Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Increase the pressing density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

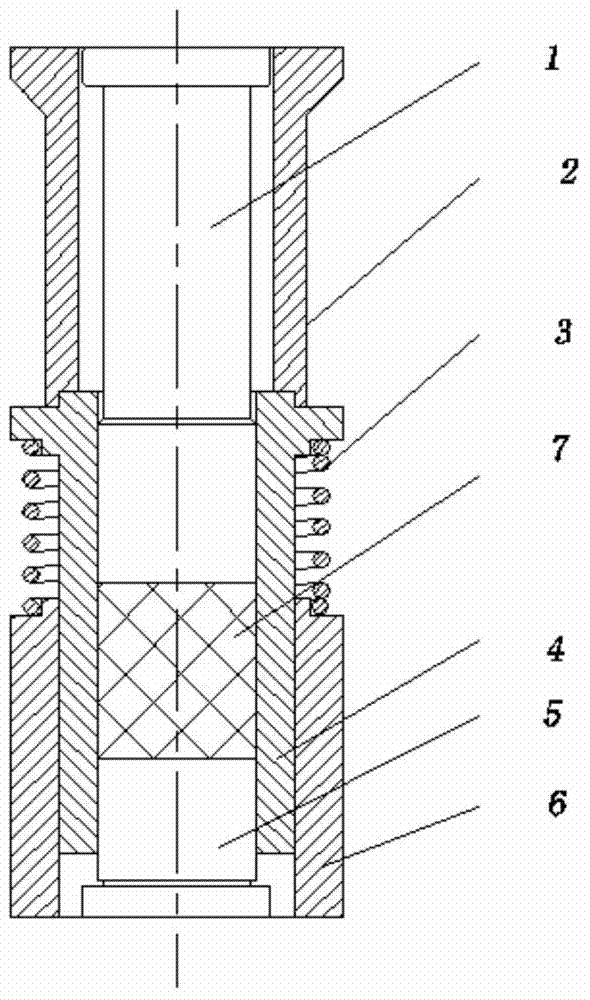

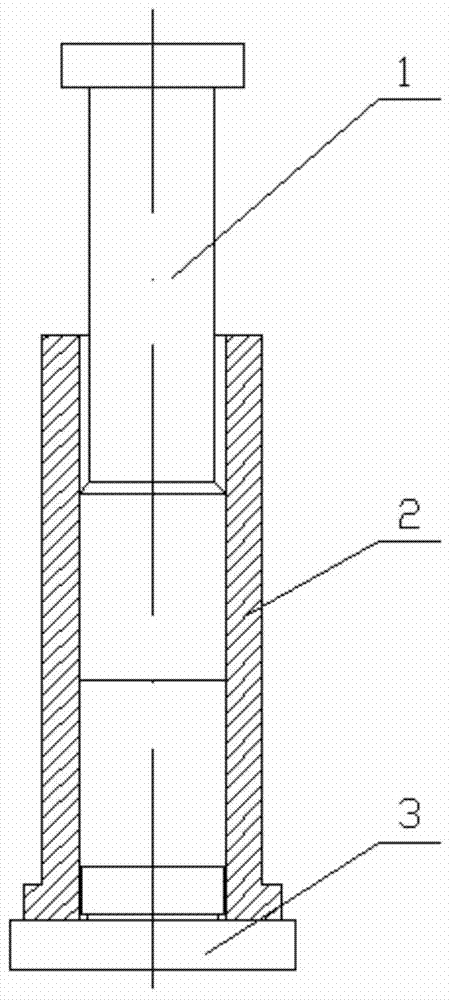

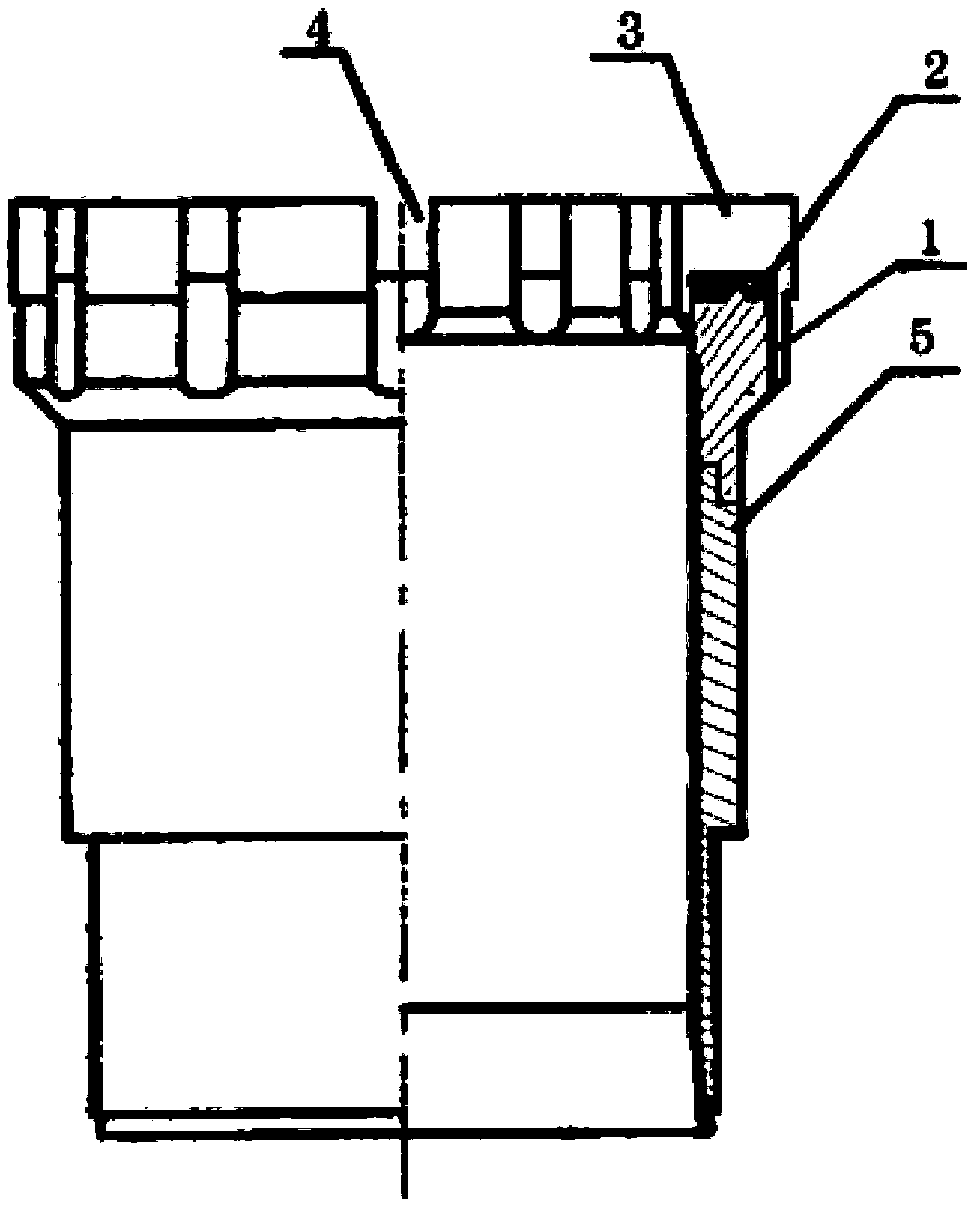

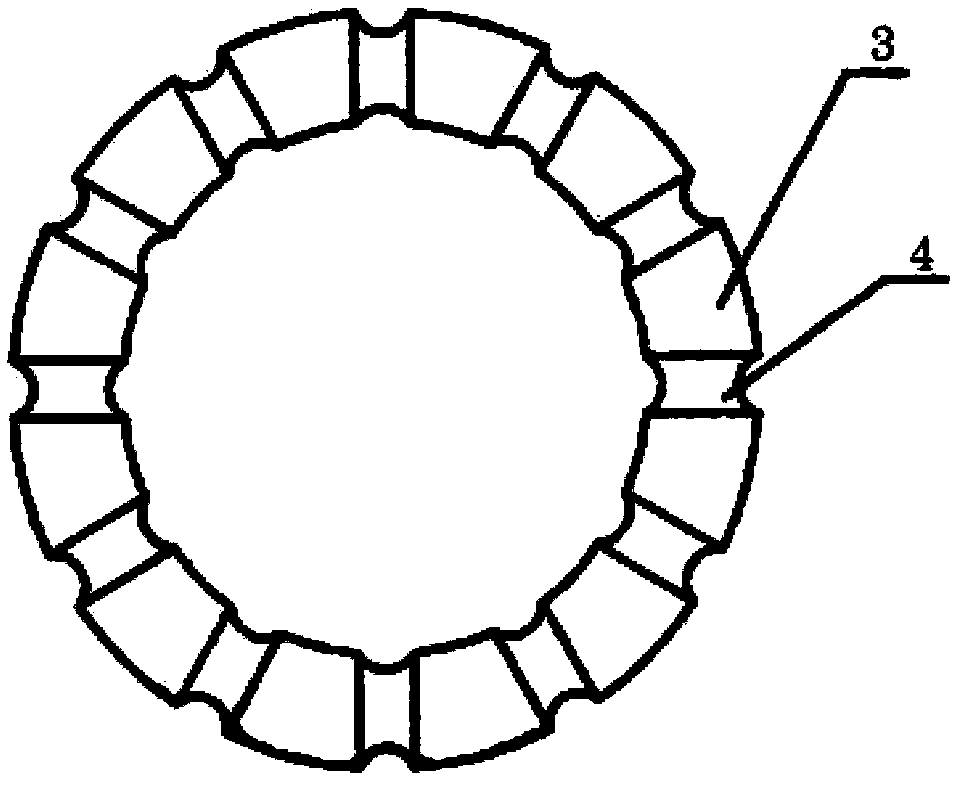

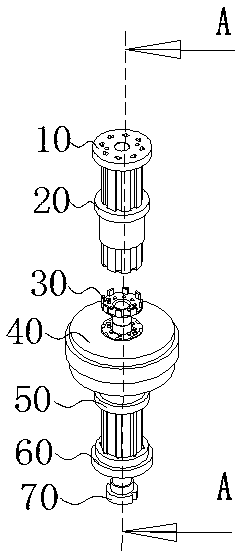

Explosive-shaped powder bidirectional pressing device

InactiveCN104290348ARealize two-way suppression functionImprove applicabilityExplosive working-up apparatusShaping pressVolumetric Mass DensityEngineering

The invention discloses an explosive-shaped powder bidirectional pressing device which is mainly composed of a punch, a die retreating cylinder, a compression spring, a die cylinder, a base and a bottom cylinder. The pressing process is safe, reliable, convenient and fast, the function of bidirectional pressing is achieved on a unidirectional die pressing machine, and the problem that the axial density of explosive pillars is not evenly distributed in the explosive-shaped powder pressing process of the unidirectional die pressing machine is solved. The explosive pillars pressed through the explosive-shaped powder bidirectional pressing device are complete in shape and even in density. The explosive-shaped powder bidirectional pressing device is suitable for the explosive die pressing technology.

Owner:XIAN MODERN CHEM RES INST

Preparation method of FeSi alloy powder with high direct current superposition characteristics

ActiveCN110039060AHigh tap densityImprove DC Superposition CharacteristicsTransportation and packagingMetal-working apparatusManganeseAlloy

The invention discloses a preparation method of FeSi alloy powder with high direct current superposition characteristics, and belongs to the technical field of alloy powder preparation. The FeSi alloypowder is mainly made of pure iron and metal silicon, and a small amount of manganese and chromium are added. The preparation method comprises the following steps of weighing the ingredients according to a specific proportion, carrying out non-vacuum melting to obtain the alloy melt of required components, and then atomizing to prepare alloy raw powder with an inert gas, obtaining fine powder after the raw powder is collected, screened and graded. According to the preparation method of FeSi alloy powder with high direct-current superposition characteristics, the alloy powder with uniform components and high purity can be obtained, and the powder spherical degree is high; the uniform and compact insulating layer can be easily formed after insulation coating, so that the contact of the alloy matrix is effectively blocked, and the pressed magnetic powder core has good direct-current superposition characteristics.

Owner:马鞍山新康达磁业股份有限公司

Ceramic thin plate manufacturing method

The invention discloses a ceramic thin plate manufacturing method. The method comprises the following steps of: (1) adding water and gluewater for wetly grinding mixed materials, and then preparing the mixed materials to mud pies, wherein the mixed materials comprise mineral fiber, clay and soapstone; (2) pressing the mud pies to a mud plate by adopting a cylinder ejection manner, and then pressing the mud plate for molding a mud blank; (3) drying the mud blank by adopting a microwave manner, and then cutting the mud blank into brick blanks; (4) glazing the brick blanks; (5) printing the glazed brick blanks; (6) heating for drying the glazed and printed brick blanks; (7) firing the glazed and printed brick blanks to semi-finished products at the high temperature in a kiln; and (8) polishing and edging the semi-finished products to obtain ceramic thin plates. By utilizing the ceramic thin plate manufacturing method, deformation of the brick blanks in the subsequent firing process can be avoided, the biscuit firing section is omitted, the energy consumption is reduced, the product water absorption is low, the product cost is reduced, and the product has high cost performance and strong international competitiveness.

Owner:厦门三荣陶瓷开发有限公司

Process for producing positive electrode active material for lithium secondary battery

ActiveUS7192672B2Solve the small densityImprove securityElectrode manufacturing processesFluoride preparationProduction rateAlkaline earth metal

To provide a process for producing a lithium-cobalt composite oxide for a positive electrode of a lithium secondary battery, which has a large volume capacity density, high safety, high charge and discharge cycle durability, high press density and high productivity.A process for producing a lithium-cobalt composite oxide represented by the formula LipCoxMyOzFa (wherein M is a transition metal element other than Co, or an alkaline earth metal element, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02), characterized in that as a cobalt source, a mixture is used which comprises cobalt hydroxide in the form of substantially spherical secondary particles with an average particle size of from 8 to 20 μm formed by agglomeration of primary particles and tricobalt tetroxide in the form of secondary particles with an average particle size of from 2 to 10 μm formed by agglomeration of primary particles, in a cobalt atomic ratio of from 5:1 to 1:5, and firing is carried out at from 700 to 1,050° C.

Owner:SUMITOMO CHEM CO LTD

High-performance powder metallurgy material and preparation method thereof

The invention discloses a high-performance powder metallurgy material and a preparation method thereof, components of the powder metallurgy material are Fe, Cr, Cu and C; components and contents thereof for preparing the powder metallurgy material are as follows (by weight percent): 0.35 to 0.5 percent of C, 1.3 to 1.5 percent of Cu, 0.6 to 1.0 percent of Cr, 0.6 percent of hard acid zinc 135, and the balance of Fe, wherein the Cr is added in the form of ferrochrome, the adopted ferrochrome is micro-carbon ferrochrome, and the ferrochrome contains 50 percent of chromium, 0.06 percent of carbon, and the balance of Fe; the hard acid zinc 135 is a lubricant; the powder mixing method of the powder metallurgy material is that the ferrochrome is first subjected to high-energy ball milling until particle diameter thereof is within the range of 0.3 to 1 Mum, and then the powder metallurgy material is mixed with other powder evenly; the pressing and sintering method of the powder metallurgy material is that cold pressing is conducted to powder mixed according to a proportion, with the pressure of 600MPa and the pressurizing speed of 150mm / min, and the powder is molded at 600MPa and then kept for 2min; and the sintering is conducted in dissociated ammonia protective atmosphere, with the temperature of 1120 DEG C, and the sintering time of 40min.

