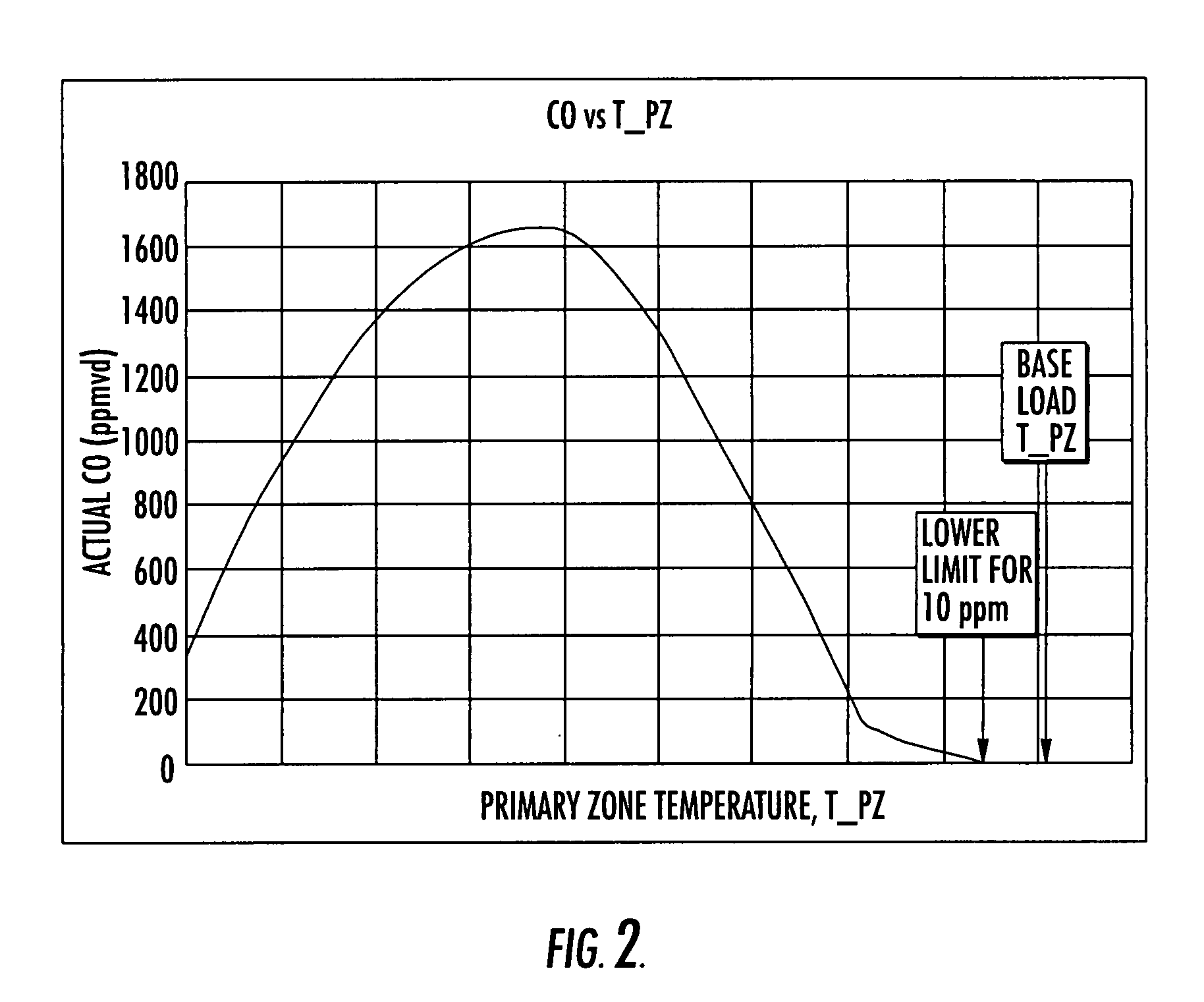

Aspects of the invention relate to a system and method for operating a turbine engine assembly. The turbine engine assembly has a turbine engine having a compressor section, a combustor section and a turbine section. The combustor section has a lower T_PZ limit and the turbine engine has a design load. The assembly further includes at least one air bleed line from the compressor and at least one valve for controlling air flow through the bleed line. Control structure is provided for opening the valve to allow bleed air to flow through the bleed line when an operating load is less than the design load. The flow rate through the bleed line is increased as the operating load is decreased, reducing the power delivered by the turbine assembly while maintaining the T_PZ above a lower T_PZ limit. A method for operating a turbine engine assembly is also disclosed.

