Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145results about How to "Avoid insufficient temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

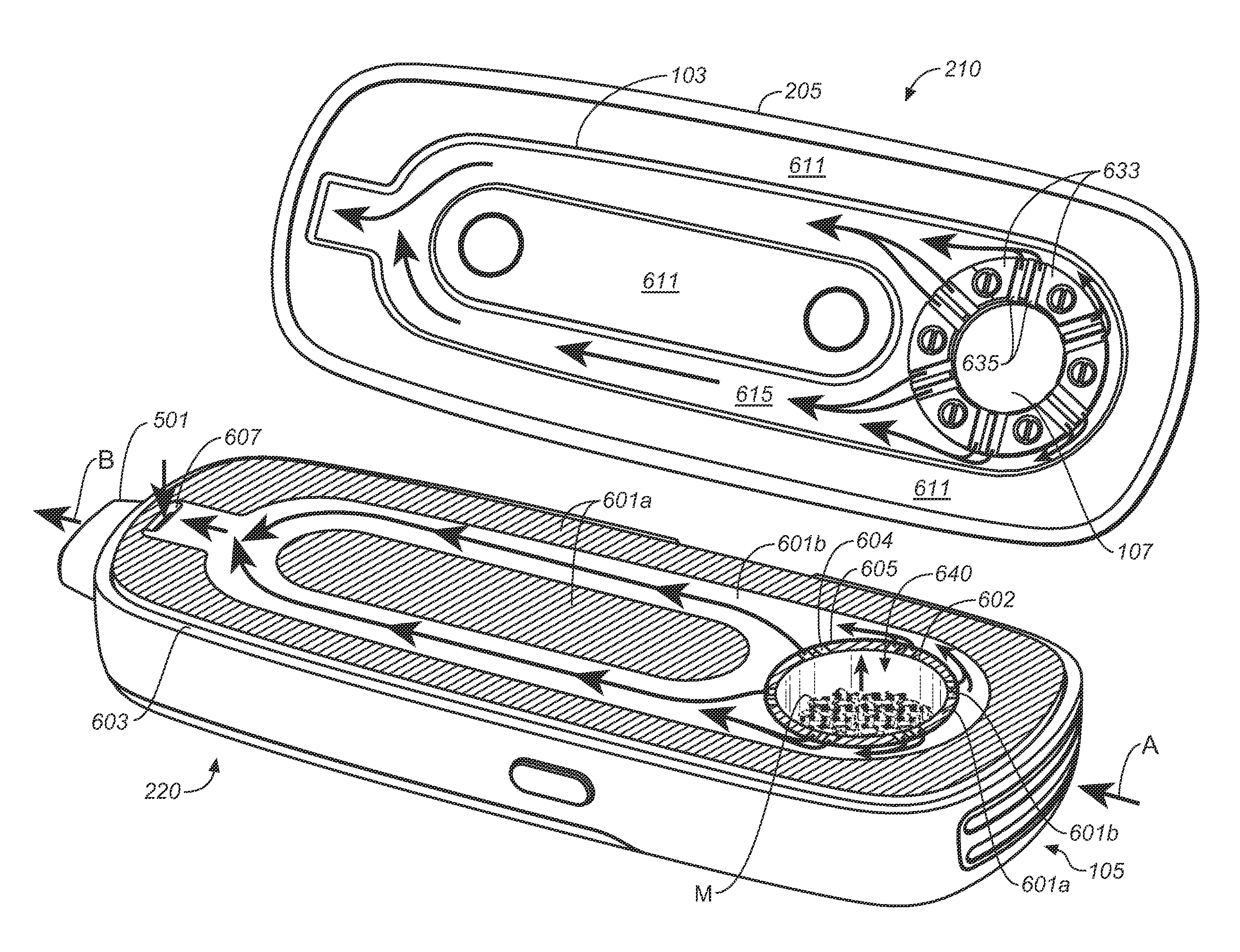

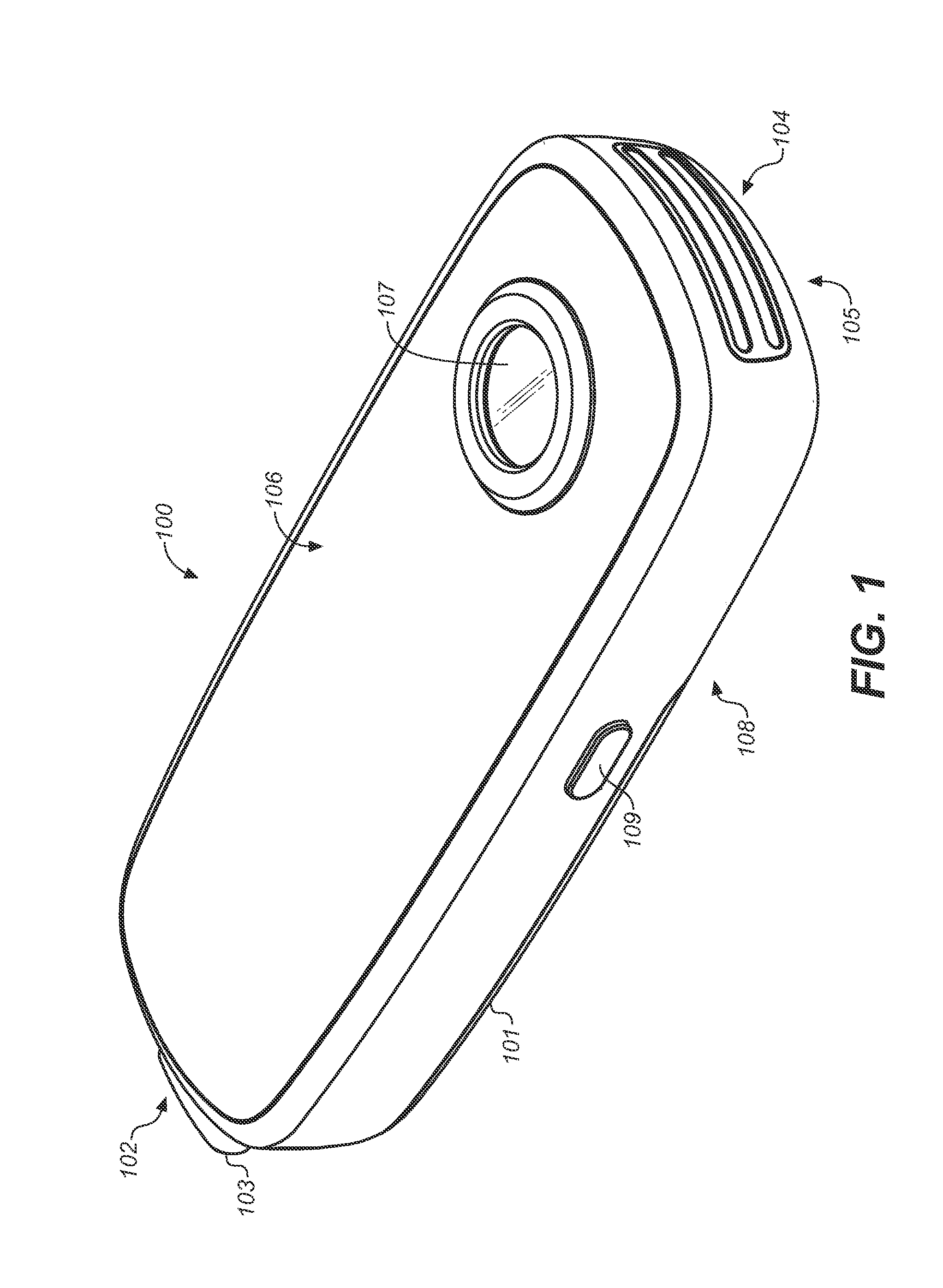

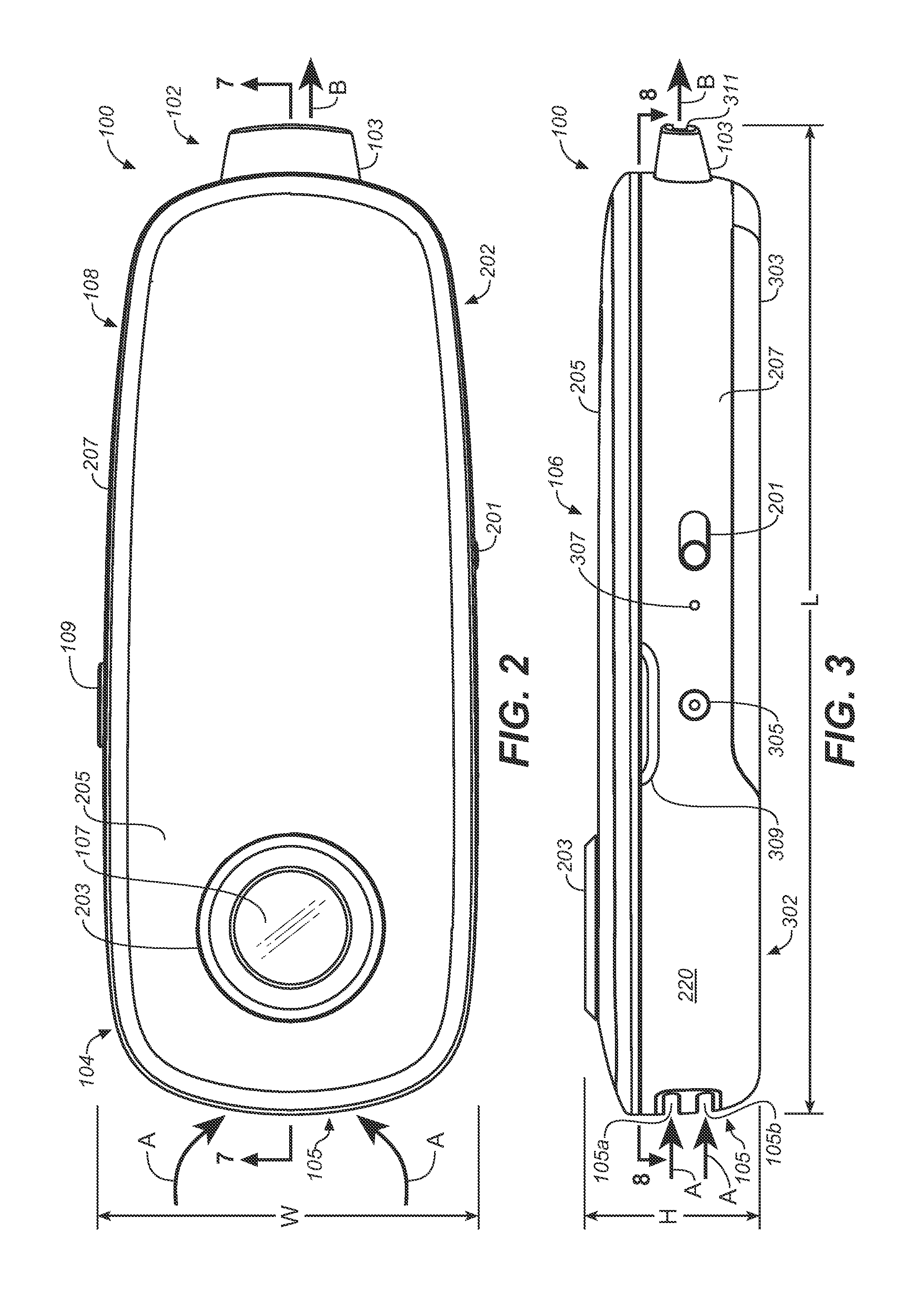

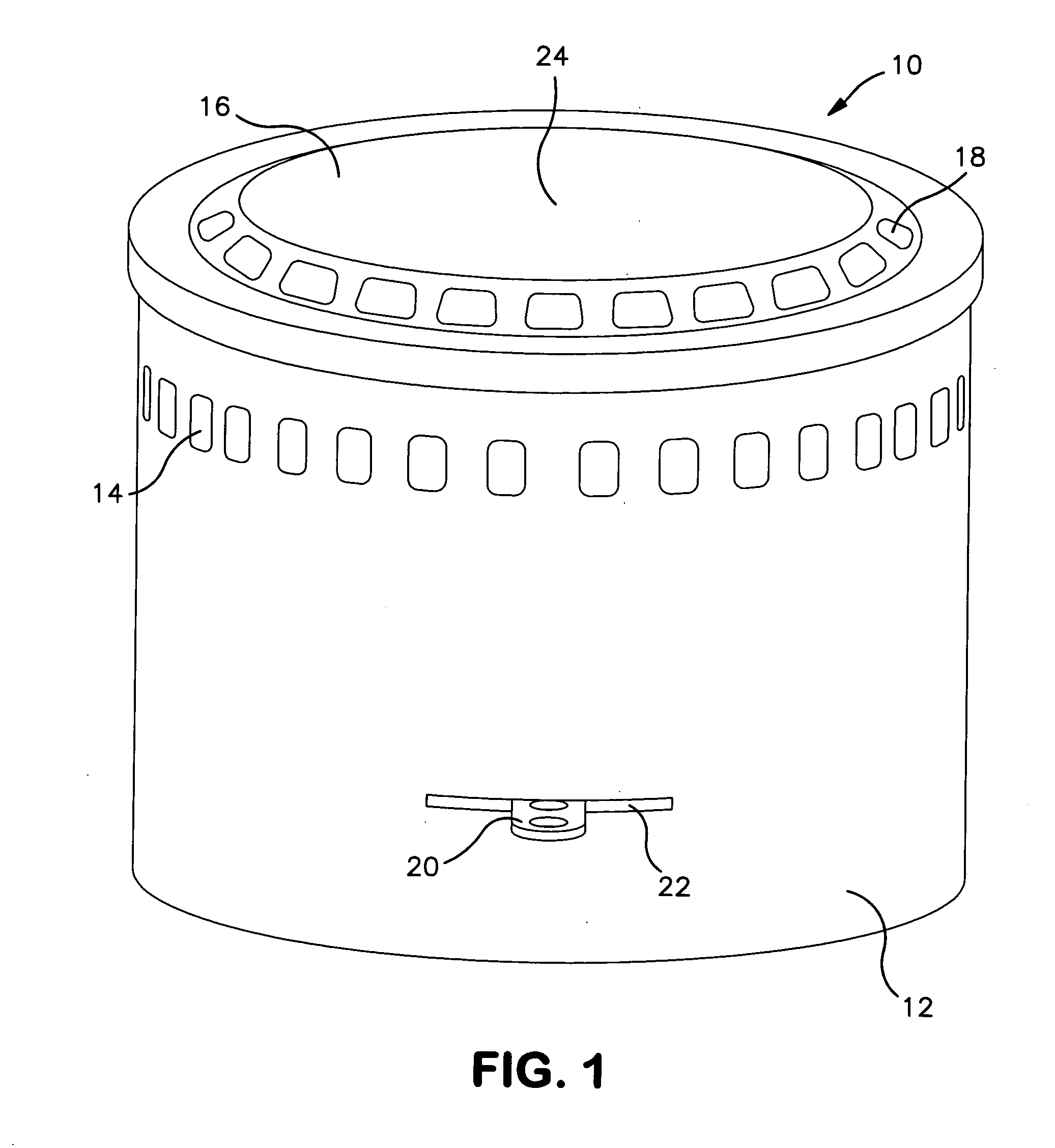

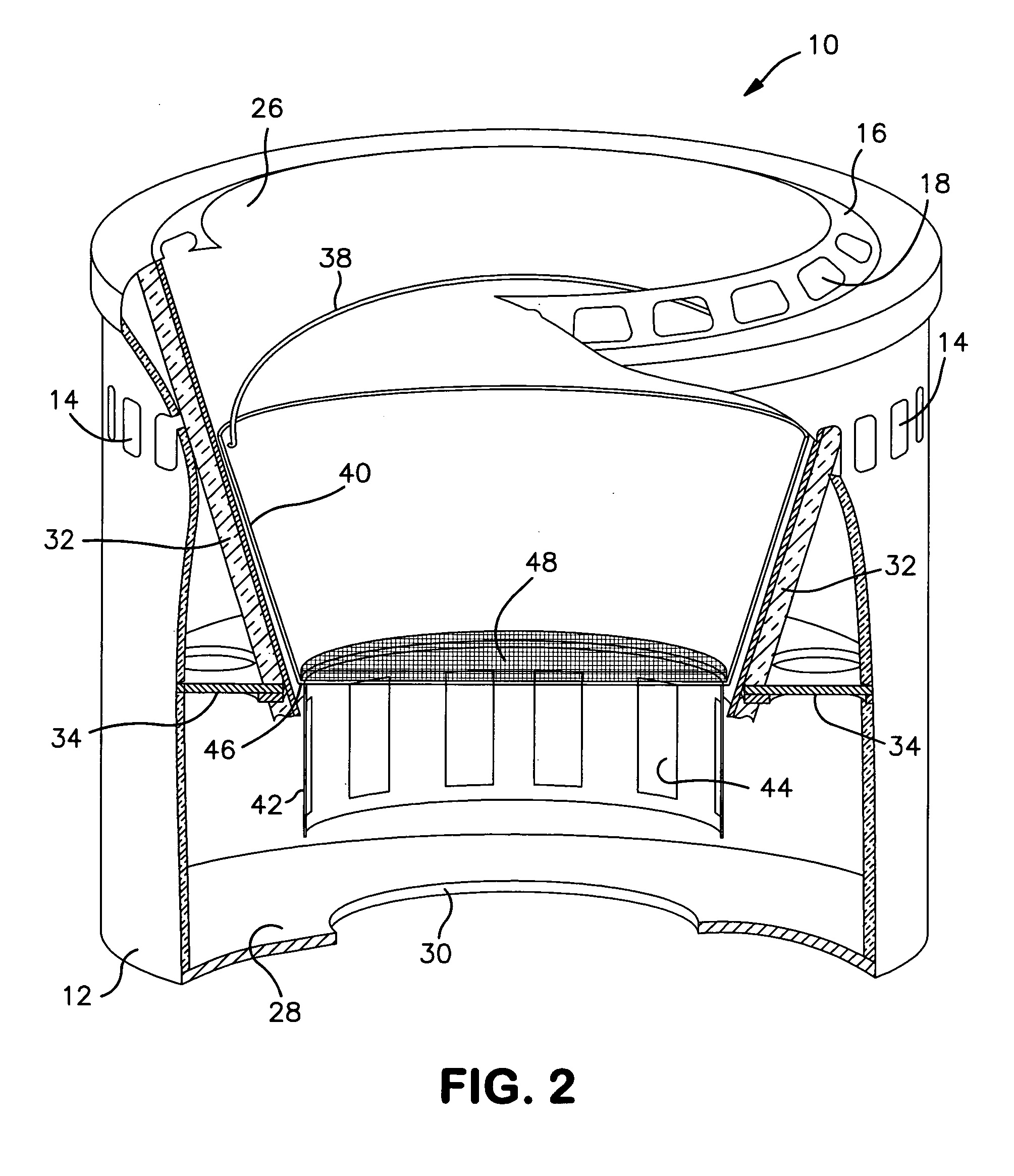

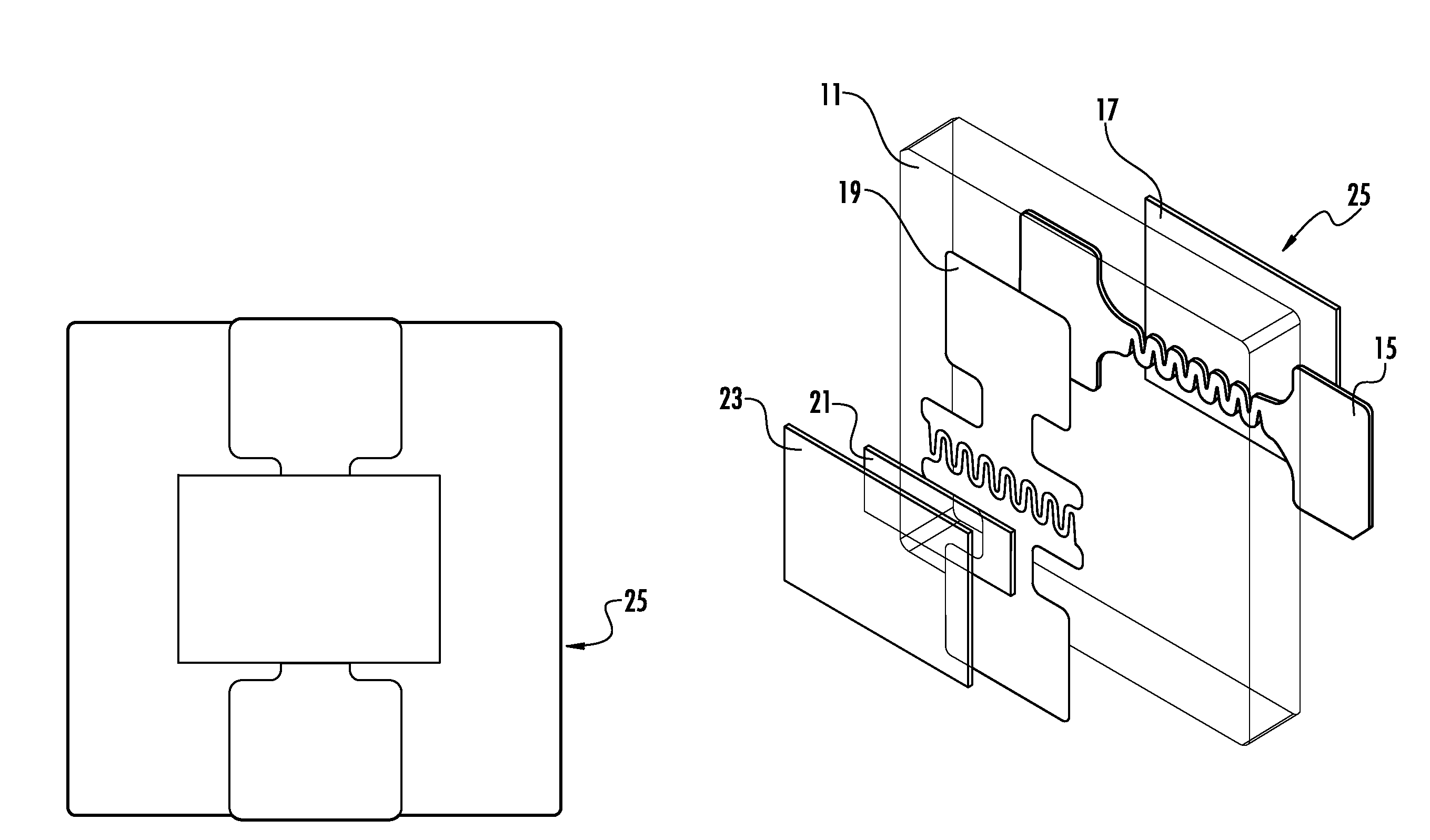

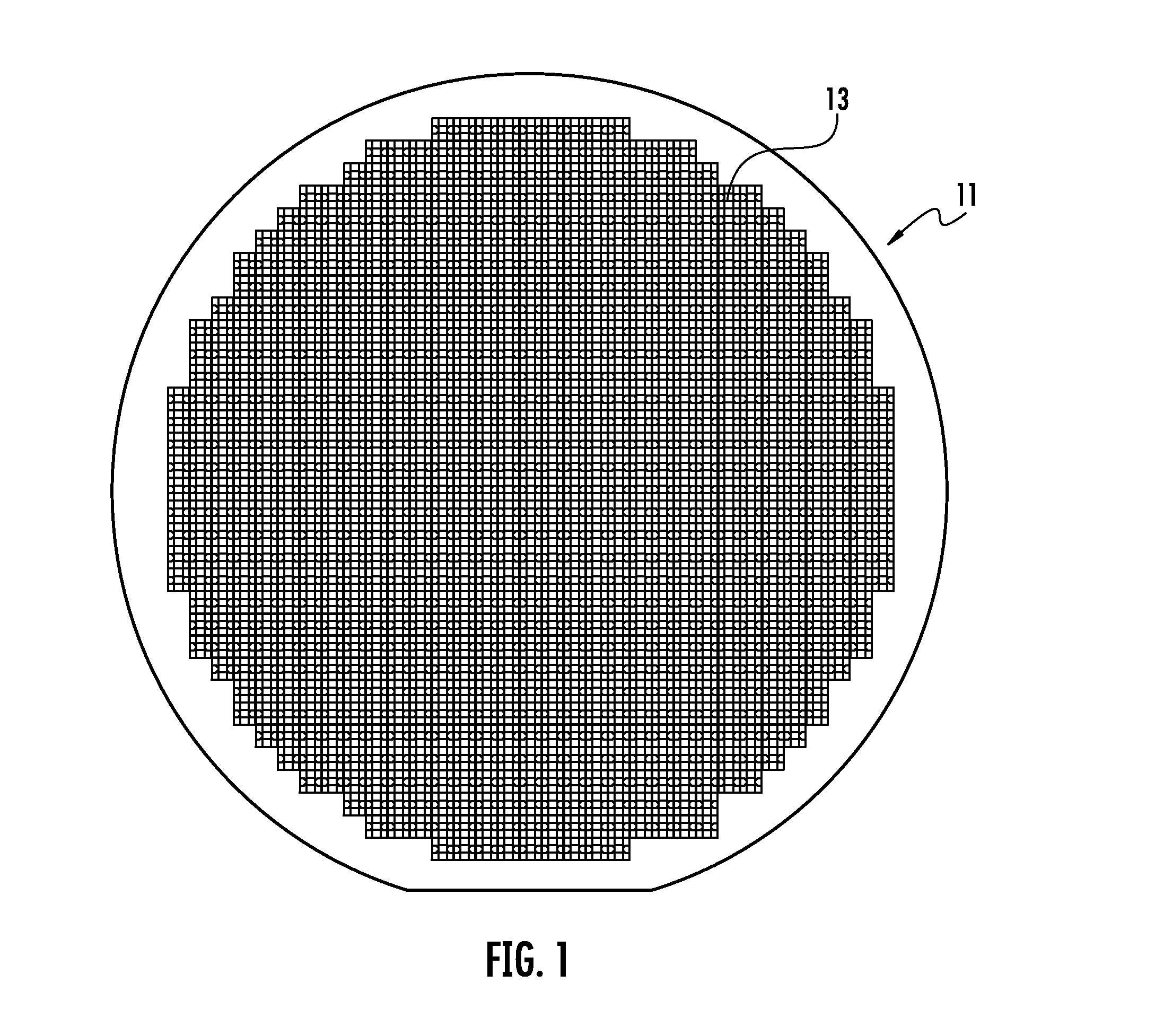

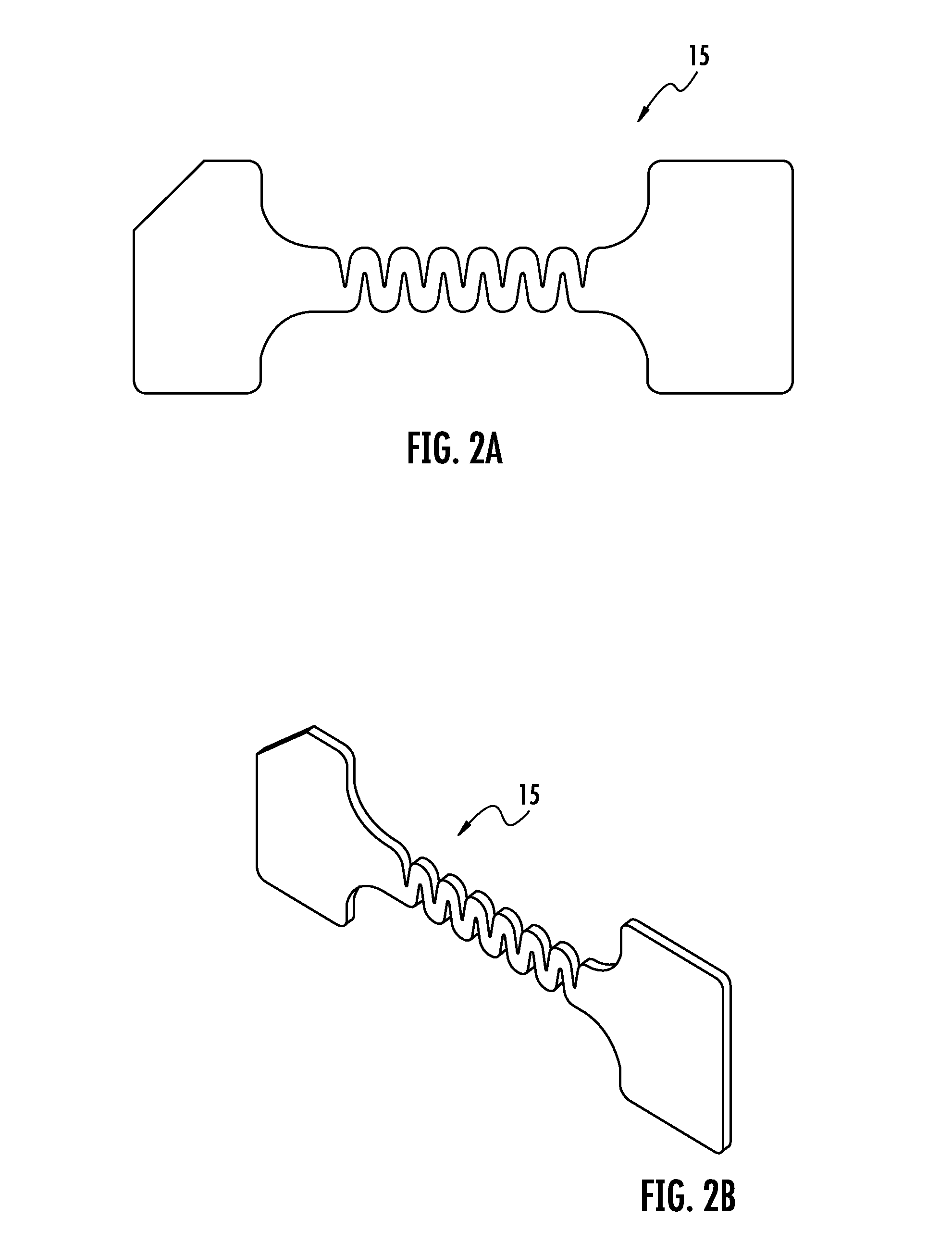

Portable vaporizer

InactiveUS20120325227A1Avoid insufficient temperatureRespiratorsMedical devicesEngineeringEvaporator

A vaporizer and method of vaporizing a botanical material is described. Embodiments of the apparatus include a self-contained, fully enclosed, battery operated vaporizer having an air inlet and a mouthpiece. The vaporizer includes a window for viewing a botanical material contained therein and a heating element that is also visible through the window and through an air inlet. The vaporizer also includes a push-button switch that rapidly provides power to heat air, which is then drawn through the botanical material by inhaling. Embodiments of the method include utilizing a push-button switch for heating vaporizer air and viewing the glow of the heating element as a signal that the vaporizer is ready for use.

Owner:NWT HLDG

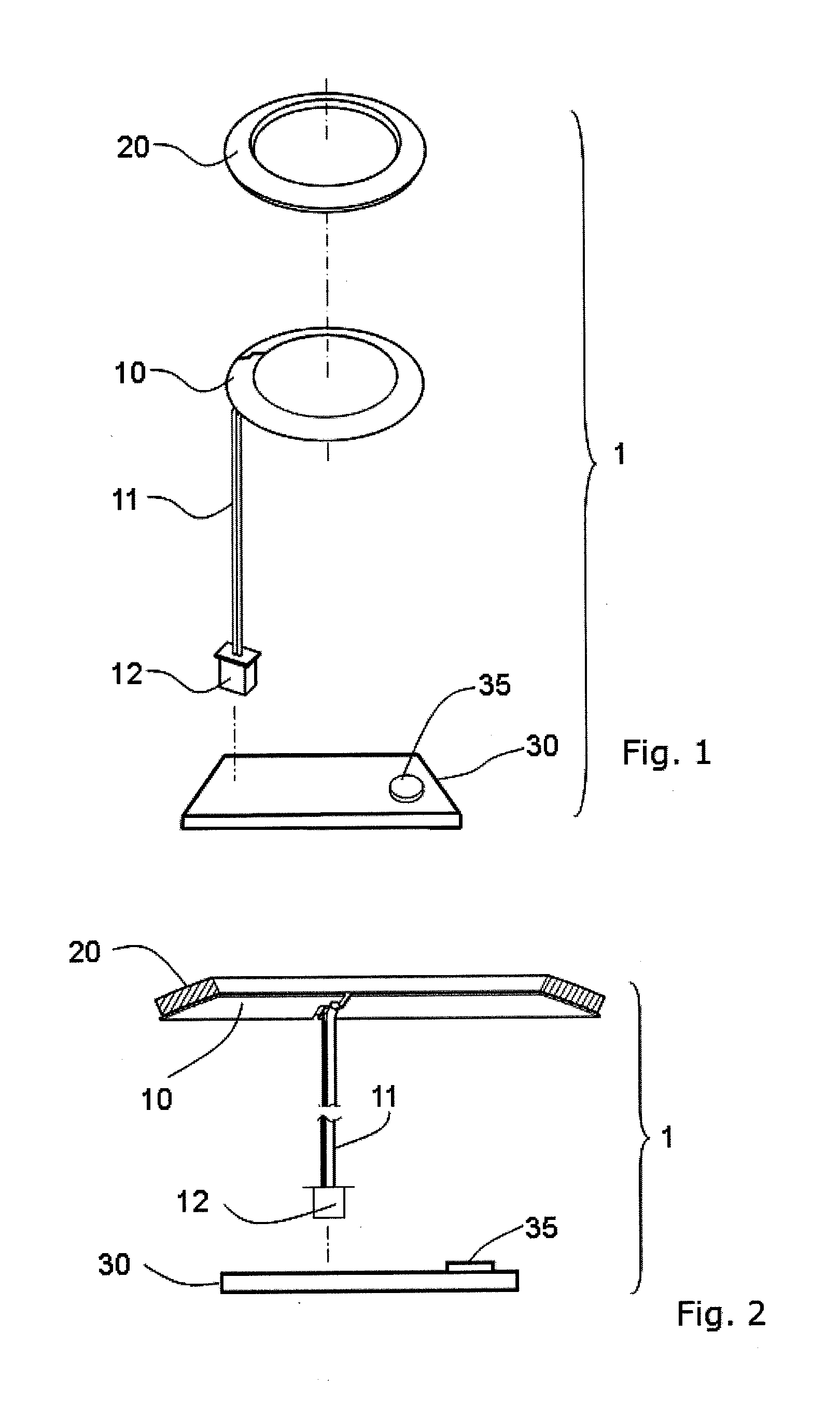

Defogging and defrosting device for protective lens of a camera

InactiveUS20120170119A1Avoid and eliminate humidificationEliminate lossCamera filtersMountingsEngineeringControl circuit

The present invention relates to a defogging and defrosting devices for the protective lens of camera, which includes a heater that is coupled to a control circuit panel, a thermal gasket that is in contact contacting with the heater, receives the heat from the heater and transmits the heat to the glass or mirror object which contacts with in order to avoid and prevent the loss of lucidity of the glass or mirror object due to humidity. The defogging and defrosting device is installed on the body of the camera instead of on the protective lens in order to avoid shading the camera view and to facilitate the removal of protective lens while adjusting the focus of the camera. It also facilitates the replacement of the protective lens of the camera.

