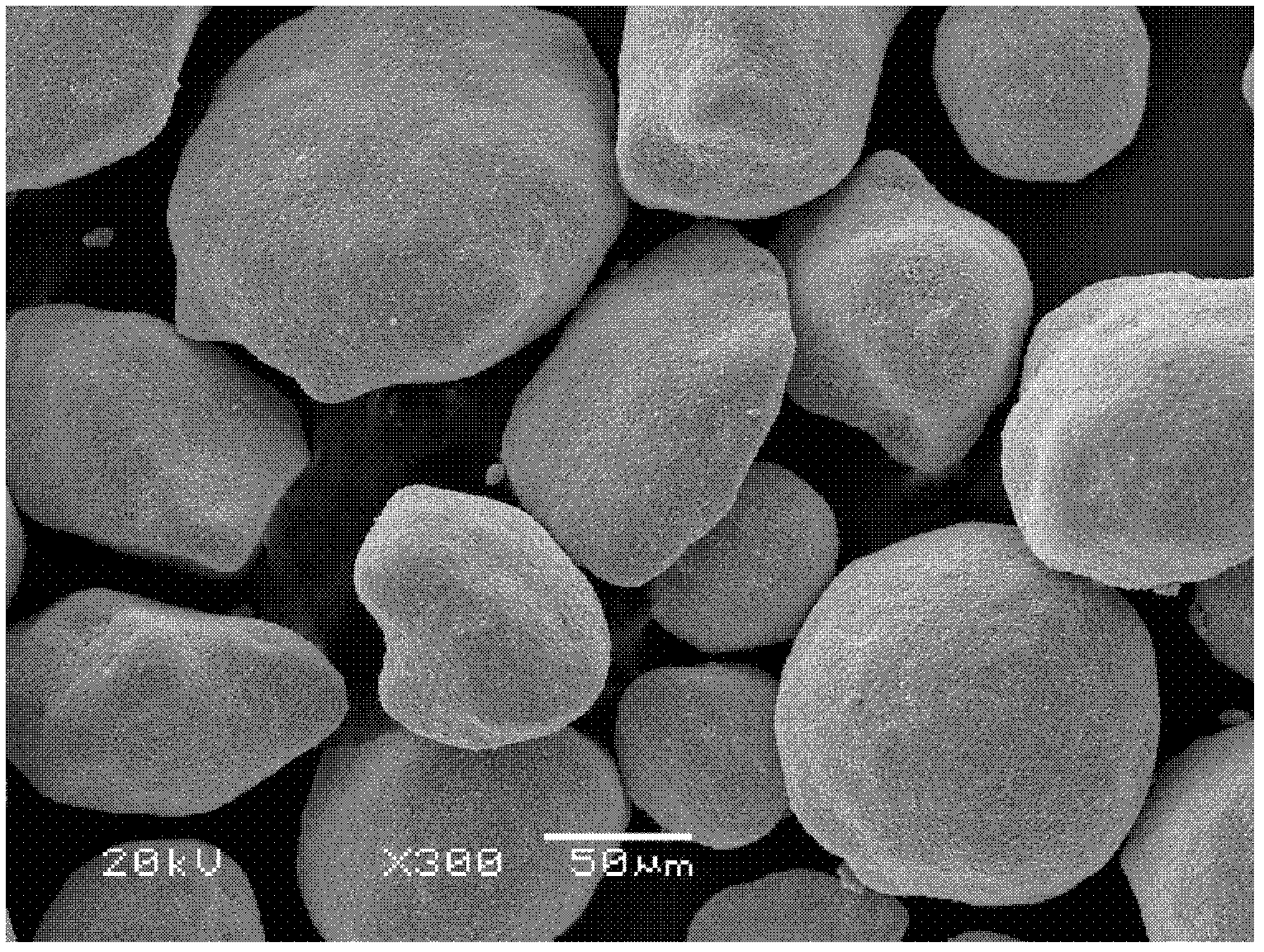

Preparation method of zinc oxide-based tubular rotary target material

A technology of rotating target and tubular base, which is applied in the field of preparation of zinc oxide-based tubular rotating targets, can solve the problems of reduced efficiency, deterioration of coating film quality, and easy generation of abnormal discharge, etc., to eliminate internal stress, reduce volume shrinkage, and avoid Density reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

