Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Excellent capacity characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

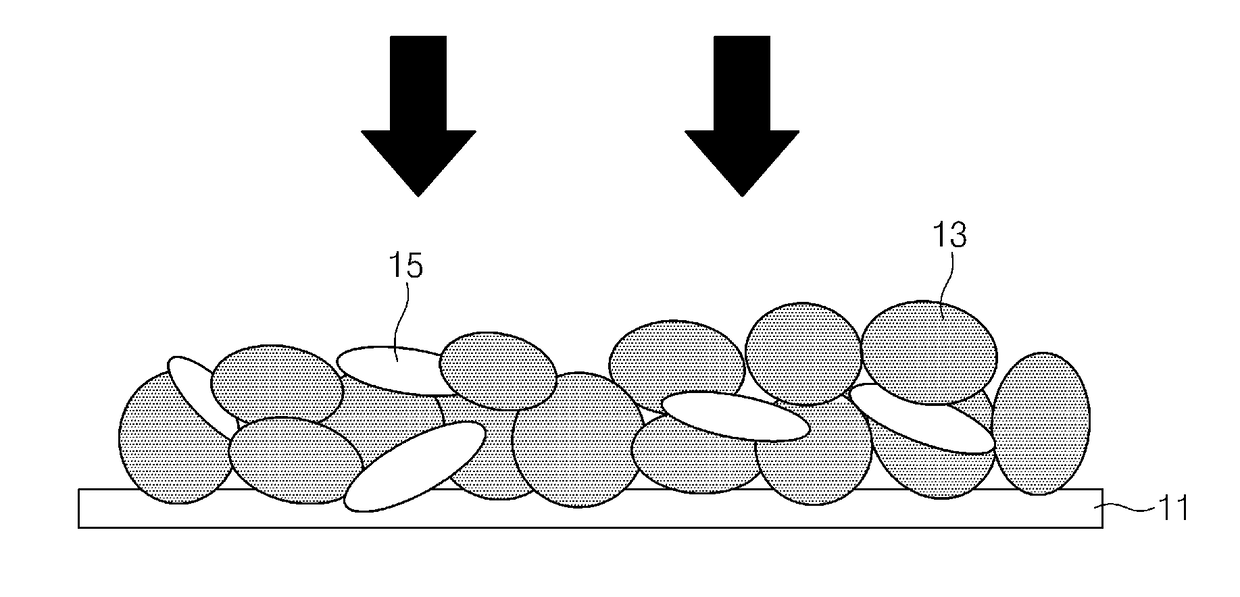

Current collector for flexible electrode, method of manufacturing same, and negative electrode including same

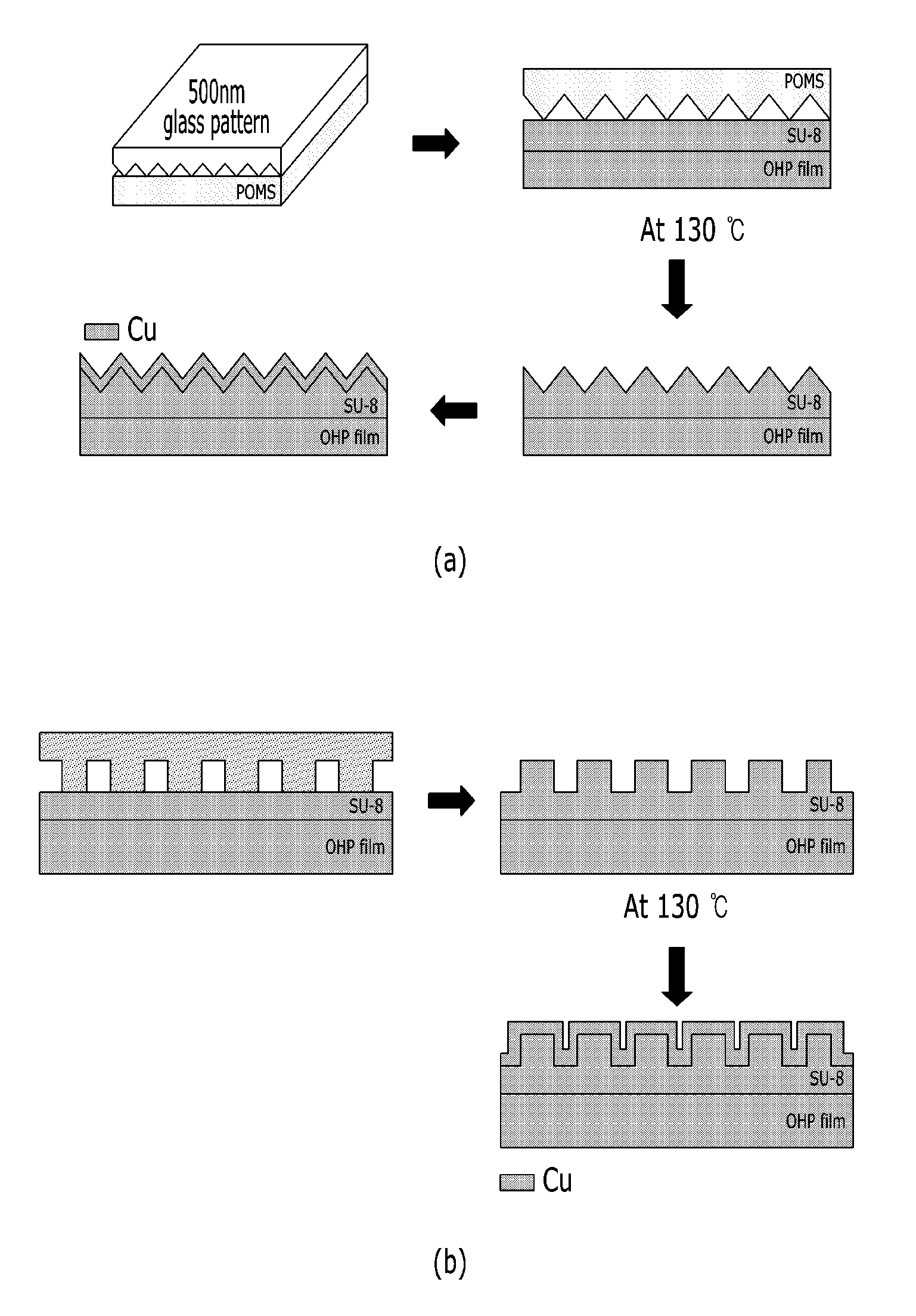

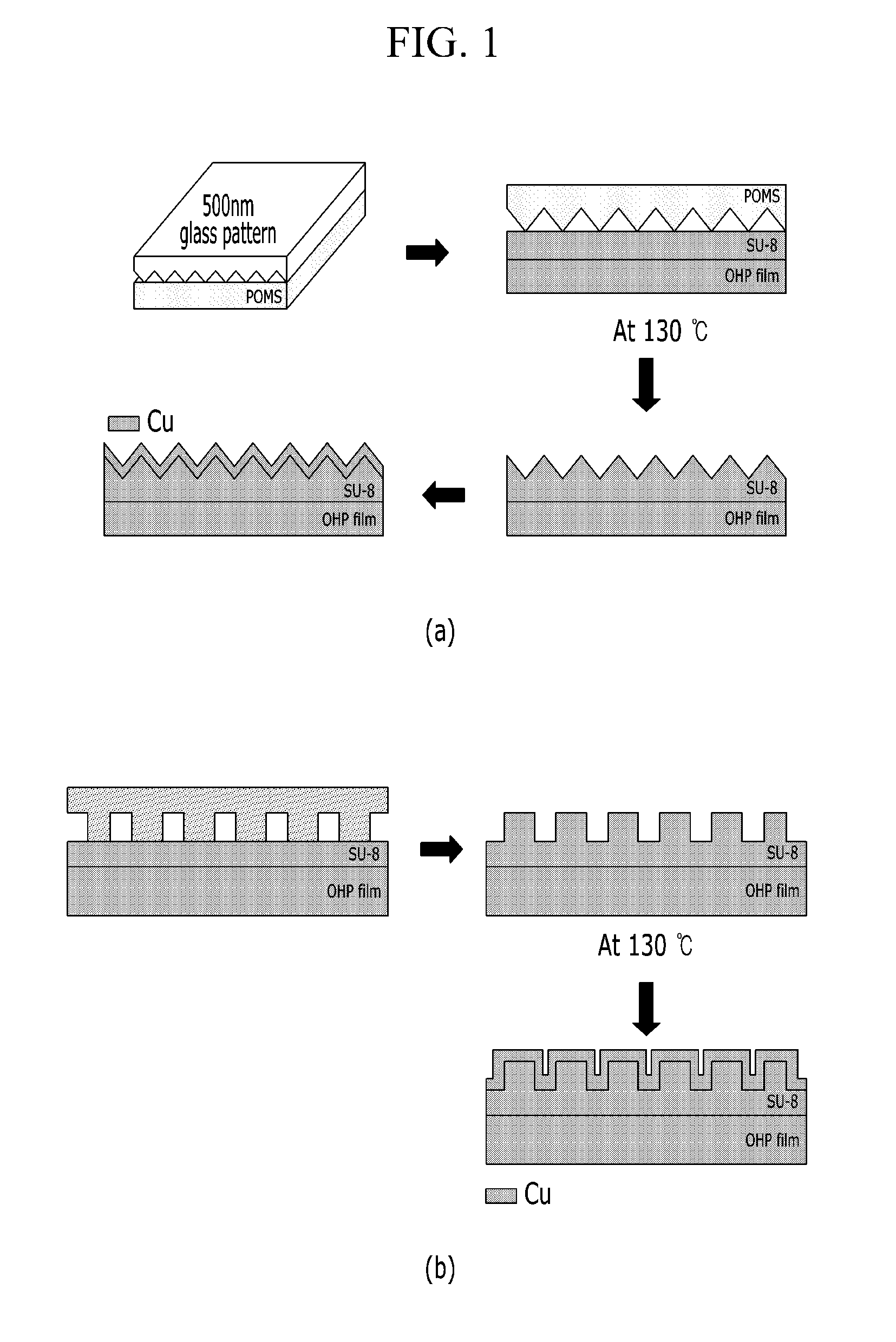

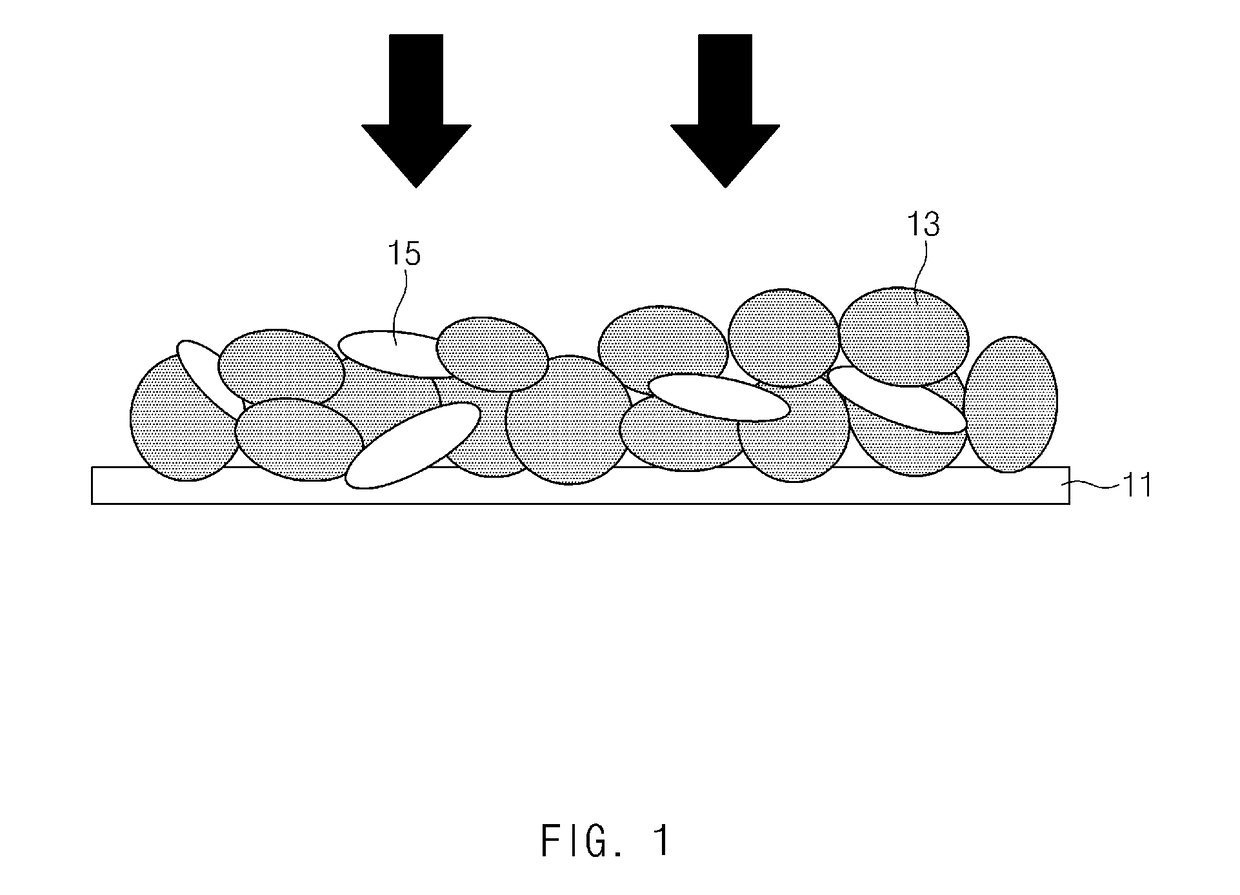

InactiveUS20130011742A1Excellent capacity characteristicsPrevent materialElectrode manufacturing processesFinal product manufacturePolymer sciencePolymer substrate

Disclosed are a current collector for a flexible electrode, a method of manufacturing the same, and a negative electrode including the same. The current collector for a flexible electrode includes: a flexible polymer substrate; a cross-linkable polymer layer disposed on the polymer substrate; and a metal layer disposed on the cross-linkable polymer layer, wherein the surface of the cross-linkable polymer layer includes a plurality of protrusions and grooves.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

Polyethylene multilayer microporous membrane, battery separator using same, and battery

InactiveCN101208198AImprove permeabilityExcellent mechanical propertiesSynthetic resin layered productsSecondary cellsVitrificationSurface layer

A multi-layer, microporous polyethylene membrane having at least three layers comprising (a) a first microporous layer amount of a polyethylene resin and constituting at least both surface layers, and (b) at least one second microporous layer made of a polyethylene resin, a heat-resistant resin having a melting point or glass transition temperature of 150°C or higher and a filler, and sandwiched by both surface layers.

Owner:东丽东燃机能膜合同会社

Oxygen storage material without rare earth metals

InactiveUS20150051067A1Simple materialImprove natureGas treatmentInternal combustion piston enginesRare-earth elementSpinel