Owner:SIEMENS ENERGY INC

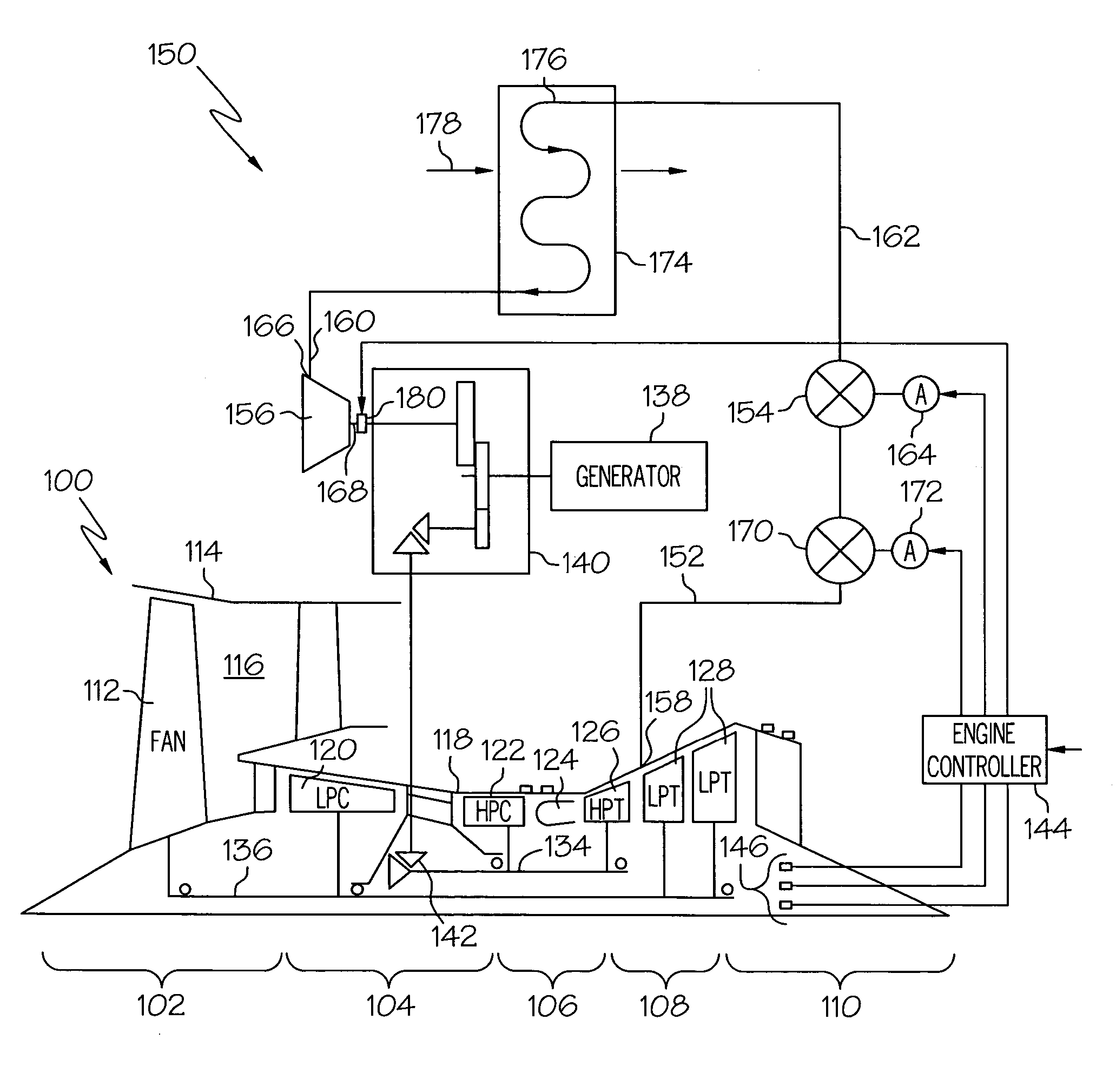

Gas turbine engine bleed air power assist system and method

A bleed air power assist system is coupled to a gas turbine engine that includes a high pressure turbine, a low pressure turbine, and an electrical generator driven by the high pressure turbine. The bleed air power assist system selectively bleeds air discharged from the high pressure turbine and supplies it to an air turbine that is also coupled to the generator. Thus, the system selectively reduces the power extracted from the high pressure turbine. This, coupled with the bleed air that is diverted from the low pressure turbine, allows the low pressure spool to run at lower speeds when high engine thrust is not needed or desired, but when the generator is still needed to supply high electrical loads.

Owner:HONEYWELL INT INC

Hypoxic aircraft fire prevention and suppression system with automatic emergency oxygen delivery system

An aircraft fire-extinguishing system provides automatic fire prevention and / or suppression simultaneously in fuel tanks, cargo compartments and, when needed, in cabin using injection of hypoxic (oxygen-depleted) air produced onboard in an air-separation device utilizing the flow and pressure of the bleed air. The same air-separation device allows supplying passengers and crew with unlimited amounts of oxygen for as long as needed. New methods of a rapid fire suppression utilizing the propulsion of water mist or fire-extinguishing foam by hypoxic air are presented. The combination of water mist or foam with hypoxic air allows to present two innovative fire-extinguishing compositions.

