Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Reduce sintering shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

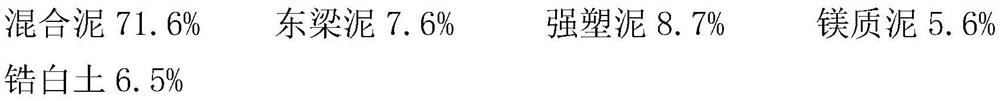

Ceramic rock plate and preparation method thereof

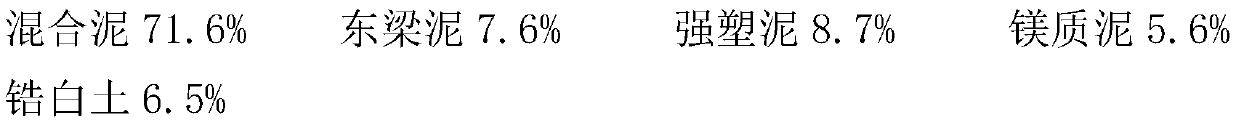

ActiveCN111470848AImprove plasticityGood molding effectCeramic materials productionClaywaresGlazeSpray dried

The invention relates to a ceramic rock plate and a preparation method thereof. A ceramic rock plate blank is composed of the following components in percentage by weight: 35-46.1% of mud; 50 to 60 percent of a water abrasive; 1-7% of a green body toughening material; 0.5 to 3 percent of a reclaimed material; and 0.1-0.8% of an additive. The preparation method comprises the following steps: preparing a green body, processing the green body, performing spray drying to prepare powder, performing dry pressing to form the green body (with a plane or concave-convex effect), drying, polishing the green body, blowing ash, spraying water, spraying white ink, spraying engobe, decorating patterns, decorating isolation glaze, decorating a transparent glaze layer, firing, polishing and edging.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +3

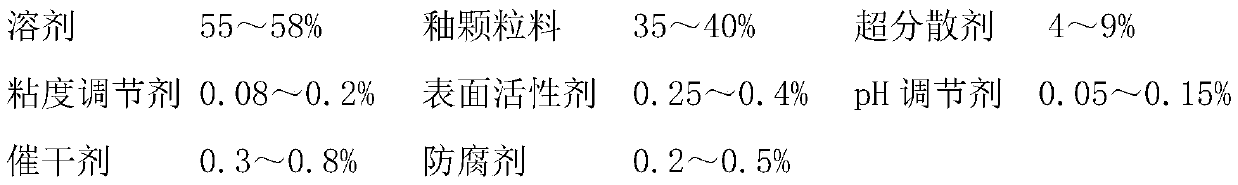

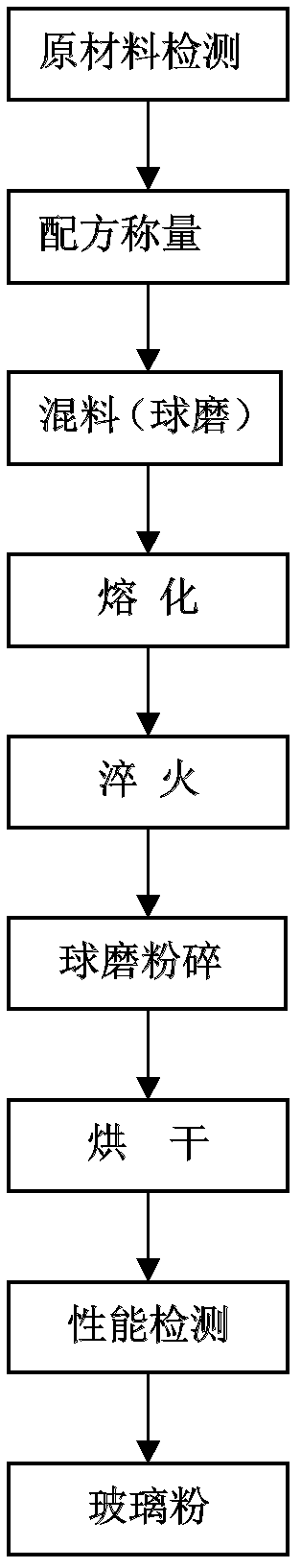

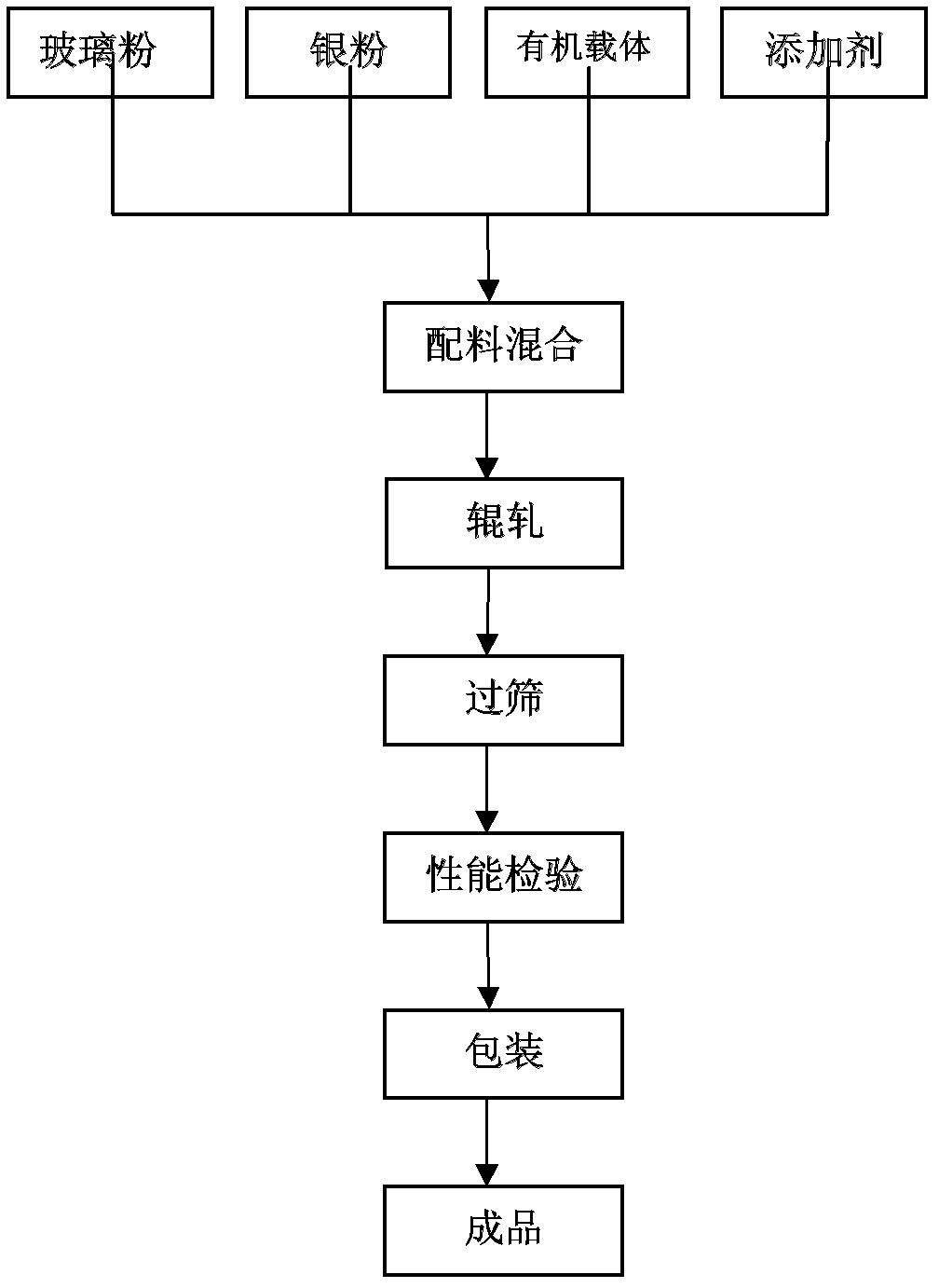

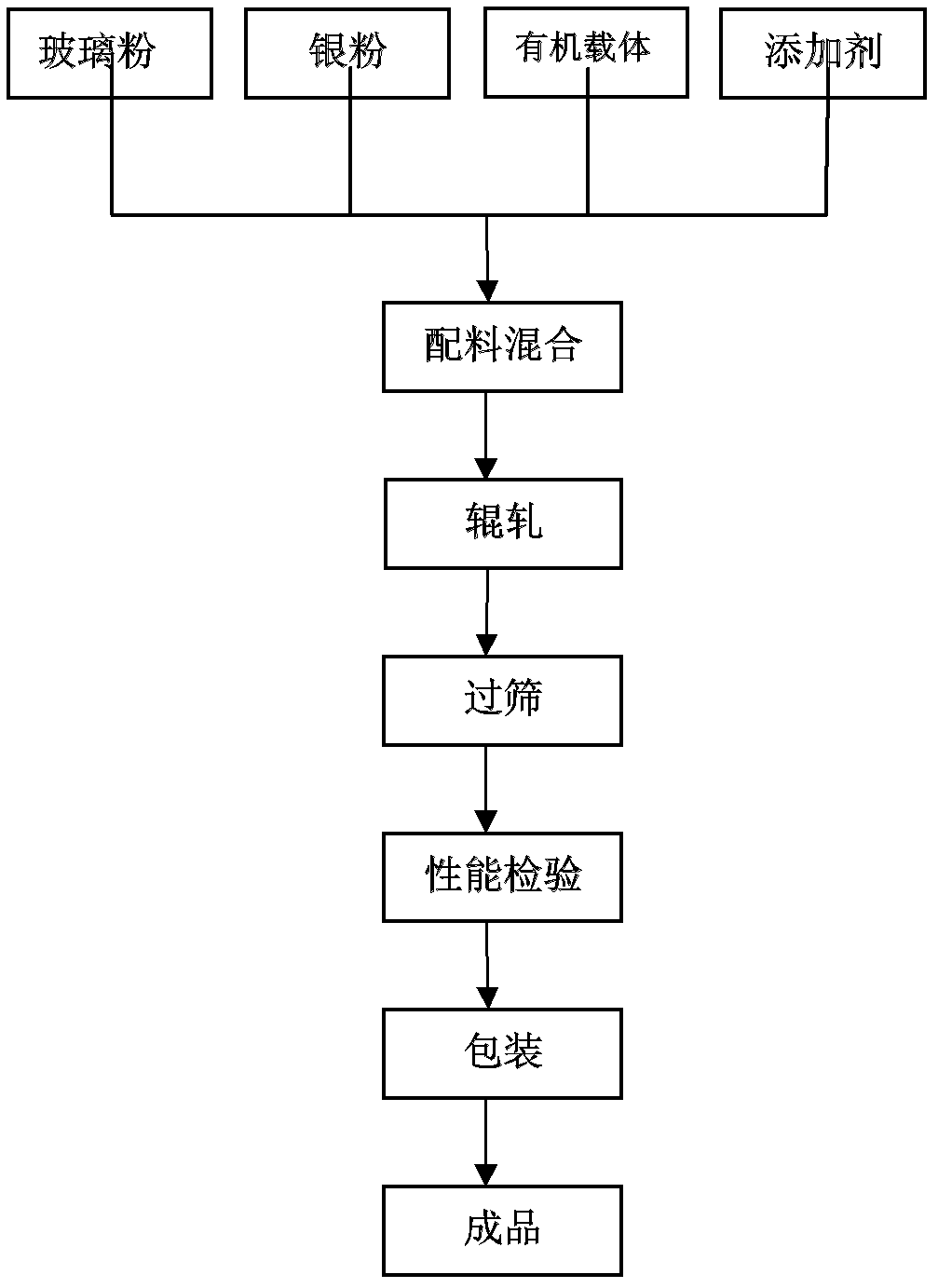

Environment-friendly lead-free semiconductor ceramic capacitive electrode silver paste and preparation method thereof

ActiveCN102568704ALow softening pointStrong adhesionFixed capacitor electrodesNon-conductive material with dispersed conductive materialCapacitanceEnvironmental resistance

The invention discloses a preparation method for an environment-friendly lead-free semiconductor ceramic capacitive electrode silver paste. The preparation method comprises the following steps of: (1) preparing glass powder, namely uniformly mixing the following components in percentage by mass: 20 to 30 percent of B2O3, 5 to 25 percent of SiO2, 50 to 70 percent of Bi2O3, 2 to 20 percent of Al2O3 and 1 to 2 percent of inorganic additive I, heating and ball-grinding until the particle size of the glass powder is less than 15 mu m, filtering and drying; (2) preparing an organic carrier; and (3) proportioning the following components in percent by mass: 50 to 75 percent of ultrathin silver powder, 4 to 10 percent of lead-free glass powder, 1 to 2 percent of inorganic additive II and 20 to 35 percent of organic carrier. The inorganic materials can meet a requirement of environment friendliness home and abroad; according to the adopted process, the stability and the consistency of the silver paste can be guaranteed; and the surface of a sintered silver layer is bright and compact, and has high continuity.