Owner:TOPVIEW OPTRONICS CORP

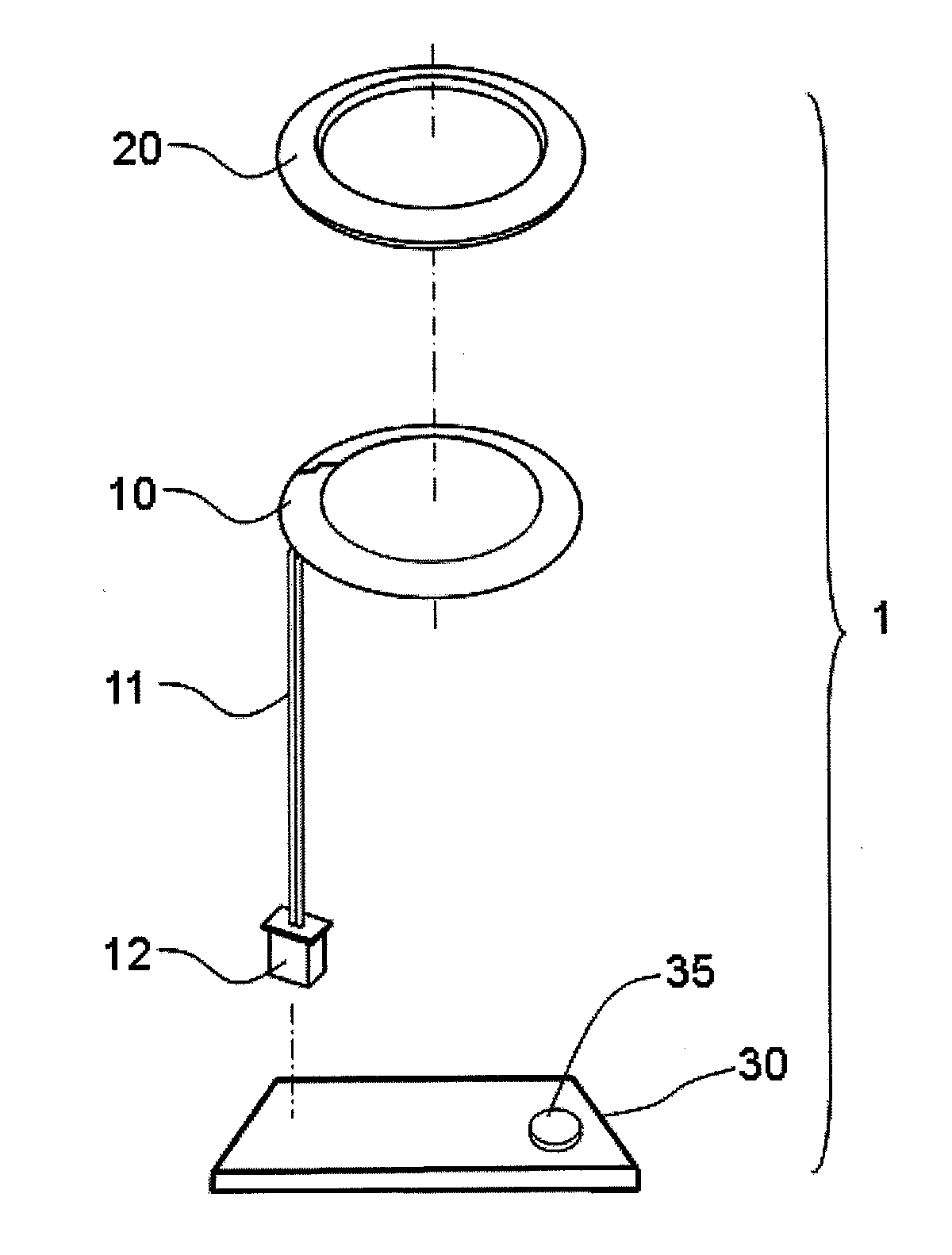

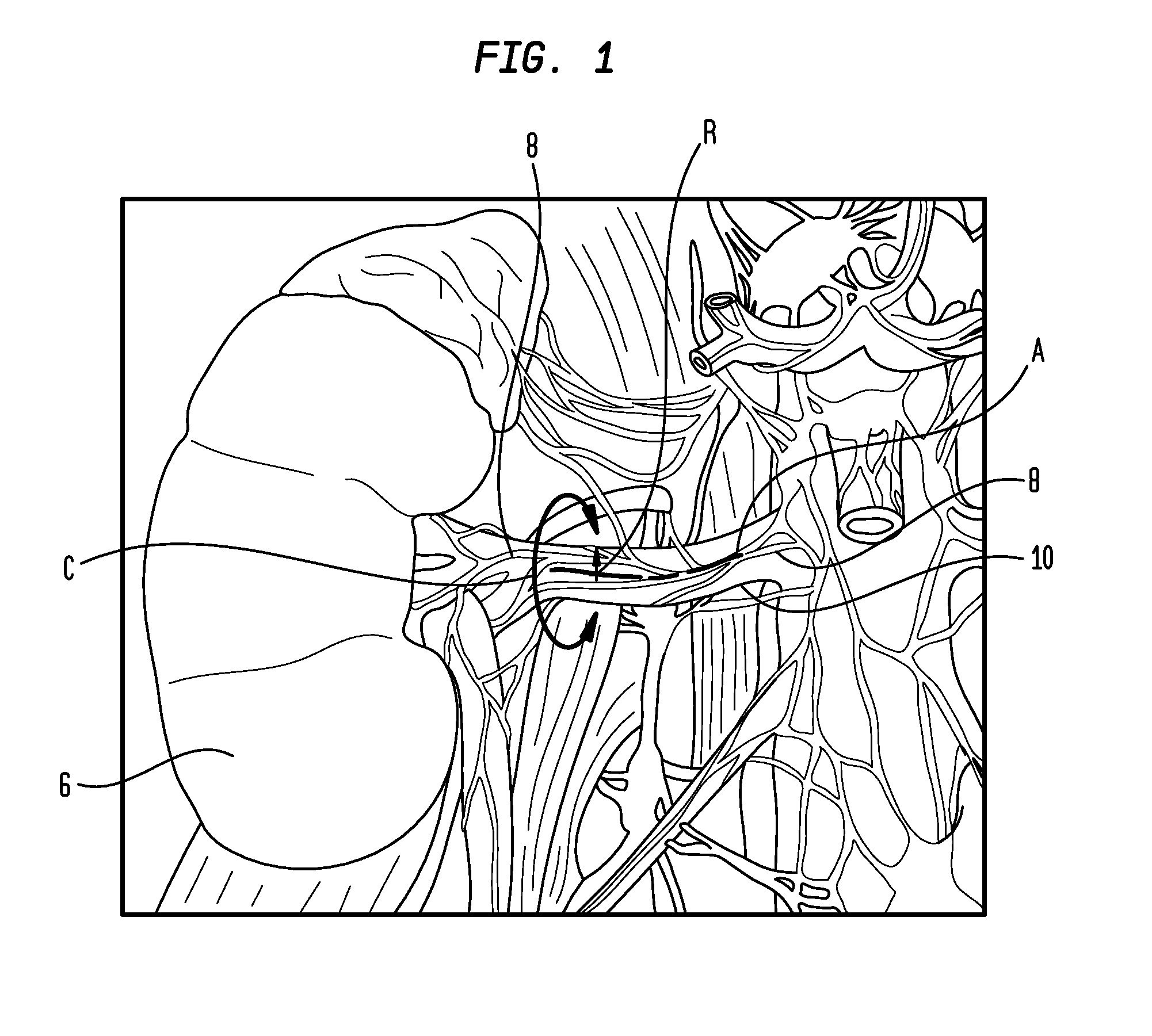

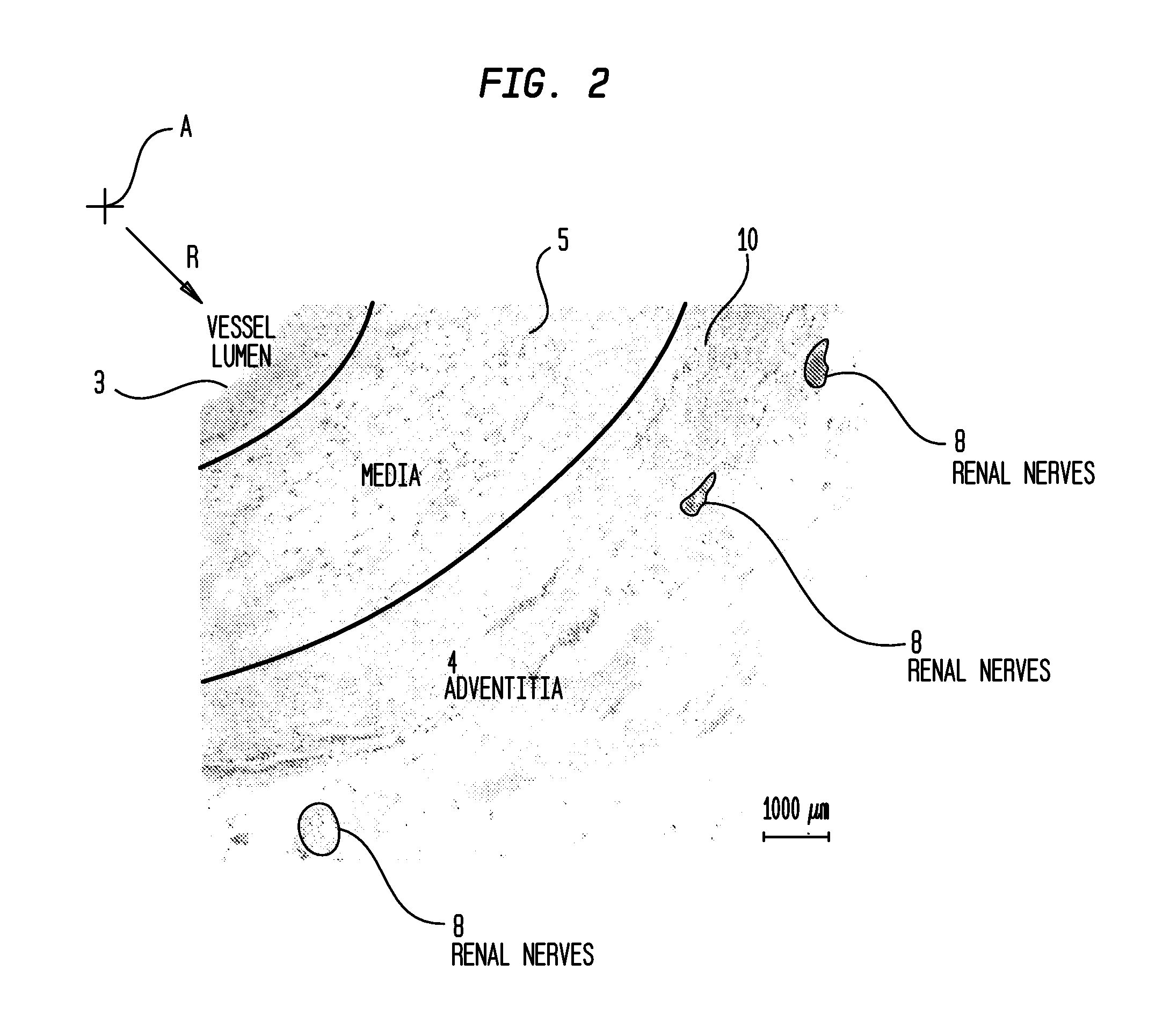

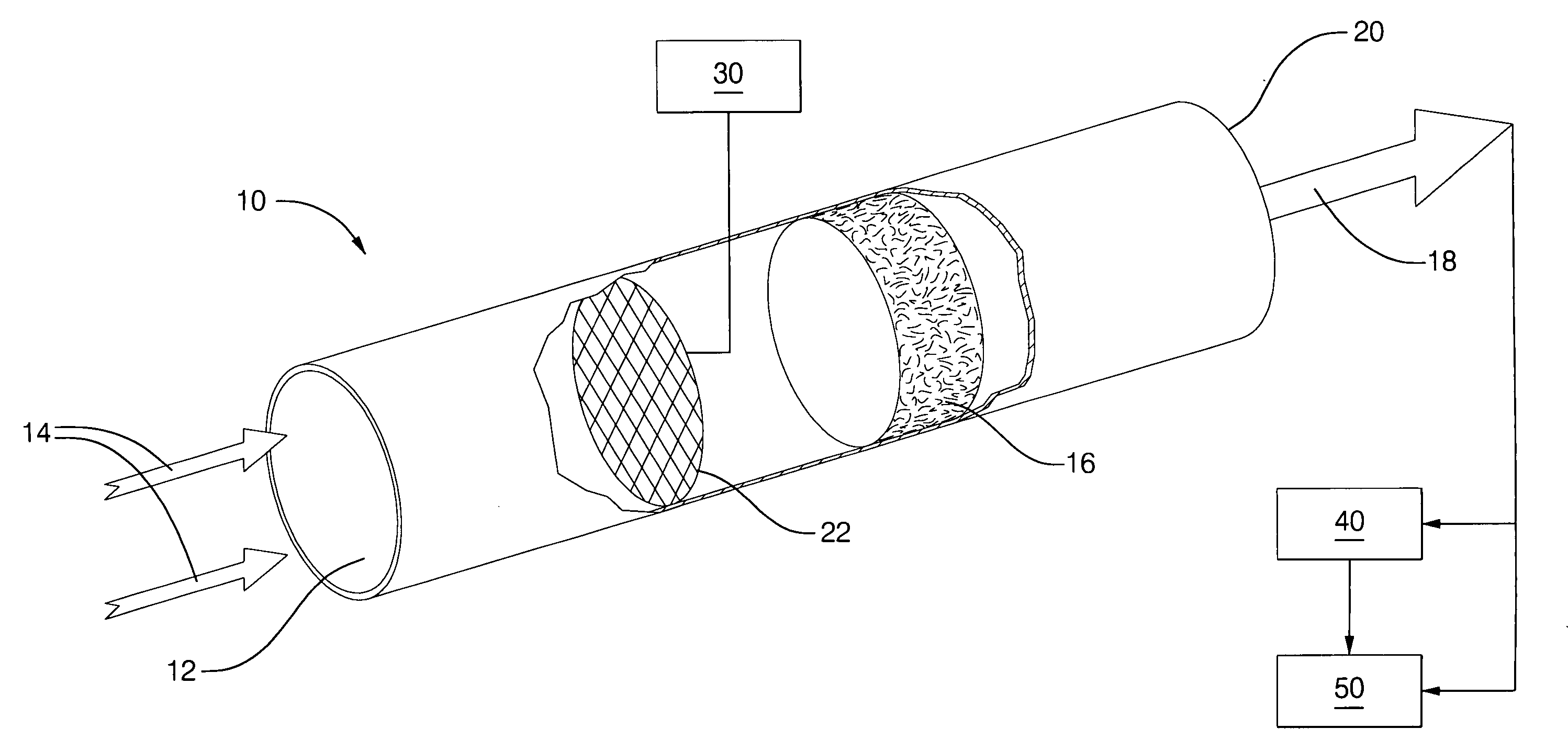

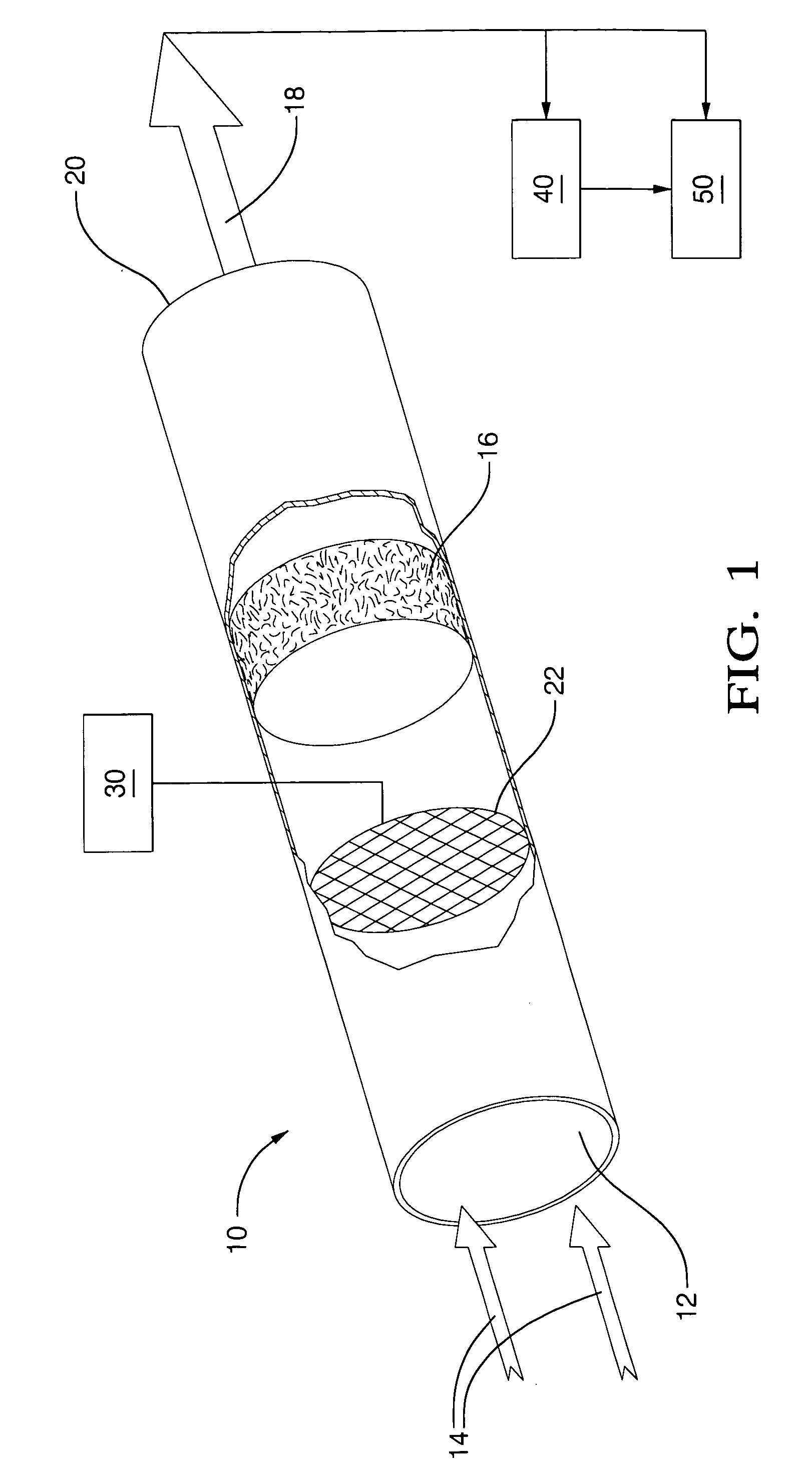

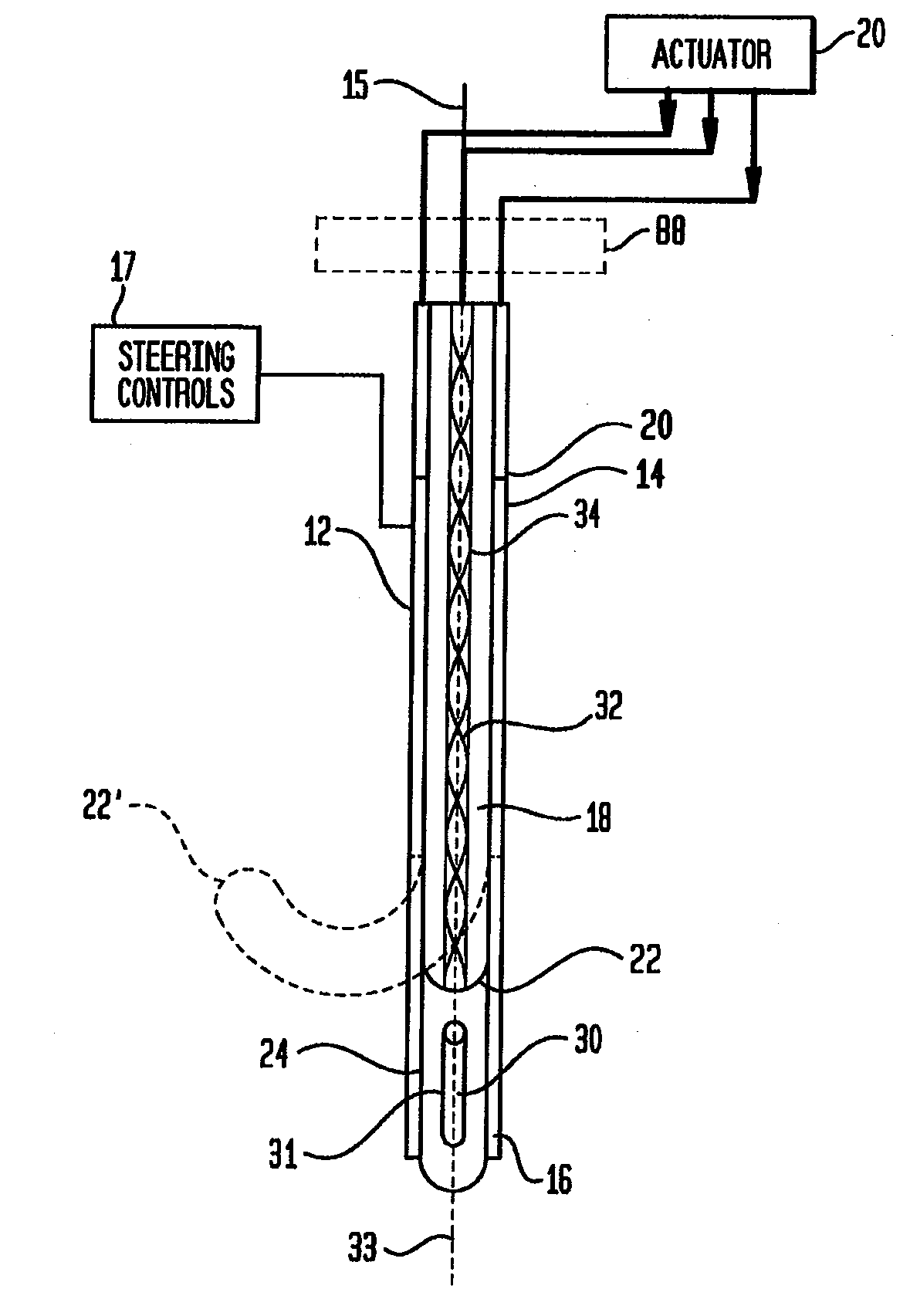

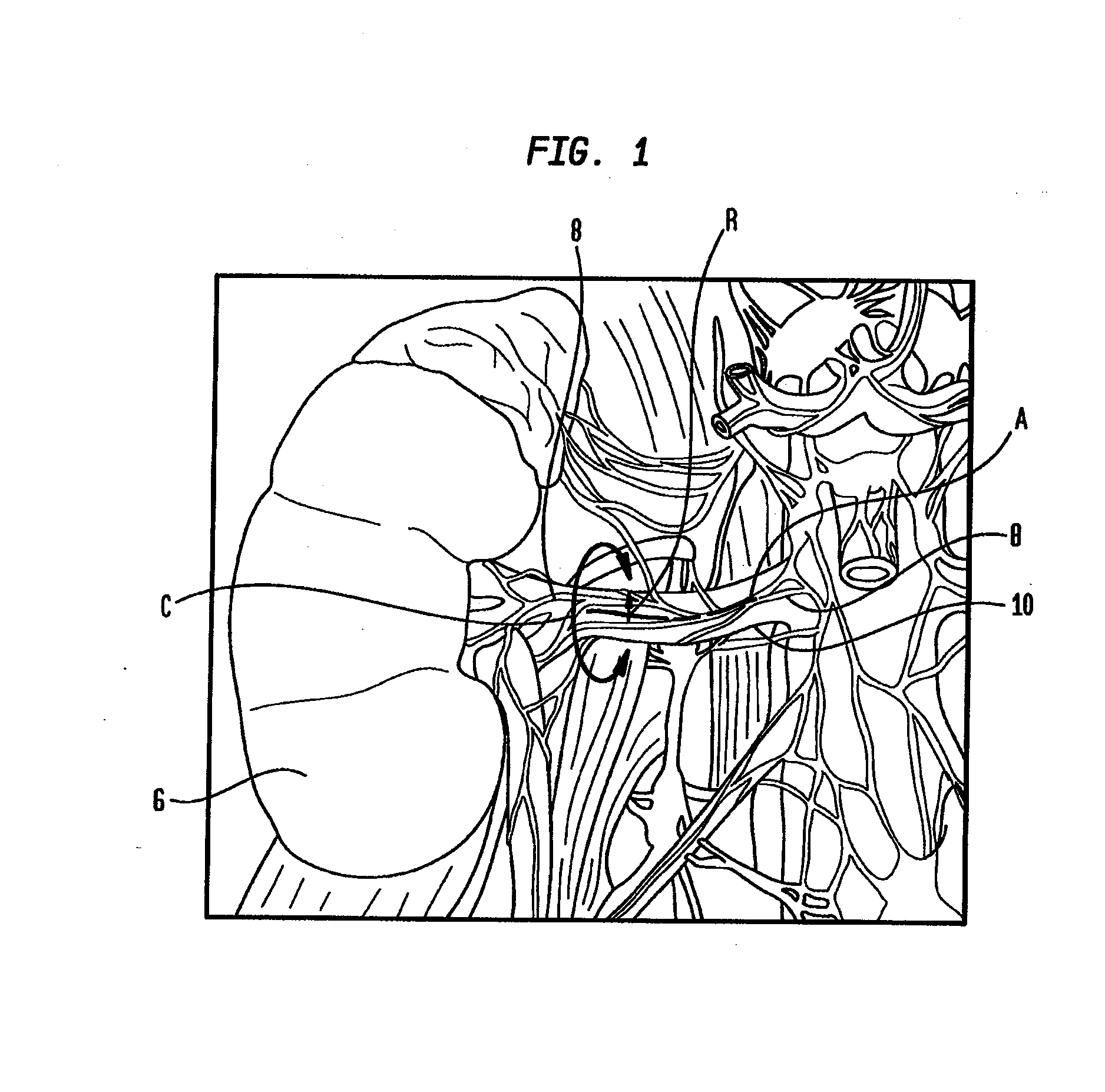

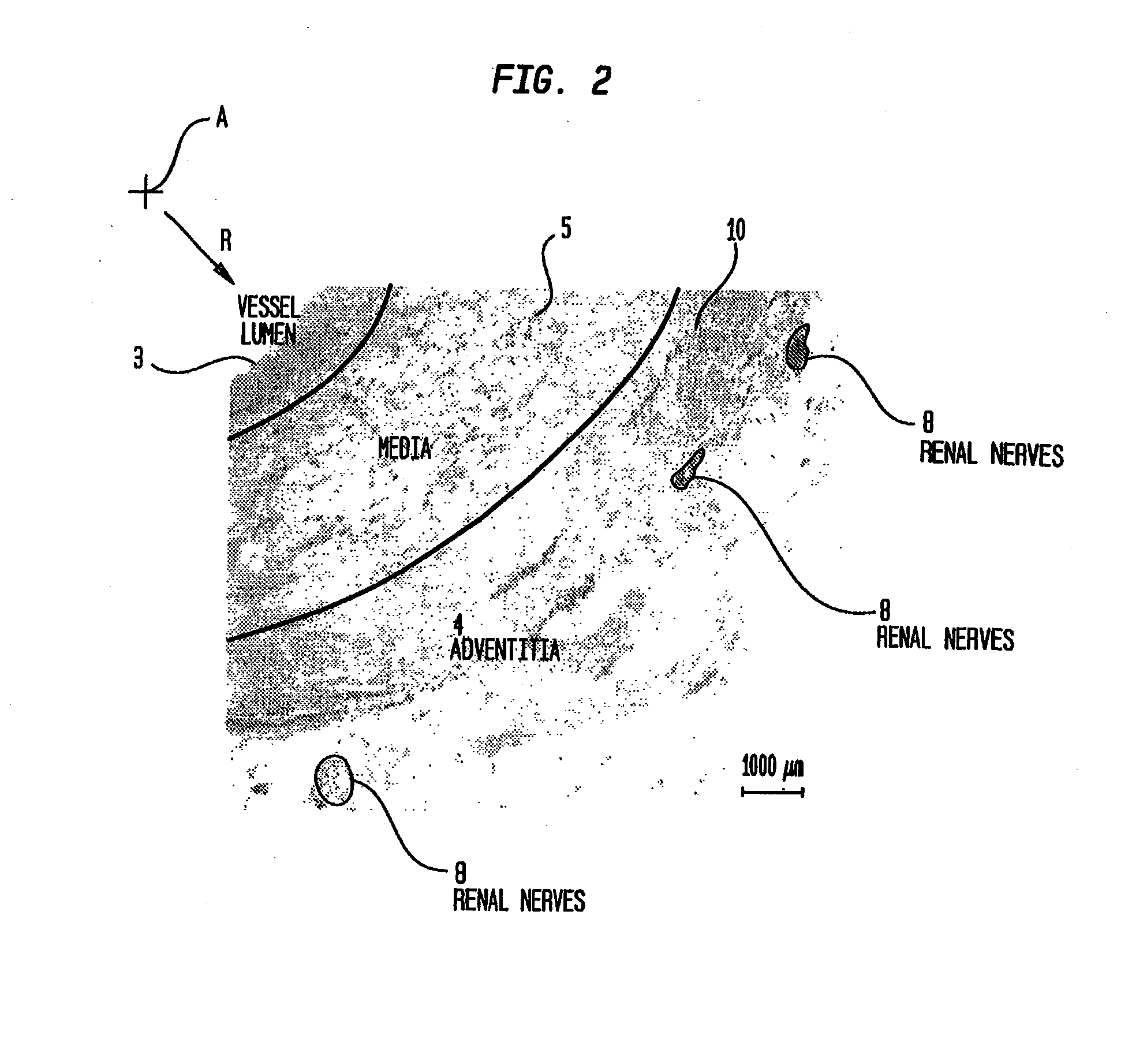

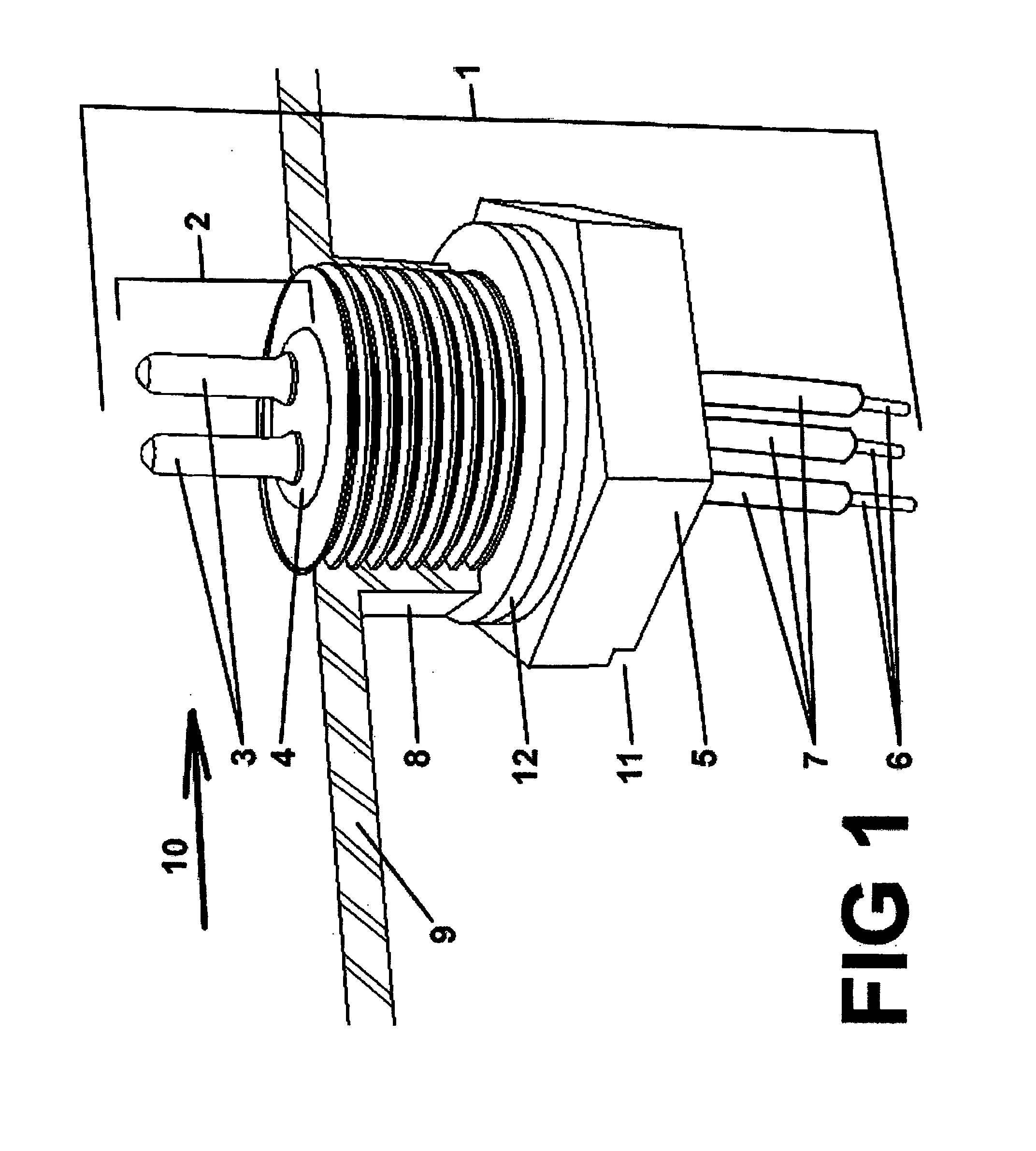

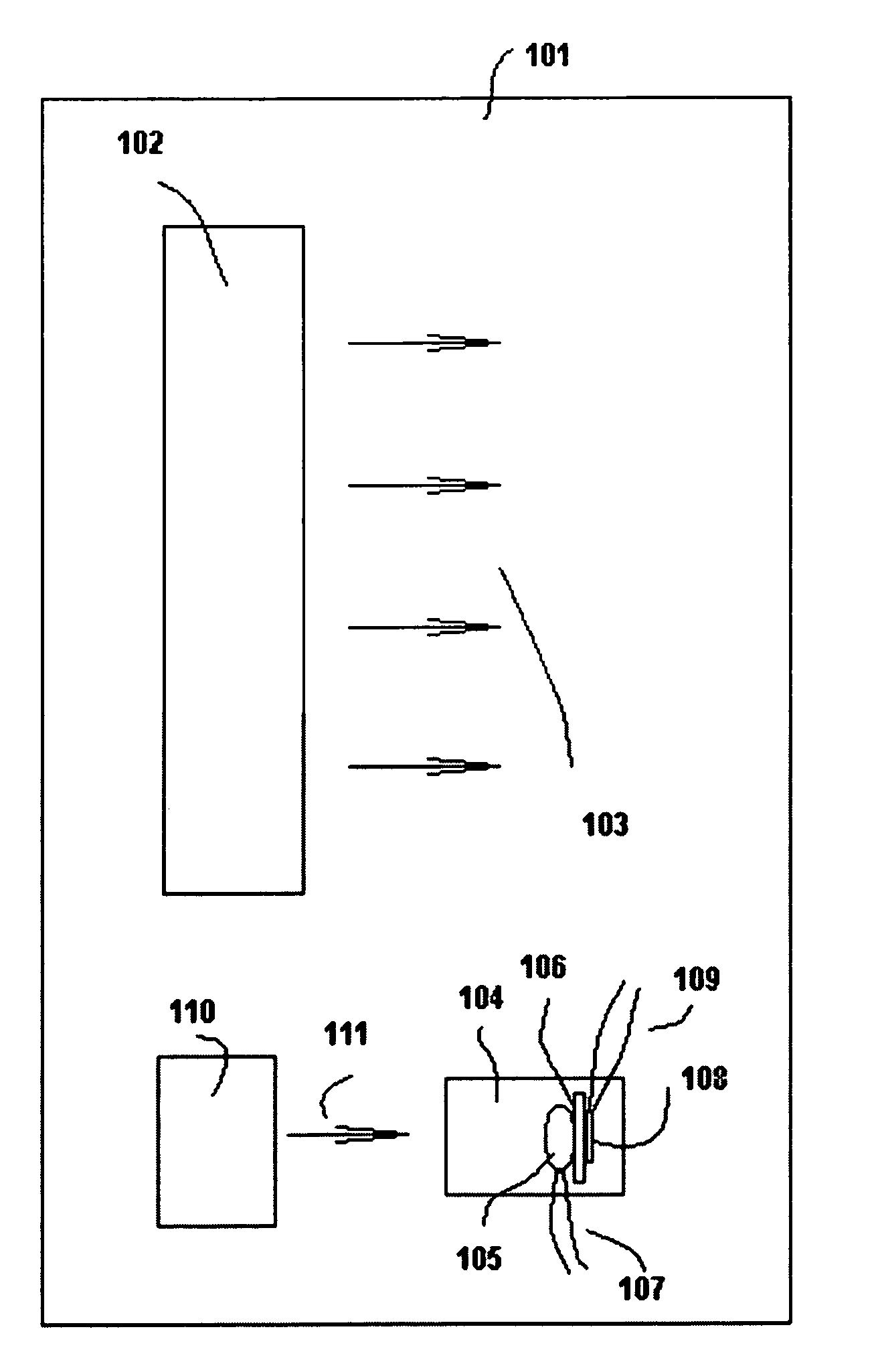

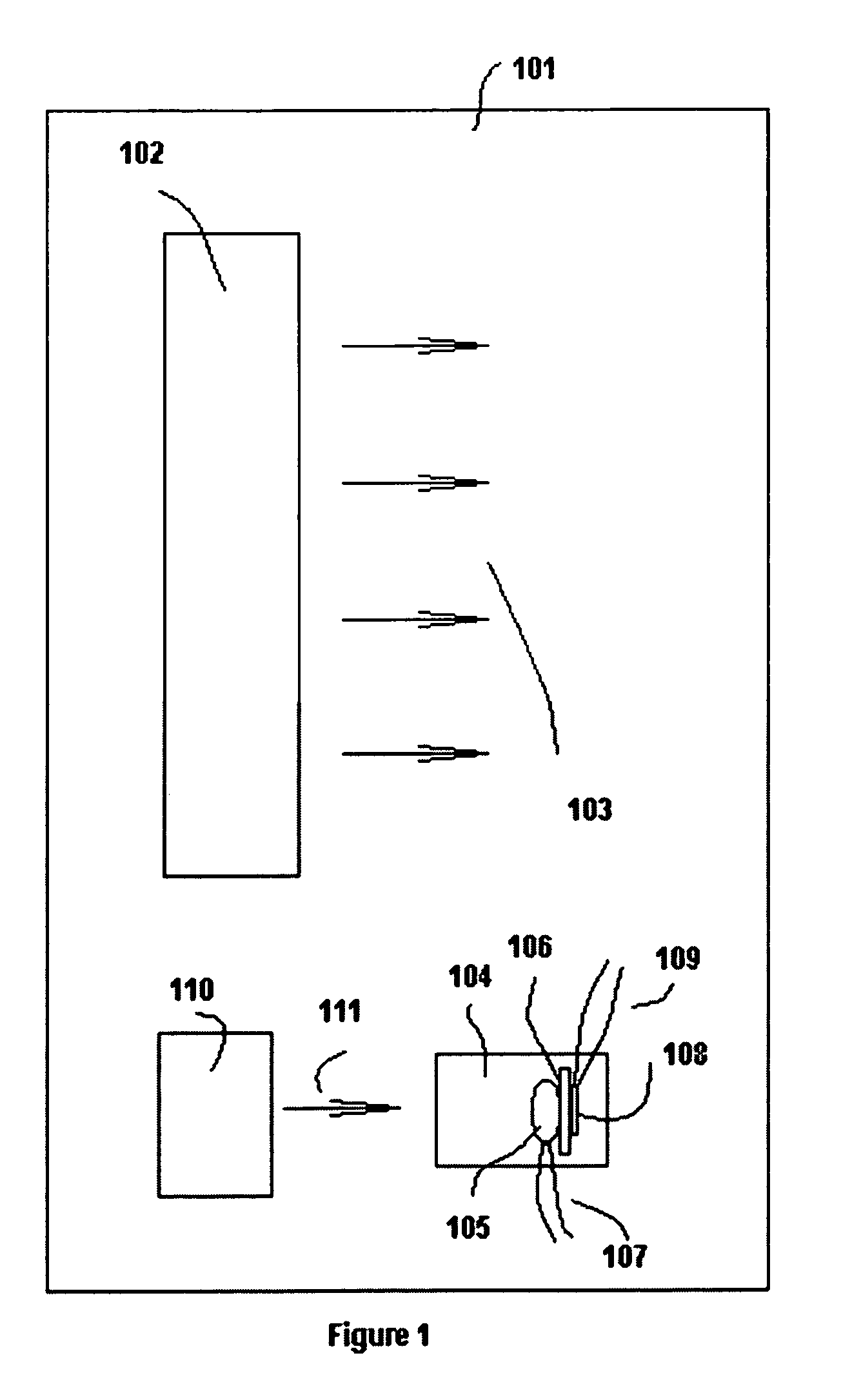

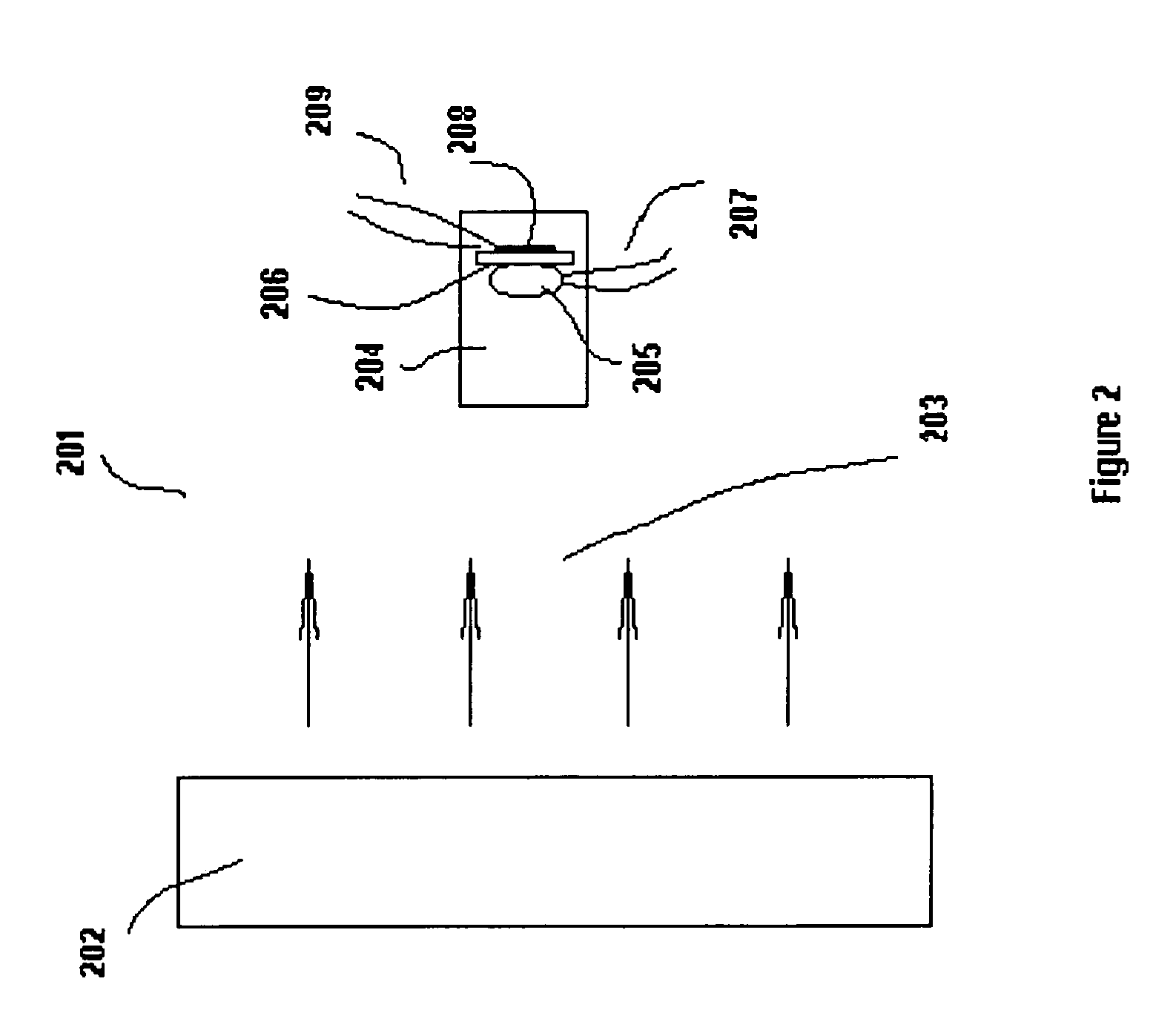

Method and Apparatus for Treatment of Hypertension Through Percutaneous Ultrasound Renal Denervation

ActiveUS20120232436A1Reduce possibilitySufficient temperatureUltrasound therapyStentsUrologyRenal nerve

Apparatus and methods for deactivating renal nerves extending along a renal artery of a mammalian subject to treat hypertension and related conditions. An ultrasonic transducer (30) is inserted into the renal artery (10) as, for example, by advancing the distal end of a catheter (18) bearing the transducer into the renal artery. The ultrasonic transducer emits unfocused ultrasound so as to heat tissues throughout a relatively large impact volume (11) as, for example, at least about 0.5 cm3 encompassing the renal