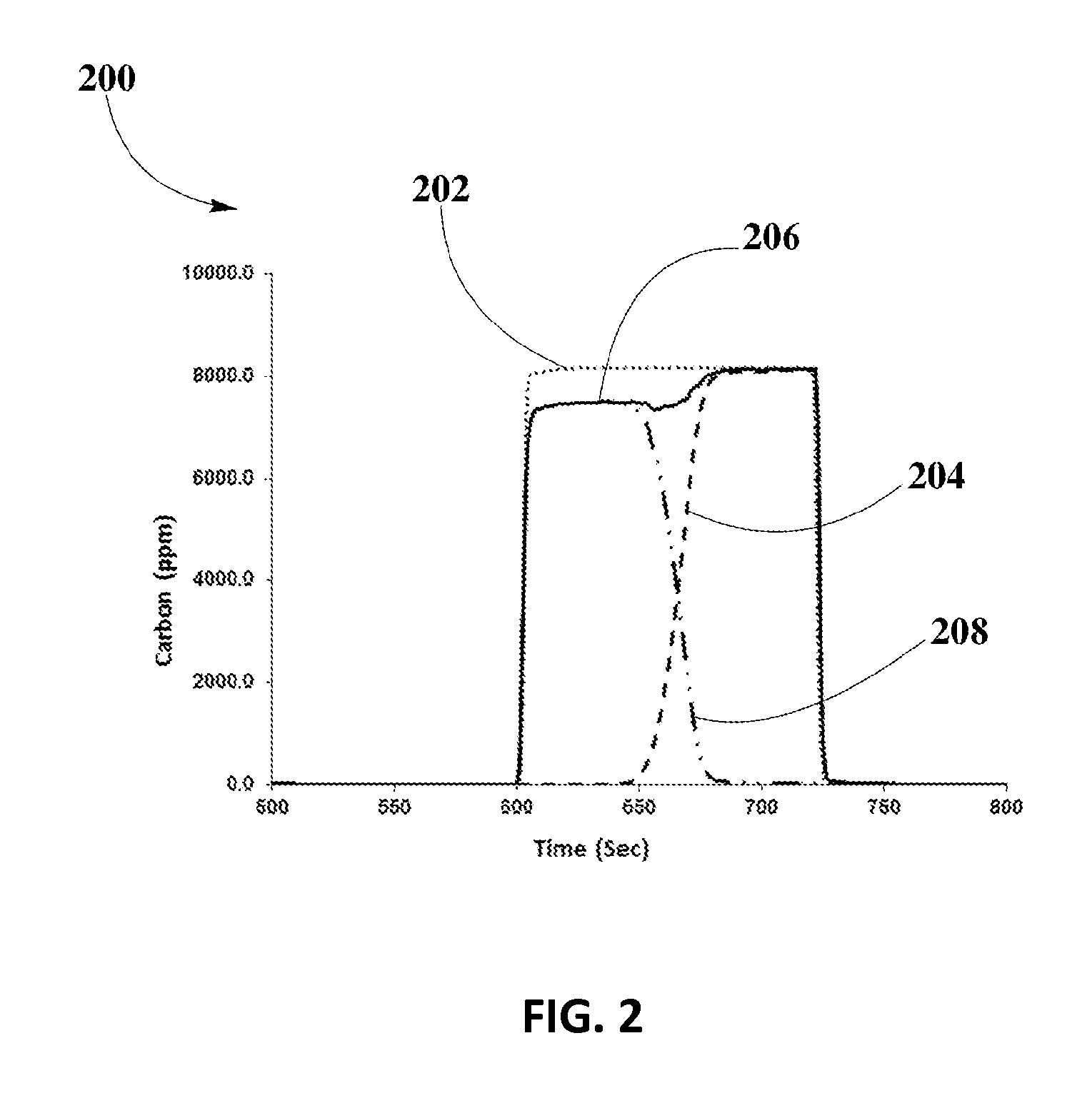

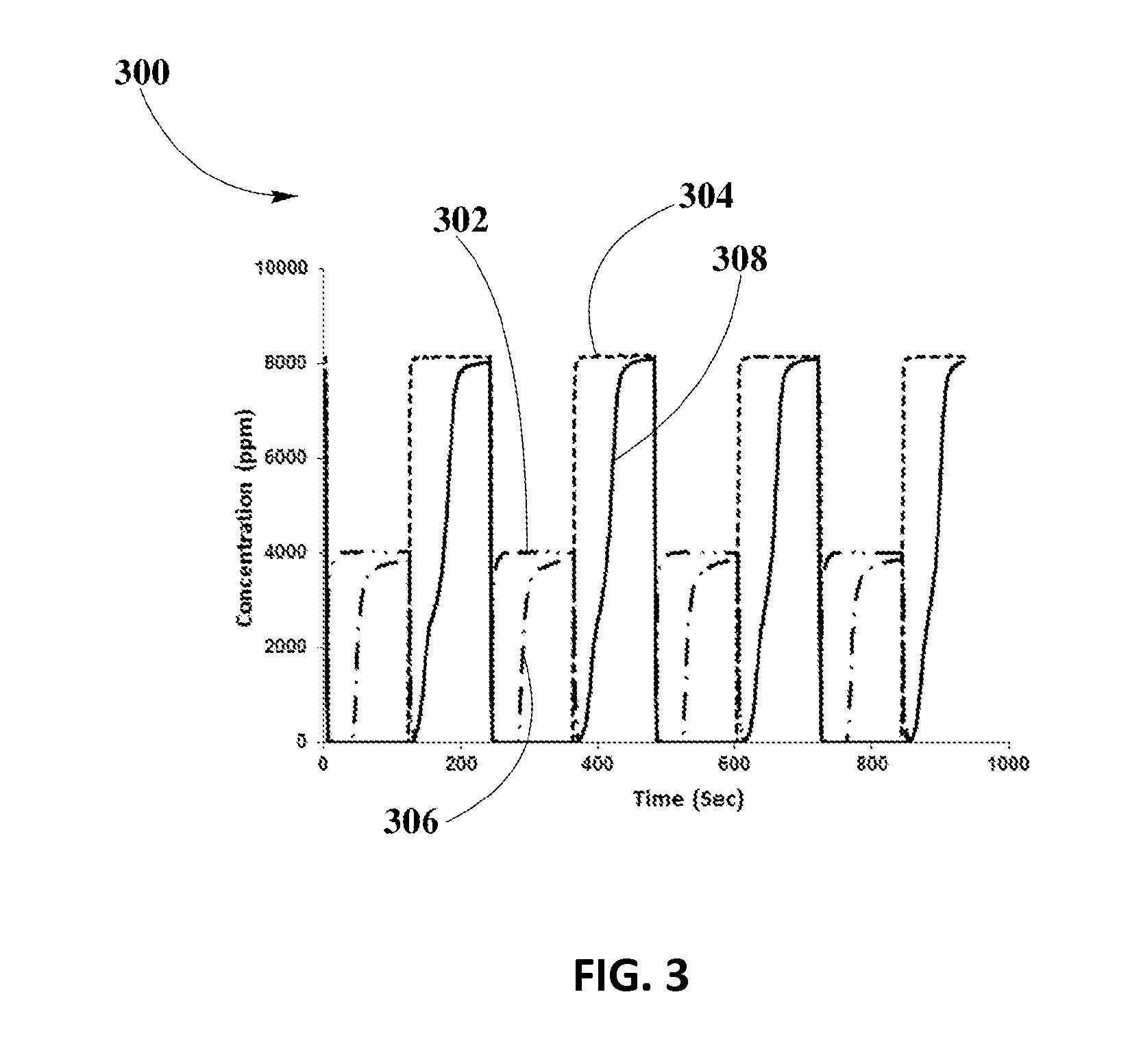

The present disclosure relates to an enhanced oxygen storage material (OSM) that may be converted into powder form and used as a raw material for a vast number of applications, and more particularly in catalyst systems. The disclosed OSM, substantially free from PGM and rare earth (RE) metals, has significantly higher oxygen storage capacity (OSC) than conventional OSM including PGM and RE metals. The disclosed OSM may be converted into powder, including a formulation of Cu—Mn spinel structure deposited on Nb—Zr oxide support. The disclosed OSM may also be coated onto a ceramic substrate as washcoat layer for characterization under OSC isothermal oscillating condition. The disclosed OSM may have an optimal OSC property that increases with the temperature, showing acceptable level of O2 storage even at low temperatures.

Owner:CLEAN DIESEL TECHNOLOGIES

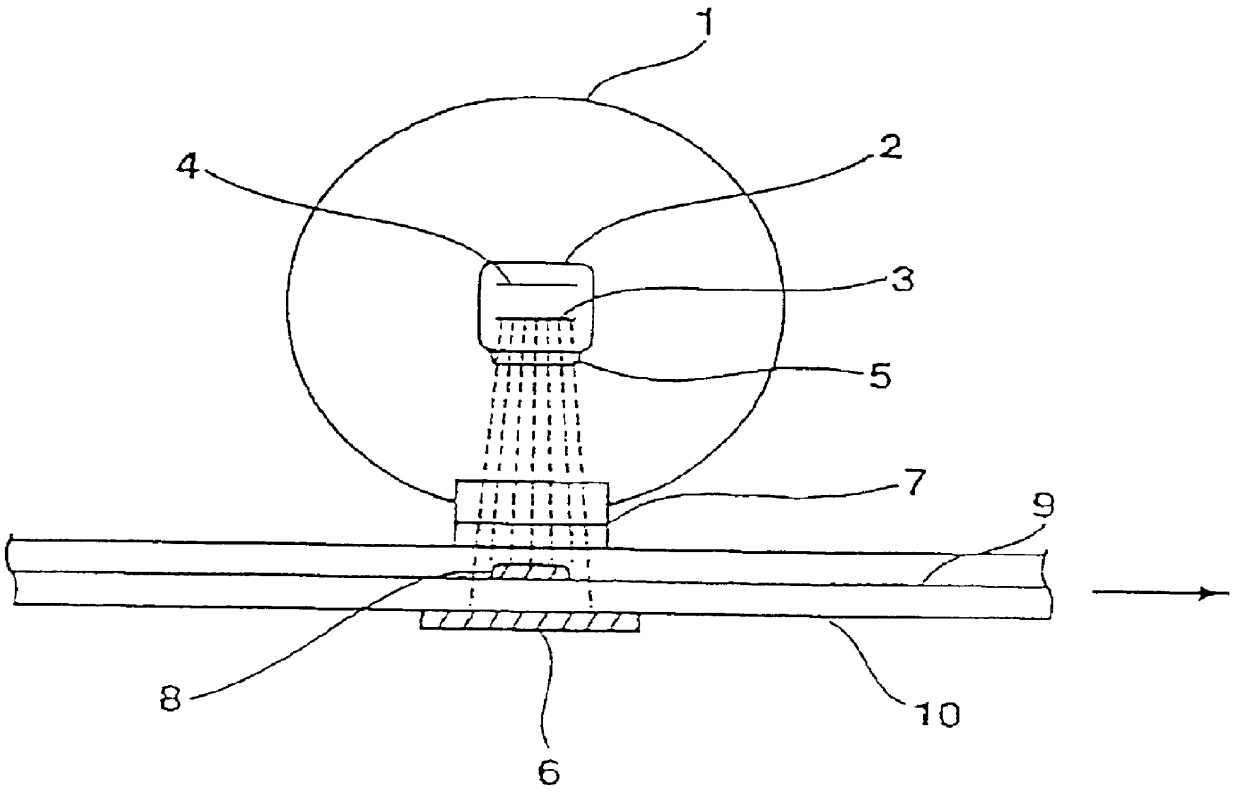

Method for producing anode material and non-aqueous electrolyte cell employing such materials

InactiveUS6136474AImprove reliabilityImprove securityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsProduct gasGaseous atmosphere

A non-aqueous electrolyte cell equipped with an anode made of a carbonaceous material capable of intercalating and deintercalating light metal ions and imparted with high capacity characteristics and favorable cyclic properties, wherein the carbonaceous material is obtained by irradiating, in a gaseous atmosphere, an electron beam accelerated in high vacuum. The anode made of a carbonaceous material is subjected to electron beam irradiation at a dose ranging from 300 kGy to 1000 kGy.

Owner:DEXERIALS CORP

Polyethylene multilayer microporous membrane, battery separator using same, and battery

ActiveCN101247955AImprove shutdown characteristicsImprove heat resistanceFinal product manufactureSynthetic resin layered productsFiberCompressibility

The polyethylene multilayer microporous film of the present invention has: (a) a first porous layer made of polyethylene resin; (b) a second porous layer containing polyethylene resin and melting point or glass A heat-resistant resin having a transformation temperature of 170° C. or higher, and the heat-resistant resin is dispersed in the form of fine particles in the polyethylene-based resin, and fibrils composed of the polyethylene-based resin have the heat-resistant The fine particles of the permanent resin are fine pores with core cracks, and the polyethylene multilayer microporous membrane has shut-off properties, ablation properties, permeability, mechanical strength, heat shrinkage resistance, and compression resistance in an excellent harmony.

Owner:TORAY IND INC

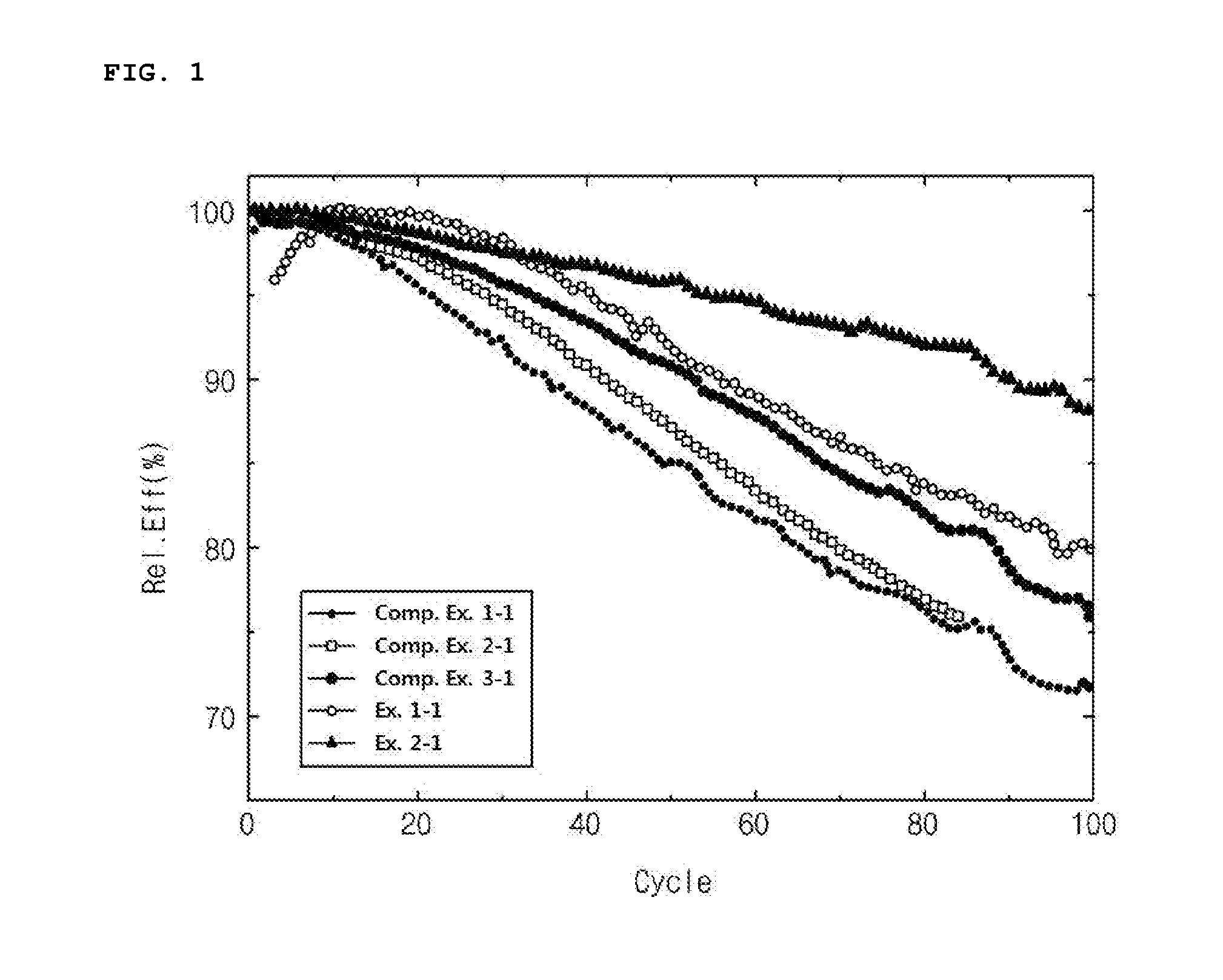

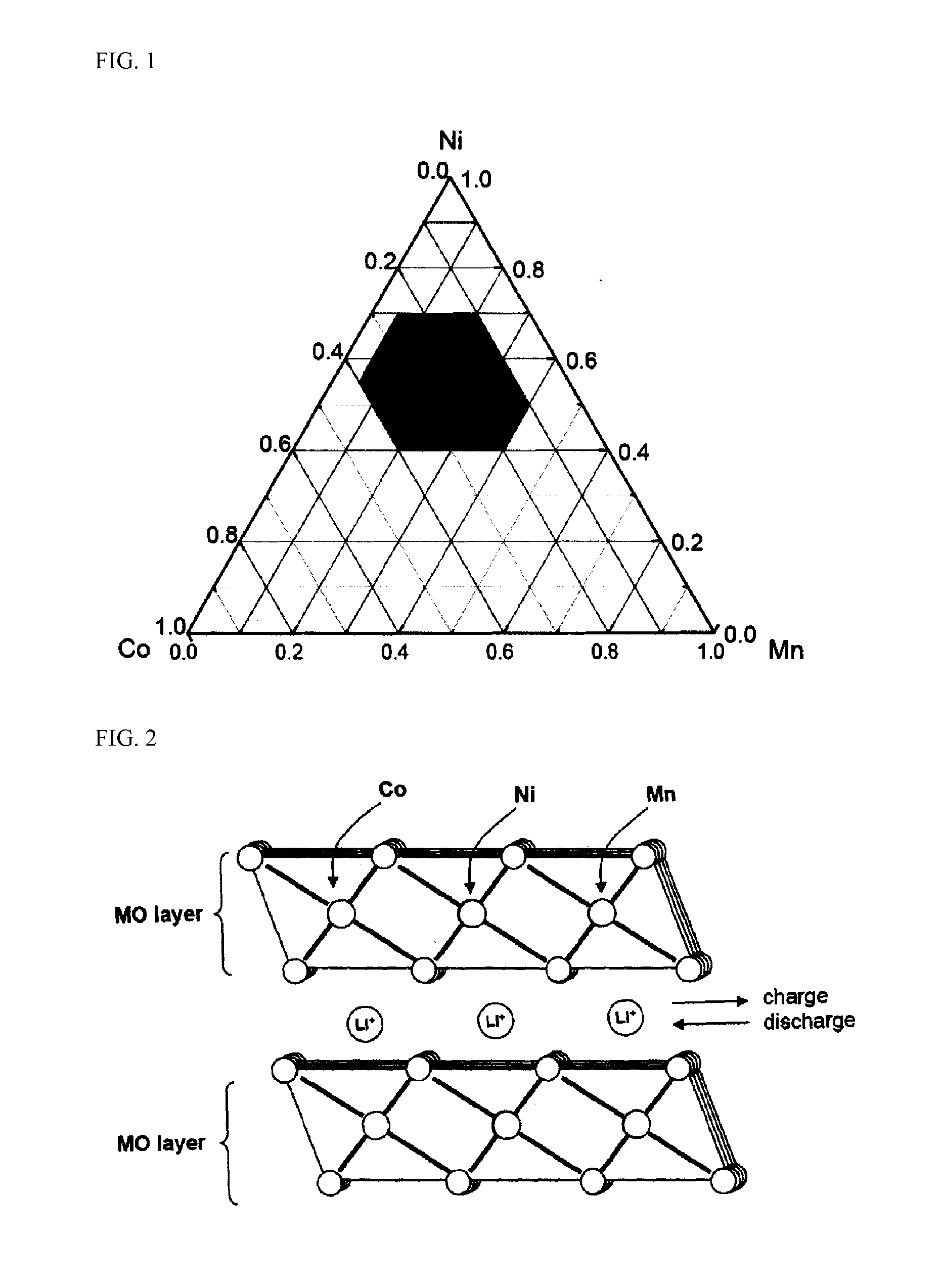

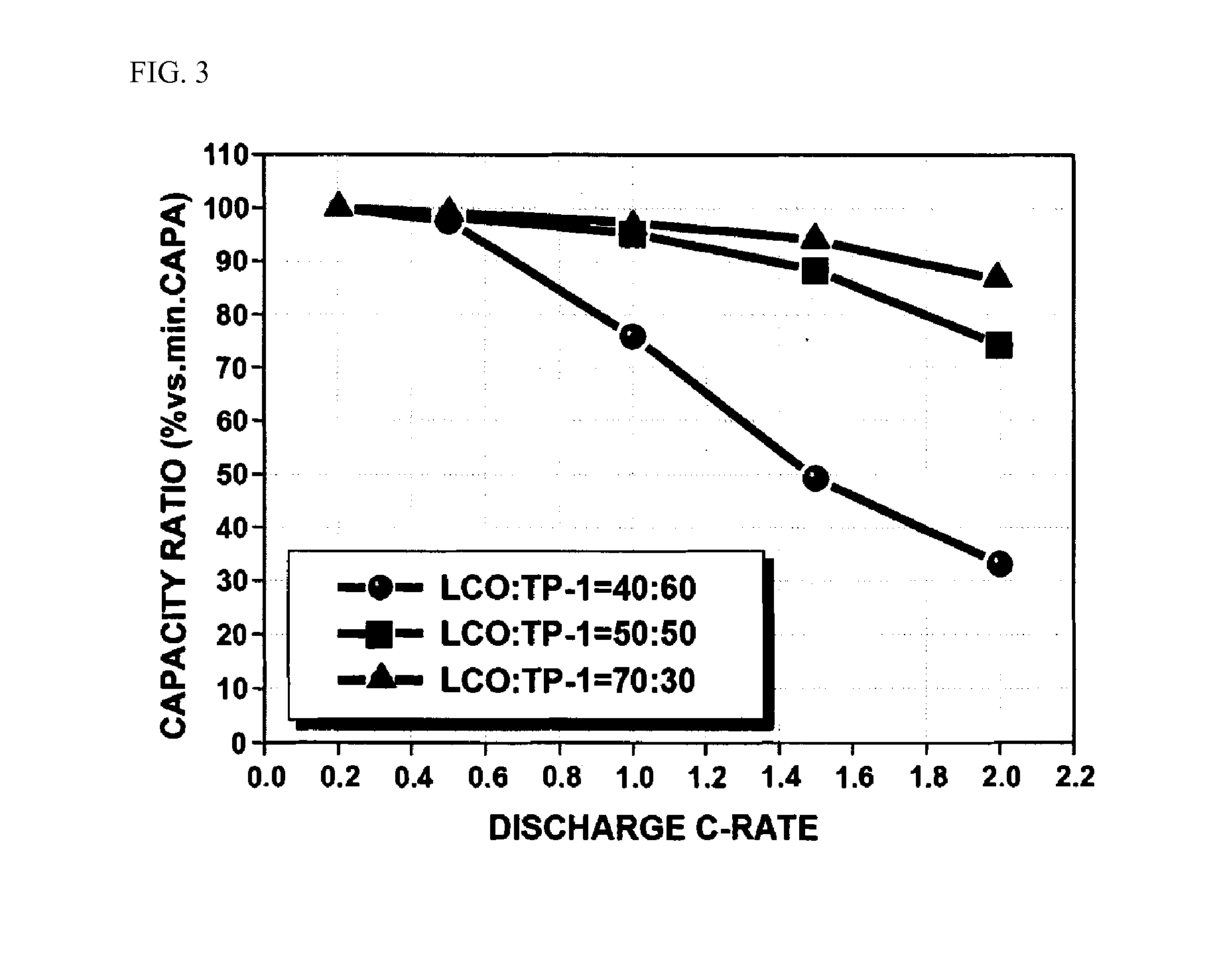

Lithium secondary battery containing cathode materials having high energy density and organic/inorganic composite porous membrane