Owner:广东羚光新材料股份有限公司

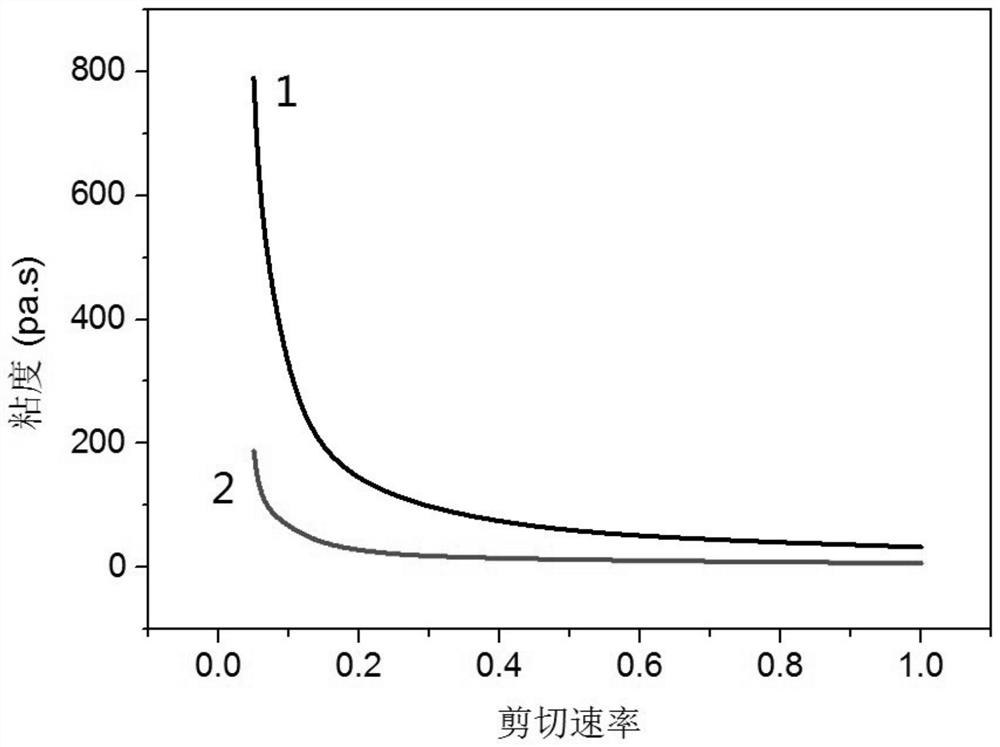

Silicon nitride ceramic slurry, preparation method of silicon nitride ceramic slurry and application of silicon nitride ceramic slurry in preparing silicon nitride cast film

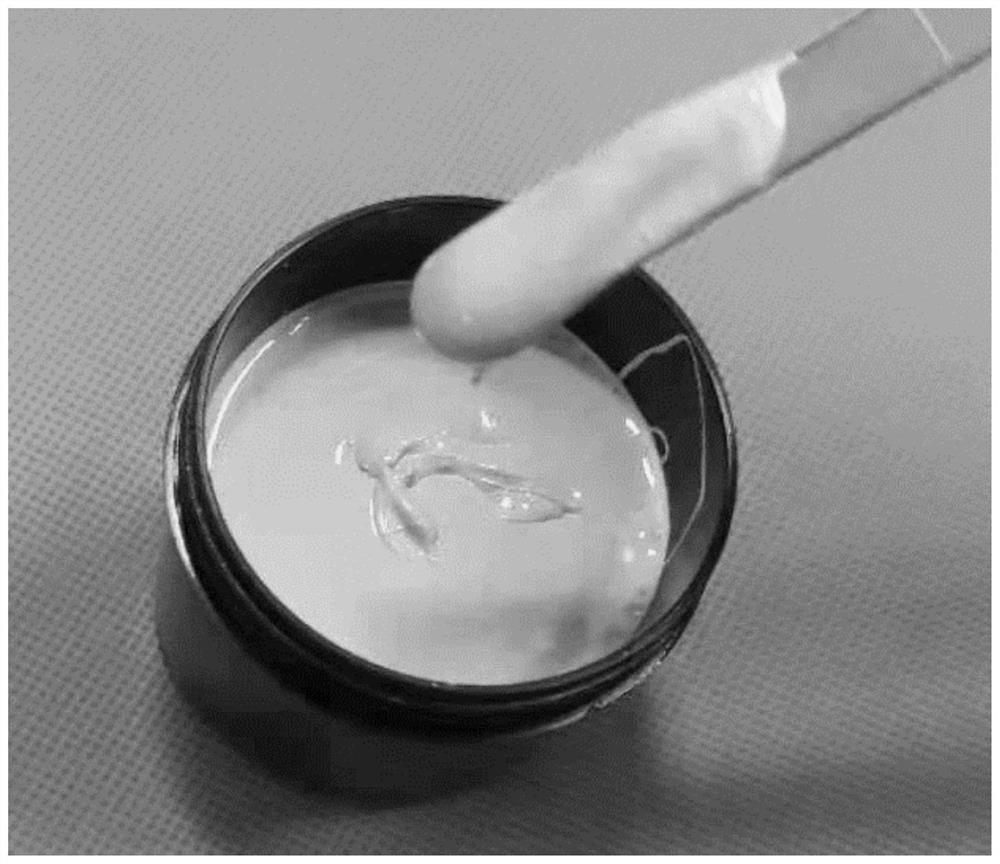

The invention provides silicon nitride ceramic slurry, a preparation method of the silicon nitride ceramic slurry and application of the silicon nitride ceramic slurry to preparation of a silicon nitride cast film. The preparation method comprises the following steps of mixing silicon nitride powder, a sintering aid, a dispersant and a solvent, performing first ball milling, then adding an adhesive and a plasticizer for secondary ball milling, and performing vacuum defoaming to obtain slurry, wherein the mass ratio of the silicon nitride powder, the sintering aid, the dispersant and the solvent is 100 to (5-15) to (49-67) to (2-3.5) to (10-20) to (10-40); and performing tape casting and drying on the slurry to obtain a smooth, uniform, dense, gentle and agreeable Si3N4 biscuit which is benefical to forming processing and sintering in a later period. The silicon nitride ceramic slurry obtained by the method is uniform, is low in viscosity, high in solid content, simple in preparation technology and liable to realize industrialization and is suitable for tape casting.

Owner:SHANGHAI UNIV

Grout silver paste applied to thick film circuit

InactiveCN101872654AImprove conductivityReduce sintering shrinkageSemiconductor/solid-state device detailsSolid-state devicesSilver pasteFrit

The invention discloses grout silver paste applied to a thick film circuit, which consists of 60 to 90 weight percent of conductive powder, 1 to 6 weight percent of frit and 10 to 35 weight percent of organic carrier, wherein the total weight of the conductive powder, the frit and the organic carrier is 100 percent. The conductive powder is the powder of gold, silver, palladium, copper, nickel, tungsten and manganese alloys or the mixed powder of the powder; and the grain diameter of the conductive powder is controlled to be 1 to 10mu m. The grout silver paste applied to the thick film circuit prepared by the invention has the characteristics of high electrical conductivity, low sintering shrinkage rate and good matrix matching performance and the using requirement of a grout process of the thick film circuit is met in the using process.

Owner:IRICO

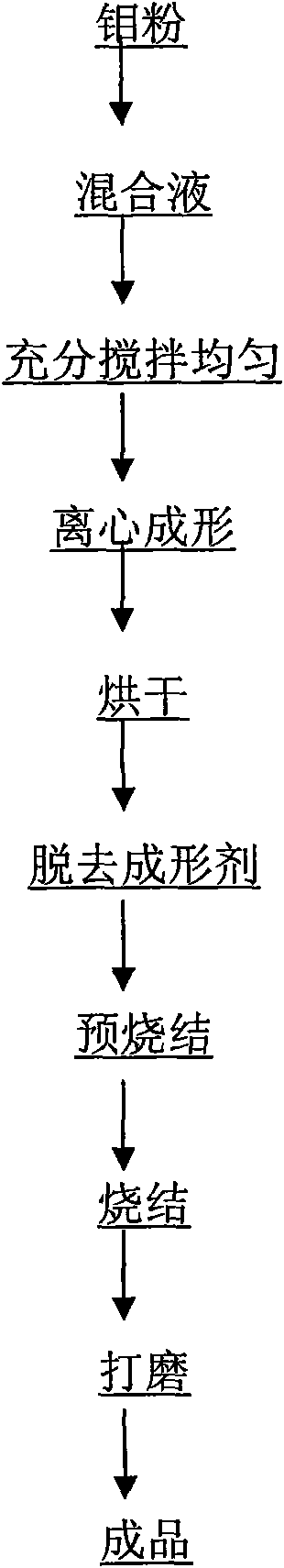

Method for preparing molybdenum tube

The invention relates to a method for preparing a molybdenum tube, in particular to a method for preparing a metal tube by a powder metallurgy method. The method is characterized by comprising the following steps: (1) evenly mixing a raw material molybdenum powder with water base adhesive solution; (2) placing the molybdenum powder and the water base adhesive solution in a centrifugal forming machine for forming; (3) drying a formed molybdenum tube blank; (4) degumming the dried molybdenum tube blank; (5) pre-sintering the degummed molybdenum tube blank; (6) sintering on the pre-sintered molybdenum tube at a high temperature; and (7) polishing the sintered molybdenum tube to obtain the molybdenum tube. By adopting the method of the invention, the preparation process of the molybdenum tubehas the advantages of easy control and simple, safe and reliable operation, thus being applicable to batch production; the preparation process can help flexibly control parameters such as diameter, wall thickness, length and the like of the molybdenum tube; and the prepared molybdenum tube has good uniformity, small sintered deformation quantity and small sintered shrinkage rate.

Owner:JINDUICHENG MOLYBDENUM CO LTD

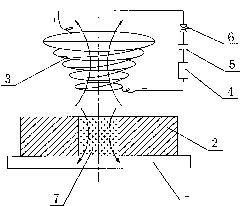

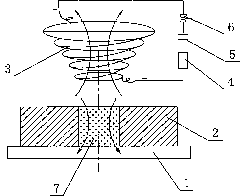

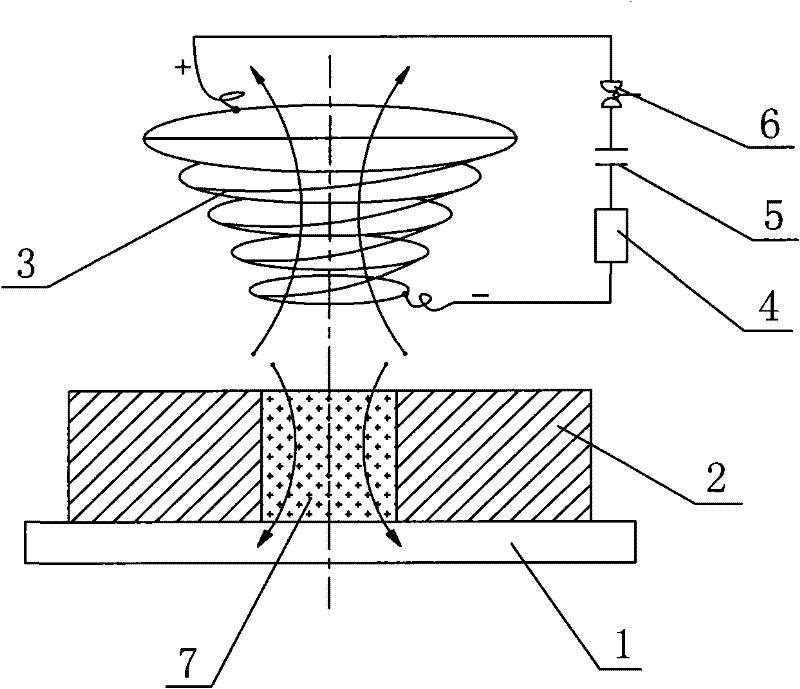

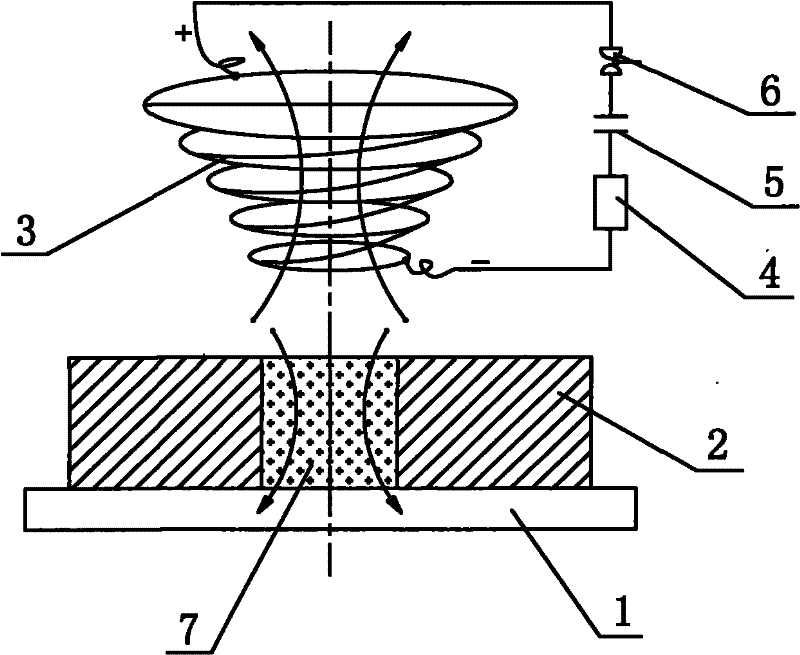

High-speed impact pressing method for metal powder

The invention discloses a high-speed impact pressing method for metal powder, which is characterized in that a die is arranged on a substrate first, a cavity is arranged on the die, a tower-shaped coil is fixed above the die, the tower-shaped coil is electrically connected with a discharge circuit, metal powder is filled in the cavity of the die, discharge processing is conducted to the tower-shaped coil, a pulsed magnetic field produced by the tower-shaped coil directly acts on the metal powder and the metal powder is pressed and formed. The invention has the advantages that the loading of impact stress waves to the metal powder is realized by using the action of electromagnetic force, the instant repetitive bidirectional compaction of the metal powder is realized by using the oscillation characteristics of the stress waves, the density of the pressed metal powder is high, the pressing time is short, the friction of the metal powder during pressing is reduced, the density distribution of the metal powder is even, the sintering shrinkage rate is reduced and the precision and the performance of parts are improved.

Owner:NINGBO UNIV

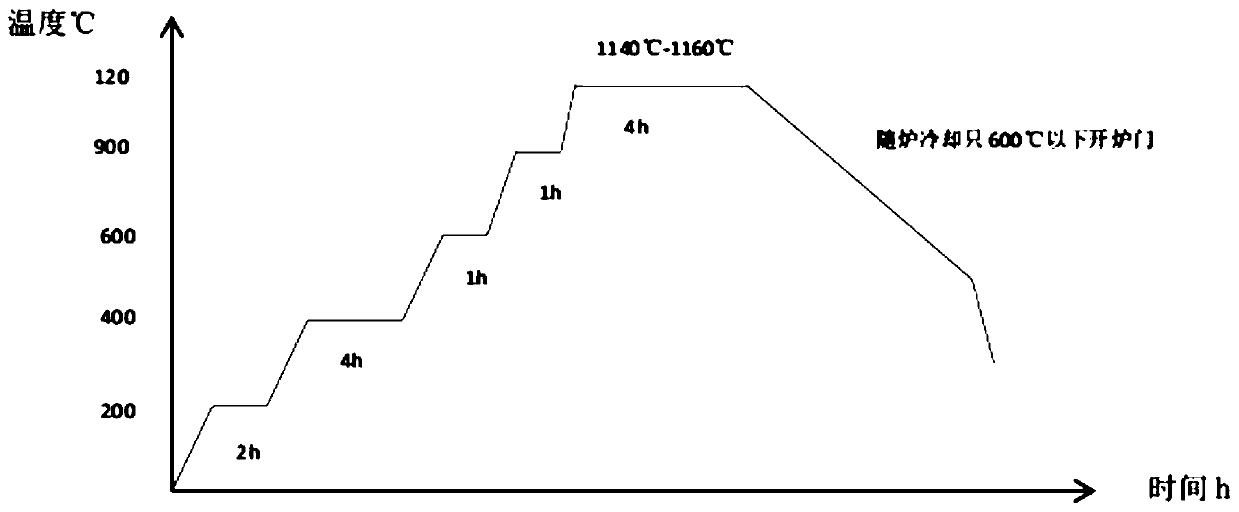

Sintering process for automobile ceramic sparking plug

InactiveCN104242068AHigh densityReduce sintering shrinkageCeramic shaping apparatusSparking plugs manufactureHigh pressureHot pressing

The invention relates to the technical field of ceramic part manufacturing, in particular to a sintering process for an automobile ceramic sparking plug. The sintering process comprises the five steps of isostatic compaction, abrasive machining, biscuit firing, glazing and high-pressure sintering. According to the sintering process, dry pressing molding is used for replacing a traditional slurry injection hot briquetting process, an isostatic press is used for conducting cold press molding on dry powder, and in the process engineering, the parameters such as the feeding amount of the dry powder, the heating temperature and time, the thickness of an enamel layer are continuously optimized. A formed sparking plug product is high in density, small in sintering shrinkage, stable in thermal performance, high in production efficiency and high in applicability.