Owner:KOTLIAR IGOR K

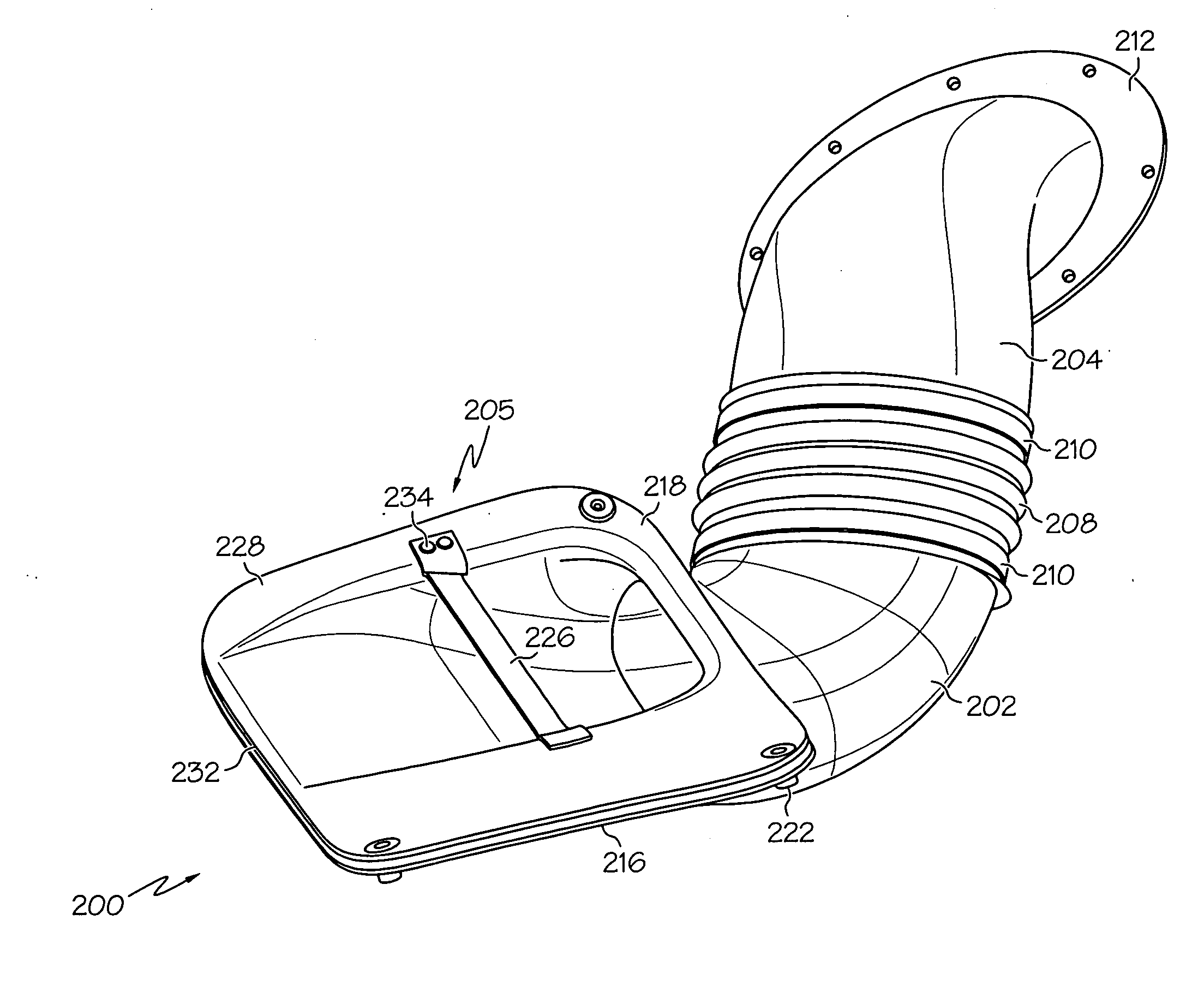

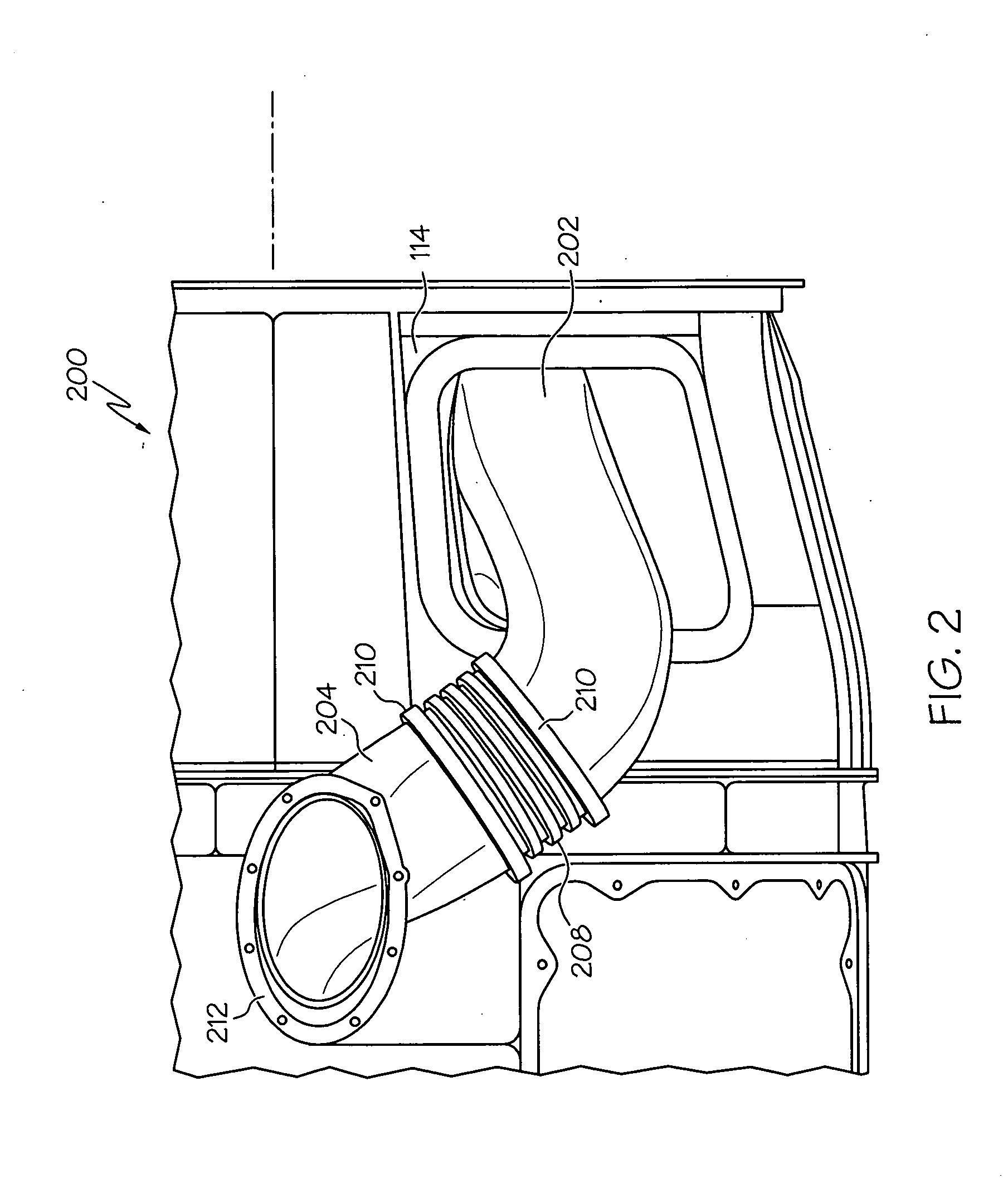

Flush inlet scoop design for aircraft bleed air system

ActiveUS20100126182A1Reduction of Helmholtz resonanceEfficient propulsion technologiesGas turbine plantsHelmholtz resonatorBleed air

Owner:HONEYWELL INT INC

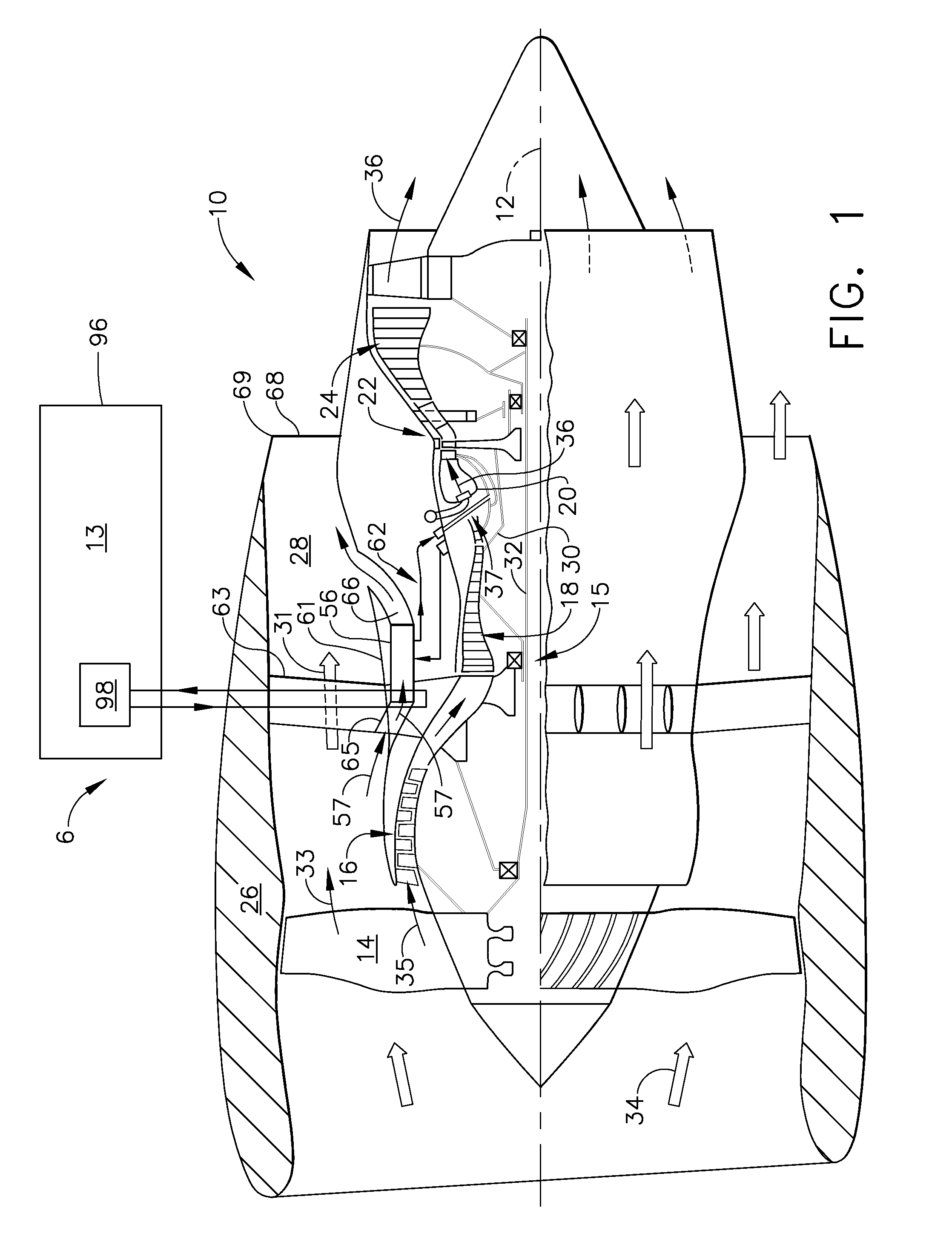

System and method for operating a precooler in an aircraft

ActiveUS20140000279A1Increasing amount of receivedImprove precooler 's performancePower plant cooling arrangmentsTurbine/propulsion engine coolingNacelleBleed air

