Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Increase green density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

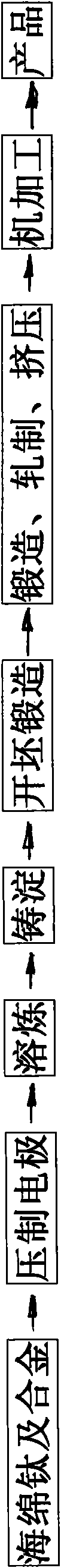

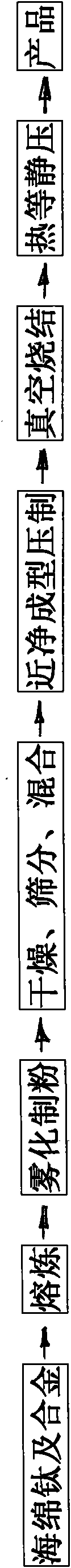

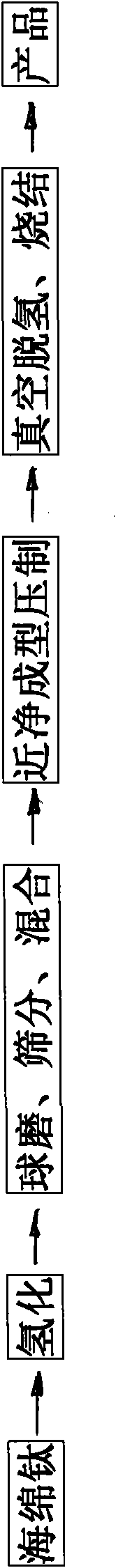

Process for preparing titanium and titanium alloy from titanium hydride powder

The invention discloses a process for preparing a metallurgical powder product from titanium hydride powder preparedmade by hydrogenating sponge titanium instead of titanium powder. The process comprises the following steps of: firstly, hydrogenating sponge titanium, crushing and, rating and mixing brittle titanium hydride, and mixing the titanium hydride with an alloy element; and then, carryingout near-net shape pressing to finish dehydrogenation in a vacuum sintering process. In the process of directly forming the titanium hydride powder, because of the secondary crushing of the brittle titanium hydride powder, the pressed green density is higher than that obtainedan occasion when titanium or titanium alloy powder is used, and the titanium is prevented from being oxidized. In the sintering process, the density of a sintering blank can rapidly rise (to be higher than 99 percent) because of the decomposition of the titanium hydride. The method has the characteristics short process flows, high yield and product density, low cost and oxygen content and good performance.

Owner:KUNMING METALLURGY INST

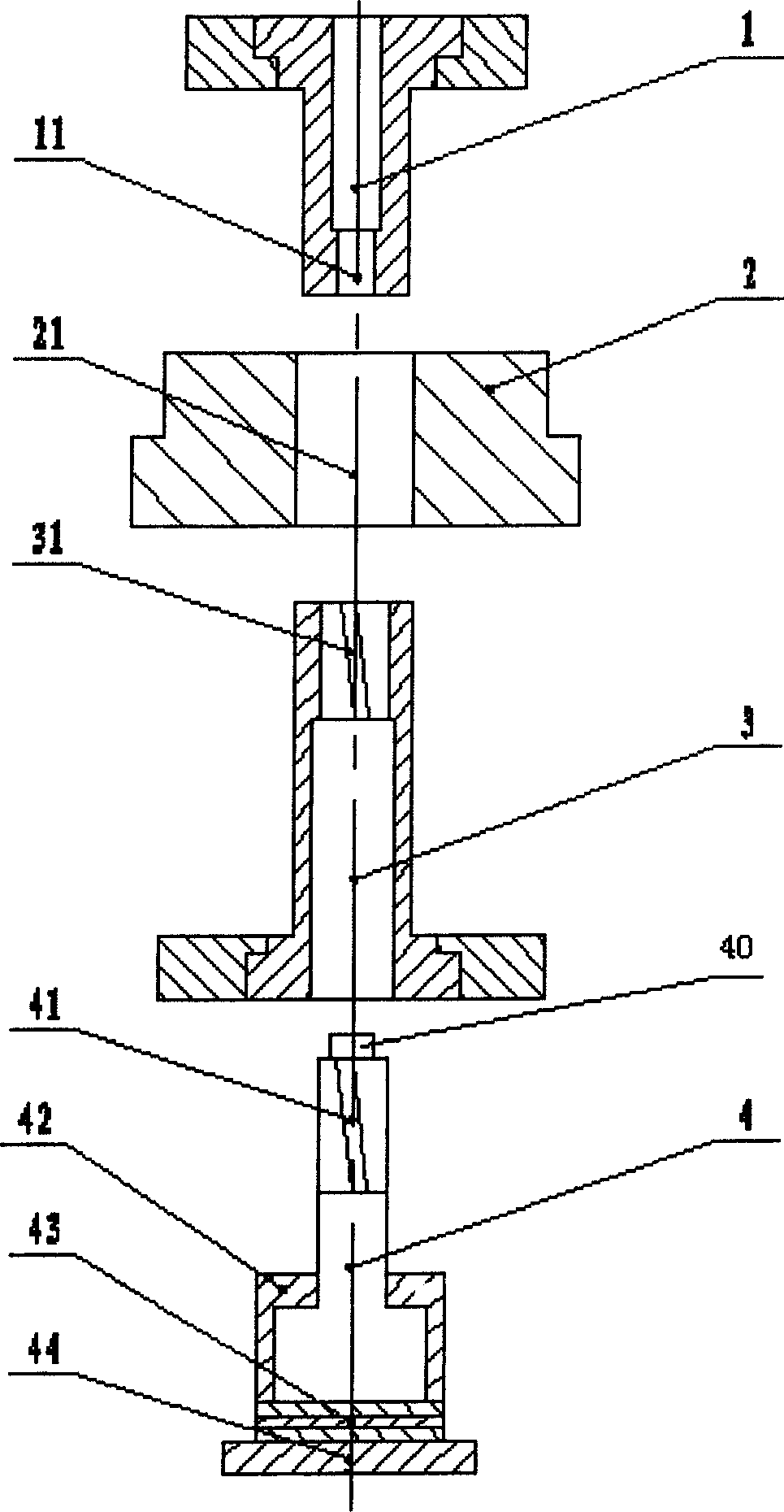

Manufacture method and die for powder metallurgy inside spin ratchet wheel

The invention relates to a method for producing powder smelt screw ratchet, which comprises: mixing the materials, compressing molding, sintering, compressing and shaping, to obtain the ratchet. The invention also discloses a relative mould, which is formed by a compressing upper punch, compressing middle mould, compressing lower punch; the upper part of lower punch has the inner screw tooth matched with the outer screw tooth; the upper punch is sliding matched with the middle mould; the middle mould is sliding matched with the lower mould; the compressing core rod has compressing core rod, friction plate, and rotation element; the upper part of compressing core rod has outer screw tooth; the lower end of core rod and the upper end of rotating element have friction plate between them, while their contact surface has lubricant. The invention, via the rotation of core rod, realizes the one-time molding and demoulding of inner screw ratchet, to improve the yield and reduce the cost.

Owner:南通市海门常乐粉末冶金厂

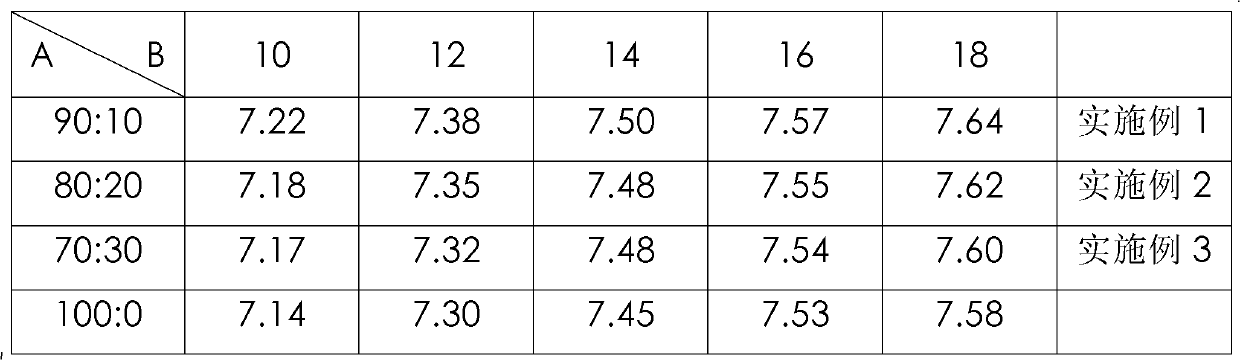

Silicon nitride ceramic slurry, preparation method of silicon nitride ceramic slurry and application of silicon nitride ceramic slurry in preparing silicon nitride cast film

The invention provides silicon nitride ceramic slurry, a preparation method of the silicon nitride ceramic slurry and application of the silicon nitride ceramic slurry to preparation of a silicon nitride cast film. The preparation method comprises the following steps of mixing silicon nitride powder, a sintering aid, a dispersant and a solvent, performing first ball milling, then adding an adhesive and a plasticizer for secondary ball milling, and performing vacuum defoaming to obtain slurry, wherein the mass ratio of the silicon nitride powder, the sintering aid, the dispersant and the solvent is 100 to (5-15) to (49-67) to (2-3.5) to (10-20) to (10-40); and performing tape casting and drying on the slurry to obtain a smooth, uniform, dense, gentle and agreeable Si3N4 biscuit which is benefical to forming processing and sintering in a later period. The silicon nitride ceramic slurry obtained by the method is uniform, is low in viscosity, high in solid content, simple in preparation technology and liable to realize industrialization and is suitable for tape casting.