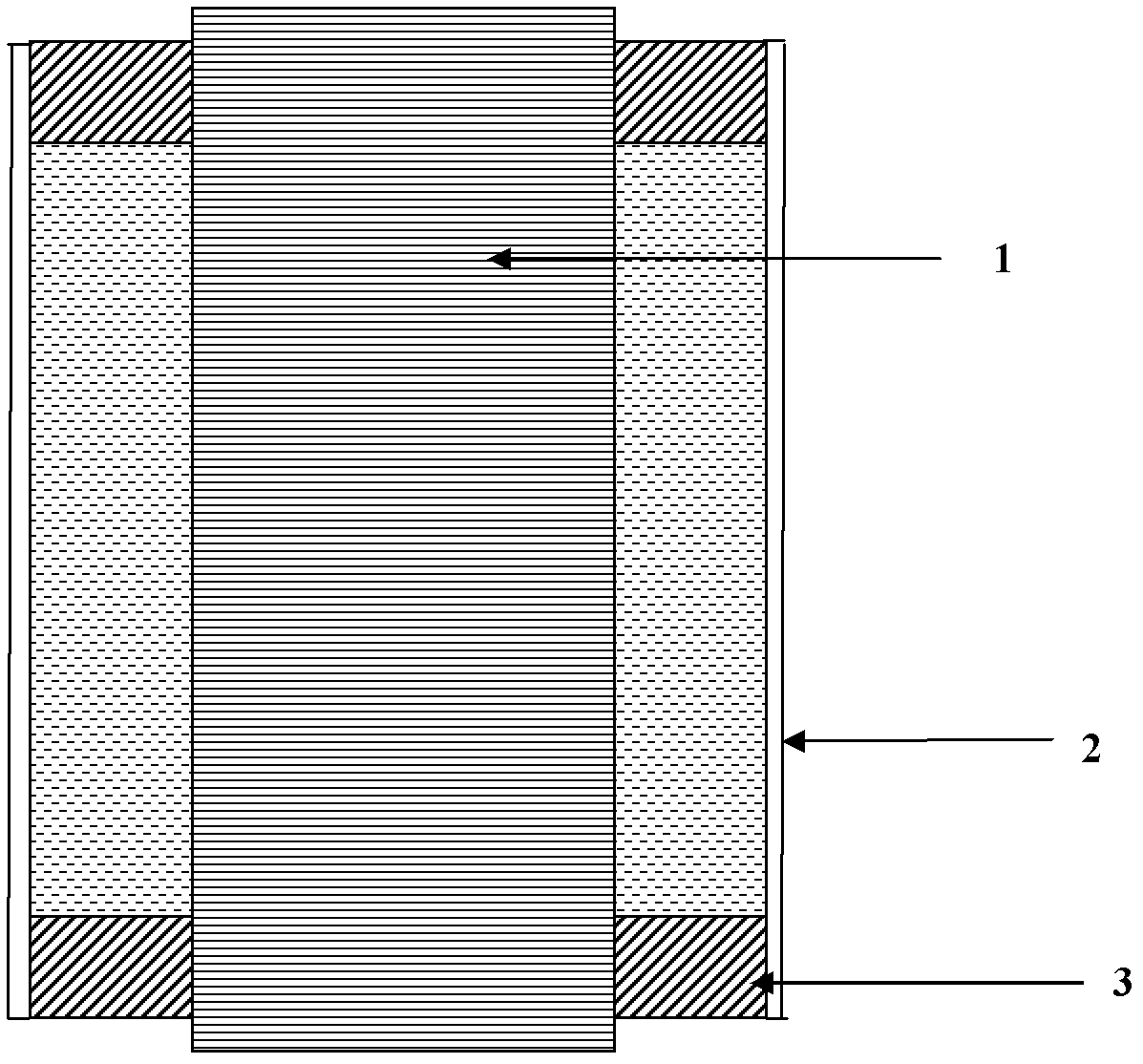

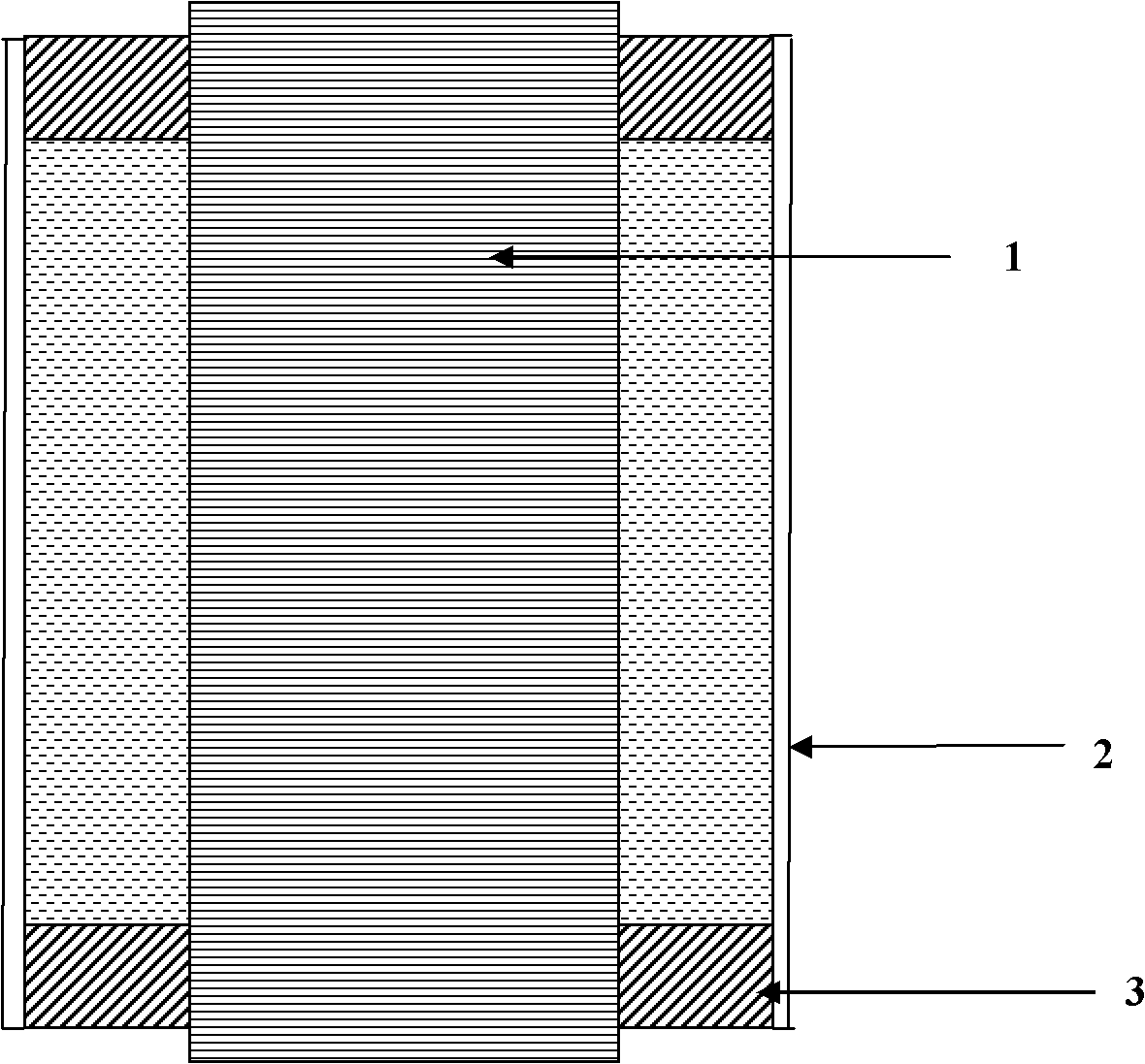

Image

Examples

preparation example Construction

[0018] The preparation method of the present invention is completed according to the following steps:

[0019] 1. Preparation of zinc salt solution: Weigh quantitative metal zinc (≥4N) and dissolve it completely with superior pure 1+1 nitric acid and dilute it with deionized water to [Zn 2+ ] concentration is 1.5-2.0mol / L;

[0020] 2. Preparation of aluminum salt solution: according to the ratio of Zn: Al=93-99: 1-7 (at%, atomic ratio), weigh Al(NO 3 ) 3 9H 2 O (excellent grade), completely dissolved in absolute ethanol. If preparing pure zinc oxide powder, this step is omitted;

[0021] 3. Precipitant solution preparation: weigh quantitative NH 4 HCO 3 (excellent pure), completely dissolved in deionized water, and prepared into a 25% (wt / v%) solution;

[0022] 4. Transfer the zinc salt solution and aluminum salt solution into the reaction kettle, stir for 20 minutes, and adjust the temperature of the reaction solution to 30-45°C.

[0023] 5. At a stirring speed of 300...

Embodiment 1

[0030] Weighing: Metal zinc 9830g (≥4N) is completely dissolved with superior grade pure 1+1 (v / v%) nitric acid, and diluted with deionized water to [Zn 2+ ] Concentration is 1.2mol / L, is mixed with zinc salt solution; Weigh Al(NO 3 ) 3 9H 2 O (excellent grade pure) 2347g, add 10L absolute ethanol to dissolve completely, be mixed with aluminum salt solution; Precipitant solution: weigh NH 4 HCO 3 (Excellent grade pure) 40000g, prepared into 25% (wt / v%) solution with deionized water.