An aircraft engine includes a precooler disposed within a nacelle. The precooler defines an ambient air passage and a bleed air passage. Air passes through the precooler from an ambient air inlet to an ambient air outlet. Bleed air passes through the precooler from a bleed air inlet to a bleed air outlet. Heat is transferred between the air and the bleed air via heat exchange within the precooler. At least one pressure relief door disposed proximate to the air outlet of the engine. A controller is operatively connected to the pressure relief door. The controller at least opens the pressure relief door based on a demand for increased flow of air through the ambient air passage.

Owner:AIRBUS CANADA LLP

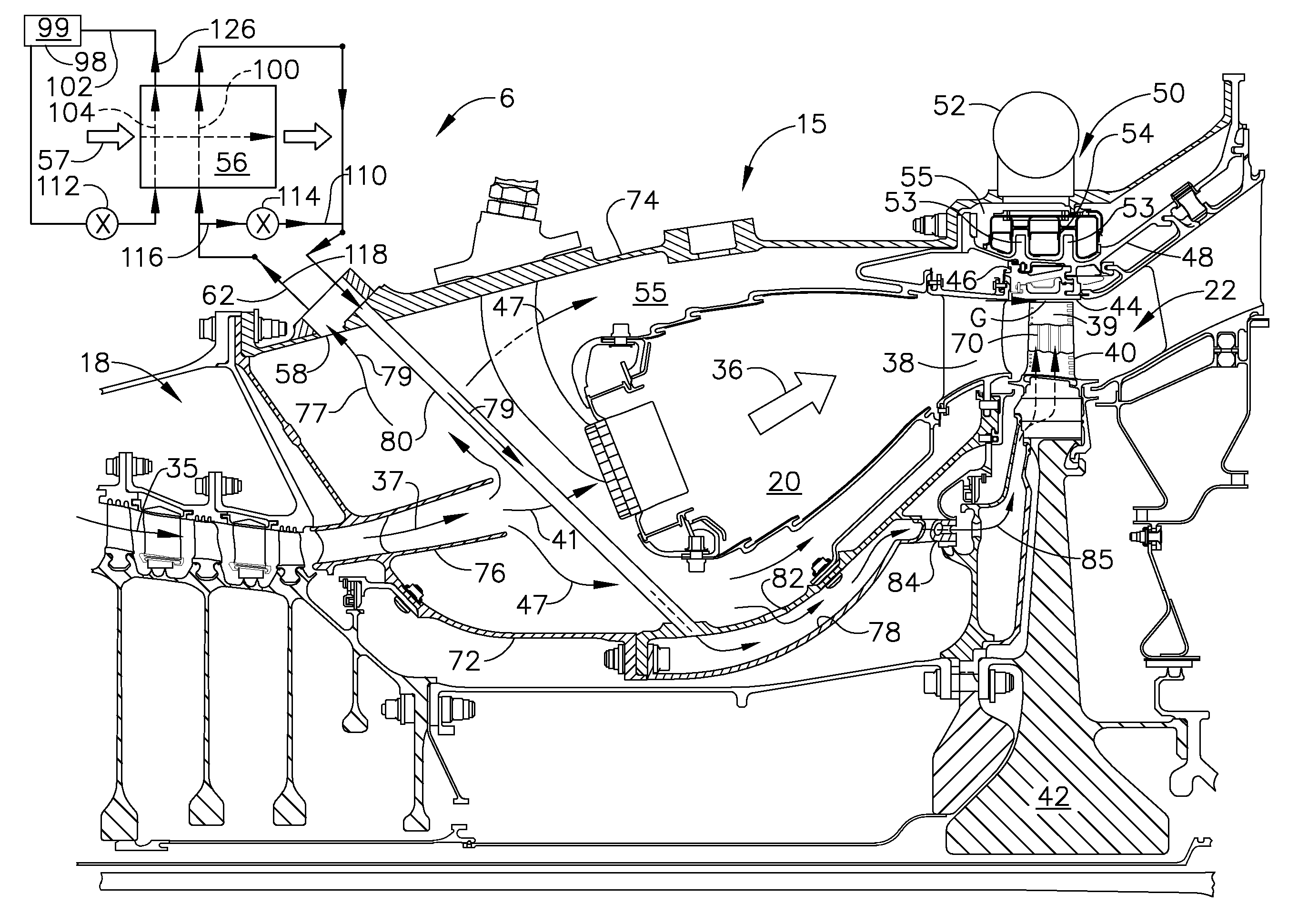

Bleed air and hot section component cooling air system and method

Combined bleed air and hot section component cooling air systems for gas turbine engines and methods of operating combined bleed air and hot section component cooling air systems are disclosed. An example system may include a high-pressure bleed air line receiving high-pressure bleed air; a precooler receiving at least some of the high-pressure bleed air and discharging cooled high-pressure bleed air; a pressure regulator receiving at least some of the cooled high-pressure bleed air and discharging pressure-regulated cooled bleed air to a pneumatic systems supply line; and / or a hot section component cooling air line connected upstream of the first pressure regulator and configured to convey at least some of the cooled high-pressure bleed air to a hot section component for use as hot section component cooling air.

Owner:GENERAL ELECTRIC CO

Aerodynamic noise reducing structure for aircraft wing slats

A hollow expandable and contractible displacement element is secured onto the concave rear surface of a slat facing the leading edge of an aircraft wing. A bleed air line supplies engine bleed air into the hollow displacement element to selectively expand or contract the displacement element, which is preferably elastically expandable. When the slat is extended, the displacement element is expanded to fill-out the concave cavity on the rear surface of the slat so as to prevent formation of a vortex in the slat air gap and thereby to reduce aero-acoustic noise. When the slat is retracted, the displacement element is contracted to be conformingly accommodated in the sickle-shaped space between the slat and the leading edge of the wing.

Owner:AIRBUS OPERATIONS GMBH

Engine brake for part load CO reduction

ActiveUS20100251727A1Increase flow rateReduce operating loadGas turbine plantsEngine controlCombustorEngineering

Aspects of the invention relate to a system and method for operating a turbine engine assembly. The turbine engine assembly has a turbine engine having a compressor section, a combustor section and a turbine section. The combustor section has a lower T_PZ limit and the turbine engine has a design load. The assembly further includes at least one air bleed line from the compressor and at least one valve for controlling air flow through the bleed line. Control structure is provided for opening the valve to allow bleed air to flow through the bleed line when an operating load is less than the design load. The flow rate through the bleed line is increased as the operating load is decreased, reducing the power delivered by the turbine assembly while maintaining the T_PZ above a lower T_PZ limit. A method for operating a turbine engine assembly is also disclosed.

