Explosive-shaped powder bidirectional pressing device

A technology of two-way pressing and molding powder, which is used in explosives, explosives processing equipment, material molding presses, etc., can solve the problems of poor axial uniformity, uneven axial density, low molding density, etc., and achieve higher pressing density. , The effect of strong product applicability and simple pressing process

Inactive Publication Date: 2015-01-21

XIAN MODERN CHEM RES INST

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing compression molding device has uneven density in the axial direction because the pressure is only applied from the upper part on the ordinary one-way press. Compared with the powder column pressed and formed on the two-way press, the molding density is low and the axial uniformity is poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

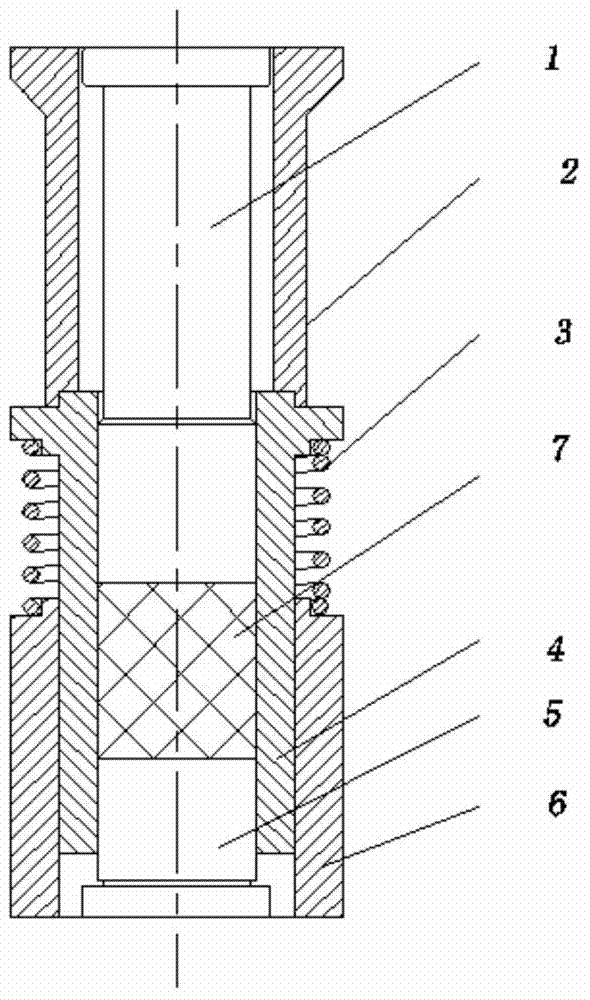

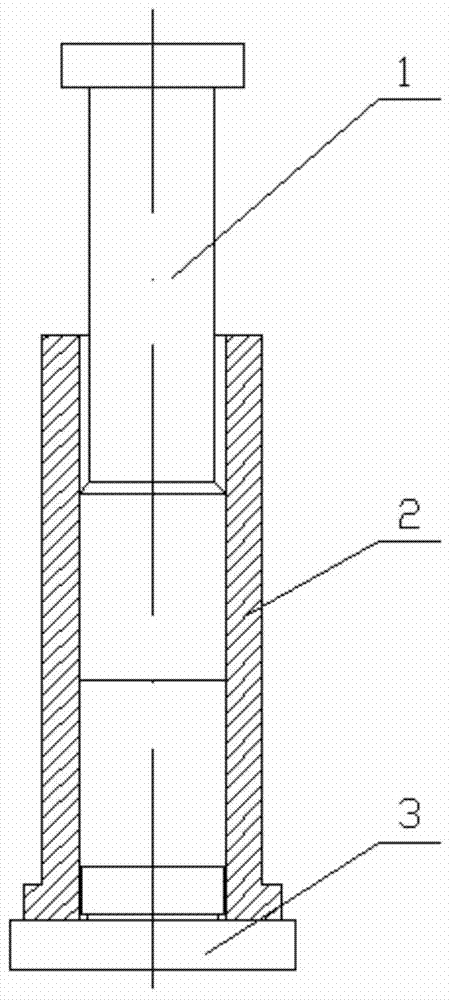

The invention discloses an explosive-shaped powder bidirectional pressing device which is mainly composed of a punch, a die retreating cylinder, a compression spring, a die cylinder, a base and a bottom cylinder. The pressing process is safe, reliable, convenient and fast, the function of bidirectional pressing is achieved on a unidirectional die pressing machine, and the problem that the axial density of explosive pillars is not evenly distributed in the explosive-shaped powder pressing process of the unidirectional die pressing machine is solved. The explosive pillars pressed through the explosive-shaped powder bidirectional pressing device are complete in shape and even in density. The explosive-shaped powder bidirectional pressing device is suitable for the explosive die pressing technology.

Description

technical field [0001] The invention relates to a two-way pressing device for explosive molding powder, which is suitable for molding and pressing technology of explosive molding powder. Background technique [0002] Explosive molding powder is used to fill ammunition after being pressed into shape by a molding machine. The existing compression molding device has uneven density in the axial direction because the pressure is only applied from the upper part on the ordinary one-way press. Compared with the powder column pressed and formed on the two-way press, the molding density is low and the axial uniformity is poor. . Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a two-way pressing device for explosive molding powder, which can improve the molding density and axial density uniformity of explosives, and realize the function of two-way pressing on ordinary one-way presses. [0004] In order to solve the above...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B30B11/04C06B21/00

Inventor 刁小强戴致鑫张为鹏赵省向王彩玲黄亚峰韩仲熙方伟李文祥姚李娜

Owner XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com