[0031] The zinc salt solution and the aluminum salt solution were transferred into the reaction kettle, stirred for 20 minutes, and the temperature of the reaction solution was adjusted to 35°C. At a stirring speed of 400 rpm, add the precipitant solution into the mixed solution of zinc salt and aluminum salt at a rate of 10 L / min, adjust the reaction pH value to 7.0-7.8, and react for 60 minutes to obtain a reaction product. Transfer the reaction product to a ceramic membrane washing filter...

Embodiment 2

[0035] Weighing: Metal zinc 10000g (≥4N) is completely dissolved with superior grade pure 1+1 (v / v%) nitric acid, and diluted with deionized water to [Zn 2+ ] Concentration is 1.2mol / L, is prepared into zinc salt solution; precipitant solution: weigh NH 4HCO 3 (Excellent grade pure) 40000g, prepared into 25% (wt / v%) solution with deionized water.

[0036] The zinc salt solution and the aluminum salt solution were transferred into the reaction kettle, stirred for 20 minutes, and the temperature of the reaction solution was adjusted to 40°C. At a stirring speed of 400 rpm, add the precipitant solution into the mixed solution of zinc salt and aluminum salt at a rate of 5 L / min, adjust the reaction pH to 6.5-7.0, and react for 60 minutes to obtain a reaction product. Transfer the reaction product to a ceramic membrane washing filter, and wash it repeatedly with deionized water until the conductivity of the washing supernatant is ≤20 μs, then stop washing. The obtained precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com