Owner:SIEMENS ENERGY INC

Low-pressure bleed air aircraft environmental control system

ActiveUS20150251765A1Eliminate pressure dropDomestic cooling apparatusAir-treatment apparatus arrangementsAir cycle machineControl system

An aircraft environmental control system (ECS) may be configured to operate in first mode and a second mode. The ECS may include an air cycle machine (ACM), a by-pass valve positioned to allow bleed air to by-pass the air cycle machine so that when the by-pass valve is open, the ECS operates in the first mode with bleed air at a first pressure and when the by-pass valve is closed the ECS operates in the second mode at a second bleed air pressure, higher than the first bleed air pressure. A bleed air system controller and ECS controller may be configured to selectively couple high pressure or low pressure bleed air ports of an engine of an aircraft to the ECS and control the by-pass valve position.

Owner:HONEYWELL INT INC

Gas turbine engine bleed air power assist system and method

InactiveUS20060010875A1Cosmonautic vehiclesCosmonautic propulsion system apparatusElectricityLow speed

A bleed air power assist system is coupled to a gas turbine engine that includes a high pressure turbine, a low pressure turbine, and an electrical generator driven by the high pressure turbine. The bleed air power assist system selectively bleeds air discharged from the high pressure turbine and supplies it to an air turbine that is also coupled to the generator. Thus, the system selectively reduces the power extracted from the high pressure turbine. This, coupled with the bleed air that is diverted from the low pressure turbine, allows the low pressure spool to run at lower speeds when high engine thrust is not needed or desired, but when the generator is still needed to supply high electrical loads.