Owner:东莞市品酷机动车配件实业有限公司

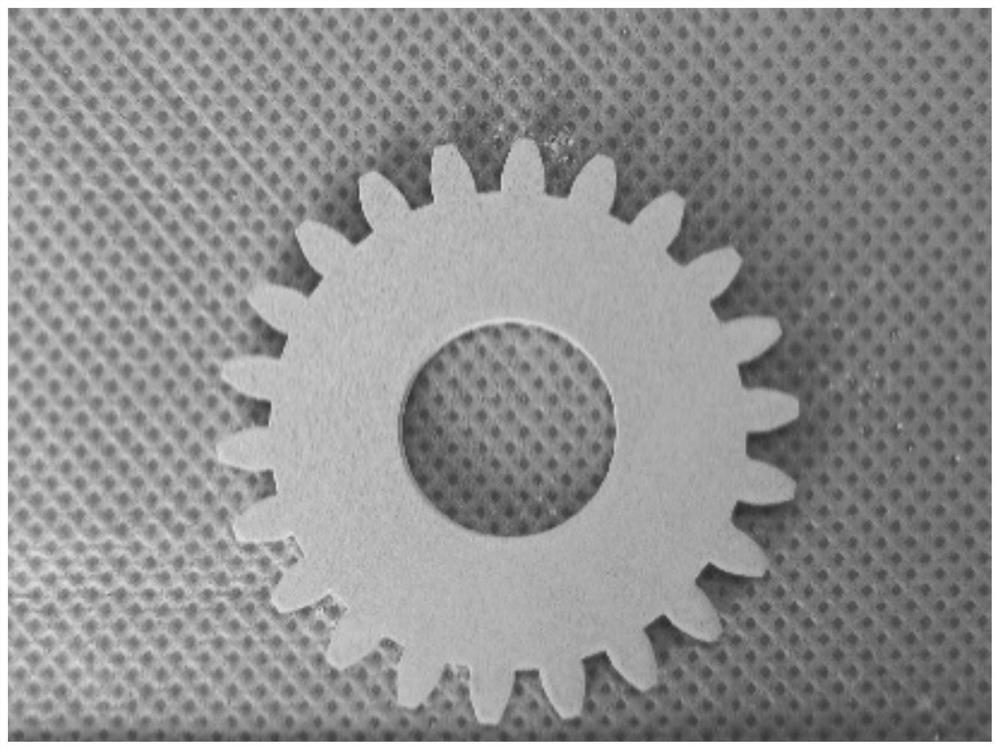

Warm-pressing process of powder metallurgy

The invention discloses a warm-pressing process of powder metallurgy. The warm-pressing process comprises the following steps of: a, weighing an alloy powder raw material, a lubricating agent and an additive; mixing the alloy powder, the lubricating agent and the additive in a weight ratio of (10-30): 1: 1 to form a mixed material; b, pressing the mixed material into a pre-formed blank; carrying out warm-pressing treatment on the pre-formed blank; controlling the temperature to 130-150 DEG C and controlling the time to 10-12 hours, wherein the pressing density of warm-pressing forming treatment is 7.5-8g / cm<3>; putting into a furnace to be sintered, wherein the sintering temperature is 1200-1400 DEG C; c, de-burring the sintered pre-formed blank; cutting and machining to form a rough product; and d, carrying out immersing treatment on the rough product; and carrying out surface steam treatment at the temperature of 420-550 DEG C to obtain a finished-product part. The process disclosed by the invention has simple steps; the pressing density is improved by adopting a warm-pressing forming treatment process and the cost of the warm-pressing process is only 1.25; the surface smoothness is good and the sintering shrinking percentage is small; and the yielding strength and the impacting toughness are better than those of a traditional process.

Owner:曹艺

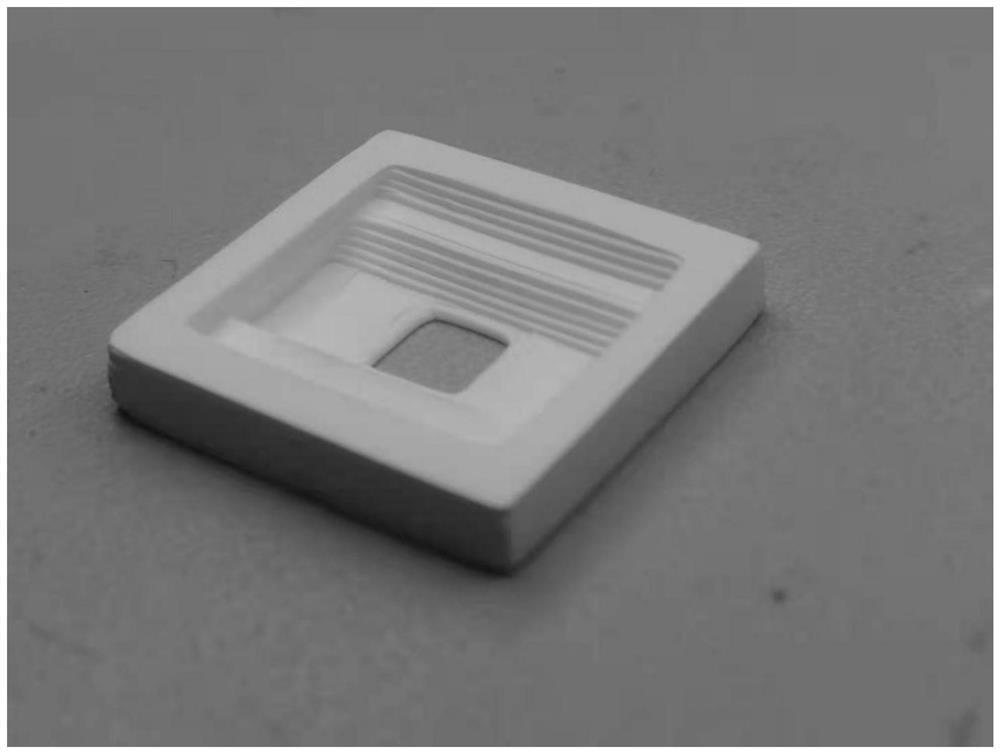

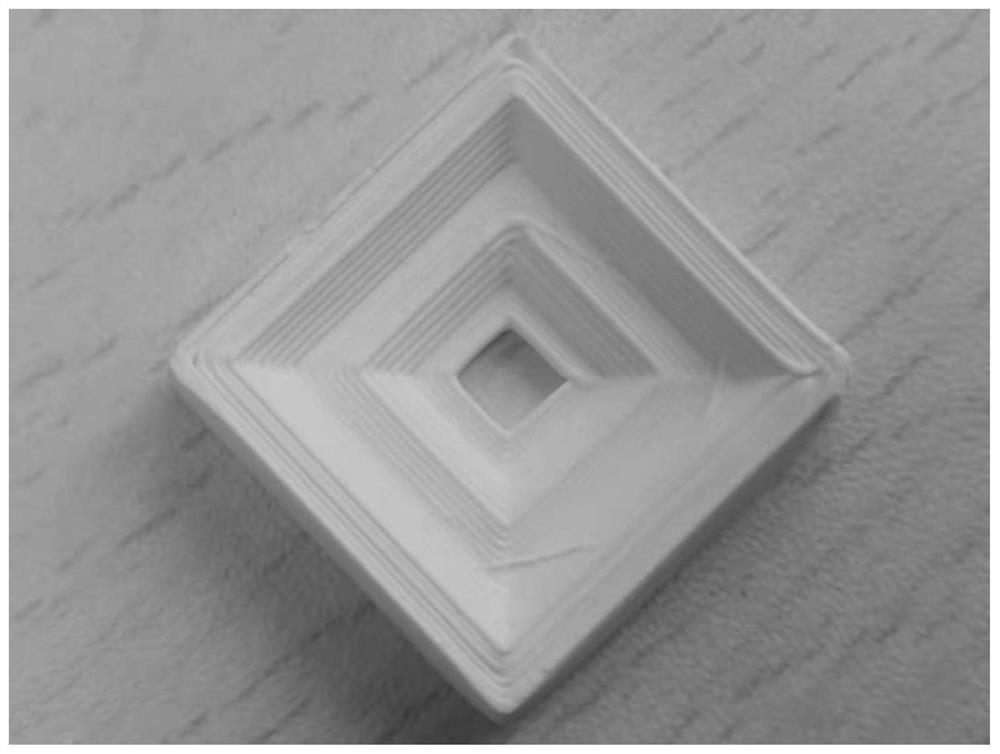

Method for 3D printing of high-solid-content low-temperature co-fired alumina ceramic complex structure

ActiveCN112759372AHigh solid contentReduce sintering shrinkageAdditive manufacturing apparatusOxide ceramicAlumina ceramic

The invention relates to a method for 3D printing of an aluminum oxide ceramic complex structure and discloses a method for 3D printing of a high-solid-content low-temperature co-fired aluminum oxide ceramic complex structure. The invention aims to solve the problems that the pH value of existing high-solid-phase-content aluminum oxide ceramic slurry needs to be adjusted, the prepared slurry is poor in stability and difficult to store for a long time, and high-speed and high-precision direct-writing type 3D printing is difficult to achieve. The method comprises the following steps: 1, weighing; 2, preparation of an organic colloid; 3, mixing of alumina powder and ceramic glass powder; 4, preparation of slurry; 5, heating for 3D printing; and 6, drying, glue discharging and sintering. The method is used for 3D printing of the high-solid-content low-temperature co-fired aluminum oxide ceramic complex structure.

Owner:HARBIN INST OF TECH

Silica-based ceramic core and preparation method thereof

PendingCN110386809AReduce sintering shrinkageExcellent high temperature bending resistanceSlurryZircon

The invention discloses a silica-based ceramic core and a preparation method thereof. The silica-based ceramic core is prepared from the following raw materials in parts by weight: 60-67 parts of silica glass powder, 30 parts of zircon sand and 3-10 parts of a SiO2 additive agent, according to a setting proportion, the raw materials are weighed, mixed and dried, and an elasticizer is added and stirred; compression moulding and demoulding of mixed slurry are conducted, a green body is obtained, and a compressed green body sample is embedded into calcination alpha-type aluminium oxide filler; and according to a set heating rate, the temperature rises for sintering, finally, the sintered sample is put into an ethyl silicate strengthening solution, after still standing, natural drying is conducted, and the core is obtained. According to the silica-based ceramic core and the preparation method thereof, sintering shrinkage of the silica-based ceramic core is low, high temperature bending strength is good, size control is good, the surface is smooth, during metal pouring, core-separating is easy, and abreuvage cannot be formed on the interfaces of metal and the core.

Owner:兴化市兴东铸钢有限公司

High-speed impact pressing method for metal powder

The invention discloses a high-speed impact pressing method for metal powder, which is characterized in that a die is arranged on a substrate first, a cavity is arranged on the die, a tower-shaped coil is fixed above the die, the tower-shaped coil is electrically connected with a discharge circuit, metal powder is filled in the cavity of the die, discharge processing is conducted to the tower-shaped coil, a pulsed magnetic field produced by the tower-shaped coil directly acts on the metal powder and the metal powder is pressed and formed. The invention has the advantages that the loading of impact stress waves to the metal powder is realized by using the action of electromagnetic force, the instant repetitive bidirectional compaction of the metal powder is realized by using the oscillation characteristics of the stress waves, the density of the pressed metal powder is high, the pressing time is short, the friction of the metal powder during pressing is reduced, the density distribution of the metal powder is even, the sintering shrinkage rate is reduced and the precision and the performance of parts are improved.

Owner:NINGBO UNIV

Method of improving liquidity of aluminum oxide mould core slurry

The invention aims at solving the problem that the liquidity of the aluminum oxide mould core slurry is poor in the prior art, and provides a method of improving aluminum oxide mould core slurry, belonging to the technical field of manufacturing of the aluminum oxide ceramic mould cores. The method comprises the following steps: adding spherical matrix powder with particle diameter of about 1 mu m into matrix powder electrically-fused corundum powder of normal particles and TiO2 to mix to obtain a mixture, and then adding a plasticizer into the mixture to obtain mould core slurry by stirring; controlling the temperature of a mould of a mould core injection-molding machine to 25-35 DEG C, controlling the temperature of the slurry to 95-105 DEG C and injecting the slurry into the injection-molding machine for pressing and molding to obtain the mould core, wherein the pressure holding time is 45-55 seconds. According to the method of improving the liquidity of aluminum oxide mould core slurry disclosed by the invention, a little spherical matrix micro fine powder is added to improve the liquidity of the mould core slurry, so that the liquidity of the slurry is improved, the mould core is prevented from being deformed during drawing and placing, the mould temperature is lowered, and the sintering shrinkage degree of the mould core is also reduced, and therefore, the product qualification rate of thin-wall directional blades and single crystal blades is increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

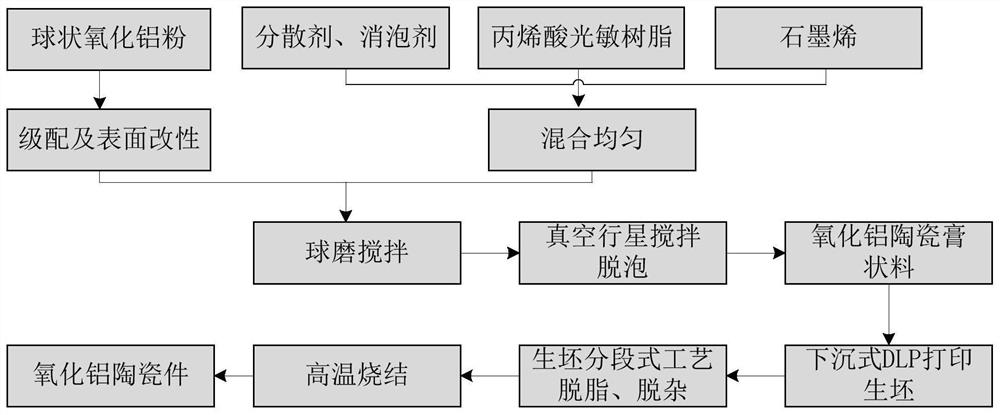

Method for preparing aluminum oxide ceramic based on sinking type DLP photocuring 3D printing

ActiveCN113956023AImprove stabilityReduce deformationAdditive manufacturing apparatusIncreasing energy efficiencyOxide ceramicDefoaming Agents

The invention discloses a method for preparing aluminum oxide ceramic based on sinking type DLP photocuring 3D printing, and the method comprises the following steps of: mixing and stirring aluminum oxide powder, a first dispersing agent and an organic solvent, conducting drying, crushing and sieving to obtain modified aluminum oxide powder, adding graphene, a second dispersing agent and a defoaming agent into acrylic photosensitive resin, performing mixing, then adding modified aluminum oxide powder, carrying out ball milling and defoaming treatment to obtain aluminum oxide ceramic paste, carrying out photocuring 3D printing by adopting a sunken DLP photocuring method, and then carrying out sectional process degreasing treatment and sintering to obtain the aluminum oxide ceramic. The method disclosed by the invention is suitable for preparation and industrial production of the large-size aluminum oxide ceramic piece with low deformation, high precision and complex structure, and the prepared aluminum oxide ceramic has the advantages of few microdefects, high density, good mechanical and physical properties and the like.