artery to a temperature sufficient to inactivate nerve conduction but insufficient to cause rapid ablation or necrosis of the tissues. The treatment can be performed without locating or focusing on individual renal nerves.

Owner:RECOR MEDICAL INC

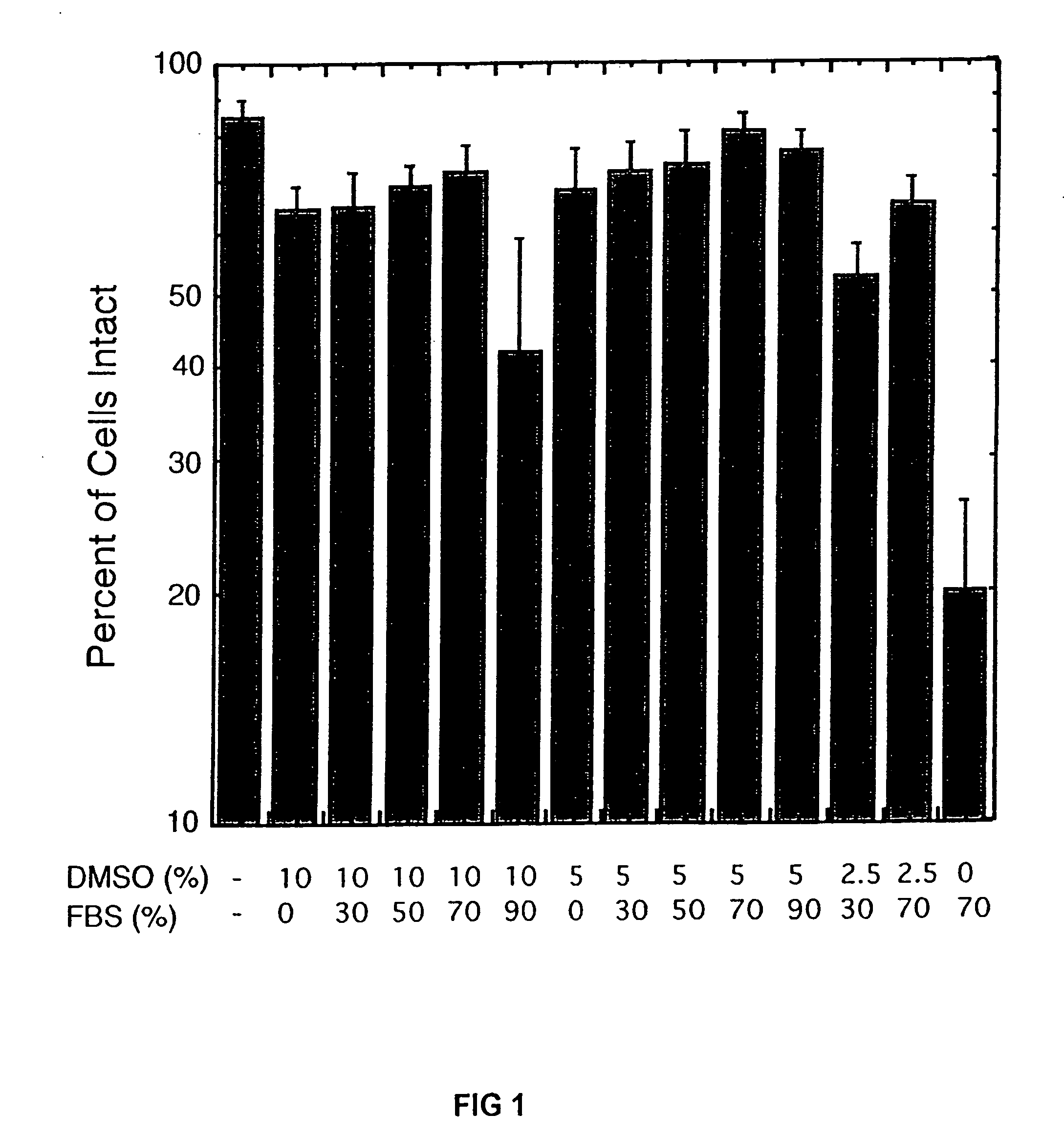

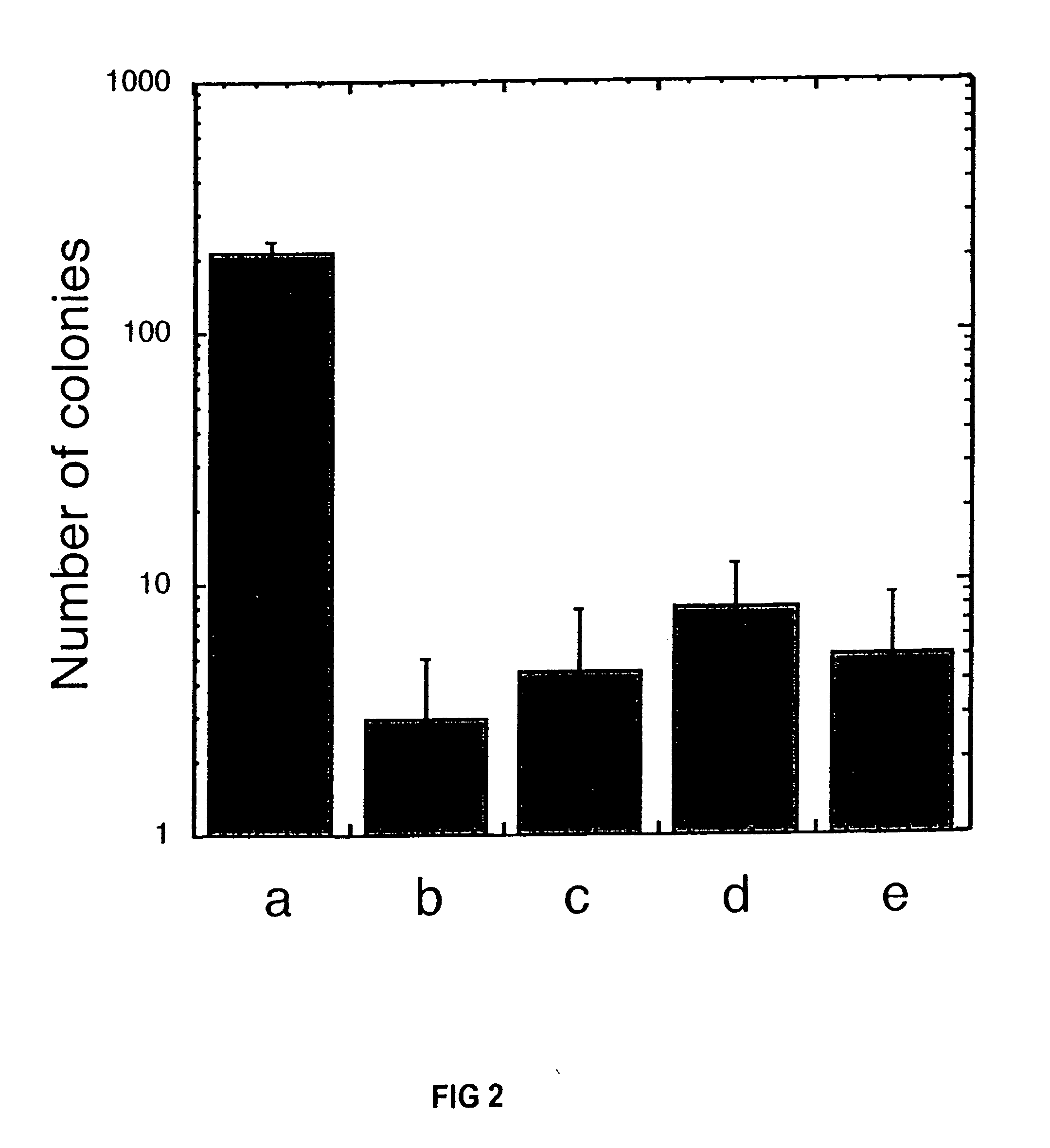

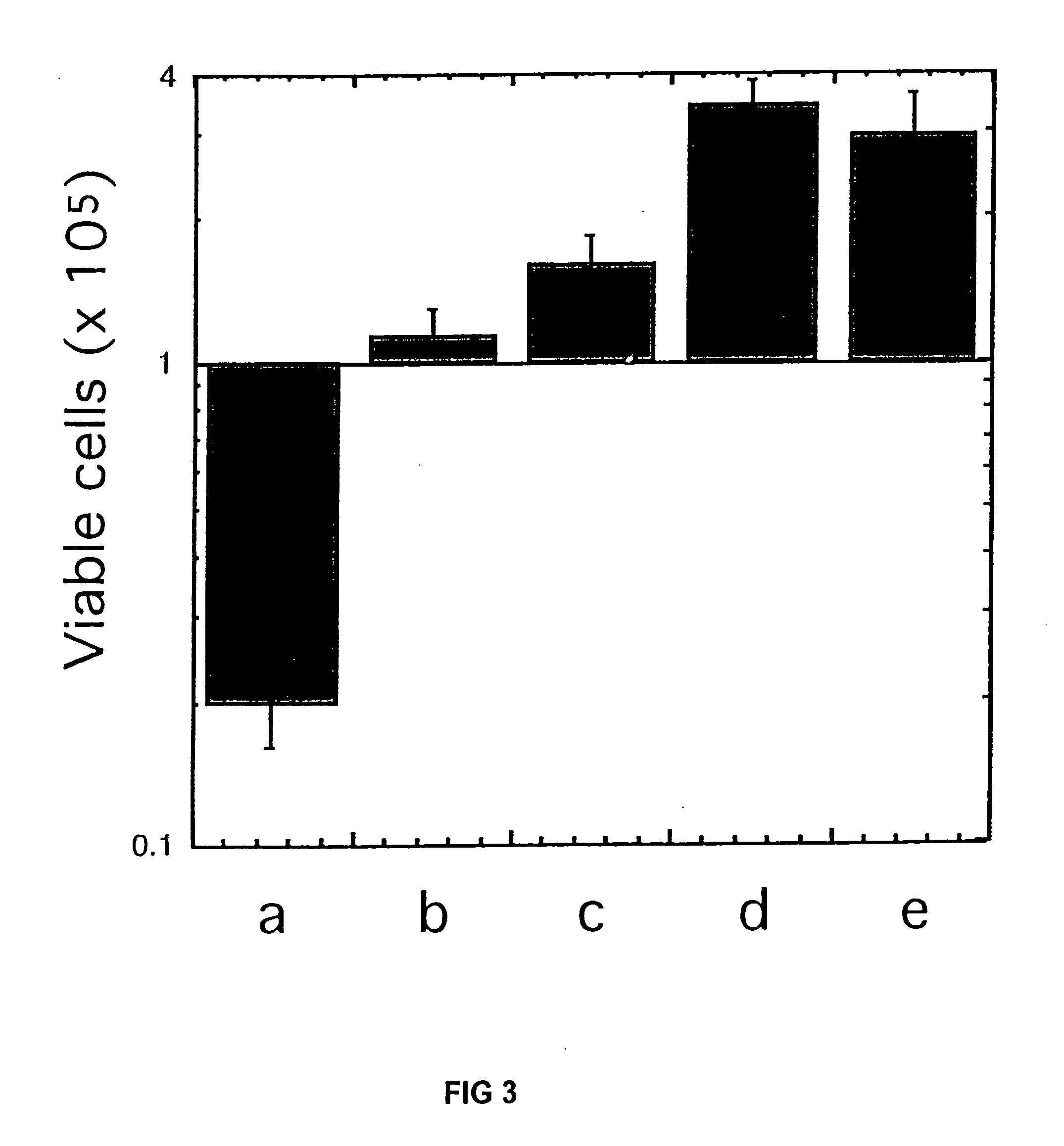

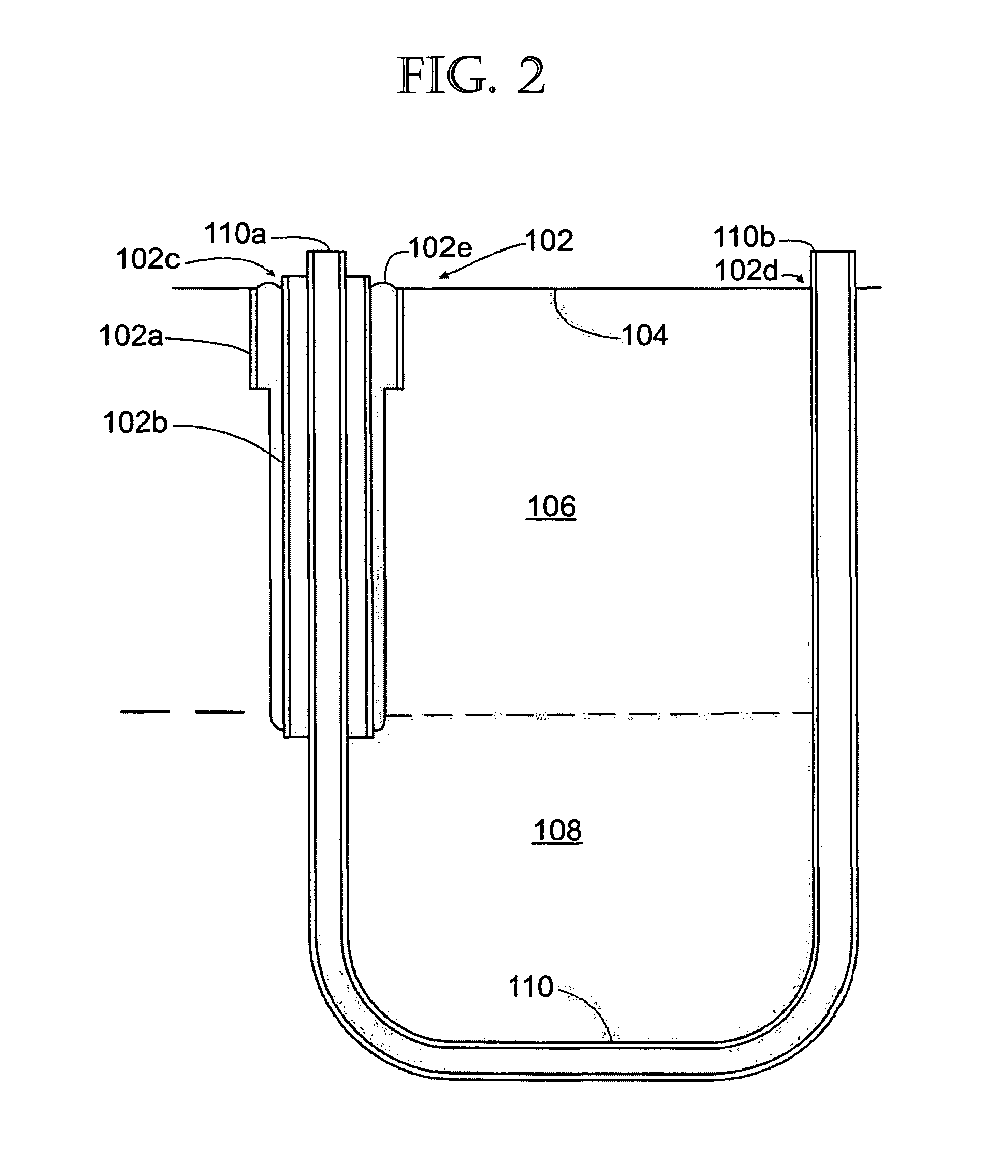

Cryopreservation of pluripotent stem cells

InactiveUS20050106554A1Shorten timeMinimize riskArtificial cell constructsVertebrate cellsCellular viabilityMolecular biology

The present invention relates to methods and compositions for the cryopreservation of pluripotent cells in general and human embryonic stem (ES) cells in particular. The stem cells are grown on a bottom layer of solid support matrix and subsequently covered by a top layer of solid support matrix forming a matrix-cell-matrix composition, to which an effective amount of cryopreservation media is added, prior to freezing. The methods of the invention yield cryopreserved cells that exhibit an increase in cell viability and a decrease in cell differentiation, facilitating storage, shipping and handling of embryonic stem cell stocks and lines for research and therapeutics.