Owner:SHANGHAI UNIV

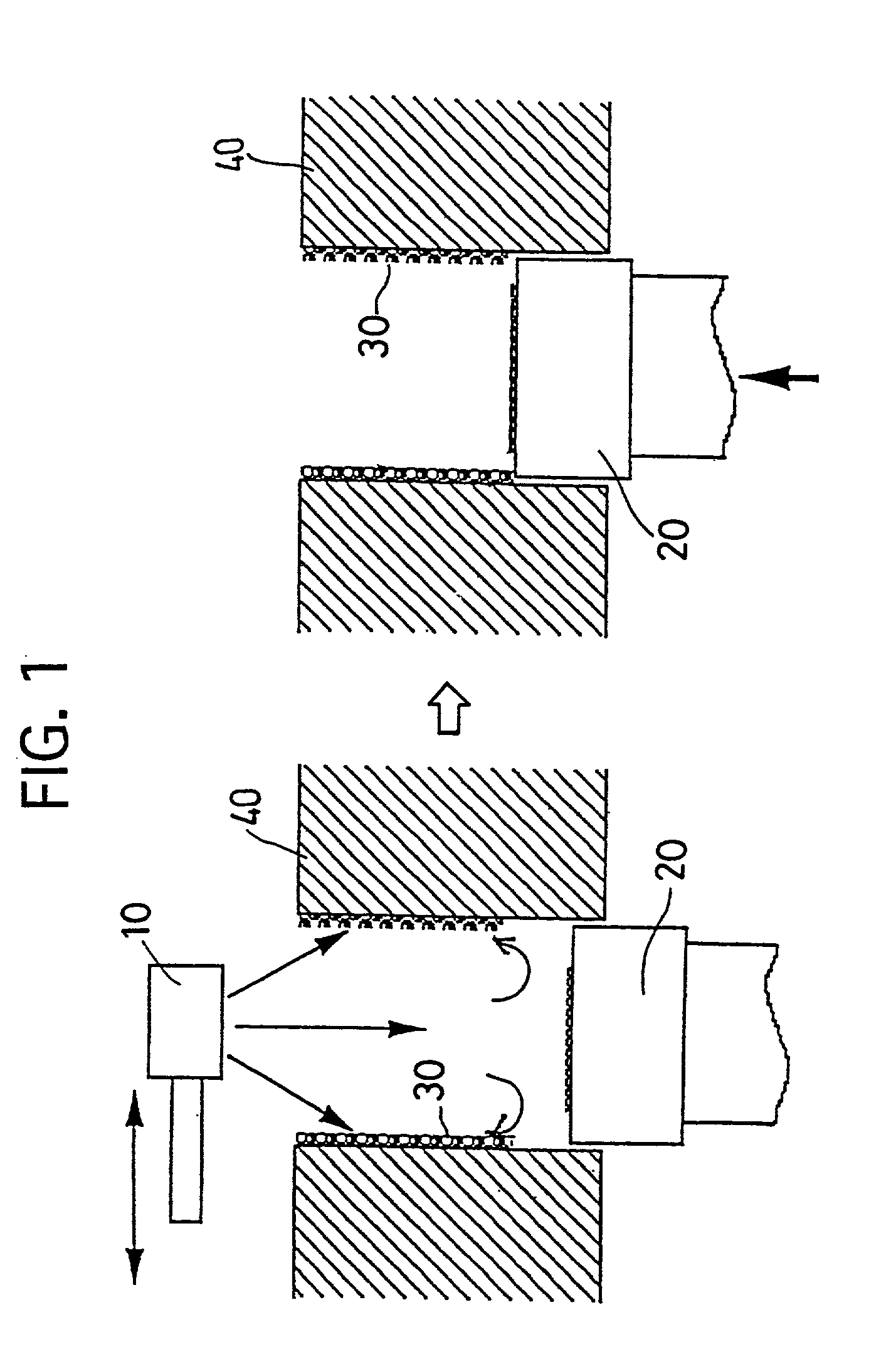

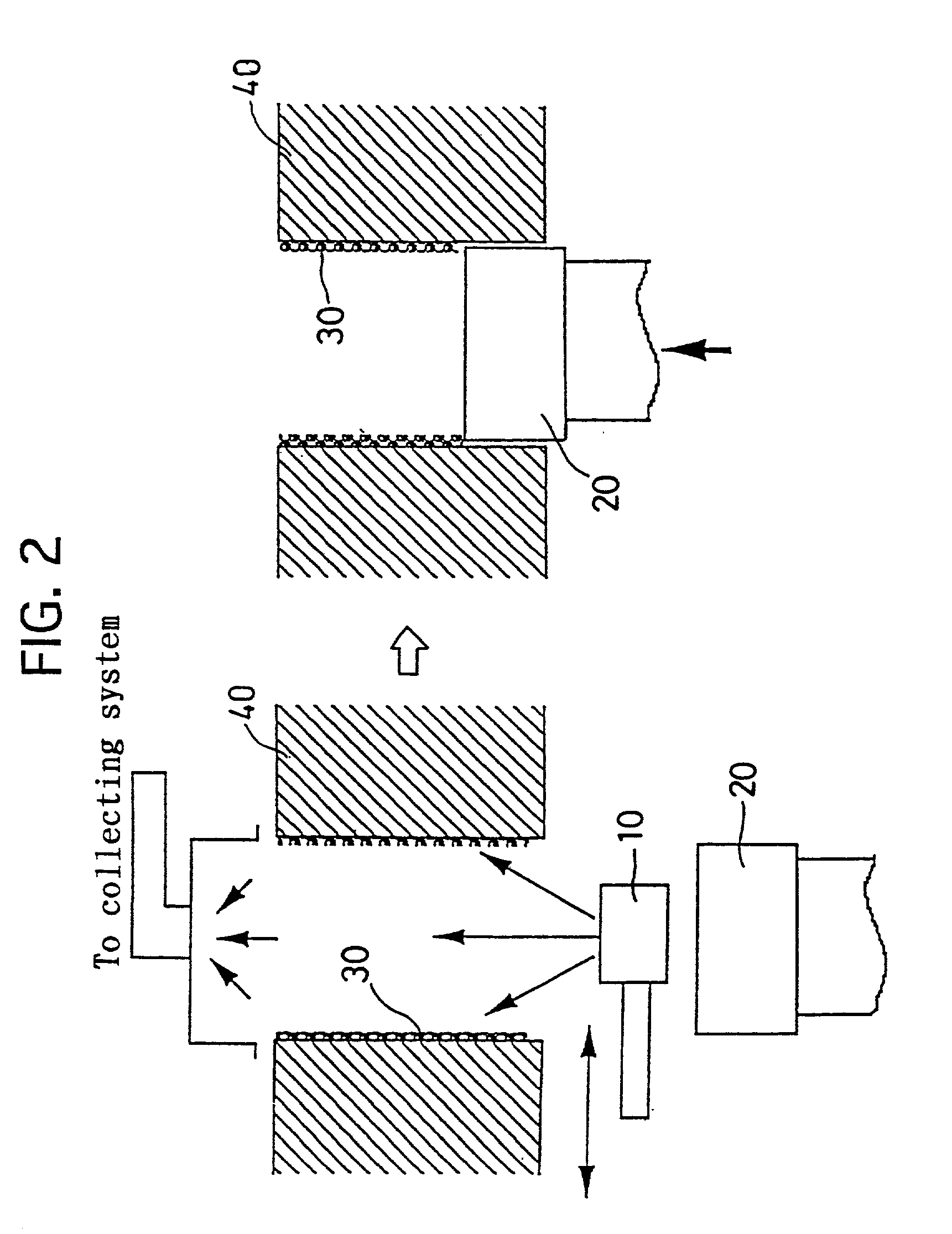

Method of forming a powder compact

This invention provides a method of forming a powder compact which can produce a high density compact under a high pressure and at the same time can reduce pressure for ejecting the compact from a die. This method comprises the application step of applying a higher fatty acid lubricant to an inner surface of a heated die, and the compaction step of filling metal powder into the die and compacting the metal powder under such a pressure as to force the higher fatty acid lubricant to be chemically bonded with the metal powder and form a metallic soap coating. Since the metallic soap coating is formed between the die and a compact, friction force between the die and the compact is decreased and ejecting pressure can be remarkably decreased despite of compaction with high pressure. Besides, a high density compact can be obtained owing to the compaction with high pressure.

Owner:TOYOTA CENT RES & DEV LAB INC +1

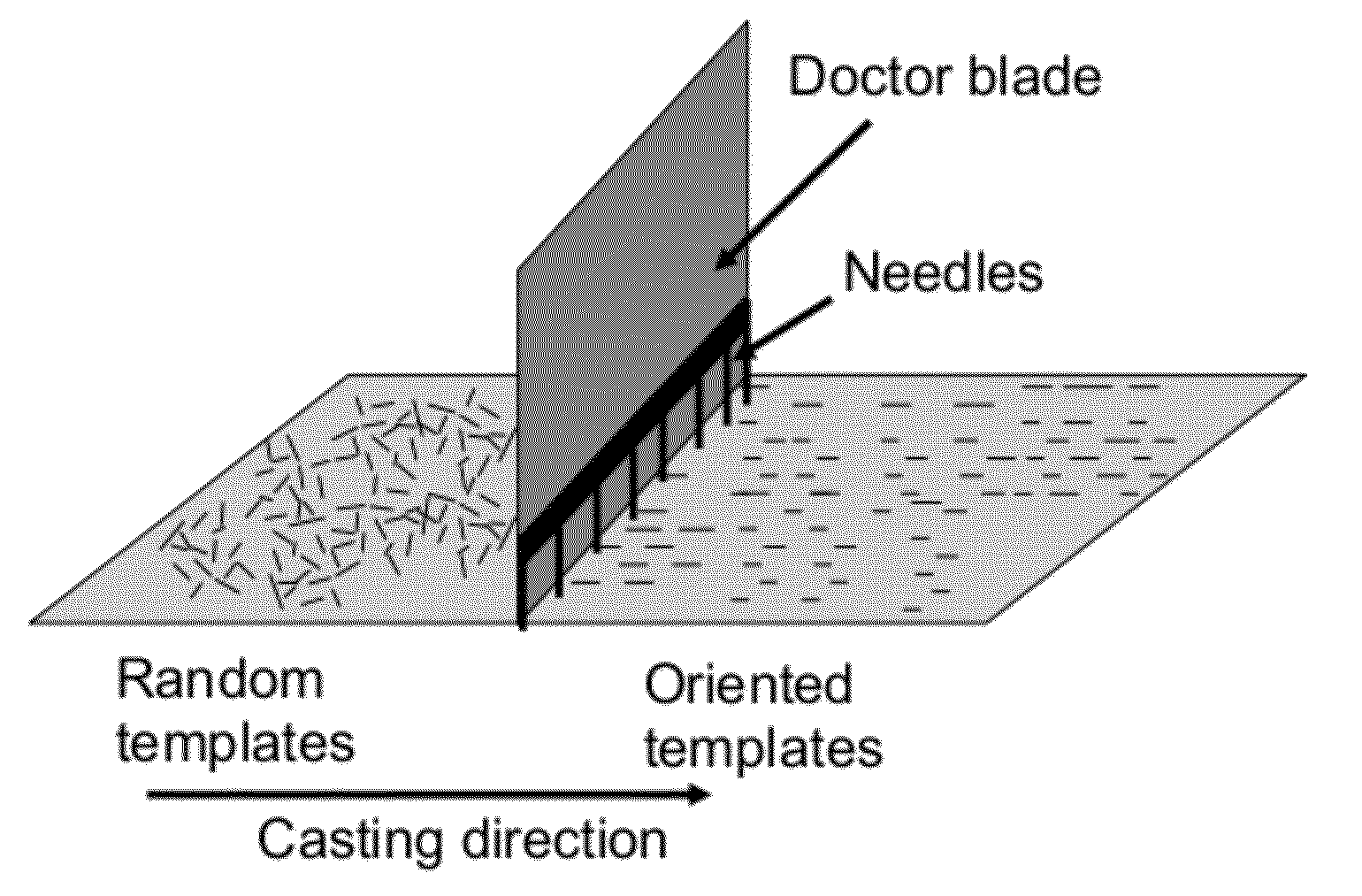

Tape casting slurry for laminated sheet type electronic component and preparation method for tape casting slurry

The invention discloses tape casting slurry for a laminated sheet type electronic component and a preparation method for the tape casting slurry. The tape casting slurry comprises 45 to 55 weight percent of ceramic or ferrite powder, 0.1 to 1.0 weight percent of dispersing agent, 30 to 48 weight percent of solvent, 3 to 8 weight percent of adhesive, 3 to 5 weight percent of plasticizer, 0.1 to 0.5 weight percent of 2-methyl-2,4-pentendiol serving as an addition agent a and 0.1 to 0.5 weight percent of silane coupling agent serving as an addition agent b. The 2-methyl-2,4-pentendiol is added, so that the problems that the viscosity of the slurry is rapidly increased, and the performance of a membrane is rapidly deteriorated because boric is added are solved; the silane coupling agent is added, so that the slurry is low in viscosity and high in dispersing performance, the green density of the membrane is increased, and the ductility is enhanced; and the finally prepared slurry is uniform, stable and suitable for large-scale production.

Owner:SHENZHEN GUDIAN ELECTRONICS

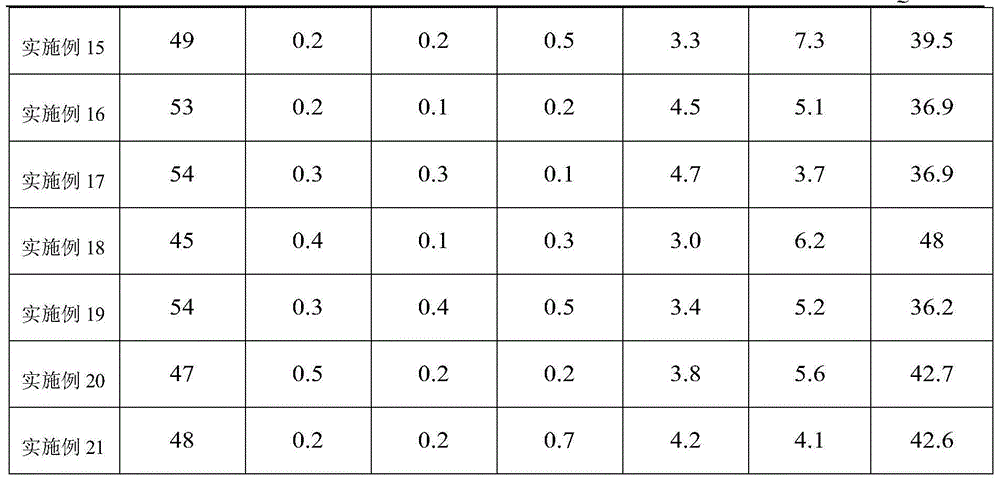

In-situ sintered dispersion particle-reinforced warm-compacting powder metallurgy material and preparation method thereof

The invention relates to a dispersion particle-reinforced warm-compacting iron-based powder metallurgy material based on in-situ sintering synthesis and a preparation method thereof. The warm-compacting iron-based powder comprises the following main components in percentage by weight: 2-3% of nickel, 0.3-0.6% of molybdenum, 1-2% of copper, 1-4% of titanium, 0.45-1.2% of carbon and the balance of ferrum. The method for preparing the warm-compacting iron-based powder by an in-situ particle sintering synthesis technology comprises the following steps: blending materials; mixing materials; pre-alloying the mixed part; screening; adding a lubricating agent and mixing; warm-compacting; and finally sintering. During the press forming process of the warm-compacting iron-based powder at the temperature of 90-110 DEG C under the pressure of 500-700MPa, the density of the powder can be up to more than 93% of the theoretical density, and the power has the advantages of good compressibility and high rate of finished products; in the warm-compacting iron-based powder, the TiC dispersion particles with the particle size of 0.05-1mu m are well bonded with a matrix interface and are uniformly distributed; and under the dispersion strengthening action of the TiC particles, with respect to the material, the mechanical properties are improved, the hardness can reach 74-82HRB (Rockwell hardness), the bending strength can reach 480-650MPa, and the wear resistance is improved by 1.2-2.8 times compared with that of the common non-warm-compacting iron-based powder metallurgical sintering material.

Owner:常熟市华德粉末冶金有限公司

Preparation method of compact zirconia ceramic plunger

The invention relates to a preparation method of a compact zirconia ceramic plunger. The preparation method comprises the following steps: fully mixing zirconia ceramic granulated powder with a compound additive; placing the obtained mixture in a die for isostatic pressing; sintering the molded sample into a compact zirconia ceramic plunger blank; and finally grinding the blank into the ceramic plunger with precise size. Compared with the prior art, by utilizing the zirconia plunger material and the preparation method thereof provided by the invention, the compactness, the forming efficiency and the finished product ratio of the ceramic plunger are effectively improved. A high-pressure plunger pump manufactured by the compact zirconia ceramic plunger has the advantages of long service life, wear resistance, corrosion resistance, expanded application range, and shortened time for maintaining and replacing a high-pressure plunger and a sealing bush in the case of shutdown, thus saving engineering operating cost.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

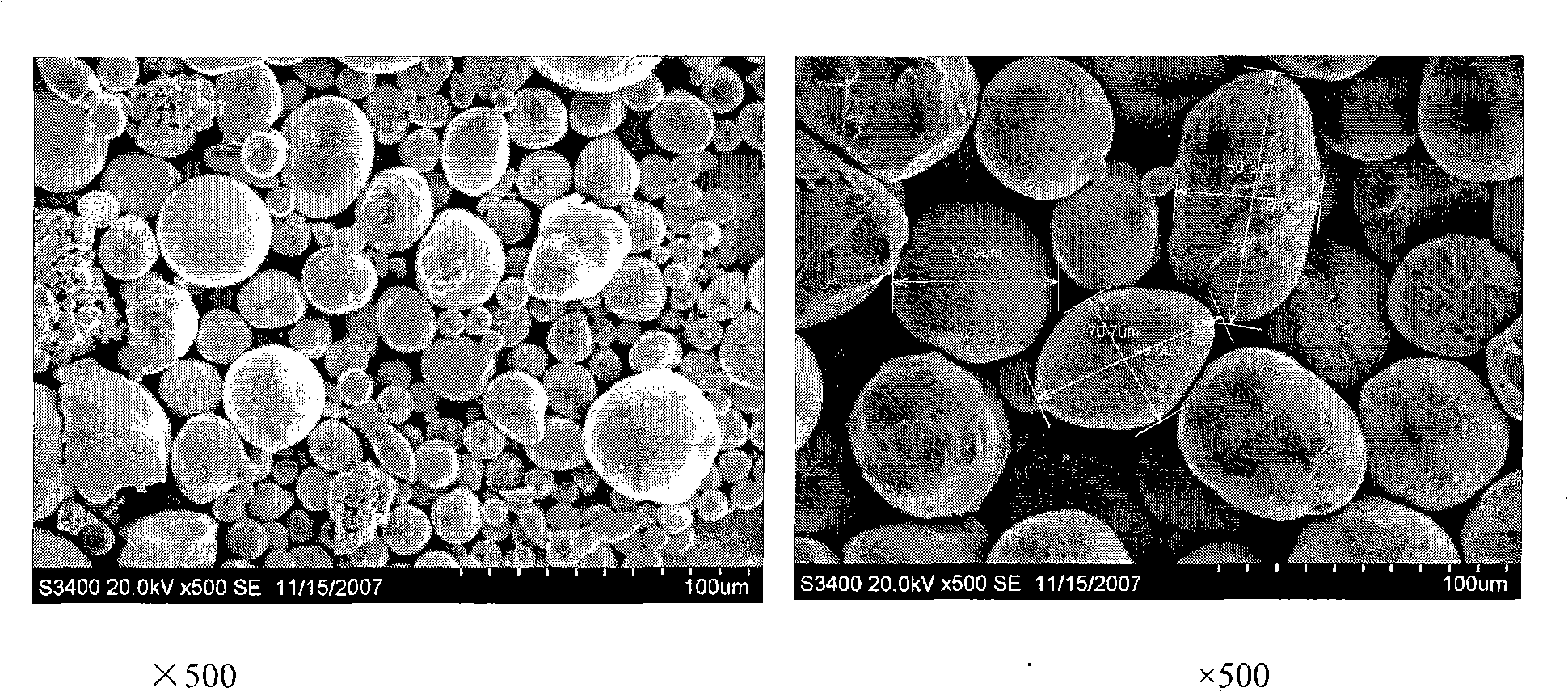

Method for preparing special type molybdenum powder

A method for preparing a special molybdenum powder relates to a method for preparing the molybdenum powder specially used for the industries of thermal spraying and machining as well as pressing fine apparatuses. The powder is characterized in that the preparing process includes the steps as follows: (1) sintering normal molybdenum powder for increasing the granularity; (2) grading the molybdenum powder, the granularity of which is increased; carrying out spheroidisation on the molybdenum powder with approximate granularity by a plasma device, then cooling and collecting the molybdenum powder; (3) reducing the molybdenum powder after being spheroidized, screening, grading and then obtaining the special molybdenum powder. The molybdenum powder prepared by the method of the invention has the advantages of good fluidity, simple technique, high finished product rate and relates to a technique for preparing the special molybdenum powder used in the fields of thermal spraying and pressing fine apparatuses.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Preparation method of zinc oxide-based tubular rotary target material