Owner:HONEYWELL INT INC

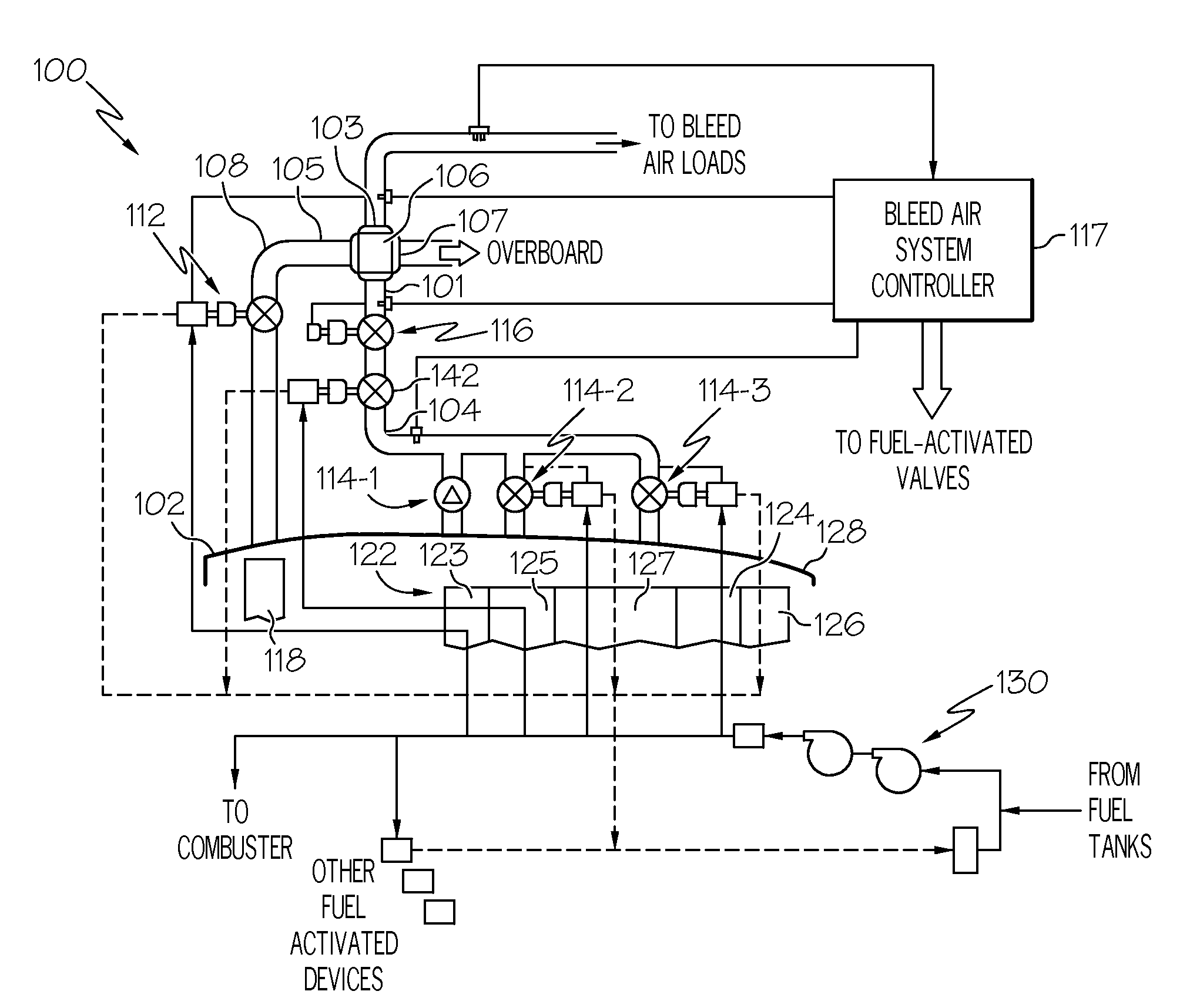

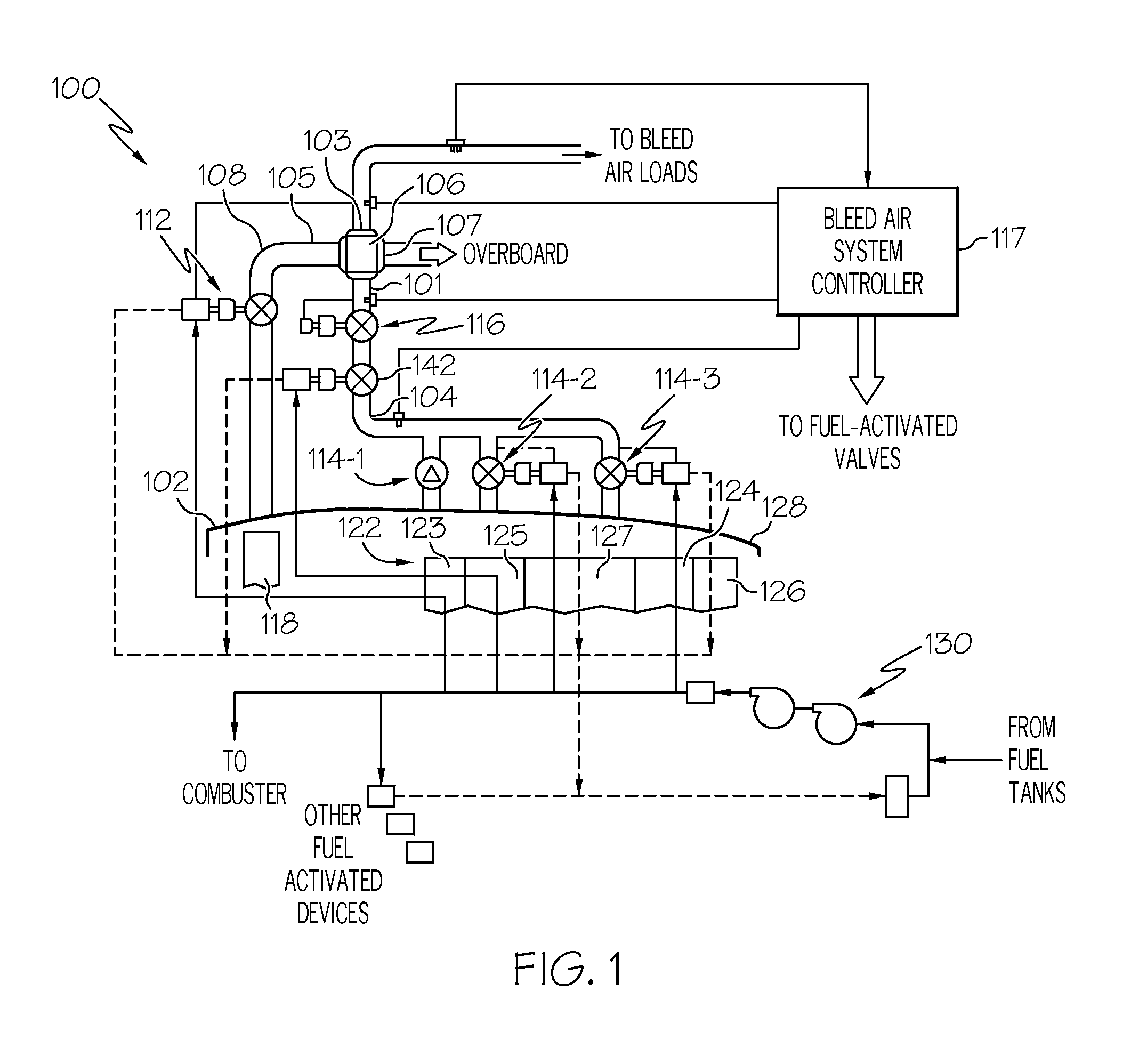

Fuel actuated bleed air system

InactiveUS20120045317A1Constant and relatively high pressureEasy to installWind motor controlCombination enginesBleed airFuel gas

A gas turbine engine bleed air system includes one or more fuel-actuated bleed air supply valves and, in some cases, a pneumatically actuated overpressure valve. Each fuel-actuated bleed air supply valve is mounted on a bleed air supply conduit and is coupled to a source of pressurized aircraft fuel. Each fuel-actuated bleed air supply valve is responsive to the pressurized aircraft fuel to move to a plurality of valve positions and to regulate compressed air pressure in the bleed air supply conduit, downstream of the fuel-actuated bleed air supply valve. The pneumatically actuated overpressure valve is mounted on the bleed air conduit downstream of each of the fuel-actuated bleed air valves and pneumatically regulates or shuts off pressure independent of fuel pressure or electrical signals.