Owner:CHANGCHUN UNIV OF TECH

Cathode material and preparation method thereof and lithium-ion battery

InactiveCN105185982AExcellent capacity characteristicsEasy to processCell electrodesSecondary cellsSurface layerHeat stability

The invention provides a cathode material, which comprises a base material and an aluminum oxide layer, wherein the base material is prepared from a compound as shown in a formula I and a compound as shown in a formula II; the compound as shown in the formula I has a secondary particle morphology which is formed by agglomeration of a plurality of single crystal grains; the compound as shown in the formula II has a single-crystal structure; and the aluminum oxide layer coats the surface of the base material. The base material in the cathode material provided by the invention is prepared from the compound with the particle morphology and the compound with the single-crystal structure; due to the two morphologies of compounds, the cathode material has relatively good capacity characteristic; and the processability can also be improved. The aluminum oxide layer coats the surface of the base material in the cathode material provided by the invention; corrosion to the surface layer of the cathode material caused by moisture and HF in a battery can be avoided or reduced by coating of the aluminum oxide layer; and due to the cathode material with an aluminum oxide layer coating layer, the prepared lithium-ion battery has relatively high working voltage and heat stability. The invention further provides a preparation method of the cathode material and the lithium-ion battery.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

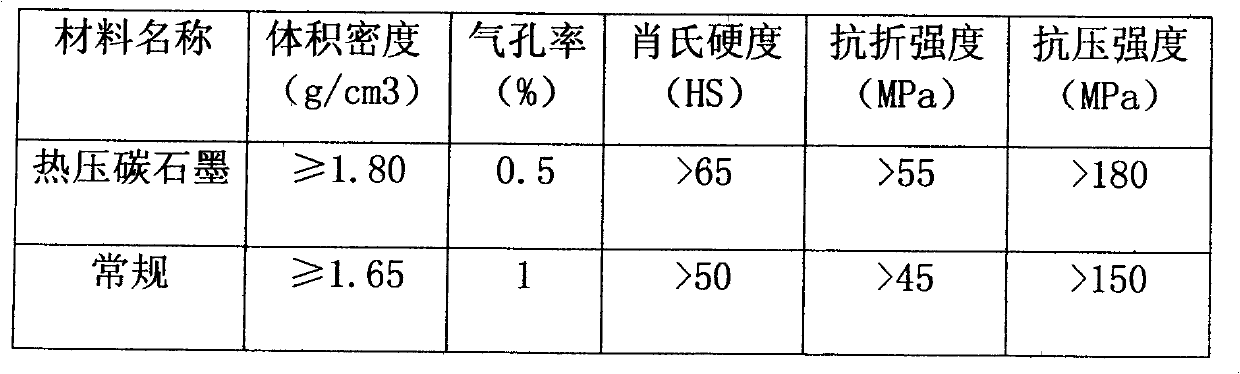

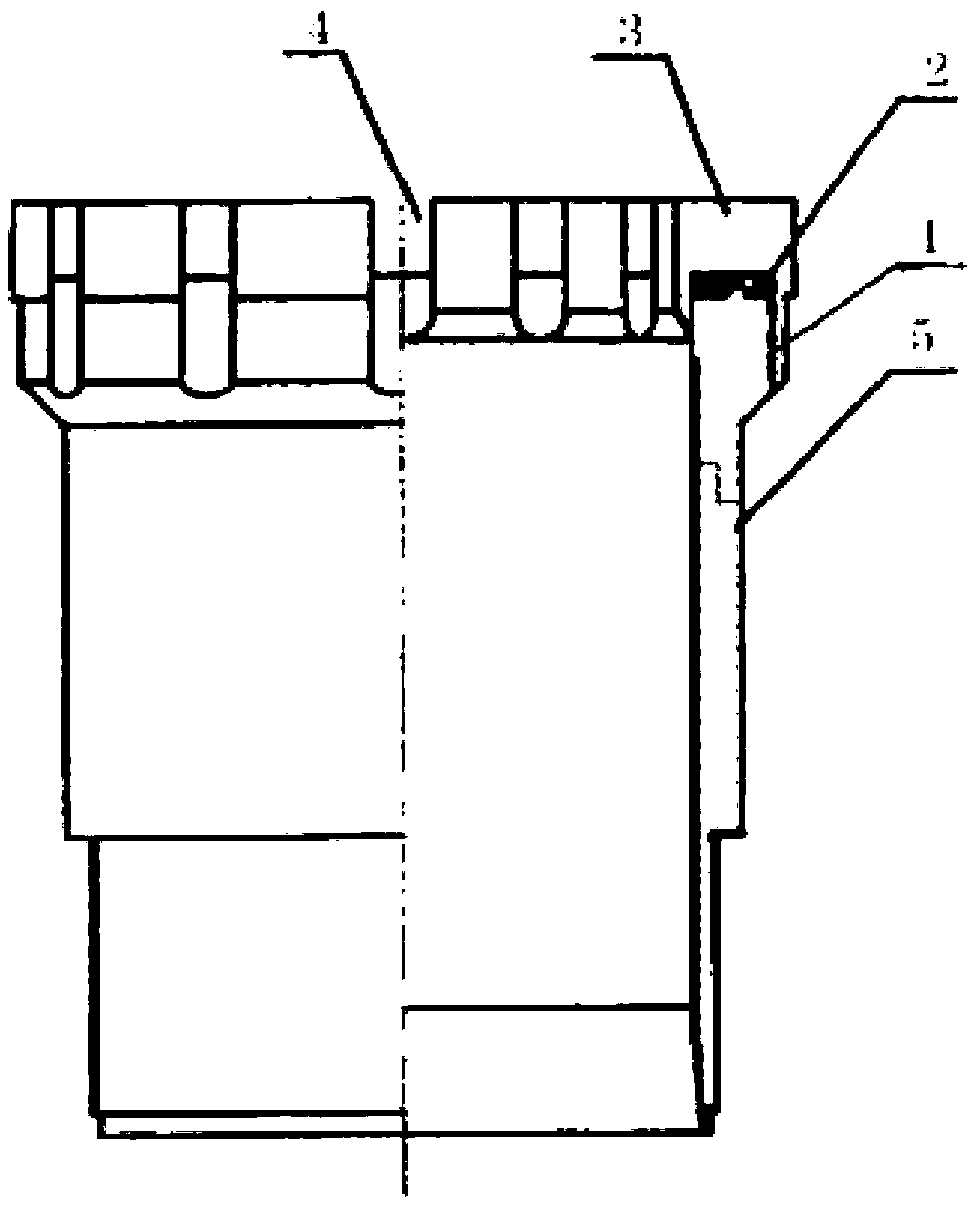

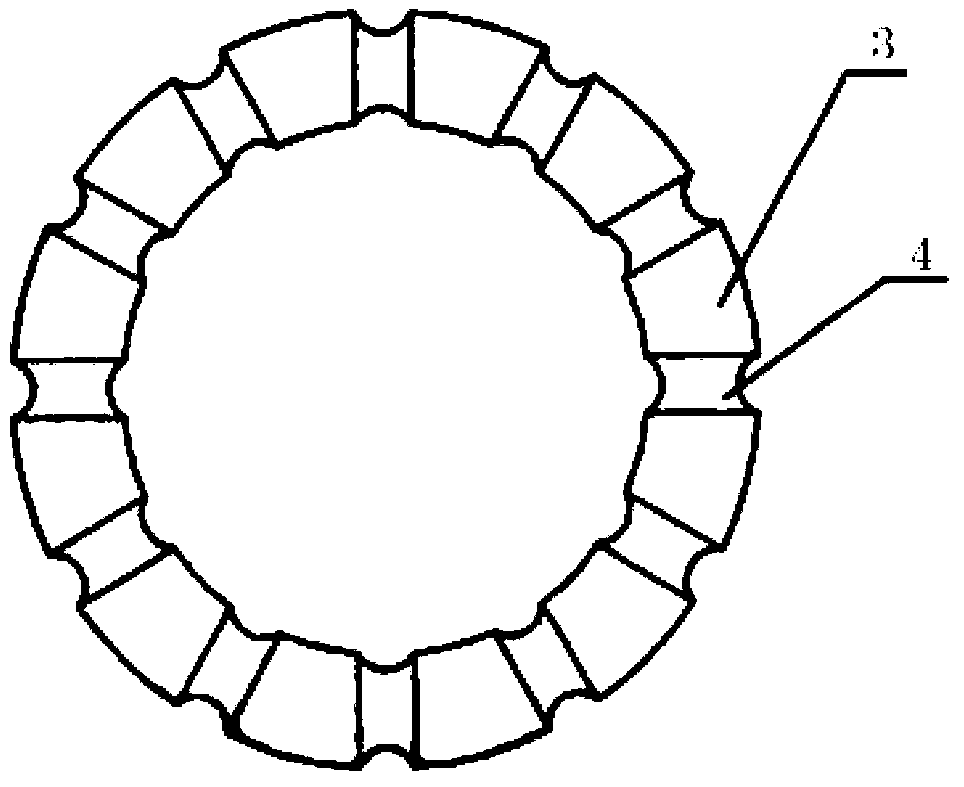

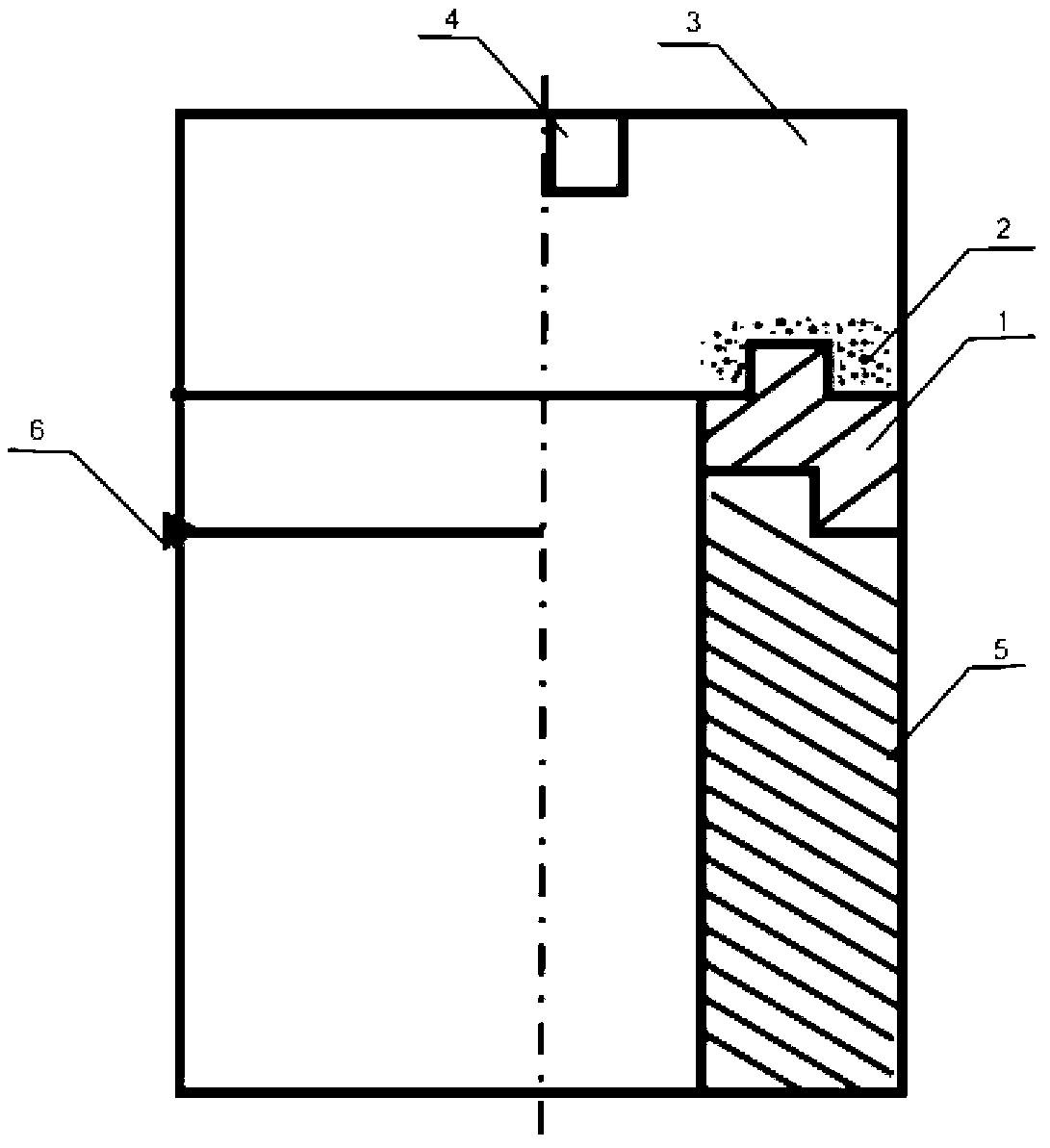

Production method of hot-pressing carbon graphite material

InactiveCN102886814AReduce porosityLow variabilityCeramic shaping apparatusPorosityHexamethylenetetramine

The invention relates to a production method of a hot-pressing carbon graphite material, and is characterized by comprising the following steps of: stirring phenolic resins, 99% alcohol, urotropine and oleic acid into a stirring kettle to prepare phenolic resin adhesive mixing solution; adding graphite powder, carbon black powder, pitch coke powder and needle type coke powder into a kneading kettle, mixing and kneading, heating, adding the phenolic resin adhesive mixing solution, stirring and mixing to obtain a clinker; cooling the clinker, grinding powder, pressing and molding, forming and mold pressing, forming and processing, removing burr and fin, cleaning, and drying or blowing to a finished product through hot blast. According to the invention, by adopting a two-section pressing method, porosity in a press is reduced, the pressed density is improved, the intensity and the wear resistance of a product are improved, materials and air holes are uniformly distributed, creep property of the finished product is reduced, the product has small deformation in a production process, and the precision of the product is improved, by adopting an advance mixing and kneading process, the amount of the resins is reduced, and the heat conductivity of the product is improved, so that the quality grade of the hot-pressing carbon graphite material product is improved, thus the hot-pressing carbon graphite material product has wider purposes.

Owner:WUXI ZHONGQIANG ELECTRIC CARBON CO LTD

Method for manufacturing dry-pressing heterosexual permanent-magnetic material

The invention discloses a method for manufacturing a dry-pressing heterosexual permanent-magnetic material, and belongs to the technical field of a permanent-magnetic material. The method comprises the following steps: crushing a pre-sintering material into crude powder, adding a quadratic formula formed by silicon dioxide and a boric acid to the crude powder and then carrying out ball-milling; scattering the slurry obtained in a ball-milling manner after baking; adding 0.1-3.0% of calcium carbonate according to the weight percent and then agitating and vibration and milling by a blender mixer to obtain mixed powder; adding allocated quantity of camphor powder and calcium stearate to the mixed powder, and then crushing at a high speed, so as to prepare the dry-pressing magnetic powder. Even dispersion can be ensured by adding the calcium carbonate after drying of fine powder is finished, and adhesion of particles is not generated. Therefore, the pressing density of a magnetic body and the control range of the drying temperature range can be improved, and meanwhile, birdnesting is opened as much as possible by a vibration and milling process. Thus, birdnesting between particles is reduced, meanwhile, a corner angle is removed, the prepared permanent-magnetic material has good orientation degree and density, and the performance is significantly improved.

Owner:BEIKUANG MAGNETS FUYANG CO LTD

Process for producing positive electrode active material for lithium secondary battery

InactiveUS7270797B2Solve the small densityImprove securityAluminium compoundsElectrode thermal treatmentProduction rateLithium carbonate

To provide a process for producing a lithium-cobalt composite oxide for a positive electrode of a lithium secondary battery excellent in volume capacity density, safety, charge and discharge cyclic durability, press density and productivity, by using in expensive cobalt hydroxide and lithium carbonate. A mixture having a cobalt hydroxide powder and a lithium carbonate powder mixed so that the atomic ratio of lithium / cobalt would be from 0.98 to 1.01, is fired in an oxygen-containing atmosphere at from 250 to 700° C., and the fired product is further fired in an oxygen-containing atmosphere at from 850 to 1,050° C., or such a mixture is heated at a temperature-raising rate of at most 4° C. / min in a range from 250 to 600° C. and fired in an oxygen-containing atmosphere at from 850 to 1,050° C.

Owner:AGC SEIMI CHEM CO LTD

High-performance powder metallurgy material and manufacturing method thereof

The invention relates to a high-performance powder metallurgy material, wherein components of the powder metallurgy material are iron powder, aluminum powder, chromium iron, zinc stearate and graphite powder; a manufacturing method of the high-performance powder metallurgy material comprises the steps of ball-grinding the chromium iron till the particle diameter is 0.3-1 microns; uniformly mixing with other powders according to the proportion; performing ball-grinding in a high-performance ball grinder for 5-15 min, wherein the ball-grinding medium is anhydrous organic liquid; in the invention, Al is added in the main component, so that the performance of the powder metallurgy material is improved; the indoor bending strength is 2500 MPa and the relative density is more than 99.9%; high pressing density can be obtained after cold-pressing (pre-pressing) is maintained for a certain time; the prepared sintered steel has a uniform texture, high strength and plasticity, excellent performances and low cost.