The invention relates to a preparation method of a zinc oxide-based tubular rotary target material. The preparation method comprises the following steps: taking NH4HCO3 as a precipitant, preparing pure zinc oxide powder and Al-doped zinc oxide powder with an atomic ratio of 1-7at% by a chemical precipitation method, presintering, conglomerating and shaping the powder, filling the powder into a mould, moulding the powder in a cold isostatic pressing manner at 300-340MPa, obtaining a biscuit with a relative density of 70-75%, sintering the biscuit under an oxidizing atmosphere, and processing the sintered biscuit to obtain the rotary target material. Compared with the prior art, the preparation method provided by the invention has the beneficial effects that the density of the biscuit is improved by 10-15%; the volume shrinkage in later stage sintering is reduced; the sintering deformation of the tubular target with a large length-diameter ratio is effectively controlled; and in the process of sintering, the circulating oxygen is served as a control atmosphere to avoid the component changing, large pores on the surface and density reduction caused by the large pores on the surface.

Owner:宁夏中色新材料有限公司

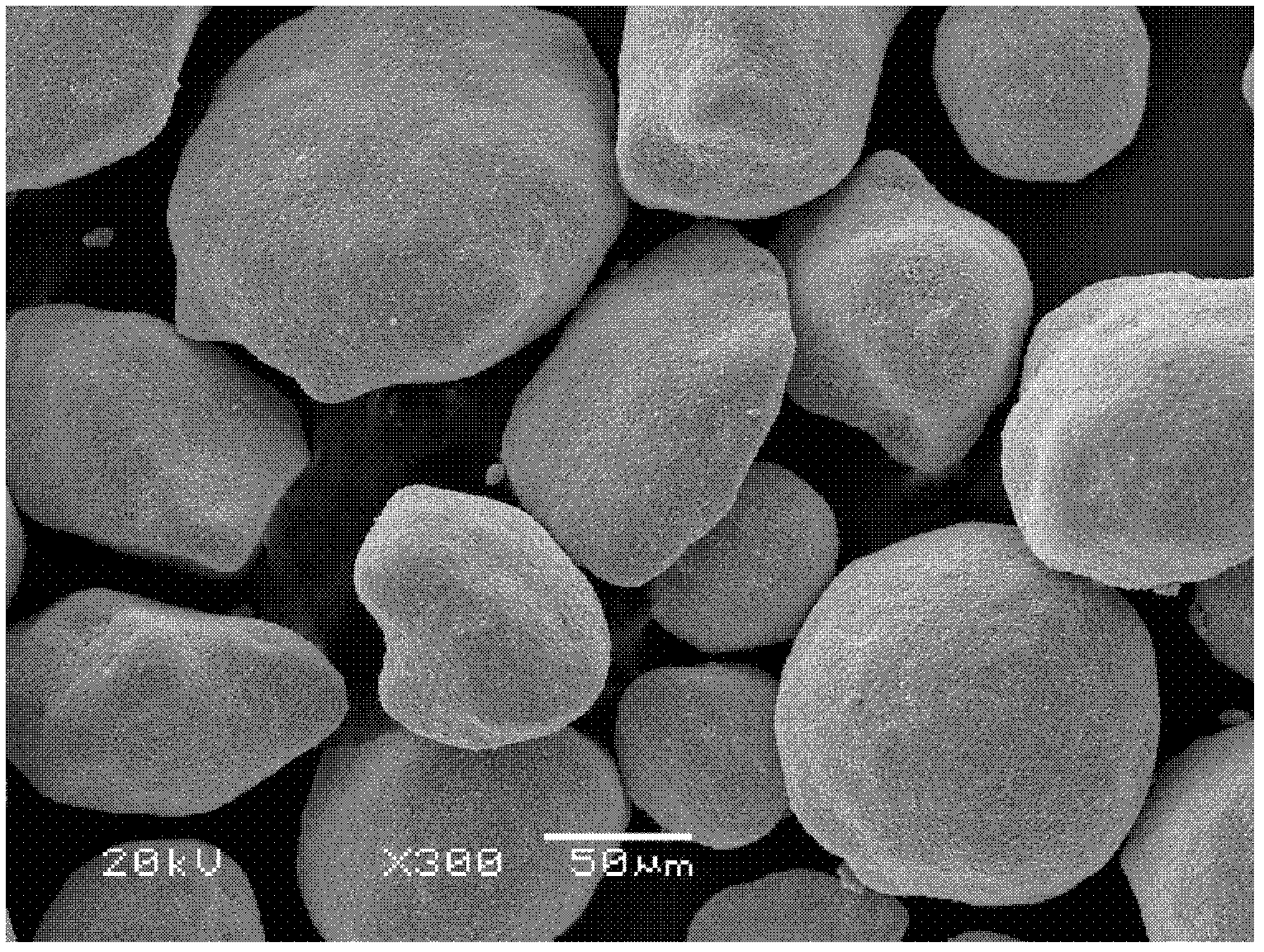

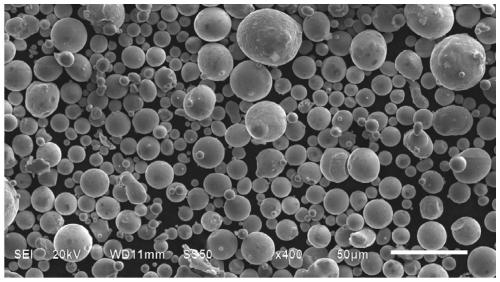

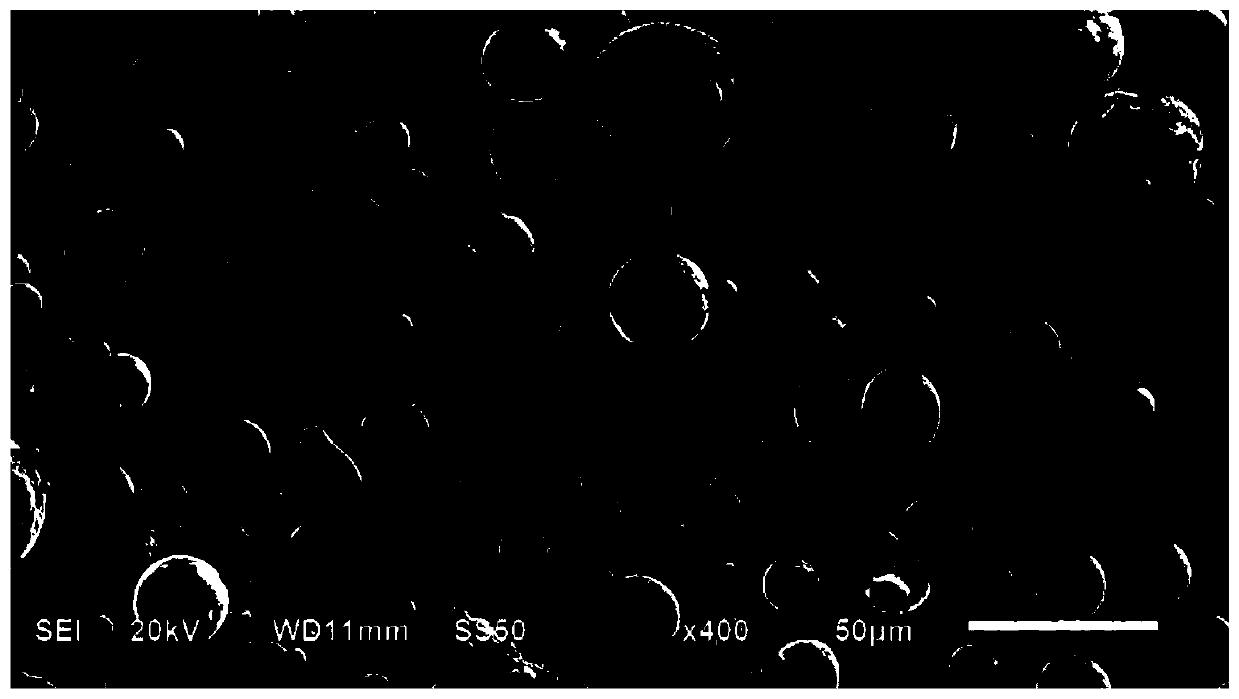

Preparation method of FeSi alloy powder with high direct current superposition characteristics

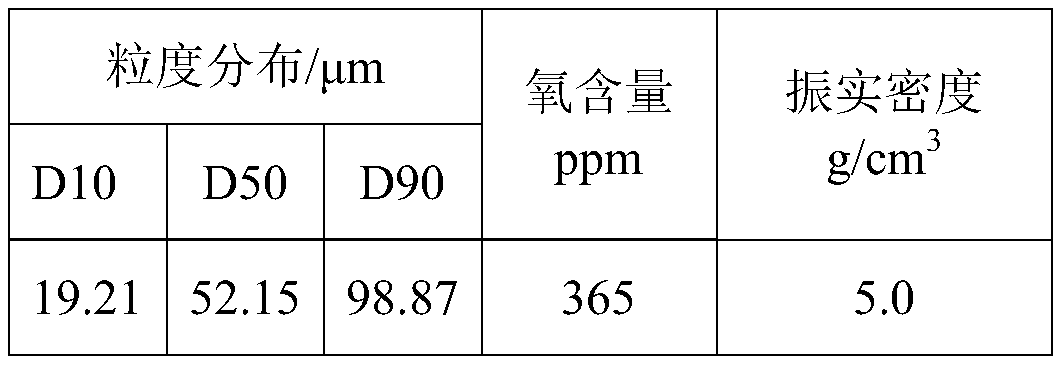

ActiveCN110039060AHigh tap densityImprove DC Superposition CharacteristicsTransportation and packagingMetal-working apparatusManganeseAlloy

The invention discloses a preparation method of FeSi alloy powder with high direct current superposition characteristics, and belongs to the technical field of alloy powder preparation. The FeSi alloypowder is mainly made of pure iron and metal silicon, and a small amount of manganese and chromium are added. The preparation method comprises the following steps of weighing the ingredients according to a specific proportion, carrying out non-vacuum melting to obtain the alloy melt of required components, and then atomizing to prepare alloy raw powder with an inert gas, obtaining fine powder after the raw powder is collected, screened and graded. According to the preparation method of FeSi alloy powder with high direct-current superposition characteristics, the alloy powder with uniform components and high purity can be obtained, and the powder spherical degree is high; the uniform and compact insulating layer can be easily formed after insulation coating, so that the contact of the alloy matrix is effectively blocked, and the pressed magnetic powder core has good direct-current superposition characteristics.

Owner:马鞍山新康达磁业股份有限公司

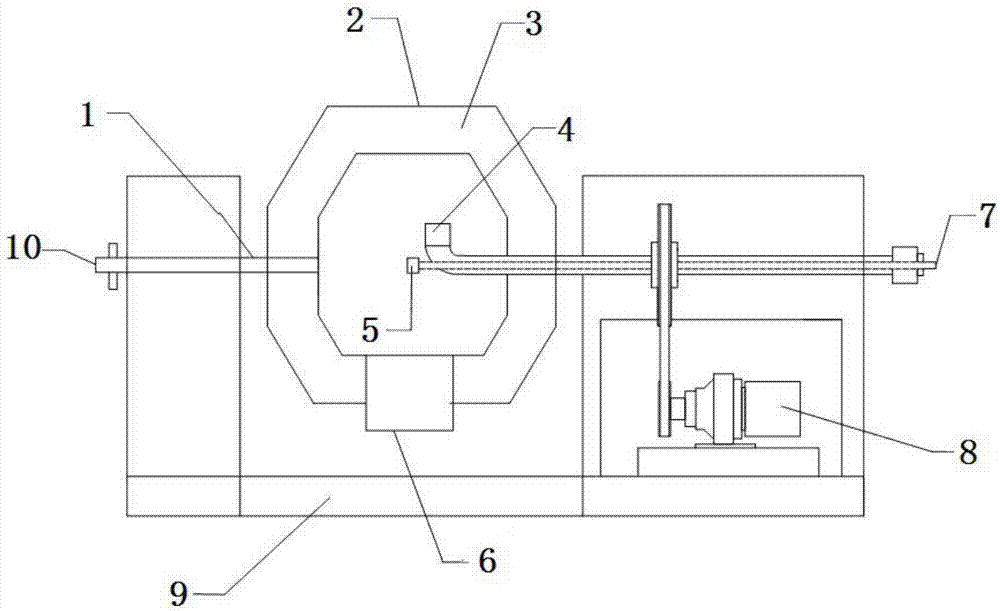

Magnetic-field temperature-pressure formation

InactiveCN101028652ALow rotational resistanceGood orientationInorganic material magnetismInductances/transformers/magnets manufactureMagnetic anisotropyAdhesive

A magnetic-field thermo-pressing process for preparing the high-performance magnetic material with magnetic anisotropy includes such steps as preparing the ultra-magnetostrictive RE powder or permanent-magnet NdFeB powder or permanent-magnet SmCo powder in vacuum or inertial gas or organic medium, mixing it with adhesive, coupling agent and lubricant, and thermopressing at 80-350 deg.C under 300-900 MPa in a magnetic field (1.5-2.5T).