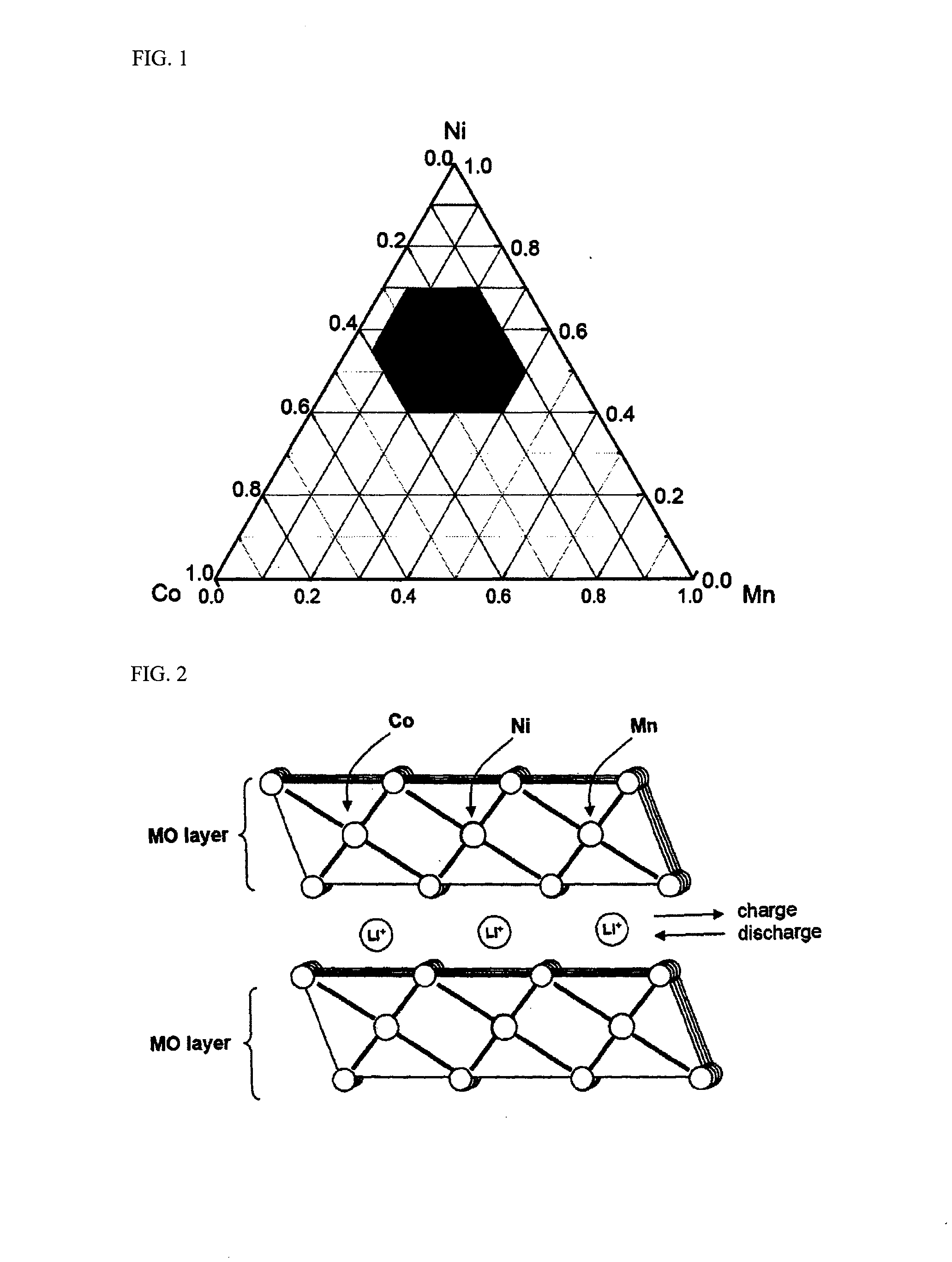

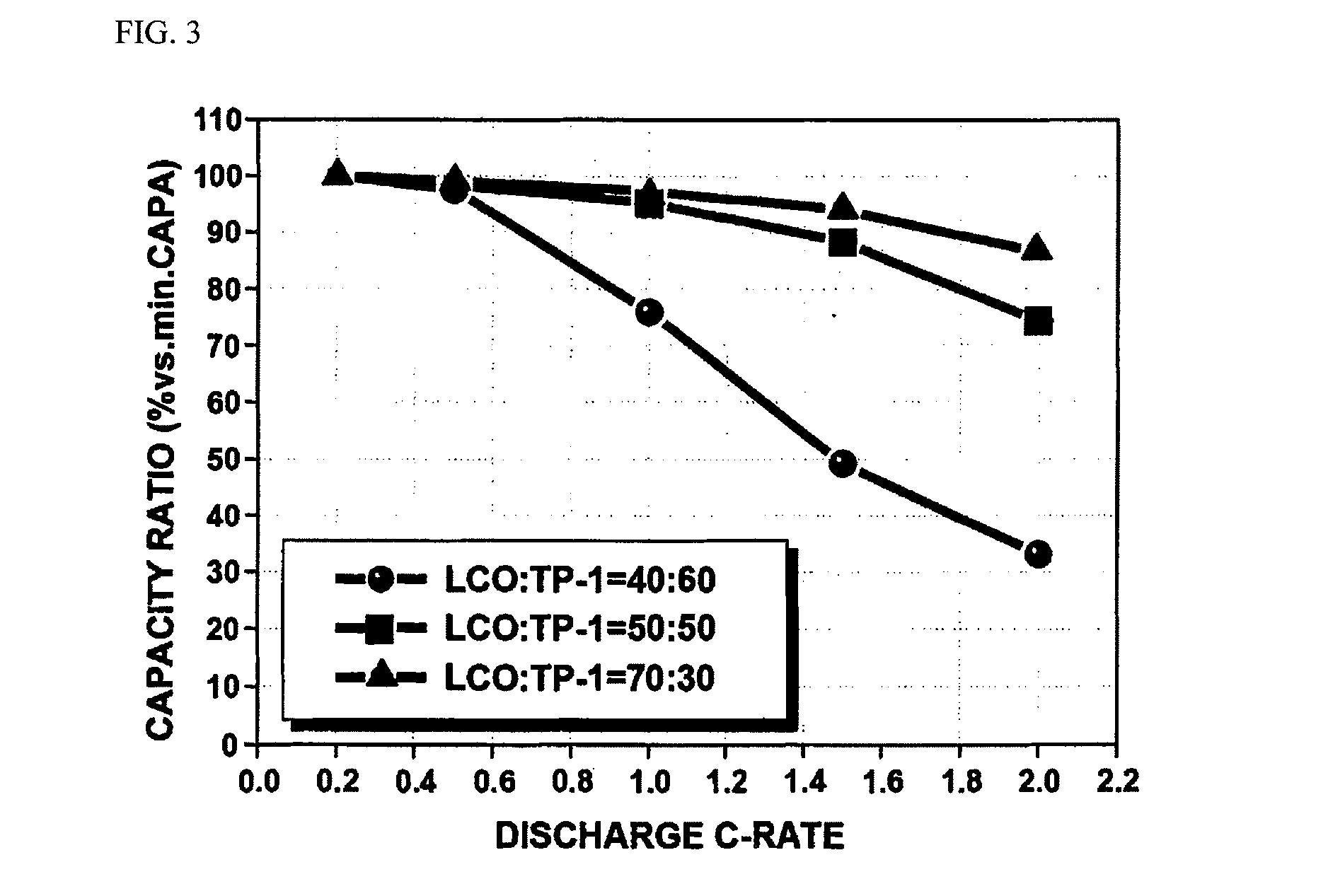

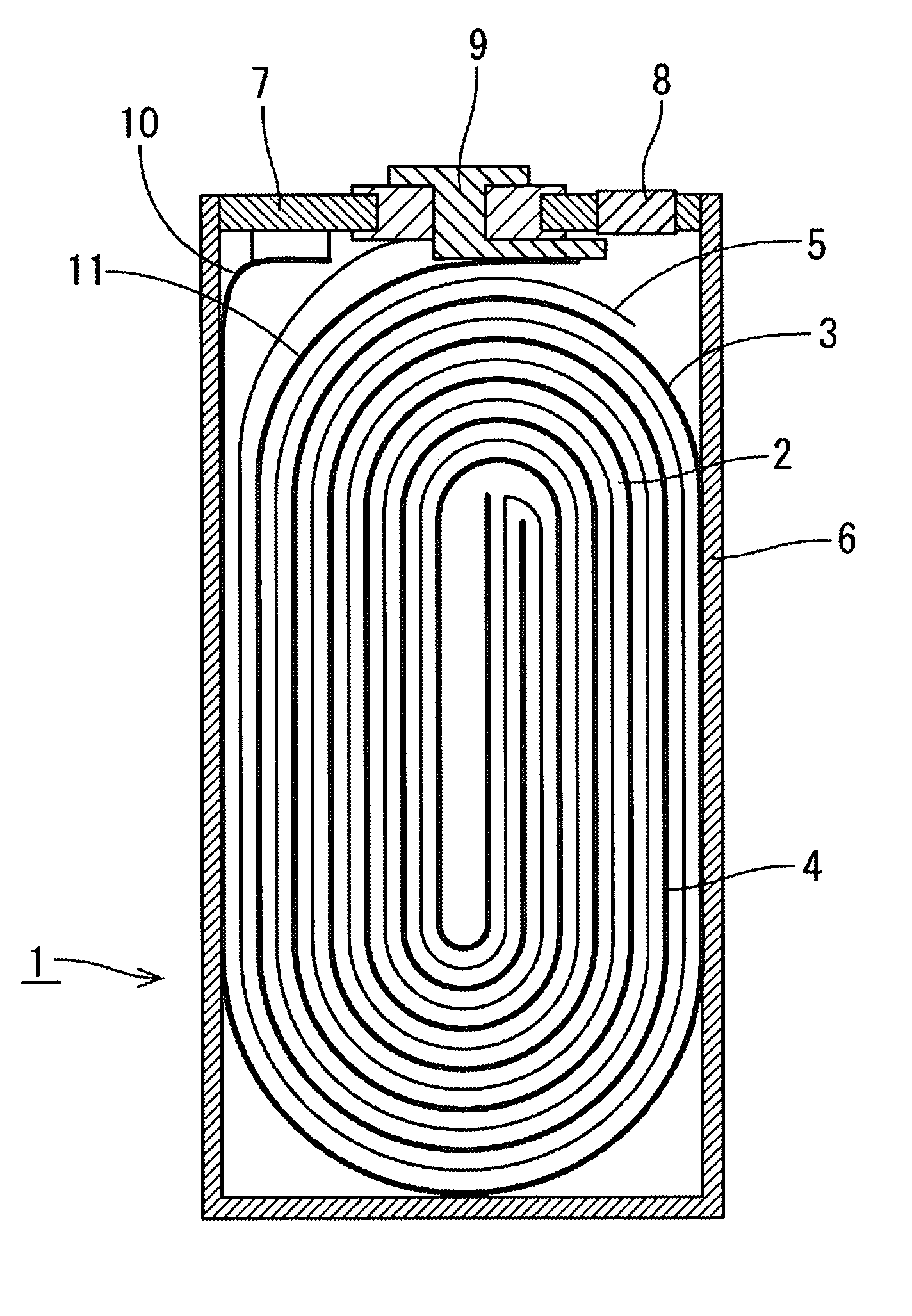

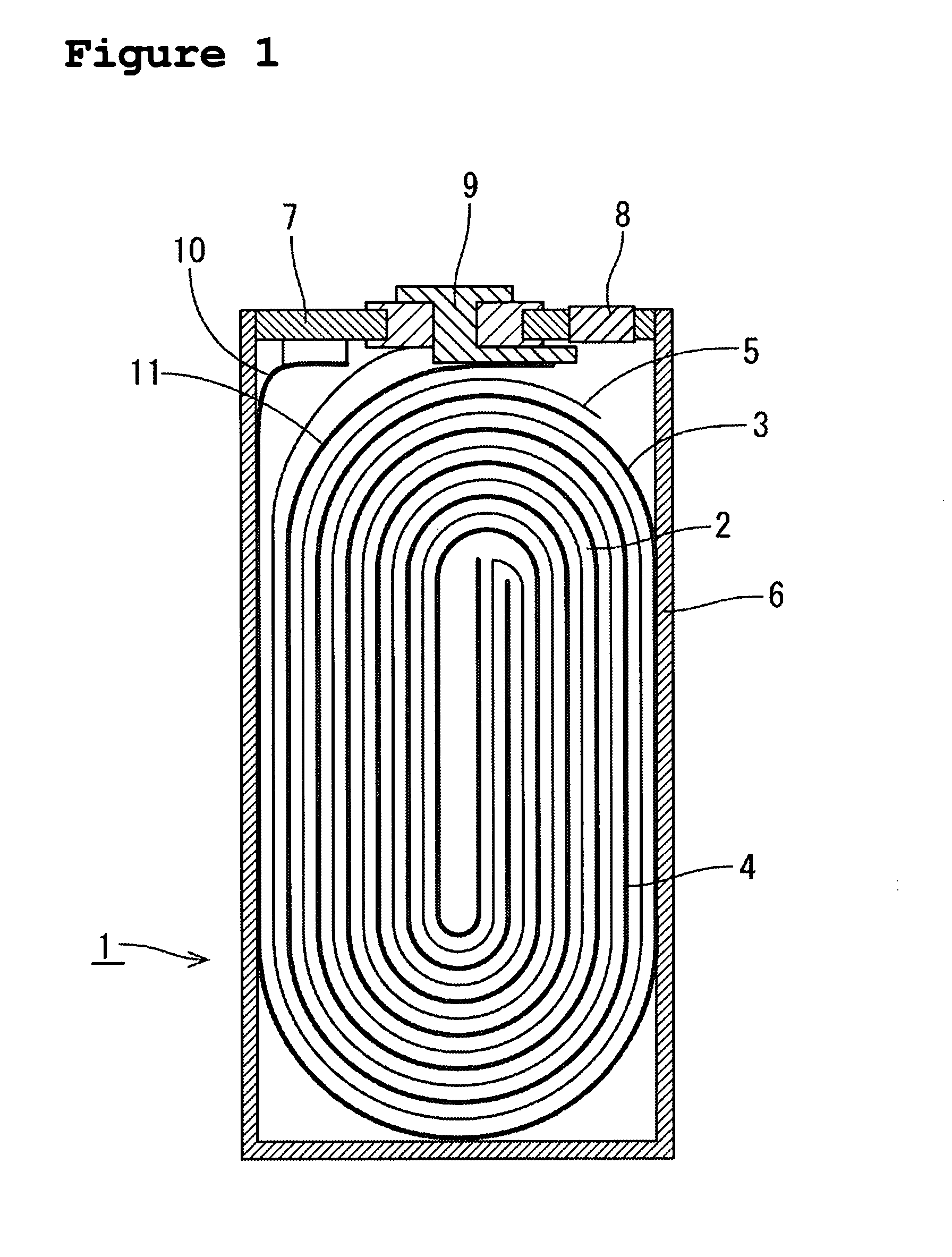

ActiveUS20120219840A1Increase energy densityExcellent capacity characteristicsPositive electrodesLi-accumulatorsPolyolefinHigh energy

Disclosed is a secondary battery including a cathode, an anode, a membrane and an electrolyte, wherein the cathode contains a mixture of a first cathode material defined herein and a second cathode material selected from the group consisting of a second-(a) cathode material defined herein and a second-(b) cathode material defined herein, and a combination thereof, wherein a mix ratio of the two cathode materials (first cathode material: second cathode material) is 50:50 to 90:10, and the membrane is an organic / inorganic composite porous membrane including (a) a polyolefin-based membrane substrate and (b) an active layer in which one or more areas selected from the group consisting of the surface of the substrate and a portion of pores of the substrate are coated with a mixture of inorganic particles and a binder polymer, wherein the active layer has a structure in which the inorganic particles are interconnected and fixed through a binder polymer and porous structures are formed by the interstitial volume between the inorganic particles.