Owner:张云

Warm-pressing process of powder metallurgy

The invention discloses a warm-pressing process of powder metallurgy. The warm-pressing process comprises the following steps of: a, weighing an alloy powder raw material, a lubricating agent and an additive; mixing the alloy powder, the lubricating agent and the additive in a weight ratio of (10-30): 1: 1 to form a mixed material; b, pressing the mixed material into a pre-formed blank; carrying out warm-pressing treatment on the pre-formed blank; controlling the temperature to 130-150 DEG C and controlling the time to 10-12 hours, wherein the pressing density of warm-pressing forming treatment is 7.5-8g / cm<3>; putting into a furnace to be sintered, wherein the sintering temperature is 1200-1400 DEG C; c, de-burring the sintered pre-formed blank; cutting and machining to form a rough product; and d, carrying out immersing treatment on the rough product; and carrying out surface steam treatment at the temperature of 420-550 DEG C to obtain a finished-product part. The process disclosed by the invention has simple steps; the pressing density is improved by adopting a warm-pressing forming treatment process and the cost of the warm-pressing process is only 1.25; the surface smoothness is good and the sintering shrinking percentage is small; and the yielding strength and the impacting toughness are better than those of a traditional process.

Owner:曹艺

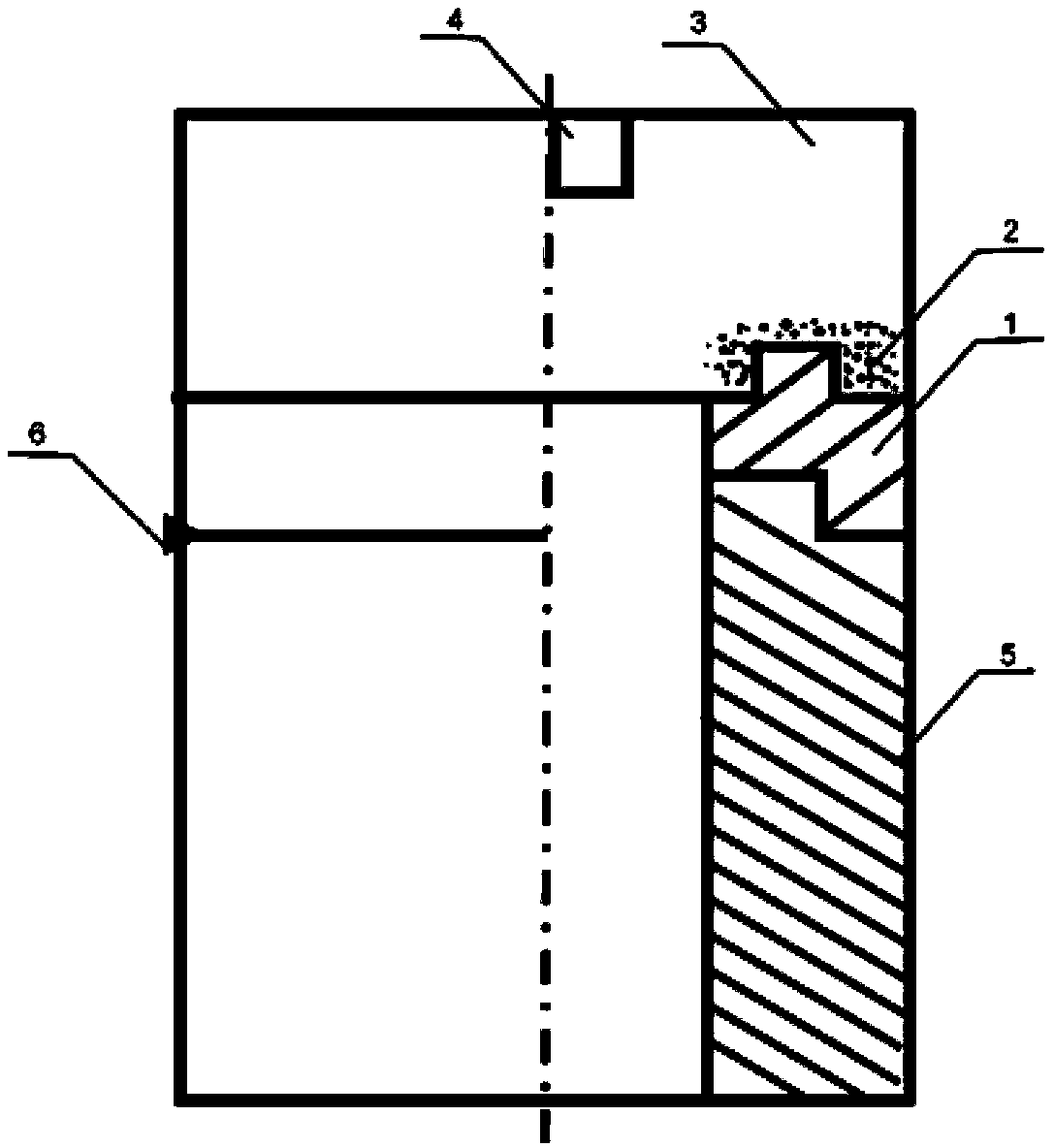

Process for preparing diamond geological coring bit

The invention discloses a process for preparing a diamond geological coring bit. The process comprises the following steps: (1) filling a water gap material in a mold, and filling a mixture of diamond and powder; (2) filling welding layer powder; (3) inserting a working steel body; (4) putting into a resistor sintering furnace, making the working steel body wait to be sintered and vertically pressed, and ensuring that the resistor area is 1 / 3 of the whole mold area; (5) heating, and applying pressure which is 1 / 3 of the total pressure 12-18MPa when the temperature is raised to 720-780DEG C; (6) applying the total pressure 12-18MPa when the temperature is raised to 850-1,000DEG C, and keeping the temperature and the pressure for 2 to 5 minutes, wherein the temperature rise speed is 100-200DEG C / min; (7) stopping heating and cooling; and (8) stopping applying pressure when the temperature is reduced to 680-720DEG C, taking out of the furnace, and cooling. The diamond geological coring bit prepared by the process has the average life of 30-70 meters and the ageing of 2-5 meters, and effectively resolves conflicts between efficiency and service life in geological drilling.

Owner:WUHAN KERUITE MUNICIPAL EXPLORATION TECH

Pressureless sintering silicon carbide and preparation process thereof

Pressureless sintering silicon carbide comprises the following components by mass: 80% to 90% of silicon carbide, 6% to 9% of resin, 0.5% to 0.8% of boron carbide, and the balance release agent. The preparation process for processing the pressureless sintering silicon carbide includes first stirring raw materials for 15 to 25 hours through a powder mixing machine to completely mix the raw materials, conducting spraying pelleting on the raw materials in the material mixing machine, forming powder materials after pelleting in press mode through a press, then filling the powder materials into a sintering furnace, conducting vacuumizing to -0.01MPA, stopping vacuumizing when the temperature rises to 1200 DEG C, filling argon into the sintering furnace to the normal pressure, then enabling temperature to rise to 1800 DEG C, keeping warm for 30 minutes, then continuously enabling the temperature to rise to the range from 2150 DEG C to 2200 DEG C, keeping warm for 30 to 50 minutes and enabling the powder materials to be naturally cooled. Due to the fact that fine powder materials are selected, compression density of product green bodies is improved, resin content is adjusted, the silicon carbide powder materials can conduct chemical reaction more fully in the sintering process, the density can reach 3.18g / cm<3>, and the hardness can reach 2400 HV0.5. The pressureless sintering silicon carbide has better abrasion resistance due to the fact that the density, the hardness and the compression strength are all improved.

Owner:乐清市东迅密封科技有限公司

Lithium ion battery having improved thermal stability

ActiveUS20170352876A1Improve thermal stabilityTest may passSecondary cellsPositive electrodesAluminium-ion batteryLithium metal

Aspects of the invention are based on the discovery that cathode materials and lithium ion batteries comprising the cathode material, having improved thermal stability may be produced from a cathode material that is comprised of a mixture of a lithium metal oxide and a lithium metal phosphate wherein the lithium metal phosphate comprises a volume fraction of secondary particles having a size of 0.1 to 3 μm that is from 5 to 100%, based on the total content of lithium metal phosphate. More specifically cathodes comprising lithium metal phosphates having the recited secondary particle ranges help provide cathode materials that are capable of passing the nail penetration test without generating smoke or flames. Methods of forming the cathode and lithium ion battery comprising the cathode are also provided.

Owner:JIANGSU HENGTRON NANOTECH CO LTD

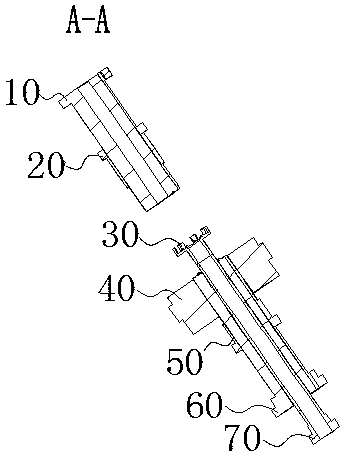

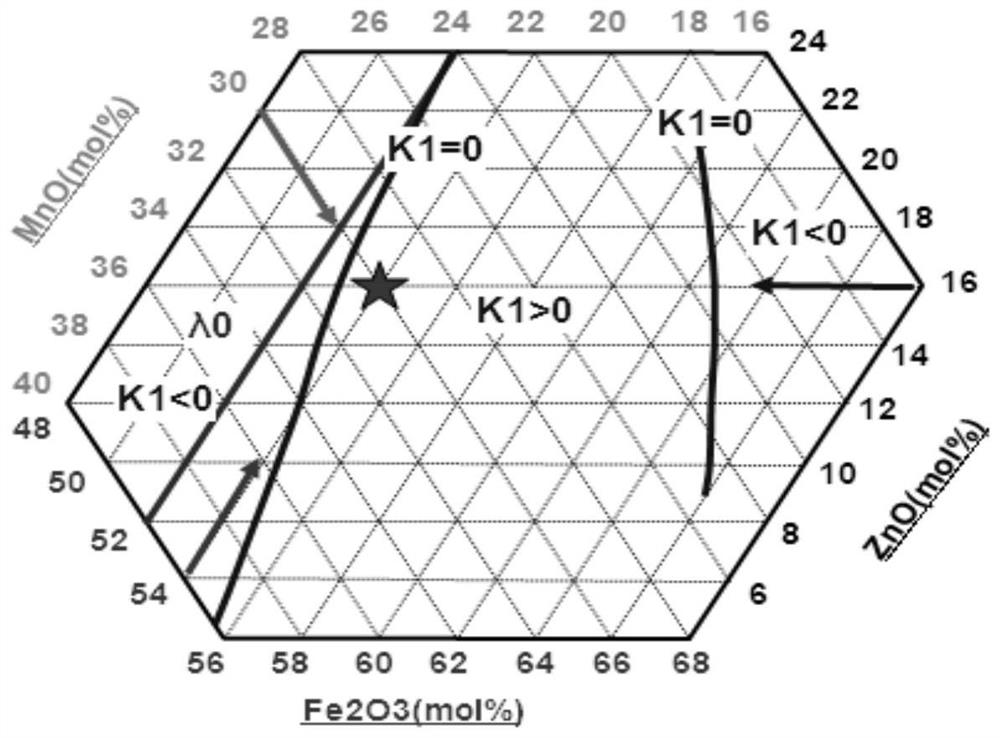

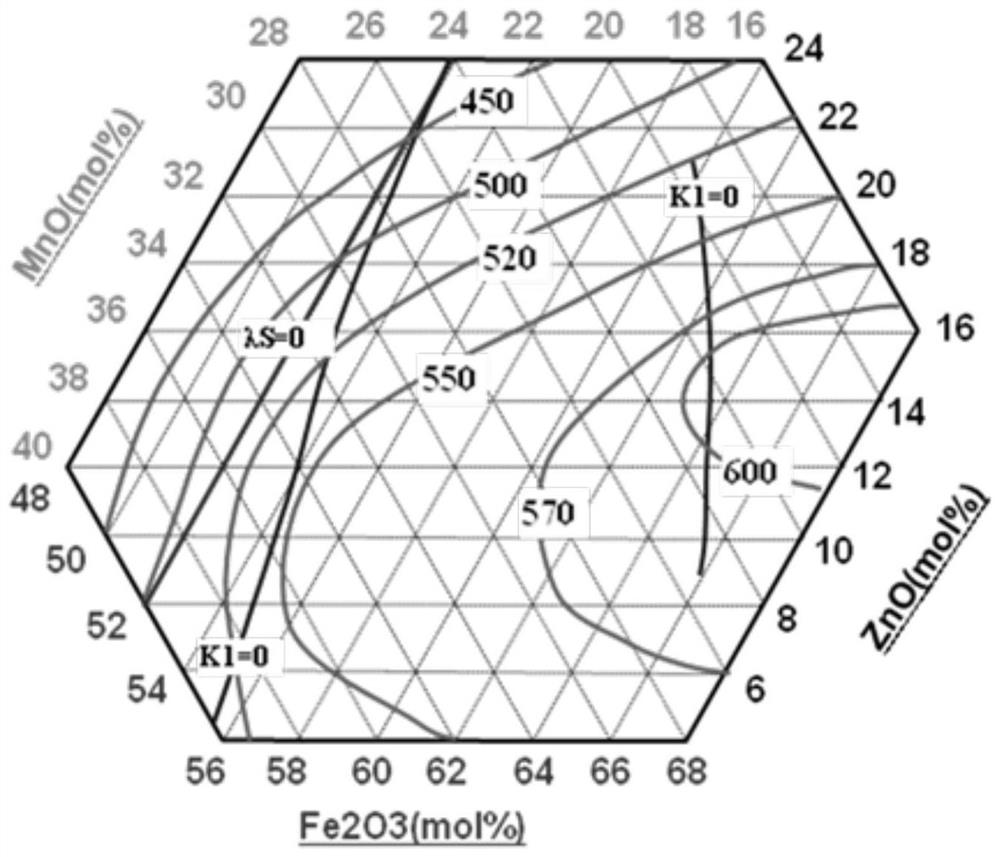

Wireless charging magnetic core for intelligent watch and preparation method thereof

ActiveCN111978079AImprove particle size distributionImprove liquidityTransformersTransformers/inductances magnetic coresPlanar inductorMechanical engineering