Owner:UNIV OF SCI & TECH BEIJING

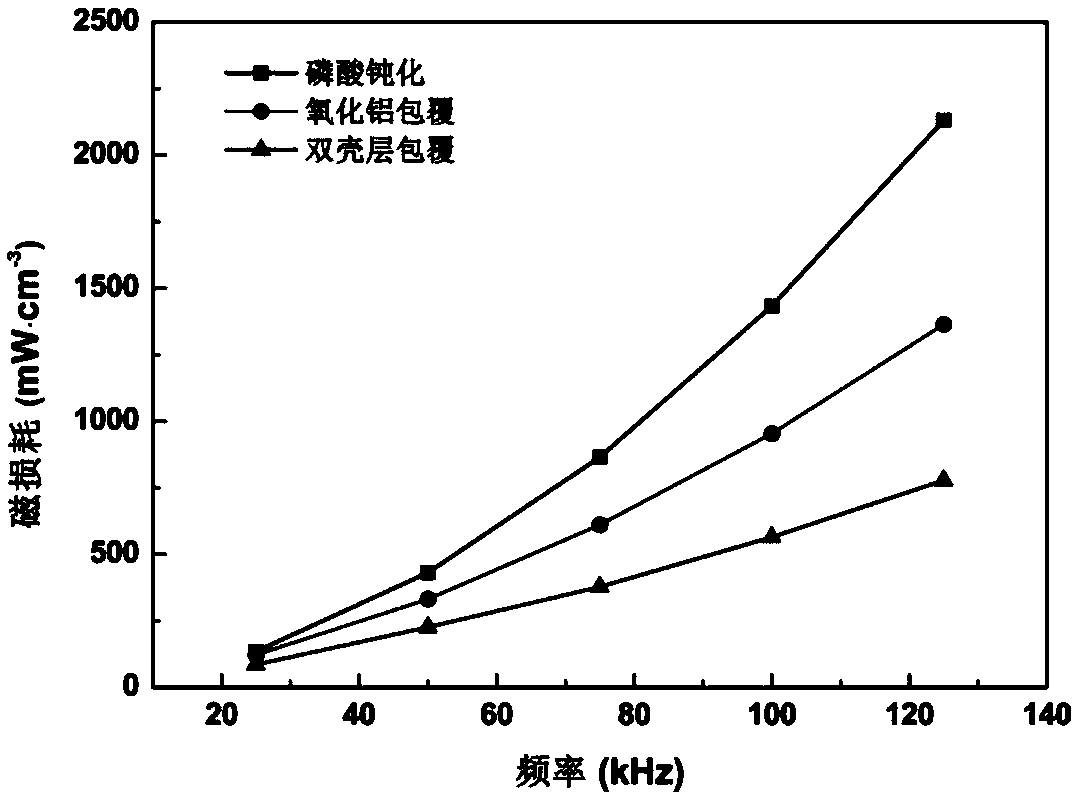

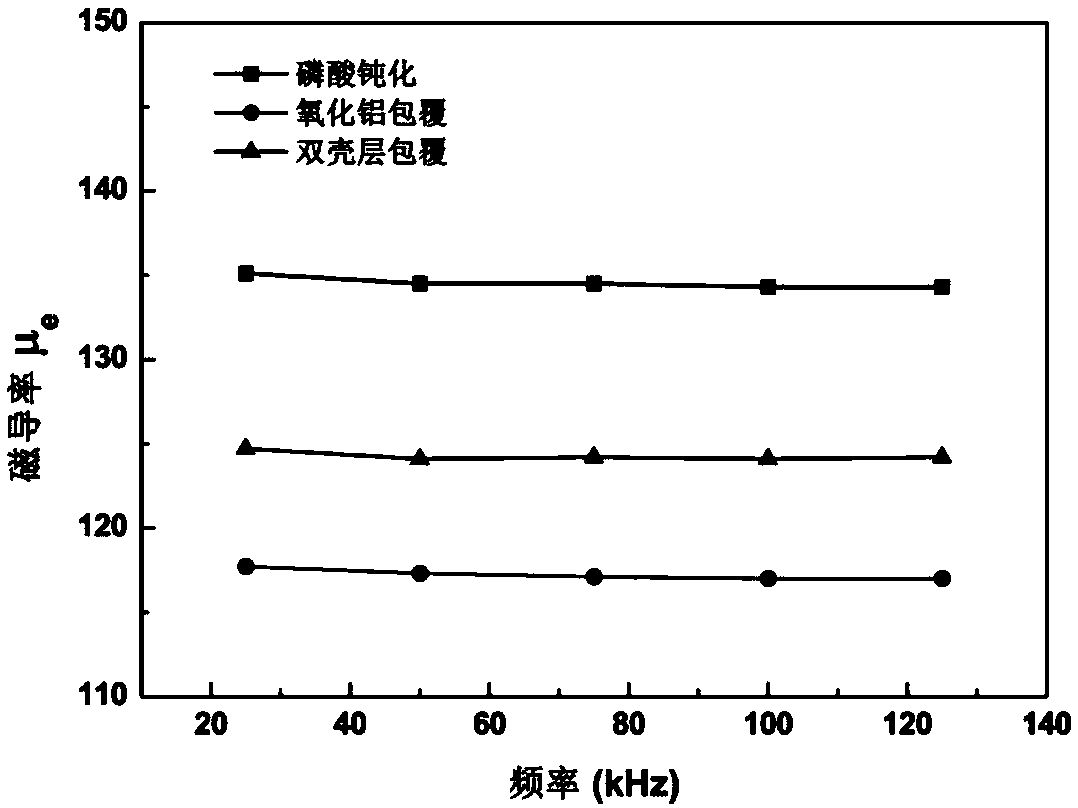

Double-shell insulation coating method of a metal soft magnetic composite material

ActiveCN109273235AReduce lossLow cost of industrializationInorganic material magnetismInductances/transformers/magnets manufactureInsulation layerDecomposition

The invention discloses a double-shell insulation coating method of a metal soft magnetic composite material, wherein an inorganic salt / oxide composite insulation layer is coated on the surface of themetal magnetic powder through a sol-gel process. As that inorganic salt in the inn layer is use as a buffer layer, the bonding strength of the insulate layer and the compact density are improved; Outer oxide can effectively hinder the decomposition of inner inorganic salt during high temperature annealing and improve the thermal stability of insulating layer. Soft magnetic composites were obtained by compression molding, high temperature heat treatment and spraying process. The invention adopts the sol-gel method to insulate and coat the metal magnetic powder, and the obtained composite coating layer has good combination with the magnetic powder, high thermal stability, does not need to add an adhesive, reduces the production cost, is both inorganic coating materials, has higher resistivity, and effectively reduces the magnetic core loss of the soft magnetic composite material.

Owner:SHANDONG UNIV OF TECH

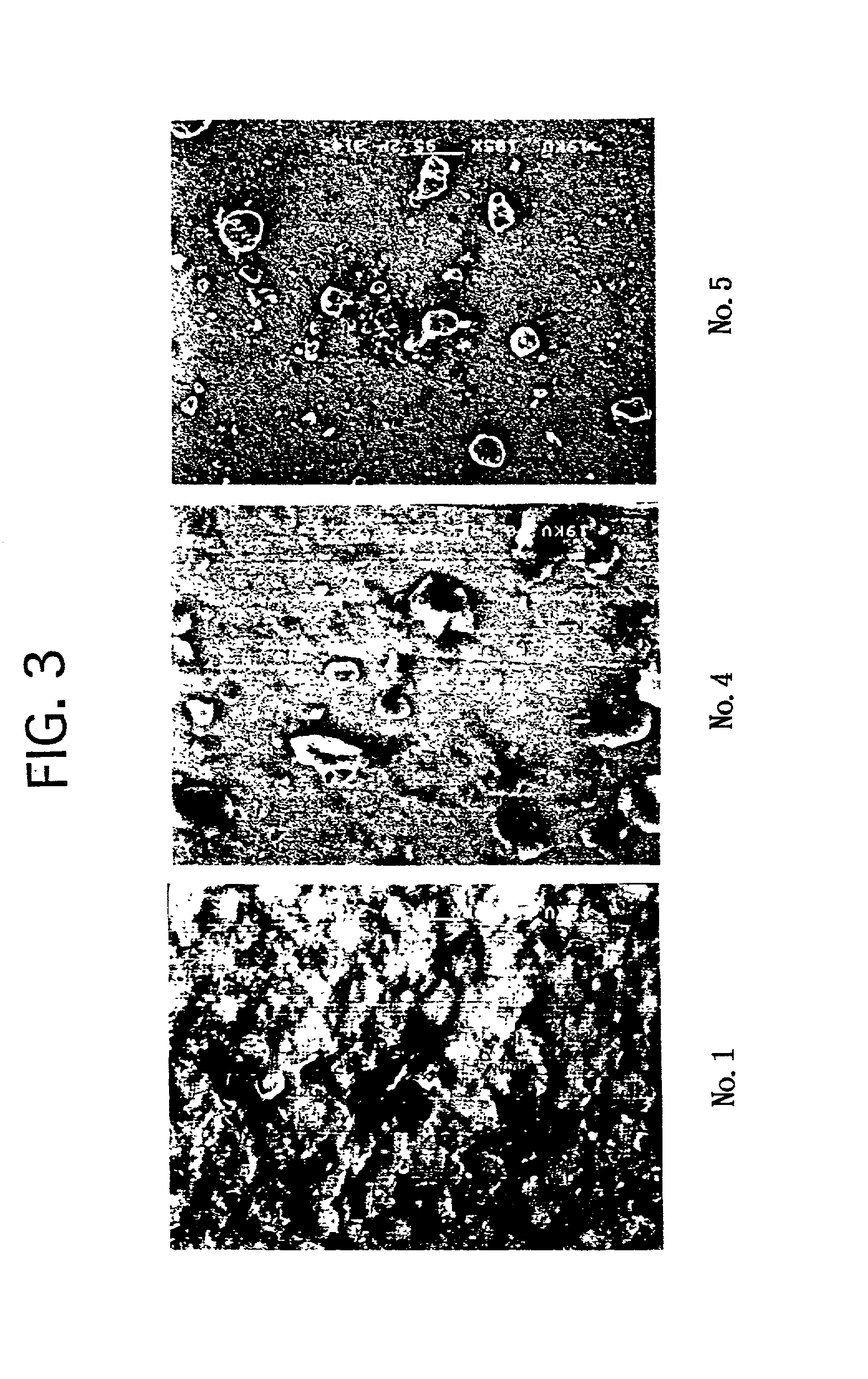

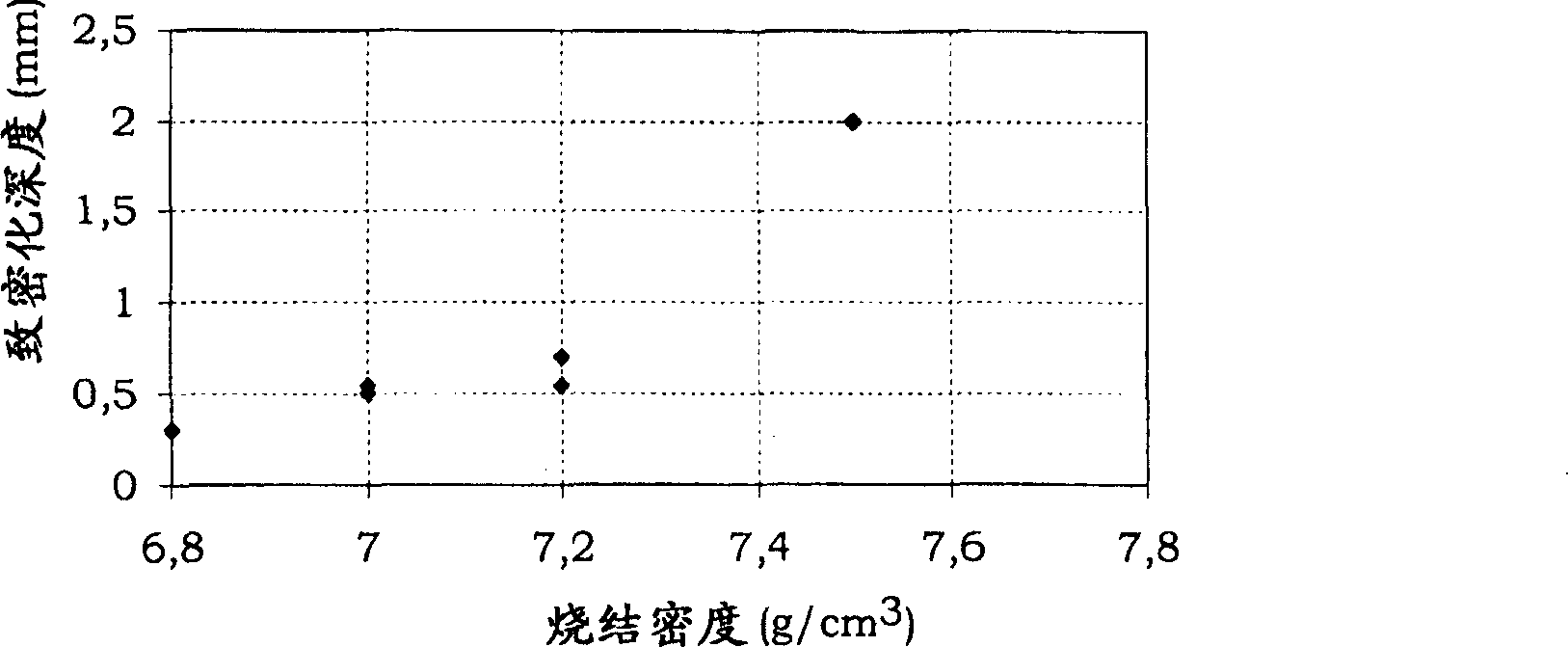

Method for the manufacturing of sintered metal parts having a densified surface

The present invention concerns a method for producing powder metal parts having a densified surface. The method comprises the steps: - compacting an iron-based powder by high velocity compacting technique to a density above 7.2 g / cm<3> - sintering the parts -subjecting the parts to a surface densifying process.

Owner:HOGANAS AB

Method for preparing ceramic compositions

InactiveUS6274080B1Improve compactionIncrease green densityNatural patternsCeramic shaping apparatusSurface finishVitrification

A method for providing improved compaction, green density, green strength and surface finish properties in simulated stone and mineral-like materials from ceramic green bodies, based on addition of selected polymer additives during ceramic processing, is disclosed. Polymer additives having weight-average molecular weights from 30,000 to 1,000,000, glass transition temperatures from -50 to +90° C., and low hygroscopicity are particularly useful in providing enhanced properties of ceramic products involving processing of large-size granule intermediates.

Owner:ROHM & HAAS CO

Warm press forming method in high density and low temperature for powder of stainless steel

A low-temp pressing technology for manufacturing high-density stainless steel part by power metallurgy of stainless steel powder (less than 147 microns in granularity) includes proportionally mixing stainless steel powder with low-temp lubricant, heating die to 80-100 deg.C, spraying EBS wax powder onto inner surface of die by electrostatic spray, preheating said mixture to 70-90 deg.C, loading it in die, and die pressing under 600-800 MPa.