Owner:LG ENERGY SOLUTION LTD

Method for producing polyolefin microporous membrane

InactiveCN101208379AExcellent mechanical propertiesImprove shutdown characteristicsSemi-permeable membranesMembranesPolyolefinSolvent

A method for producing a microporous polyolefin membrane by extruding a melt blend comprising a polyethylene resin, polypropylene having a mass-average molecular weight of 1 × 10 5 or more and an ethylene content of 5% by mass or less, and a membrane-forming solvent through a die, slowly cooling the resultant extrudate to form a gel-like sheet, stretching the gel-like sheet, and removing the above membrane-forming solvent, the slow-cooling speed of the extrudate being 30°C / second or less.

Owner:TONEN CHEM CORP

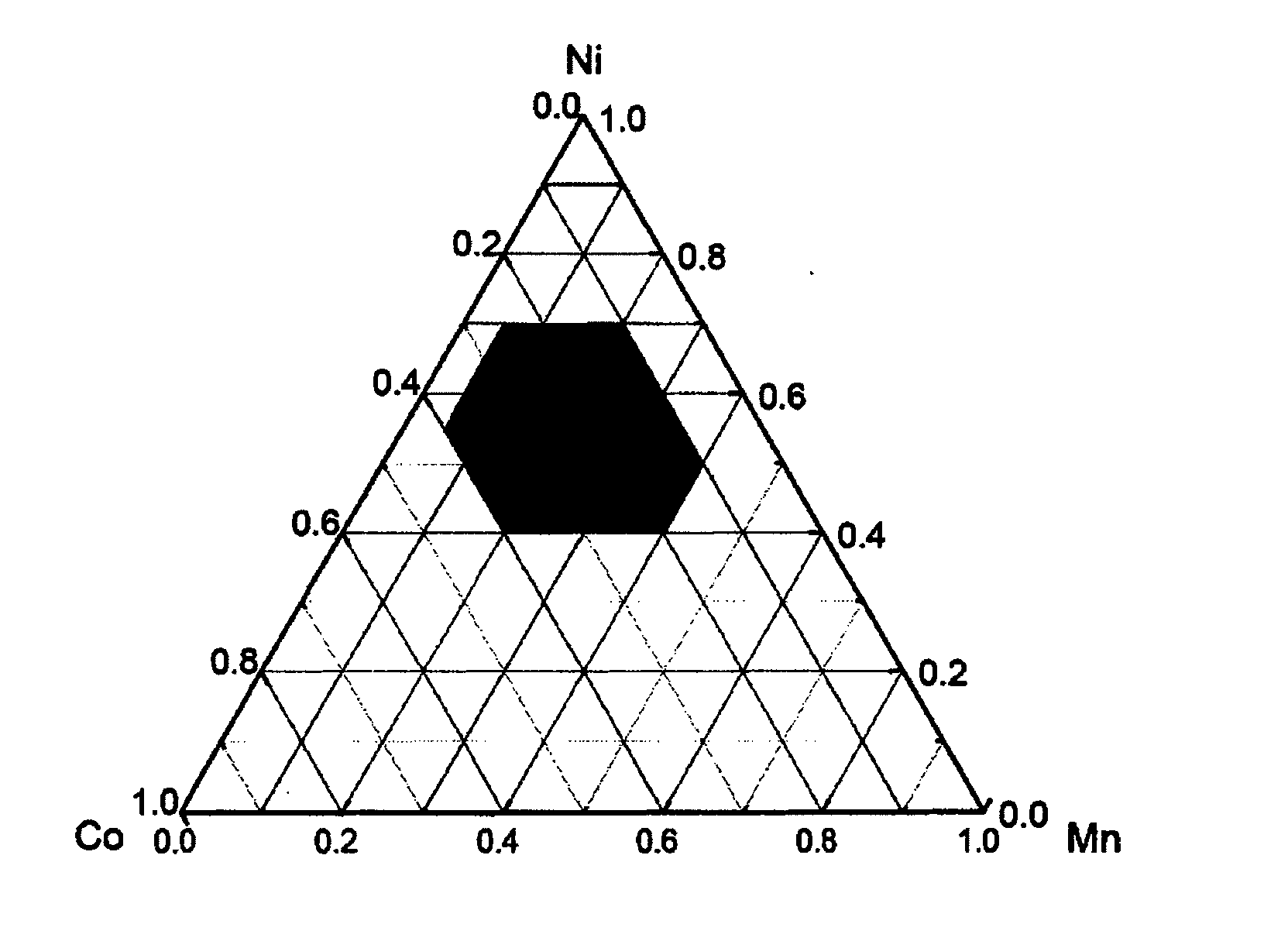

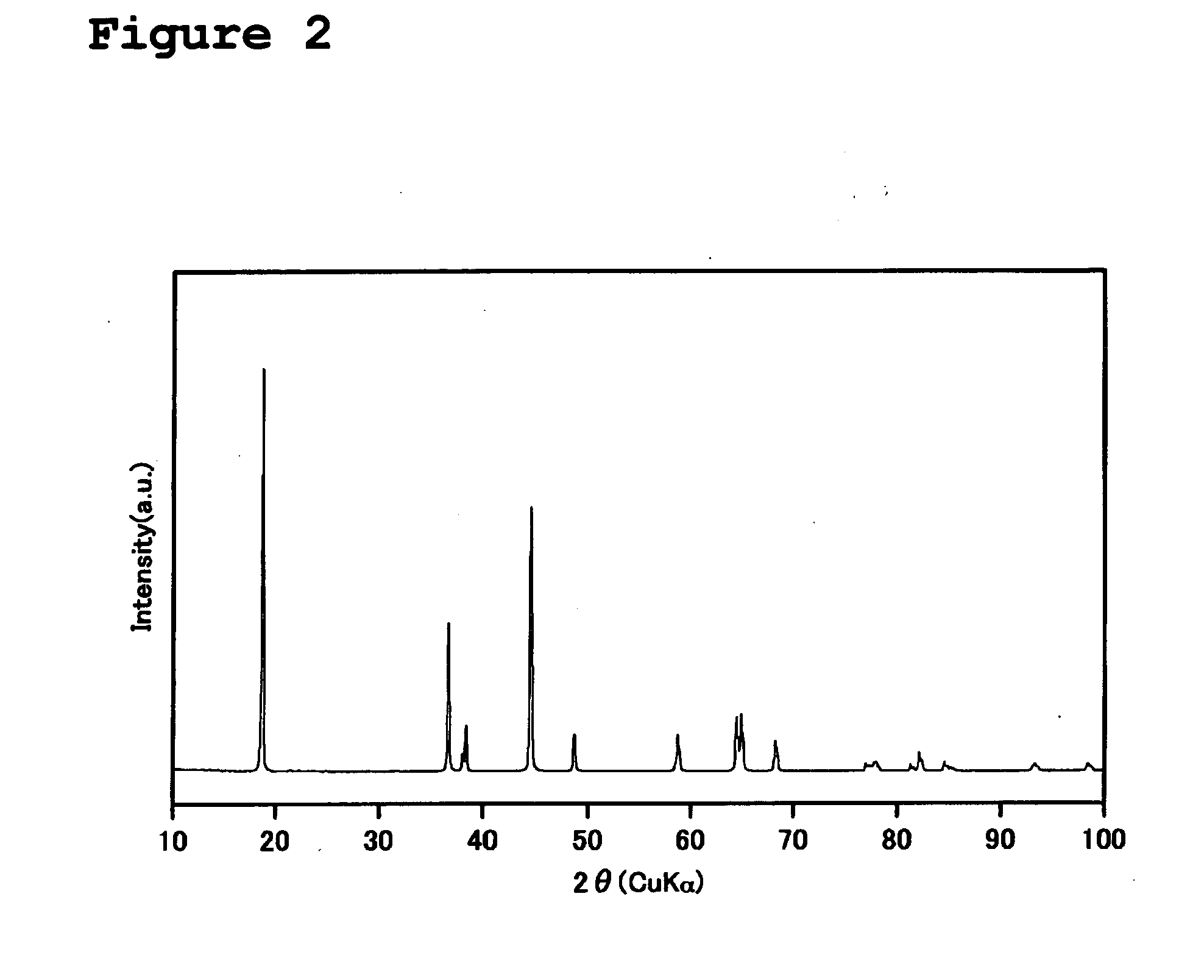

Non-aqueous electrolyte secondary cell

InactiveUS20050142444A1Improve battery safetyIncrease discharge voltageLi-accumulatorsNon-aqueous electrolyte accumulator electrodesX-rayConductive materials

The present invention aims to improve cycling characteristics with maintaining high capacity, which is a feature of lithium-nickel composite oxide, and provides a non-aqueous electrolyte secondary battery comprising a positive electrode which is configured by applying on a current collector a mixture which comprises: a lithium-containing composite oxide having a hexagonal system structure, wherein Co is substituted for part of nickel in a lithium-nickel composite oxide (the substitution percentage ranges from 5 to 30%) and, in addition, at least one kind of such elements as Al, Mn, Ti, and Mg is substituted (the substitution percentage is less than 20%); a binder; and a conductive material; and said lithium-containing composite oxide is characterized in that a half width of the (110)-plane-based diffraction peak obtained from powder X-ray diffraction method, in which CuKα line is used as characteristic X-ray, is larger than 0.13° and smaller than 0.20°, and that the ratio of the (003)-plane-based diffraction peak intensity to the (104)-plane-based diffraction peak intensity is larger than 1.2 and smaller than 1.8.

Owner:JAPAN STORAGE BATTERY CO LTD

Cathode Active Material For A Lithium Rechargeable Battery And A Production Method Therefor

ActiveUS20120094181A1Excellent capacity propertyExcellent capacity characteristicsElectrode manufacturing processesFinal product manufactureEngineeringLithium-ion battery

The present invention relates to negative-electrode active material for a lithium secondary battery exhibiting excellent capacity property and cycle life property, a method of preparing the same, and a lithium secondary battery using the negative-electrode active material, wherein the negative-electrode active material for a lithium secondary battery comprises a nanotube having a tube shape defined by an outer wall with a thickness of nanoscale, the outer wall of the nanotube comprises at least one non-carbonaceous material selected from the group consisting of silicon, germanium and antimony, and an amorphous carbon layer with a thickness of 5 nm or less is formed on the outer wall of the nanotube.

Owner:LG ENERGY SOLUTION LTD +1

Method for preparing lithium metal phosphate

ActiveUS7988879B2Good physical propertiesExcellent capacity characteristicsAluminium compoundsPhosphatesGroup 12 elementLithium metal

Owner:LG ENERGY SOLUTION LTD

Lithium-nickel based positive electrode active material, method of preparing the same, and lithium secondary battery including the same

ActiveUS20160293951A1Improve structural stabilityInhibit swellingElectrode thermal treatmentFinal product manufactureAlkaline earth metalPhosphate

The present disclosure relates to a positive electrode active material which reduces lithium by-products and improves structural stability and includes a lithium-nickel based transition metal composite oxide in which an alkaline earth metal having oxidation number of +2 is doped and a phosphate coated layer formed on the outer surface of the composite oxide. Accordingly, a second battery including the positive electrode active material has excellent capacity characteristics, and also improves structural stability during charging / discharging and prevents swelling, thereby being capable of exhibiting excellent life characteristics. Therefore, the present invention may be easily applied to industry in need thereof, and particularly to electric vehicles industry requiring high capacity and long-term life characteristics.