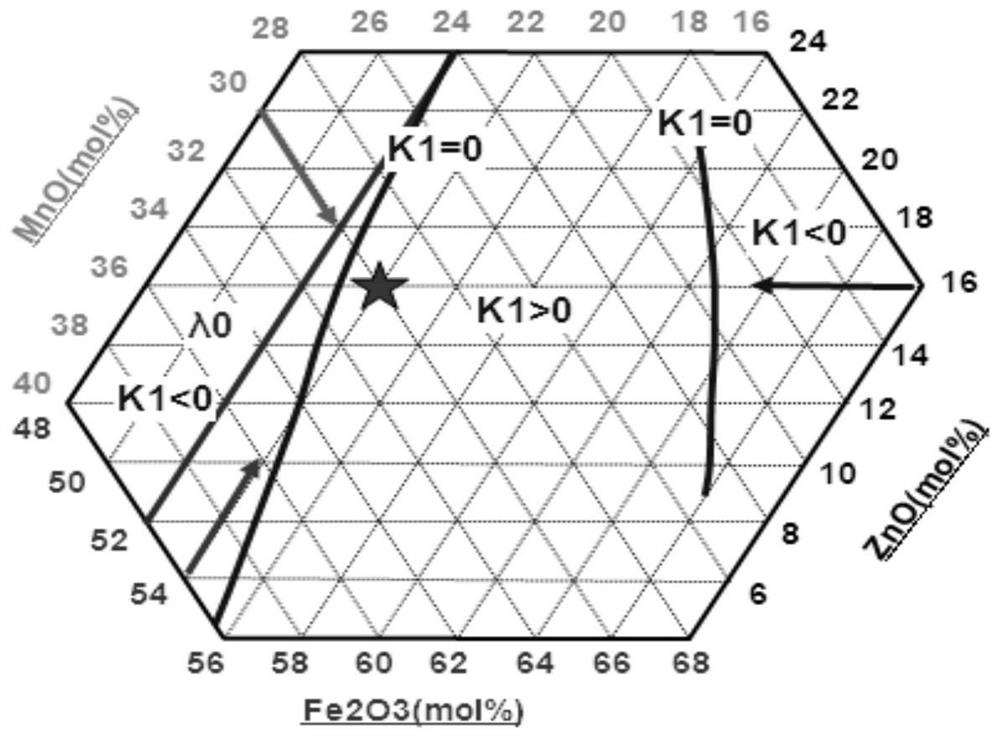

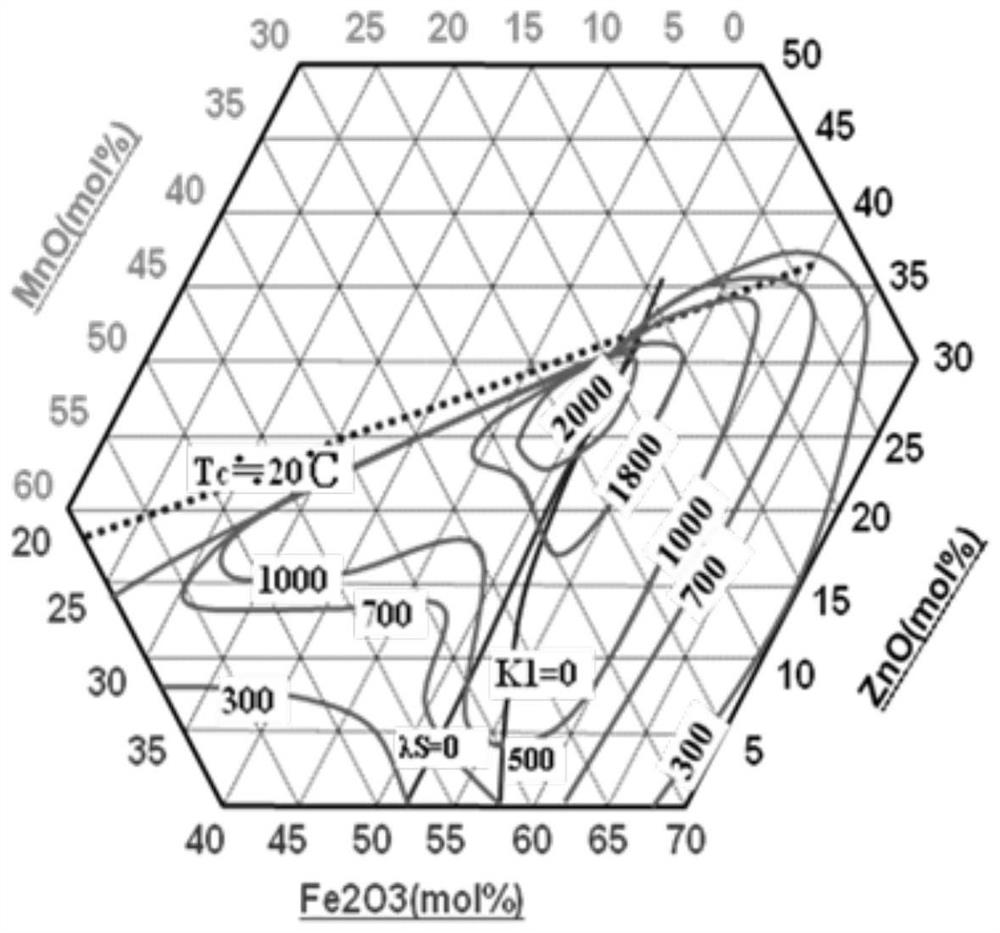

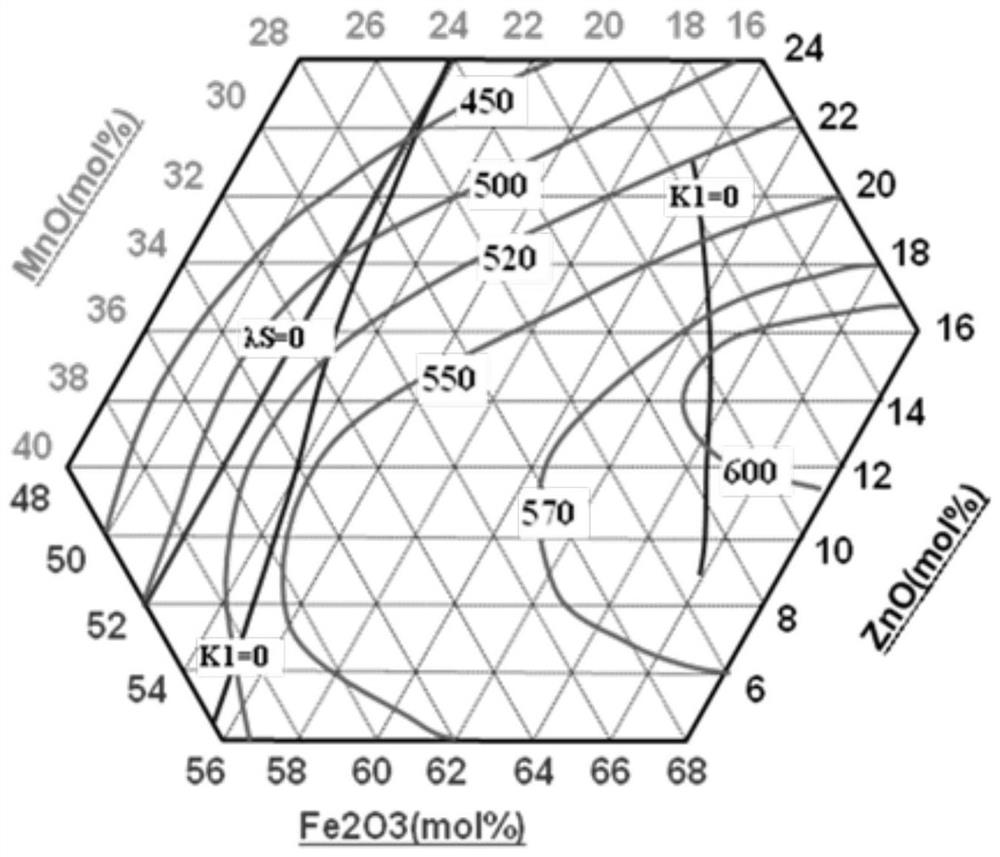

The invention discloses a wireless charging magnetic core for an intelligent watch and a preparation method thereof. Raw materials of the wireless charging magnetic core comprise a main component andan additive, the main component comprises 51.5 to 53.5% Fe2O3, 9.0 to 12.5% ZnO by mole percent, and the balance is MnO; and the additive comprises 100-600 ppm V2O5, 0-200 ppm MoO3, 2000-4500 ppm Co2O3, 100-1000 ppm CaCO3, and 100-500 ppm Nb2O5. The preparation method adopts centrifugal granulation and adopts sealing molding during integral molding. According to the wireless charging magnetic core, types and dosage of main component and additive are reasonably selected, and centrifugal granulation and sealing molding are used. The prepared wireless charging magnetic core has high planar inductance and profiling inductance, low loss in a wide temperature range, sufficient strength and toughness to meet the requirements of use.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Preparation method of high-voltage ultra-small-capacity non-solid electrolyte tantalum electrolytic capacitor

ActiveCN110797216AHigh strengthNot easy to drop blocks and missing cornersCapacitor manufactureElectrolysisTantalum capacitor

The invention belongs to the technical field of tantalum capacitor preparation and particularly relates to a preparation method of a high-voltage ultra-small-capacity non-solid electrolyte tantalum electrolytic capacitor. The method is characterized in that pressing density is improved, a molding mode is changed, the increasing sintering temperature and sintering time are increased, so the strength of a tantalum core is enhanced, tantalum cores are not easy to fall off and have unfilled corners, impurities in tantalum powder are effectively removed, a tantalum core with excellent electrical performance is obtained through an improved forming method, aging process treatment is combined, so the voltage of the prepared non-solid electrolyte tantalum capacitor can reach 180V, the capacitance can reach 0.047 mu F, and the non-solid electrolyte tantalum capacitor has the characteristics of high voltage and ultra-small capacitance.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