Owner:WISCONSIN ALUMNI RES FOUND

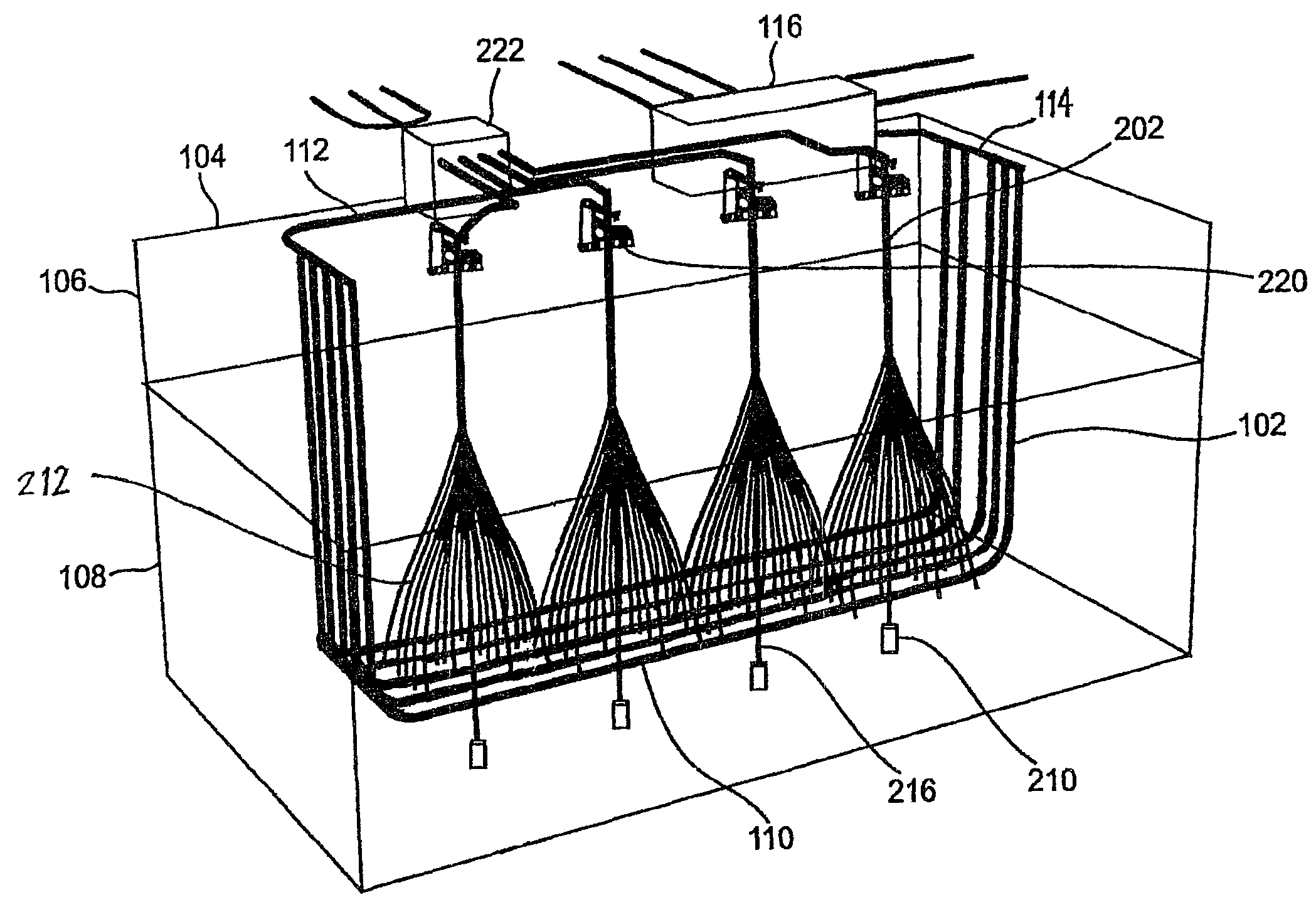

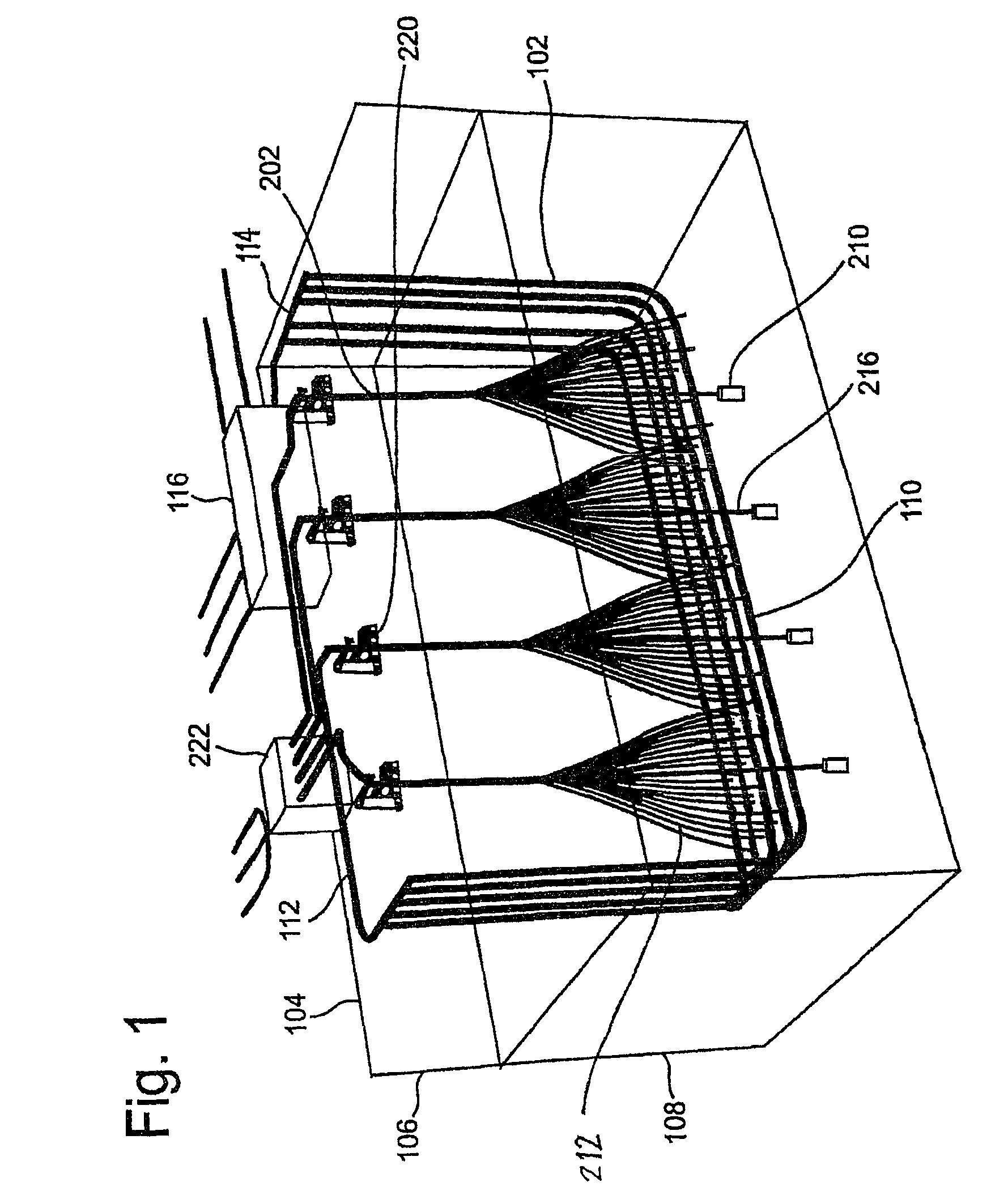

In situ method and system for extraction of oil from shale

ActiveUS7743826B2Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

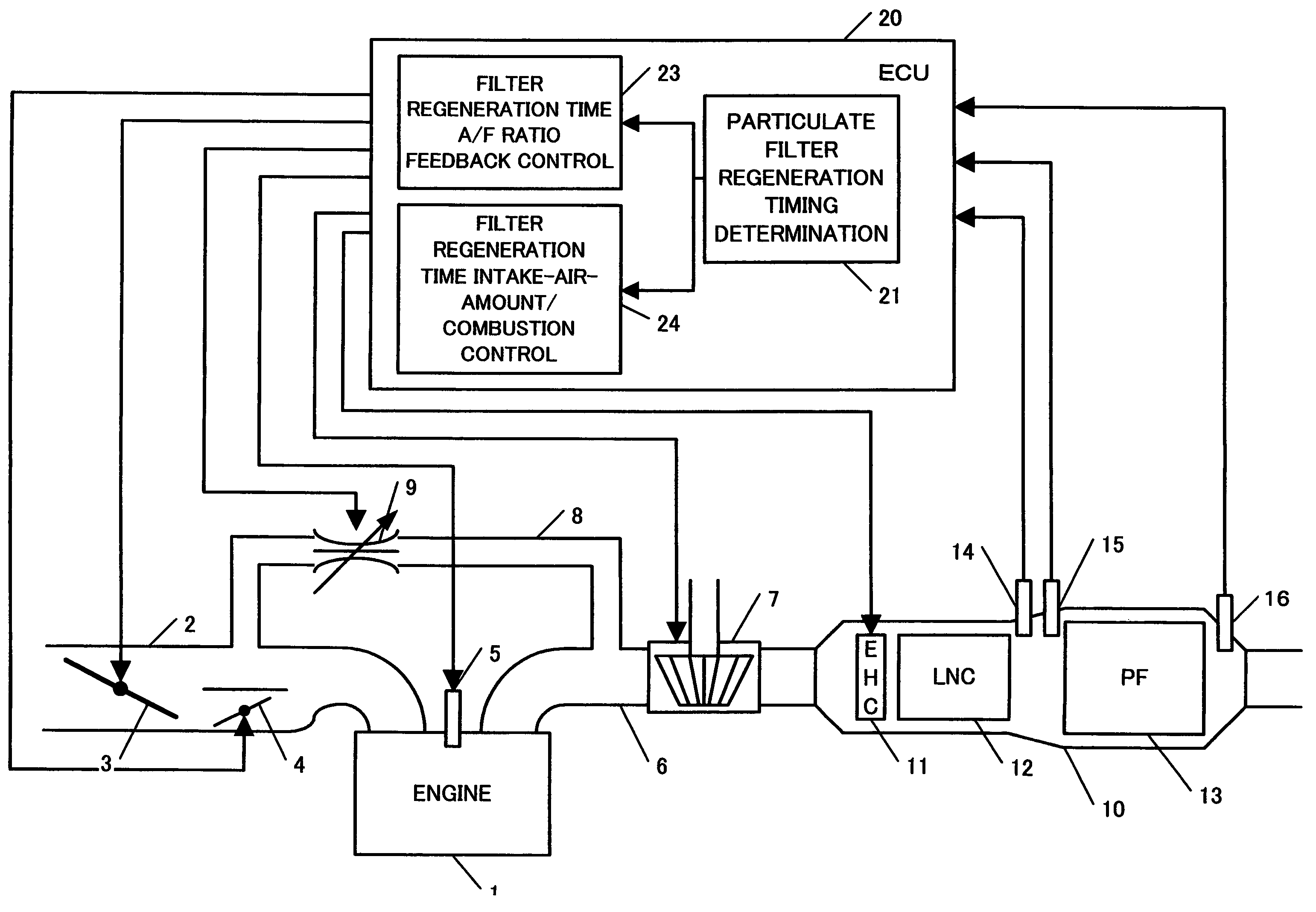

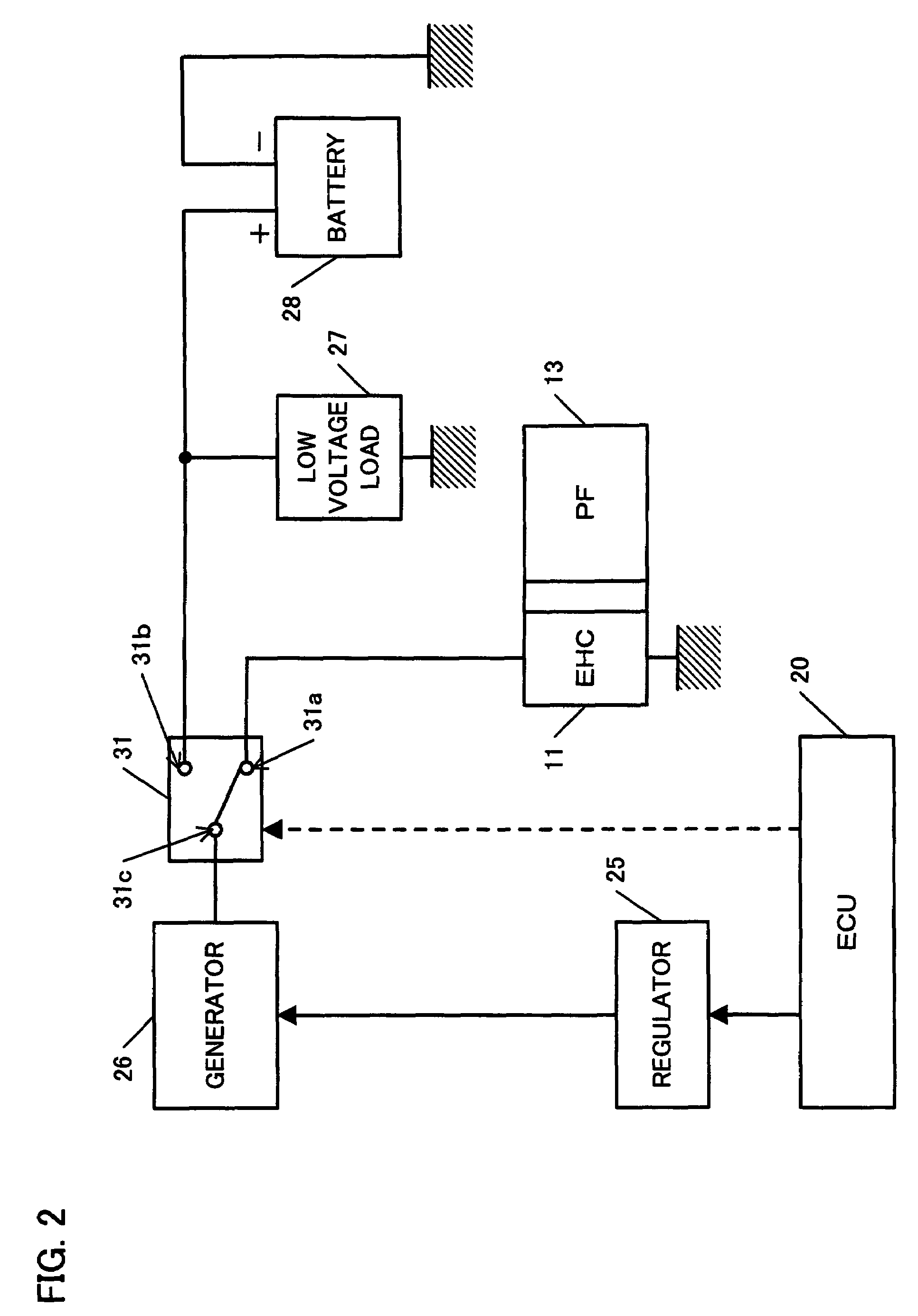

Exhaust gas purification device

InactiveUS7104051B2Emission is deterioratedInhibit deteriorationElectrical controlInternal combustion piston enginesParticulatesCombustion

The invention provides an exhaust gas purification device that can prevent deterioration of the emission during a regeneration process for a particular filter for trapping particulates contained in the exhaust gas.Particulate filter regeneration timing determining unit estimates the amount of particulates trapped by the particulate filter to determine the filter regeneration timing based on the estimated particular amount. In response to the regeneration timing determination, heating unit heats the particulate filter to raise an exhaust gas temperature, so that a particulate filter regeneration process starts. At this time, intake air amount reducing unit reduces the intake air amount to raise the exhaust gas temperature while combustion maintaining unit controls the combustion in the internal-combustion engine so as to be maintained in a desired condition.

Owner:HONDA MOTOR CO LTD

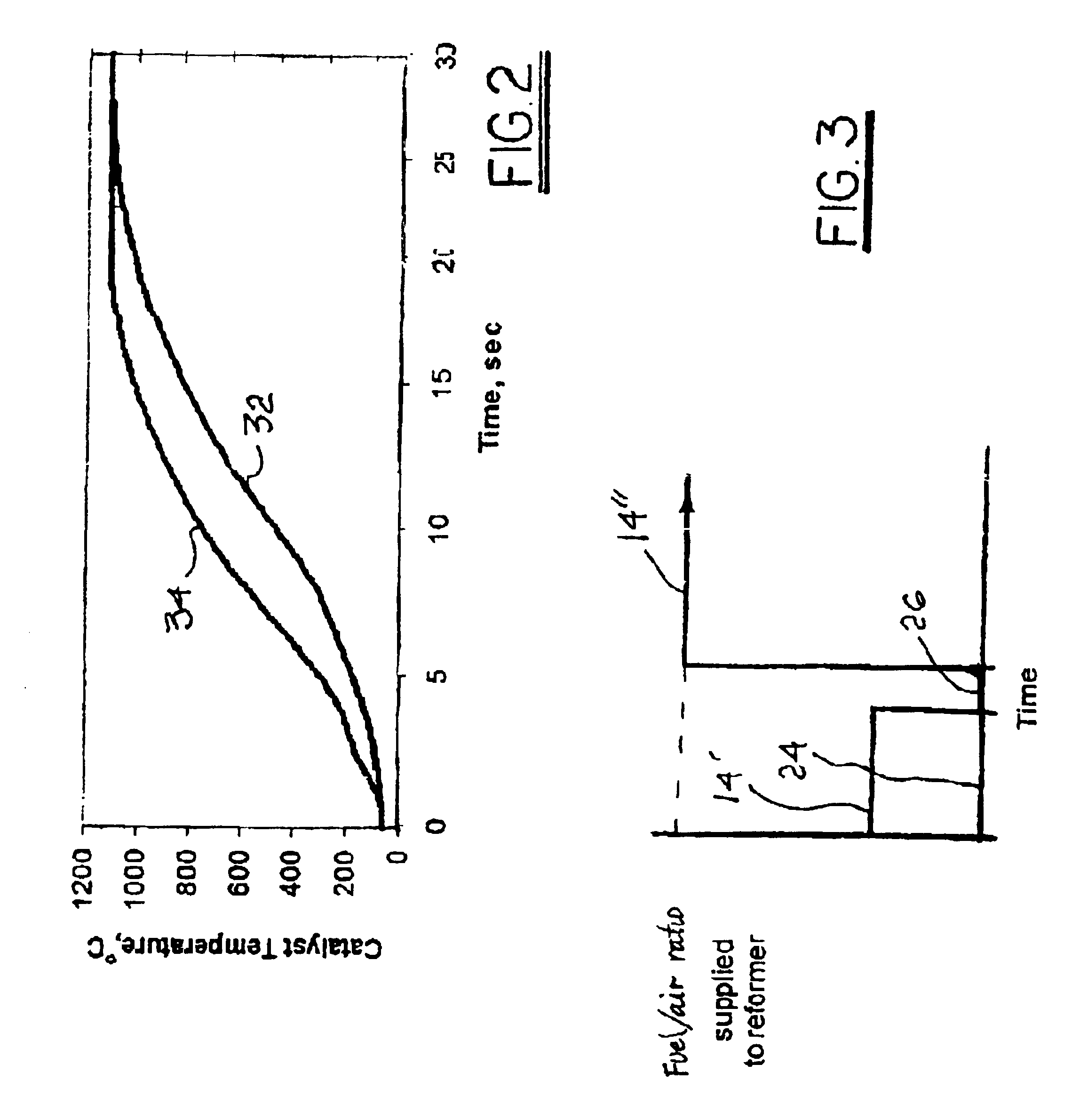

Method for starting a fast light-off catalytic fuel reformer

InactiveUS6869456B2Optimize reformate yieldStart fastCombination devicesHydrogenCatalytic reformingControl system

A method for starting a fast light-off catalytic reformer for producing hydrogen-rich reformate fuel from hydrocarbon fuel and air, the reformer having means for receiving flows of fuel and air, a reforming catalyst for reforming the fuel and air mixture, and an ignition device. A control system selects fuel and air flow rates to form a lean fuel / air mixture and operates the ignition device to ignite the lean mixture to produce hot exhaust gases that flow over and heat the reforming catalyst for a first length of time. Fuel flow is then stopped temporarily for a second length of time, and further ignition is terminated. Fuel flow is then restarted and adjusted to provide a rich fuel / air mixture which is directed to the heated catalyst for reforming into reformate fuel. Air flow may also be adjusted in setting the lean and / or rich fuel / air mixtures.

Owner:DELPHI TECH INC

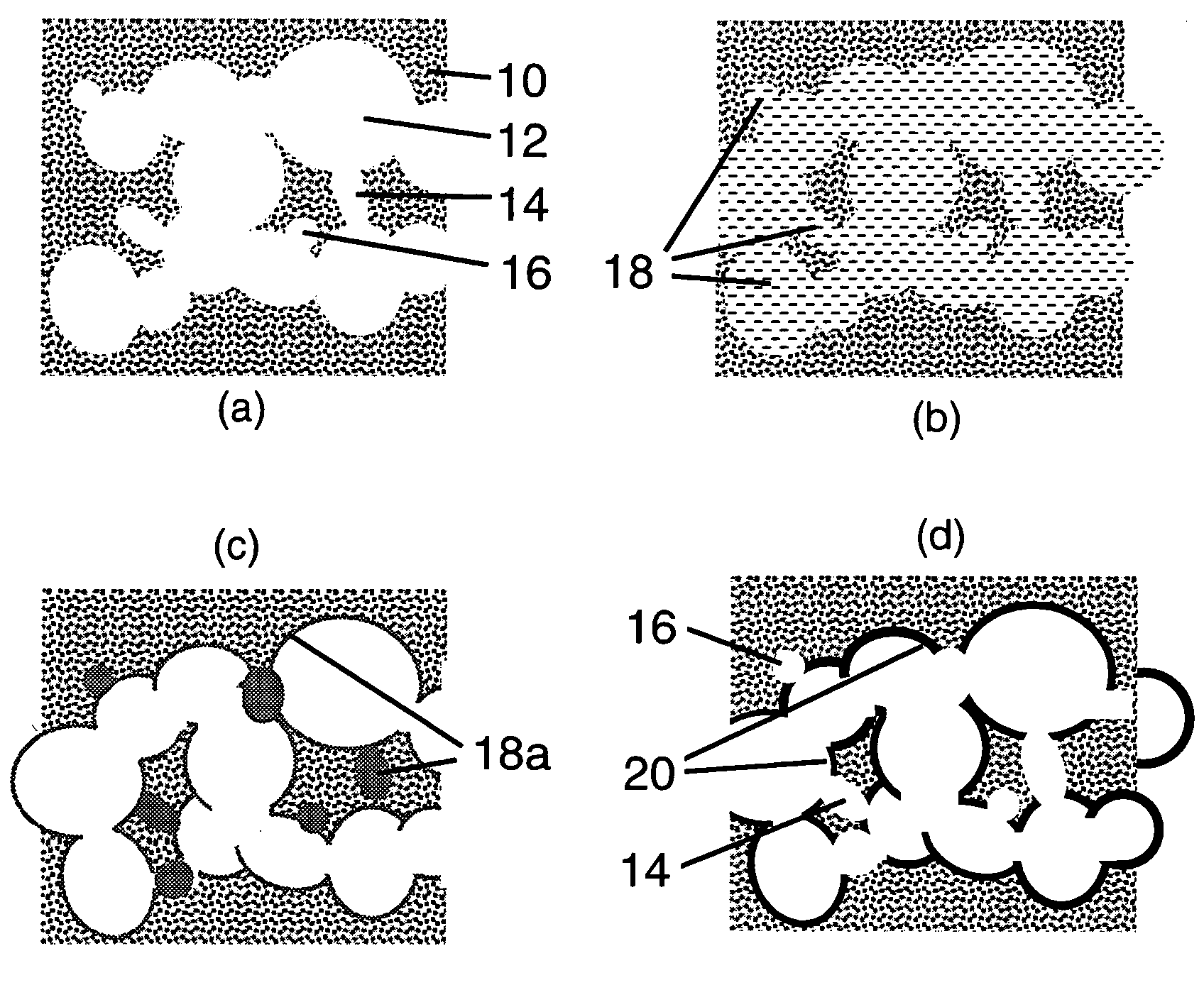

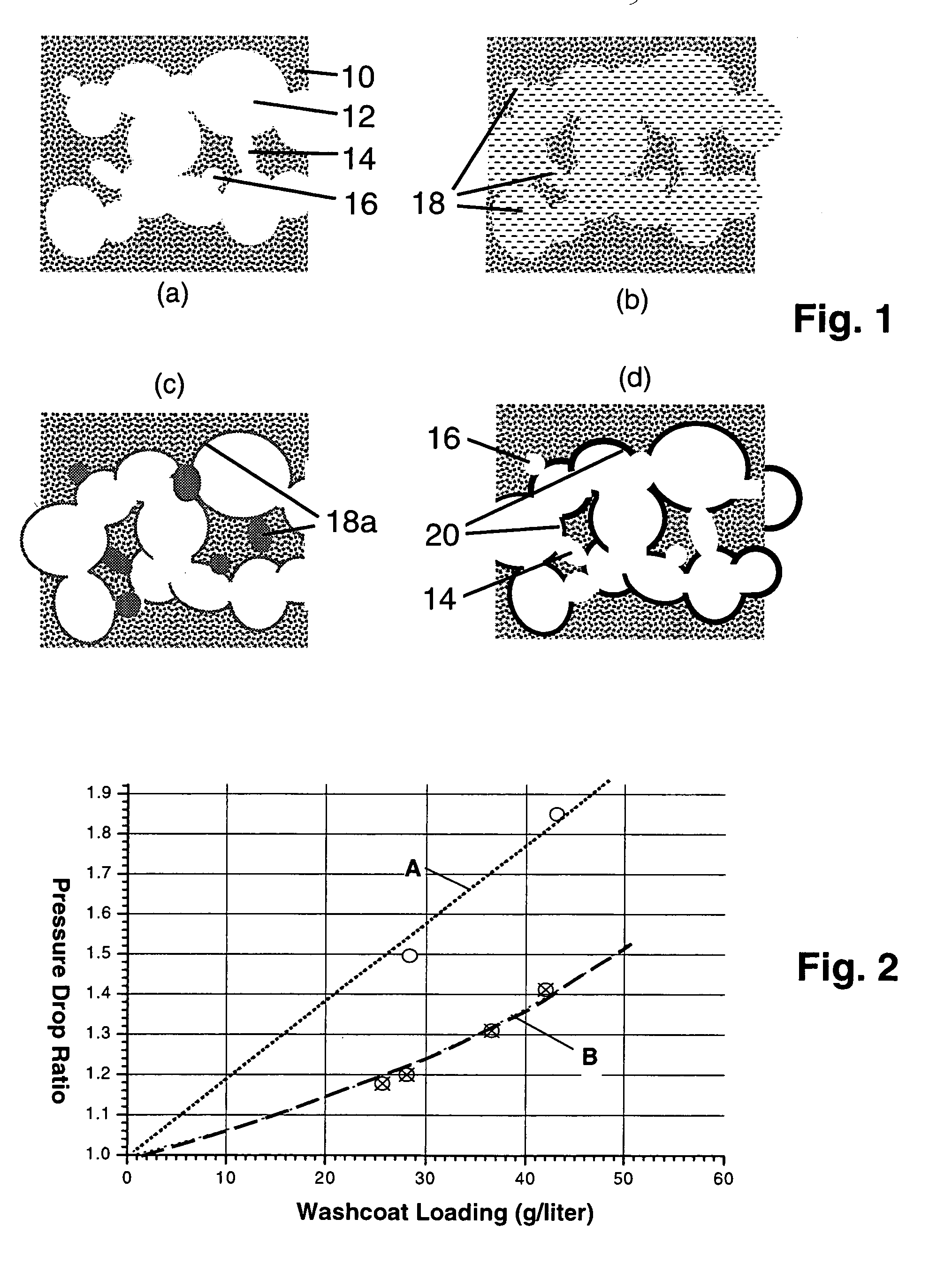

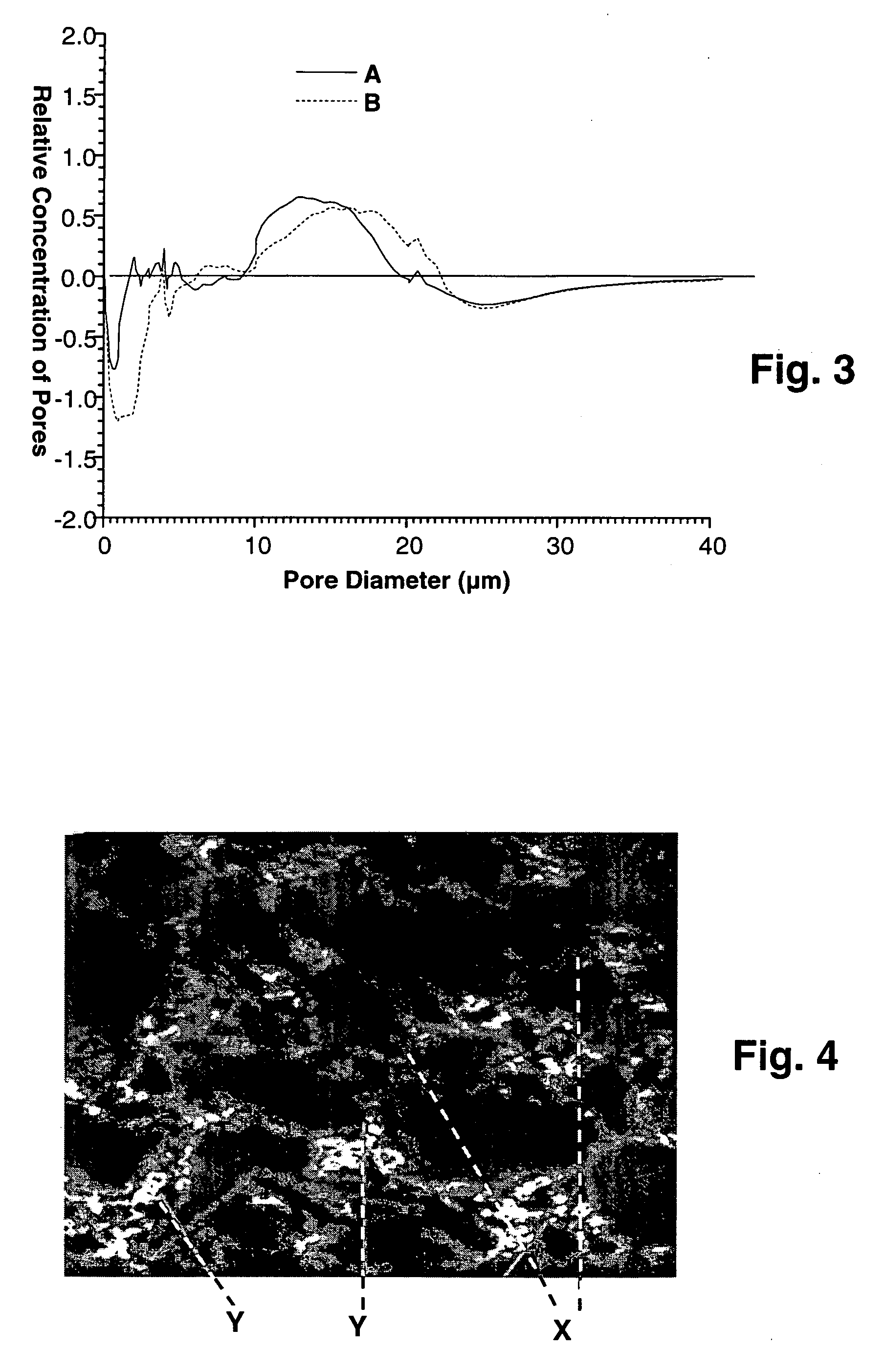

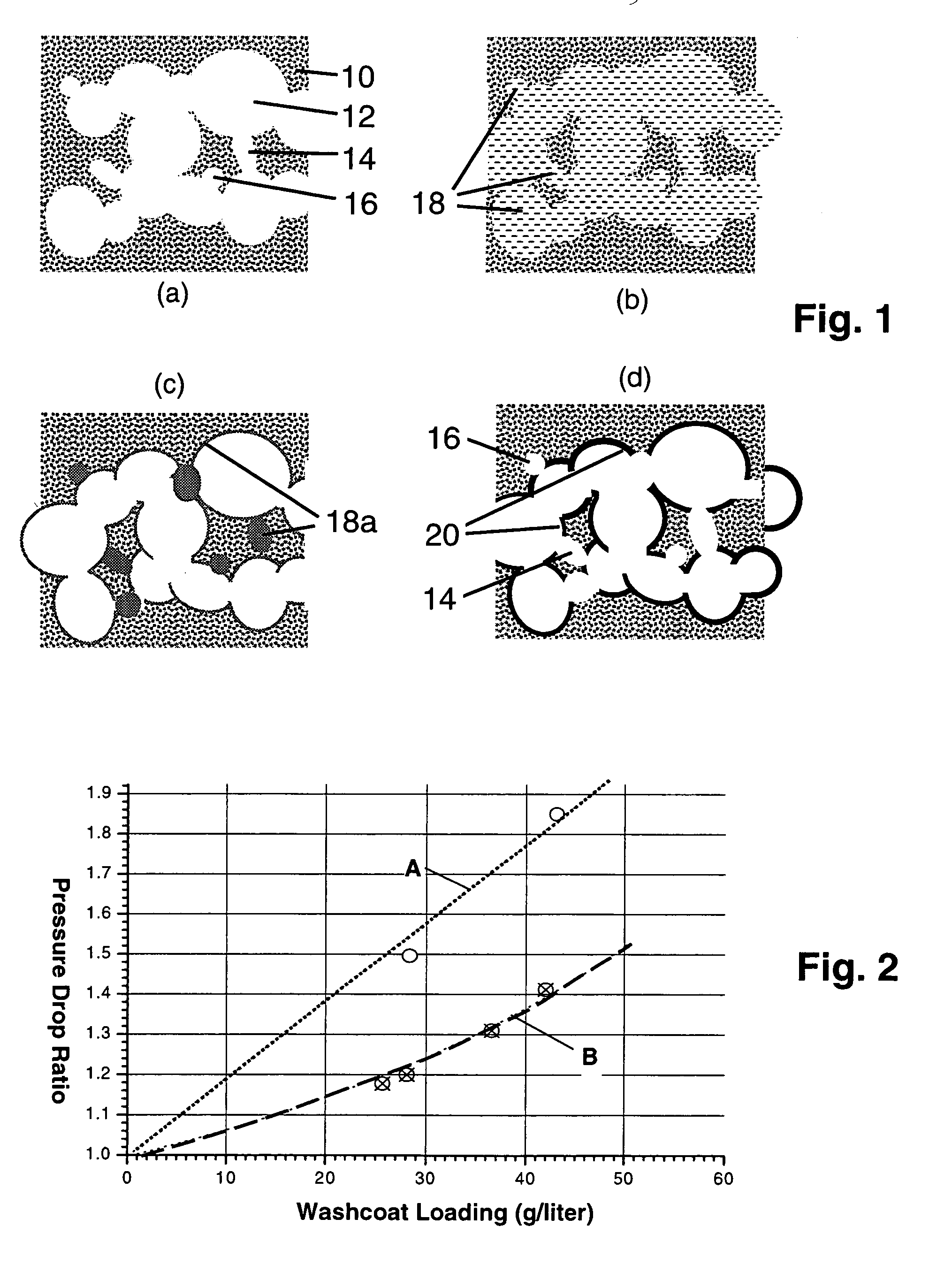

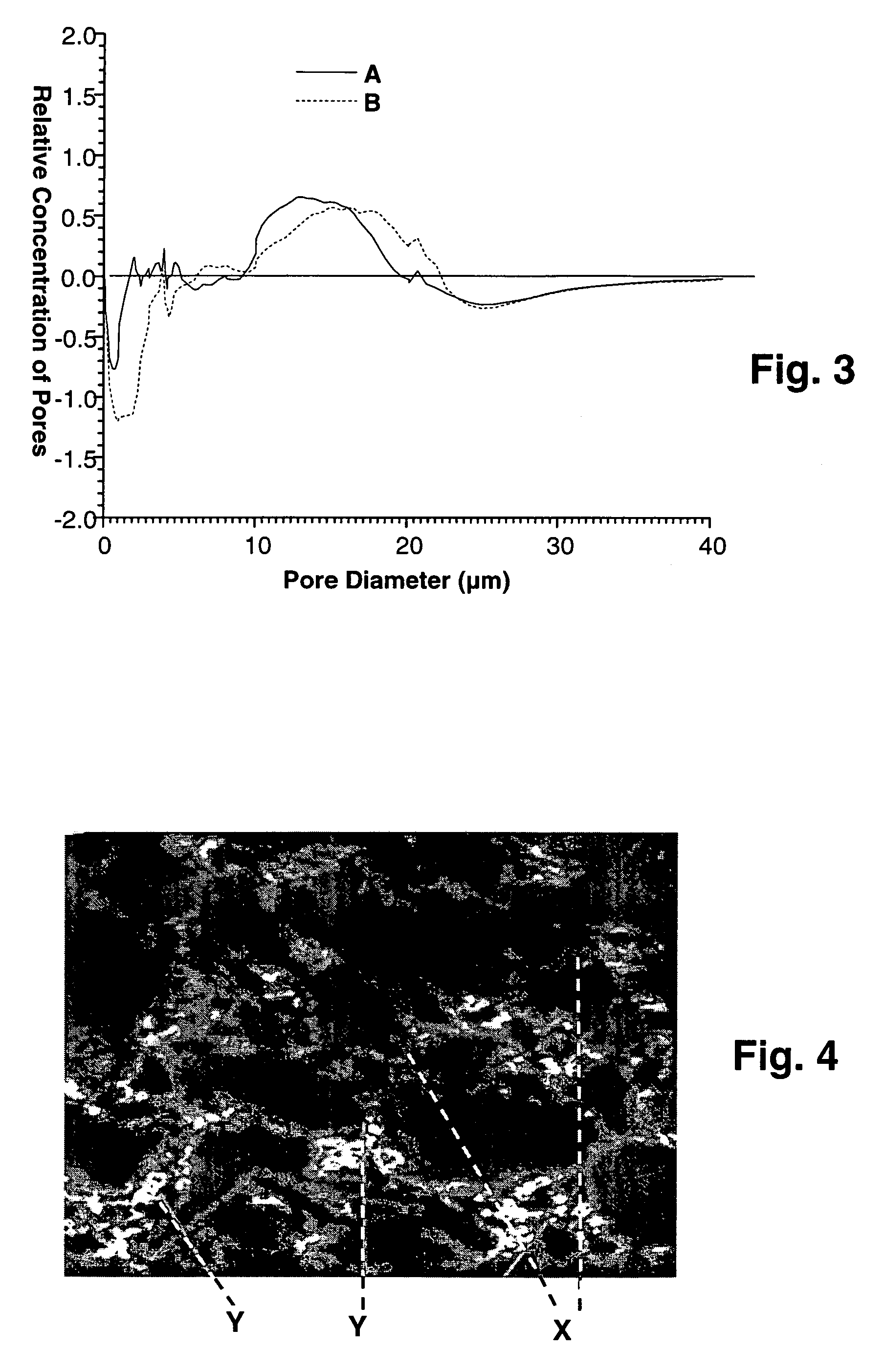

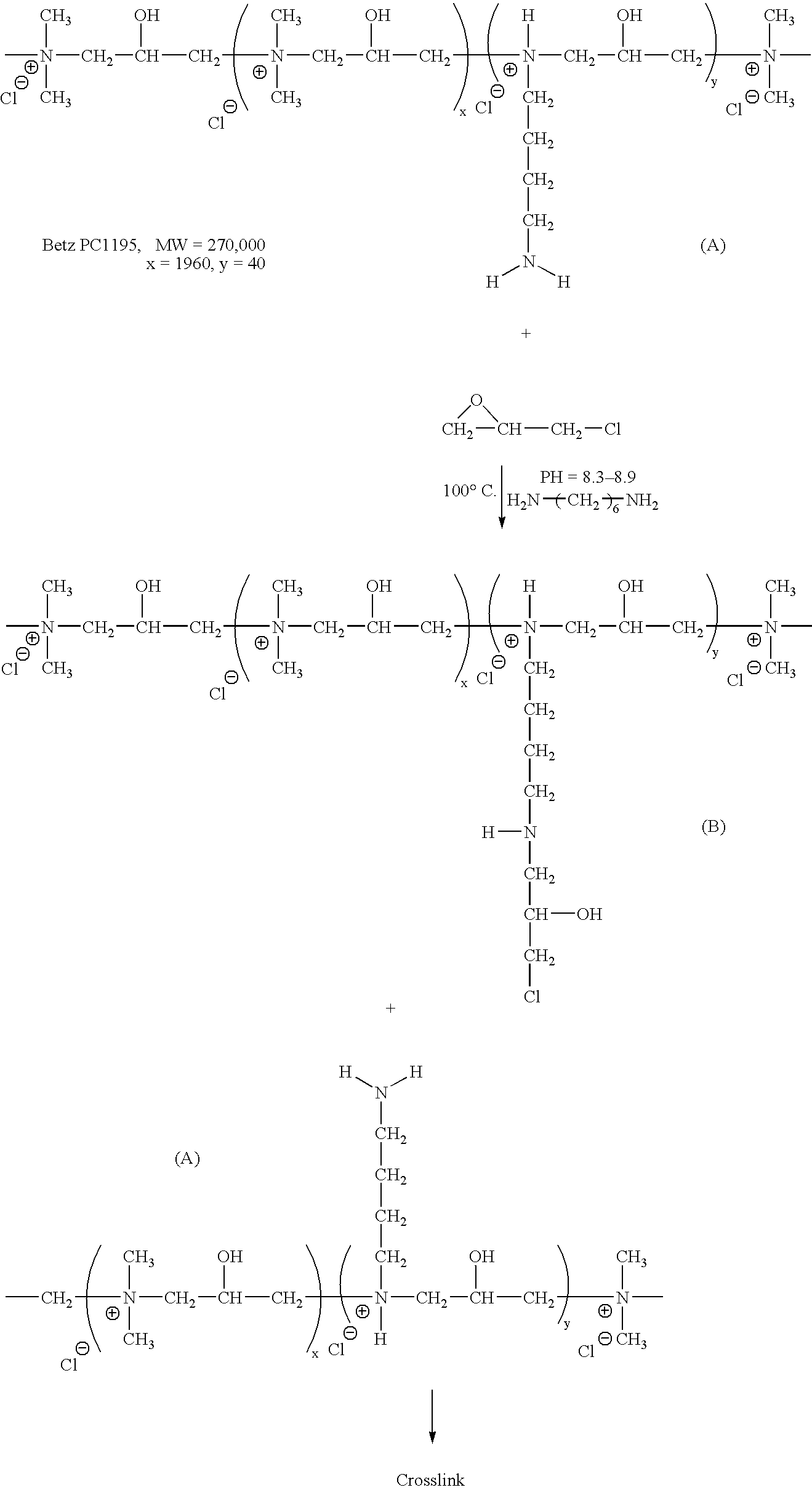

Porous ceramic filters with catalyst coatings

ActiveUS20050191480A1Effective penetrationExtensive cross-linking of the polymerLayered productsCatalyst activation/preparationCross-linkBiological activation

Porous ceramic catalyst supports or filters to be provided with catalyst coatings via oxide washcoating processes are pre-coated with cross-linked polymer barrier layers to prevent washcoat nanoparticle intrusion into the microcracked and / or microporous surfaces of the ceramics, the barrier coatings being formed by thermally cross-linking hydrocarbon polymers that are vaporizable at moderate washcoat stabilization or catalyst activation temperatures and being preferentially