Owner:LG ENERGY SOLUTION LTD

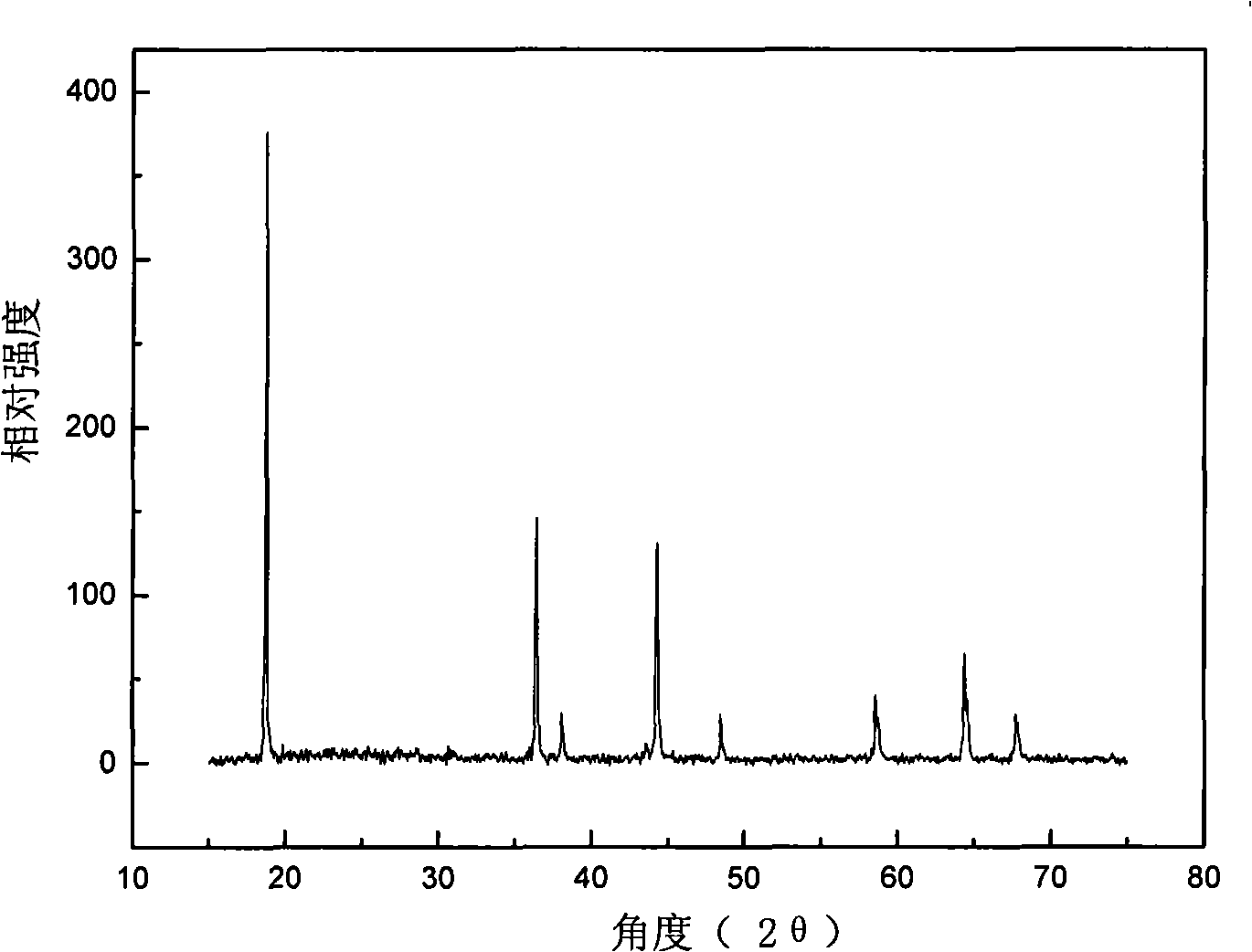

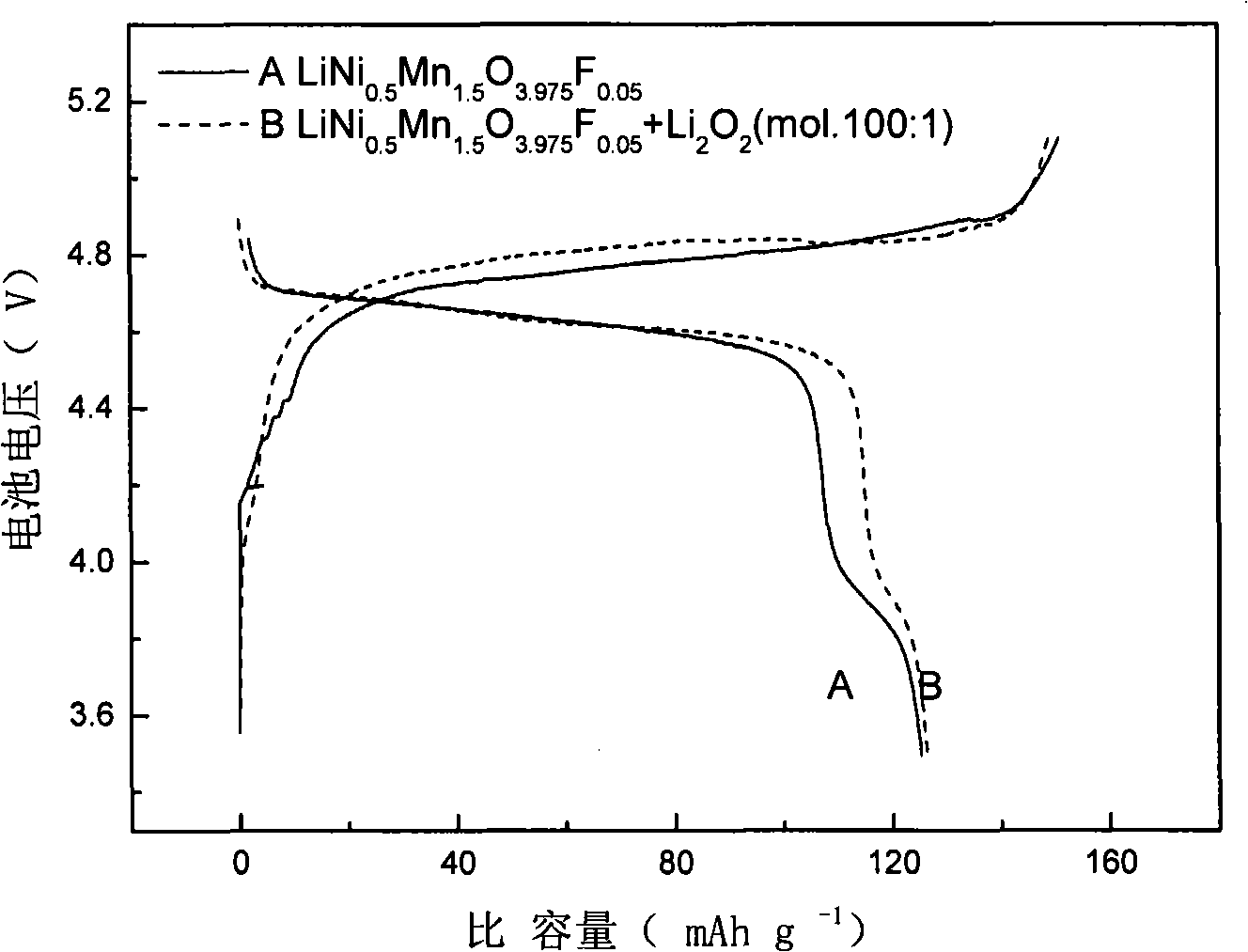

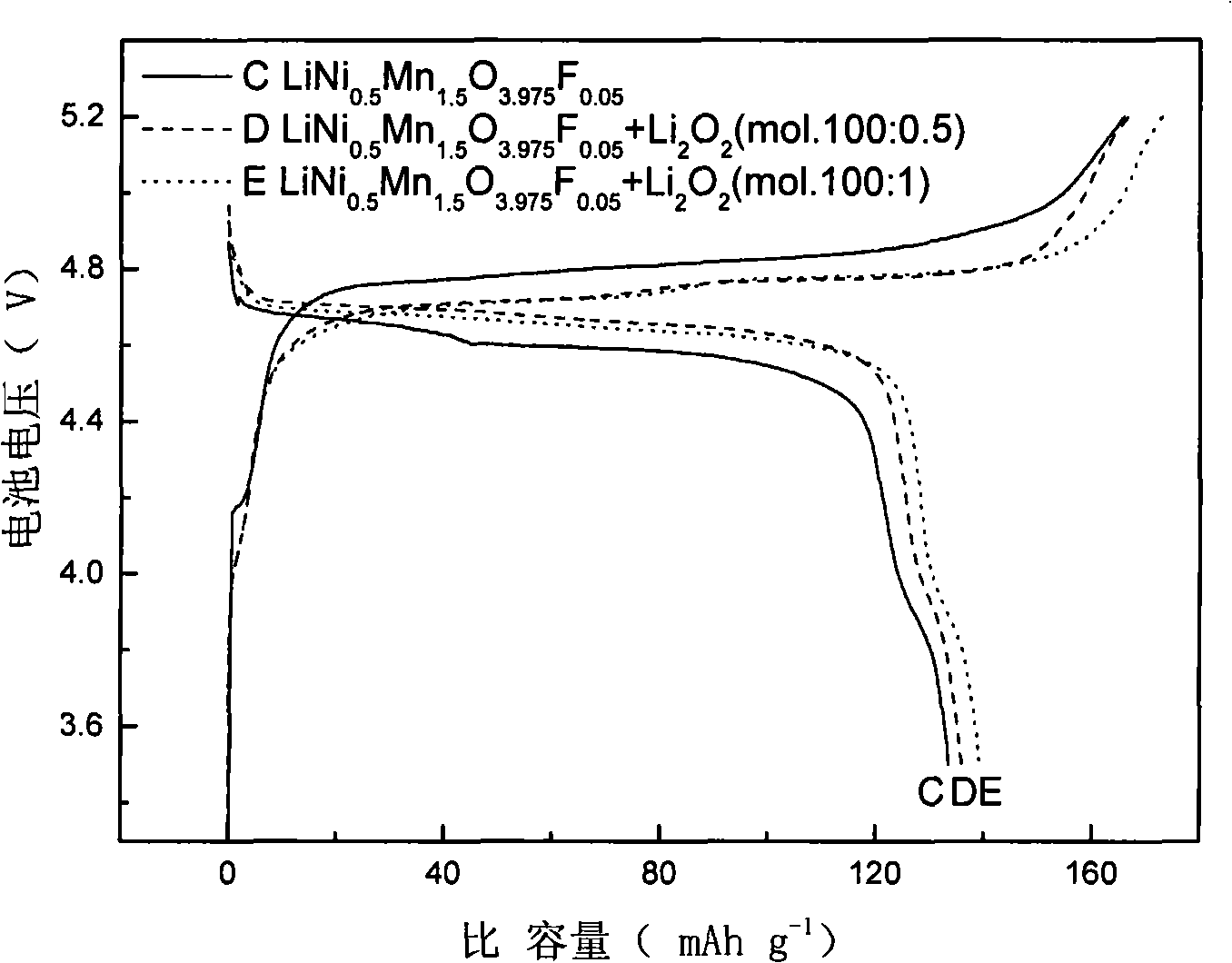

Method for preparing anode material for lithium ion battery

InactiveCN101409346AIncrease capacityImprove cycle stabilityElectrode manufacturing processesNickel compoundsChemistryCharge and discharge

The invention relates to a preparation method of an anode material for a lithium ion battery. Component of the anode material is LiNi0.5Mn1.5O4-deltaFx, wherein, the delta equals 0.5x, and x is not less than 0.01 and not more than 0.08; the anode material is prepared by combining gel and lithium peroxide under high-temperature heat treatment; the process is simple and the preparation course is easy to be controlled. The first discharge capacity of the material can reach 140mAh / g<-1>, wherein, 5V voltage platform characteristic is obviously improved, and 4V voltage platform is well removed, the charge and discharge efficiency reach more than 96% after repeating the previous cycles, and the material has excellent cycle performance.

Owner:PANASONIC CORP +1

Positive electrode active material for secondary battery, and secondary battery including the same

ActiveUS20180294477A1Excellent capacity characteristicsImprove output characteristicsElectrode thermal treatmentFinal product manufactureLithium oxidePhysical chemistry

The present invention provides a positive electrode active material for secondary battery and a secondary battery including the same. The positive electrode active material includes a core including a lithium composite metal oxide of Formula 1 below, a first surface-treated layer positioned on the surface of the core and including a lithium oxide of Formula 2 below, and a second surface treated layer positioned on the core or the first surface-treated layer and including a lithium compound of Formula 3. Thus, the present invention can improve capacity characteristics and output characteristics of a battery and also reduce the generation of gas,LiaNi1-x-yCoxM1yM3zM2wO2 [Formula 1]LimM4O(m+n) / 2 [Formula 2]LipM5qAr [Formula 3](in formulae 1 to 3, A, M1 to M5, a, x, y, z, w, m, n, p, and q are the same as those defined in the specification).

Owner:LG ENERGY SOLUTION LTD

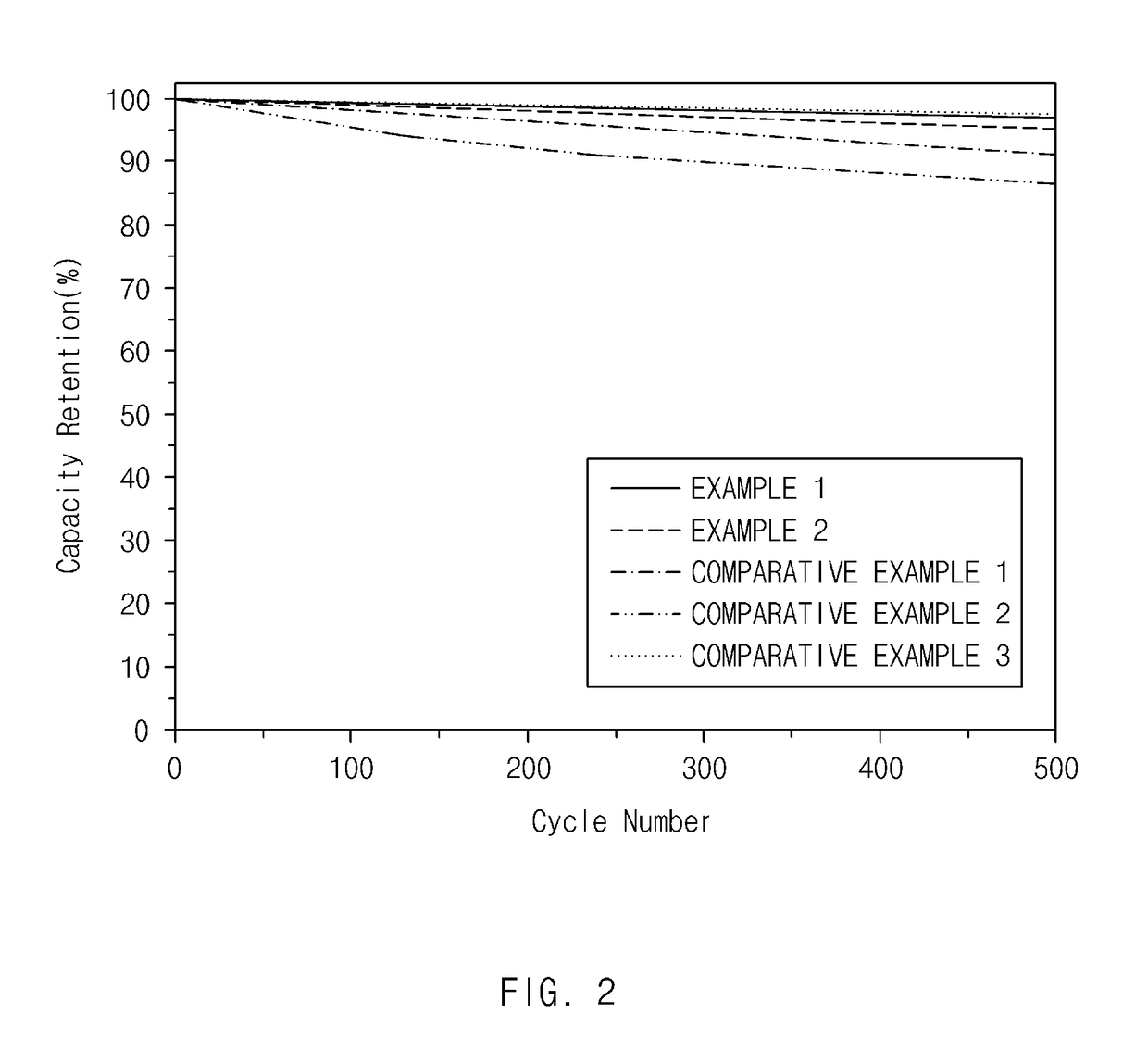

Negative electrode active material and negative electrode for secondary battery comprising the same

ActiveUS20170133682A1Improve rolling effectImprove discharge characteristicsNegative electrodesLi-accumulatorsLithiumFlake graphite

Provided are a negative electrode active material including spherical artificial graphite and natural flake graphite, wherein the spherical artificial graphite and the natural flake graphite are included in a weight ratio of 80:20 to 95:5, and a negative electrode for a lithium secondary battery including the same.

Owner:LG ENERGY SOLUTION LTD

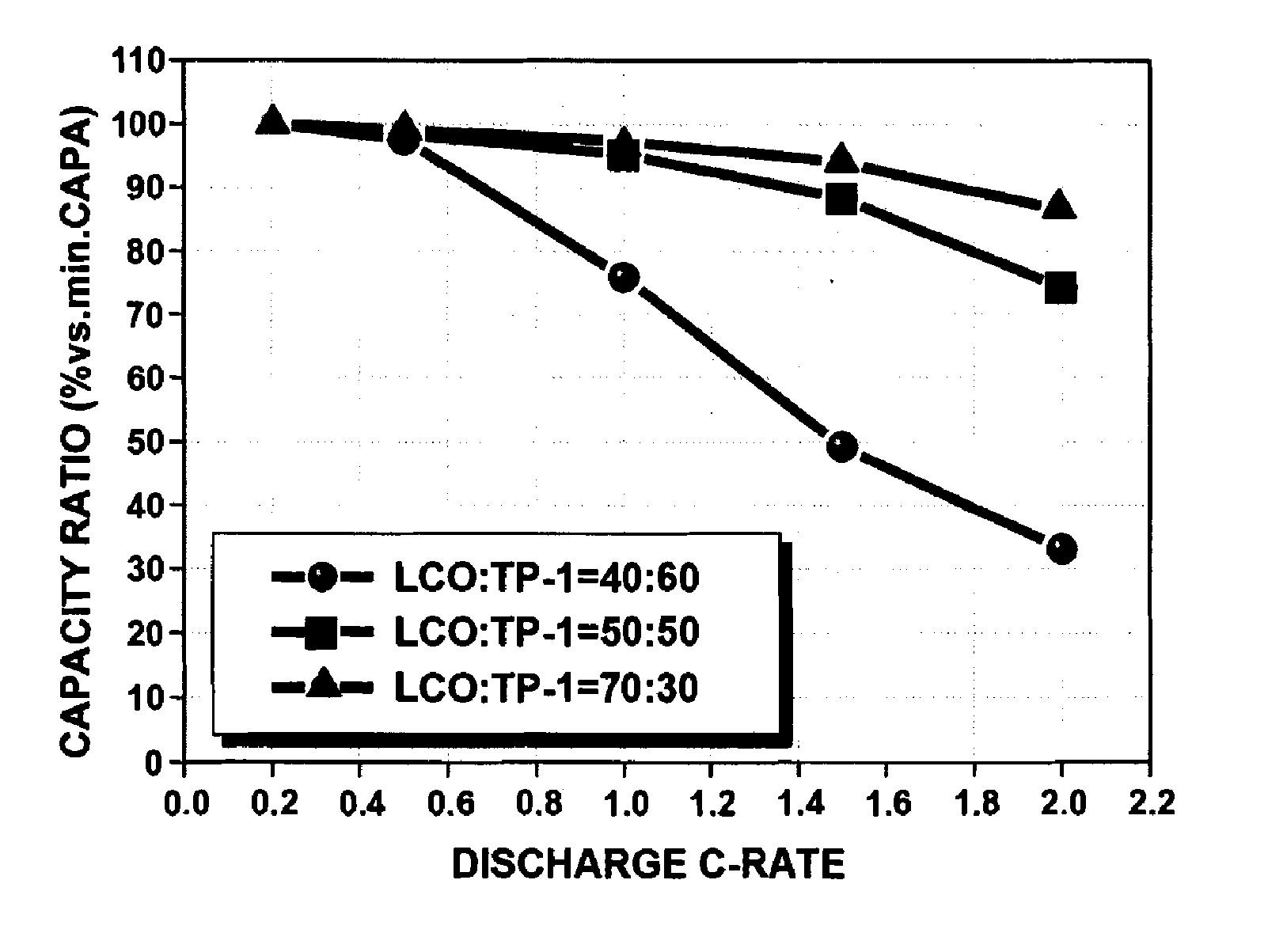

Positive Electrode Material, Positive Electrode, and Lithium Secondary Battery Which Include Spinel-Structured Lithium Manganese-Based Positive Electrode Active Material

ActiveUS20200083524A1Improve rolling densityImprove high temperature stabilityPositive electrodesCobalt compoundsElectrical batteryManganese

The present disclosure relates to a positive electrode material including a spinel-structured lithium manganese-based first positive electrode active material and a lithium nickel-manganese-cobalt-based second positive electrode active material, wherein the first positive electrode active material includes a lithium manganese oxide represented by Formula 1 and a coating layer which is disposed on a surface of the lithium manganese oxide, the second positive electrode active material is represented by Formula 2, and an average particle diameter of the second positive electrode active material is greater than an average particle diameter of the first positive electrode active material, and a positive electrode and a lithium secondary battery which include the positive electrode material:Li1+aMn2-bM1bO4-cAc [Formula 1]Li1+x[NiyCozMnwM2v]O2-pBp [Formula 2]

Owner:LG ENERGY SOLUTION LTD

Manufacture of web superabsorbent polymer and fiber

InactiveUS7144980B2Increase capacityExcellent capacity characteristicsNon-fibrous pulp additionPaper/cardboardPolymer scienceSuperabsorbent polymer

A web of superabsorbent polymer and fiber made by an in situ neutralization, wet-laid process, wherein the degree of neutralization of the superabsorbent polymer is partial, preferably less than about 80 mol %. The web exhibits an excellent centrifuge retention capacity property, as compared to prior webs of superabsorbent polymer and cellulosic fiber made by in situ neutralization, wherein the degree of neutralization is total, such as 100 mol % or more.