Owner:HONEYWELL INT INC

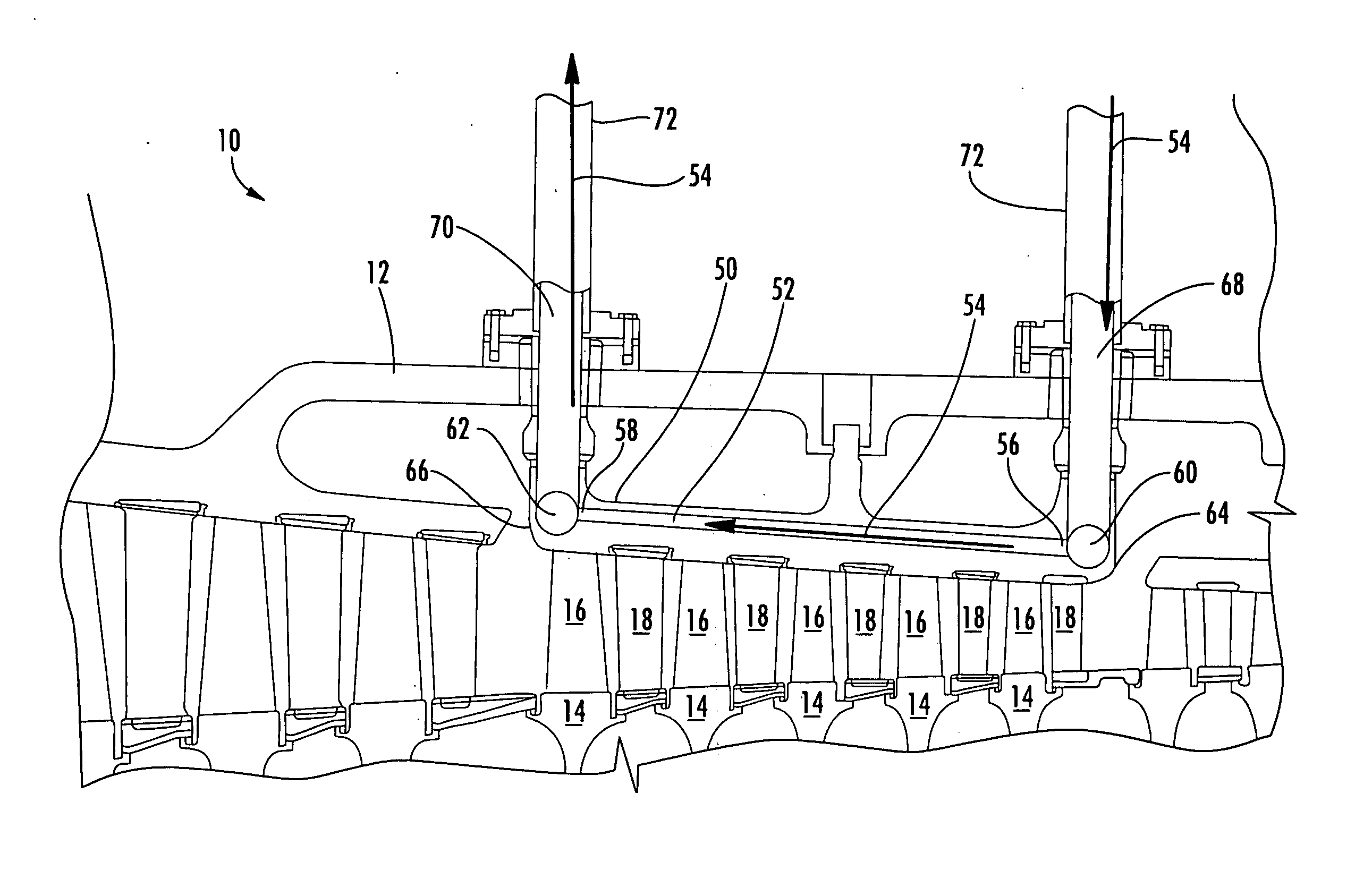

Rear hub cooling for high pressure compressor

In one exemplary embodiment, a gas turbine engine includes a turbine and a high pressure compressor. The high pressure compressor includes a last stage having a last stage compressor blade and a last stage vane. The gas turbine engine includes a first flow path through which bleed air flows to the turbine and a second flow path through which air from the last stage of the high pressure compressor flows. The bleed air in the first flow path exchanges heat with a portion of the air in the second flow path in a heat exchanger to cool the air in the second flow path. The cooled air in the second flow path is returned to the high pressure compressor to cool the high pressure compressor.

Owner:RTX CORP

System for actively controlling compressor clearances

InactiveUS7434402B2Compressor clearances can beReduce gapPump componentsEngine fuctionsEngineeringBleed air

Aspects of the invention relate to a system and method for actively controlling compressor clearances in a turbine engine by passing a thermal fluid in heat exchanging relation through a compressor vane carrier. During some operational conditions, such as hot restart or spin cool, it may be desirable to heat the vane carrier to enlarge or at least prevent a decrease in compressor clearances. In such cases, a heated thermal fluid can be provided by reclaiming residual exhaust energy from a heat recovery steam generator. At any condition where improved performance is desired, such as at base load operation, the vane carrier can be cooled to minimize compressor clearances. A cooled thermal fluid can be bleed air from an upstream portion of the compressor, water-cooled high pressure bleed air from a downstream portion of the compressor, or feed water from the bottoming cycle in a combined cycle engine.