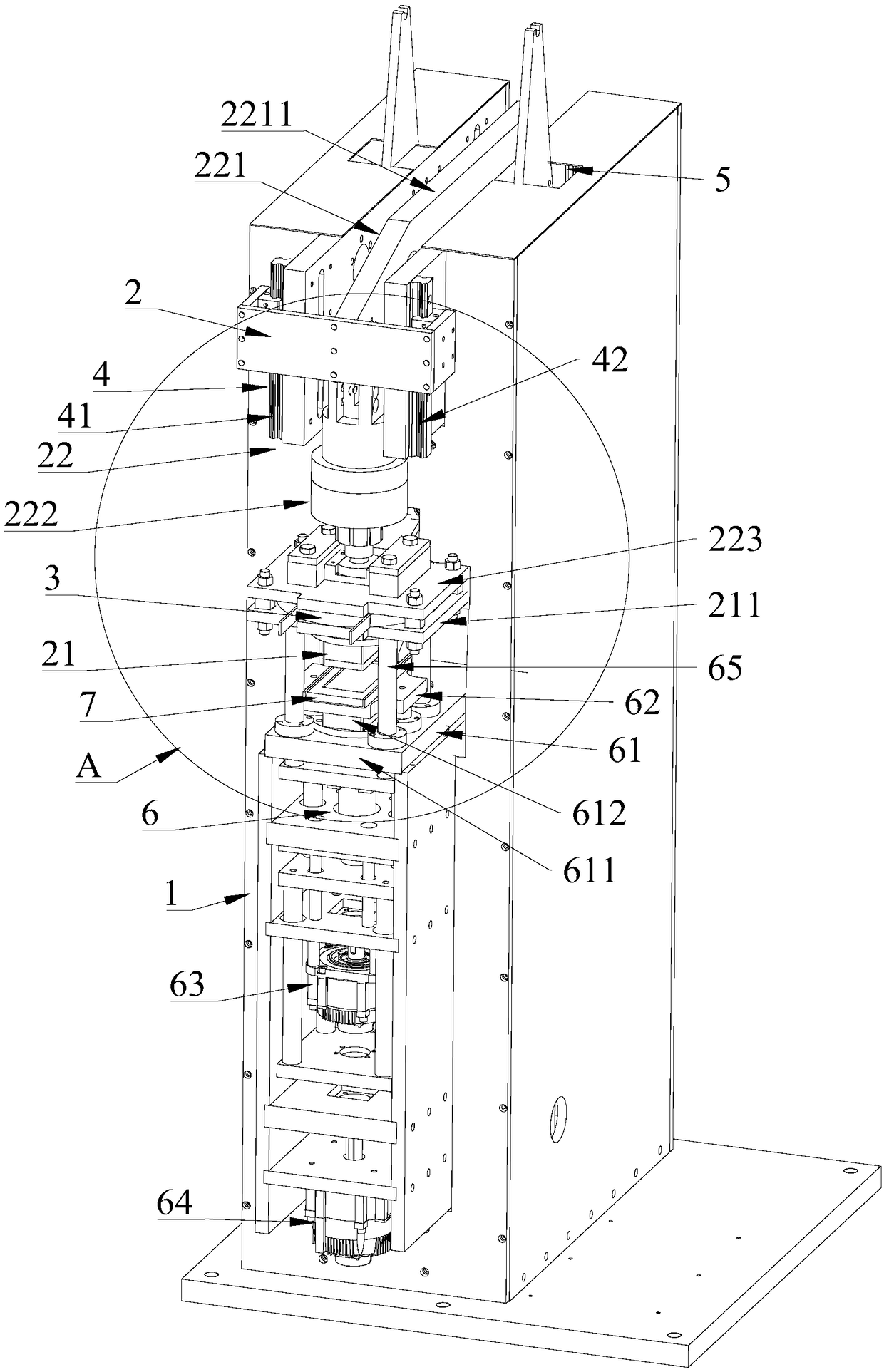

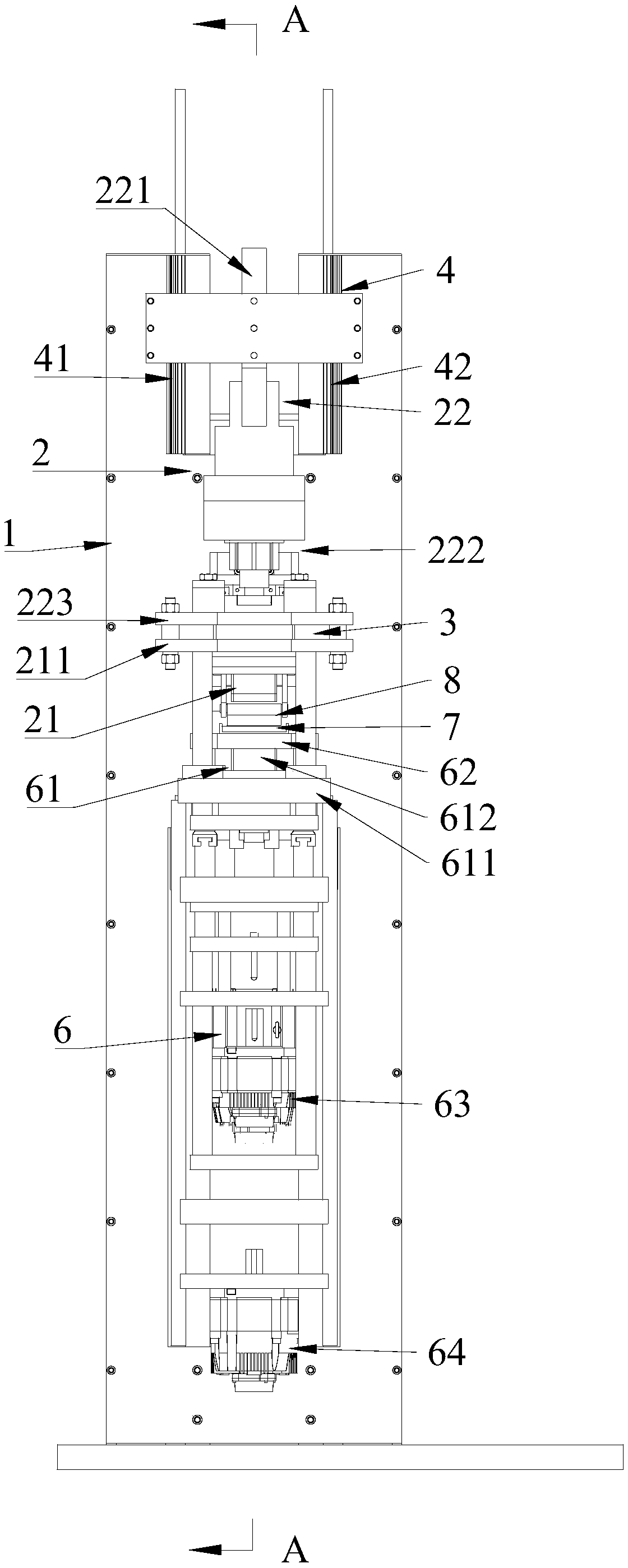

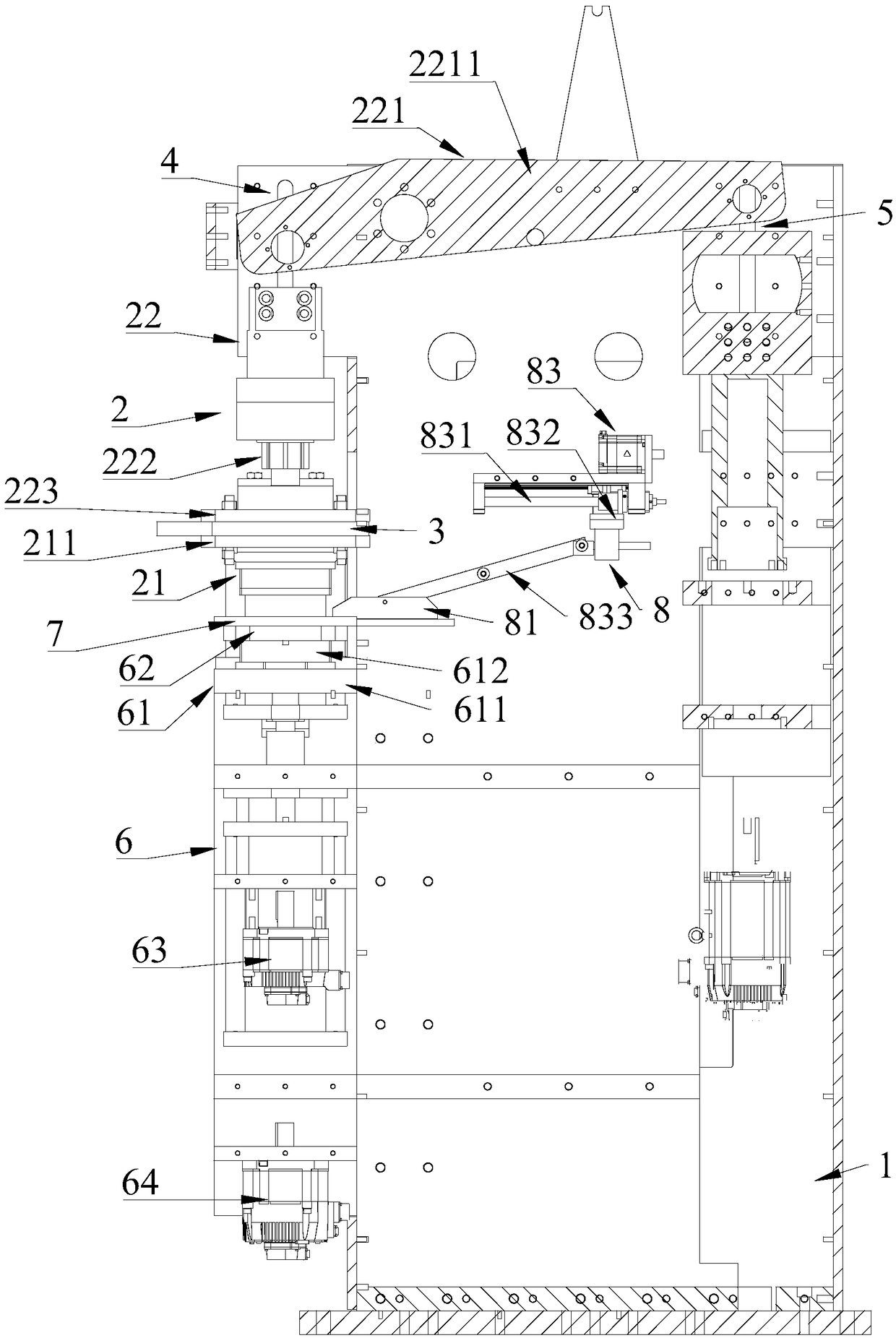

Powder pressing machine

The invention relates to a powder pressing machine. The powder pressing machine comprises a rack, an upper punching device, a lower punching device and a die device, wherein the upper punching deviceand the lower punching device are respectively located on the upper and lower sides of the die device, the lower punching device comprises a lower punch assembly which is installed on the rack, a connecting seat which is connected with the die device and a first driving mechanism which is in driving connection with the connecting seat, the die device can move up and down relative to an upper punchassembly under the action of the first driving mechanism, the upper punching device is provided with the upper punch assembly, a second driving mechanism and a coil assembly, the coil assembly is installed between the upper punch assembly and the second driving mechanism, and an electric box is electrically connected to the coil assembly. Compared with the prior art, the powder pressing machine is combined with a servo punching mode and a pulse punching mode so as to punch a pressing piece for two times, so that the density of finished products is greatly increased.

Owner:东莞市新日宝成形机器设备有限公司

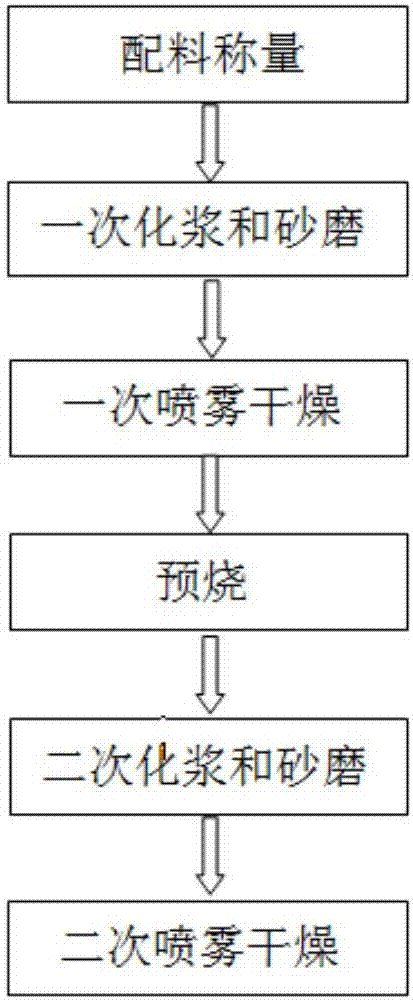

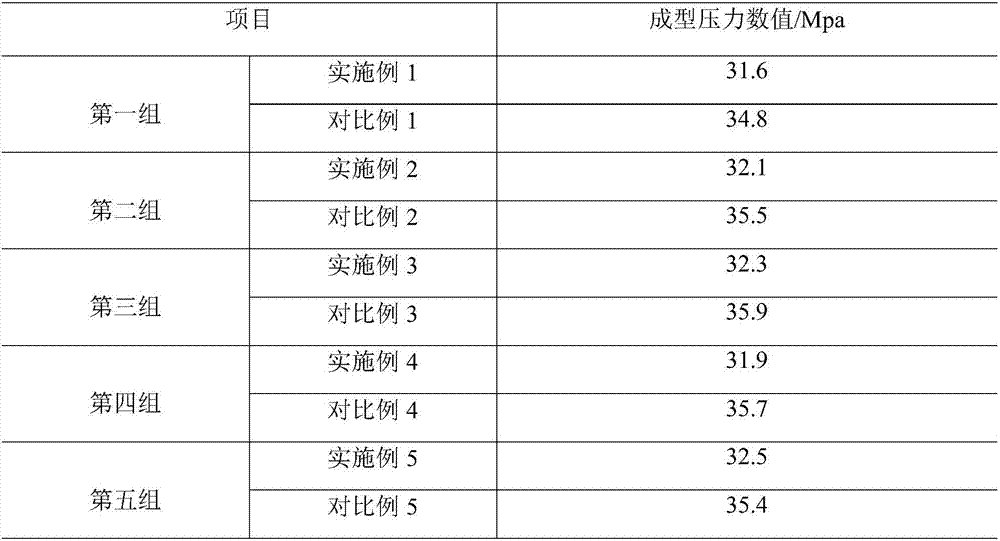

Automatic production process for soft magnetic manganese zinc ferrite granules

ActiveCN107129290AIncrease the pressing densityExtended service lifeInorganic material magnetismMagnetic corePlasticizer

The invention discloses an automatic production process for soft magnetic manganese zinc ferrite granules and belongs to the technical field of production of soft magnetic manganese zinc ferrite granules. The process comprises the following steps: batch weighing, primary pulping and grinding, primary spray-drying, pre-sintering, secondary pulping and grinding and secondary spray-drying, adding a plasticizer before secondary spray-drying, uniformly stirring and mixing, and performing spray-drying, wherein the plasticizer refers to a phthalic ester plasticizer. With the adoption of the phthalic ester plasticizer, on one hand, the plasticity of the powder is enhanced, plastic deformation (crushing) of powdered granules is easily caused, and the pressed density of a magnetic core is improved. Under the same strength condition of the magnetic core, the molding pressure of the granules can be reduced from 34-36Mpa to 31-33Mpa, the wear rate of a press is reduced by 0.1-0.5%, and the service life of the mold is prolonged by 0.1-0.5%; and the layering phenomenon in the magnetic core pressing process is reduced, and the production efficiency and product quality of the magnetic core are improved.

Owner:马鞍山新康达磁业有限公司

Process for preparing diamond geological coring bit

ActiveCN102704855BExtend your lifeAdjust the blade heightDrill bitsElectrical resistance and conductancePolymer science

Owner:WUHAN KERUITE MUNICIPAL EXPLORATION TECH

Additive used for improving stainless steel sintered density and method for manufacturing relevant stainless steel sintered component with additive

ActiveCN105648300AIncrease the pressing densityThe formula is scientific and reasonableRise rateOrganic matter

The invention discloses an additive used for improving the stainless steel sintered density and a method for manufacturing a stainless steel sintered component with the additive. The additive is composed of low-melting-point ferroalloy powder, low-carbon organic acid matter and low-temperature lubricant. After the additive is added to stainless steel powder, the stainless steel powder is pressed under the pressure of 600-900 MPa, and the component is sintered at the temperature of 1200-1350 DEG C. Fast temperature-rising is adopted when the temperature-rising period is 600 DEG C or above, and the temperature-rising rate is 15-60 DEG C / min. The high-density stainless steel sintered component is obtained after sintering. Due to the fact that low-melting-point organic matter is added, when die pressing is conducted, part of liquid lubricant is generated and diffused to the die wall, so that die wall friction is reduced, and the pressing density of the stainless steel powder is well improved. The stainless steel powder is coated with the organic matter and activated before sintering (600-900 DEG C). Meanwhile, low-melting-point alloy is liquefied during sintering, so that a facilitating function is achieved on sintering of the stainless steel powder. The formula of the additive is scientific and reasonable, so that the pressing density of the stainless steel powder can be effectively improved, and a sintered product has higher density and mechanical performance.

Owner:NBTM NEW MATERIALS GRP

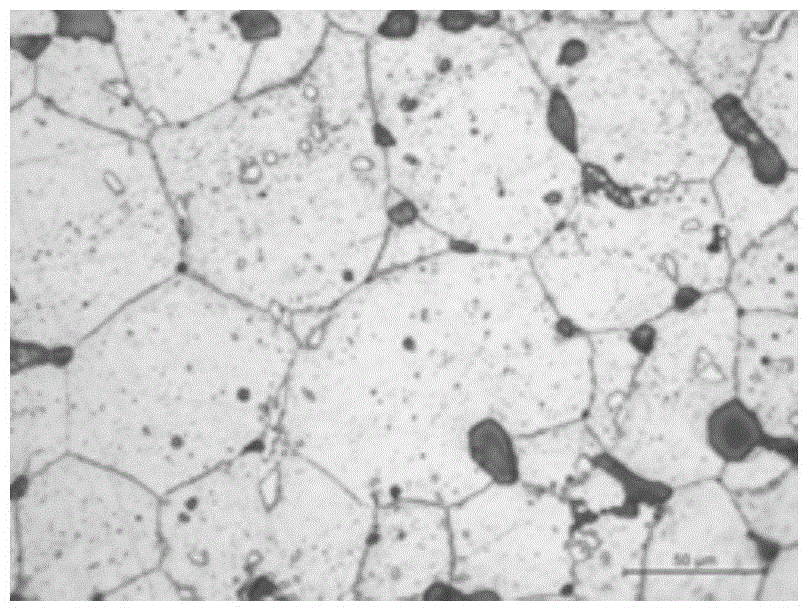

Lithium cobalt oxide, method for manufacturing the same, and nonaqueous electrolyte secondary battery

ActiveUS20080087862A1Fine powderLarge discharge capacitySecondary cellsActive material electrodesElectrical batteryPhysical chemistry

Lithium cobalt oxide, which can provide a nonaqueous electrolyte secondary battery having an excellent initial capacity and an excellent capacity retention, and a method for manufacturing the same are provided. The lithium cobalt oxide has a tap density of at least 1.7 g / cm3 and a pressed density of 3.5 to 4.0 g / cm3. A method for manufacturing the lithium cobalt oxide includes the step of selecting a lithium cobalt oxide (A) and a lithium cobalt oxide (B) so that a difference in the tap density between the lithium cobalt oxide (A) and the lithium cobalt oxide (B) is at least 0.2 g / cm3; and mixing the lithium cobalt oxide (A) and the lithium cobalt oxide (B).

Owner:NIPPON CHECMICAL IND CO LTD

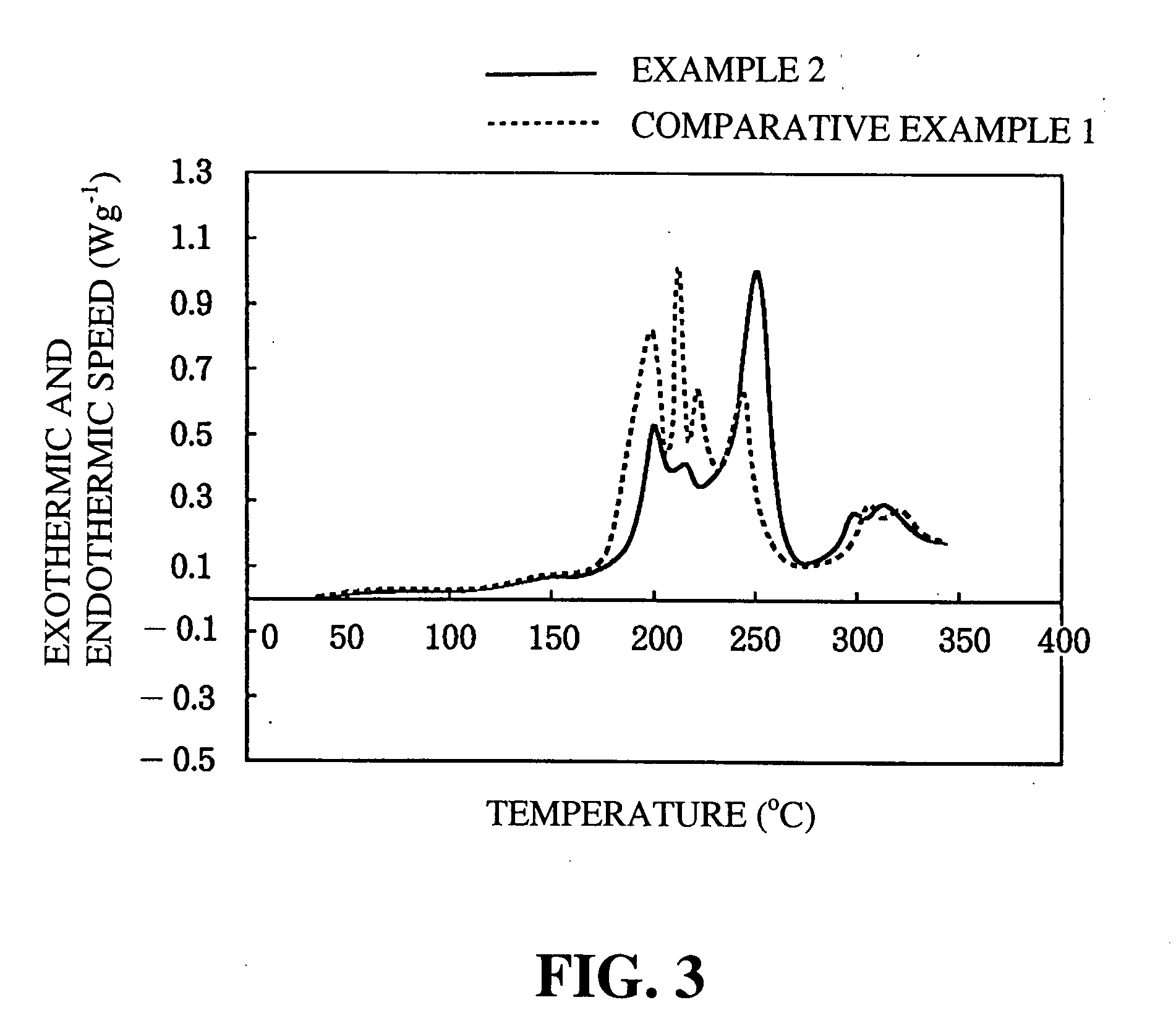

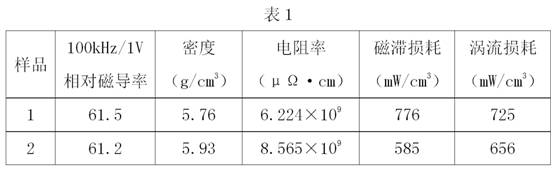

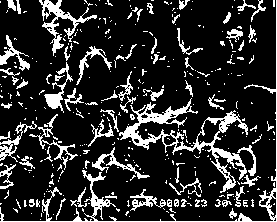

Preparation method of low-loss soft magnetic composite material

ActiveCN113539662AHigh resistivityReduce eddy current lossInorganic material magnetismInductances/transformers/magnets manufactureAluminium chlorideOxide composite

The invention provides a preparation method of a low-loss soft magnetic composite material, and belongs to the technical field of magnetic materials. The preparation method comprises the following steps of: putting metal magnetic powder into a mixed solution of magnesium chloride and aluminum chloride, then adding excessive ammonia water into the mixed solution, and carrying out two-step calcination, pressing and annealing treatment to obtain the magnesium oxide and aluminum oxide composite insulated low-loss soft magnetic composite material. Taking the aerosolized Fe-Si-Al soft magnetic composite material with the relative permeability level of 60 as an example, compared with a magnetic core prepared by a conventional method, the magnetic core prepared by the method has the advantages that the pressing density is improved by 2.8%, and the magnetic hysteresis loss is reduced by 24.6%. The specific resistance of the soft magnetic composite material is improved from 6.224 * 10 < 9 > [mu]omega cm to 8.565 * 10 < 9 > [mu]omega cm, and the eddy current loss at 500 kHz / 50 mT is reduced by 69 mW / cm < 3 >. A magnesium oxide and aluminum oxide composite insulating layer obtained through two-step calcination obviously improves the pressing density and specific resistance of the soft magnetic composite material, and meanwhile reduces the magnetic hysteresis loss and the eddy current loss of the soft magnetic composite material.