Owner:STOCKHAUSEN GMBH & CO KG DEGUSSA-HUELS AKTIENGESE

Cathode material and preparation method thereof and lithium-ion battery

InactiveCN105185982AExcellent capacity characteristicsEasy to processCell electrodesSecondary cellsSurface layerHeat stability

The invention provides a cathode material, which comprises a base material and an aluminum oxide layer, wherein the base material is prepared from a compound as shown in a formula I and a compound as shown in a formula II; the compound as shown in the formula I has a secondary particle morphology which is formed by agglomeration of a plurality of single crystal grains; the compound as shown in the formula II has a single-crystal structure; and the aluminum oxide layer coats the surface of the base material. The base material in the cathode material provided by the invention is prepared from the compound with the particle morphology and the compound with the single-crystal structure; due to the two morphologies of compounds, the cathode material has relatively good capacity characteristic; and the processability can also be improved. The aluminum oxide layer coats the surface of the base material in the cathode material provided by the invention; corrosion to the surface layer of the cathode material caused by moisture and HF in a battery can be avoided or reduced by coating of the aluminum oxide layer; and due to the cathode material with an aluminum oxide layer coating layer, the prepared lithium-ion battery has relatively high working voltage and heat stability. The invention further provides a preparation method of the cathode material and the lithium-ion battery.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

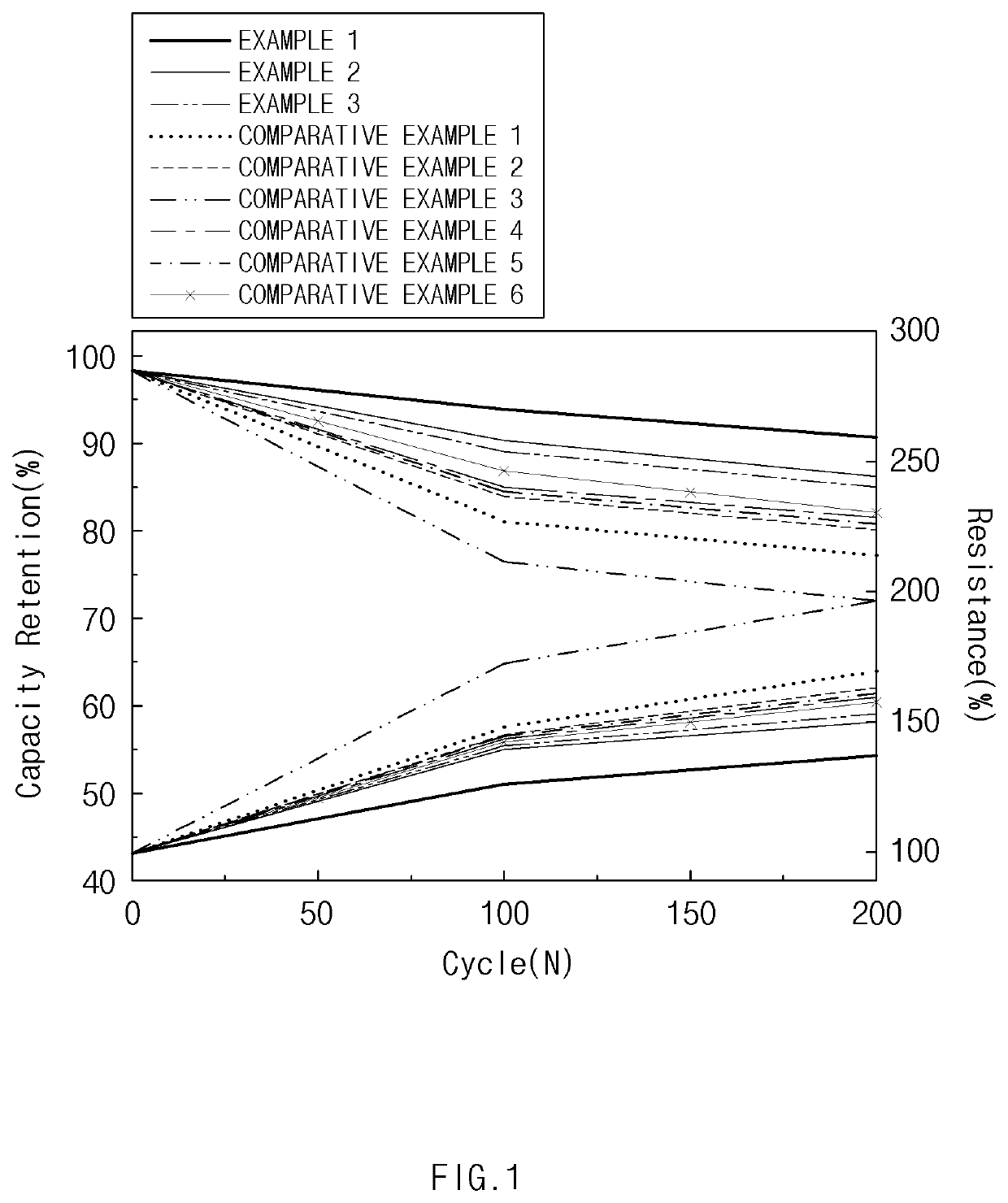

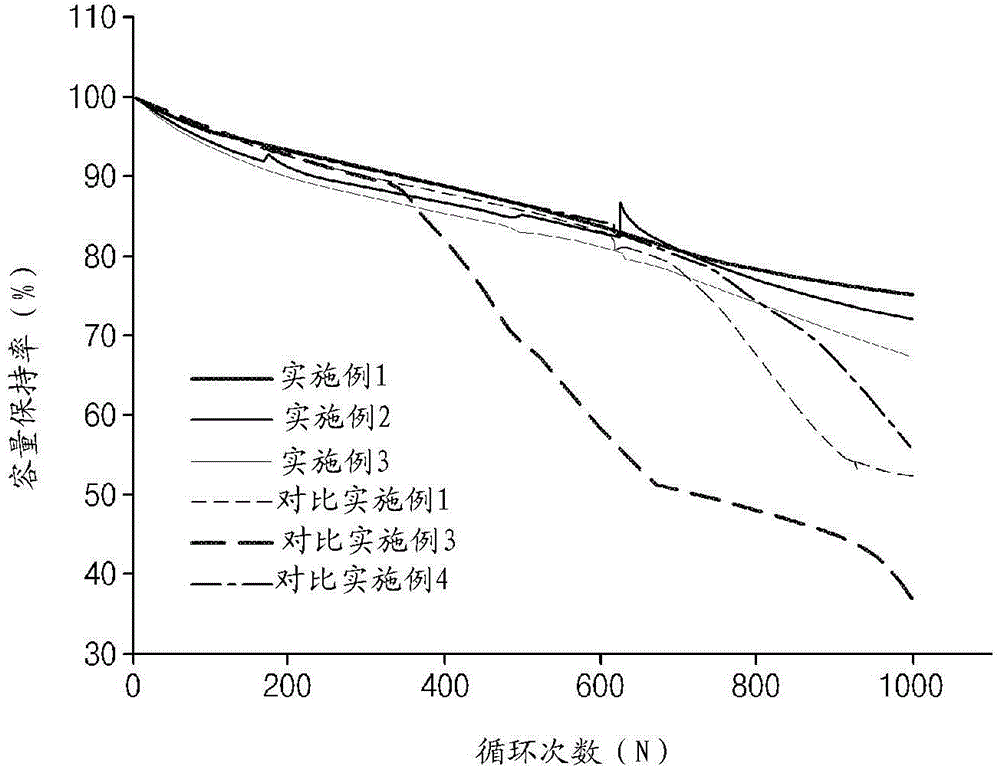

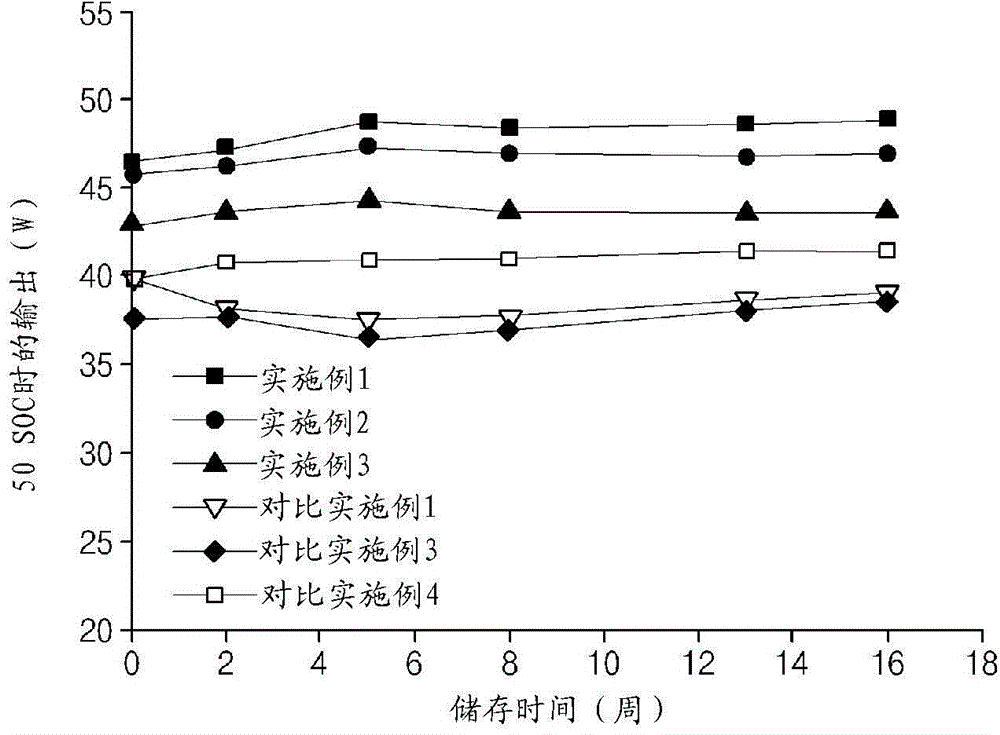

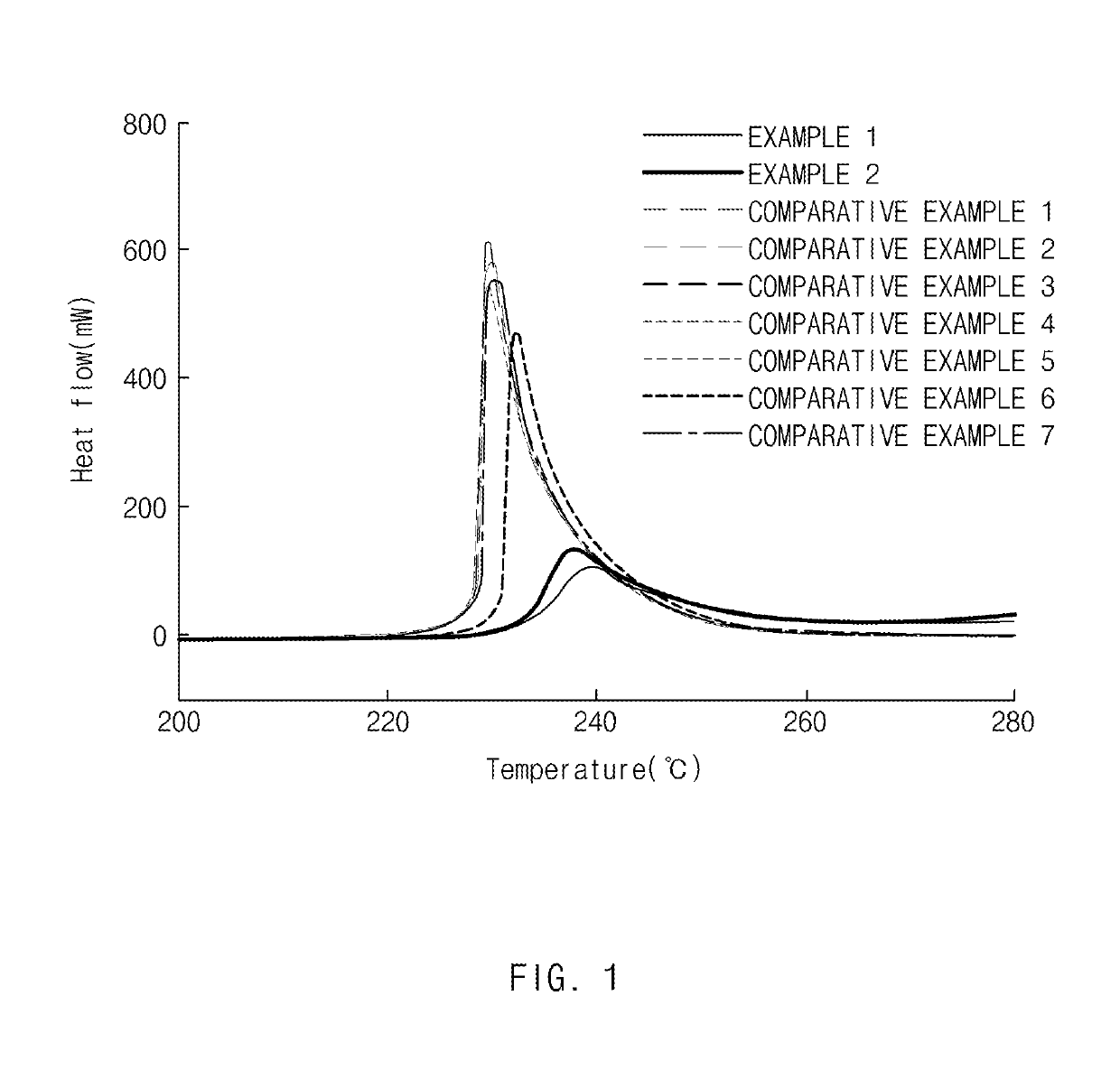

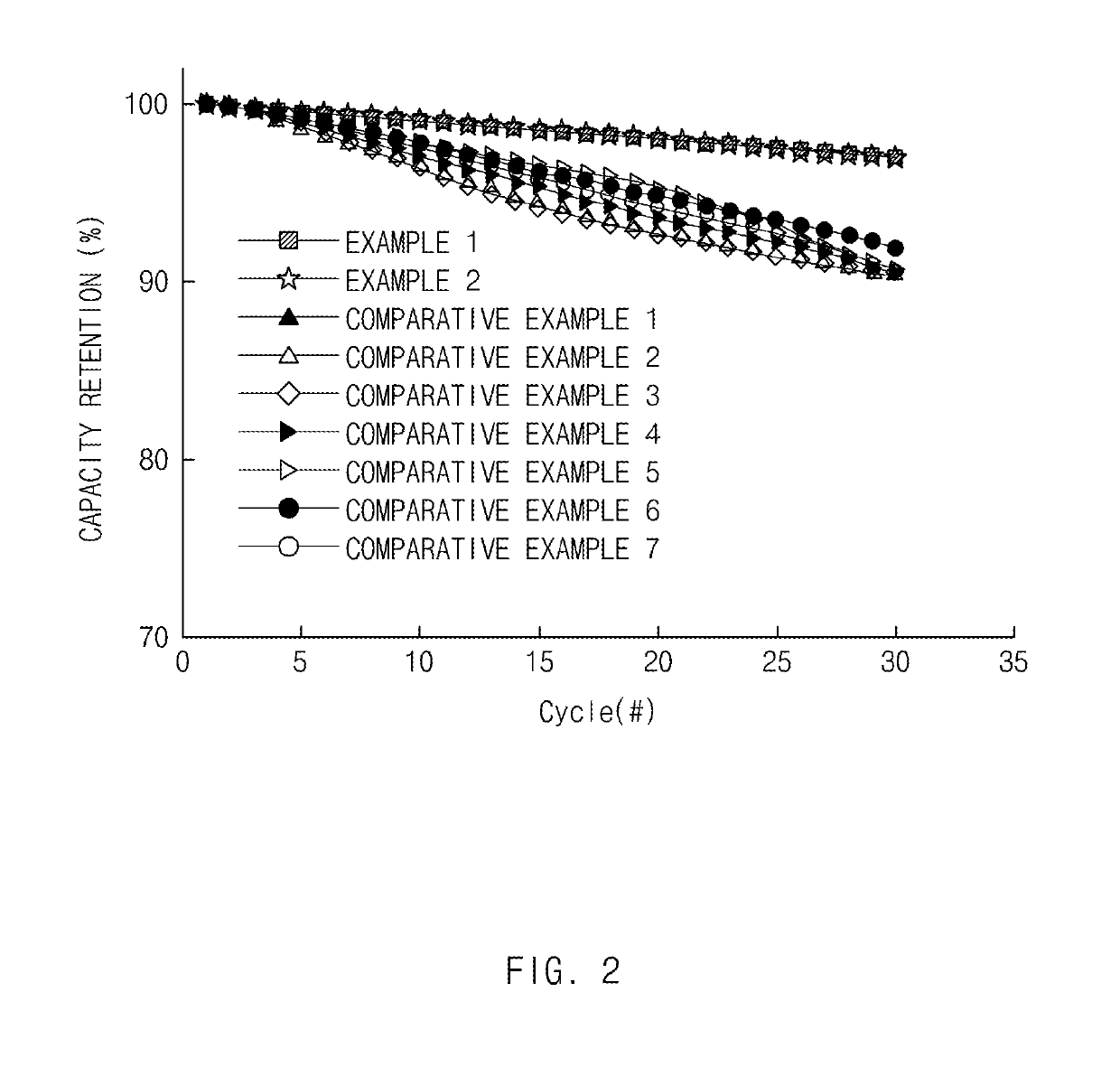

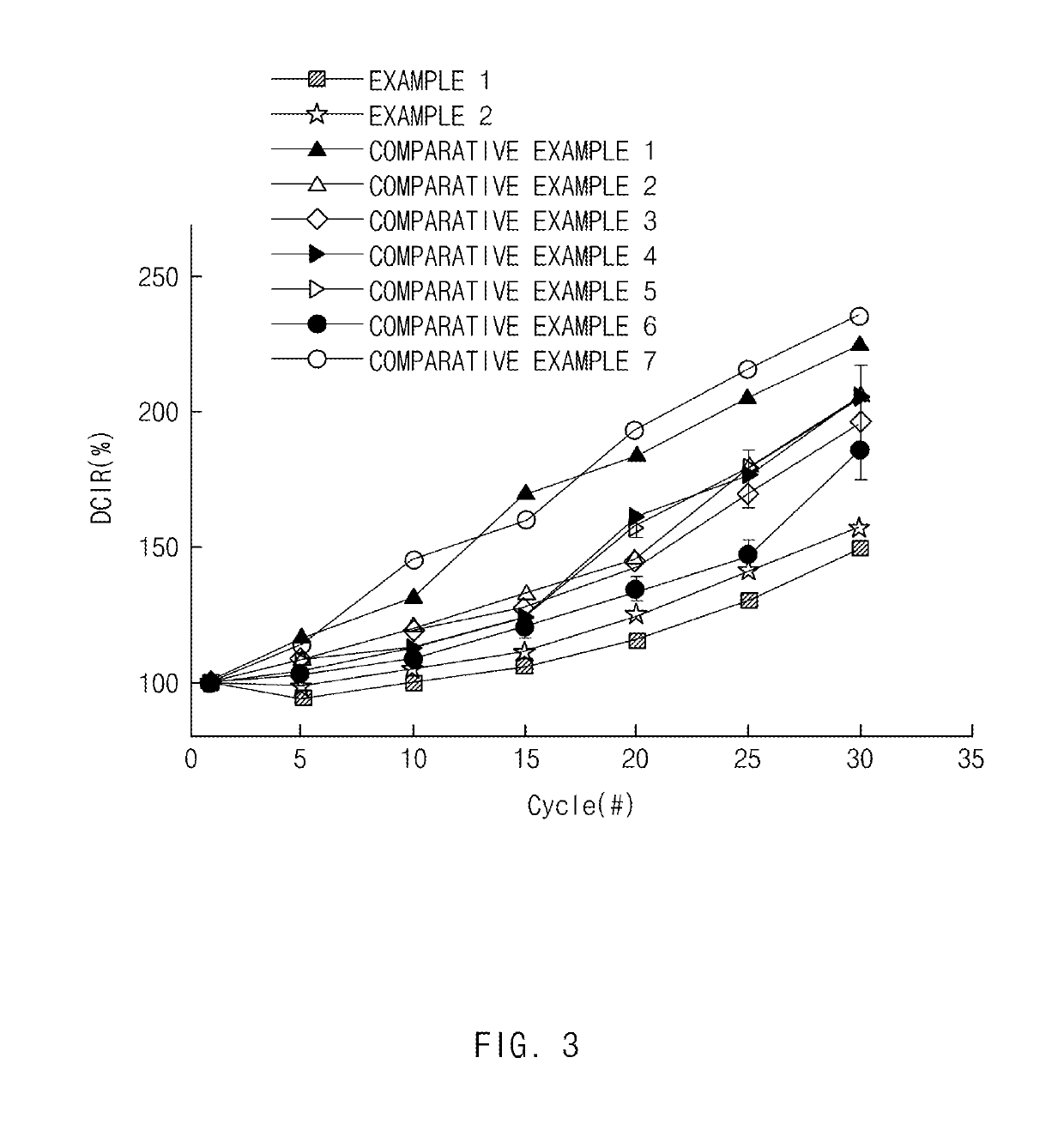

Non-aqueous electrolyte and lithium secondary battery comprising same

ActiveCN104604014AImprove output characteristicsImproved high temperature cycle characteristicsLi-accumulatorsHigh temperature storageImide

Provided are a non-aqueous electrolyte solution, which includes a non-aqueous organic solvent including propylene carbonate (PC) and an ester-based solvent, and lithium bis(fluorosulfonyl)imide (LiFSI), and a lithium secondary battery including the non-aqueous electrolyte solution. According to the non-aqueous electrolyte solution of the present invention, since a robust solid electrolyte interface (SEI) may be formed on an anode during initial charge of a lithium secondary battery including the non-aqueous electrolyte solution, high-temperature cycle characteristics and capacity characteristics after high-temperature storage as well as low-temperature, room temperature, and high-temperature output characteristics may be simultaneously improved.