Owner:SIEMENS ENERGY INC

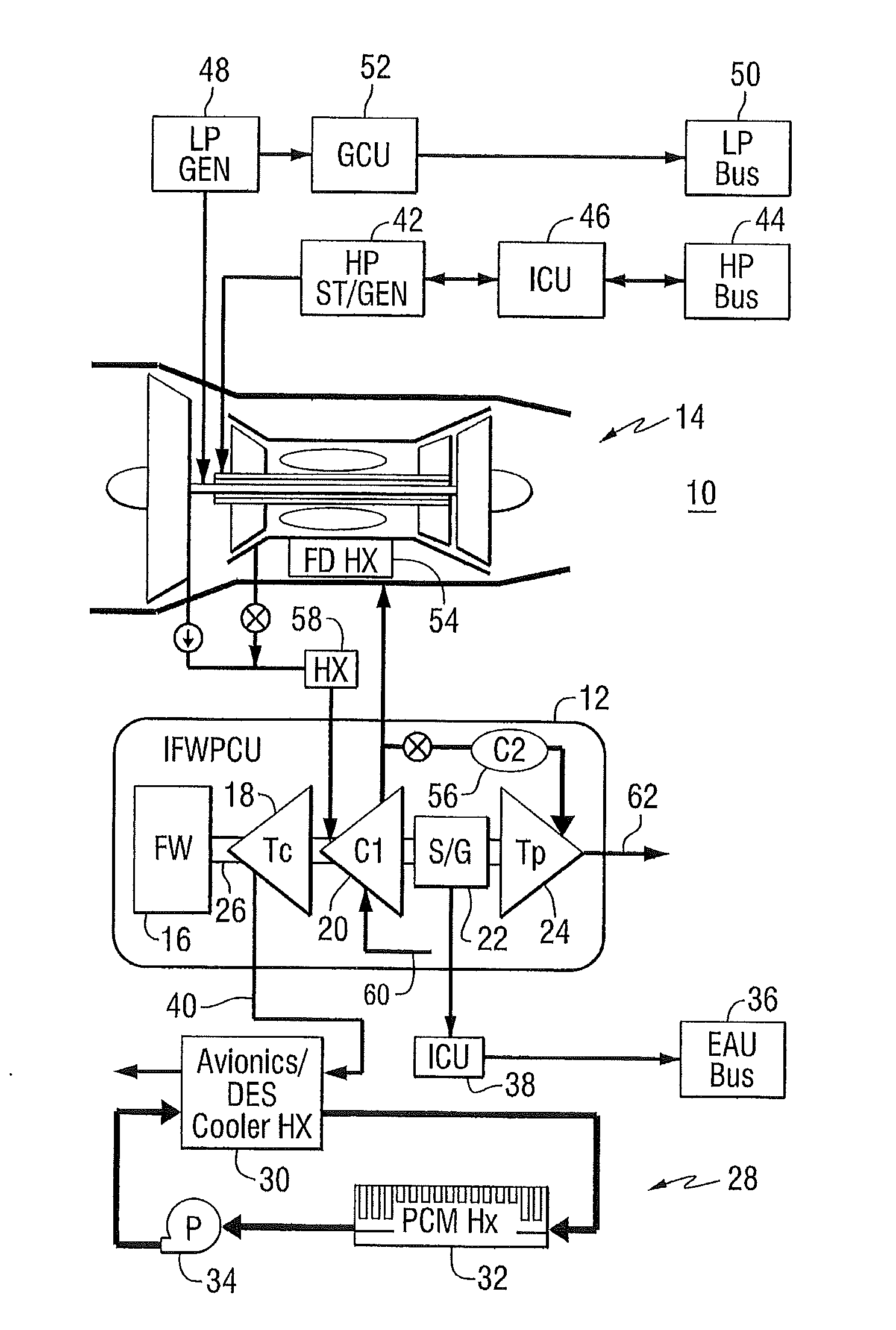

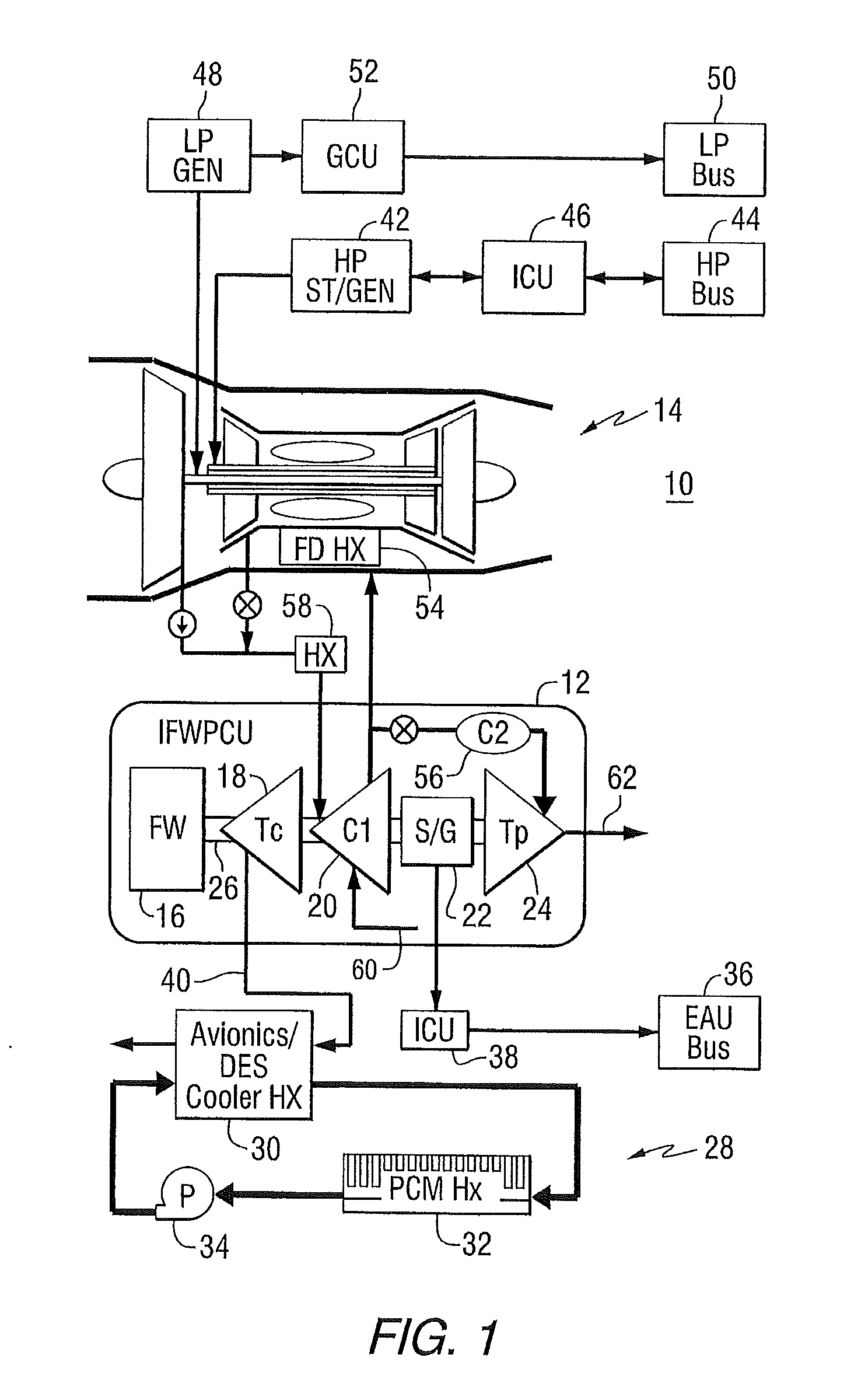

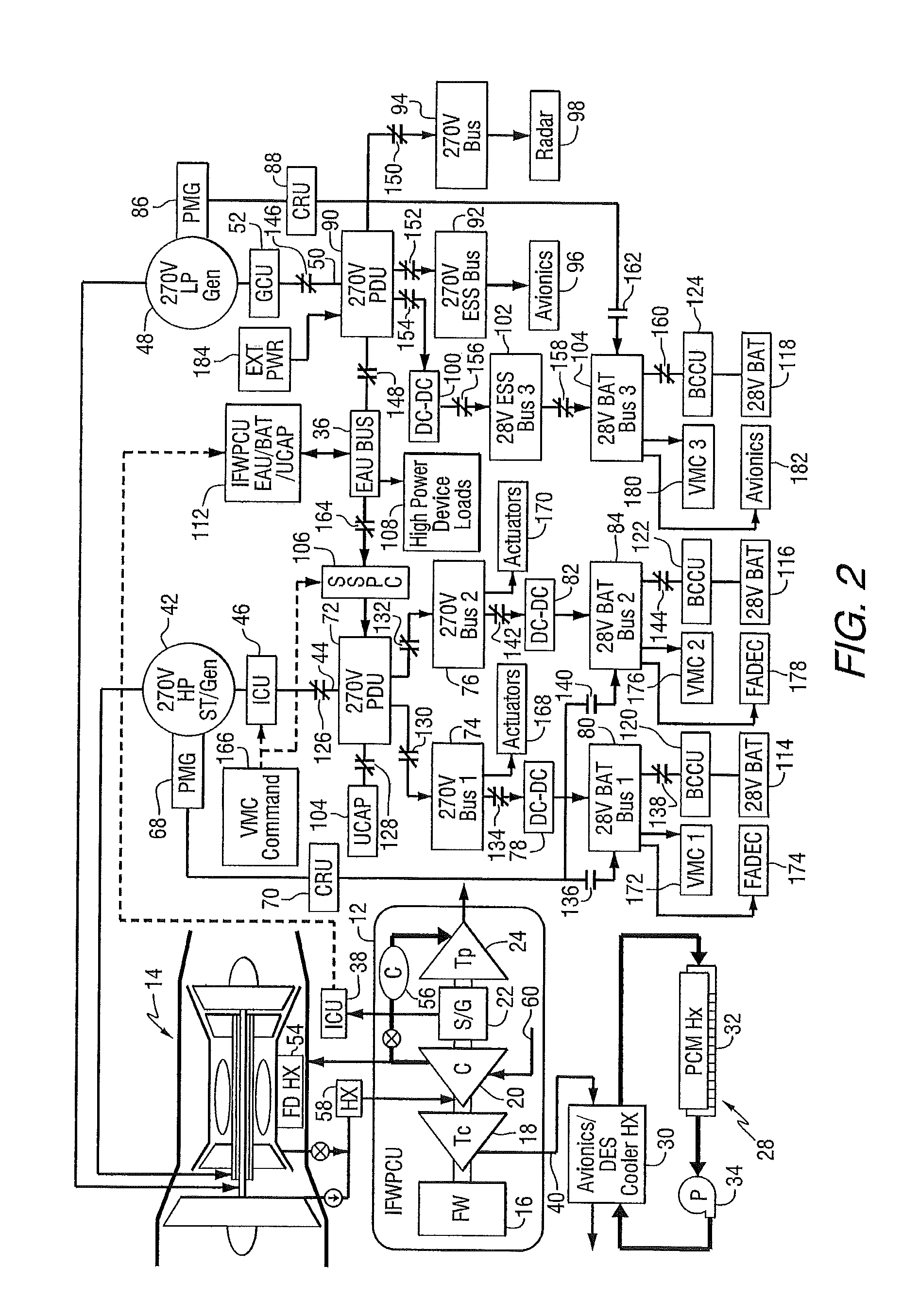

Apparatus for aircraft with high peak power equipment

An apparatus is provided for supplying electrical power and cooling for an aircraft. The apparatus includes a cooling turbine coupled to a shaft, a compressor coupled to the shaft, and including an input for receiving engine bleed air or ambient air, and an output for discharging compressed air, a flywheel coupled to the shaft, a power turbine coupled to the shaft, and a starter generator coupled to the shaft between the compressor and the power turbine.

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com