Owner:SOUTH CHINA UNIV OF TECH

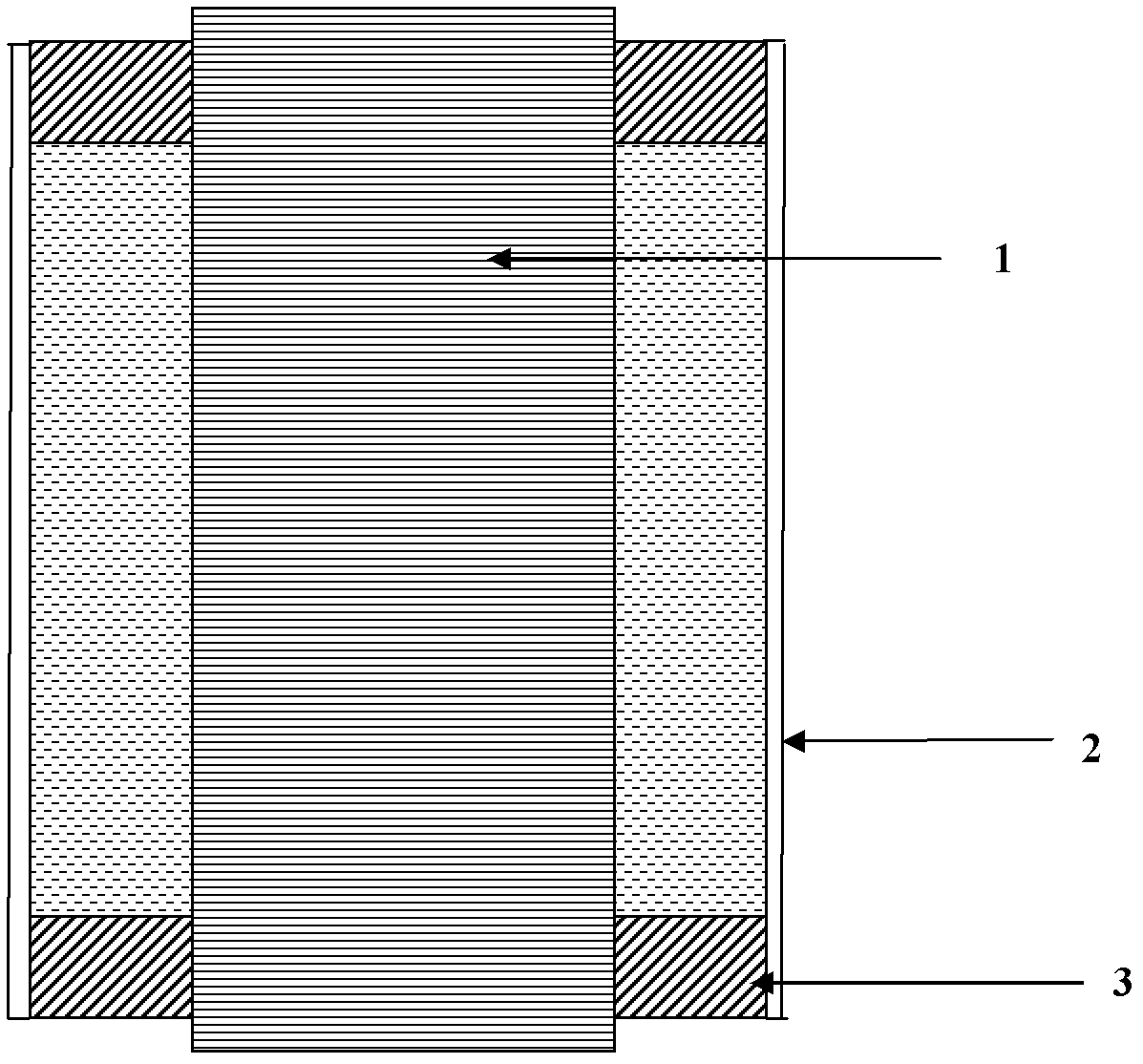

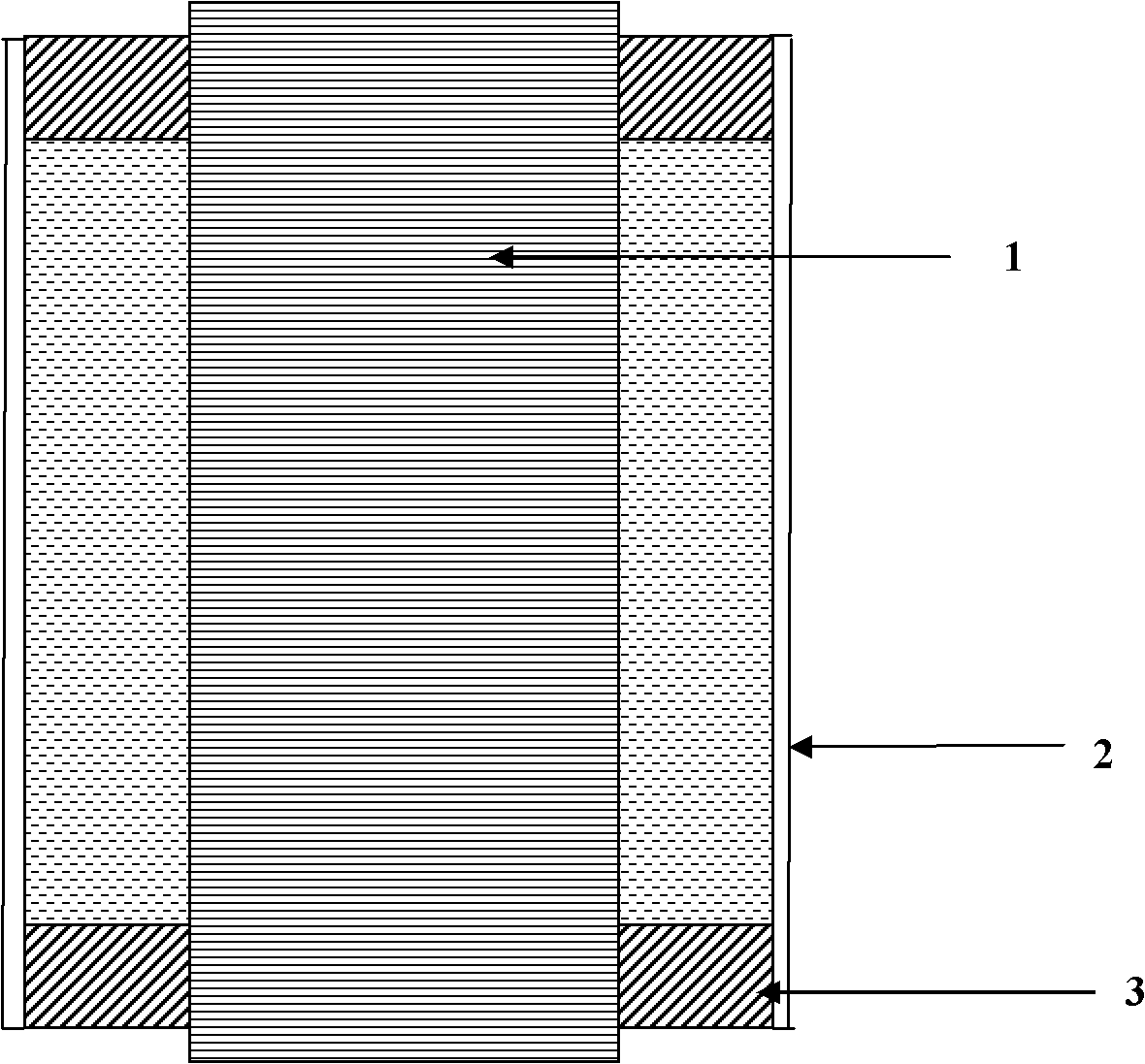

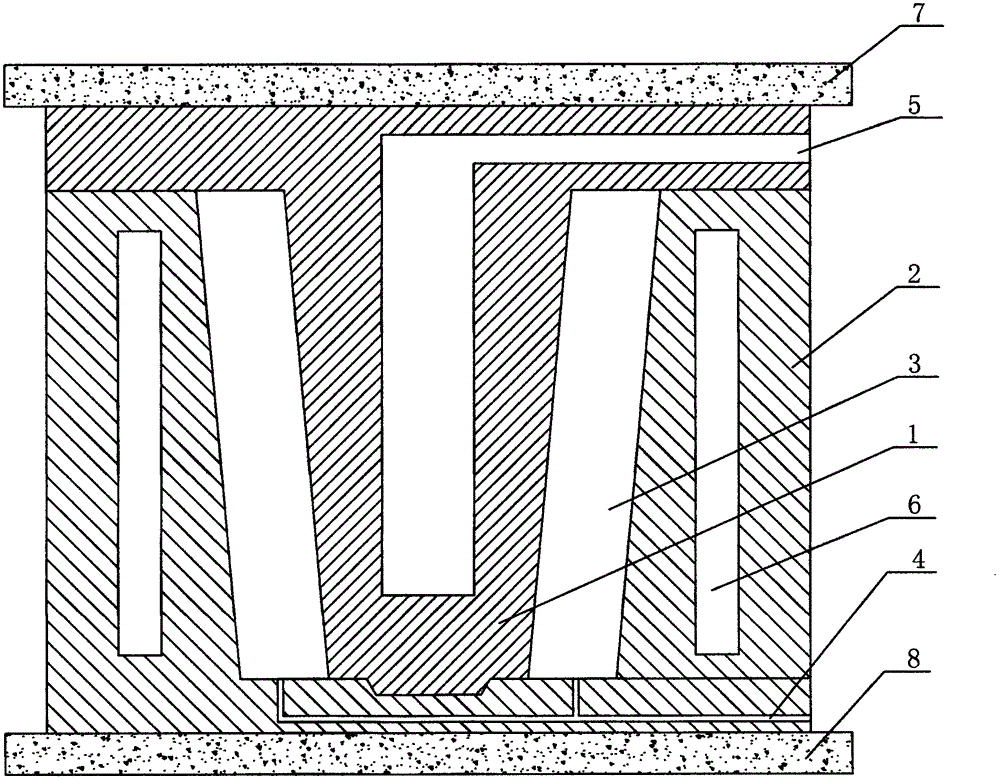

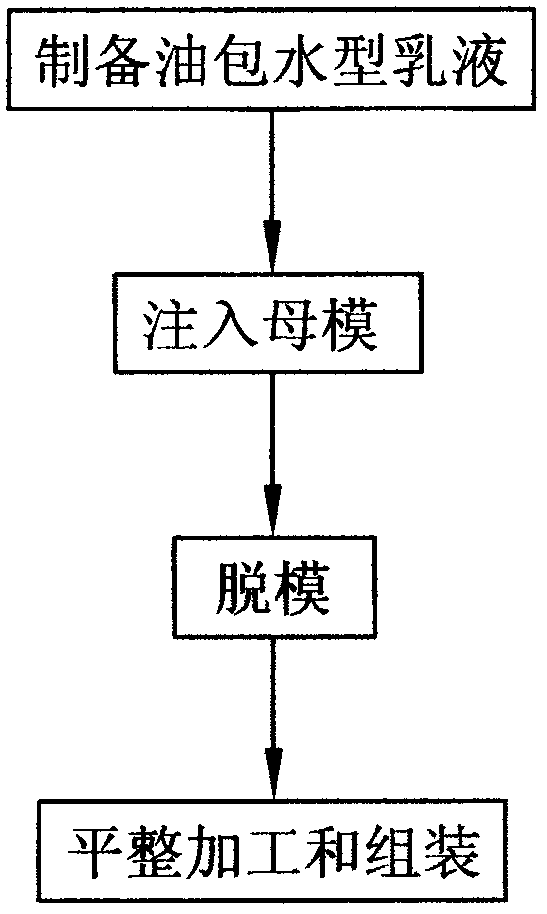

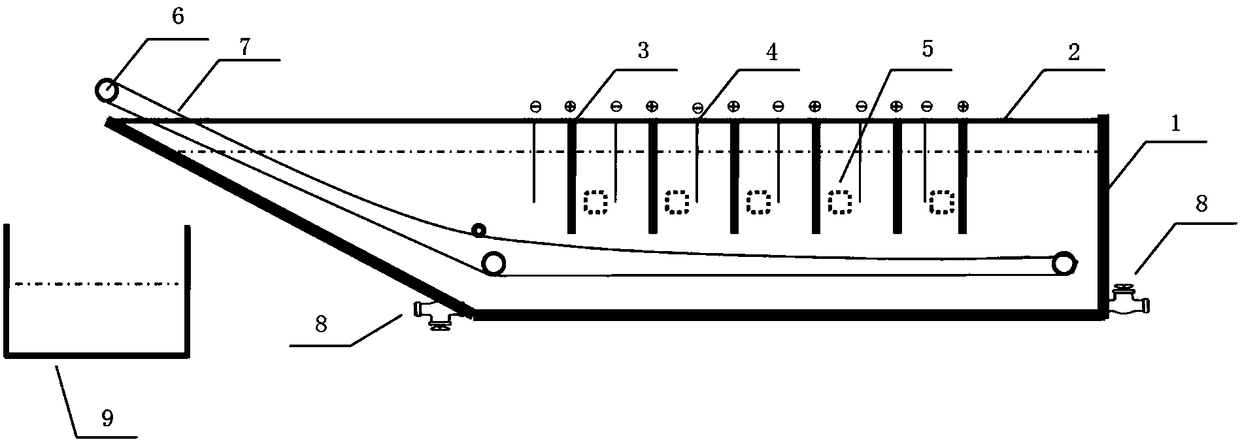

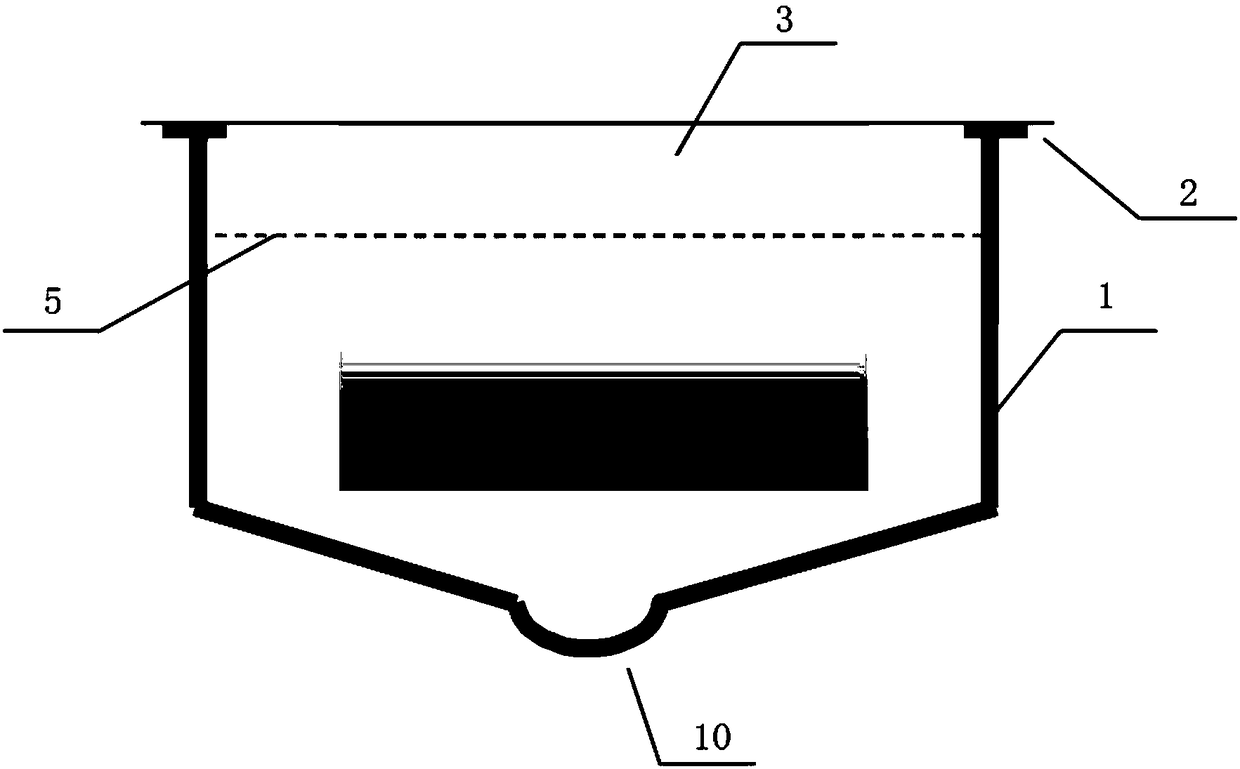

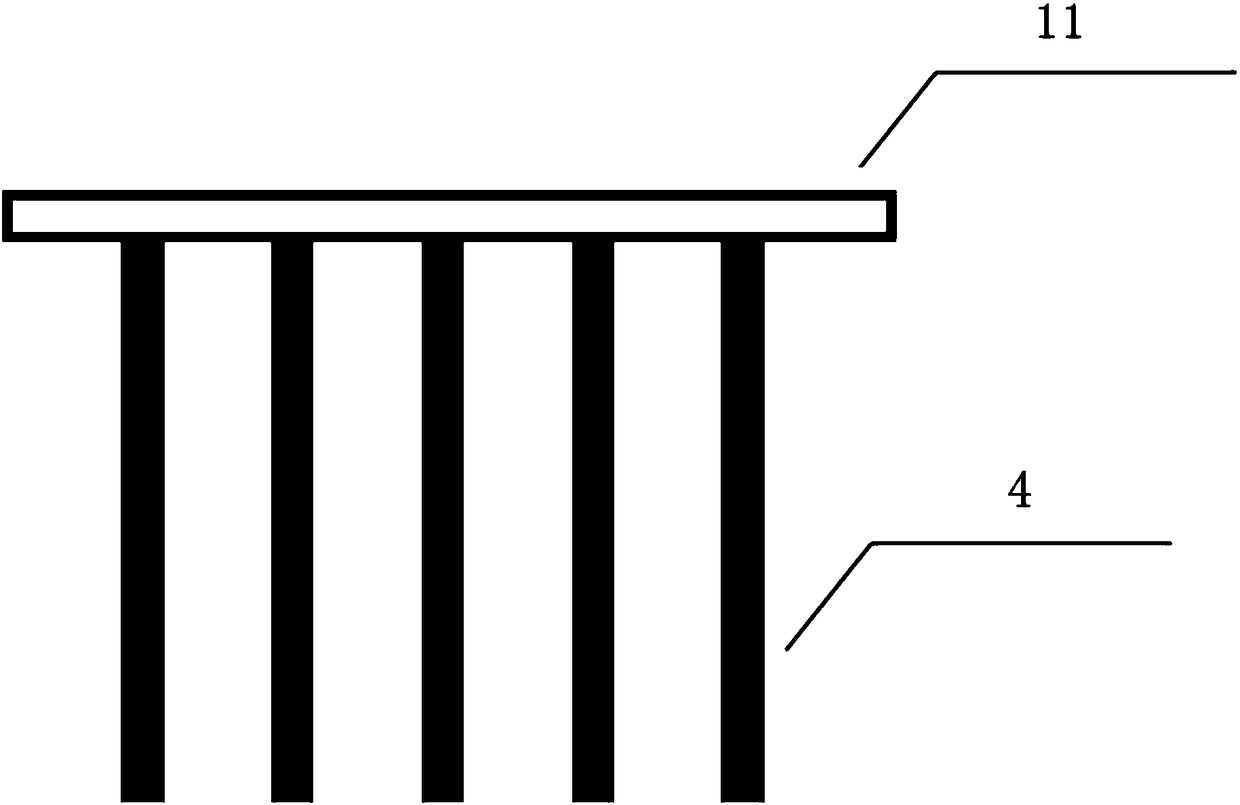

Ceramic rotary target slip casting die and manufacturing method thereof

ActiveCN104589461AIncrease green densityAvoid cloggingSlip casting mouldsSlurryVolumetric Mass Density

The invention relates to ceramic rotary target slip casting die and a manufacturing method thereof. The die is characterized by comprising an internal die (1) and an external die (2), wherein the external die (2) is hollow, and the upper part of the external die (2) is provided with an opening; the internal die (1) is T-shaped and is fixedly arranged in the hollow part of the external die (2); the upper edge of the internal die (1) is pressed on that of the external die (2); a cavity (3) is formed between the outer side wall of the internal die (1) and the inner side wall of the outer die (2); the bottom of the external die (2) is provided with a slurry inlet hole path (4) which is communicated with the cavity (3); the internal die (1) is internally provided with an air blowing hole path (5); the outer die (2) is internally provided with a drainage channel (6). The die has the effects that the die material strength is high, so that a mold made of a gypsum material can be replaced by the die, products cast by the die are high in density and uniform in density, the production period is short, and the labor intensity is low.

Owner:河北东同光电科技有限公司

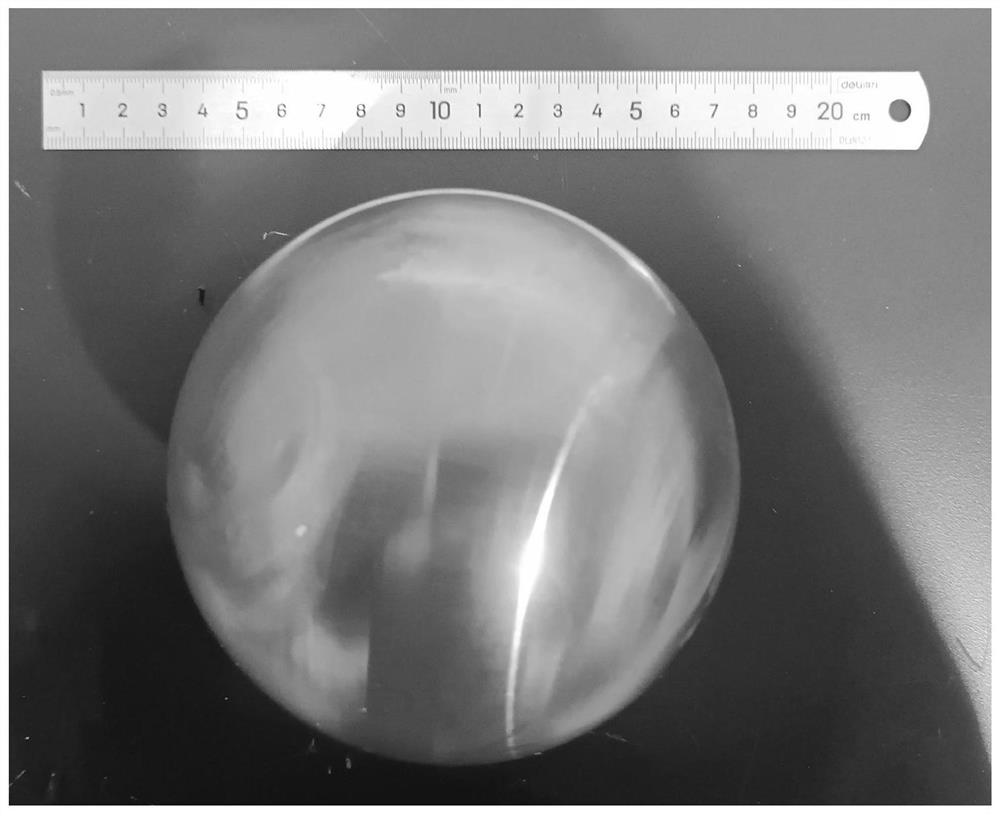

Large-size silicon nitride ceramic ball and preparation method thereof

The invention provides a silicon nitride ceramic ball and a preparation method thereof, and belongs to the technical field of ceramic materials. According to the invention, a vacuum injection-coagulation forming method is adopted, so that the forming of large-size and oversized silicon nitride ceramic balls with high sphericity degree and uniform density can be realized. Microwave drying is adopted, the drying speed is high, and deformation of a green body is small. According to the invention, the cold isostatic pressing treatment is carried out on the degummed ceramic balls, so that the compactness of the sintered ceramic balls is improved. A two-step air pressure sintering process is adopted, so that internal air holes of the ceramic ball can be removed, and the density can be further improved. According to the invention, the surfaces and the core parts of the large-size and oversized silicon nitride ceramic balls prepared by adopting the method of combining injection coagulation forming with cold isostatic pressing forming and two-step air pressure sintering have no obvious difference in properties such as relative density, Vickers hardness and fracture toughness. Homogenization of density and mechanical properties of large-size and oversized silicon nitride ceramic balls can be realized.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD +1