Owner:NAT UNIV OF DEFENSE TECH

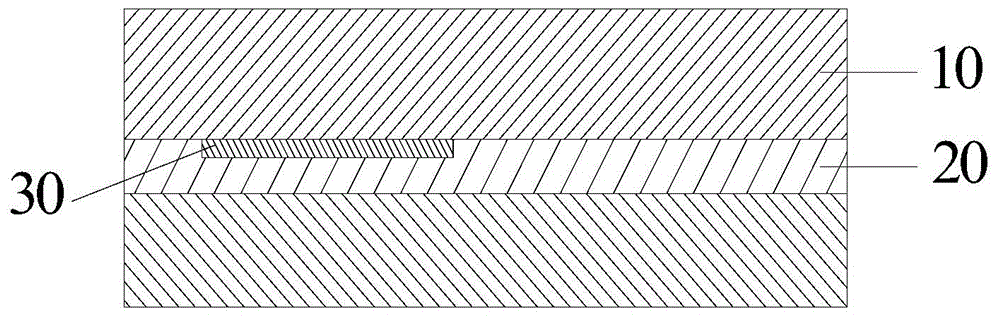

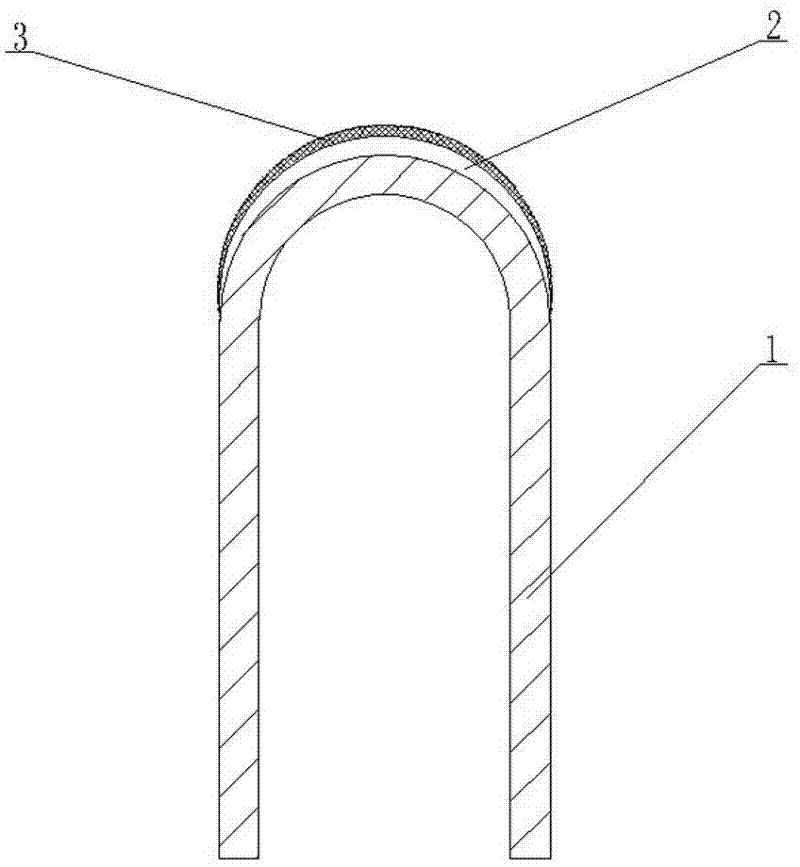

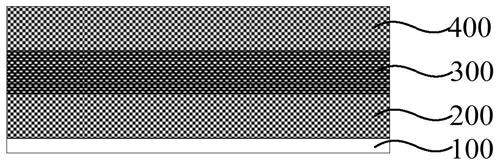

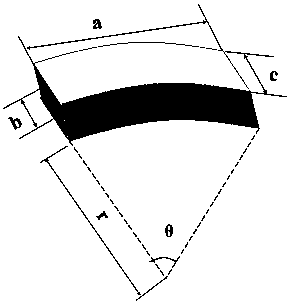

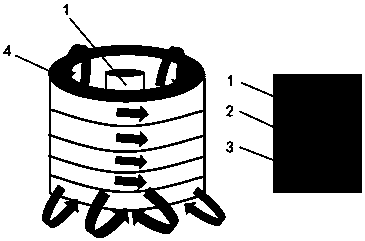

Metamaterial and preparation method thereof

The invention provides a metamaterial and a preparation method thereof. The metamaterial comprises substrates and a tape casting piece, which are arranged in a laminated manner in sequence. The surface of the tape casting piece is provided with a metal microstructure. The substrate is a quartz-fiber-reinforced silicon dioxide base body. The quartz-fiber-reinforced silicon dioxide base body is a sintering compound of silica-sol-based slurry and quartz fiber. The substrate is the quartz-fiber-reinforced silicon dioxide base body, and the quartz-fiber-reinforced silicon dioxide base body is the sintering compound of the silica-sol-based slurry and the quartz fiber, so that the formed metamaterial is low in sintering shrinkage rate, can be co-fired with the silver-based paste, and has higher strength and lower loss; and the metamaterial has higher wave transmissivity.