Owner:安徽瑞德磁电科技有限公司

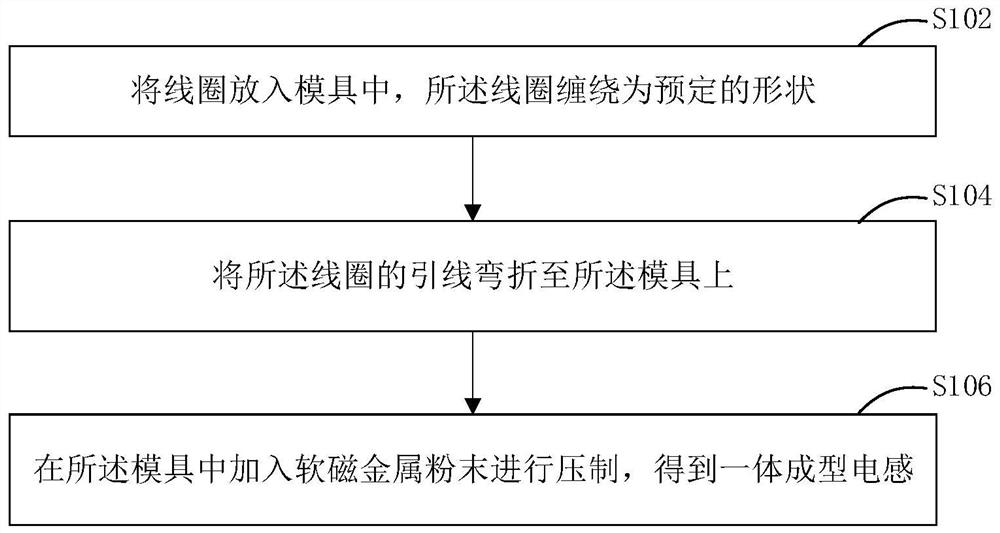

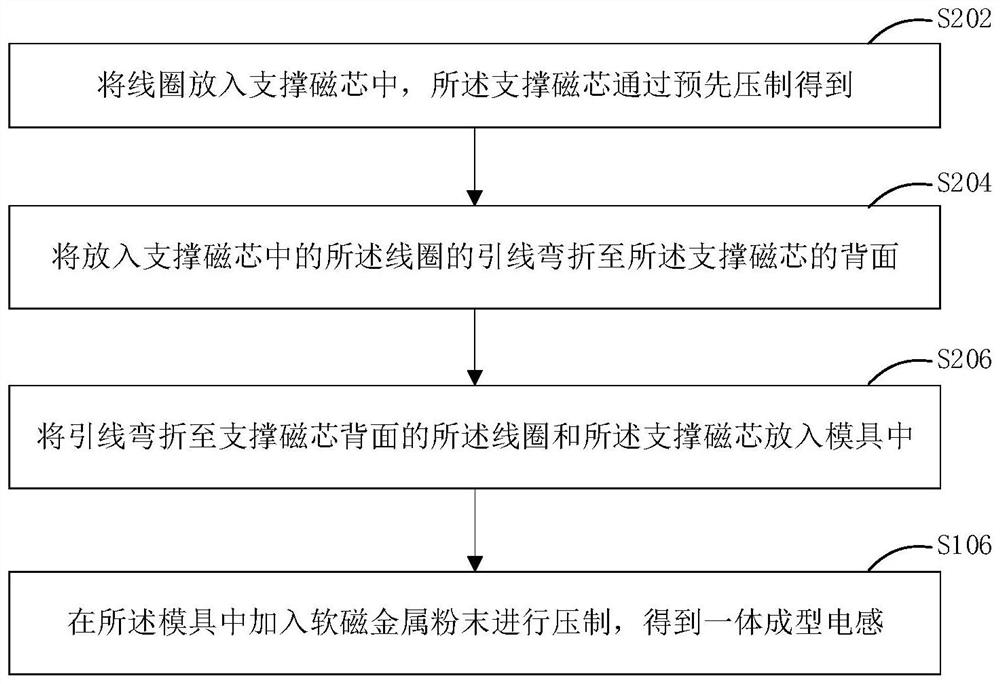

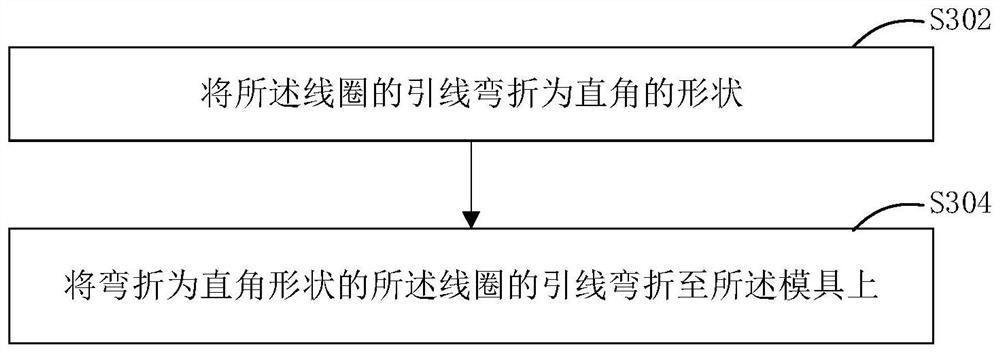

Integrally-formed inductor and manufacturing method thereof

PendingCN114694948ASimple structureIncrease productivityCoils manufactureTransformers/inductances detailsInductorMetal powder

The invention relates to an integrally formed inductor and a manufacturing method thereof. The method comprises the following steps: placing a coil into a mold, and winding the coil into a preset shape; bending a lead wire of the coil to the mold; soft magnetic metal powder is added into the mold for pressing to obtain the integrally-formed inductor, so that the coil of the integrally-formed inductor is simple in structure and high in production efficiency, the production cost of the integrally-formed inductor is reduced, the design space of the coil can be increased, the pressing density of the soft magnetic metal powder is improved, and the production efficiency of the integrally-formed inductor is improved. The material characteristics of the soft magnetic metal powder are fully exerted, and it is guaranteed that the position of the coil in the magnetic core is not inclined.