Owner:CORNING INC

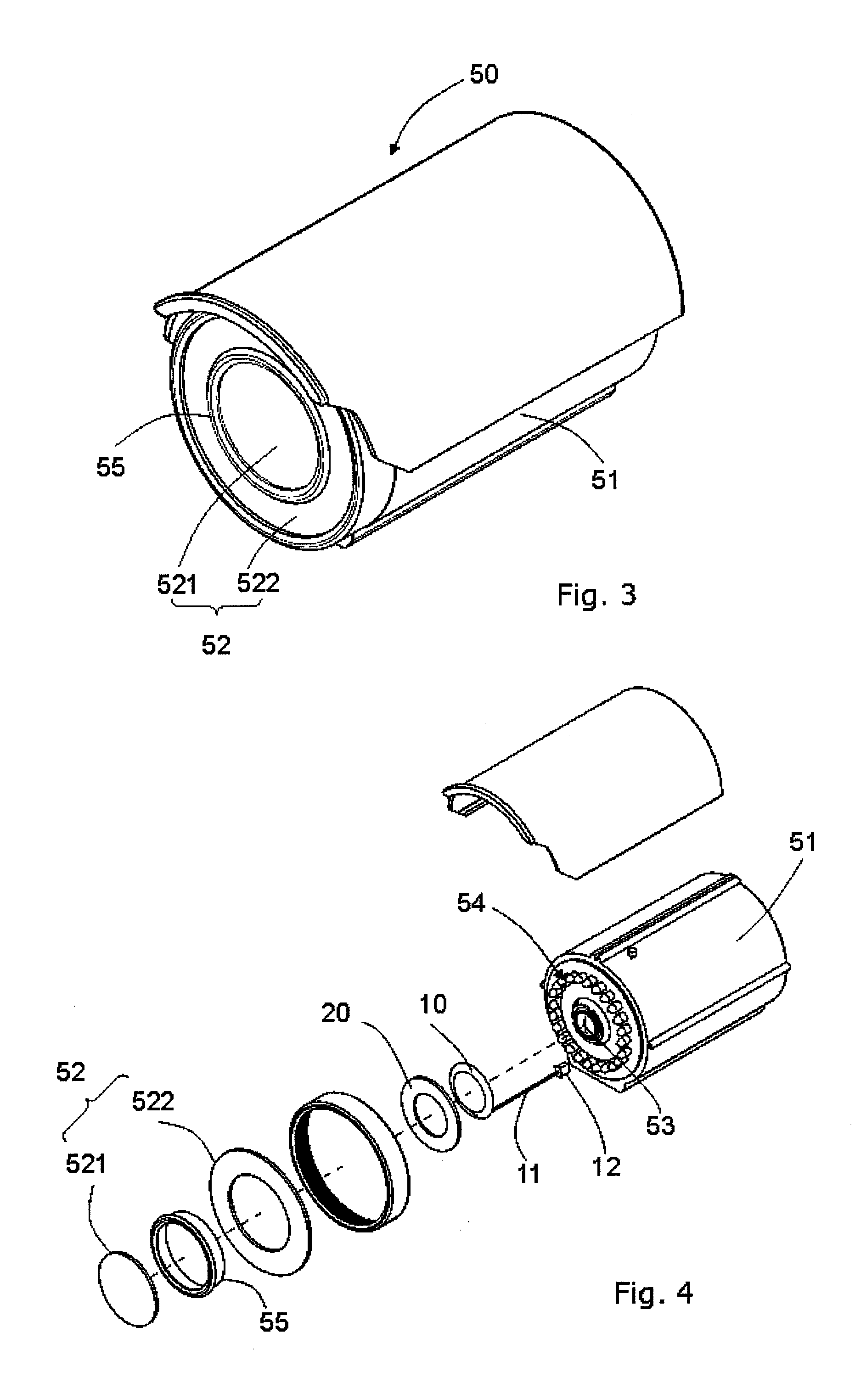

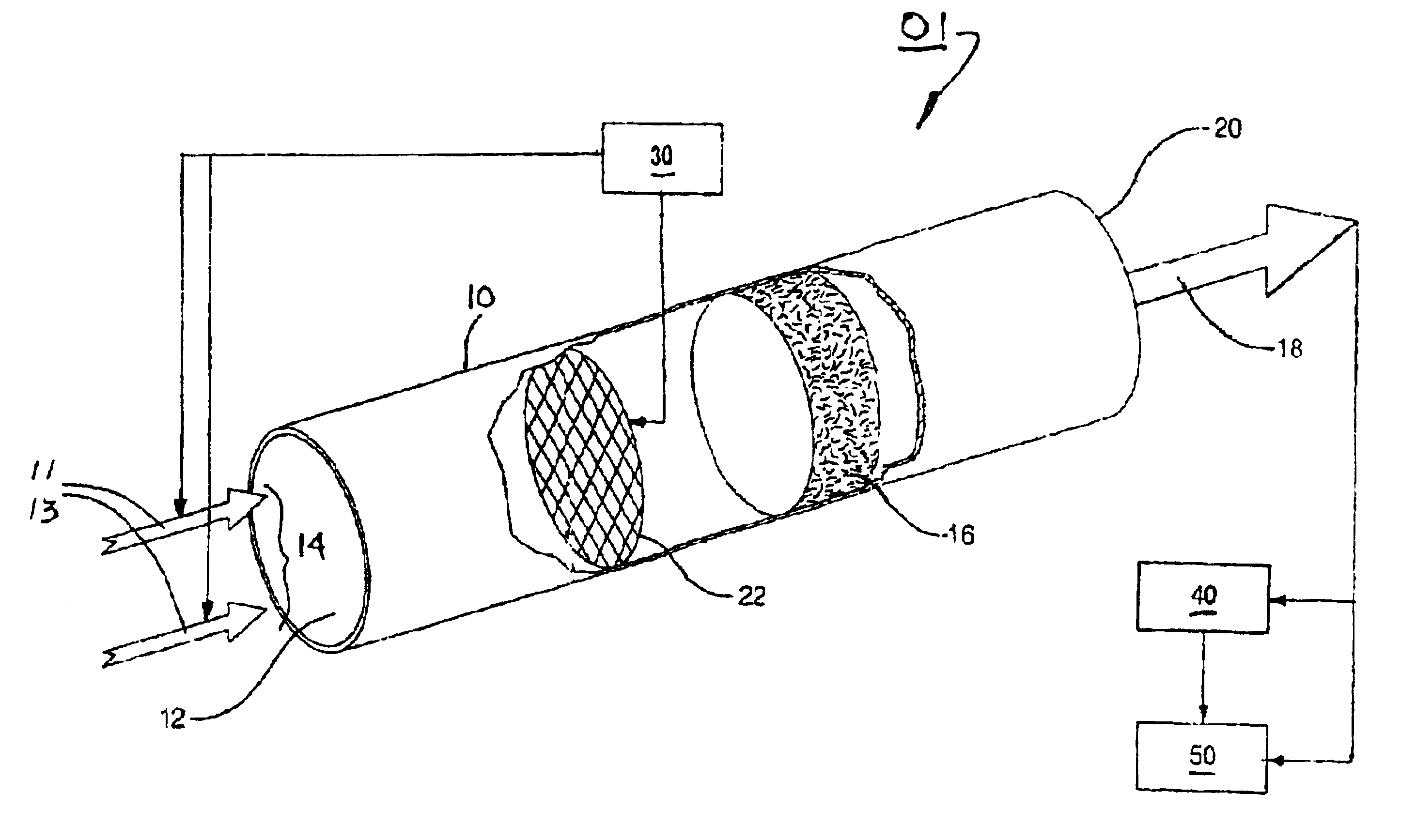

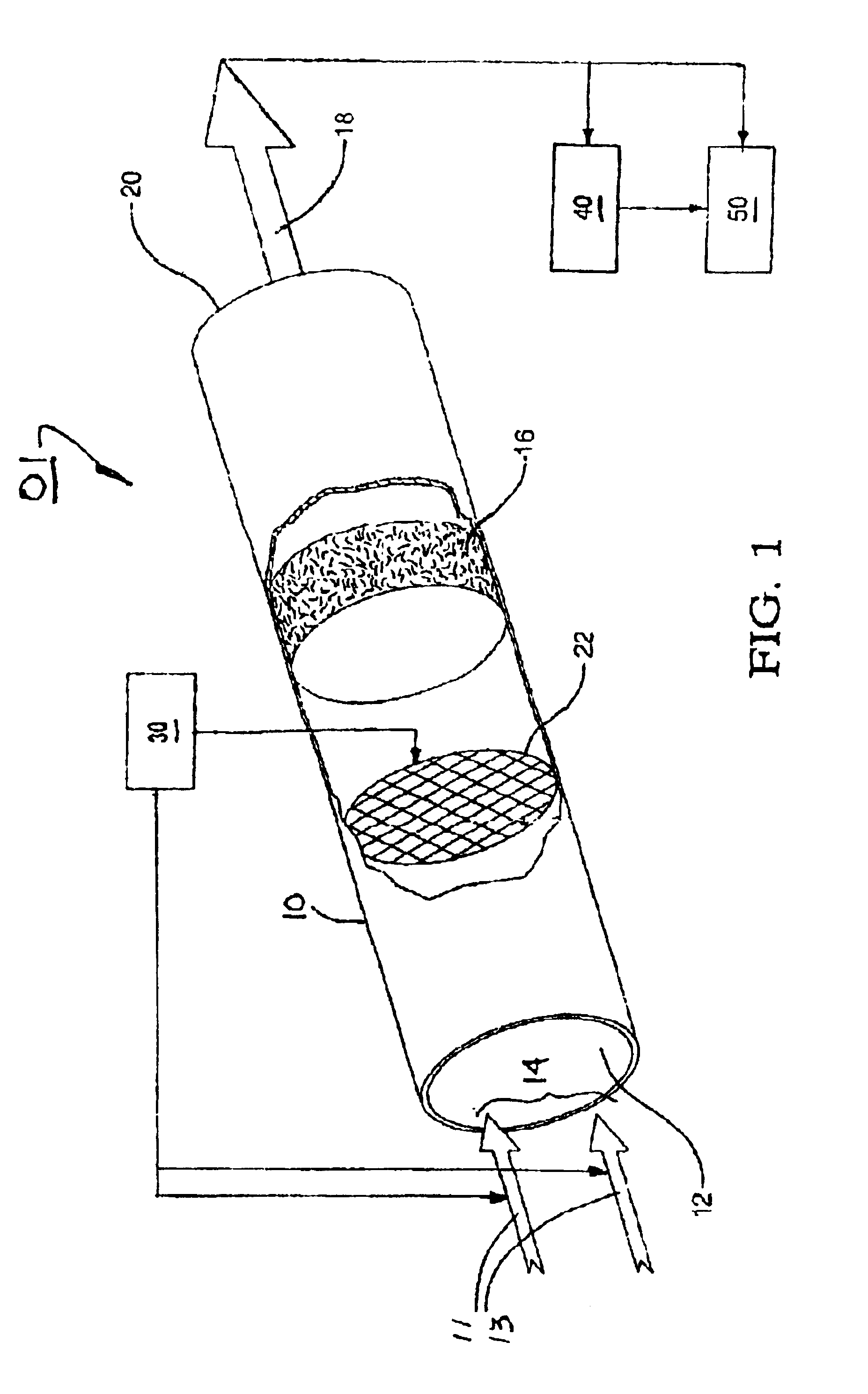

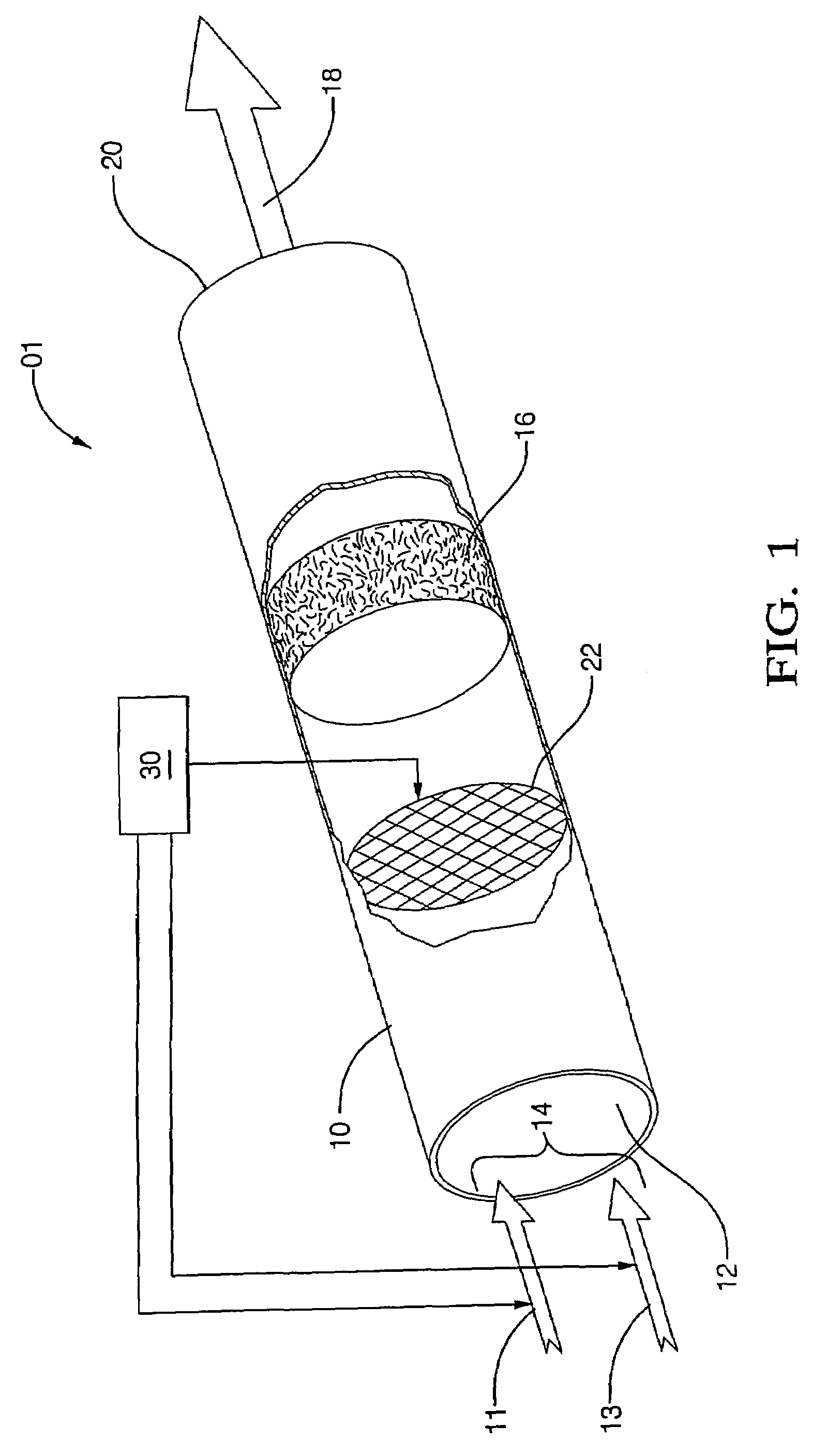

Fast light-off catalytic reformer

InactiveUS6887436B1Optimize reformate yieldHeating fastCombination devicesHydrogenCatalytic reformingOn board

A fast light-off catalytic reformer and method includes at least one preferably substantially cylindrical reactor tube having an inlet for receiving a flow of fuel and a flow of air, a reforming catalyst disposed within the reactor tube for converting the fuel and air to a reformate stream, and an outlet for discharging the produced reformate stream. An ignition device disposed within the reactor tube initiates an exothermic reaction between the fuel and air. Heat generated thereby provides fast light-off of the reforming catalyst. An associated control system selects fuel and air flow delivery rates and operates the ignition device to achieve fast light-off of the reforming catalyst at start-up and to maintain the catalyst at a temperature sufficient to optimize reformate yield. The rapid production of high yields of reformate is particularly suitable for use in an on-board reforming strategy for meeting SULEV emissions with spark-ignition engines, especially with larger, higher emitting vehicles.

Owner:DELPHI TECH INC

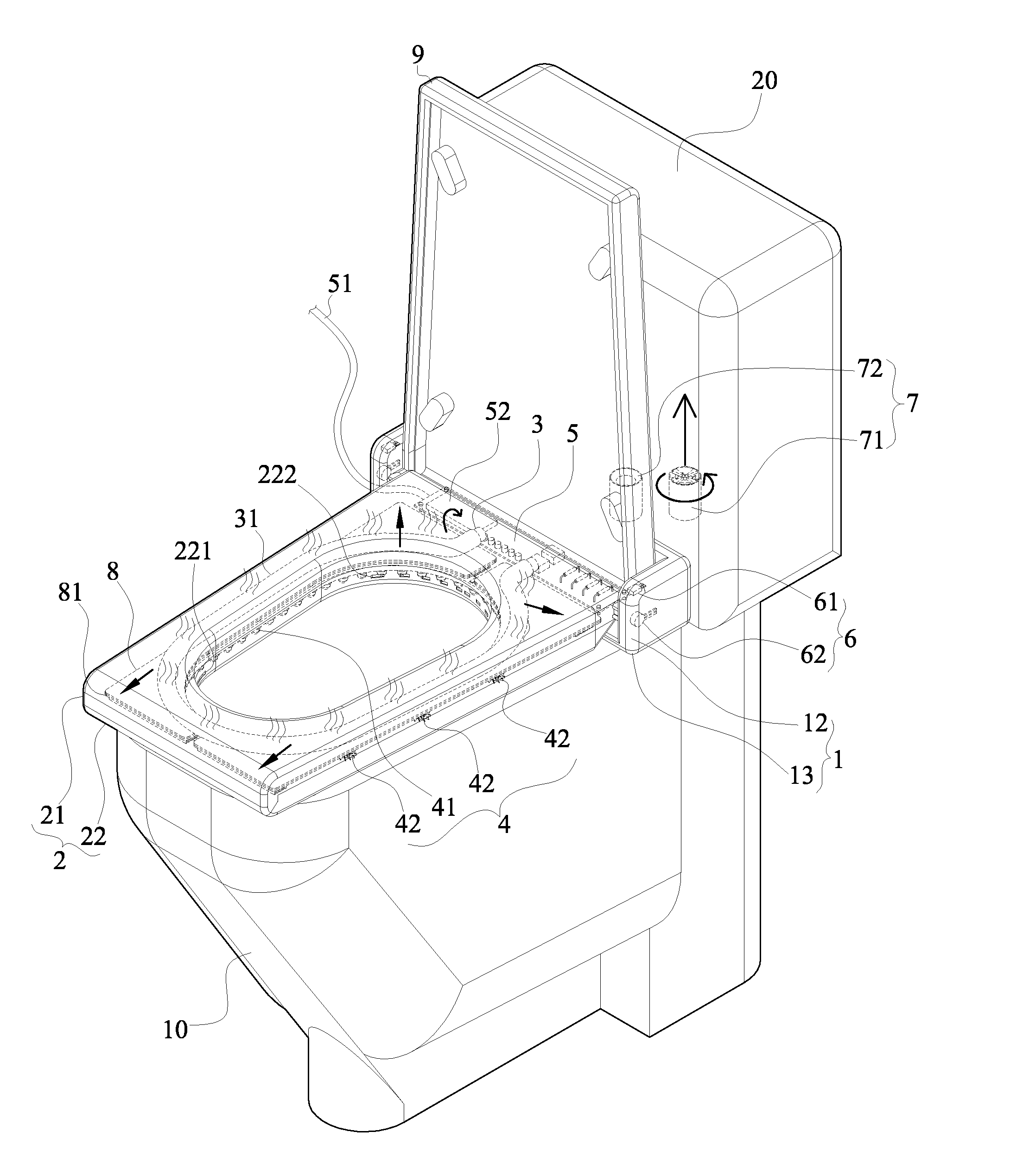

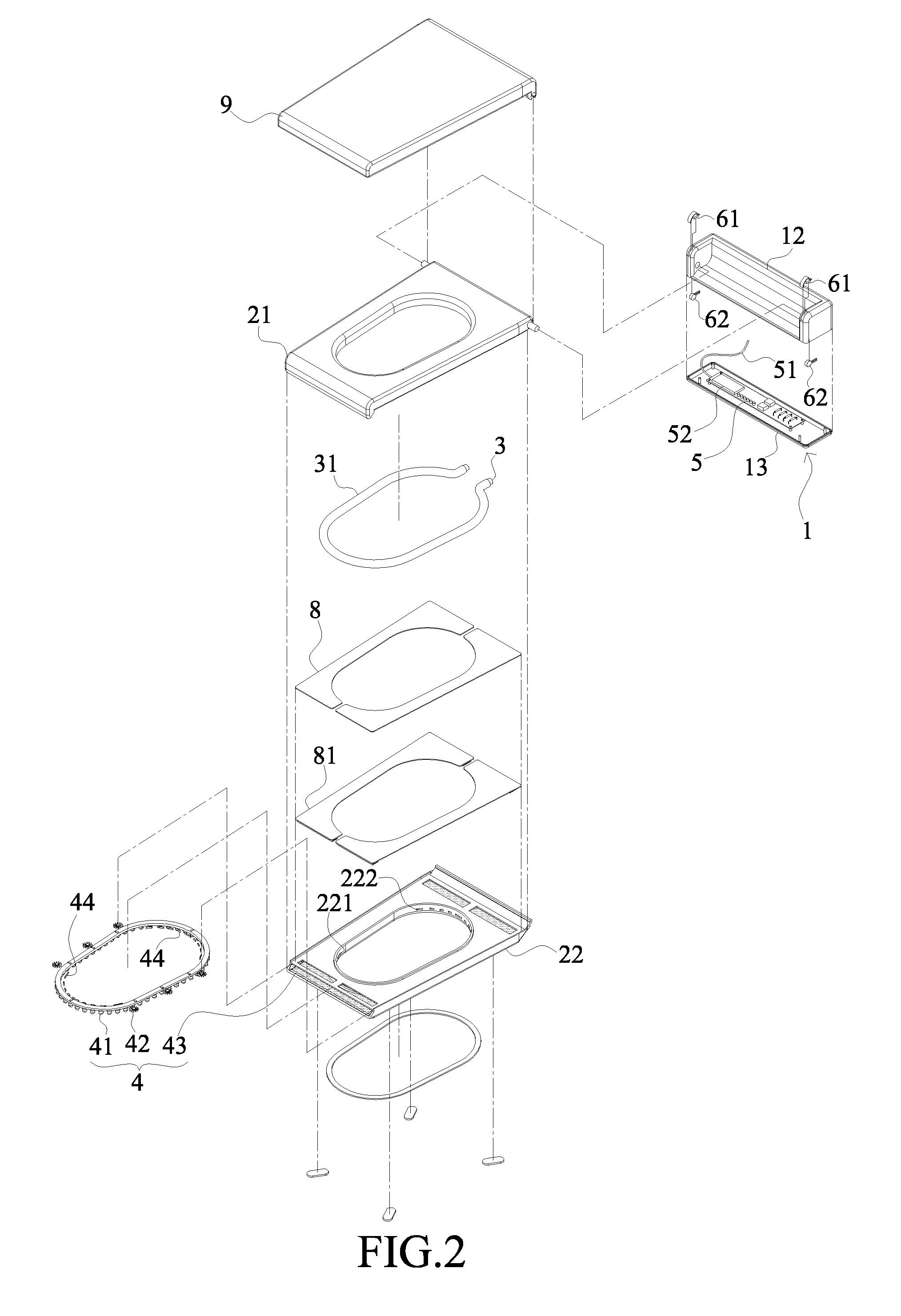

Sanitary toilet seat

InactiveUS20110191950A1Avoid unnecessary wasteReduce power consumptionBathroom coversTemperature controlUltraviolet lights

An energy saving and intelligent electronic sanitary seat comprises a hinge base, a seat portion, a temperature controlling unit, a germicidal device, a control unit, a sensing unit, a hydroelectric unit and a thermoelectric unit. The seat portion includes an upper and lower seat plates. Said germicidal device consists of a plurality of light emitting diodes (LEDs) which can emit ultraviolet light, a ventilation system and a photocatalytic layer. Said sensing unit comprises of two infrared sensors and two pressure monitoring devices. The hydroelectric unit consists of a first and second hydroelectric generators provided respectively about an inlet and outlet of a water tank of a toilet.

Owner:LIU LIN HO

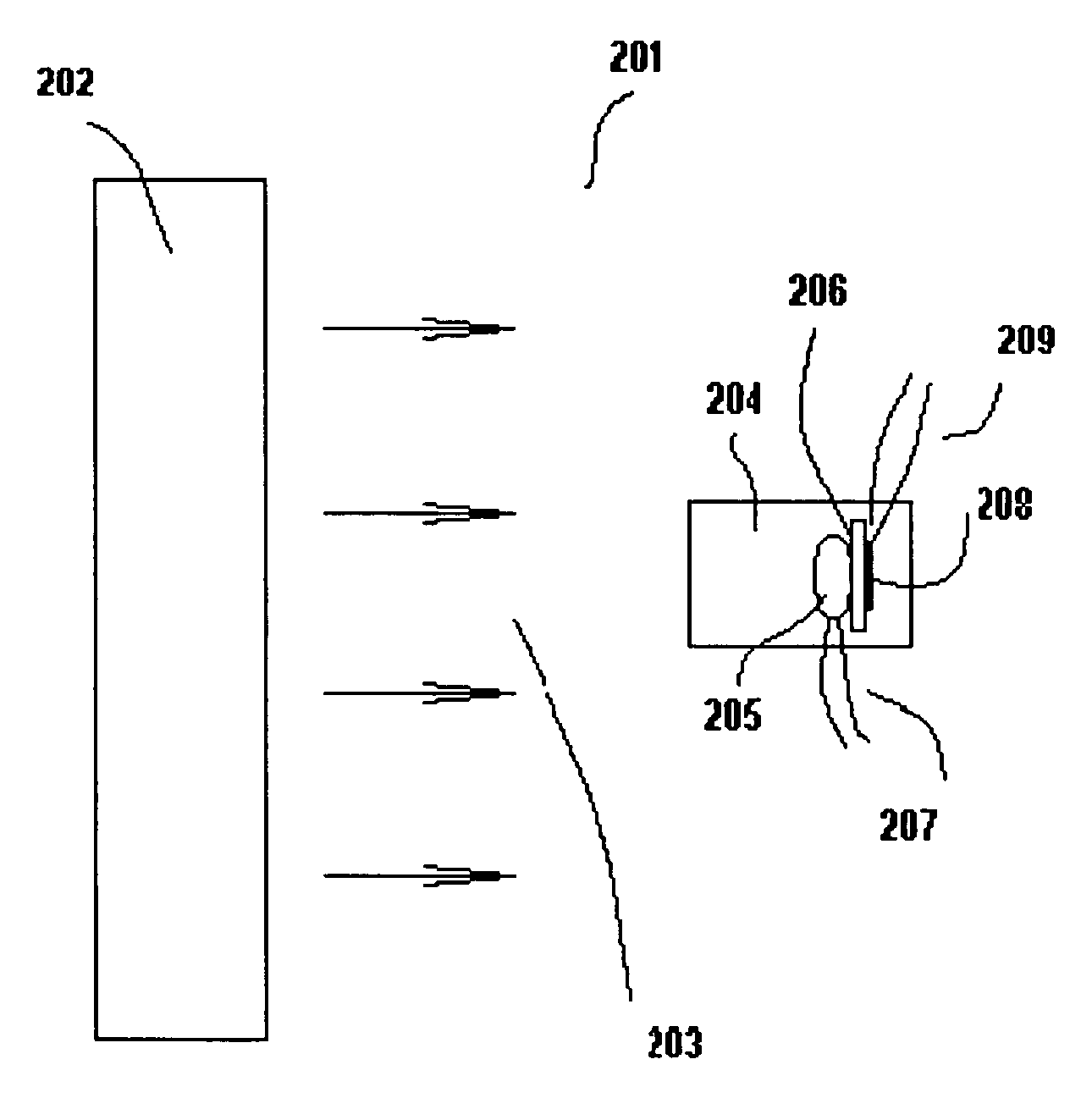

Method and Apparatus for Treatment of Hypertension Through Percutaneous Ultrasound Renal Denervation

ActiveUS20140031727A1Reduce the possibilityAvoid insufficient temperatureUltrasound therapyStentsUltrasonic sensorRenal nerve

Apparatus and methods for deactivating renal nerves extending along a renal artery of a mammalian subject to treat hypertension and related conditions. An ultrasonic transducer (30) is inserted into the renal artery (10) as, for example, by advancing the distal end of a catheter (18) bearing the transducer into the renal artery. The ultrasonic transducer emits unfocused ultrasound so as to heat tissues throughout a relatively large impact volume (11) as, for example, at least about 0.5 cm3 encompassing the renal artery to a temperature sufficient to inactivate nerve conduction but insufficient to cause rapid ablation or necrosis of the tissues. The treatment can be performed without locating or focusing on individual renal nerves.

Owner:RECOR MEDICAL INC

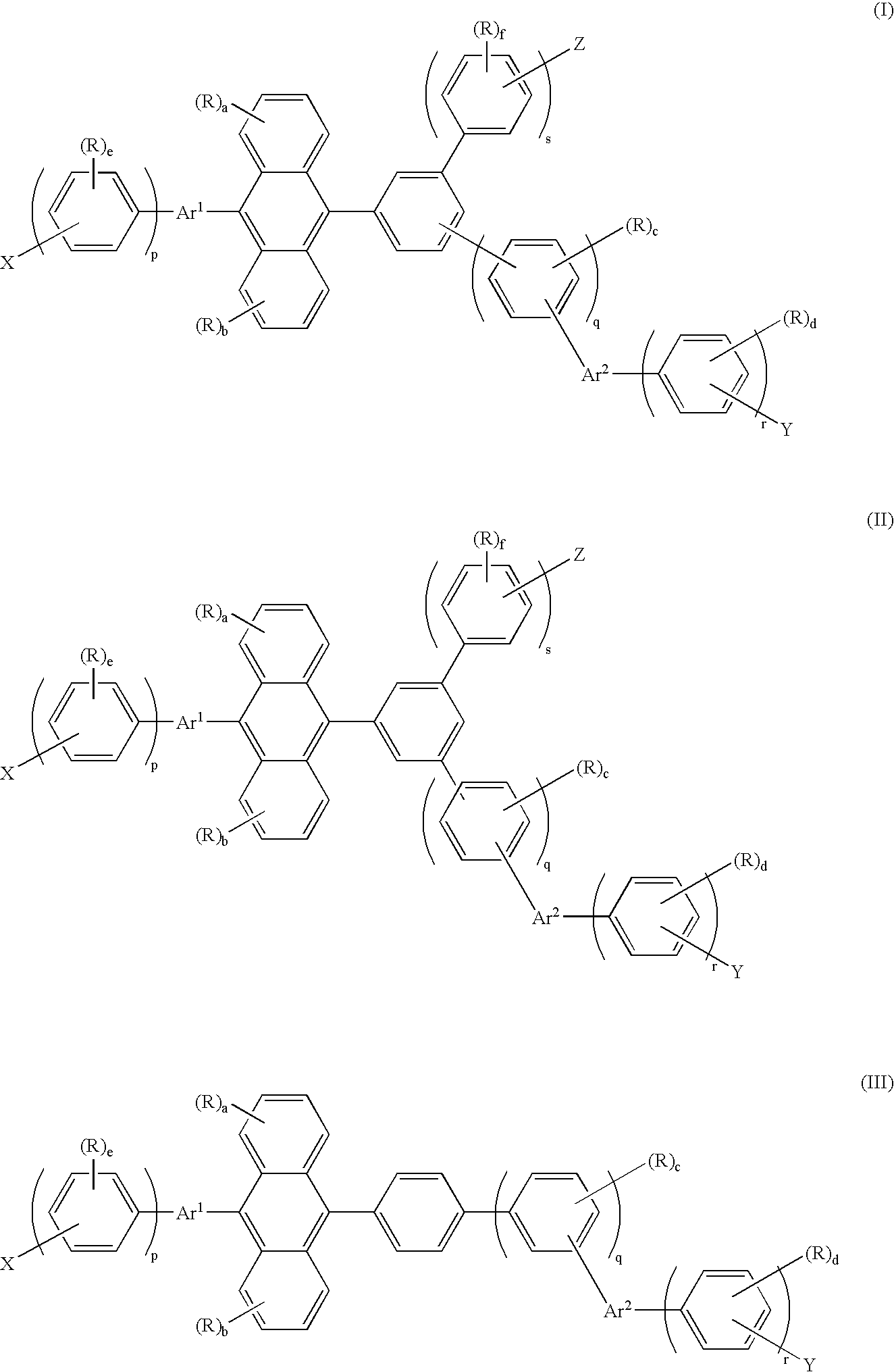

Anthrylarylene derivative, material for organic electroluminescence device and organic electroluminescence device using same

InactiveUS20070088185A1Improve efficiencySolution to short lifeOrganic chemistryOrganic compound preparationOrganic electroluminescenceGlass transition

An anthrylarylene derivative having a specific structure and an organic electroluminescence device comprising an organic thin film layer which comprises at least one layer comprising at least a light emitting layer and is disposed between a cathode and an anode, wherein at least one layer in the organic thin film layer comprises the anthrylarylene derivative singly or as a component of a mixture. The device exhibits a great efficiency of light emission and has a long life. The anthrylarylene derivative has a sufficient glass transition temperature and is greatly advantageous as the light emitting material used in the above organic electroluminescence device.

Owner:IDEMITSU KOSAN CO LTD

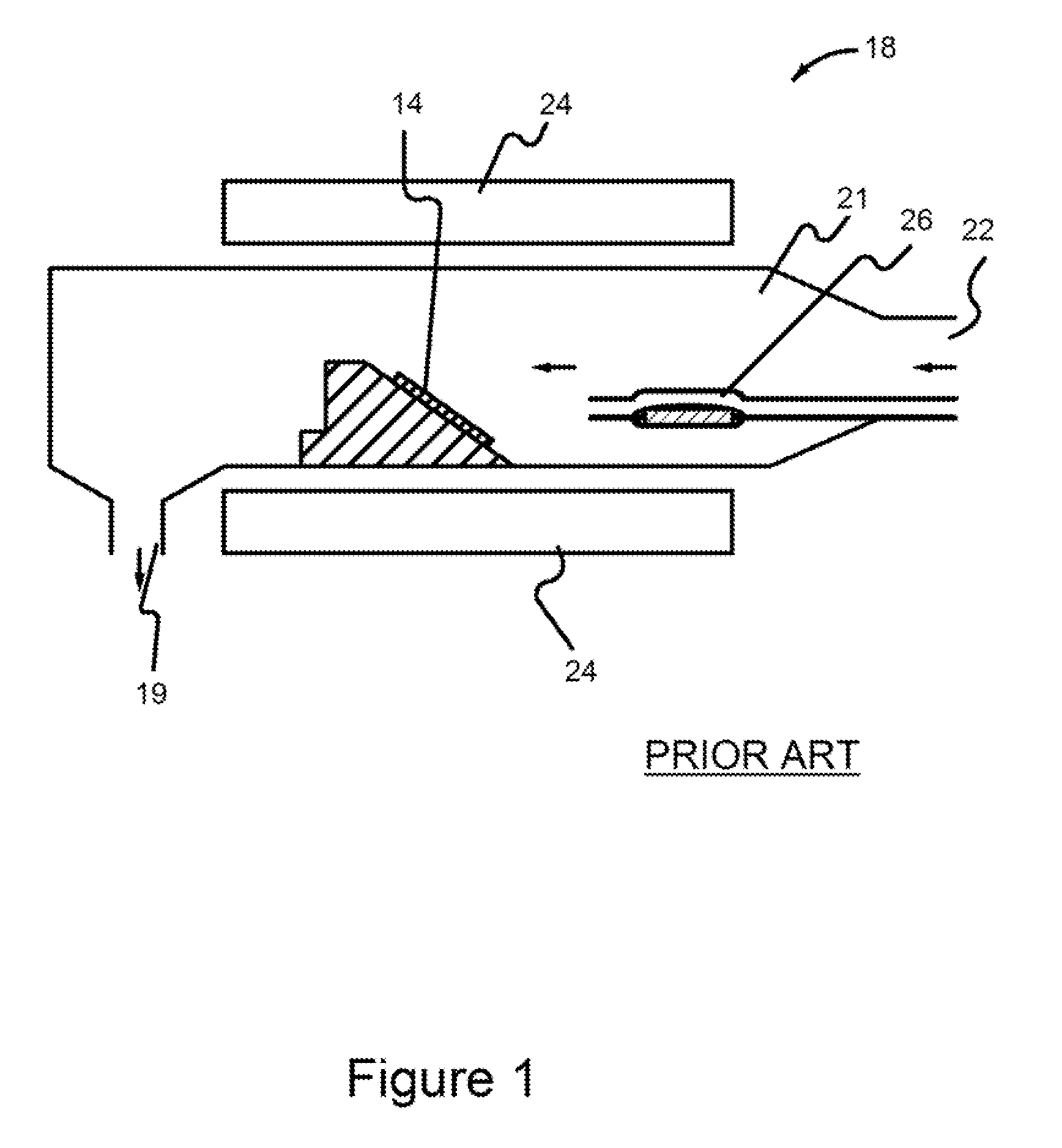

Modern hydride vapor-phase epitaxy system & methods

ActiveUS20110155049A1Uniform flow rateReduce distancePolycrystalline material growthFrom chemically reactive gasesChemical reactionSusceptor

Hydride vapor-phase deposition (HVPE) systems are disclosed. An HVPE hydride vapor-phase deposition system may include a reactant source chamber and a growth chamber containing a susceptor coupled to the reactant source chamber. The reactant source chamber may be configured to create a reactant gas through a chemical reaction between a solid or liquid precursor and a different precursor gas. The reactant source chamber can be configured to operate at a temperature T(M) significantly above room temperature. The reactant gas can be chemically unstable at or near room temperature. The susceptor is configured to receive a substrate and maintain the substrate at a substrate temperature T(S). The growth chamber includes walls can be configured to operate at a temperature T(C) such that T(M), T(S) are greater than T(C).