Owner:SHENZHEN KUANG CHI GANG DA INNOVATIVE TECH LTD

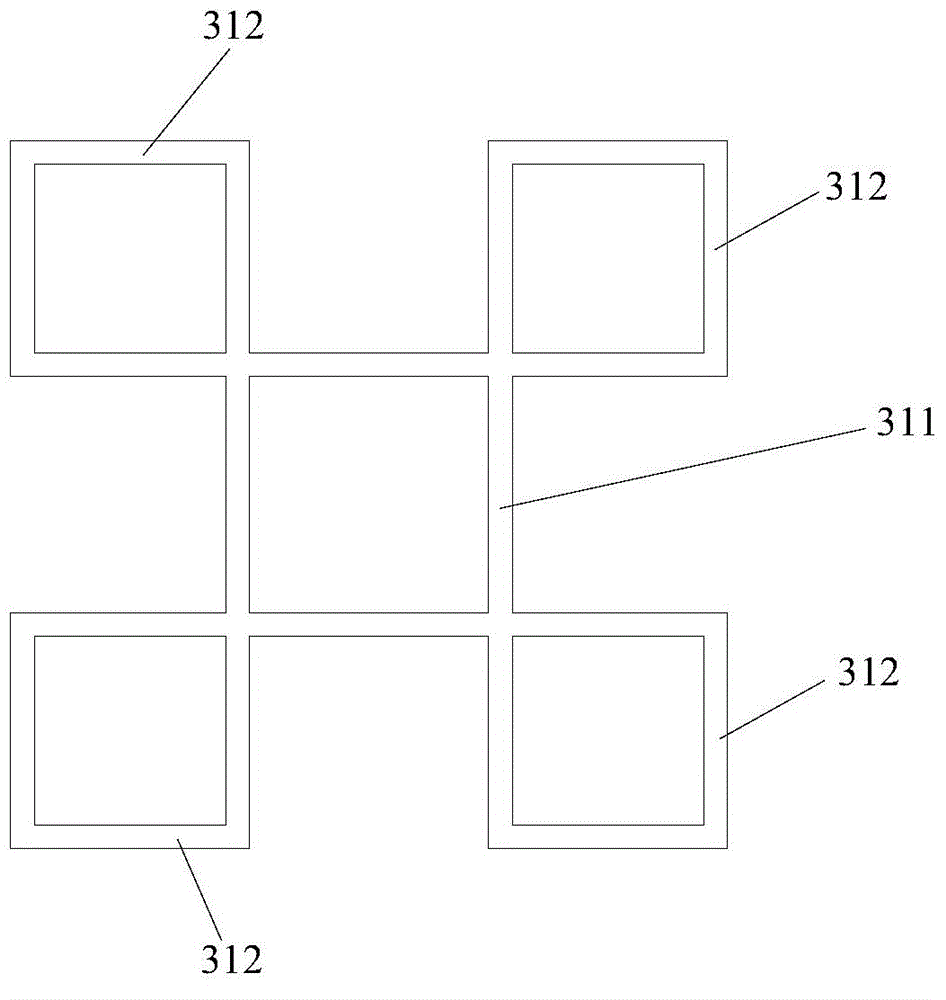

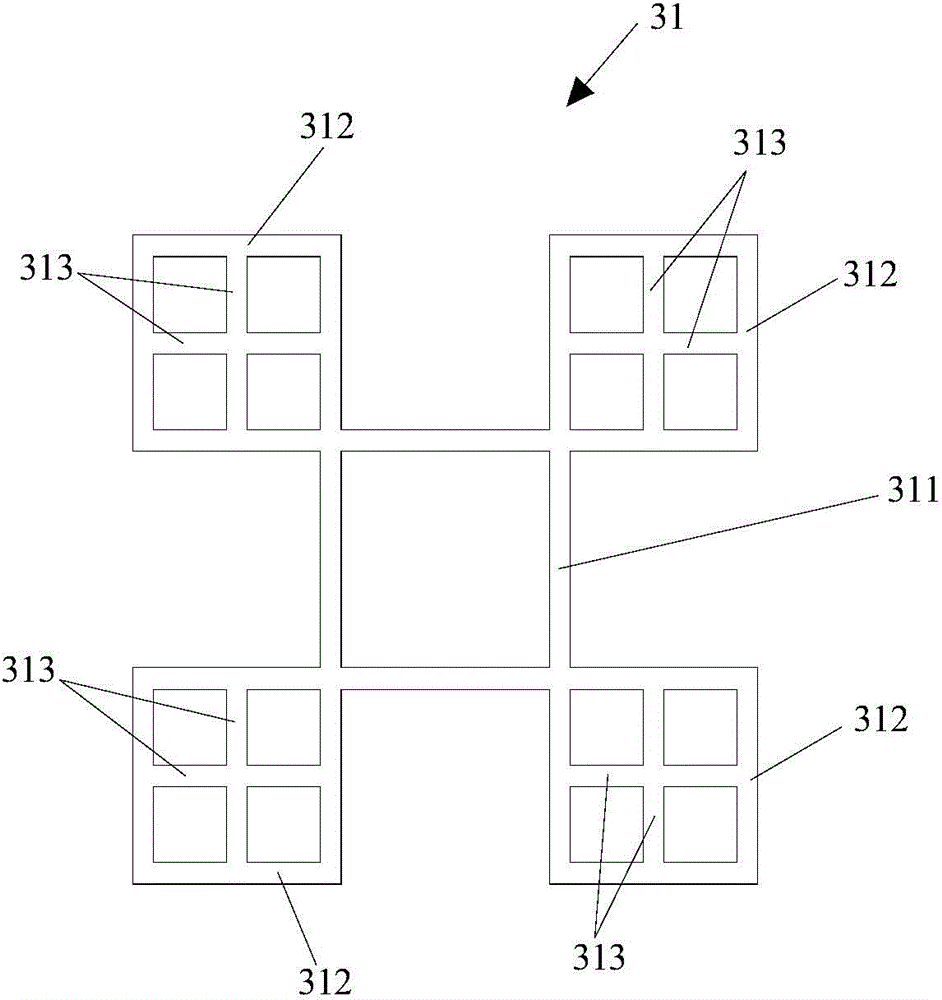

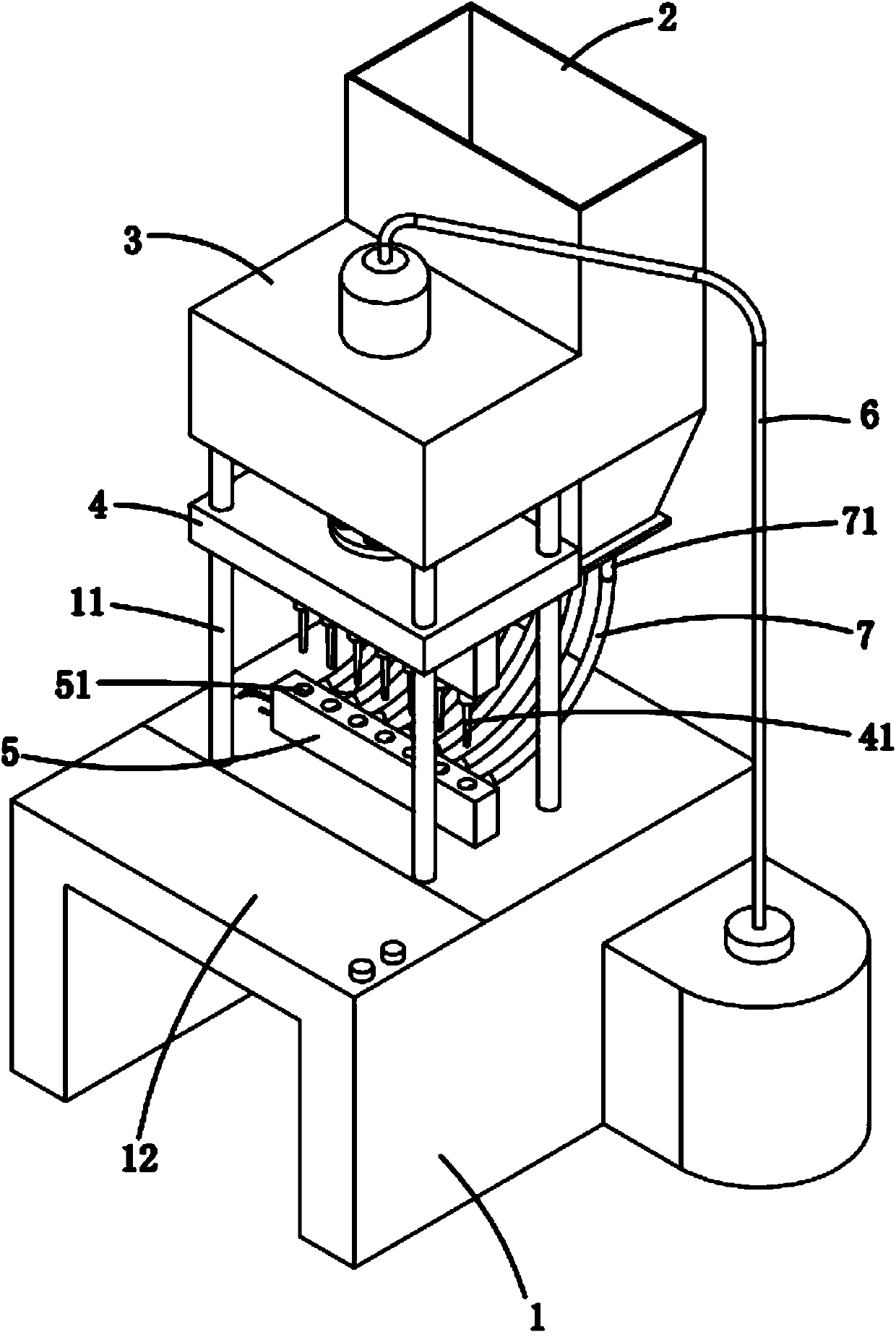

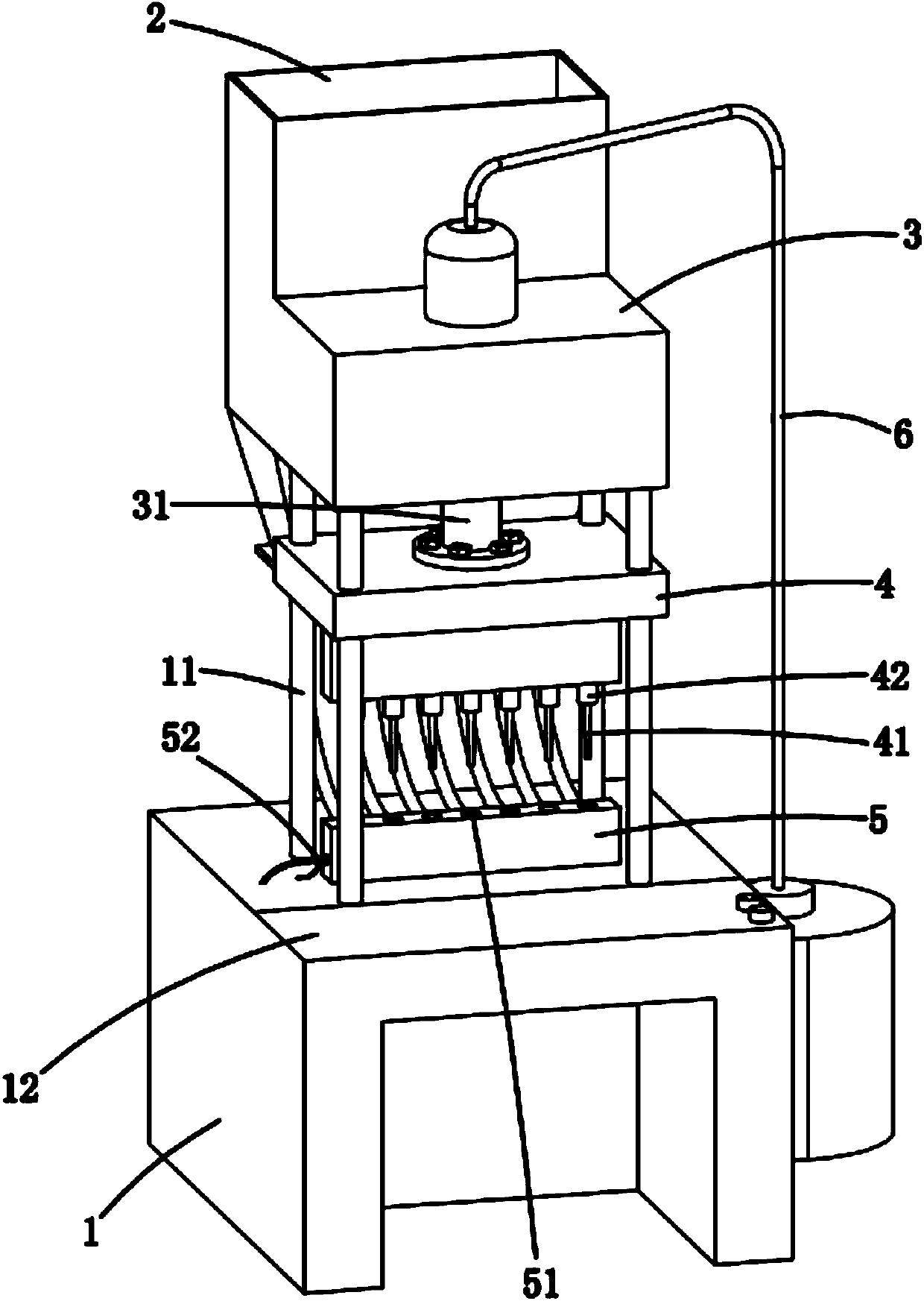

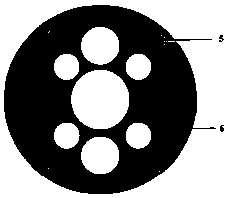

Isostatic-pressing dry-powder molding device

InactiveCN104175387AIncrease productivityHigh densityShaping press ramHydraulic cylinderCommunications system

The invention relates to an isostatic-pressing dry-powder molding device which comprises a mounting seat, a hopper used for holding powder materials, a hydraulic cylinder, an upper die mold, a lower mold and a PLC (programmable logic controller) system or an upper computer DSC (data communication system). The position at each of four corners of the bottom of the hydraulic cylinder is provided with a guide pillar fixed on the mounting seat, the upper mold is fixedly connected with a hydraulic cylinder piston, the four corners are sleeved with the guide pillars, and a plurality of punches are vertically evenly distributed on the bottom surface of the upper mold; the lower mold is arranged on the mounting seat, and mold cavities in one-to-one correspondence to the punches evenly distributed on the lower mold; the hopper is fixed on the rear side of the hydraulic cylinder, a plurality of connecting pipes communicated with the interior of the hopper are evenly arranged at the bottom of the hopper, and tail ends of the connecting pipes are in one-to-one correspondence to the mold cavities. By the arrangement, shortcomings that of easy occurrence of air vents, sinkholes and unstable thermal performance in traditional hot-press molding with slurry injection are removed, and the isostatic-pressing dry-powder molding device is high in product density, small in sintering shrinkage, high in production efficiency, adjustable in machining dimensional accuracy of sparking plugs and highly adaptable.

Owner:长兴威力窑业有限公司

3d printing method for manufacturing metal part or ceramic part through resin

PendingCN112439901AIncrease contentHigh viscosityAdditive manufacturing apparatusTransportation and packagingSlurryCeramic particle

The invention discloses a 3d printing method for manufacturing a metal part or a ceramic part through resin. The 3d printing method comprises the following steps that S1, a photosensitive resin preparation process is conducted; S2, nano metal particles can be pretreated or not pretreated, and nano ceramic particles must be pretreated; S3, slurry is prepared; S4, FDM printing is carried out; S5, the printed object is cleaned; S6, supports are removed, wherein redundant supports on the printed object are removed; S7, degreasing is carried out; S8, sintering is conducted, wherein some metals needto be sintered in a specific atmosphere or vacuum. As an FDM method needs high-viscosity resin, the sedimentation problem of particles does not need to be considered. Compared with the prior art, a resin material with metal particles or ceramic particles having a volume fraction of 60%-95% can be prepared.

Owner:杜晖

Method for preparing mullite porous ceramics by freeze-drying method

The invention relates to a method for preparing mullite porous ceramics by a freeze-drying method. The method comprises the following steps: (1) adding modified opoka, alpha-alumina and sintering aidsinto an agate jar, and ball milling at a rate of 300 revolutions per minute for 2 hours by using a planetary ball mill so as to obtain uniformly mixed powder; (2) mixing the uniform powder and water,and preparing ceramic slurry having the starch content of 6-10 vol%; (3) rapidly pouring the prepared ceramic slurry into a mold of a certain shape for casting and molding, performing vacuum degassing, removing bubbles in the slurry, placing the sample in a cryogenic refrigerator, enabling the sample to be completely frozen, and demolding; (4) performing freeze drying on the sample in a vacuum freeze drier at the temperature of 30 DEG C below zero at a vacuum degree of 10 Pa for 36 hours; (5) sintering, and cooling, thereby obtaining the mullite porous ceramics. According to the method disclosed by the invention, the opoka serves as the main ingredient and a pore forming material, so that the void ratio of the mullite ceramics can be effectively improved, the usage amount of the adhesiveis reduced, and the strength of the product is further improved.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

Spinel-magnesium-based ceramic core and preparation method thereof

ActiveCN112794711ASufficient bending strengthImprove thermal shock resistanceFoundry mouldsFoundry coresCompression moldingSlurry

The invention discloses a spinel-magnesium-based ceramic core and a preparation method thereof, and belongs to the field of ceramic core preparation in the field of precision casting. Raw materials of the spinel-magnesium-based ceramic core comprise a powder raw material and a binder, and the powder raw material comprises the following components in percentage by mass: 50%-90% of spinel powder, 0%-30% of zirconium oxide powder, 0%-5% of titanium dioxide powder and the balance of magnesium oxide powder; and the mass of the binder accounts for 15-25% of the mass of the powder raw material. The preparation method of the spinel-magnesium-based ceramic core comprises the following steps: mixing powder according to the ratio, preparing a binder, mixing the preheated mixed powder and the binder to prepare slurry, carrying out compression molding on the slurry by adopting a hot-press injection molding method, and sintering to obtain the spinel-magnesium-based ceramic core. The spinel-magnesium-based ceramic core has the advantages of being high in strength, small in shrinkage rate and easy to remove, and meanwhile the thermal shock resistance is improved.

