Method for the manufacturing of sintered metal parts having a densified surface

A technology of densification and parts, which is applied in the field of manufacturing sintered metal parts, can solve the problems of reduced tooth surface contact fatigue strength, reduced bending fatigue strength, and large energy consumption, so as to improve mechanical properties, reduce pressing steps, and increase surface densification effect of depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] The cylinders were pressed from a powder metallurgical composition comprising pre-alloyed powder Astaloy Mo with 0.3% graphite additive and an amide wax lubricant. In order to obtain a density higher than 7.2g / cm 3 The green body is pressed at high speed; in order to make the density up to 7.2g / cm 3 , using conventional uniaxial pressing. The pillars were sintered at 1120°C for 30 minutes in an atmosphere of 90% nitrogen and 10% hydrogen. Surface densification was performed by radial rolling, during which the diameter was reduced by 0.3 mm. Densification depth was assessed using image analysis and was defined as the shortest distance from the surface to the point at which the density had decreased to 98% of theoretical density.

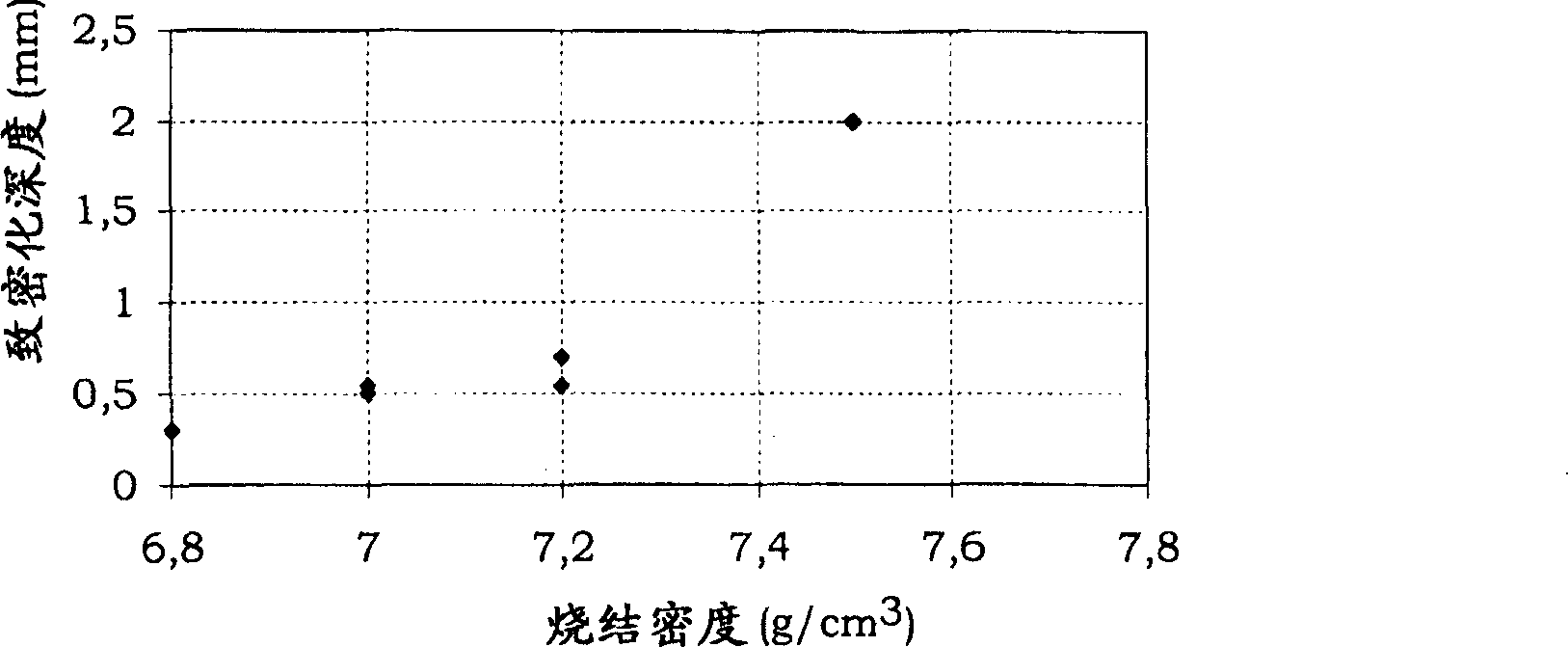

[0026] available from figure 1 The relationship between the sintered density of the blank and the densification depth obtained for the densified part is seen in .