Owner:CBL TECH

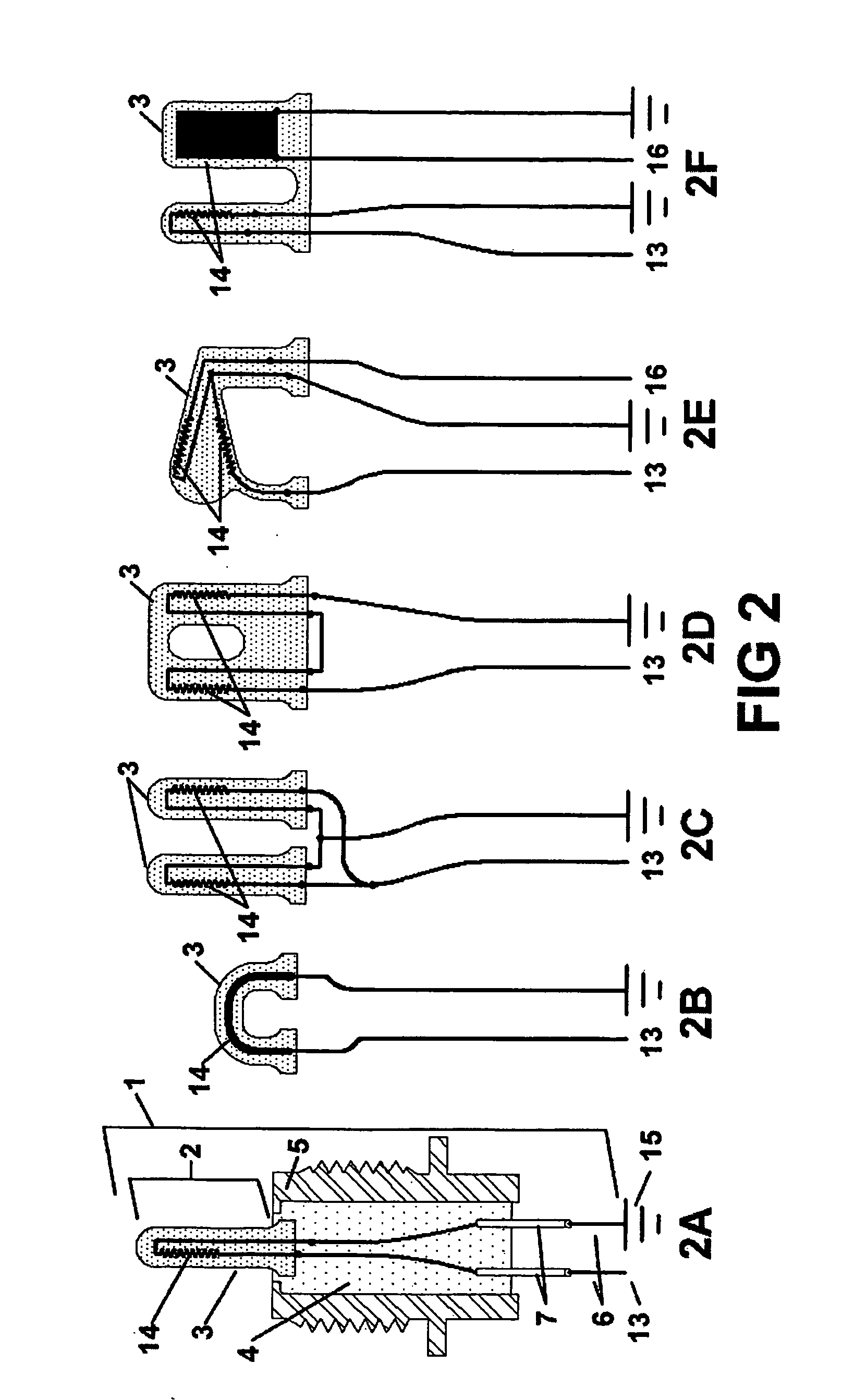

Ceramic-encased hot surface igniter system for jet engines

InactiveUS20080141651A1Increased voltageIncreasing power flowBurnersIncandescent ignitionCeramicSilicon nitride

A ceramic-encased hot surface igniter system for jet engines is presented. The advanced ceramic-encased hot surface igniter system comprises at least one electrical resistance heated element encased in a durable, thermal and mechanical shock resistant, high temperature advanced ceramic compound such as silicon nitride. The one or more advanced ceramic-encased hot surface igniter elements are mounted proximally upstream or within a combustion chamber of a jet engine enclosure or within the afterburner section of a jet propulsion engine's exhaust. The surface temperature of each ignition element's encasement being of sufficient temperature to cause the ignition of a gaseous, atomized, or liquid fuel.

Owner:STATE OF FRANKLIN INNOVATIONS

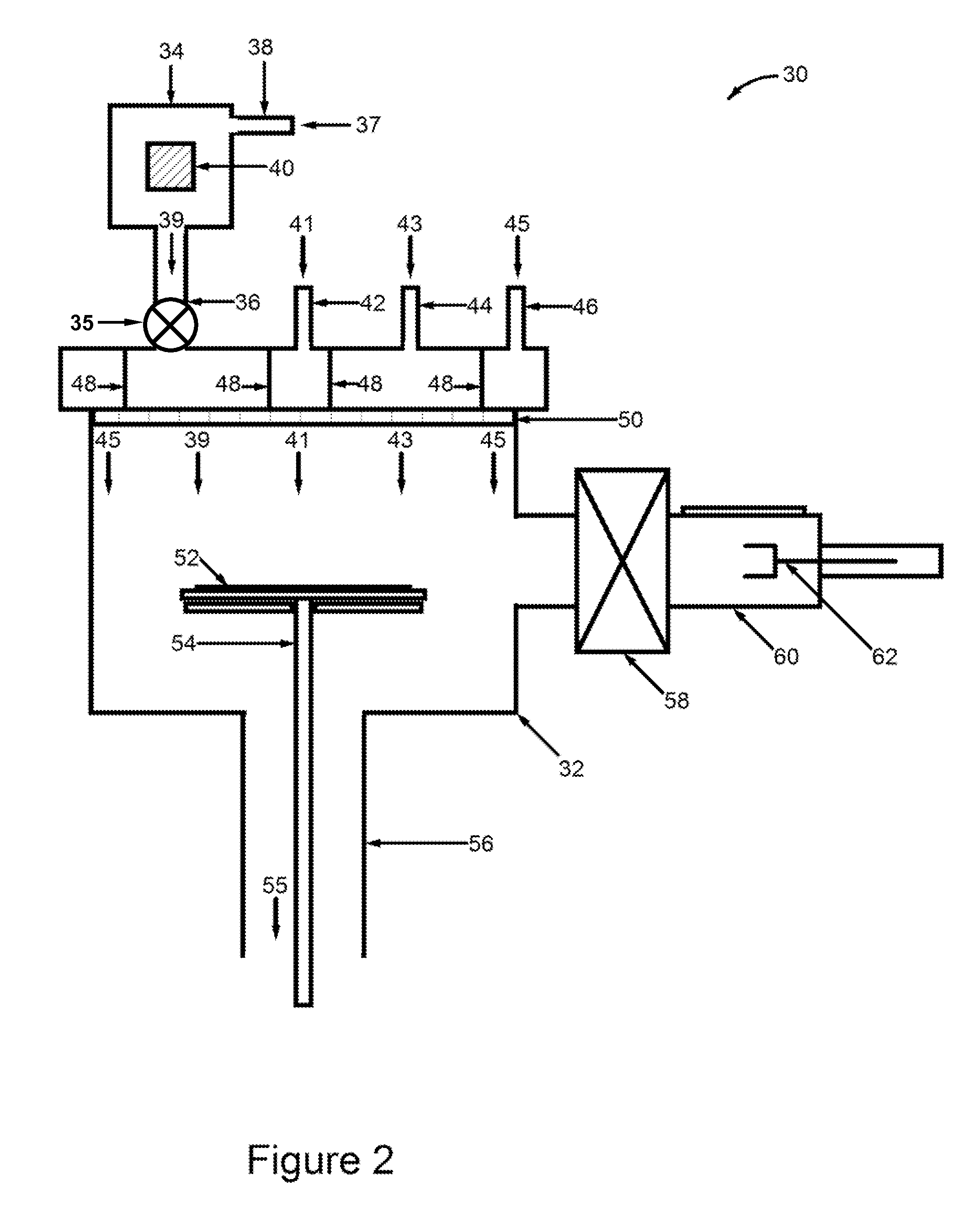

Method and apparatus for fuel/air preparation in a fuel cell

ActiveUS7037349B2Fast startupOptimize reformate yieldExhaust apparatusGas modification by gas mixingExhaust gasNuclear engineering

A fast start-up catalytic reformer for producing hydrogen-rich reformate from hydrocarbon fuel includes a reactor having an inlet for receiving a flow of fuel and a flow of air, a reforming catalyst disposed within a reforming chamber in the reactor, and an outlet for discharging the produced reformate stream. An ignition device within the reactor tube ignites a first lean mixture in combustion mode to generate exhaust gases to warm the catalyst which also warms the wall of the reactor adjacent the catalyst. The reactor then switches over to a rich fuel / air mixture during reforming mode. A jacket concentrically surrounds the reactor, defining a mixing chamber therebetween which communicates with the reforming chamber via openings in the wall of the reactor. Fuel entering the reformer in combustion mode is injected directly into the reforming chamber to provide rapid warming of the catalyst. Fuel entering the reformer in reforming mode is sprayed onto the outside of the reactor in the mixing chamber, preferably in the heated region of the tube for very rapid vaporization.

Owner:APTIV TECH LTD

Porous ceramic filters with catalyst coatings

ActiveUS7122612B2Effective penetrationExtensive cross-linking of the polymerLayered productsPretreated surfacesCross-linkNanoparticle

Owner:CORNING INC

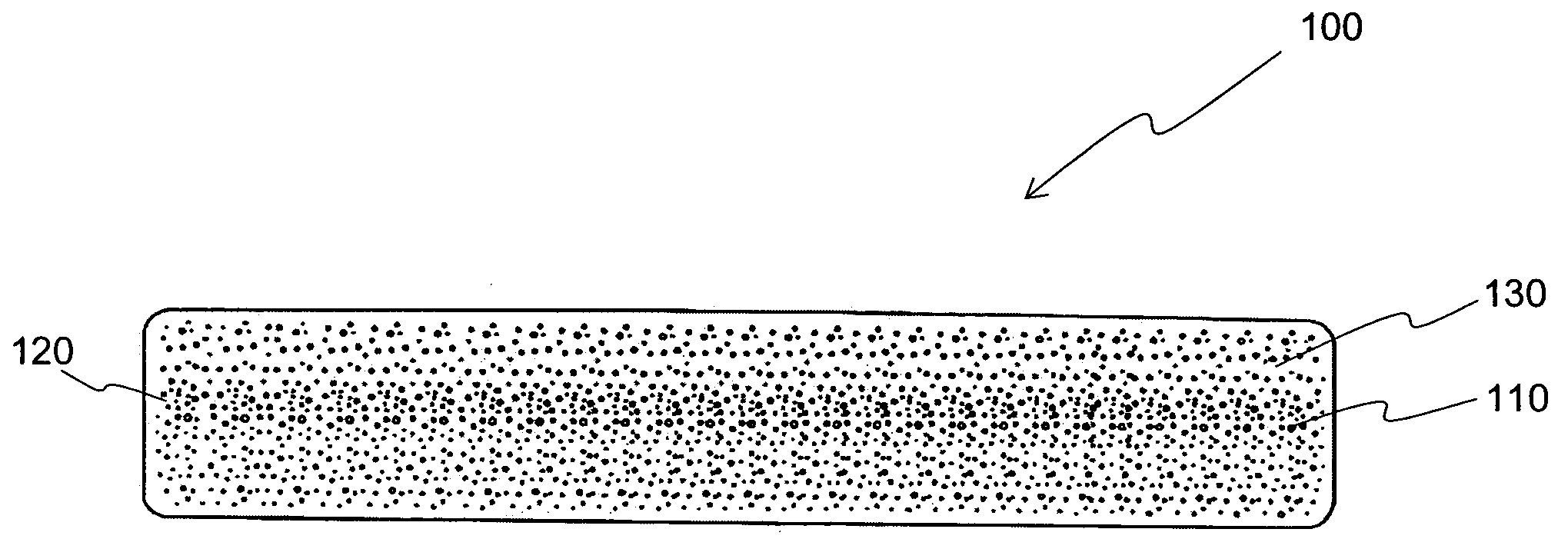

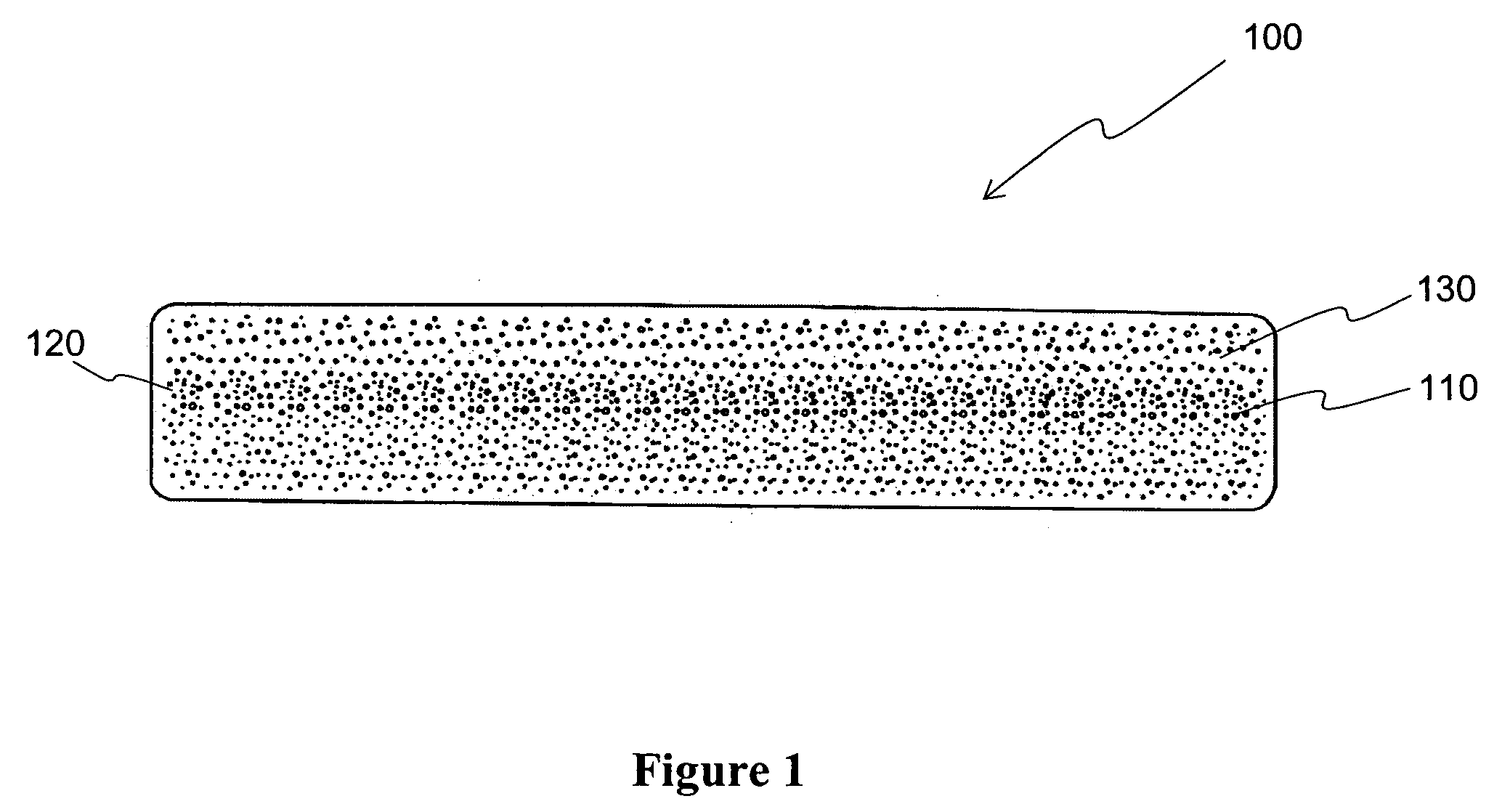

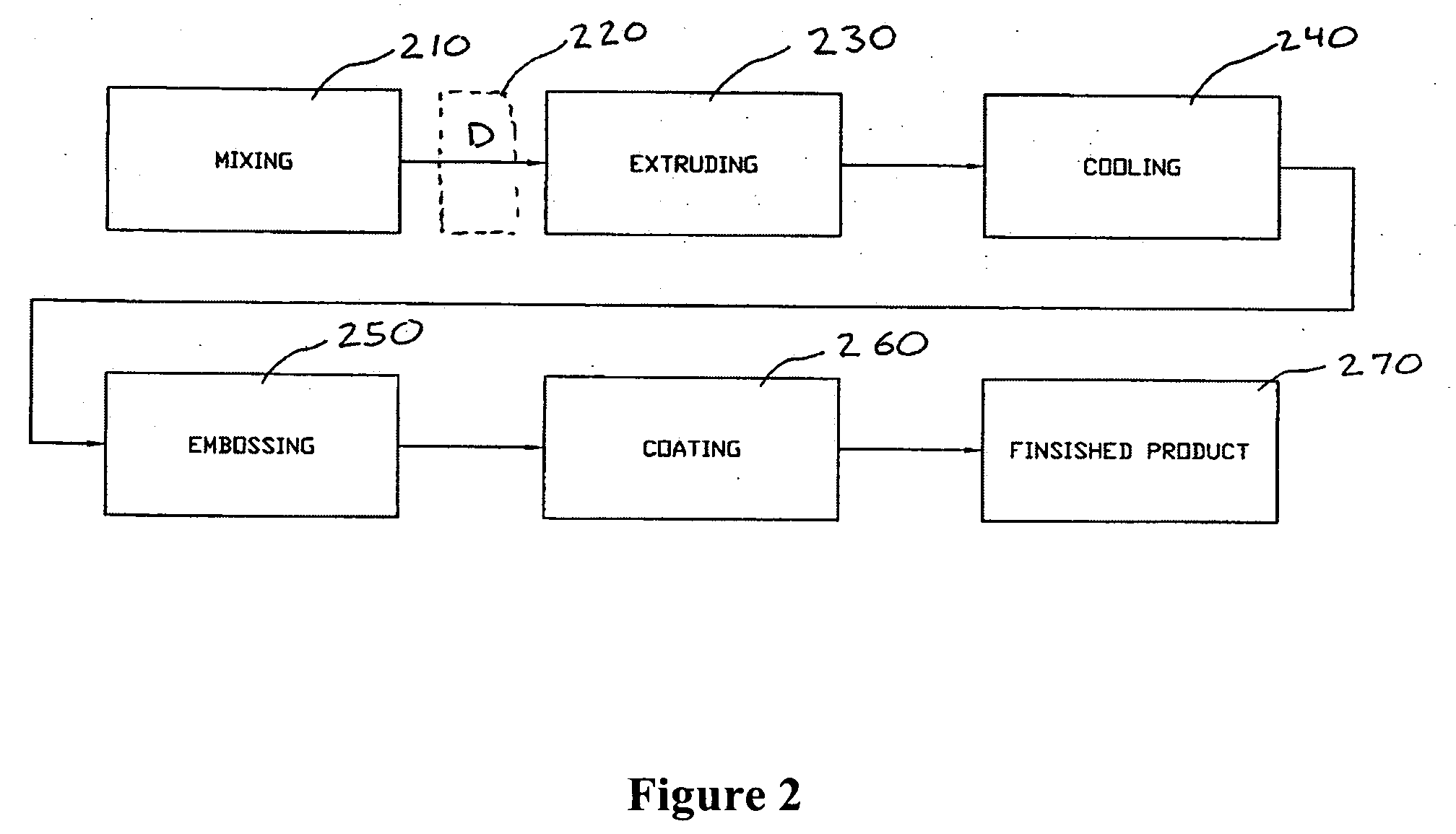

Composite building material and method for making composite building material

InactiveUS20080193740A1Prevent degradationAvoid insufficient temperatureLayered productsPretreated surfacesFoaming agentProcedure Agents

A composite building material and a method for its manufacture are provided. The method comprises the steps of: providing a foamable mixture comprising a polymeric matrix material, a filler, a processing aid, one or more lubricants, a thermal stabilizer, and a blowing agent; foaming said foamable mixture to form a foamed composite substrate; optionally embossing the substrate; and coating the substrate with a polyurethane / acrylic coating to form the composite building material, wherein the polyurethane / acrylic coating is keyed chemically and / or physically to the foamed composite substrate.

Owner:FIBER COMPOSITES

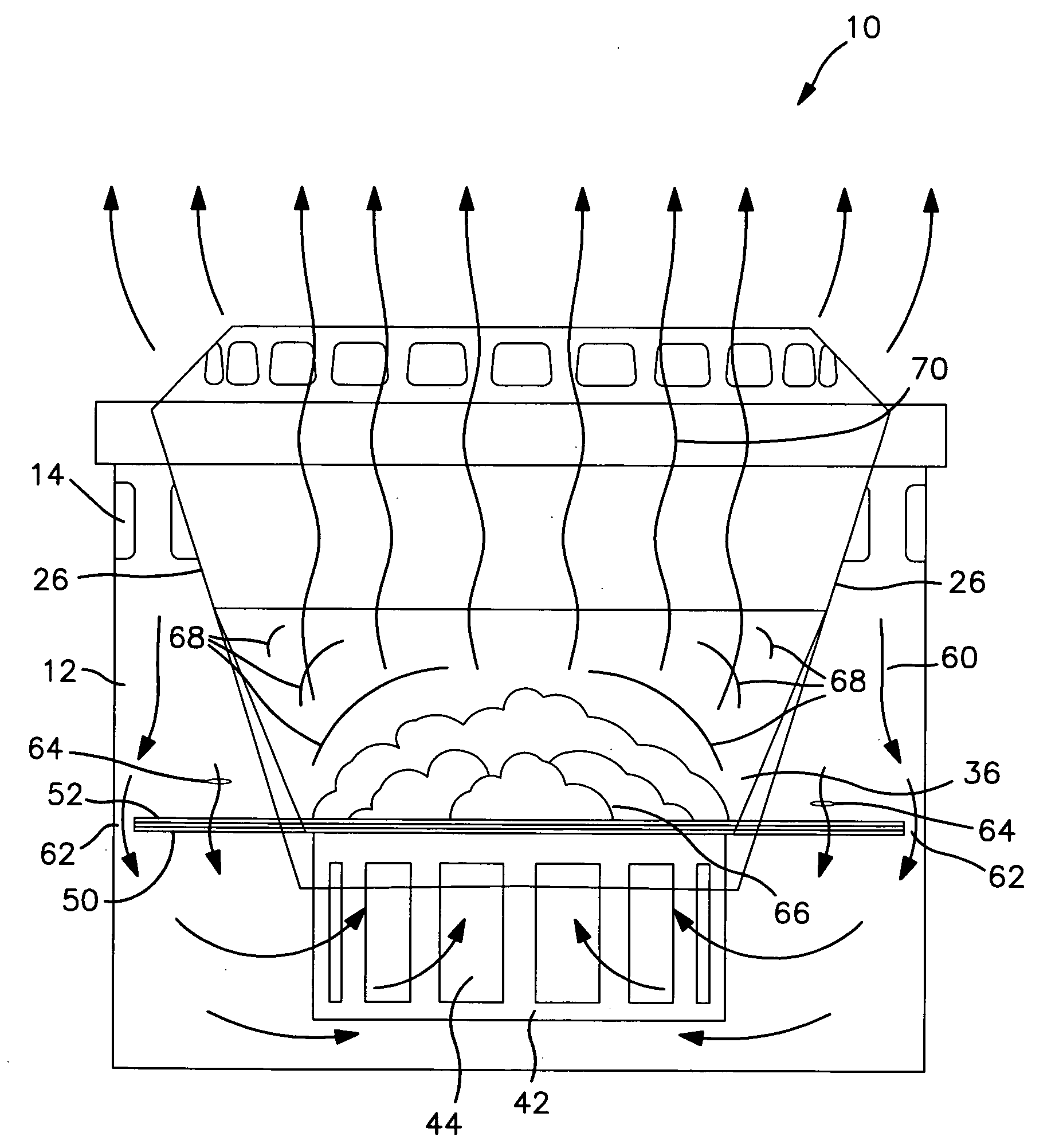

High efficiency combustion stove

InactiveUS20090165772A1Increase efficiencyImprove heating efficiencyLighting and heating apparatusCombustion-air/flue-gas circulation for stovesCombustion chamberAirflow

The invention is a stove that is portable, has a double walled external structure for the passage of air used in combustion of the fuel, which air also maintains the external surface at a cool enough temperature that it can be touched, and which air flow prevents the waste of heat laterally to the ambient air from a hot outer surface. This increases cooking efficiency, because almost all heat that reaches the air flow between the two walls is drawn right into the combustion chamber in the form of preheated air by reason of the chimney effect. Thus almost no heat can escape the outside wall except by reaching the cooking pot bottom and pot sides after passing out the cover vents as exhaust. The stove is preferably powered with coal, and uses about half as much coal as a conventional coal fired stove resulting from cooking efficiency.

Owner:ENVIRO FUELS MFG

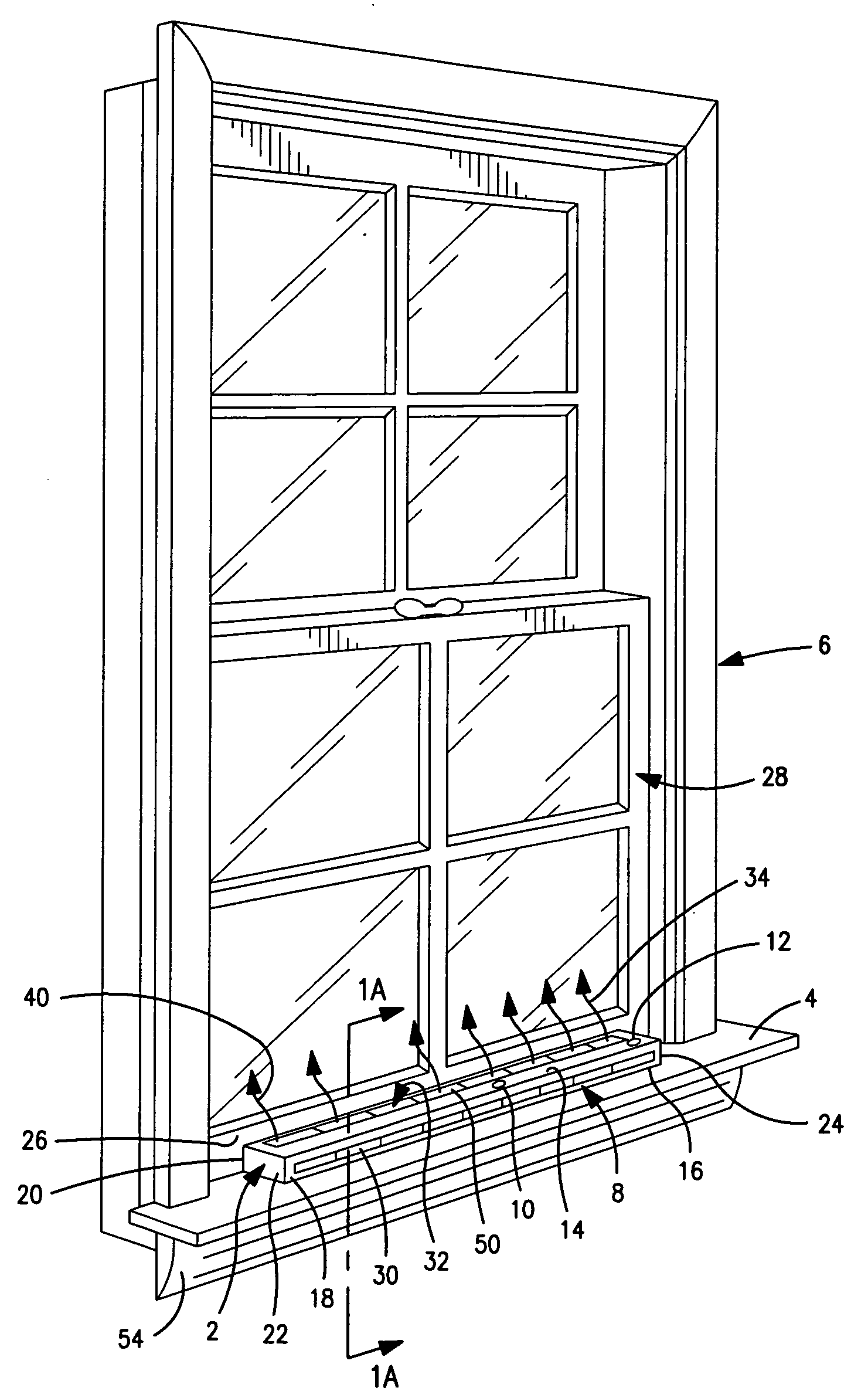

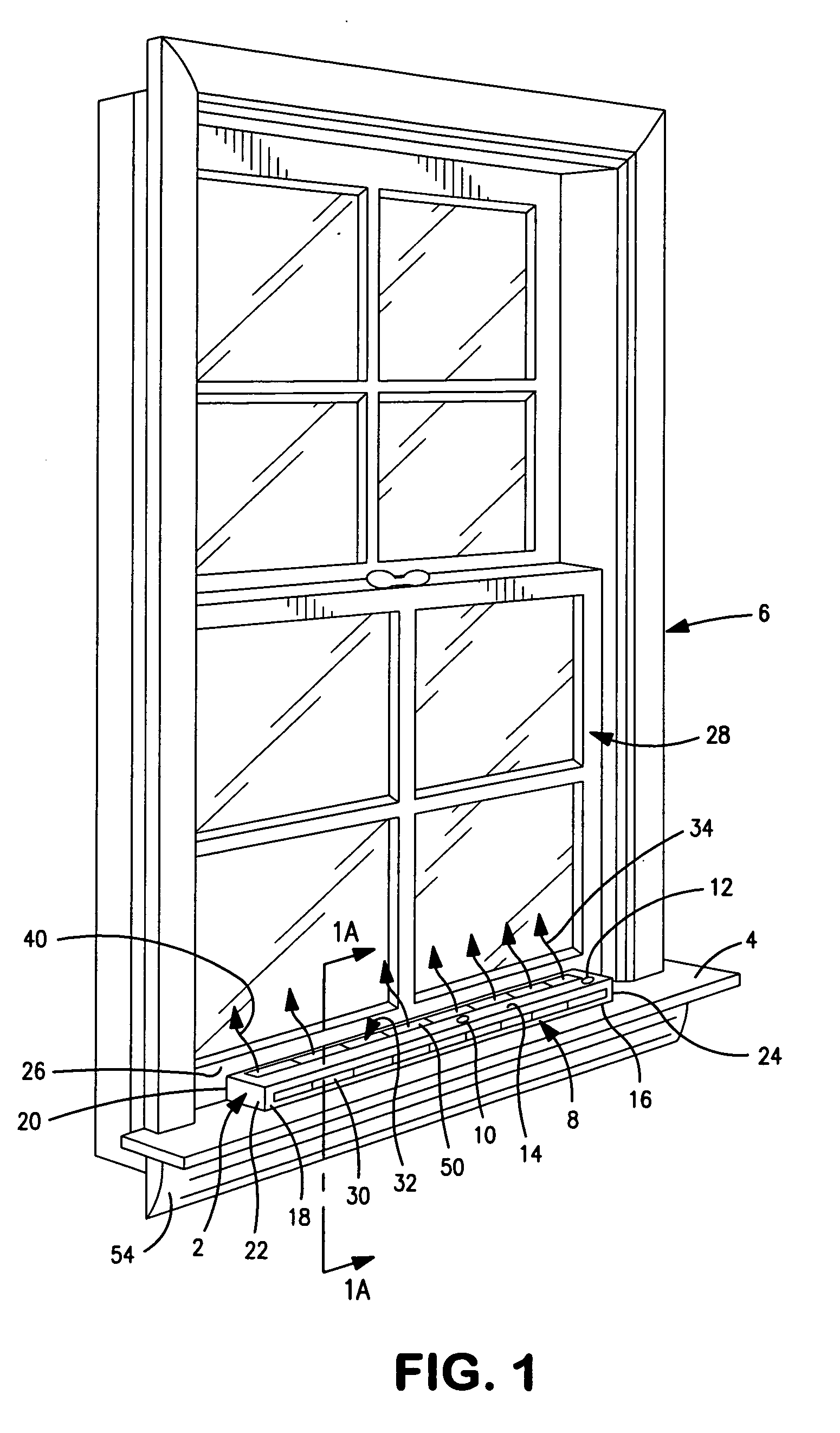

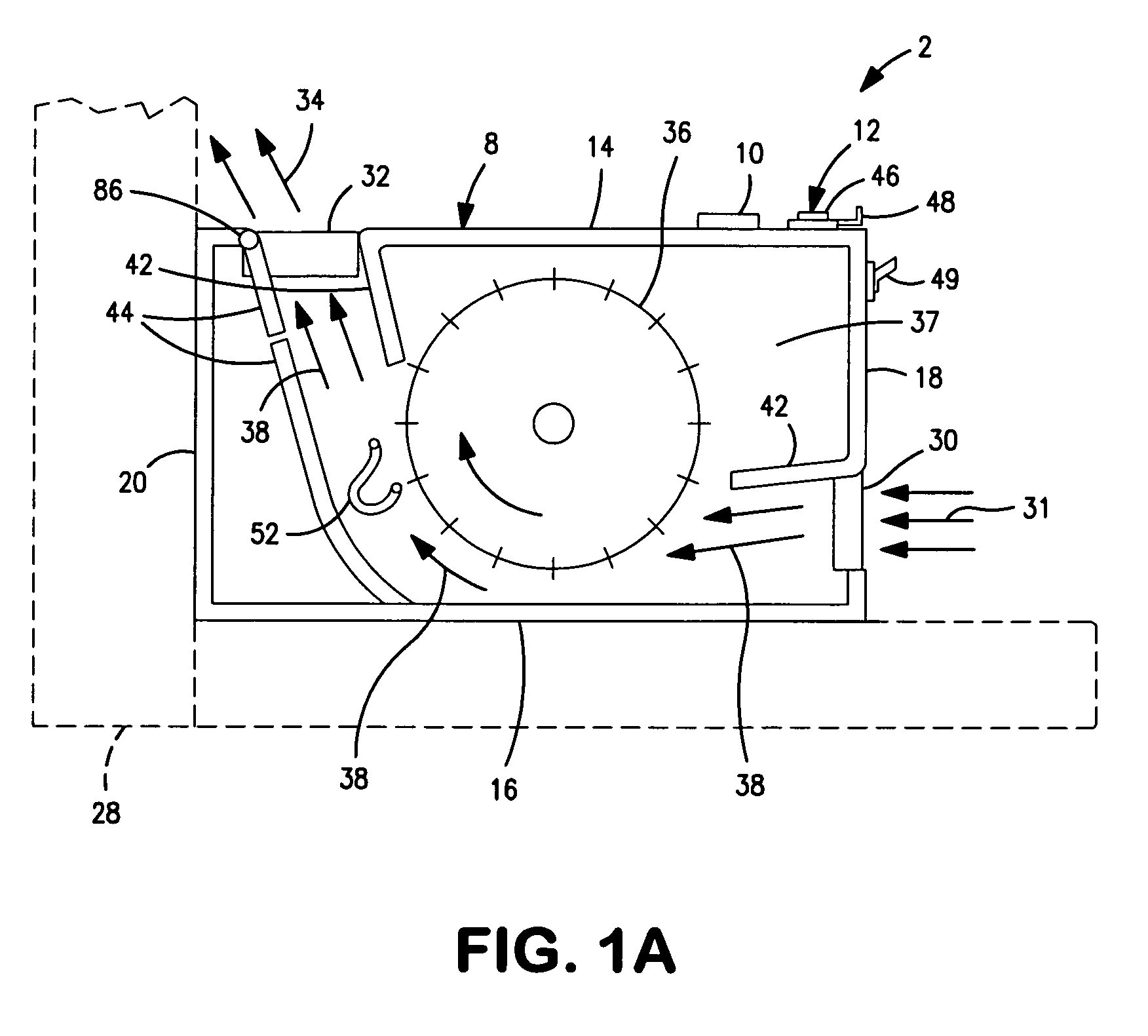

Window condensation control

InactiveUS20090270023A1Eliminate condensationAvoid insufficient temperatureLighting and heating apparatusVentilation arrangementGlass windowHeating system

An air handler draws air from inside a building, optionally from a building space heating system, and expresses that air such that the air travels along the inside surface of a window glazing unit which is susceptible to condensation. The air can be expressed at ambient temperature or with a modest amount of supplemental heat. As the air is expressed onto the window, a convection curtain of relatively warmer air passes adjacent the inside surface of the glass, warming the glass enough that condensation does not form on the glass. The system can be controlled using a sensor, optionally controlled by a computer or other controller, which controls the air flow according to needs sensed at the window. Such computer can be used to provide individualized control of condensation on each of multiple windows. A blower may be used to achieve increased control of rate and persistence of air flow.