Owner:KUNSHAN MAJI ELECTRONICS

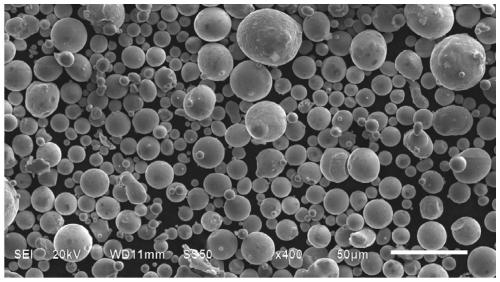

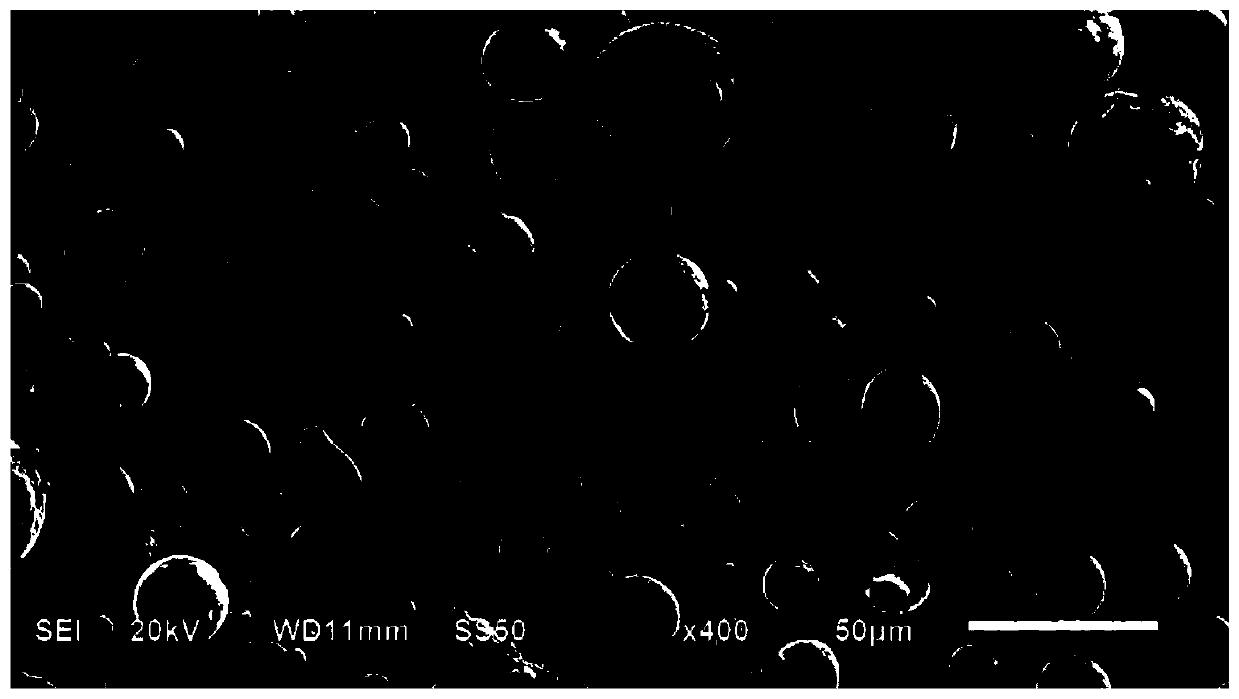

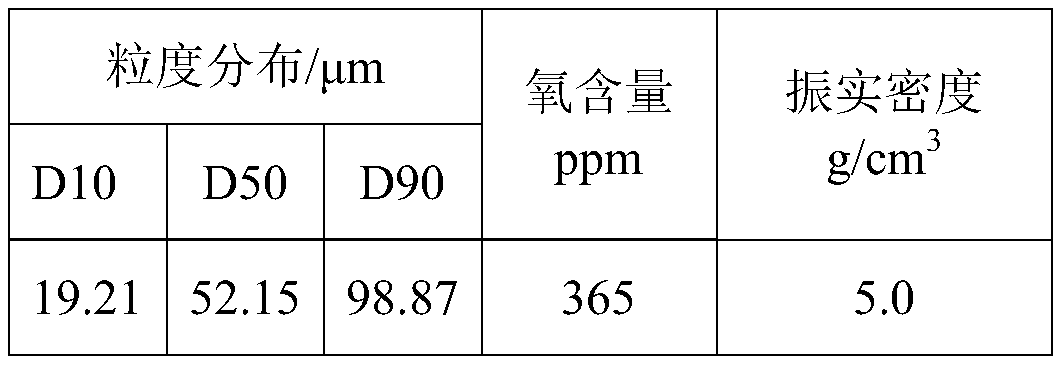

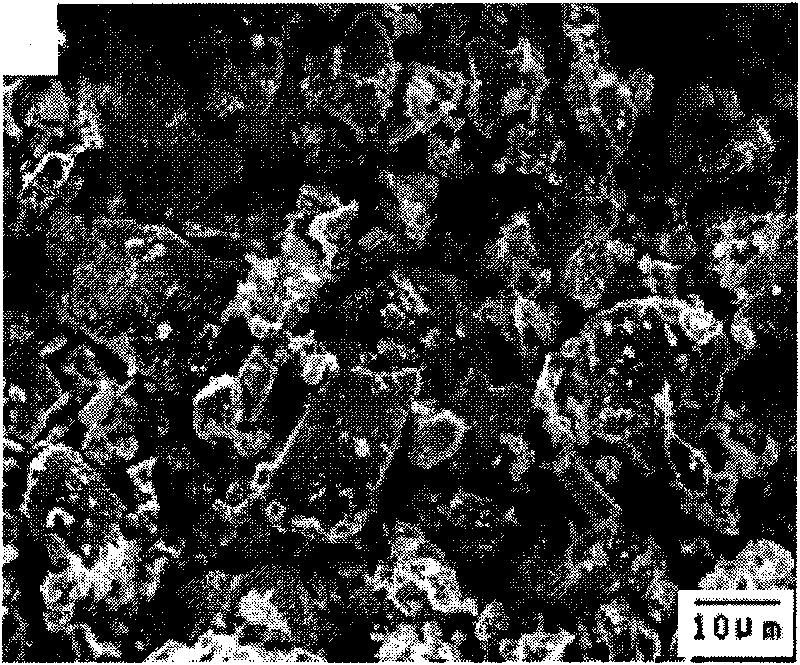

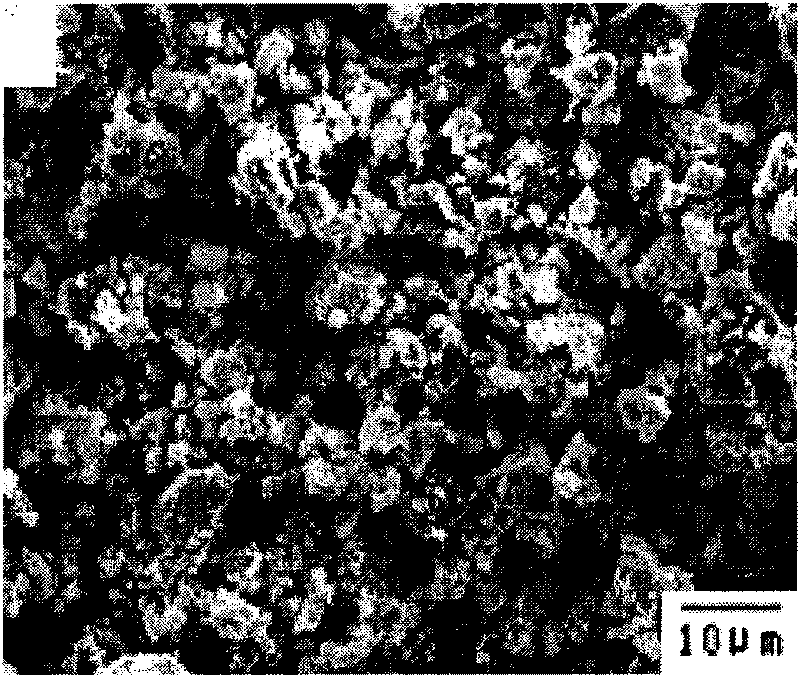

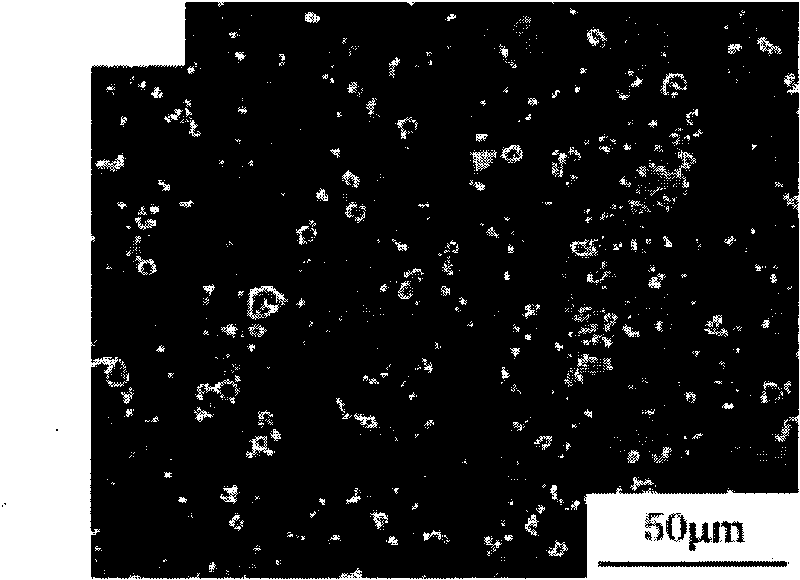

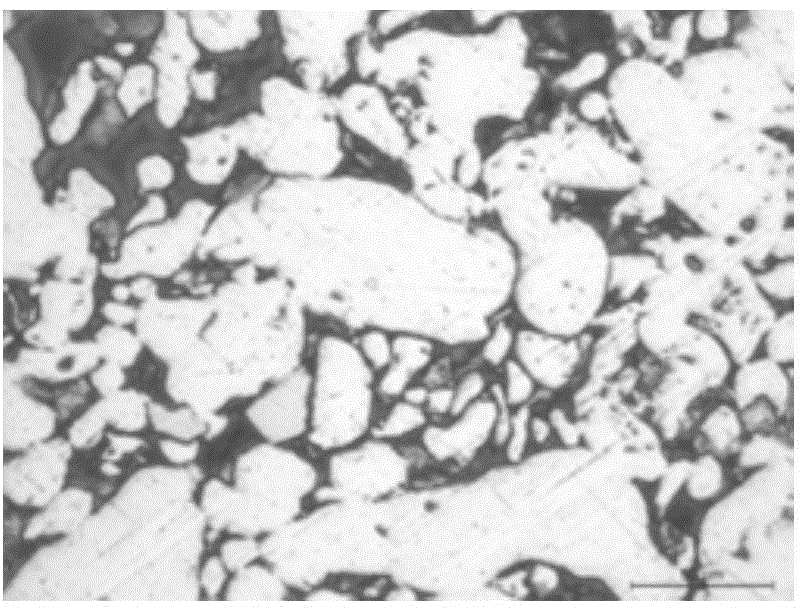

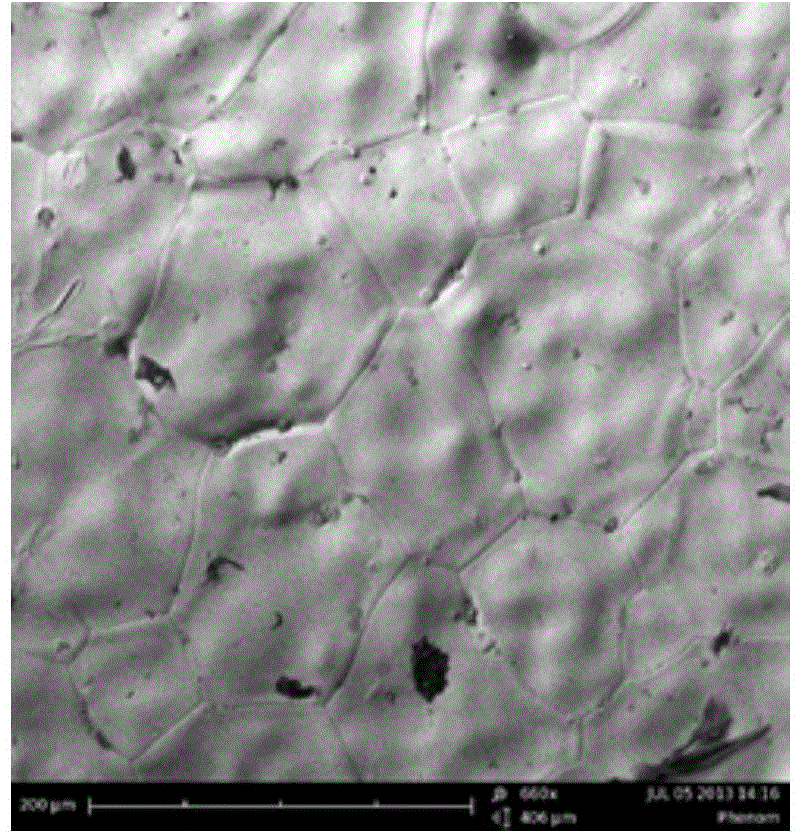

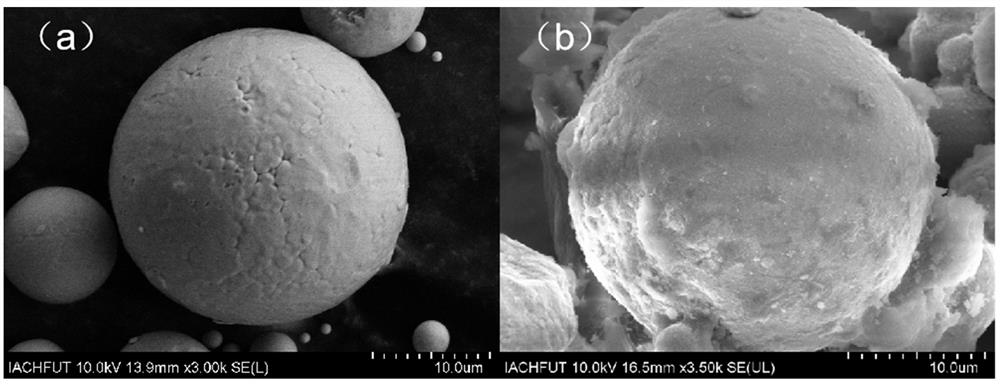

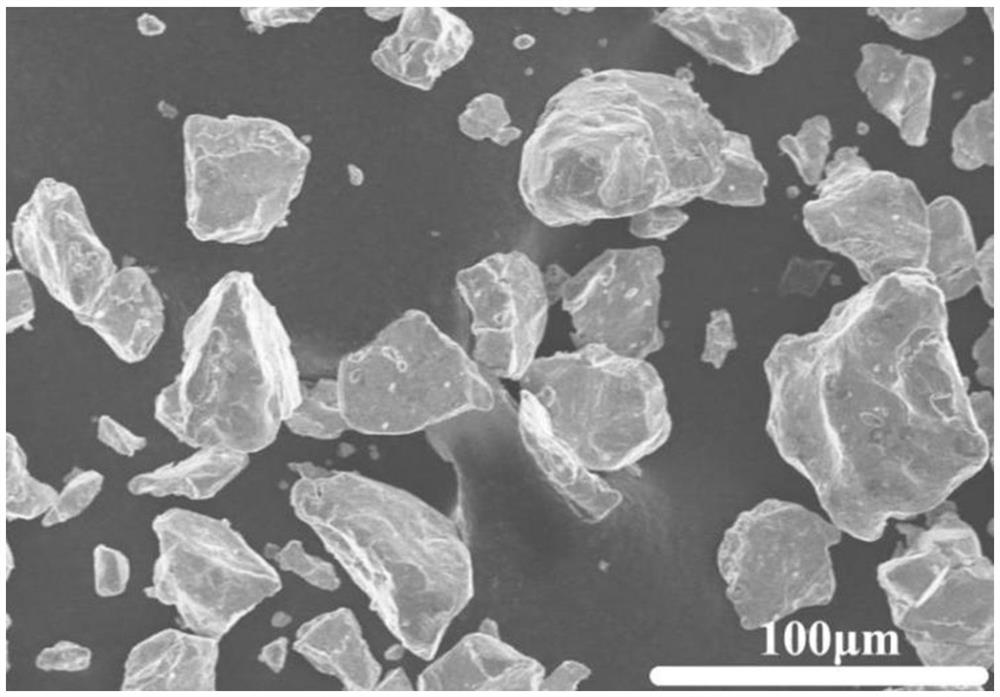

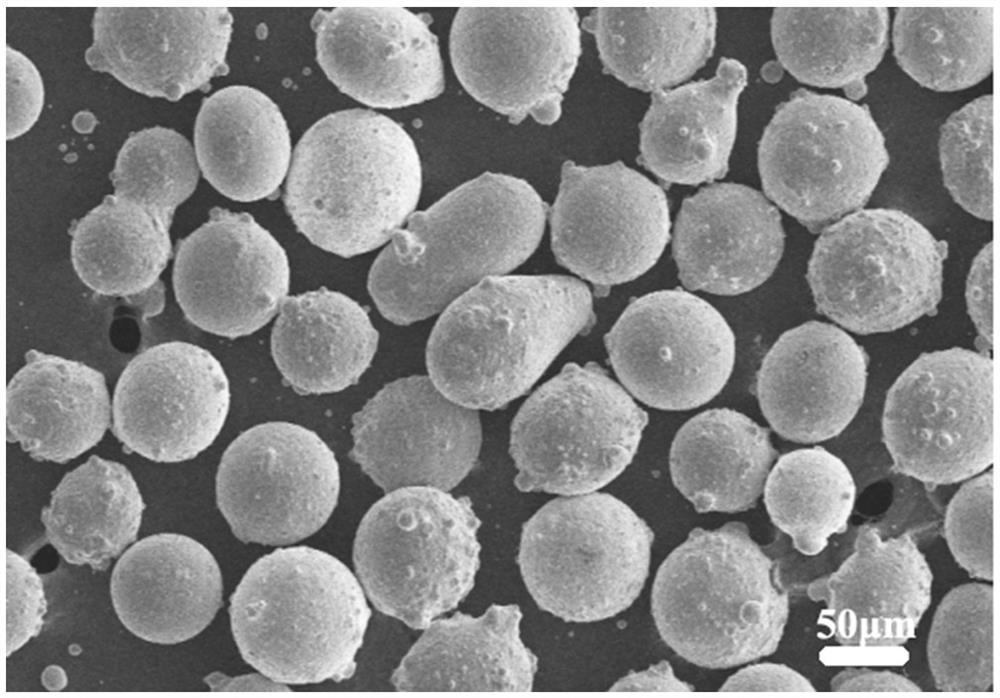

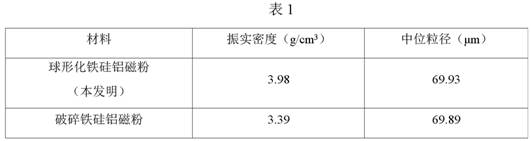

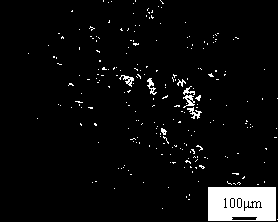

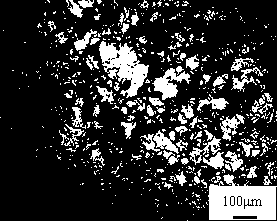

Spheroidizing preparation method of crushed Fe-Si-Al magnetic powder particles

ActiveCN113936906AImprove liquidityHigh sphericityInorganic material magnetismInductances/transformers/magnets manufactureAl powderMetal powder

The invention discloses a spheroidizing preparation method of crushed Fe-Si-Al magnetic powder, which belongs to the technical field of preparation of metal powder. The preparation method comprises the following operation steps of 1, carrying out ultrasonic cleaning on crushed Fe-Si-Al magnetic powder in an acetone solution, 2, adding the cleaned magnetic powder into a nitric acid aqueous solution for ultrasonic treatment, 3, carrying out sanding treatment on the acidified magnetic powder in a sand mill by adopting mixed zirconia grinding balls with three diameters, and 4, carrying out annealing treatment to obtain the spherical Fe-Si-Al magnetic powder with the median particle diameter of 40-70 microns. The tap density reaches 3.50 to 3.98 g / cm<3>. Compared with a common broken Fe-Si-Al powder core, the powder core prepared from the Fe-Si-Al magnetic powder as a raw material has the advantages that when the relative magnetic conductivity is 59.82-60.15, the density of the powder core reaches 5.90-6.02 g / cm<3>, meanwhile, the direct current bias performance of 100Oe reaches up to 52.85-55.73%, and the magnetic core loss of 50kHz / 100mT is only 232.94-248.31 mW / cm<3>.

Owner:安徽瑞德磁电科技有限公司

Preparation method of high-billet-strength tungsten powder

The invention relates to a preparation method of high-pressure blank strength tungsten powder, and aims to further improve the dependence of a preparation method of tungsten powder in the prior art on specific raw materials and further improve the blank strength of the tungsten powder. According to the method, the specific reduction technology in the tungsten powder preparation process is improved, the hydrogen flow and the gas inlet and outlet flow ratio of the first reduction process, the second reduction process and the third reduction process in the hydrogen reduction process are controlled, the reduction temperature and time are further controlled, and therefore the tungsten powder with the higher pressure blank strength is prepared. The preparation method of the tungsten powder with the high compact strength can be suitable for various wide tungsten oxide raw materials such as yellow tungsten, blue tungsten and purple tungsten, the tungsten powder with the compact strength larger than or equal to 4.7 MPa can be stably prepared without adopting special tungsten oxide raw materials, and the application market prospect is very wide.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

Low-temperature sintering method for high-performance Fe-based powder metallurgy parts

A low-temperature sintering method for high-performance Fe-based powder metallurgy parts belongs to the technical field of powder metallurgy. In order to reduce the sintering temperature of the Fe-based powder metallurgy parts and improve the performance of the Fe-based powder metallurgy parts at the same time, the low-temperature sintering method adopts the scheme that nanocrystalline copper powders are added to common Fe-based powder metallurgy parts, obvious surface effect and small size effect of the nanocrystalline copper powders are utilized to reduce the sintering temperature and improve the performance of the parts at the same time; and in order to ensure that the added nanocrystalline copper powders and added release agents can be mixed with basal ferrous powders uniformly, the Fe-based powder metallurgy parts satisfying the performance requirements can be obtained through combining with effective cold-pressing and sintering technology within appropriate powder mixing time under lower temperature. By adopting the low-temperature sintering method, the sintering temperature in the Fe-based powder metallurgy technology is reduced by about 240 DEG C, the production efficiencyis effectively improved, meanwhile, the energy consumption is reduced and the service life of production equipment is prolonged, and higher economic benifits and social benefits are achieved; in addition, the performance can also improved, so that the low-temperature sintering method plays a pushing effect in development of expanding the application field of the Fe-based powder metallurgy parts.

Owner:溧阳常大技术转移中心有限公司

A preparation method of a high-voltage ultra-small capacity non-solid electrolyte tantalum electrolytic capacitor

ActiveCN110797216BHigh strengthNot easy to drop blocks and missing cornersCapacitor manufactureElectrolysisTantalum capacitor

The invention belongs to the technical field of tantalum capacitor preparation, in particular to a method for preparing a high-voltage ultra-small capacity non-solid electrolyte tantalum electrolytic capacitor. By increasing the compaction density, changing the molding method, and increasing the sintering temperature and sintering time, the strength of the tantalum core is improved. Reinforced, the tantalum core is not easy to drop blocks and corners, and the impurities in the tantalum powder are effectively removed. Through the improved formation method, a tantalum core with excellent electrical properties is obtained. Combined with the aging process, the prepared non-solid electrolyte tantalum The voltage of the capacitor can reach 180V, and the capacitance can reach 0.047μF, which has the characteristics of high voltage and ultra-small capacitance.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

A powder metallurgy method and product for preparing a bearing sleeve of an automobile seat lifter

ActiveCN105033259BHigh strengthHigh dimensional accuracyTurbinesOther manufacturing equipments/toolsCar seatVolumetric Mass Density

The invention discloses a method and a product for preparing a bearing sleeve of an automobile seat lifter by powder metallurgy, belonging to the technical field of powder metallurgy production. The method is specifically carried out according to the following steps: (1) powder mixing; (2) forming; (3) sintering; (4) machining; (5) heat treatment; (6) finishing; (7) polishing and degreasing. The advantages are: 1) Using a special lubricant, a higher pressing density can be obtained under a lower pressing pressure, and the final structural shape of the bearing sleeve can be formed at one time, reducing mold loss, and its material utilization rate can reach more than 99%; 2) The product has good consistency, high precision, and does not require excessive machining processes; 3) The use of diffusion alloyed steel powder can make the material alloyed more uniformly and fully at a lower sintering temperature, and improve the strength and dimensional accuracy of the bearing sleeve ; 4) Using the existing production equipment, the output of one press shift is 2000-2500 pieces, which is only equivalent to 60% of the original cold pier molding.

