Method for preparing molybdenum tube

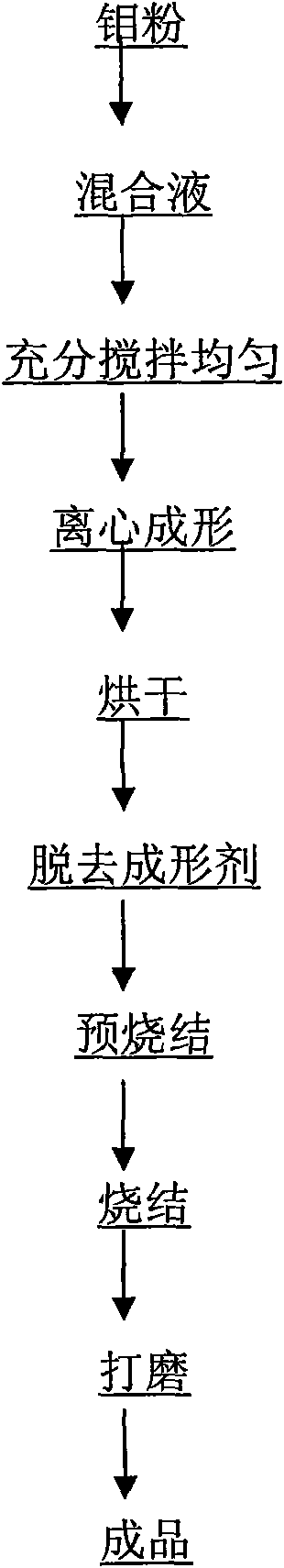

A molybdenum tube and a preparation process technology, applied in the field of metal tubes prepared by powder metallurgy, can solve the problems of difficult control of tube diameter and tube wall thickness, large amount of mechanical processing, poor wall thickness uniformity, etc., and achieve small sintering deformation, Small sintering shrinkage and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The particle size is 4.0μm, and the bulk density is 2.8g / cm 3 , 50kg of molybdenum powder with good fluidity is used as a spare. The molybdenum powder was placed in 150kg of water-based binder polyvinyl alcohol solution with a concentration of 20%, and stirred evenly for 2 hours. Then pour the molybdenum powder mixture into a centrifugal forming machine for molding at a speed of 3000 rpm. Stop the centrifugal forming machine, lift out the mold carefully, and demould the formed molybdenum tube billet. Afterwards, drying is carried out at a drying temperature of 200° C. and a drying time of 4 hours.

[0025] The dried molybdenum tube billets are subjected to degumming treatment at a degumming temperature of 600°C for 3 hours. Pre-sinter the molybdenum tube without the forming agent, the pre-sintering temperature is 1100°C, and the time is 4h.

[0026] The pre-sintered molybdenum tubes were sintered in an intermediate frequency furnace, the sintering temperature was 19...

Embodiment 2

[0029] The particle size is 3.5μm, and the bulk density is 1.7g / cm 3 10kg of molybdenum powder with good fluidity is used for spare. Put the molybdenum powder in 40kg of water-based binder polyvinyl alcohol solution with a concentration of 30%, and stir evenly for 2 hours. Afterwards, pour the molybdenum powder mixture into a centrifugal forming machine for forming at a speed of 5000 rpm. Stop the centrifugal forming machine, lift out the mold carefully, and demould the formed molybdenum tube billet. Afterwards, drying is carried out at a drying temperature of 200° C. and a drying time of 2 hours.

[0030] The dried molybdenum tube billets are subjected to degumming treatment at a degumming temperature of 600°C for 3 hours. Pre-sinter the molybdenum tube without the forming agent, the pre-sintering temperature is 1100°C, and the time is 4h.

[0031] The pre-sintered molybdenum tubes were sintered in an intermediate frequency furnace, the sintering temperature was 1900°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com