Owner:BARTMANN JOSEPH J

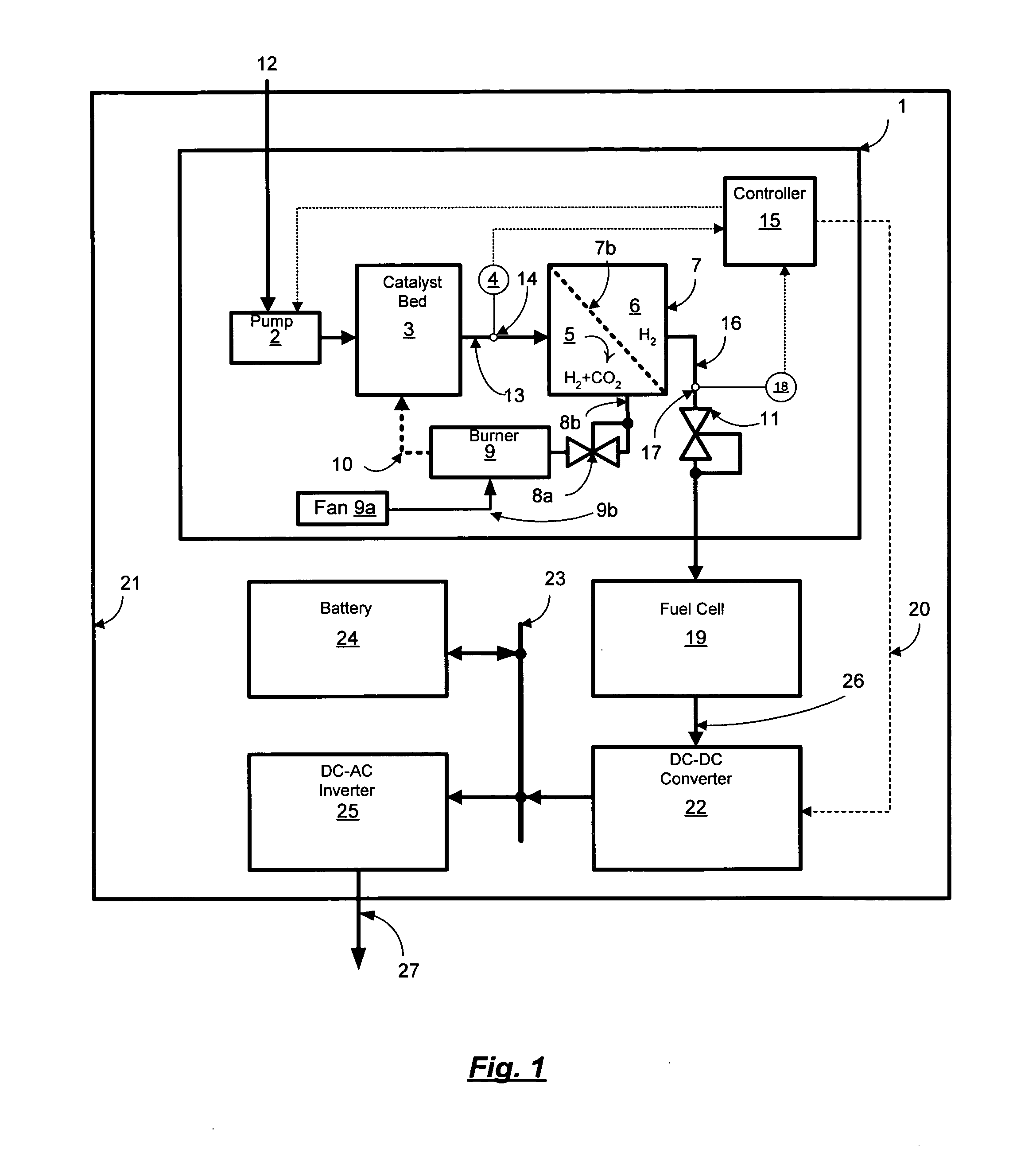

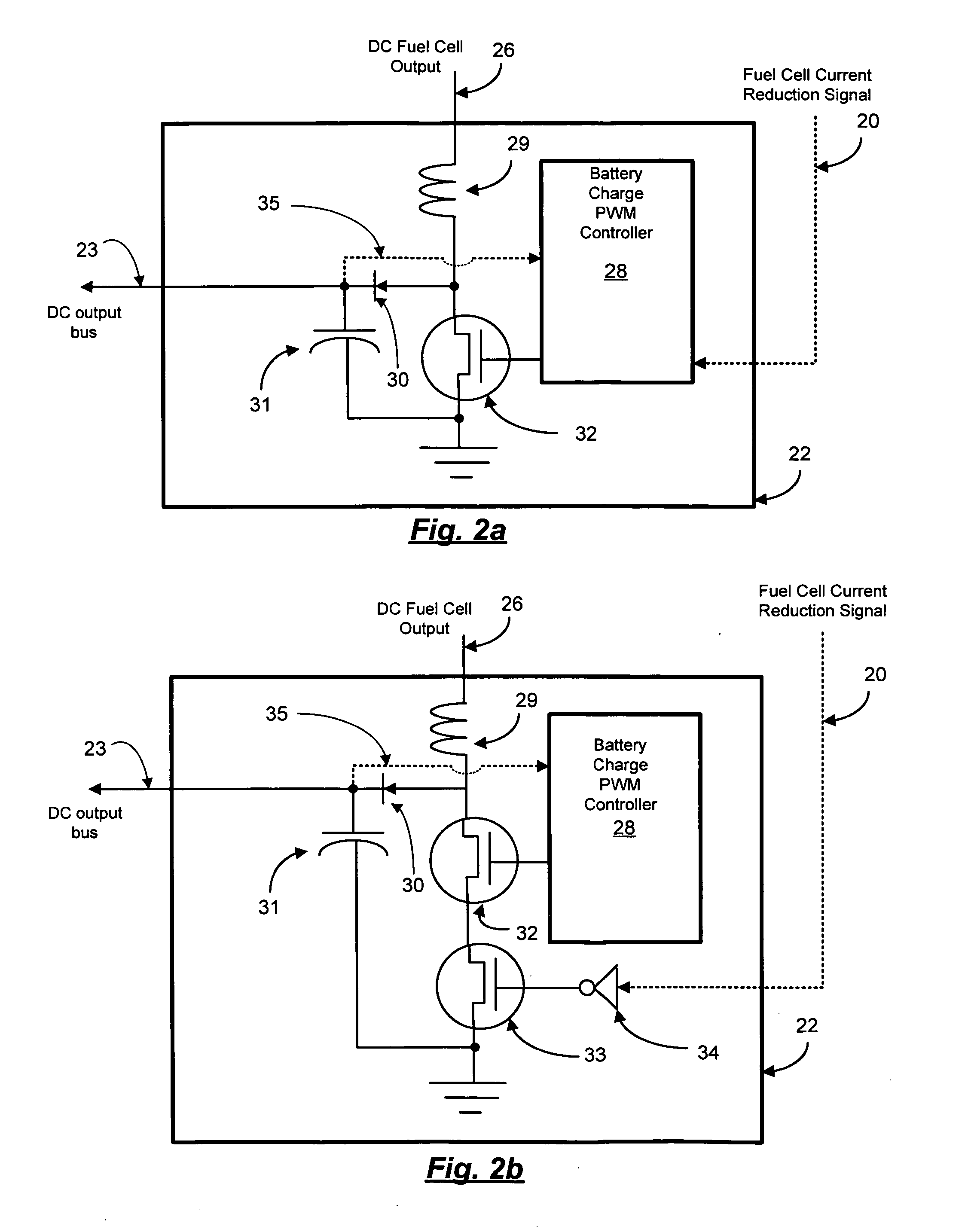

Reformer and fuel cell system control and method of operation

InactiveUS20070190380A1Reduce current outputEasy to integratePhysical/chemical process catalystsReactant parameters controlFuel cellsHydrogen pressure

A fuel cell system includes a reformer producing hydrogen from fuel, a regulator for regulating the output pressure of the produced hydrogen, a fuel cell utilizing the produced hydrogen, a pressure sensor for monitoring the pressure of the hydrogen upstream of the pressure regulator, a temperature sensor for monitoring at least one temperature within the reformer, a pump for introducing the fuel into the reformer, a first controller for controlling the output current of the fuel cell, and a second controller for controlling at least the fuel introduction rate into the reformer. The introduction rate of the fuel is responsive to output hydrogen pressure from the reformer in order to maintain at least one temperature within the reformer above a minimum level, as well as maintaining the pressure of the delivered purified hydrogen above a set pressure. Further, the output current of the fuel cell is reduced responsive to the pressure of the purified hydrogen in order to maintain a minimum hydrogen pressure to the fuel cell.

Owner:GENESIS FUEL TECH INC

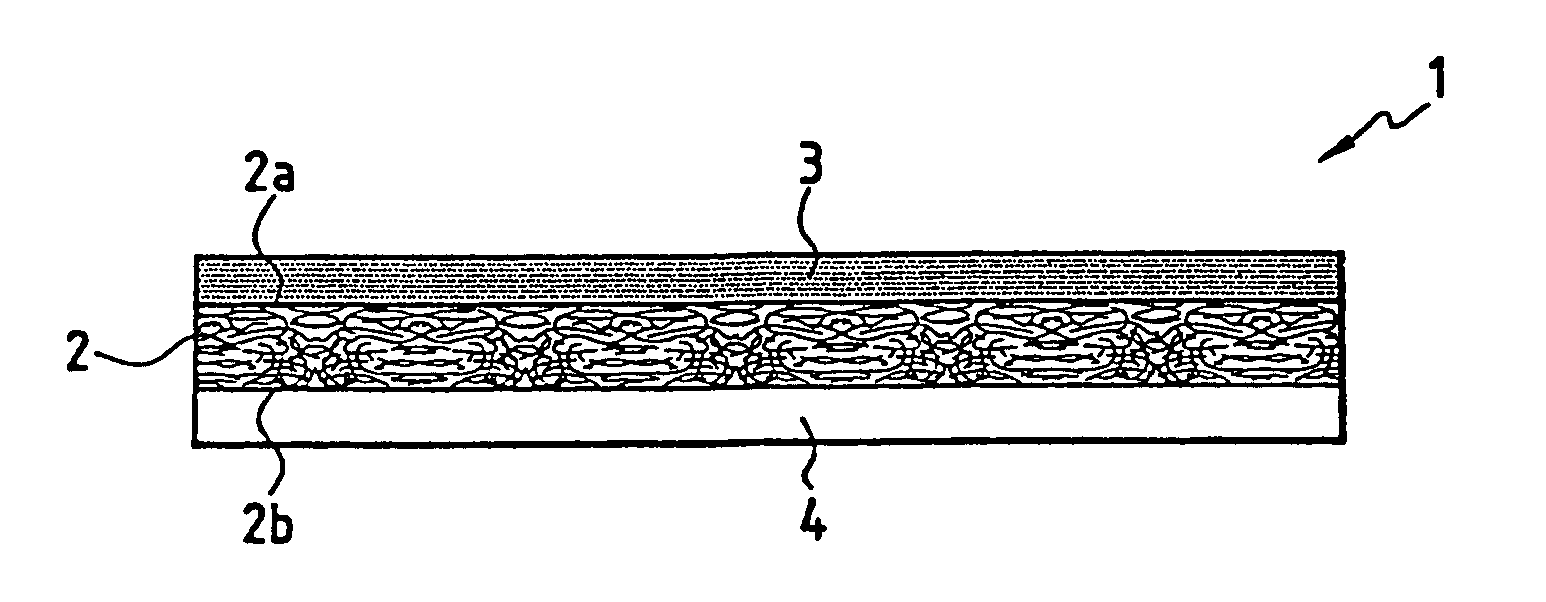

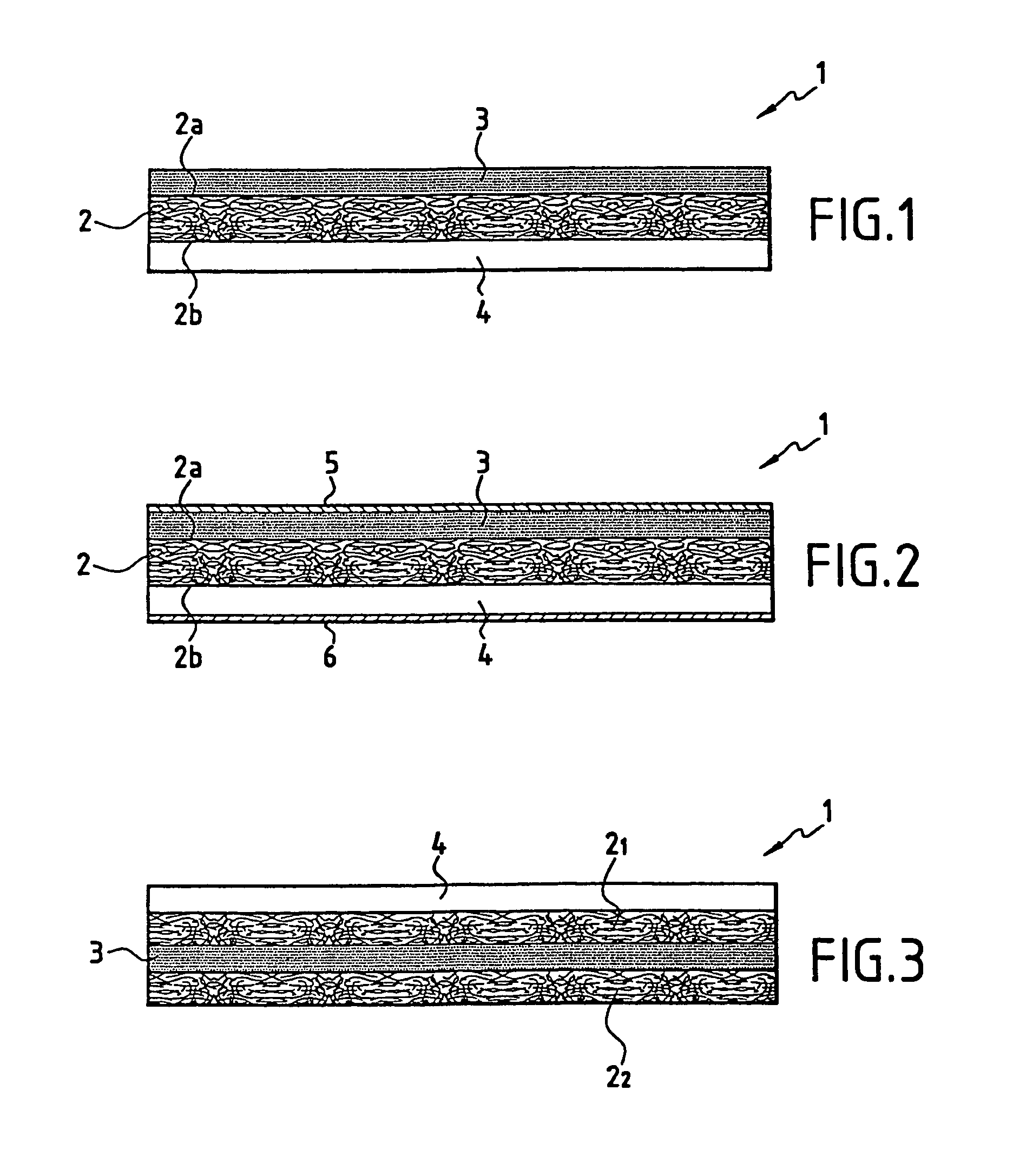

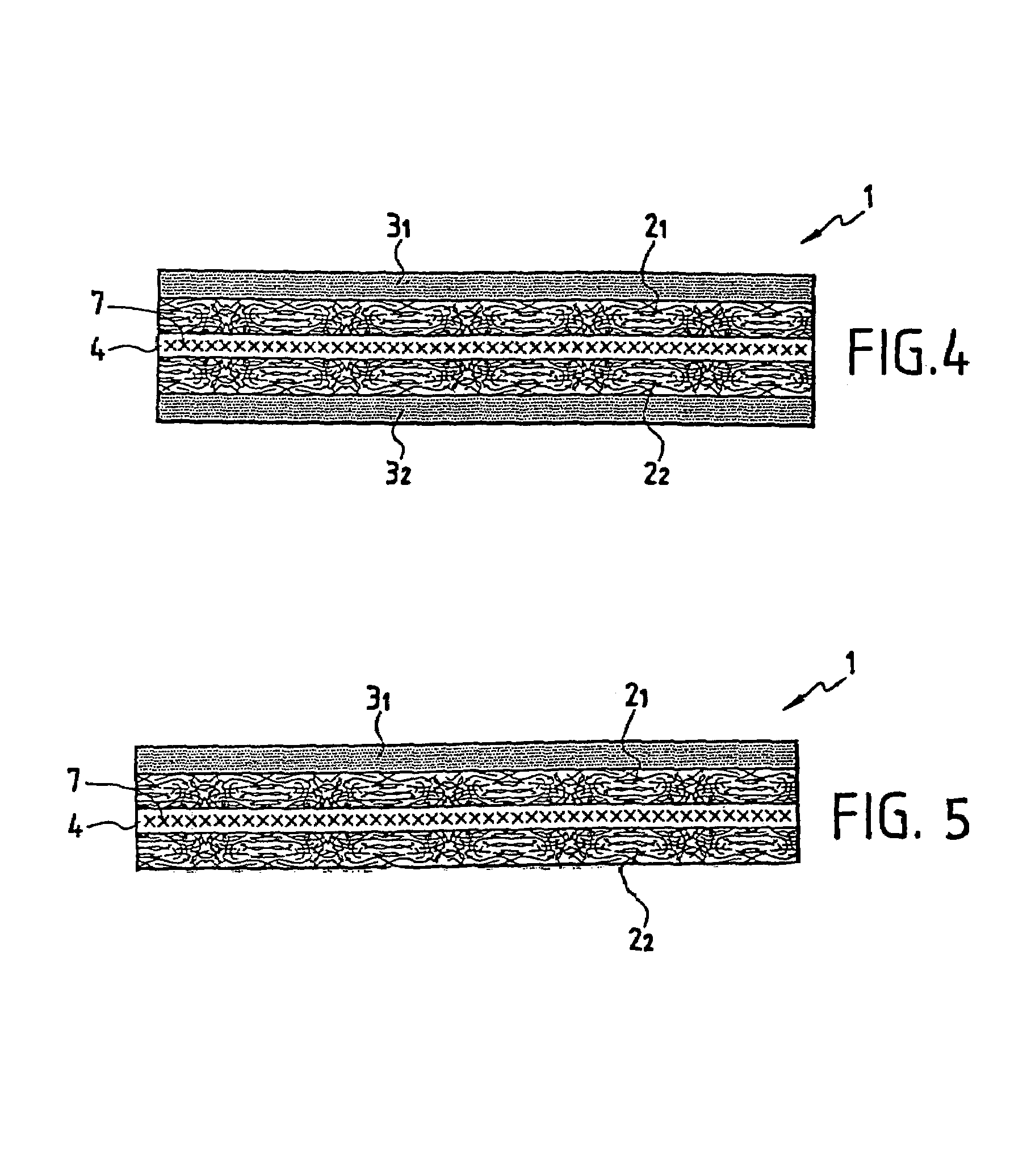

Composite products and molded articles obtained from said products

ActiveUS7267868B2Easy to implementEasy to handleBox making operationsPaper-makingPhysical BarrierFibre reinforcement

An uncured composite product having a middle fibrous reinforcement, a thermosetting-resin based layer and a hardening-agent based layer for the thermosetting resin. The thermosetting-resin based layer is placed on one side of the fibrous reinforcement and the hardening-agent based layer is placed on the other side so that the fibrous reinforcement forms a physical barrier between the thermosetting resin and the hardener. When heated, the thermosetting resin and / or hardener flows across the physical barrier to provide mixing and resultant curing.

Owner:HEXCEL COMPOSITES SAS

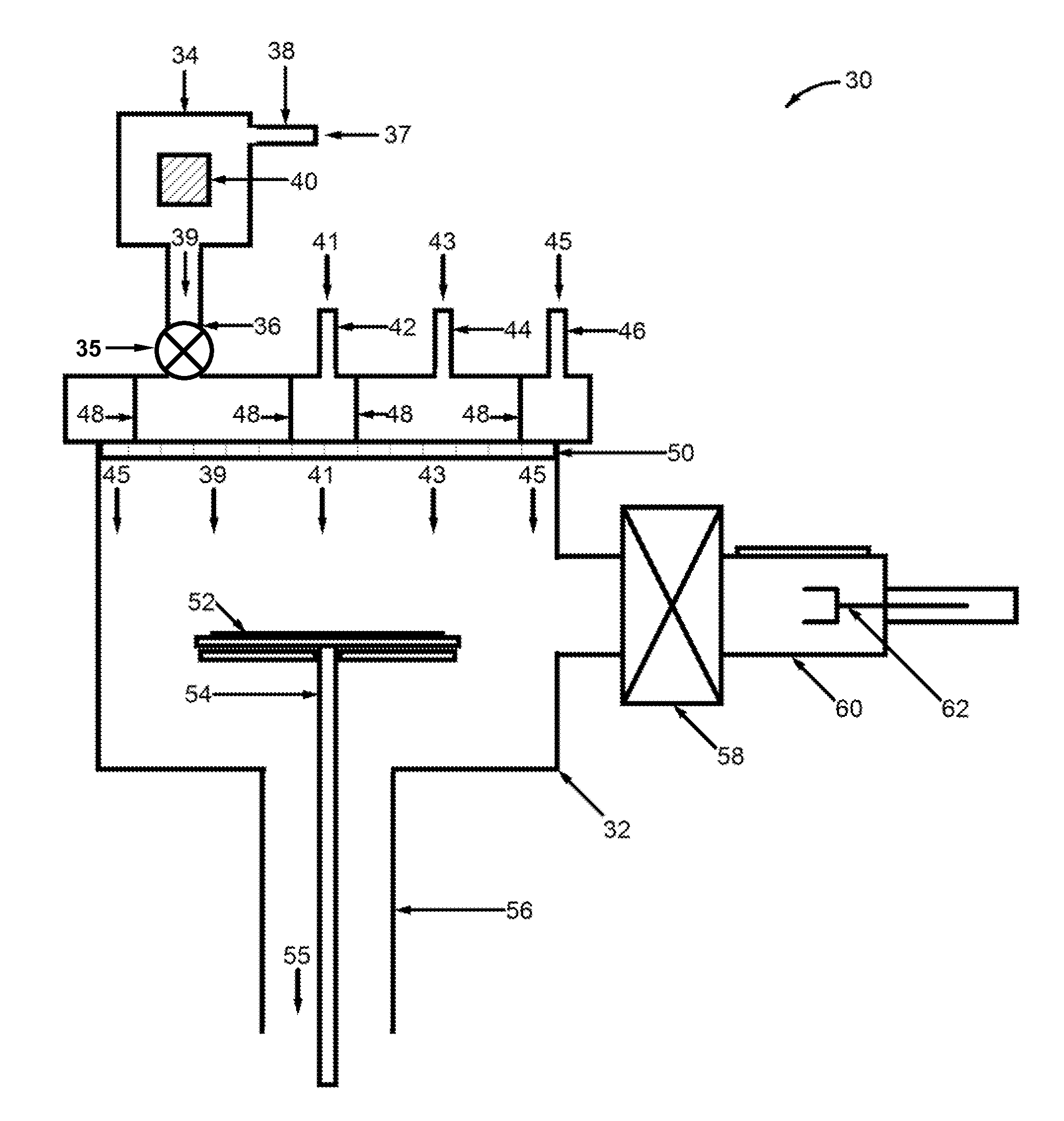

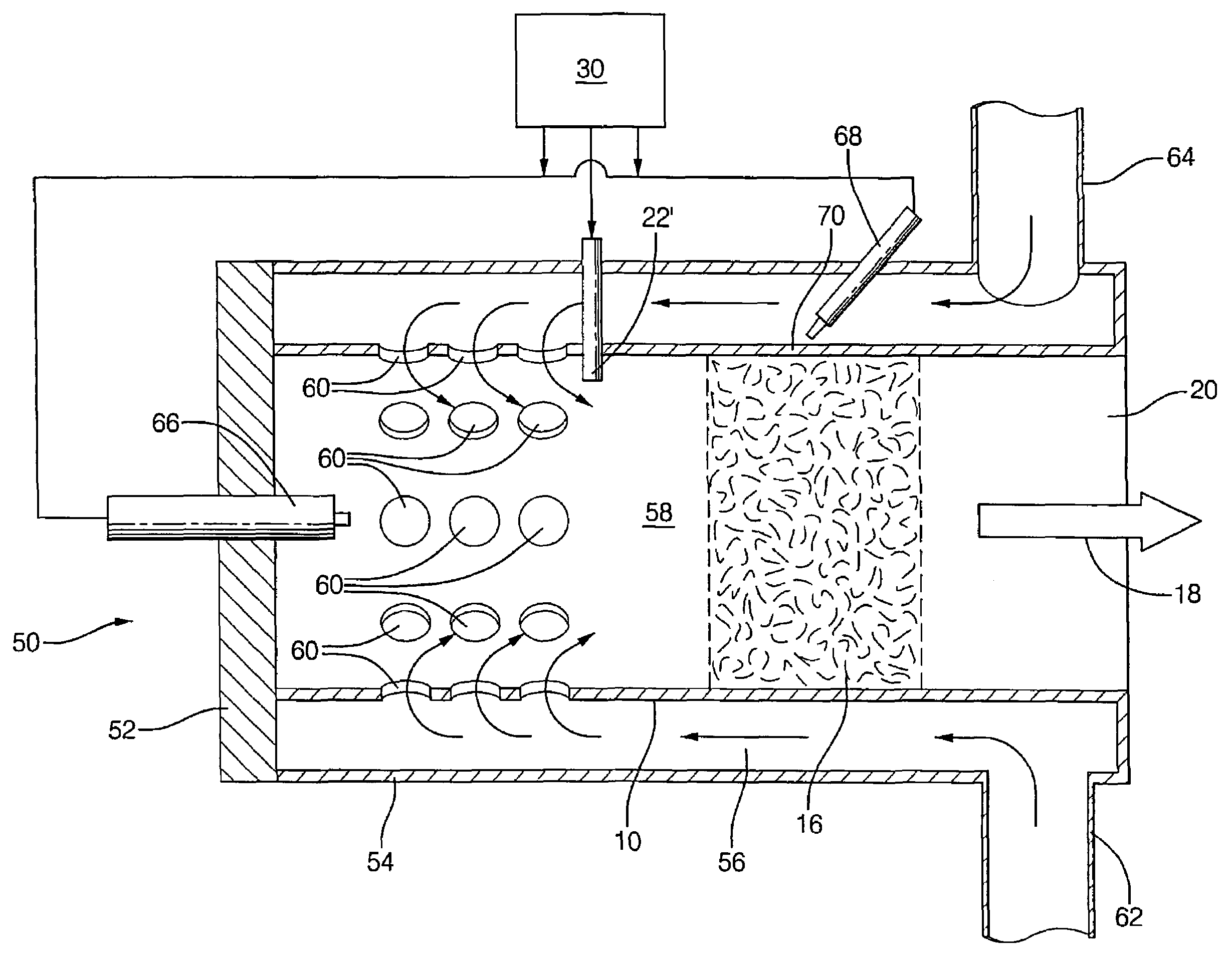

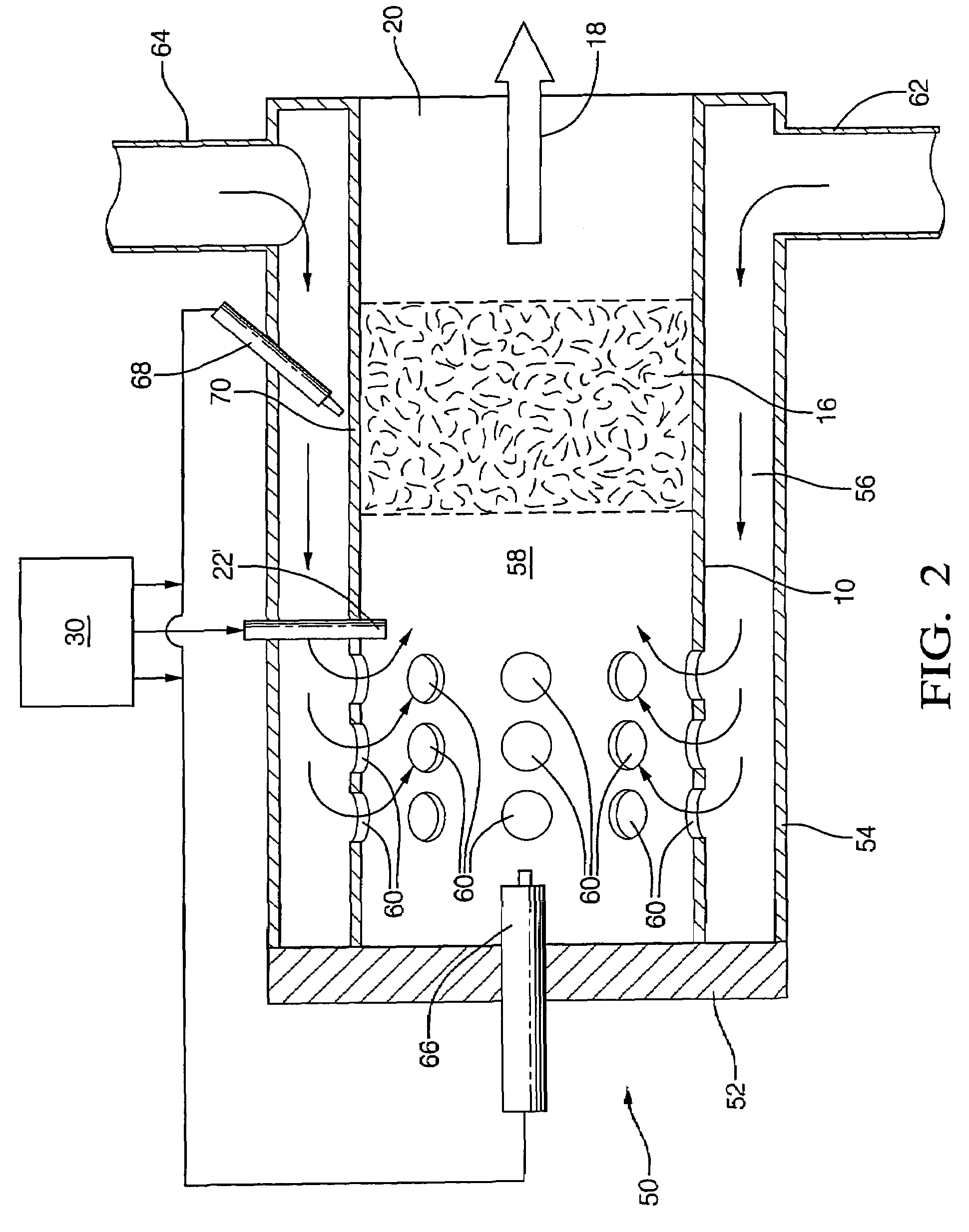

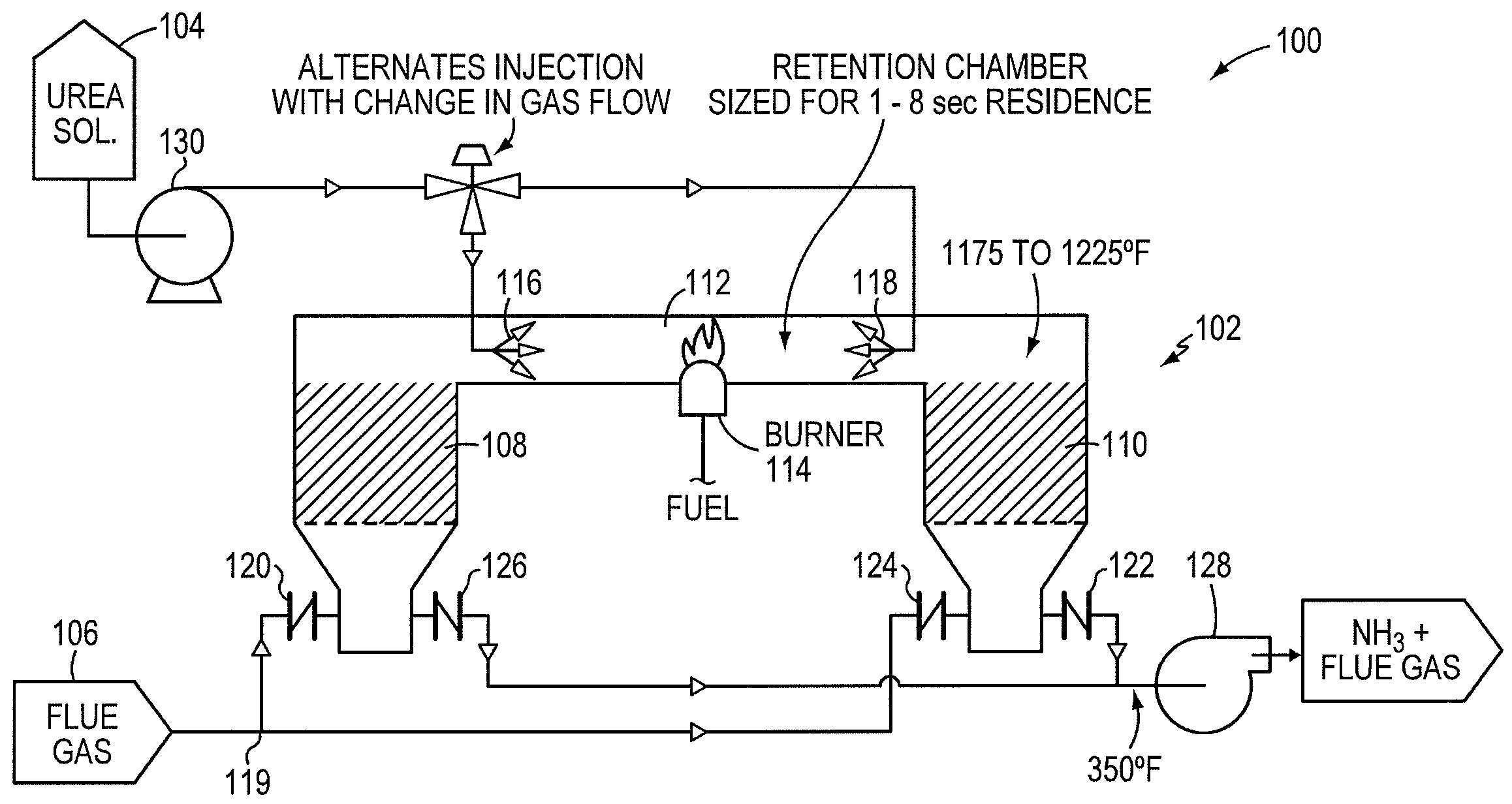

Thermal decomposition of urea in a side stream of combustion flue gas using a regenerative heat exchanger

InactiveUS7682586B2Avoid insufficient temperatureHeat produced by the burner is conservedNitrogen compoundsExhaust apparatusFlue gasThermal efficiency

This invention relates generally to the treatment of NOx in combustion flue gas. In certain embodiments, the invention relates to the use of a regenerative heat exchanger (RHE) to convert urea to ammonia in a side stream of flue gas. Ammonia and / or other urea decomposition products exit the heat exchanger, are mixed with the rest of the flue gas, and enter a selective catalytic reduction (SCR) unit for reduction of NOx in the flue gas. The use of an RHE significantly improves the thermal efficiency of the overall process. More particularly, in certain embodiments, the regenerative heat exchanger is a dual chamber RHE.