Owner:NORTHEASTERN UNIV

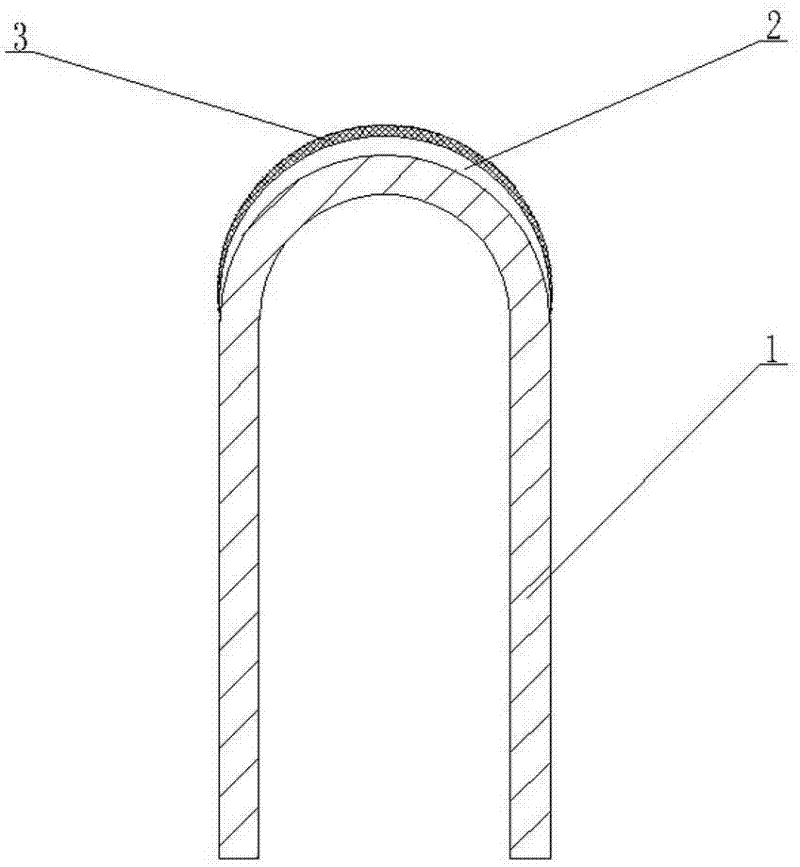

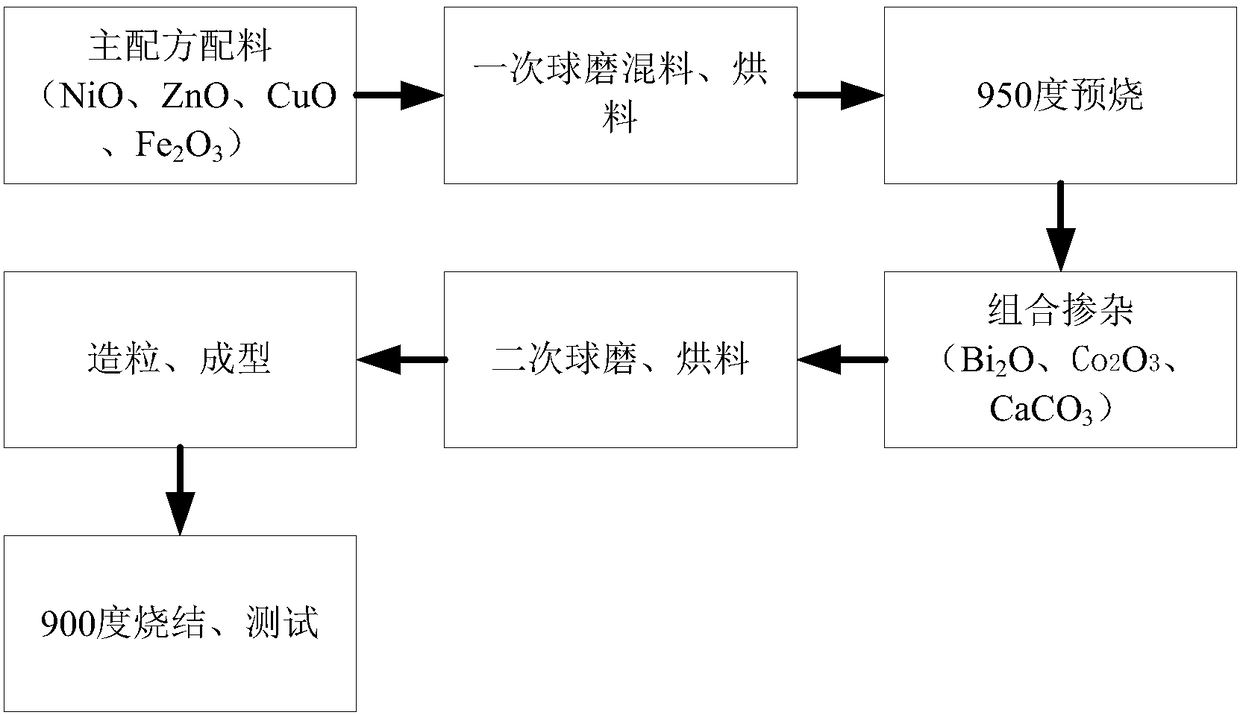

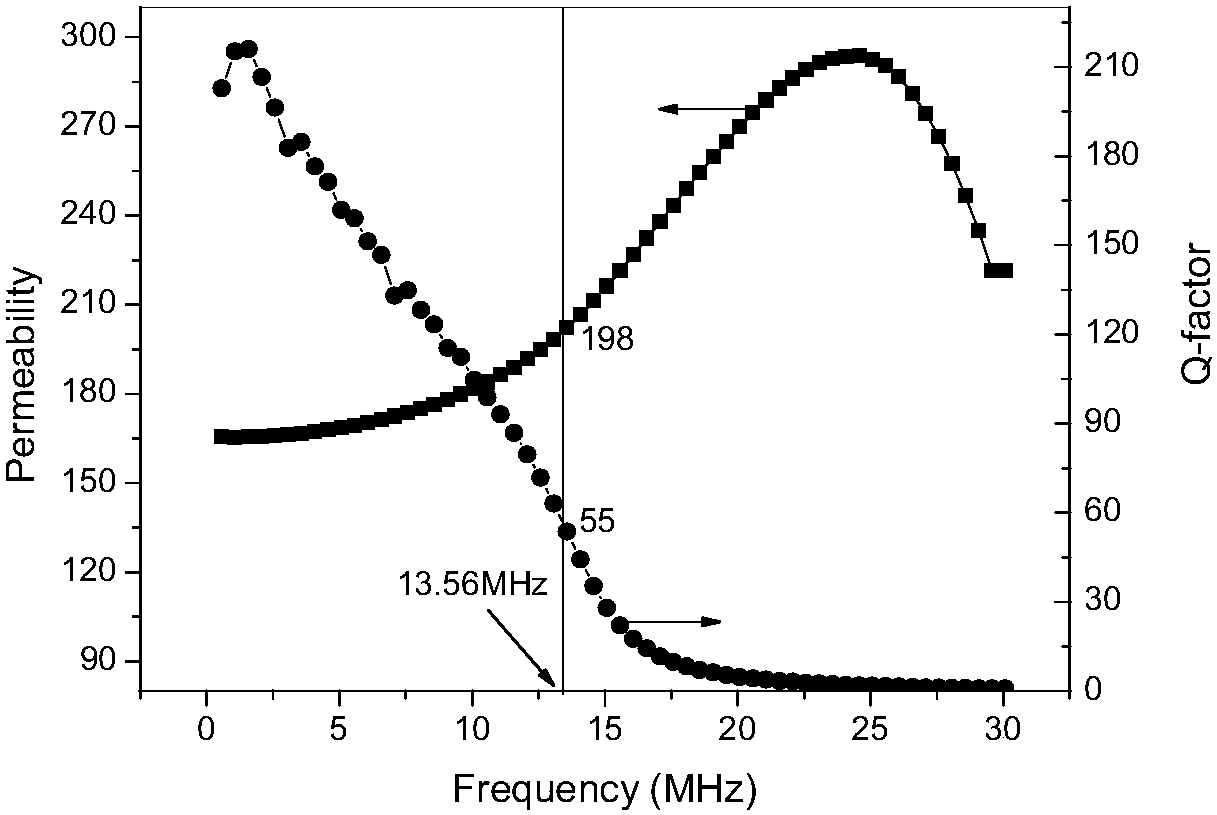

A kind of NFC mobile phone payment ferrite magnetic shielding material and preparation method thereof

ActiveCN105777094BIncrease distanceThe implementation effect is goodShielding materialsDopantInitial permeability

The invention belongs to the technical field of electronic ceramic materials, and in particular relates to an NFC mobile phone payment ferrite magnetic shielding material with high magnetic permeability and high quality factor and a preparation method thereof. The main crystal phase of the ferrite magnetic shielding material is spinel structure, and the molecular structure expression is Ni0.34‑xZn0.48+xCu0.18Fe1.98O4, where 0<x≤0.01; the main formula is composed of analytically pure Raw materials NiO, ZnO, CuO, Fe2O3 are composed of molar ratio (0.34‑x): (0.48+x): 0.18: 0.99; dopant is Bi2O3: 0.5wt%, Co2O3: 0.4wt% and CaCO3: 0.04wt%~ 0.06 wt%. The ferrite magnetic shielding material has an initial magnetic permeability of 195-205 and a quality factor of 50-60 at an operating frequency of 13.56 MHz. The pre-firing temperature is higher than the final sintering temperature, and the shrinkage rate is greatly reduced, which better ensures that warping and cracking are not easy to occur when processing NFC magnetic sheets. The production raw materials are cheap, the process is simple, the operation is convenient and the cost is low.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Forming method of sagger for lithium battery cathode material

InactiveCN111037710AUniform tissue structureHigh densityCeramic shaping apparatusHigh densityPhysical chemistry

The invention relates to the technical field of preparation of sagger kiln furniture, and particularly relates to a forming method of a sagger for a lithium battery cathode material. The forming method comprises the following steps of powder pretreatment, die filling and prepressing, drying, die filling and forming, wherein the forming specifically comprises the following steps of putting an elastic die which is tightly coated with a semi-finished sagger blank and is sealed into a high-pressure cylinder, and suspending the elastic die in the high-pressure cylinder by using a high-pressure-resistant rope; covering a high-pressure cylinder sealing cover; and continuously injecting liquid between the inside of the high-pressure cylinder and the elastic die for pressurization, when the internal pressure reaches 5,000kgf / cm <2>, maintaining the pressure for 12 hours, discharging the liquid, slowly releasing the pressure, taking out the sagger blank after the pressure is released, opening the sagger blank, and removing the elastic die to obtain a finished sagger blank. The sagger blank obtained by pressing by the method has the advantages of uniform tissue structure, high density, low sintering shrinkage and low die cost; and the method has high production efficiency, can be used for forming slender products with complex shapes, large-size products and precise-size products, and is suitable for automatic operation.