example 2

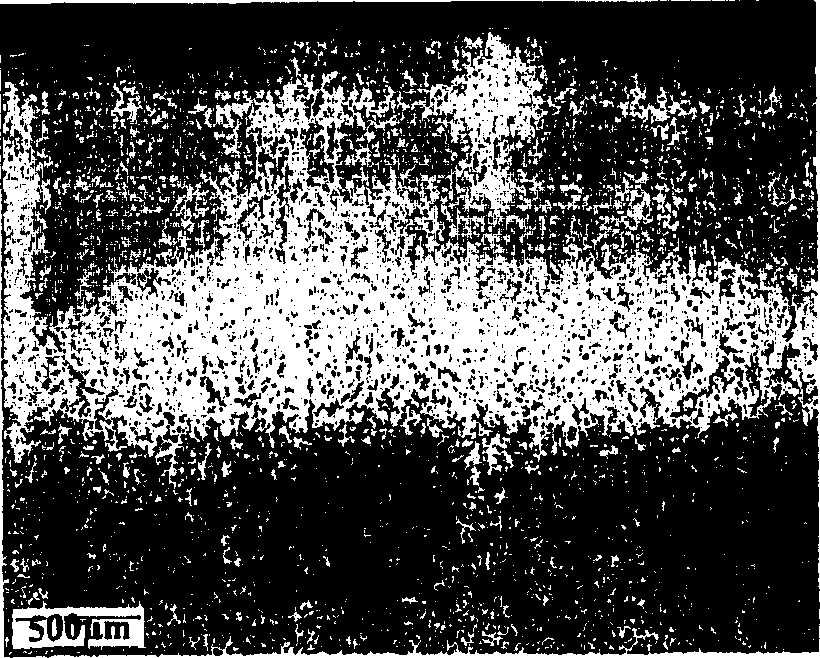

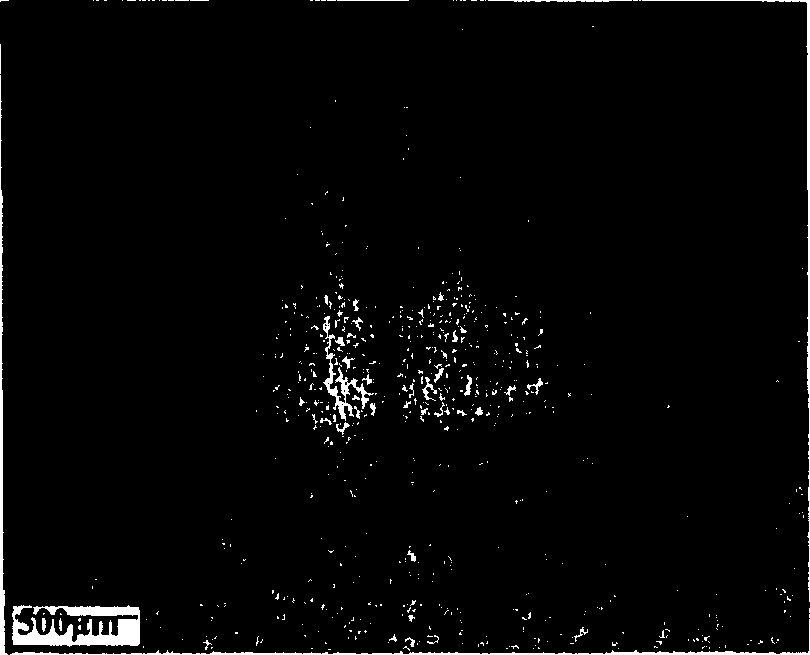

[0028] A photomicrograph of the pressed, sintered and surface-densified columns is shown in FIG. 2 . Figure 2a The columnar body in is pressed by conventional means to reach 7.0g / cm 3 and the obtained densification depth is 1 mm, while shown in Figure 2b The columnar body in it reaches 7.5g / cm through high-speed pressing 3 and a densification depth of 2 mm was obtained.

example 3

[0030] Cylindrical bodies pressed at high speed at 90 / 10N 2 / H 2 sintered at 1120°C for 30 minutes in an atmosphere of 1120°C, and then surface densified by rolling in a two-roll calender. The diameter is reduced by 0.3 mm during the rolling process. Polished cross-sections of the rolled cylinders were examined in a lightweight light microscope, and image analysis was used to assess the densification depth. The depth of densification obtained by rolling the cylinders is shown in Table 1 .

[0031] sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com