Owner:BABCOCK POWER ENVIRONMENTAL INC (US)

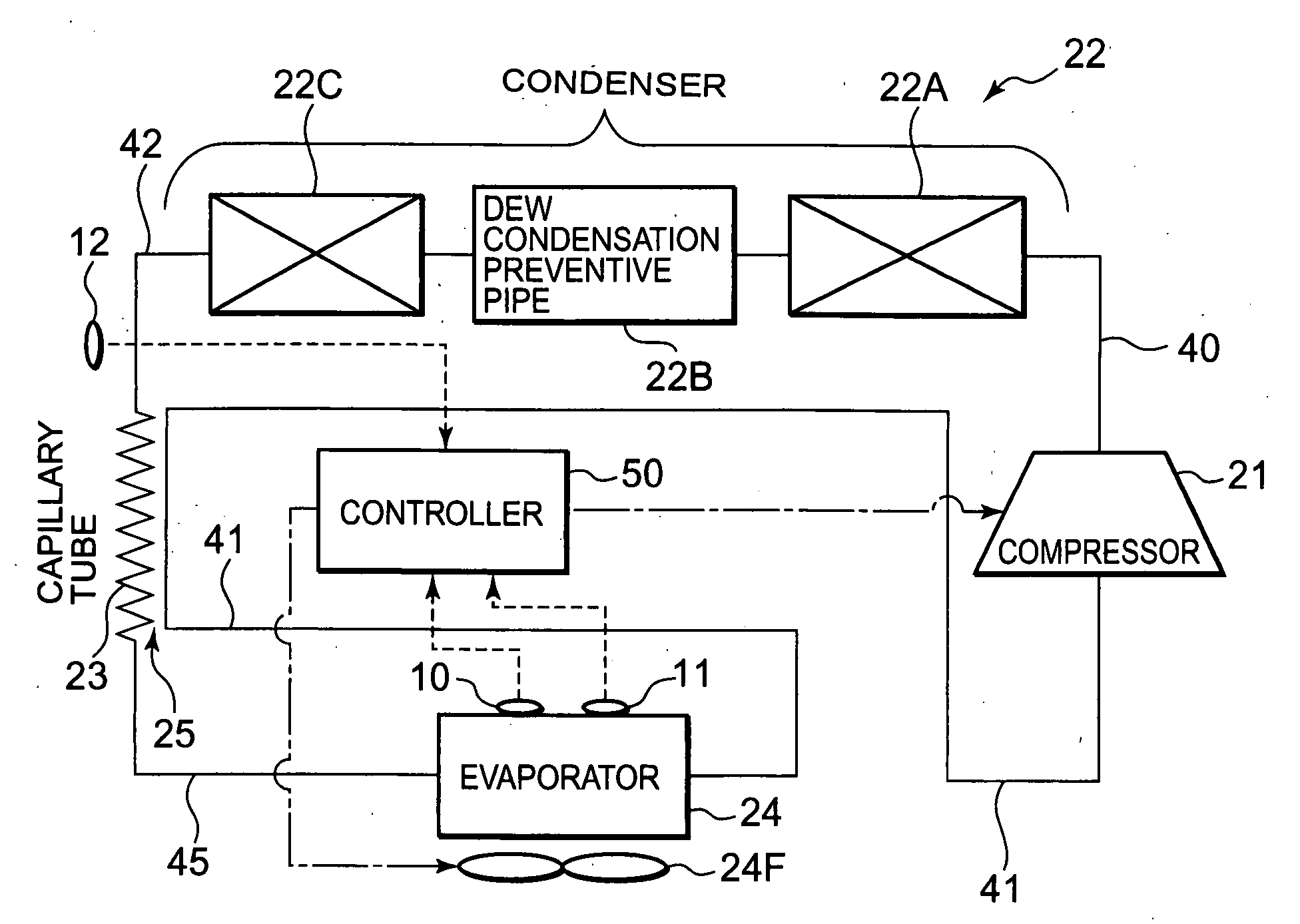

Refrigerator

InactiveUS20070214824A1Improve abilitiesAvoid condensationCompression machines with several condensersCorrosion preventionDewEngineering

There is disclosed a refrigerator in which a refrigerant circuit on a high-pressure side is operated in a supercritical state, and an object of the refrigerator is to improve a freezing capacity while securely preventing dew condensation at an opening edge by a condenser. In the refrigerator including the refrigerant circuit constituted of a compressor, the condenser, a throttle means and an evaporator; and a dew condensation preventive pipe constituting a part of the condenser and disposed along the opening edge of an insulation box member, the refrigerant circuit on the high-pressure side is operated in the supercritical state, and the dew condensation preventive pipe is positioned on an upstream side of a refrigerant downstream region of the condenser.

Owner:SANYO ELECTRIC CO LTD

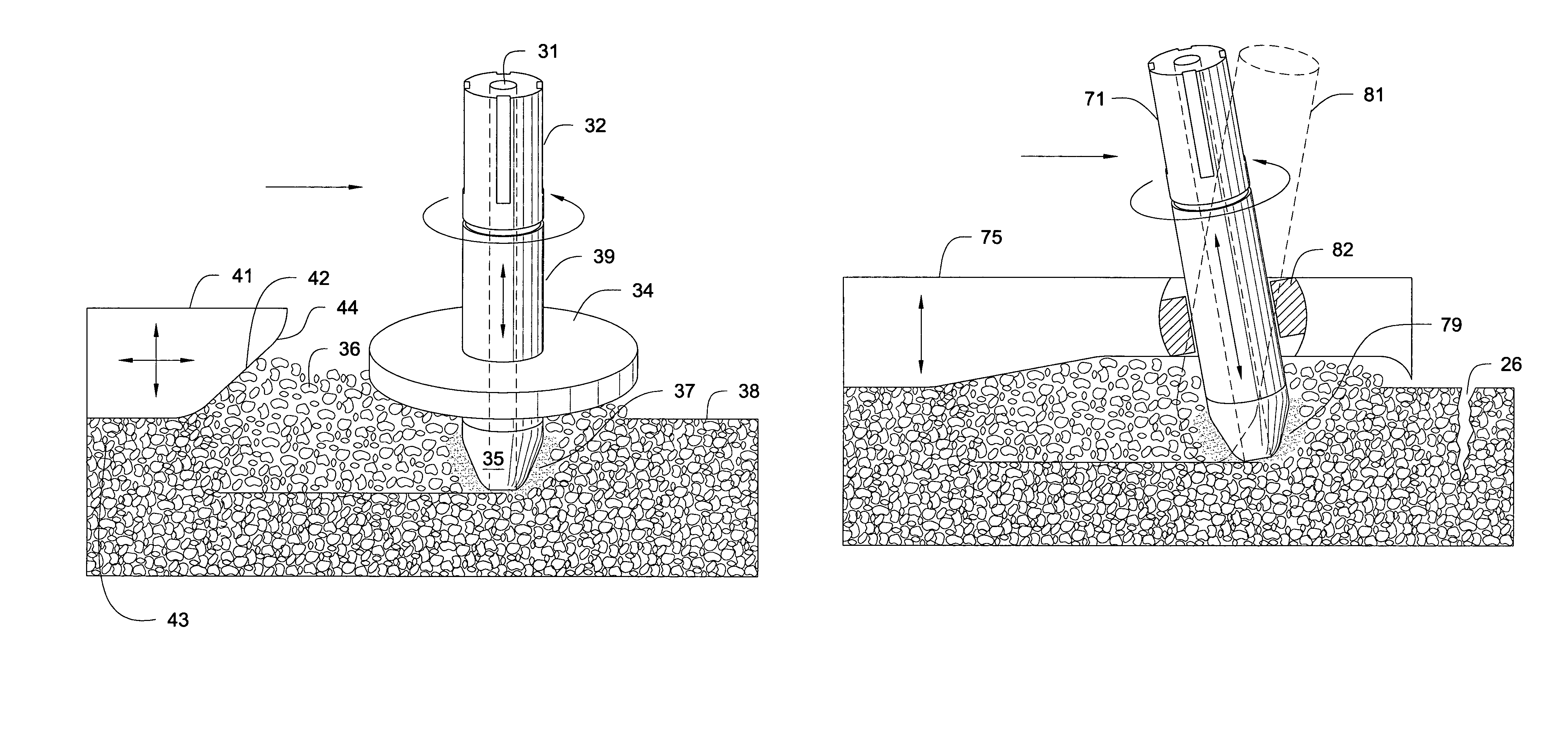

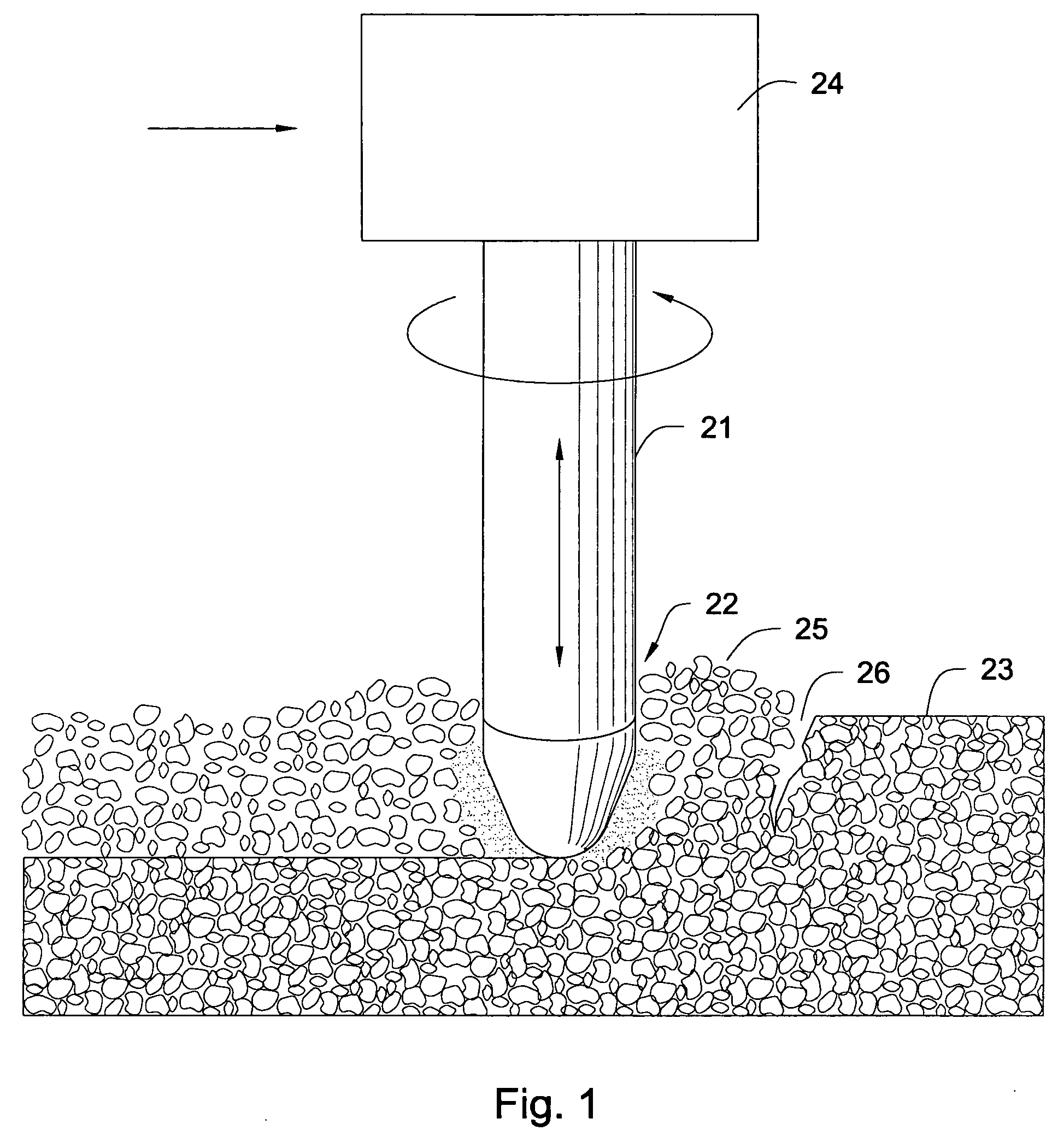

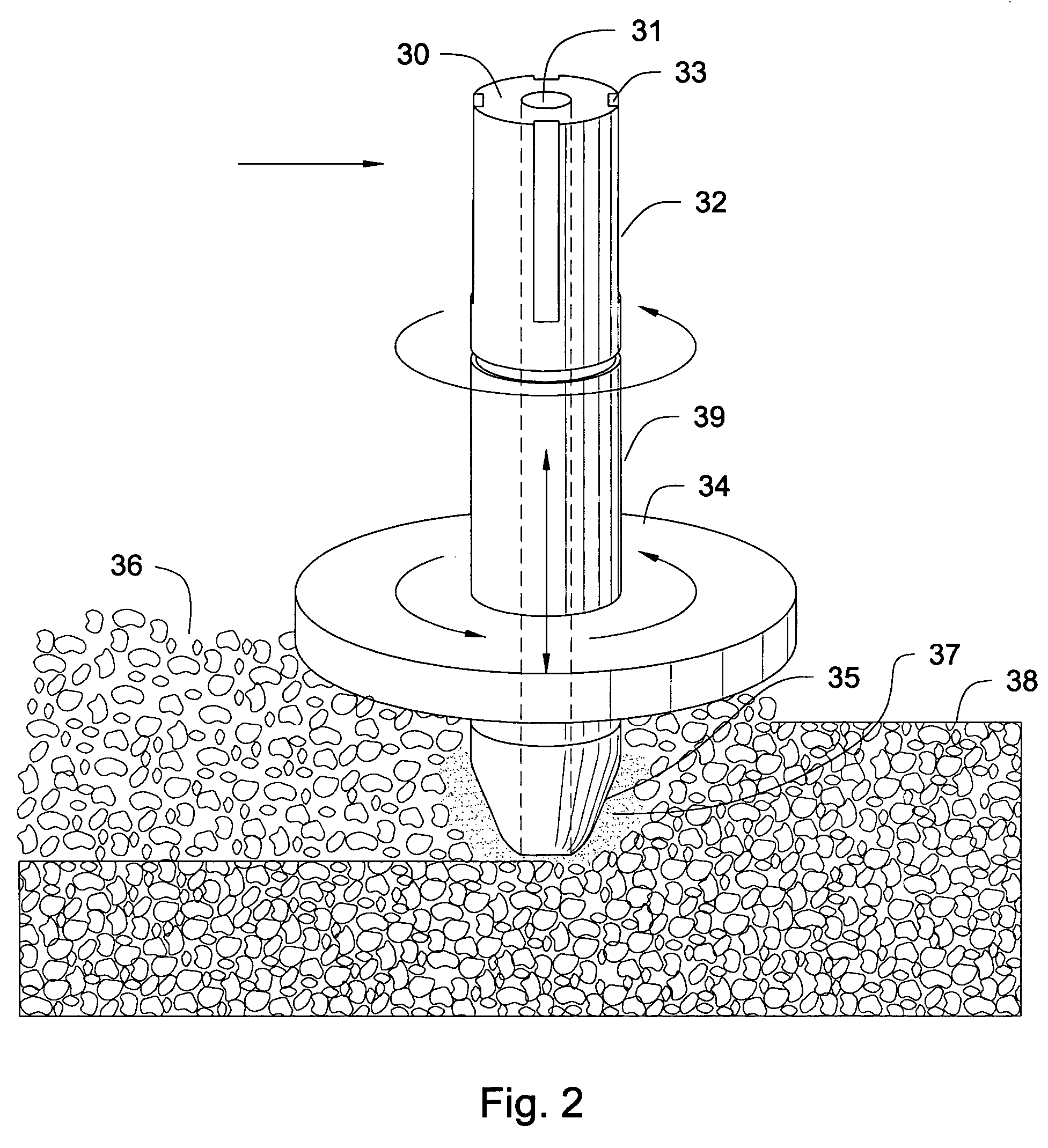

Apparatus and method for working asphalt pavement

InactiveUS7179018B2Reduce frictionEasy to wearDisloding machinesThermal drillingClosed loopPolycrystalline diamond

A method and apparatus for working asphalt pavement, comprising one or both of a mechanical, hydraulic, electric, or pneumatic means for providing high-speed rotation; a rotary tool comprising a first end comprising a working surface and a second end adapted for connection to the means for providing high-speed rotation; and a screed, cooperatively arranged with the rotary tool, and comprising a working surface adjacent the working surface of the rotary tool, wherein the rotary tool is spun at high speed and applied to the asphalt pavement, frictionally heating the asphalt pavement to a temperature sufficient to work the pavement locally adjacent rotary tool and the screed. The screed and rotary tool comprising abrasion resistant materials selected from the group consisting of high-strength steel, hardened alloys, cemented metal carbide, polycrystalline diamond, and cubic boron nitride. The rotary tool and the screed apparatus may comprise a closed loop control system.

Owner:NOVATEK IP

Electrostatic fluid accelerator for and method of controlling a fluid flow

InactiveUS20060226787A1Increase diameterPrevent sagSamples introduction/extractionElectrostatic separationElectrode arrayEngineering

An electrostatic fluid accelerator includes an electrode array including an array of corona discharge electrodes and an array of accelerating electrodes. A detector is configured to sense a constituent component of the fluid as present in an output from the electrode array. A control circuit supplies power to the electrode array, the control circuit being responsive to an output from the detector for operating the electrode array responsive a level of the constituent component.

Owner:TESSERA INC

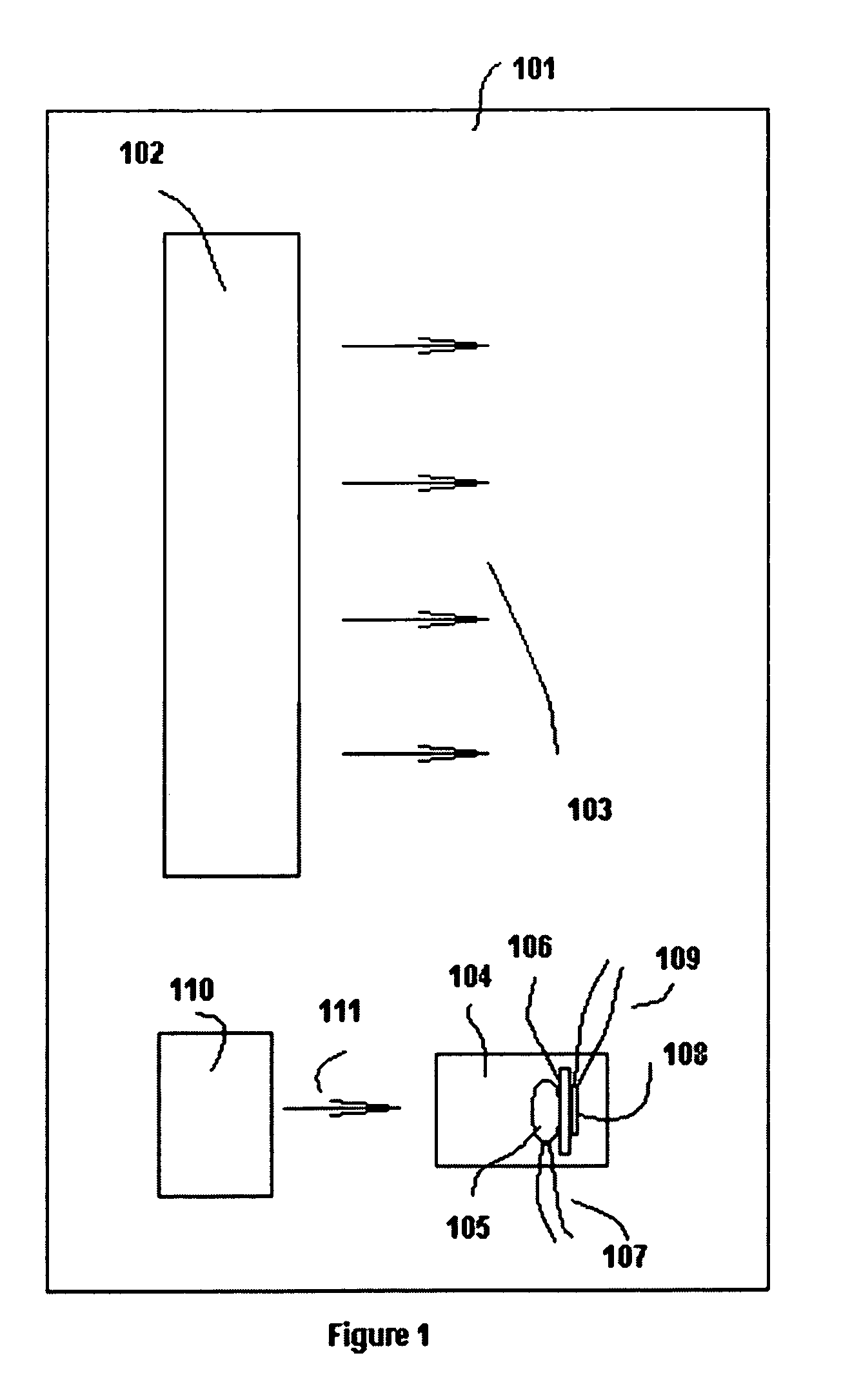

Smoke-free roaster

InactiveUS20120024166A1Good for healthSmoke-free roastingRoasters/grillsFrying pansFiberCarbon fibers

A smoke-free roaster includes a roaster body having a bottom to which a grease collection tray is mounted, a roasting grating mounted on a top of the roaster body, and a heating structure mounted inside the roaster body. The roasting grating includes grating bars, between which solid sloping plates are formed and gently inclined downward from front and rear side edges in a direction along the grating bars toward a central portion of the roaster body and the heating structure comprises reflector assemblies, which includes heating modules respectively mounted below the sloping plates and respectively receive therein carbon fiber heating tubes that irradiate and thus heat the roasting grating and comprise electrical terminals forming power supply connection modules. The sloping plates increase the surface area on the two opposite sides of the roaster body for heat transfer and heat accumulation thereby raising roasting temperature on the two side portions.

Owner:GRAND HALL ENTERPRISE COMPANY

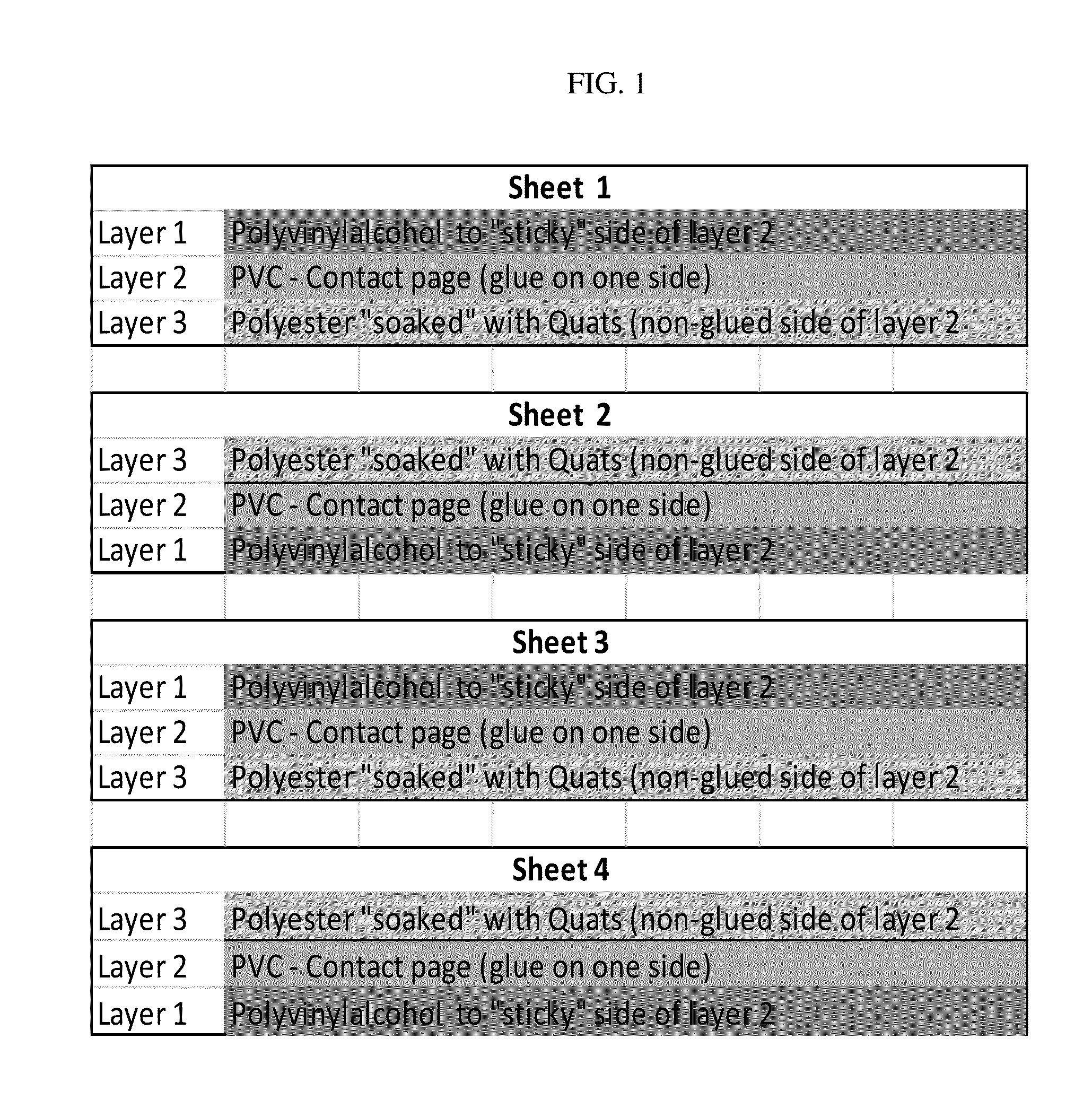

Wrinkle reducing and deodorizing dryer sheet and methods of making and using

ActiveUS20150126430A1Reduce wrinklesAvoid insufficient temperatureCationic surface-active compoundsOrganic detergent compounding agentsStatic clingWrinkle skin

Provided are wrinkle reducing and deodorizing dryer sheets and methods of making and using the dryer sheets. In one form of the dryer sheet, the wrinkle reducing and deodorizing dryer sheet includes an absorbent wet substrate in sheet form with a polyvinyl alcohol sheet adhered to one surface of the substrate. In another form the PVA sheet is added separately from that of the absorbent wet substrate sheet. The PVA sheet is preferably in the form of an uncoated non-woven of a thickness of 8 mil or less. The wet impregnated sheet contains a solution of quaternary ammonium salts of different water solubility. The method for using, the wrinkle reducing and deodorizing dryer sheet is added to a rotary dryer with a load of wet or dried garments to reduce wrinkling in the garments during the drying process, reduce static cling and refresh the treated clothing.

Owner:JR CHEM LLC

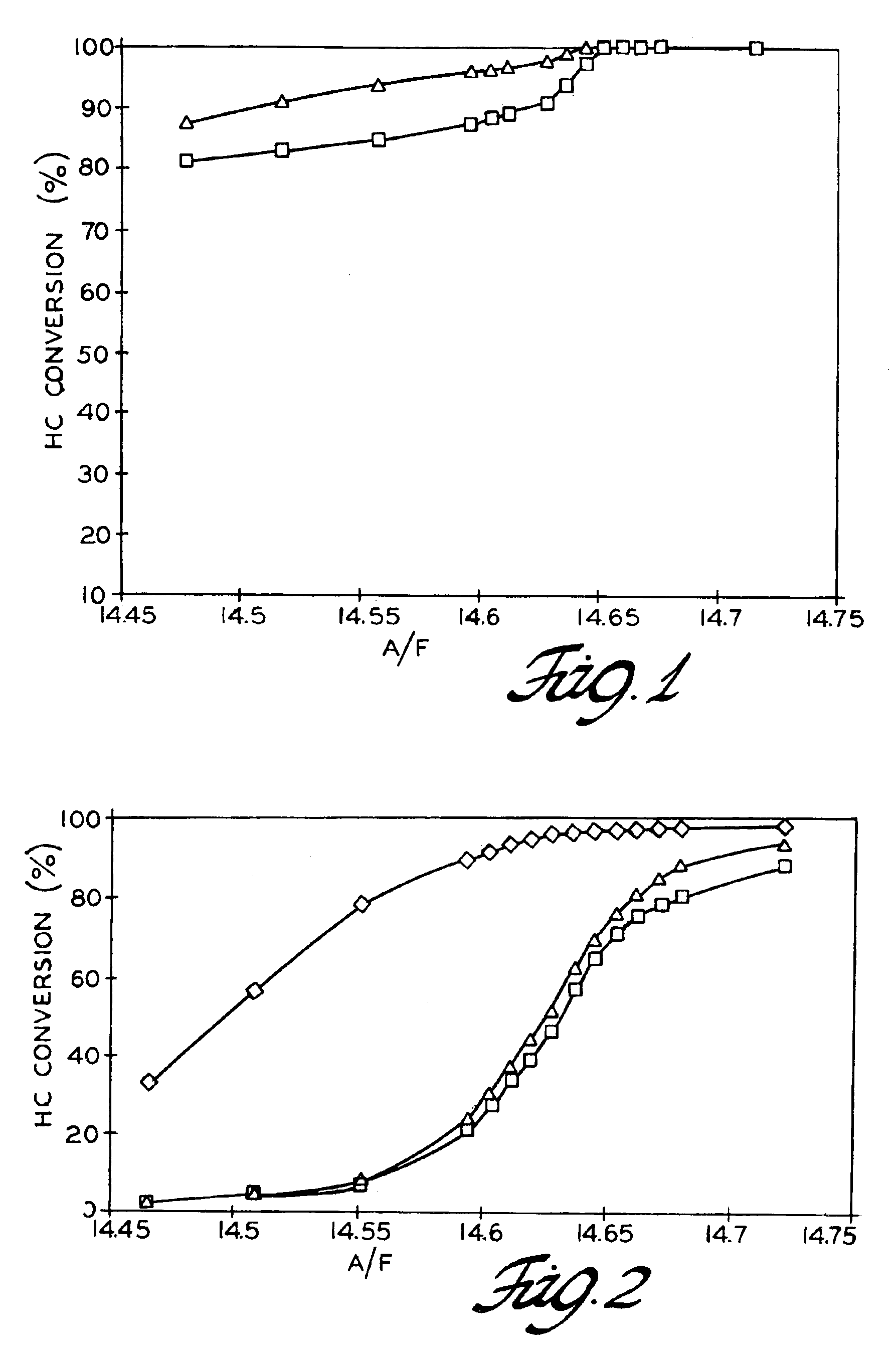

Noble metal catalyst

ActiveUS6956007B2Avoid insufficient temperatureEvenly dispersedInternal combustion piston enginesMolecular sieve catalystsEffective surface areaNanometre

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for Producing a Subminiature "Micro-Chip" Oxygen Sensor for Control of Internal Combustion Engines or Other Combustion Processes, Oxygen Sensor and an Exhaust Safety Switch

ActiveUS20110186446A1Reduce resistanceTemperature effect is minimizedElectrical controlWeather/light/corrosion resistanceContact padMultiple sensor

A method of making a sub-miniature “micro-chip” oxygen sensor is provided where multiple sensor elements are applied to a dielectric ceramic substrate consisting of a heater pattern, followed by a dielectric layer. Intermeshing electrodes are then applied either over the heater pattern / dielectric layers or on the opposite side of the substrate. The space between the intermeshing electrodes is filled with an n-type or p-type high temperature semiconductor which is covered by a porous protection layer. After singulation (dicing), the sensor element is assembled having conductors applied to the contact pads on the element and is packaged in an assembly for introduction to the exhaust stream of a combustion process. A large step-wise change in the resistance of the element takes place as a result of changes in oxygen content in the exhaust whereby one can determine if the exhaust is rich or lean for use in an engine management or combustion management systems for emissions control. A circuit is proposed to convert the change in resistance to a voltage signal to be used for control algorithms in engine or combustion control. Utilizing multiple units of the device for individual cylinder control of multi-cylinder engines is described. A method of using one embodiment of the invention for use as a safety switch is also revealed.

Owner:KERDEA TECH

Method of controlling a fluid flow

InactiveUS7410532B2Prevents the corona wires from saggingIncrease the diameterSamples introduction/extractionElectrostatic separationEngineeringElectrode array

An electrostatic fluid accelerator includes an electrode array including an array of corona discharge electrodes and an array of accelerating electrodes. A detector is configured to sense a constituent component of the fluid as present in an output from the electrode array. A control circuit supplies power to the electrode array, the control circuit being responsive to an output from the detector for operating the electrode array responsive a level of the constituent component.

Owner:TESSERA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com