Owner:LG ENERGY SOLUTION LTD

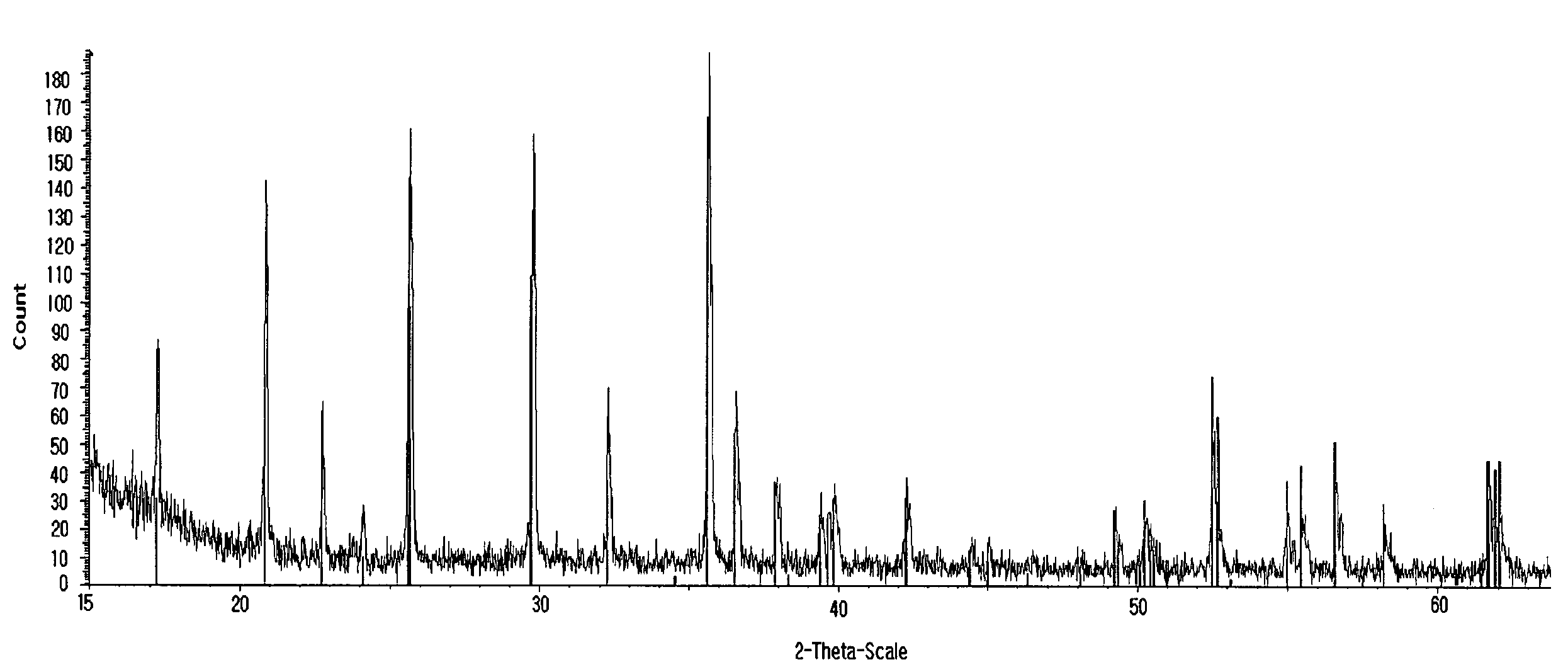

Negative active material for non-aqueous rechargeable battery, and non-aqueous rechargeable battery including same

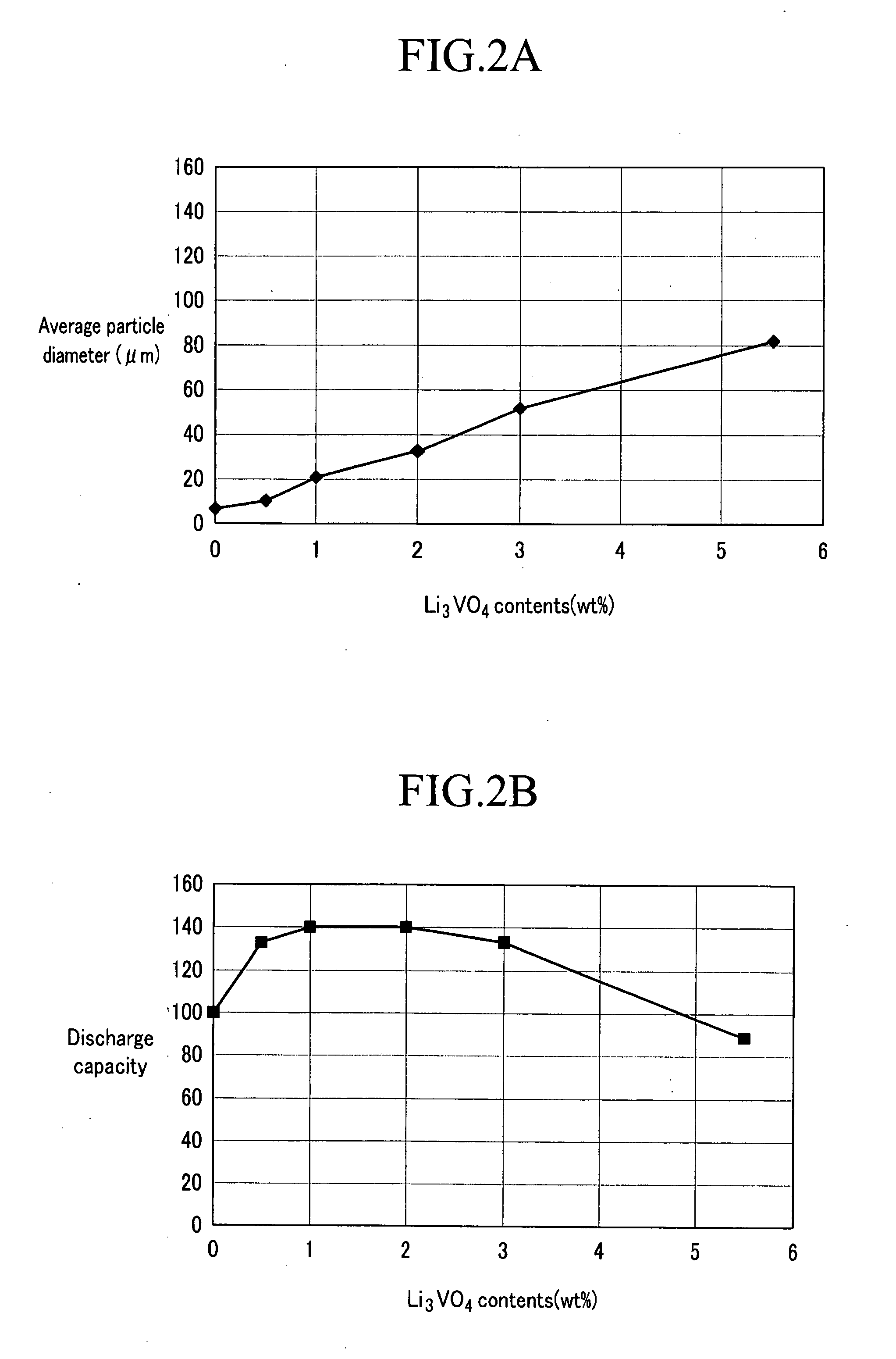

ActiveUS20080070118A1Improve discharge performanceExcellent capacity characteristicsNon-aqueous electrolyte cellsNegative electrodesLithiumVanadium oxide

The negative active material for a non-aqueous rechargeable battery includes a main component of lithium vanadium oxide, and at least one selected from the group consisting of Li3VO4, vanadium carbide, and mixtures thereof. The Li3VO4 is included in an amount of 0.5 to 3.0 wt % based on the total weight of the negative active material, and the vanadium carbide is included in amount of 0.5 wt % or less based on the total weight of the negative active material. The negative active material can improve discharge capacity of the non-aqueous rechargeable battery.

Owner:SAMSUNG SDI CO LTD

Cathode material for lithium secondary battery, and cathode and lithium secondary battery which comprise same

ActiveCN111316480AExcellent capacity characteristicsHigh densityElectrode carriers/collectorsNegative electrodesElectrical batteryBattery cell