Owner:湖南太子新材料科技有限公司

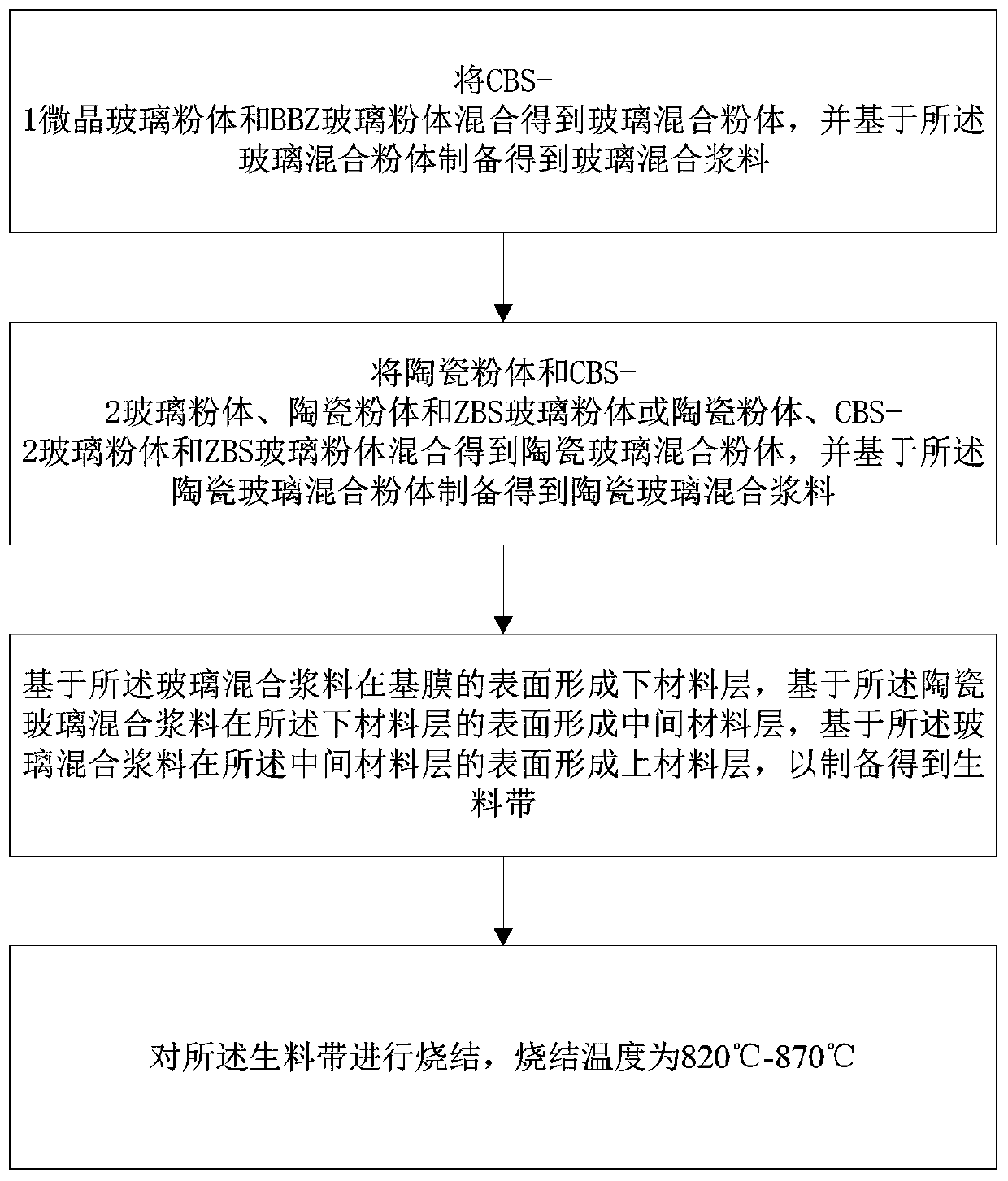

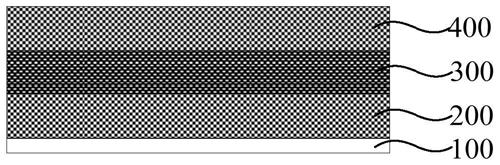

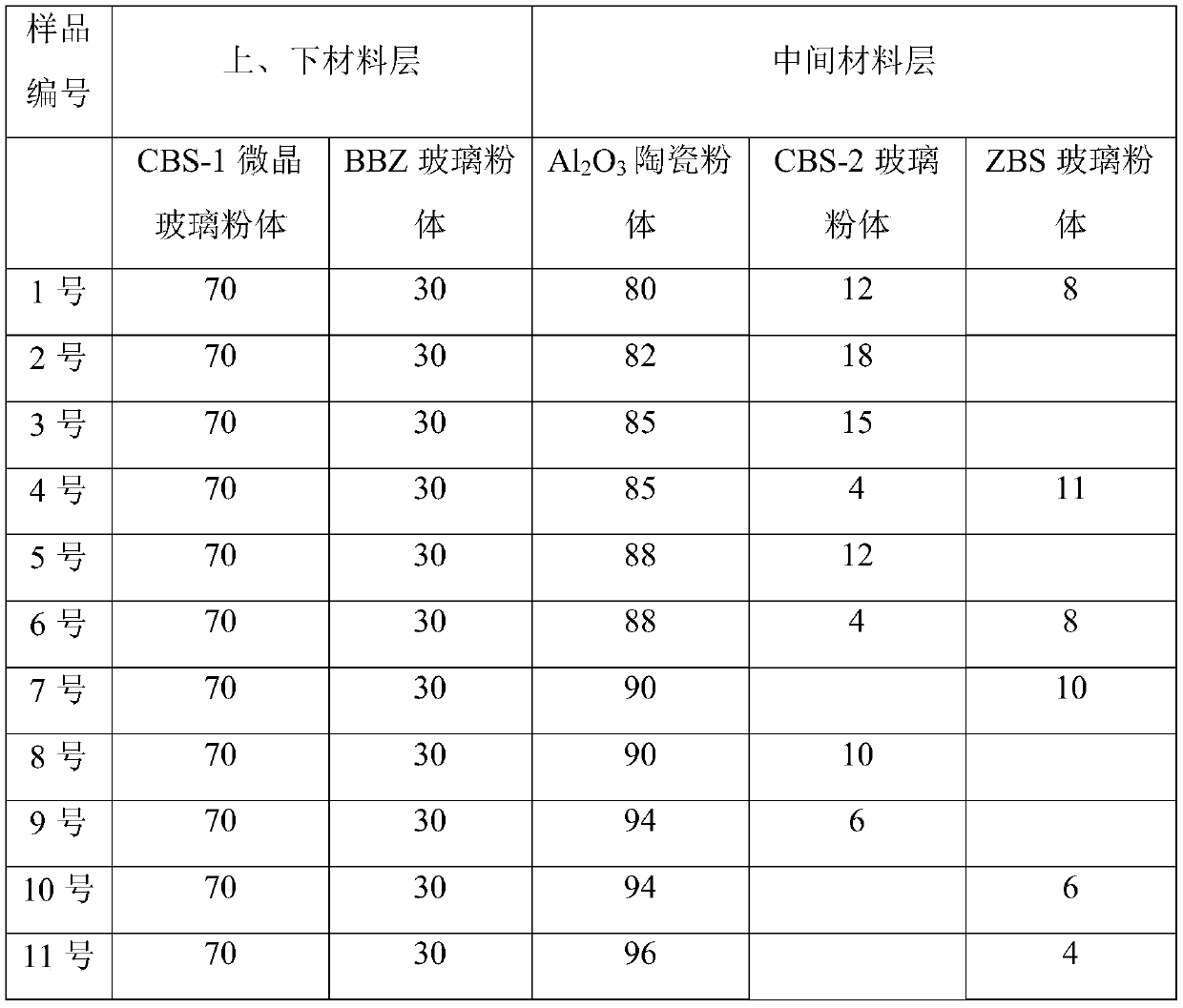

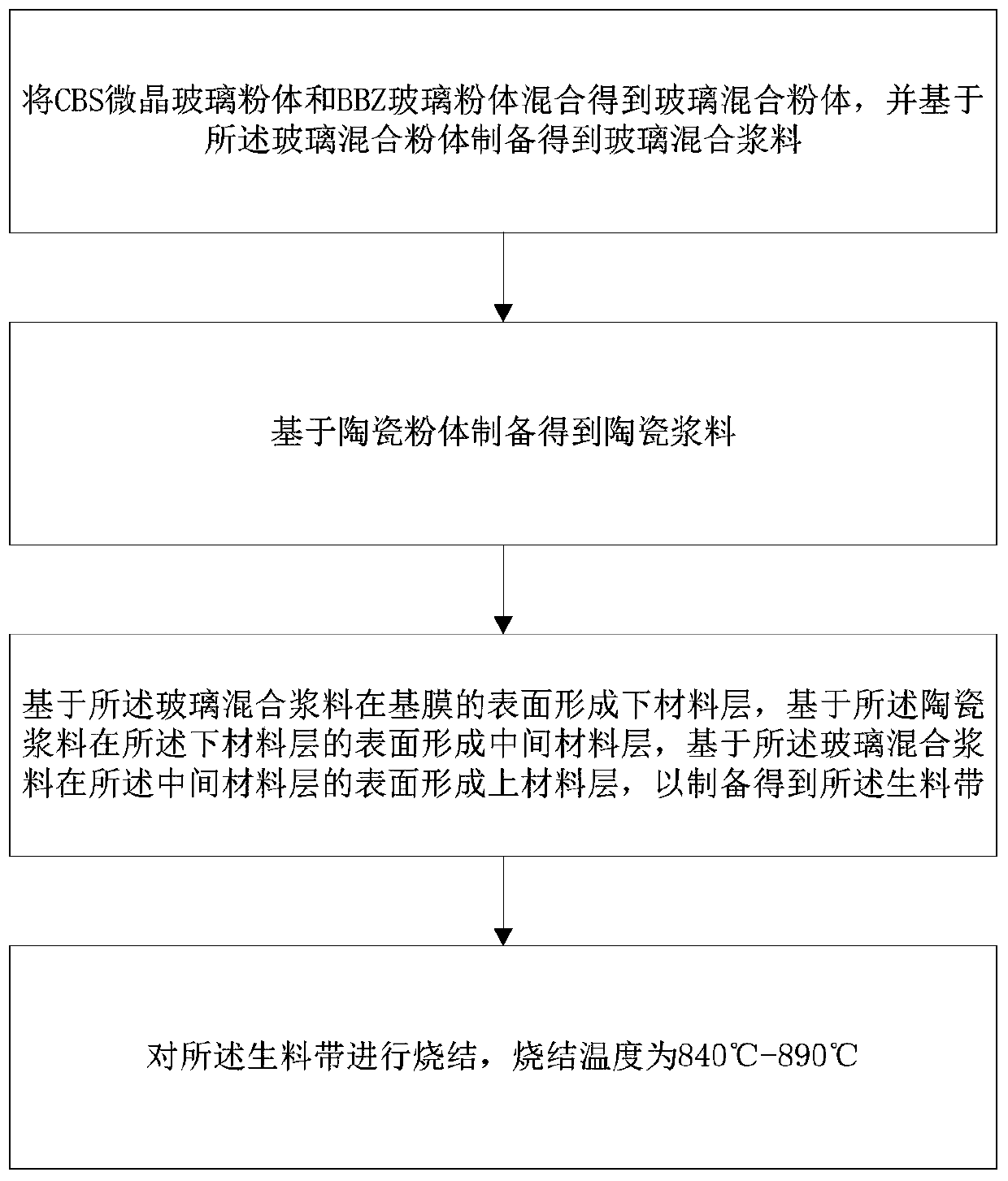

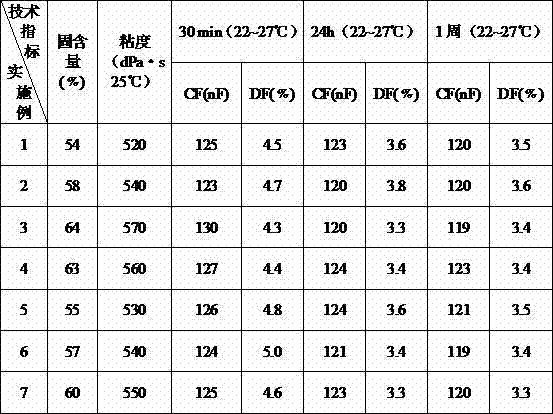

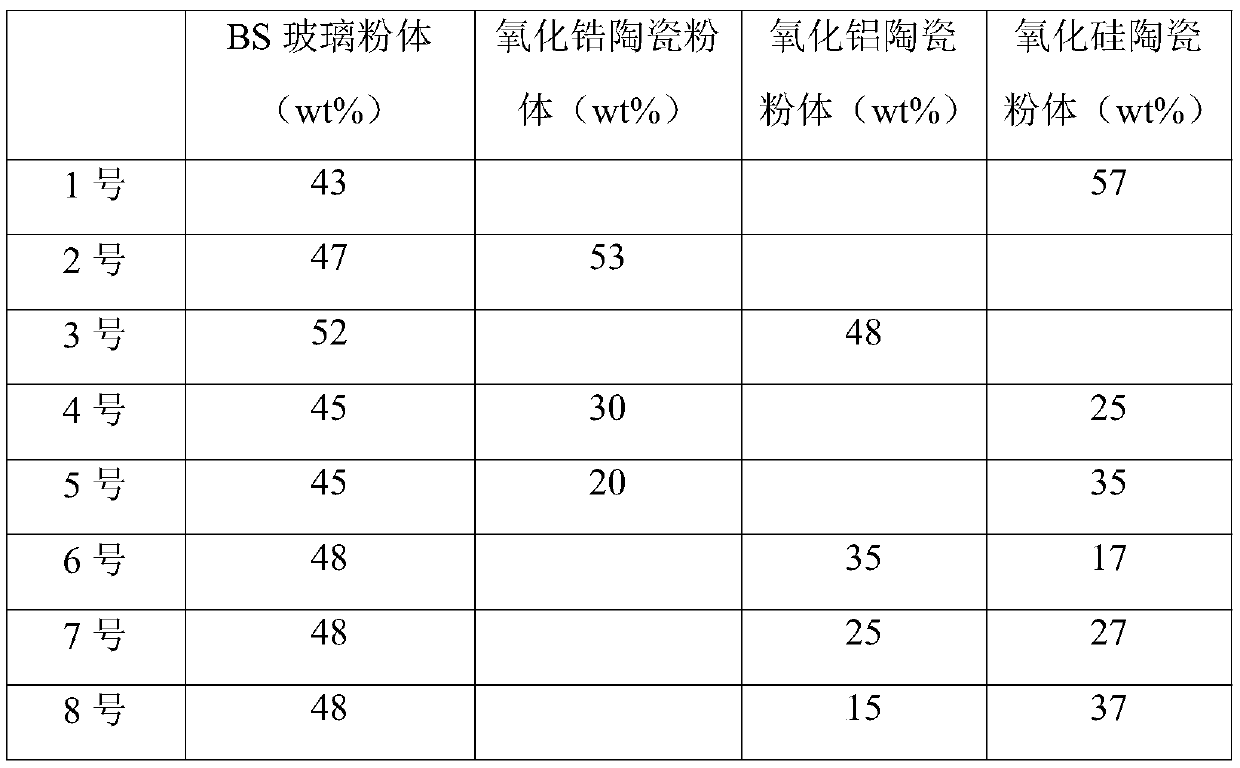

Low-temperature co-fired ceramic raw material belt and preparation method thereof

The invention provides a low-temperature co-fired ceramic raw material belt and a preparation method thereof. The preparation method comprises the following steps: mixing CBS-1 microcrystalline glasspowder and BBZ glass powder to obtain glass mixed powder, and preparing glass mixed slurry on the basis of the glass mixed powder; mixing ceramic powder and CBS-2 glass powder, mixing the ceramic powder and ZBS glass powder or mixing the ceramic powder, the CBS-2 glass powder and the ZBS glass powder to obtain ceramic-glass mixed powder, and preparing ceramic-glass mixed slurry based on the ceramic-glass mixed powder; and forming a lower material layer on the surface of a base film based on the glass mixed slurry, forming an intermediate material layer on the surface of the lower material layer based on the ceramic-glass mixed slurry, and forming an upper material layer on the surface of the intermediate material layer based on the glass mixed slurry to prepare the raw material belt. According to the invention, the problem of large sintering shrinkage rate in the X-axis direction and the Y-axis direction after the existing LTCC raw material belt material is sintered is solved.

Owner:上海晶材新材料科技有限公司

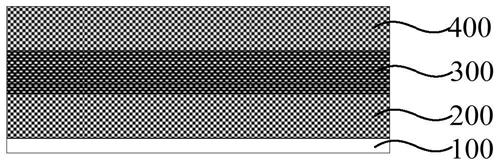

Low-temperature co-fired ceramic raw material belt and preparation method thereof

The invention provides a low-temperature co-fired ceramic raw material belt and a preparation method thereof. The preparation method comprises the following steps: mixing CBS microcrystalline glass powder and BBZ glass powder to obtain glass mixed powder, and obtaining glass mixed slurry on the basis of the glass mixed powder; preparing ceramic slurry based on the ceramic powder; and forming a lower material layer on the surface of the base film based on the glass mixed slurry, forming an intermediate material layer on the surface of the lower material layer based on the ceramic slurry, and forming an upper material layer on the surface of the intermediate material layer based on the glass mixed slurry to prepare the raw material belt. According to the invention, the problem of large sintering shrinkage rate in the X-axis direction and the Y-axis direction after the existing LTCC raw material belt material is sintered is solved.

Owner:上海晶材新材料科技有限公司

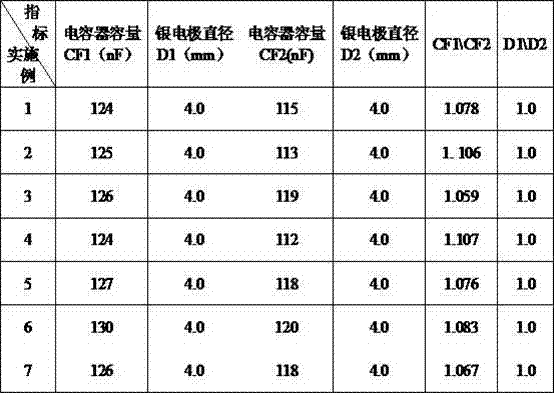

Silver conductor paste for semiconductor ceramic capacitor electrode and preparation method of silver conductor paste

ActiveCN103117112AIncrease capacityGood dispersionFixed capacitor electrodesNon-conductive material with dispersed conductive materialElectrical conductorElectric capacity

The invention relates to the technical field of silver conductor paste and a preparation method thereof, in particular to silver conductor paste for a semiconductor ceramic capacitor electrode and a preparation method of the silver conductor paste. The silver conductor paste comprises, in weight percent, 50-60% of Ag, 0.1-1.8% of other metals, 1.5-4.5% of inorganic additives, 0.05-0.1% of glass powder and 35-48% of organic carriers. Consumption of silver powder is decreased, the other metals are added, the obtained silver conductor paste is fine in dispersity, small in particle size distribution, low in sintering shrinkage, high in adhesive force, excellent in electrical performance and free of pungent smell, lead and cadmium and is applied to the semiconductor ceramic capacitor electrode, the electric capacity of a capacitor can be effectively improved by 5-10nF, silver consumption corresponding to a single capacitor is reduced by about 7%, accordingly, production cost can be reduced, and market competitiveness can be improved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Preparation method of self-setting silicon nitride foamed ceramic

The invention discloses a preparation method of self-setting silicon nitride foamed ceramic, and belongs to the technical field of advanced ceramics. The method comprises the following steps: 1) preparing inorganic continuous long fibers into chopped fibers, and obtaining a fibrofelt with a certain shape, thickness and fiber volume fraction by using felt making equipment; 2) putting the mixed micro powder of silicon powder and silicon nitride into a solvent, adding a surfactant and a binder, and carrying out ball milling to obtain silicon-containing slurry; 3) placing the fiber felt in the silicon-containing slurry, fully impregnating the fiber felt with the silicon-containing slurry under the action of pressure, taking out the fiber felt, and drying the fiber felt to obtain a slurry hanging product; 4) placing the slurry hanging product in nitrogen or nitrogen-hydrogen mixed atmosphere, nitriding the silicon powder at high temperature to generate silicon nitride, and realizing reactive sintering in the continuous conversion process of the silicon nitride to obtain fiber-reinforced silicon nitride foamed ceramic; and 5) placing the silicon nitride foamed ceramics in the silicon-containing slurry, and repeating the steps 3) and 4) to obtain the self-setting silicon nitride foamed ceramics with different pore sizes and porosities. Micropores and microcracks are few, the junction temperature is low, and the shrinkage rate is small.