Stainless steel powder composite material and its warm-pressing method

This invention offers a kind of composite which can deposit sclerotic stainless steel powder and its warm-pressing method. The composite's components and their mass's percentage content is 0.02-0.07%C, 15.0-17.5%Cr, 3.0-5.0%Ni, 3.0-5.0%Cu, 0-0.6%Mn, 0.15-0.45%Nb, 0-0.1%Mo, and others are Fe and inevitable impurity element. Besides, 0-10% of the whole mass said above of NiC granule and 0.1-0.3% anti-friction material are added. This method uses electrostatic spraying to spray EBS wax powder onto the bore of the die to make the die wall greasing, and the thickness of the paintcoat is between 0.01mm and 0.1mm. The density of the green ware body shaped by warm-pressing is 0.15-0.25g / cm3 higher than the body shaped by cold-pressing, while the intensity increases by 6.2-15%. The characteristics of this invention are high density, low cost, easy operation and that the lamination crack is not easy to happen. So it can largely improve the density and intensity of stainless steel powder composite parts' green ware body. In a word, it can be widely used in the parts production of mechanics, car and chemical industry.

Owner:SOUTH CHINA UNIV OF TECH

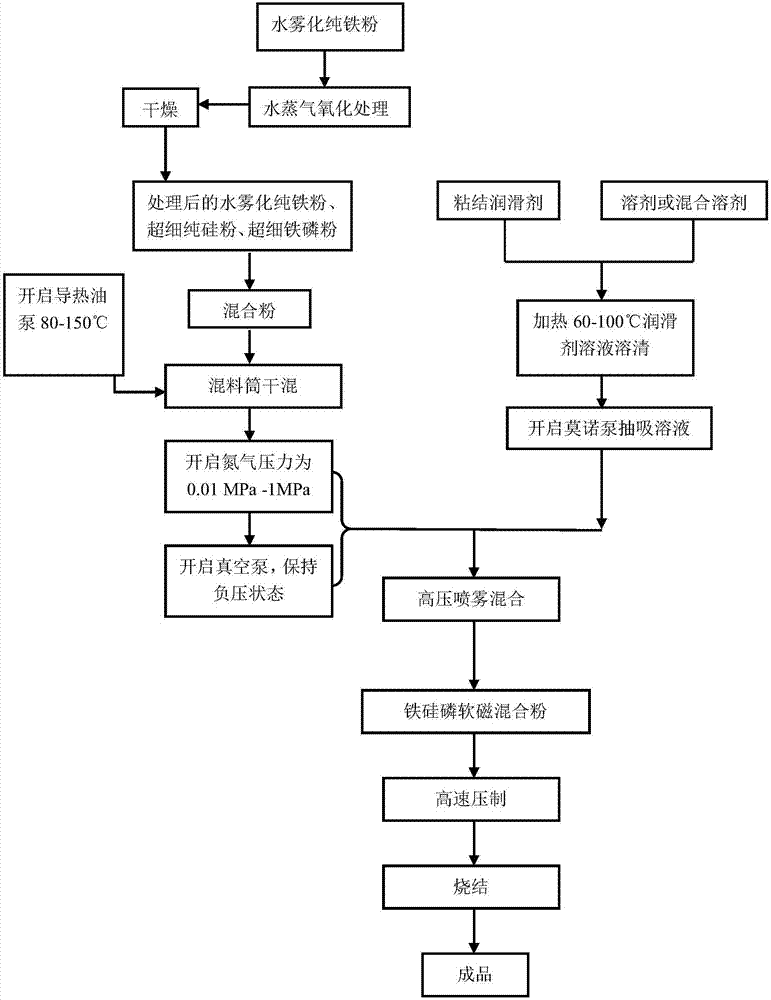

Preparation method of sintered iron powder base soft magnetic composite

ActiveCN107256752APrevent oxidationImprove permeabilityTransportation and packagingMetal-working apparatusWater vaporAlloy

The invention provides a preparation method of a sintered iron powder base soft magnetic composite, and belongs to the technical field of soft magnetic composites. The technological process includes the steps that initially, pretreatment is conducted on water atomized iron powder by means of high-temperature steam treatment, then cementation treatment is conducted by means of a double tapered spraying blender, a binder solution is atomized and evenly sprayed on materials continuously tumbling under the effect of a high-pressure gas, ultrathin pure silica powder and ultrathin iron-phosphorus alloy powder evenly adhere to the surfaces of iron powder particles, and sintered iron base powder is obtained. High-density compact is prepared by high-speed compacting through a warm mold with the mold wall lubricated, then fast sintering densification at low temperature is conducted, and finally an iron-silicon-phosphorus soft magnetic composite is obtained. The sintered iron powder base soft magnetic composite has the advantages of high magnetic permeability, low eddy-current loss and high strength, and is suitable for high-frequency application.