Owner:马鞍山市华东粉末冶金厂

A wireless charging magnetic core for smart watches and its preparation method

ActiveCN111978079BImproved saturation magnetizationGood curie strengthTransformersTransformers/inductances magnetic coresPlanar inductorMechanical engineering

The invention discloses a wireless charging magnetic core for a smart watch and a preparation method thereof. The raw material includes a main component and an additive, and the main component includes 51.5-53.5% Fe in molar percentage 2 o 3 , 9.0~12.5% ZnO, the balance is MnO; additives include 100~600ppm V 2 o 5 , 0~200ppm of MoO 3 , 2000~4500ppm of Co 2 o 3 , 100~1000ppm of CaCO 3 and 100~500ppm Nb 2 o 5 . In the preparation method, centrifugal granulation is adopted and sealing molding is adopted during integral molding. The present invention rationally selects the types and dosages of the main components and additives, and uses centrifugal granulation and sealing molding, so that the prepared wireless charging magnetic core has high planar inductance and profiling inductance, low loss in a wide temperature range, and sufficient strength and toughness to meet the requirements of use.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

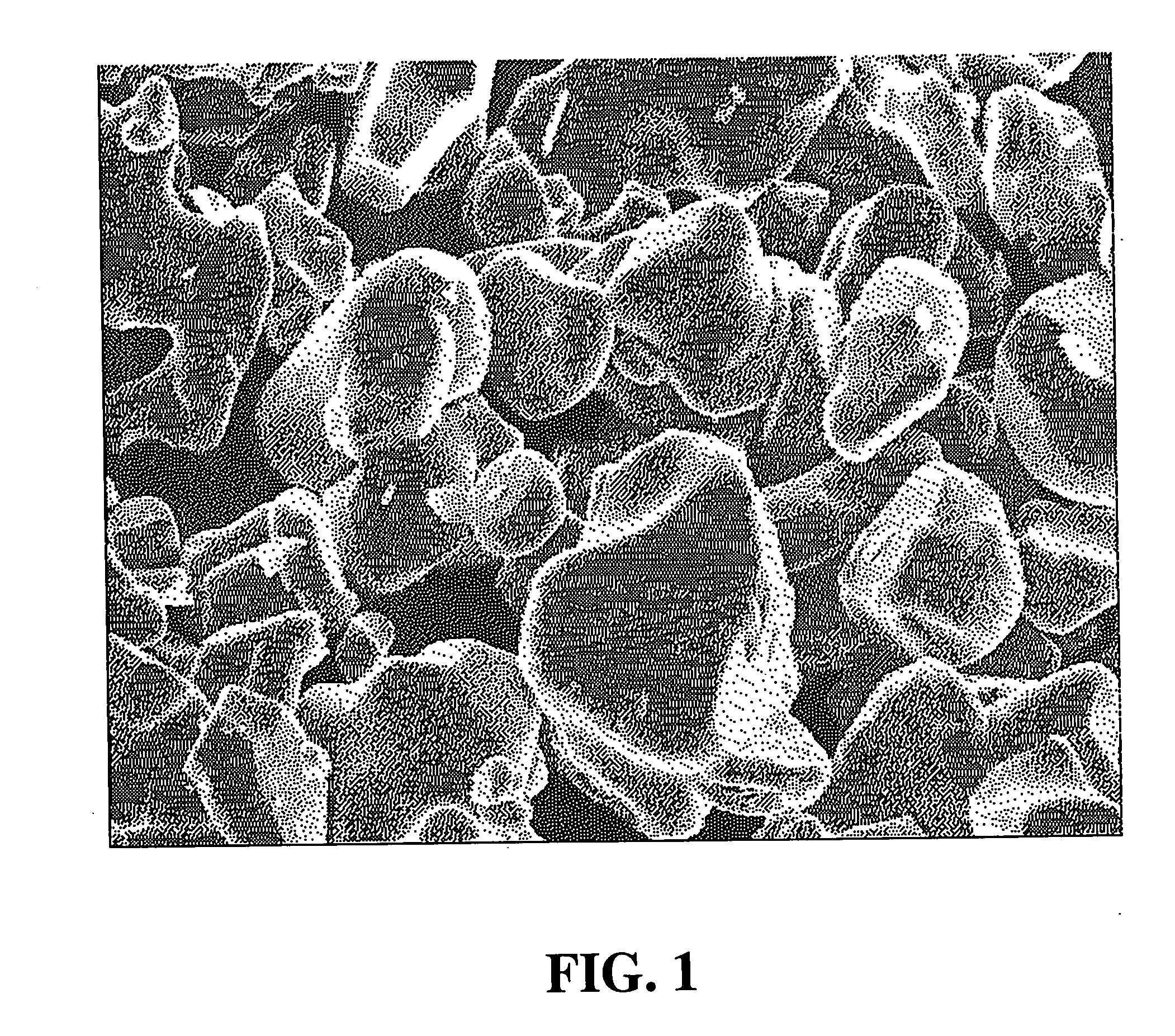

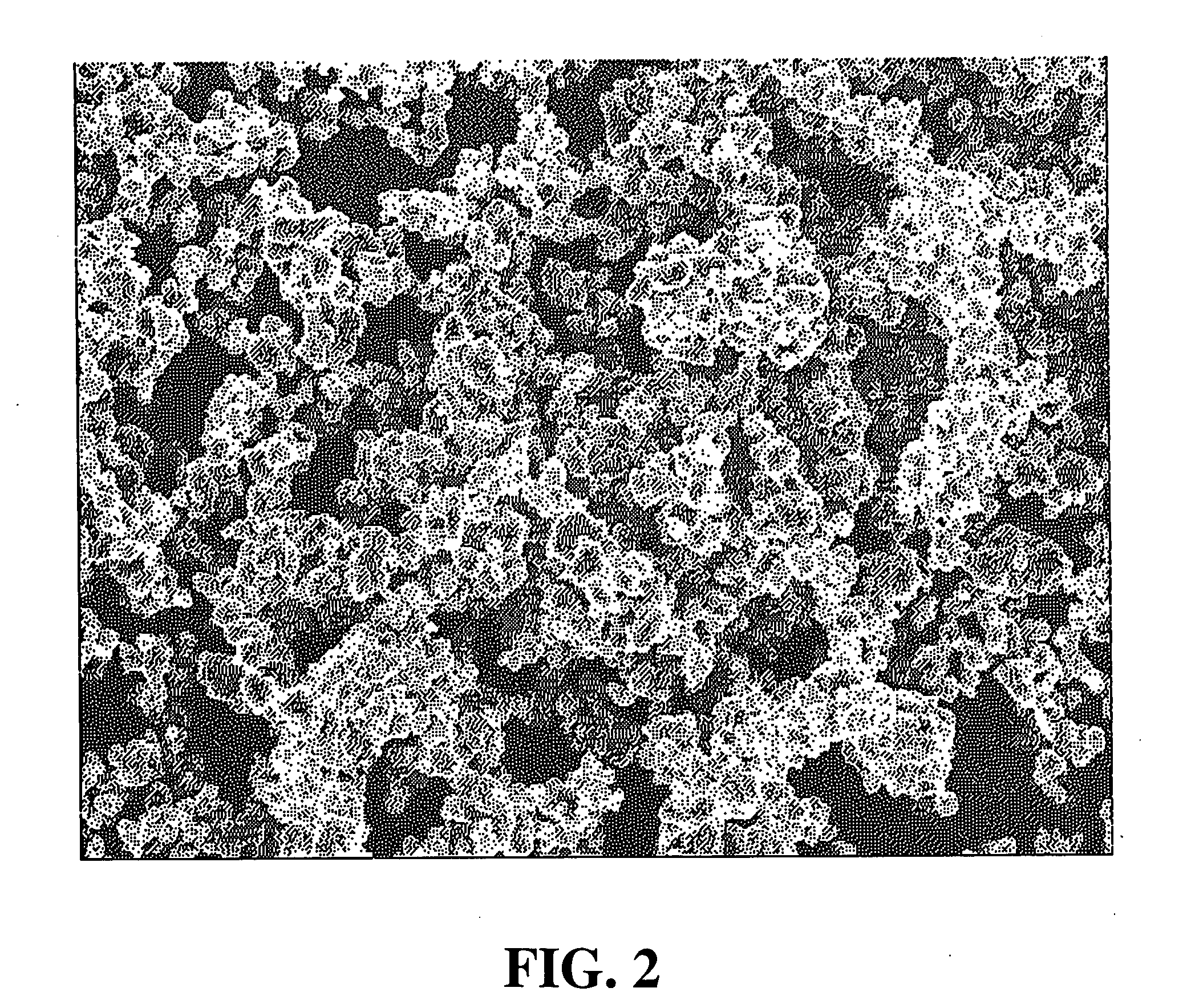

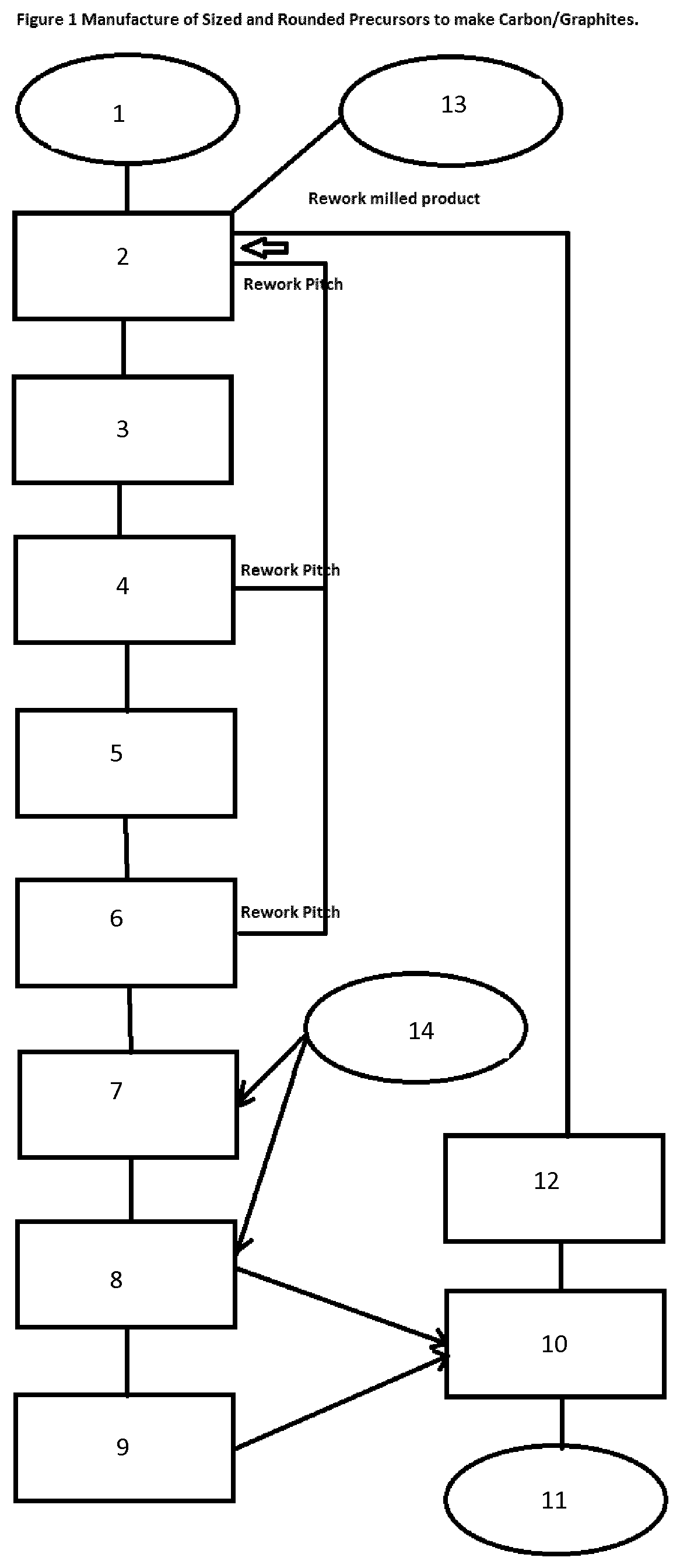

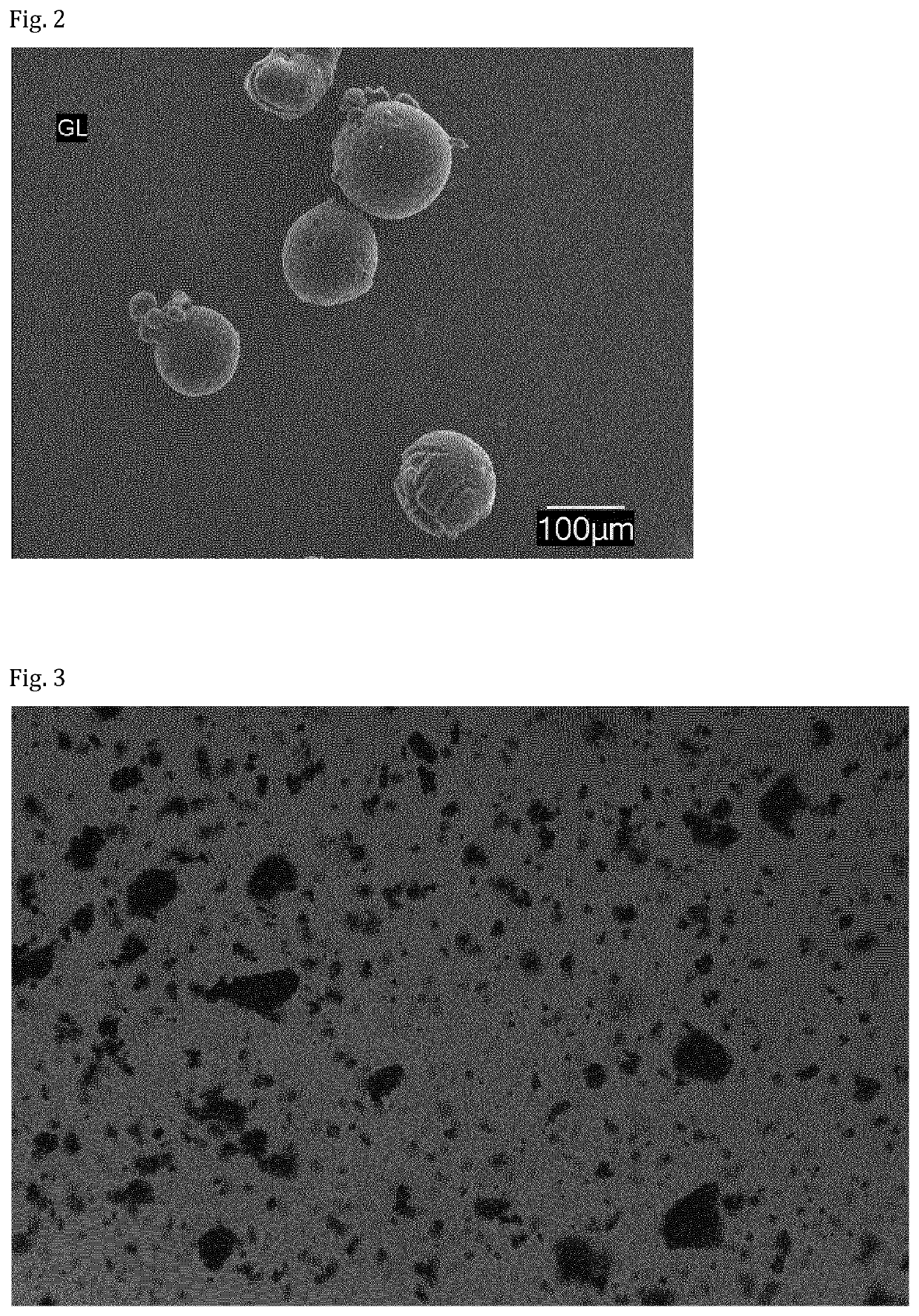

Carbon Powders And Methods Of Making Same

ActiveUS20200002169A1Small surface areaIncrease the pressing densityCarbon preparation/purificationMineralogyCarbon particle

A method for producing carbon powder having a defined carbon particle size distribution comprises the steps of:—a) selecting a carbon precursor powder of a defined precursor particle size distribution, the carbon precursor powder consisting of or comprising particles of one or more meltable carbon precursors; b) treating the carbon precursor powder to round at least some of the particles of the carbon precursor and thereby produce a rounded carbon precursor; and c) carbonizing the rounded carbon precursor; wherein the defined precursor particle size distribution is such that on carbonization the powder of defined carbon particle size distribution is produced.

Owner:NAT ELECTRICAL CARBON PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com