Material quantitative and shaping pressing device

A technology of pressing molds and pressing molding, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., which can solve problems such as time-consuming and labor-intensive, difficult to achieve quantitative automatic pressing, and no self-contained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

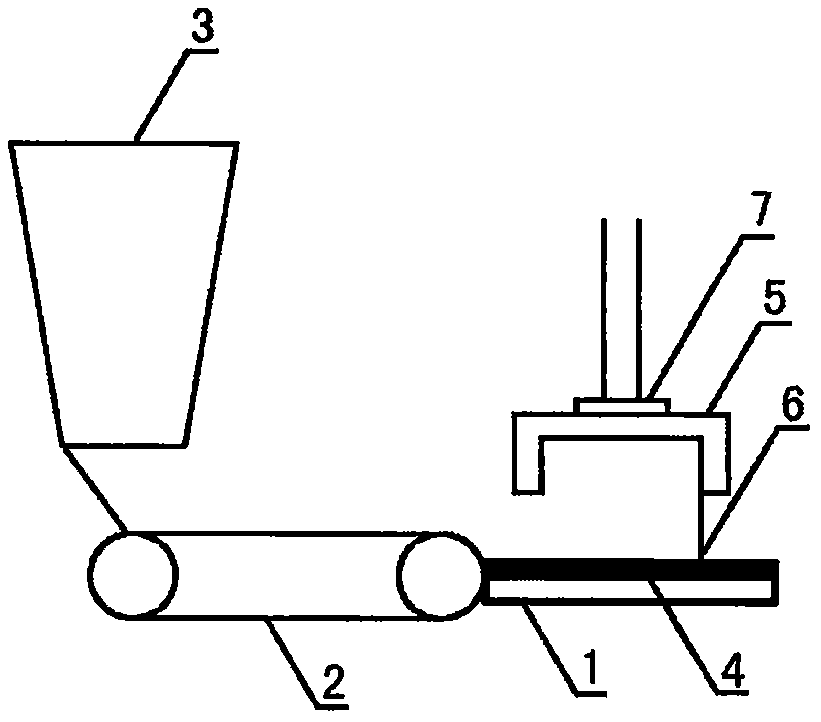

[0013] Embodiment: as shown in the accompanying drawing. The material quantitative setting and pressing device includes a base (1), an electric conveyor belt (2) is arranged on the left side of the base, and a grinder (3) is arranged on the left side of the electric conveyor belt (2), which can be placed when a large object is encountered. After entering for grinding, it is transported to the pressing place along with the conveyor belt.

[0014] The material quantitative shaping pressing device is provided with a weight measurement module (4) on the base, which can measure the weight of the pressing material above it.

[0015] The material quantitative setting and pressing device is provided with a pressing mold (5) above the base, which can carry out setting and pressing of the material.

[0016] The material quantitative shaping pressing device is provided with a baffle plate (6) on the lower side of the pressing mold (5), which can gather the material powder transported by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com