Owner:UNIV OF SCI & TECH BEIJING

Process

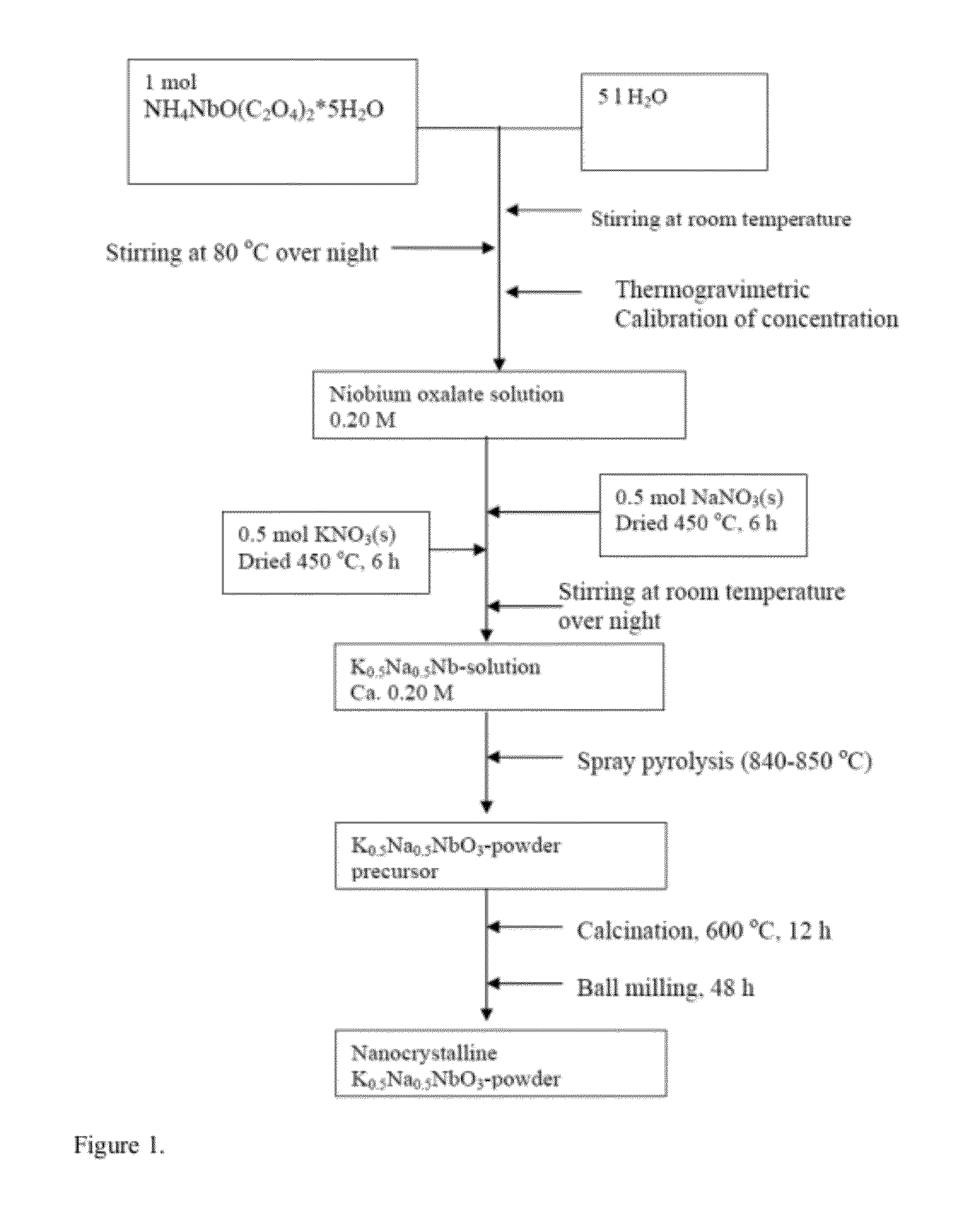

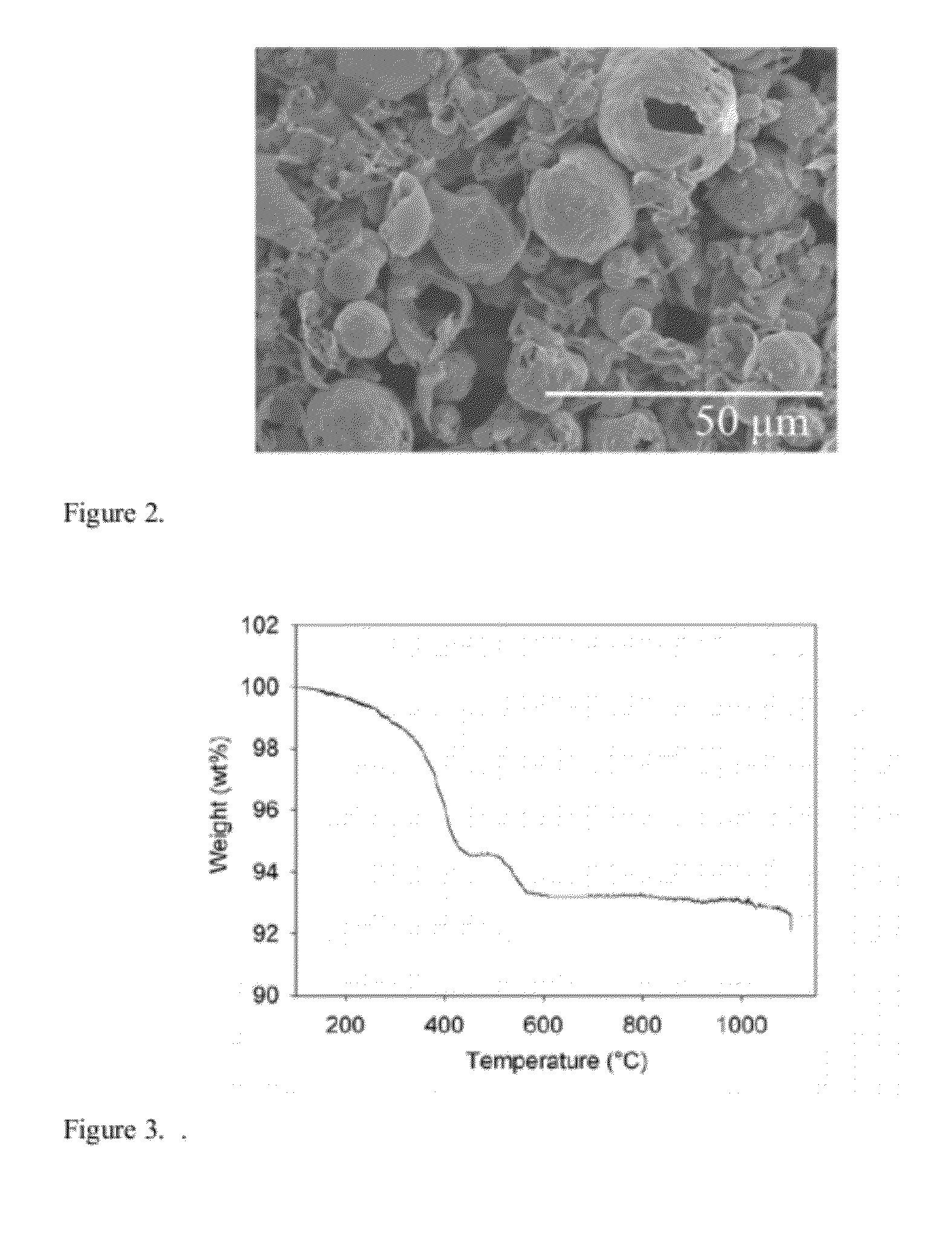

ActiveUS20120091389A1Improve propertiesHigh densityTantalum compoundsAlkali metal oxidesAlkaline earth metalNiobium

A process for the preparation of a niobium compound of formula (I):DαNbβEγO3-δ (I)whereinD is an alkali metal (e.g. Li, Na, K, Rb, Cs and / or Fr), alkaline earth metal (such as Ba, Ca, Mg and / or Sr), La and / or Bi and may be present as a mixture of two or more metals;E is Ta, Sb and / or Fe and may be present as a mixture of two or more metals;α is a positive numberβ is a positive numberγ is zero or a positive numberδ is a number 0≦δ≦0.5;and wherein the formula (I) has the perovskite or tungsten bronze structure;comprising spray pyrolising a solution, for example an aqueous solution, comprising metal (D) ions, Nb ions and if present, metal (E) ions.

Owner:CERPOTECH

Method for improving iron powder forming property

A method for improving an iron powder forming property belongs to the technical field of powder metallurgy forming. Pressed blank density can be increased by using good lubricating performance of sulfide. Iron powder and ferrous sulfide powder are mixed in a ball mill and annealed in a hydrogen furnace after being mixed evenly, and the ferrous sulfide is distributed on the surface of the iron powder evenly. In a pressing process, the ferrous sulfide has a lubricating effect, friction condition among powder particles is improved, the forming property is improved, and a blank with the density as 7.2g / cm<3>-7.6g / cm<3> can be obtained. The method has the advantages that the iron powder forming property is good, the blank with higher density can be obtained under low pressing pressure, loss of a grinding tool is reduced, simultaneously sulfur does not affect the performance of iron-based parts, and the process is simple and suitable for industrialized production.

Owner:UNIV OF SCI & TECH BEIJING

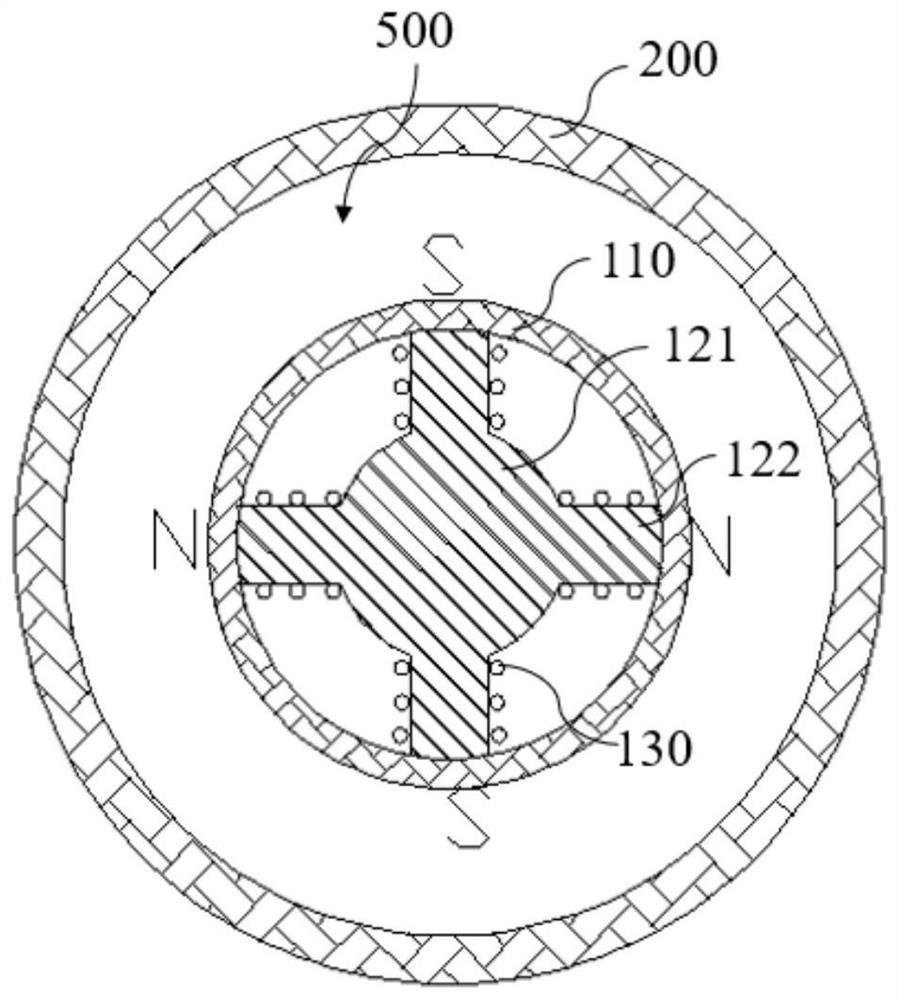

Anisotropic inner circle orientation multi-pole magnetic ring and mold and preparation method thereof

InactiveCN112086259ANo flux leakageQuiet and smooth operationPermanent magnetsInductances/transformers/magnets manufactureCopper wireElectric machinery

The invention discloses an anisotropic inner circle orientation multi-pole magnetic ring and a mold and a preparation method thereof, and belongs to the field of magnetic ring manufacturing. The multi-pole magnetic ring is an anisotropic 2n-pole magnetic ring with an oriented inner circle, n is a natural number, and the waveform of a magnetic circuit on the surface of the inner circle of the magnetic ring is a sinusoidal waveform; the mold comprises a core rod, an outer cylinder, an upper pressing head and a lower pressing head, and the core rod, the upper pressing head, the lower pressing head and the outer cylinder are matched and sleeved to form a mold cavity. The core rod comprises a sleeve and a magnet yoke, the magnet yoke comprises a base body and protruding parts, 2n protruding parts are distributed on the side face of the end, stretching into the upper pressing head, of the base body in the circumferential direction, copper wires are wound around the protruding parts respectively, and the protruding parts are sleeved with the sleeve in a matched mode. The preparation method comprises the following steps of: filling magnetic powder into the mold cavity, pressing the magnetic powder, electrifying a copper wire, applying a direct-current or pulsed magnetic field to the magnetic powder, orienting the magnetic powder, sintering, grinding and magnetizing to obtain the anisotropic inner circle orientation multi-pole magnetic ring. The multi-pole magnetic ring is directly manufactured into an integral stator magnetic ring, and stable and quiet operation of a motor is facilitated.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

Preparation method of silicon carbide ceramic pot using graphene to enhance heat conductivity

The invention discloses a preparation method of a silicon carbide ceramic pot using graphene to enhance heat conductivity. The preparation method comprises the following steps of according to scientific and reasonable component proportional ratio, compounding silicon carbide micropowder, boron carbide micropowder, liquid phenolic resin, and graphene component; performing ball milling, granulating, isostatic pressing forming, non-pressure sintering and the like, so as to obtain the silicon carbide ceramic pot. The silicon carbide ceramic pot has the advantages that the density of a prepared blank is large, the uniformity is good, the strength is high, and the sintering can be performed through simple drying; by adopting the non-pressure sintering, the energy consumption is decreased. The preparation method has the advantages that the method is simple, the industrial control is convenient, the raw material cost is low and the obtaining is easy, and the non-toxic and non-harmful ceramic pot which can be in direct contact with food can be prepared; the heat conductivity is higher, the boiling time of foods is accelerated, and the energy-saving effect is realized.

