Large-size silicon nitride ceramic ball and preparation method thereof

A silicon nitride ceramic ball and silicon nitride powder technology, applied in the field of ceramic materials, can solve the problems affecting the uniformity of the density and mechanical properties of ceramic balls, the difference in density and microstructure of ceramic ball cores, and large-scale ceramics. Problems such as large volume of the ball, to achieve the effect of increased density, high sphericity, and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of silicon nitride ceramic ball, comprises the following steps:

[0031] The silicon nitride powder, the sintering aid and the reinforcing phase are ball-milled and mixed in absolute ethanol, and then granulated to obtain granulated powder;

[0032] Mix ammonium acrylate monomer, crosslinking agent, dispersant and water to obtain a premix;

[0033] Dispersing the granulated powder in the premixed liquid, adding a catalyst and an initiator to the resulting slurry to obtain a gelling slurry;

[0034] Carrying out vacuum coagulation molding to the coagulation slurry, and obtaining a ceramic ball green body after microwave drying;

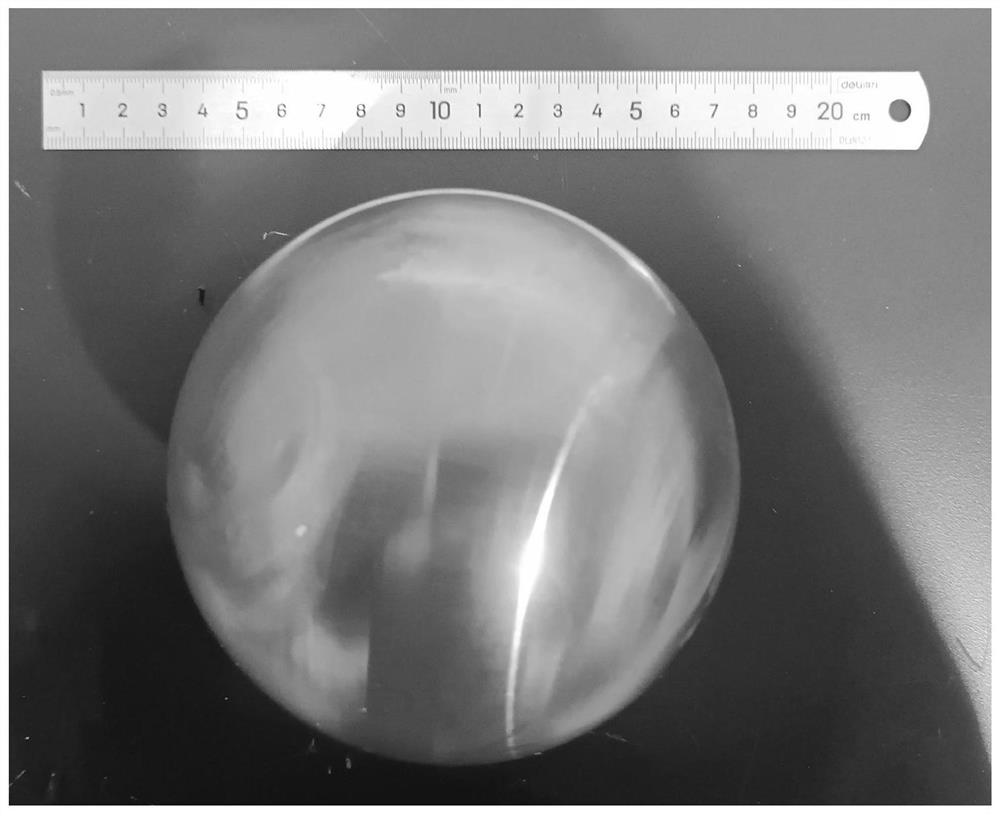

[0035] Carrying out debinding, cold isostatic pressing, air pressure sintering and processing the ceramic ball green body in sequence to obtain silicon nitride ceramic balls; the diameter of the silicon nitride ceramic balls is 20-200mm;

[0036] The air pressure sintering method is two-step ...

Embodiment 1

[0062] raw material:

[0063] Silicon nitride powder (α-Si 3 N 4 The content is 93%, the average particle size D 50 0.7μm): 44kg

[0064] Alumina (purity 99.9%, average particle size D 50 1μm): 2kg,

[0065] Yttrium oxide (purity 99.9%, average particle size D 50 1μm): 3kg,

[0066] Titanium carbide (purity 99%, average particle size D 50 0.5μm): 1kg.

[0067] 1. Powder preparation

[0068] Mix the above raw materials in proportion, use absolute ethanol as a solvent to obtain a slurry with a solid phase content of 40%, the grinding medium is silicon nitride balls, and perform wet ball milling. The ball milling device is a horizontal ball mill, and the mixing time is 24h. The uniformly mixed slurry is spray-dried and granulated by using a nitrogen-protected centrifugal spray granulator to obtain granulated powder with a particle size of 20-200 μm.

[0069] 2. Injection forming

[0070] 1) Prepare the premix:

Embodiment 2

[0085] raw material:

[0086] Silicon nitride powder (α-Si 3 N 4 The content is 93%, the average particle size D 50 0.7μm): 45kg

[0087] Alumina (purity 99.9%, average particle size D 50 1μm): 1.5kg,

[0088] Yttrium oxide (purity 99.9%, average particle size D 50 1μm): 2kg,

[0089] Titanium nitride (99% purity, average particle size D 50 0.5μm): 1.5kg.

[0090] 1. Powder preparation

[0091] Mix the above raw materials in proportion, use absolute ethanol as a solvent to obtain a slurry with a solid phase content of 40%, the grinding medium is silicon nitride balls, and perform wet ball milling. The ball milling device is a horizontal ball mill, and the mixing time is 24h. The uniformly mixed slurry is spray-dried and granulated by using a nitrogen-protected centrifugal spray granulator to obtain granulated powder with a particle size of 20-200 μm.

[0092] 2. Injection forming

[0093] 1) Prepare the premix:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com