Owner:XIAMEN UNIV

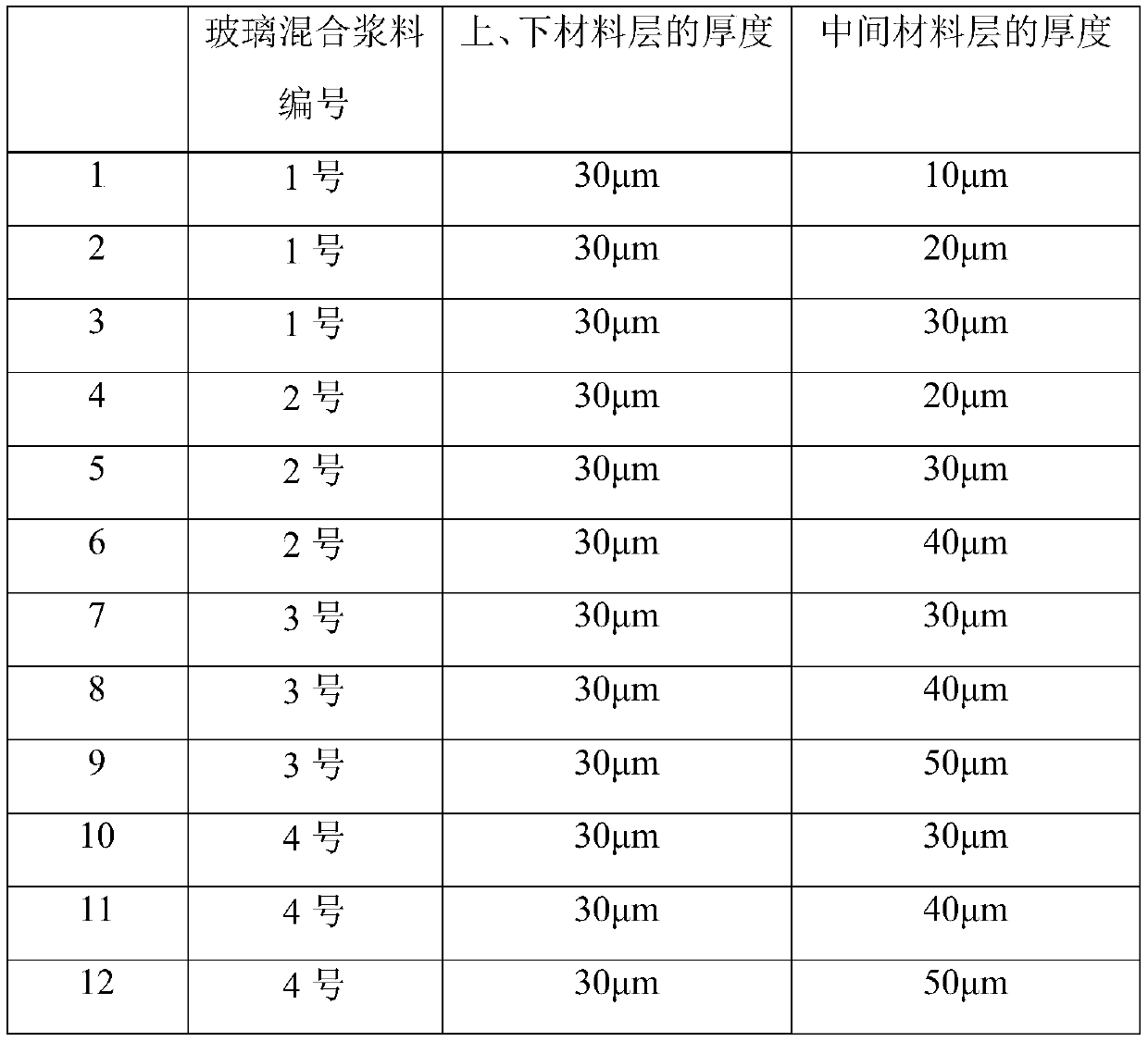

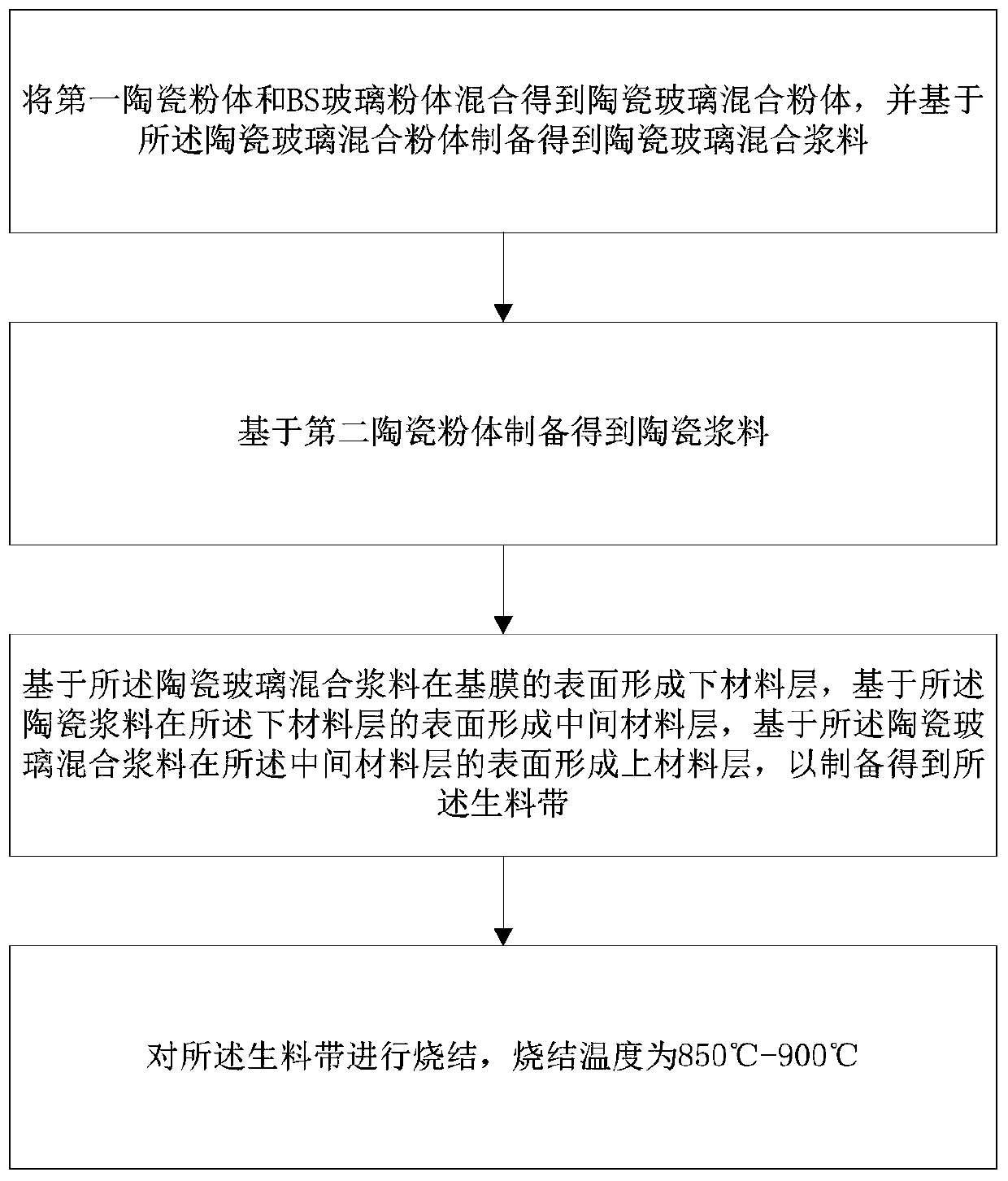

Low-temperature co-fired ceramic raw material belt and preparation method thereof

The invention provides a low-temperature co-fired ceramic raw material belt and a preparation method thereof. The preparation method comprises the following steps: mixing first ceramic powder and BS glass powder to obtain ceramic-glass mixed powder, and forming ceramic-glass mixed slurry based on the ceramic-glass mixed powder; preparing ceramic slurry based on the second ceramic powder; and forming a lower material layer on the surface of the base film based on the ceramic glass mixed slurry, forming an intermediate material layer on the surface of the lower material layer based on the ceramic slurry, and forming an upper material layer on the surface of the intermediate material layer based on the ceramic glass mixed slurry to prepare the raw material belt. According to the invention, the problem of large sintering shrinkage rate in the X-axis direction and the Y-axis direction after the existing LTCC raw material belt material is sintered is solved.

Owner:上海晶材新材料科技有限公司

A kind of preparation method of diamond composite material

ActiveCN107043882BImprove thermal conductivityReduce bloatTransportation and packagingMetal-working apparatusWear resistantOxidation resistant

The invention discloses a method for preparing a diamond composite material, which belongs to the technical field of composite material preparation. The preparation method of the diamond composite material in the present invention is to pretreat the diamond particles in advance, then uniformly mix the high manganese steel powder and the diamond particles and press them into a preform, and finally carry out vacuum sintering to obtain the diamond composite material. The sintering temperature of the method of the present invention is low, the diamond can be evenly distributed in the high manganese steel matrix, and the composite material produced has good consolidation strength, flatness and sharpness, and does not contain impurities, and has high comprehensive performance and is beneficial to Environmentally friendly, it can serve in complex working conditions such as severe cold and heat, impact wear, etc. It can be used in various disc abrasives and wear-resistant workpieces, and has good wear resistance, impact resistance, oxidation resistance and corrosion resistance ability.

Owner:KUNMING UNIV OF SCI & TECH

Ceramic rock plate and its preparation method

ActiveCN111470848BImprove plasticityGood molding effectCeramic materials productionClaywaresGlazeSpray dried

The invention relates to a ceramic rock slab and a preparation method thereof. The ceramic rock slab body is composed of the following weight percentages: mud material 35-46.1%; water abrasive 50-60%; green body toughening material 1-7%; recycled material 0.5% ~3%; additive 0.1~0.8%. Preparation method: body batching→blank processing→spray-drying powder making→dry pressing molding green body (flat or concave-convex effect)→drying→blank throwing→soot blowing→water spraying→white ink spraying→make-up soil→pattern decoration→isolation Glaze decoration → transparent glaze layer decoration → firing → polishing and edging.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +3

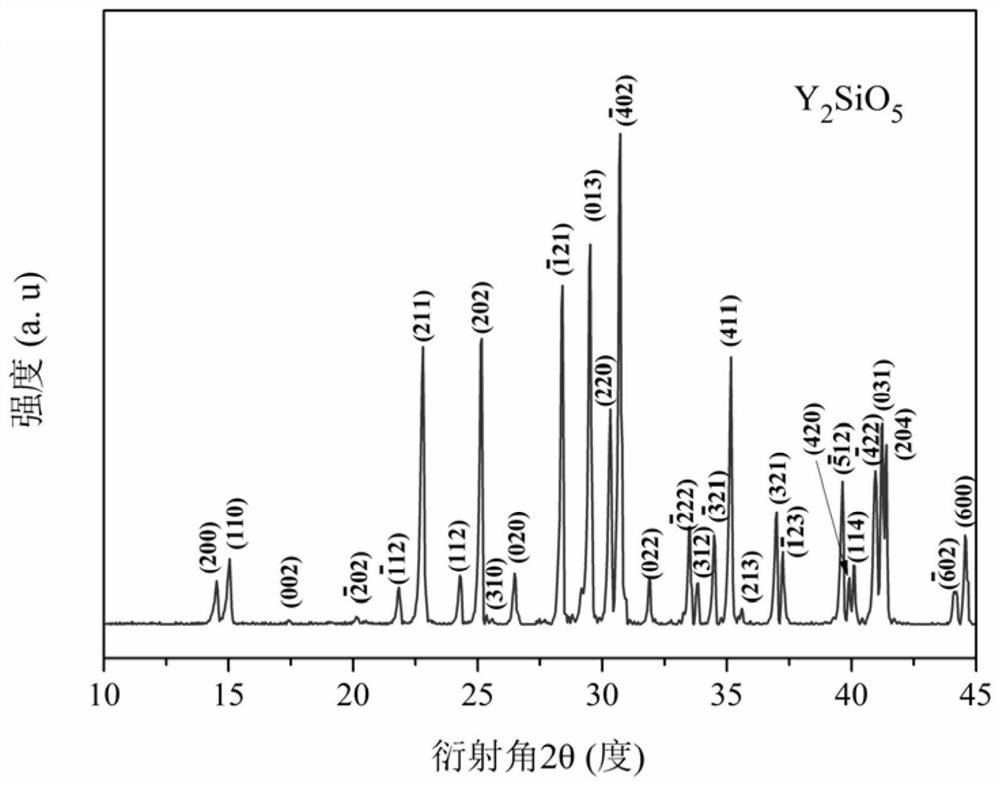

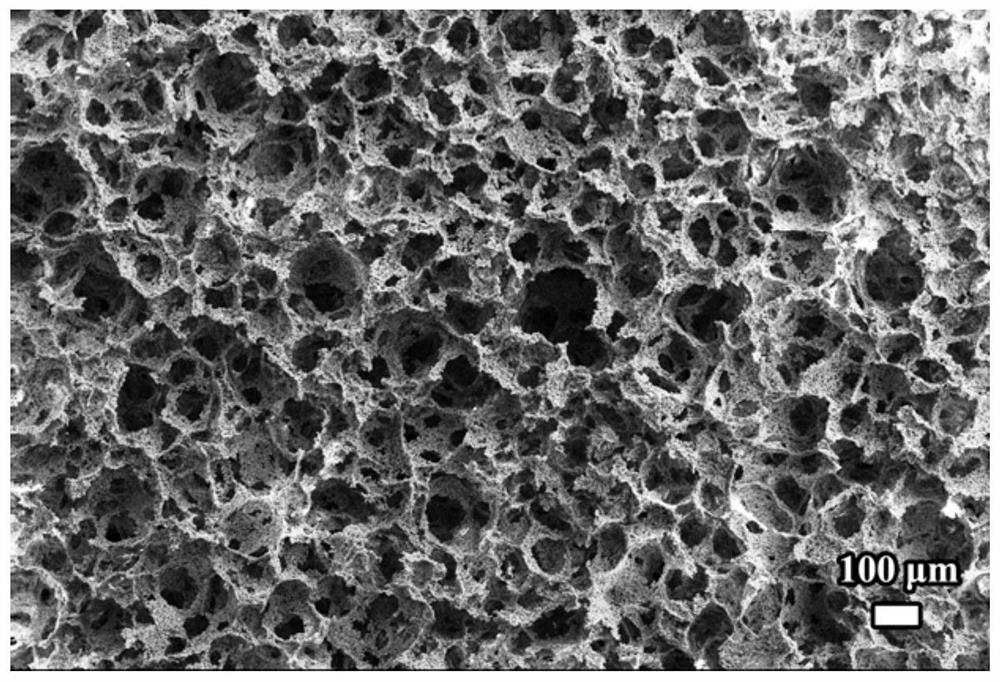

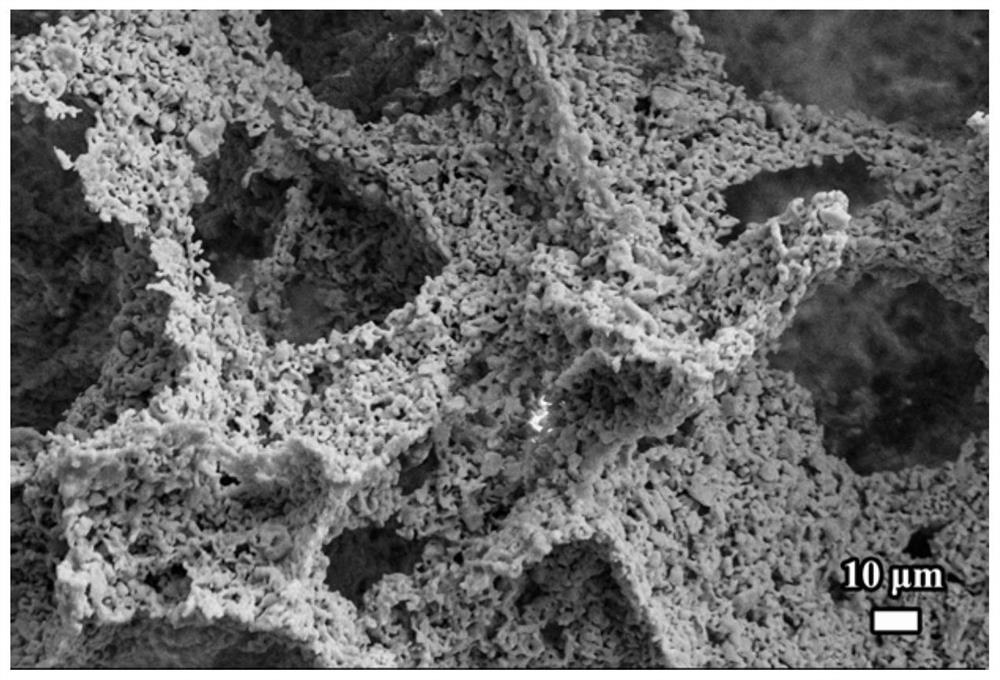

A kind of ultra-high porosity and low body shrinkage y 2 sio 5 Preparation method of porous ceramics

The invention relates to the field of thermal protection materials, particularly to a preparation method of an Y2SiO5 porous ceramic with characteristics of ultra-high porosity and low billet shrinkage rate. The preparation method comprises: using yttrium oxide powder and silicon oxide powder as reactants, using water as a dispersion medium, adding a dispersing agent, and continuously stirring toprepare a ceramic slurry; heating the slurry; adding a foaming agent, rapidly and mechanically stirring, and foaming; adding gelatin and a surfactant; injecting into a mold, carrying out low-temperature freezing, carrying out vacuum drying, demolding the billet, and drying in an oven; and carrying out high temperature sintering to prepare the Y2SiO5 porous ceramic. According to the present invention, with the preparation method, the difficulty of high billet shrinkage rate or severe deformation during the demolding drying can be solved, and the Y2SiO5 porous ceramic with characteristics of ultra-high porosity, low density, low thermal conductivity and high-temperature resistance is synthesized, and has wide application prospects in the field of heat protection materials; and the preparation method has advantages of low cost and high operability, can prepare the porous material with the ultra-high porosity through the novel and simple production process, and has broad industrial production prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of sintering process of ceramic spark plug for automobile

InactiveCN104242068BHigh densityReduce sintering shrinkageCeramic shaping apparatusSparking plugs manufactureCeramic sinteringManufacturing technology

The invention relates to the technical field of manufacturing ceramic parts, and more specifically relates to a sintering process for ceramic spark plugs for automobiles, including five steps of isostatic pressing, grinding, bisque firing, glazing and high-temperature sintering. The present invention replaces the traditional grouting hot-pressing forming process by using dry pressing, uses an isostatic pressing machine to carry out cold-pressing forming on the dry powder, and controls the feeding amount of the dry powder, heating temperature and time, and the thickness of the glaze layer during the process. And other parameters are continuously optimized, the formed spark plug product has high density, small sintering shrinkage, stable thermal performance, high production efficiency and strong applicability.

Owner:东莞市品酷机动车配件实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com