Owner:安徽省含山瓷业股份有限公司

Method utilizing powder metallurgy friction reducing materials to manufacture gears

InactiveCN110004373AHigh oil contentHigh hardnessTransportation and packagingMetal-working apparatusCeriumTin

The invention discloses a method utilizing powder metallurgy friction reducing materials to manufacture gears. Surface layer materials including graphite, molybdenum, titanium, copper, cerium dioxide,zinc stearate, tin and iron are uniformly mixed by a ratio. Base body materials including nickel, molybdenum, titanium, graphite, a lubricating agent, a sintering aid and iron powder are uniformly mixed after being previously dispersed. Then, the surface layer materials and the base body materials which are mixed together are sequentially put in the same mould, and a green is pressed at 60-120DEGC under the pressure of 500-600Mpa. Low-temperature pre-sintering and high-temperature sintering are carried out under the protection of hydrogen and argon. Then, oil immersion is carried out, and afinished product is finally obtained. The finished product comprises a surface layer and a base body layer, the base body layer is high in density, high in strength and high in hardness, has high carrying capability and is used for carrying, the surface layer is a porous layer and provides a lubricating function, and at the same time, TiC particles produced on the surface layer ensure the strengthand hardness of the surface layer.

Owner:益阳市再超粉末冶金有限公司

Method for preparing tungsten slab by low-temperature sintering

ActiveCN105478745AWell mixedHigh sintering activation energyTransportation and packagingMetal-working apparatusHigh densityHydrogen atmosphere

The invention discloses a method for preparing a tungsten slab by low-temperature sintering. The method comprises the following steps: (1) mixed tungsten powder is prepared; (2) the mixed tungsten powder is pressed to a slab by a cold isostatic pressing mode; and (3) under hydrogen atmosphere, the slab is heated and sintered, and is naturally cooled to obtain the tungsten slab. The method uniformly mixes the tungsten powder with three particle size ranges in proportion; on the one hand, excellent filling capacity is realized, higher pressing blank density is obtained, and higher sintering density is obtained; and on the other hand, quick actuation of densification process at a lower temperature is guaranteed, and the highest sintering temperature and insulation time are reduced; and in addition, through controlling the slab sintering temperature and time, the phenomenon of difficult elimination of a core hole of the sintered slab caused by the surface dentification speed of the sintered slab far faster than the core dentification speed due to excessive fast heating speed or shorter insulation time in medium-low-temperature phase can be prevented, and each part of the slab has better structure uniformity and higher density.

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

Method for recycling cadmium from metallurgical cadmium-contained dust and device for recycling cadmium from cadmium-ammonia solution

ActiveCN108220999AReduce cleaning burdenImprove qualityPhotography auxillary processesElectrolysis componentsDistillationImpurity ions

The invention discloses a method for recycling cadmium from metallurgical cadmium-contained dust and a device for recycling cadmium from a cadmium-ammonia solution. The metallurgical cadmium-containeddust is subject to ammoniacal circular leaching, when the lead / cadmium molar ratio in the solution is smaller than 0.01, the circular leaching process is ended; after leaching is finished, liquid solution separation is carried out, and the cadmium-ammonia solution is obtained; the proper amount of vulcanizing agent is added to enable impurity ions in the cadmium-ammonia solution to be subject tovulcanization precipitation separation. After impurity removal, liquid is placed in an ultrasonic enhancing electric strengthening replacement cadmium extraction key device to be subject to efficientcadmium extraction, and high-grade sponge cadmium and zinc-ammonia solution can be obtained. The sponge cadmium can be directly used for briquetting distillation or fusion casting-electrolytic refining to obtain high-purity cadmium. The zinc- ammonia solution can be directly turned into an electric zinc system to produce electric zinc.

Owner:CENT SOUTH UNIV

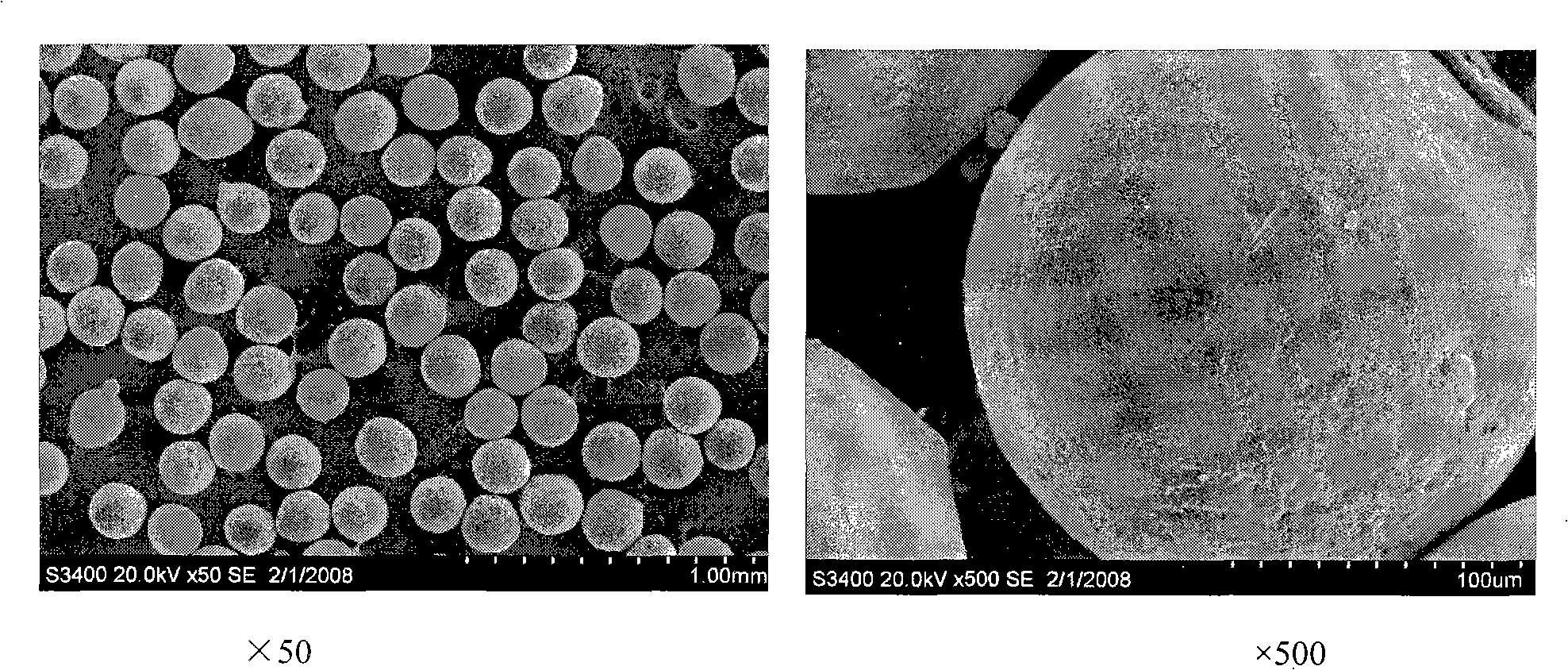

99%-above alumina granulating powder and preparation method thereof

The invention relates to 99%-above alumina granulating powder and a preparation method thereof. The 99%-above alumina granulating powder comprises the following components in parts by weight: 100-200 parts of high-aluminum alumina balls, 50-150 parts of a calcined material CT-3000SG, 1-5 parts of a binder, 0.1-1 part of a dispersant, 0.1-1 part of a demolding agent, 0.1-1 part of yttria, 0.1-1 part of magnesia and 50-150 parts of deionized water. The preparation method comprises the following steps: carrying out ball milling, sieving after pulp is obtained, stirring, and processing with magnets; carrying out centrifugal spraying granulation; removing coarse and fine particles from granulated powder by virtue of a sieve, then removing iron and impurities, and finally homogenizing. The granulating powder is low in water content and high in apparent density; after blank molding, a green body is high in density, good in stability and tenacity and excellent in post-machining performance and does not easily collapse from corners; the preparation method is simple in process and low in cost and has good application prospect.

Owner:SHANGHAI COMPANION PRECISION CERAMICS

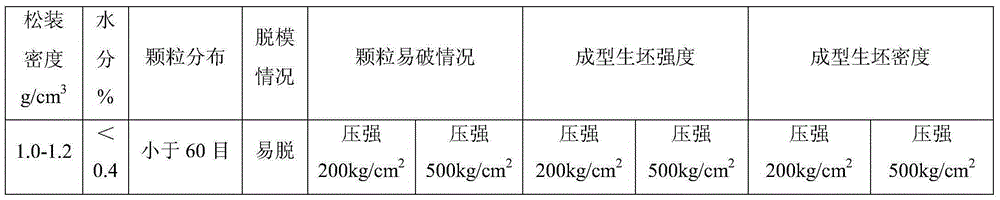

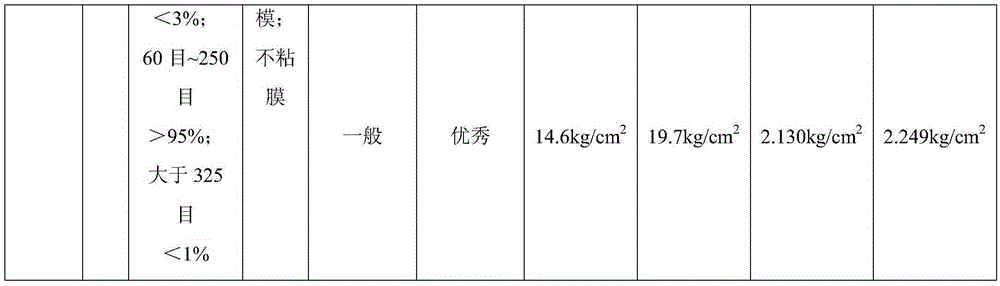

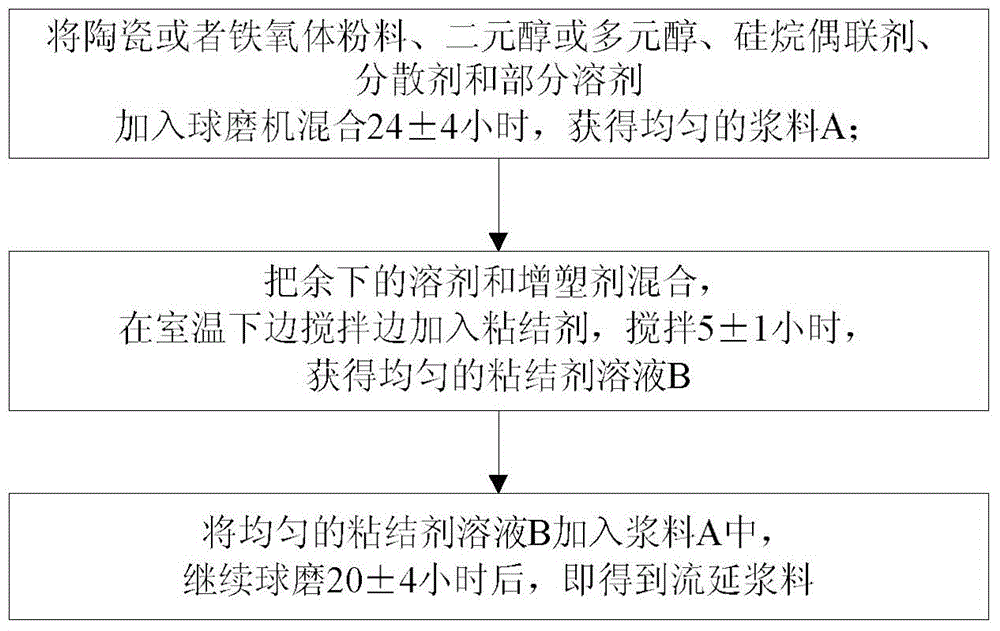

Cast film slurry of ultrathin lamination flaky inductor and manufacturing method for cast film of ultrathin lamination flaky inductor

InactiveCN104961471AGood effectSolve the problem of sharp performance degradationSolventSlurry viscosity

The invention provides a cast film slurry of an ultrathin lamination flaky inductor and a manufacturing method for a cast film of the ultrathin lamination flaky inductor. The cast film slurry comprises ceramic or ferrite powder, dihydric alcohol or polyhydric alcohols, a silane coupling agent, a dispersing agent, a plasticizer, binders and a solvent. By adding hexylene glycol, the hexylene glycol and a boron-containing sintering aid are subject to complexing reaction, so the problems of rapidly increased slurry viscosity and rapidly deteriorated diaphragm performance caused by addition of boron are solved; combining between the power and the binder as well as between the binders can be enhanced by adding the silane coupling agent, so the slurry viscosity is reduced, the dispersion is excellent, the diaphragm green-pressing density is increased, ductility is enhanced, and a diaphragm thinning effect is more obvious.

Owner:SHENZHEN GUDIAN ELECTRONICS

Method for increasing density of stainless steel powder metallurgy part

The invention discloses a method for increasing the density of a stainless steel powder metallurgy part. The method comprises the following steps of: uniformly mixing 70-90% by mass of stainless steel powder with particle size of 44-75mum and 10-30% by mass of stainless steel powder with particle size of less than 44mum; taking a lithium stearate absolute ethyl alcohol suspension as a die wall lubricant; then respectively heating the mixed powder and the die to 120-160 DEG C; and finally, pressing at high speed of at least 8m / s to form. The density of a green body of the stainless steel powder metallurgy part is increased by 0.04-0.08g / cm<3> as compared with the density of the green body of the stainless steel powder metallurgy part pressed by adopting single 44-75mum warm powder, increased by 0.4g / cm<3> as compared with the density of the green body of the stainless steel powder metallurgy part pressed at room temperature and high speed and increased by 0.7 g / cm<3> as compared with the density of the green body of the stainless steel powder metallurgy part pressed by adopting a warm-pressing technology. In the invention, a warm powder high-speed pressing technology is successfully applied to stainless steel parts, the aim of manufacturing high-performance parts with low cost is achieved, and the development of the high-speed pressing technology in the powder metallurgy field is promoted.

Owner:广州市华维诺科技有限公司

Preparing method for TiC matrix steel base steel bond hard alloy

InactiveCN106811659AUniform pore size distributionImprove uniformityTransportation and packagingMetal-working apparatusCemented carbideSolvent

The invention relates to a preparing method for a TiC matrix steel base steel bond hard alloy. The preparing method includes the following steps that titanium carbide powder and matrix steel matrix powder are weighed according to the proportion, alloy powder is put into a ball grinding machine to be mixed and smashed, added absolute ethyl alcohol is a process control agent, and the wet mixed powder is put into a vacuum drying box to be dried after ball grinding and is used for standby use after drying; an organic monomer and an initiator are added into a solvent to prepare pre-mixed liquid; an additive improving slurry fluidity and dispersity is added; a catalyst and a pH modifier are added and are evenly stirred, and slurry is obtained; and the slurry is injected into an injection and coagulation die, vacuum suction or vibration gas removing is conducted, after the slurry is cured to be formed, a blank is put into the vacuum drying box to be dried, the dried blank is subjected to integrated degumming and sintering in a vacuum sintering furnace, and the steel bond hard alloy is prepared. The preparing method has the beneficial effects that the technology is simple, the cost is relatively low, and parts large in size and complex in shape are easy to prepare on the basis that the macro performance of the steel bond hard alloy is ensured.

Owner:丹阳惠达模具材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com