Owner:LG ENERGY SOLUTION LTD

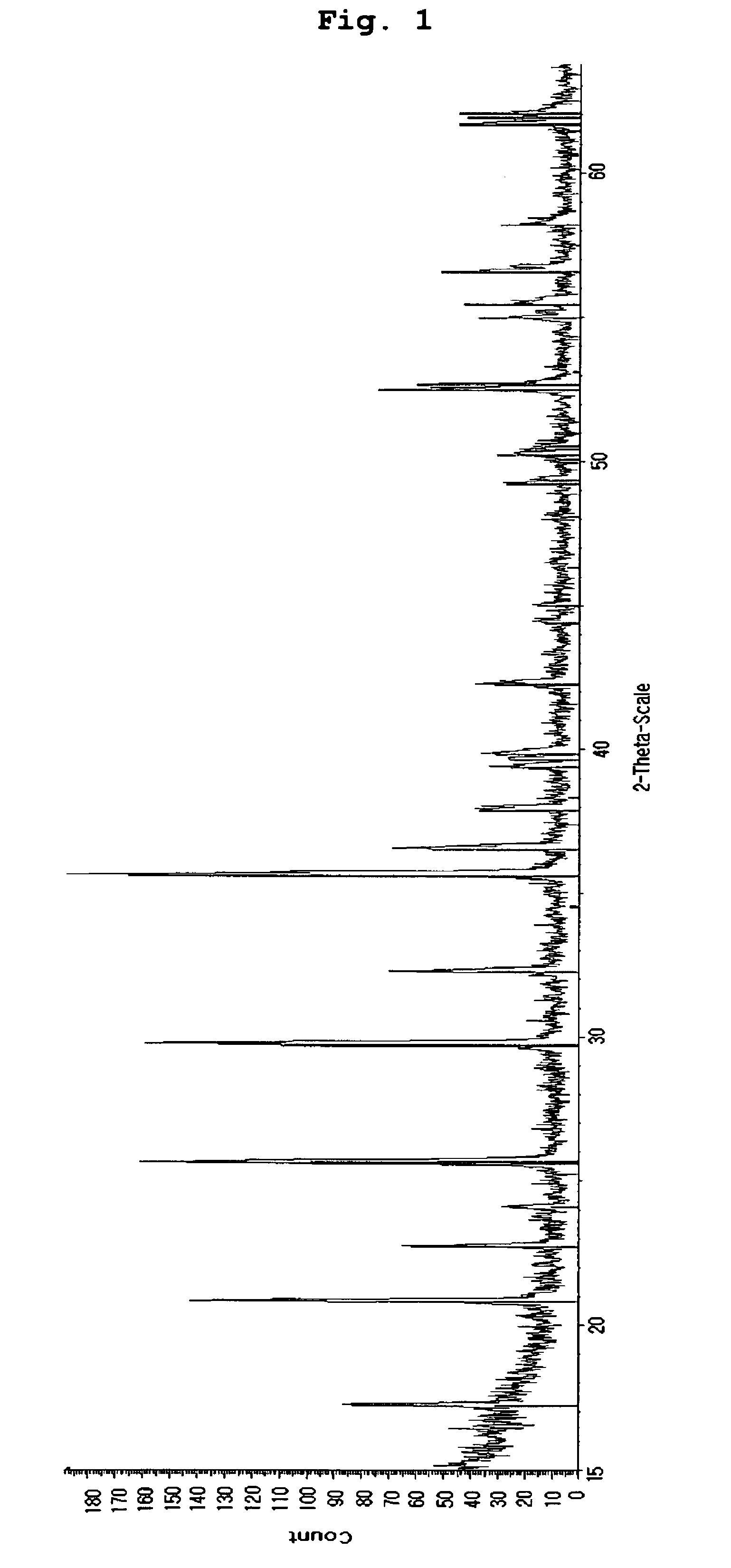

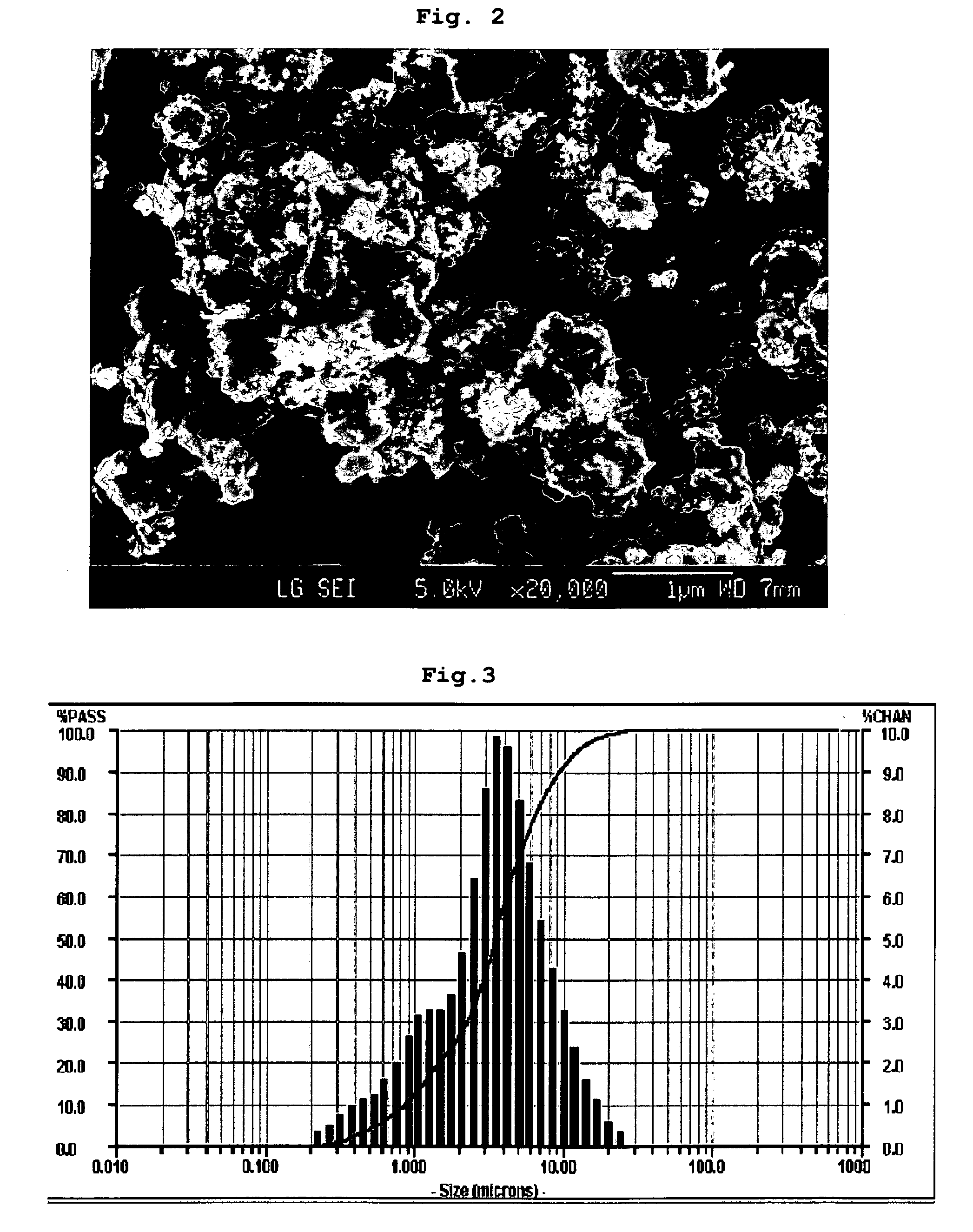

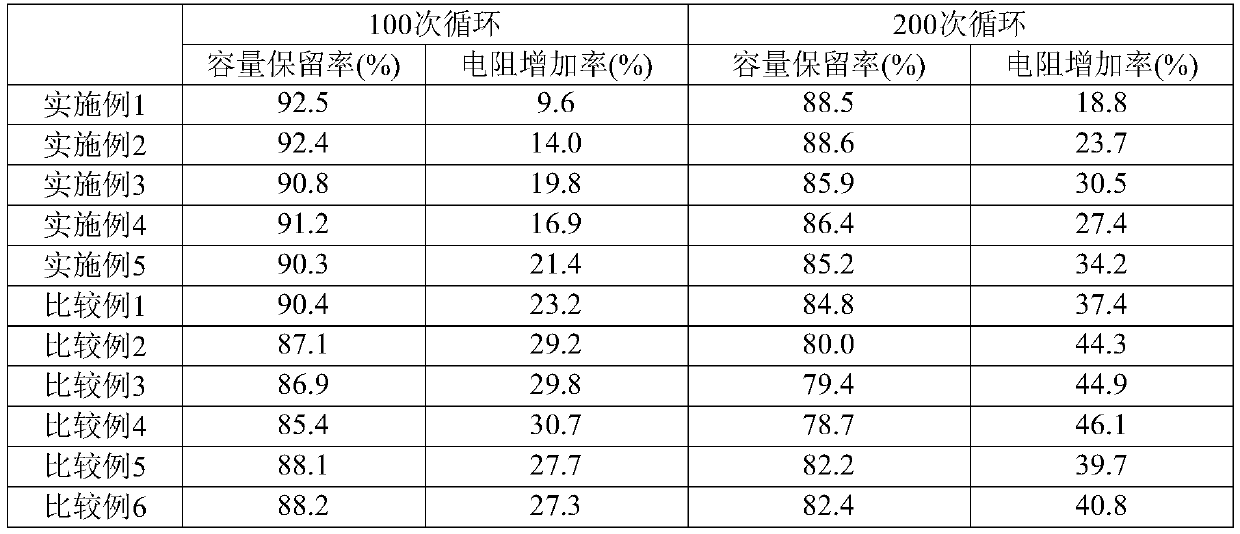

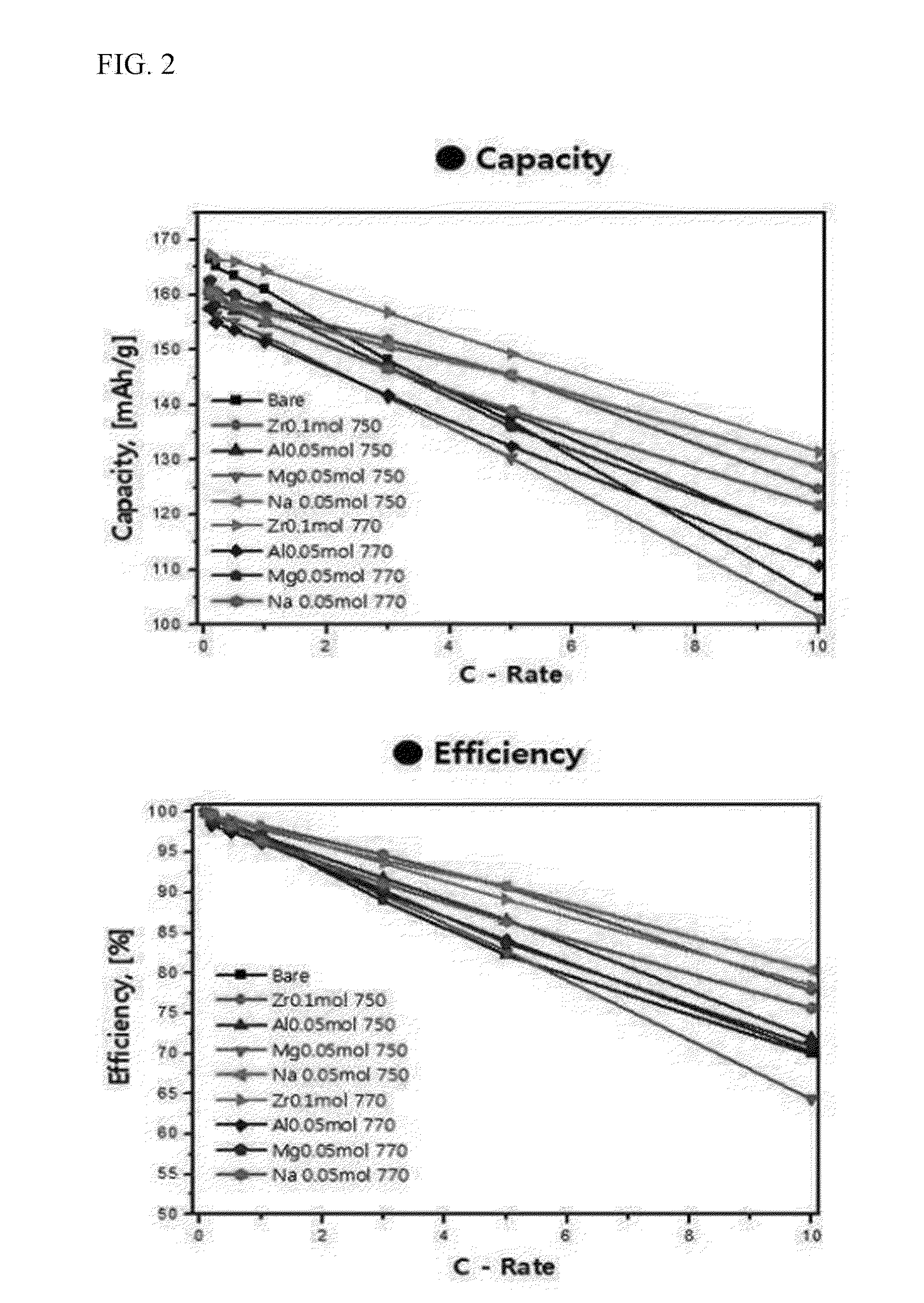

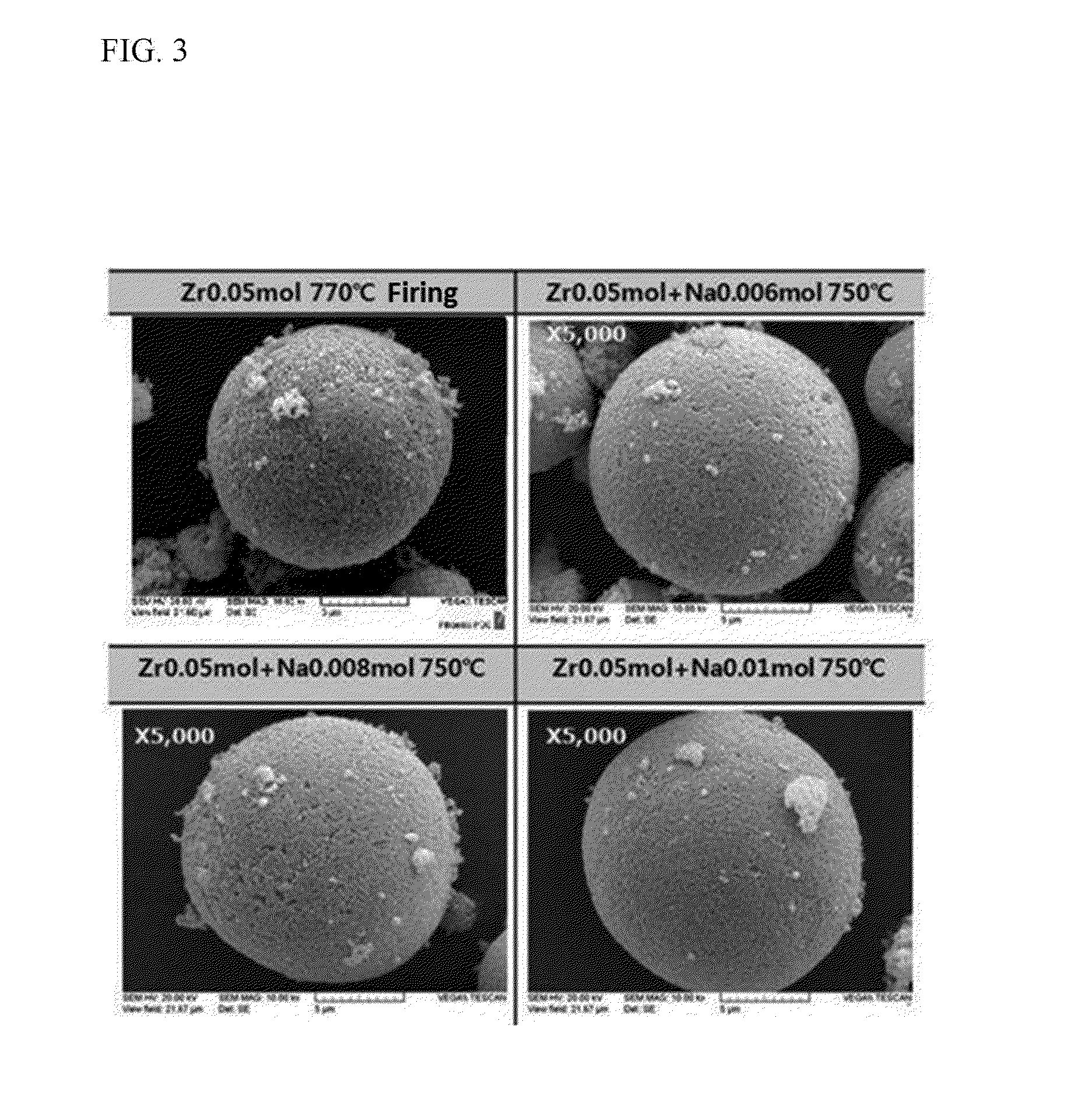

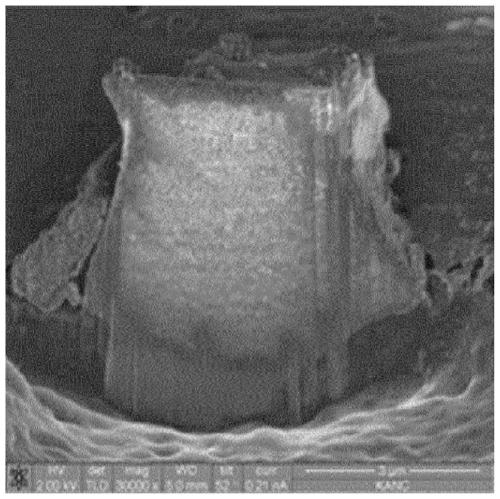

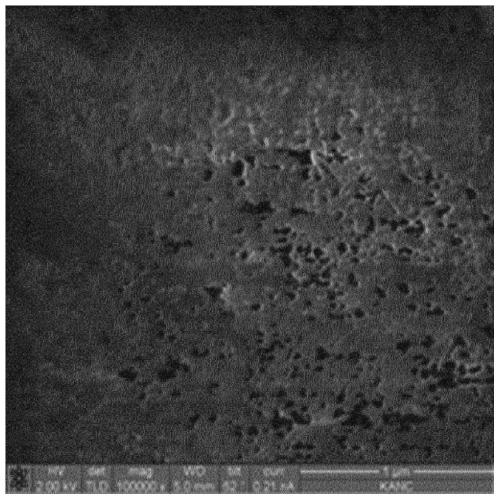

Manufacturing method of lithium-titanium composite oxide in which different metals are doped, and lithium-titanium composite oxide manufactured thereby in which different metals are doped

InactiveUS20160079594A1Increase battery capacity and crystallinityExcellent characteristicHeat treatmentsAlkali titanatesSolid phasesComposite oxide

Provided is a manufacturing method of a lithium-titanium composite oxide doped with different metals, solid-phase mixing after adjusting a mixing ratio of two kinds of different metals and pulverizing the same, and spray drying the same to adjust contents of impurities, and a lithium-titanium composite oxide doped with different metals manufactured therefrom. By doping two kinds of different metals on the surface of the lithium-titanium composite oxide after adjusting the ratio of the two different metals to be a desirable ratio, the contents of rutile-type titanium dioxide, anatase-type titanium dioxide and Li2TiO3 which have been included as impurities are reduced, thereby manufacturing titanium dioxide having excellent capacity characteristics and structural characteristics, and a battery including the titanium dioxide having excellent battery characteristics of high initial charge and discharge efficiency and rate capability.

Owner:POSCO CHEM +1

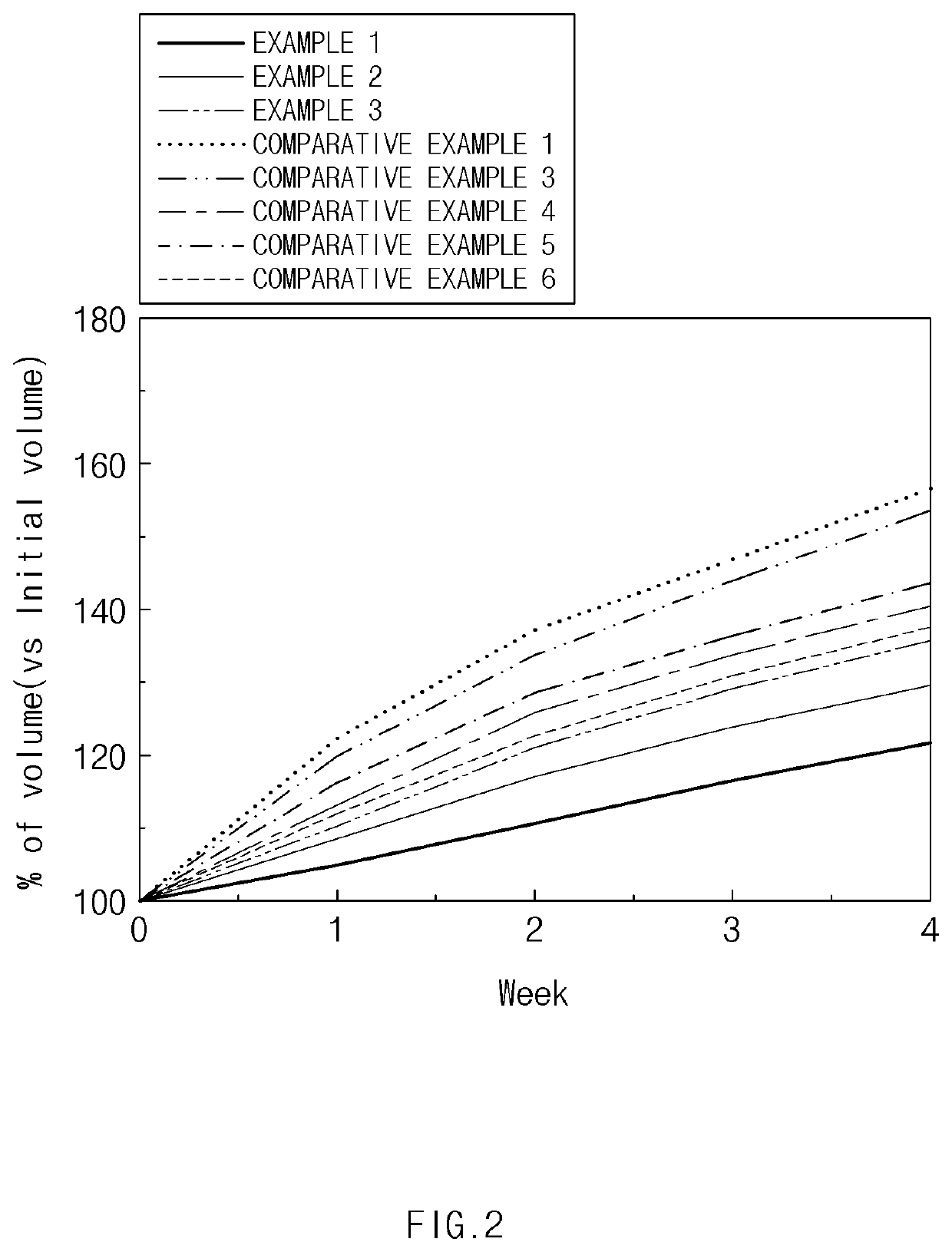

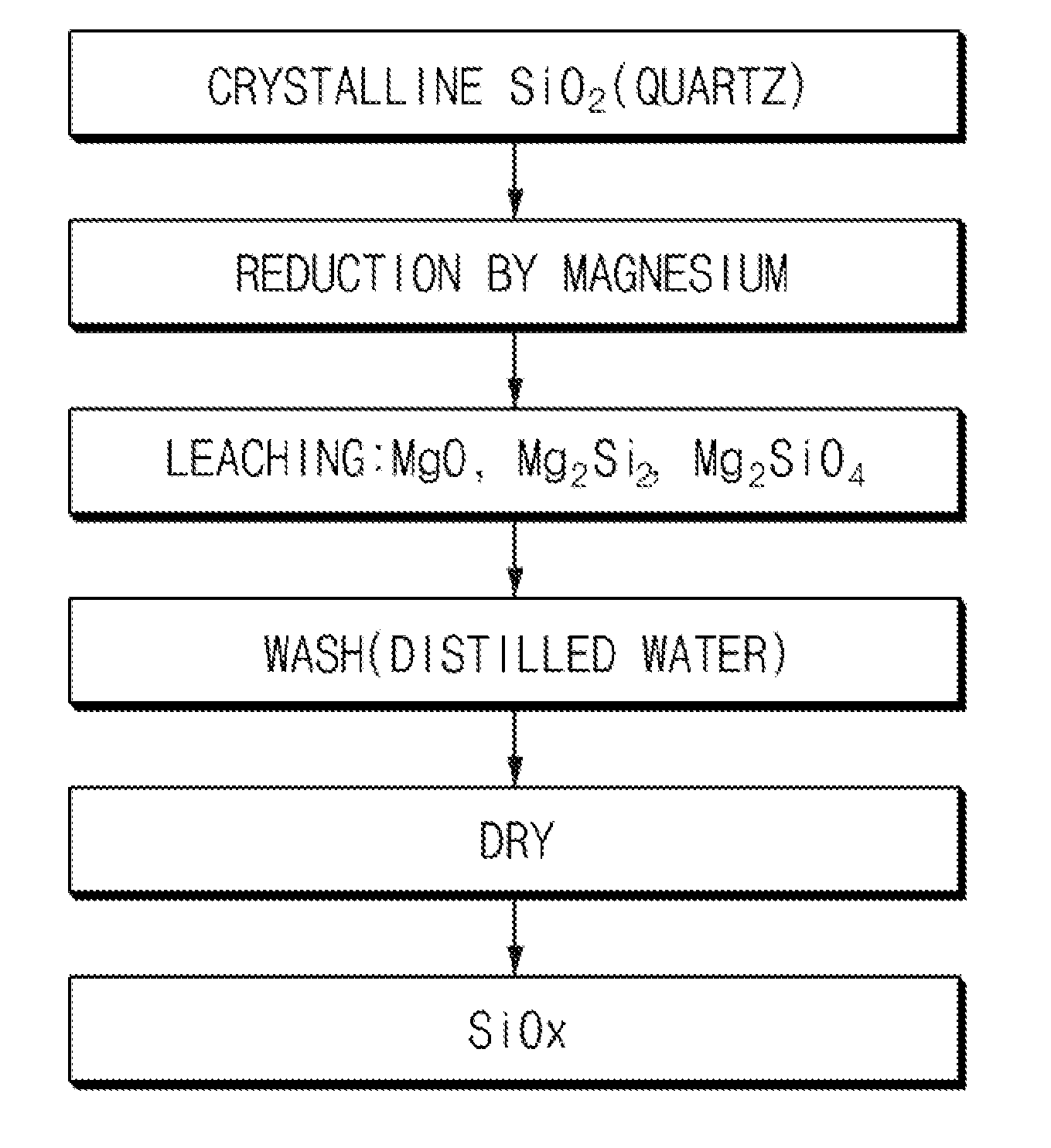

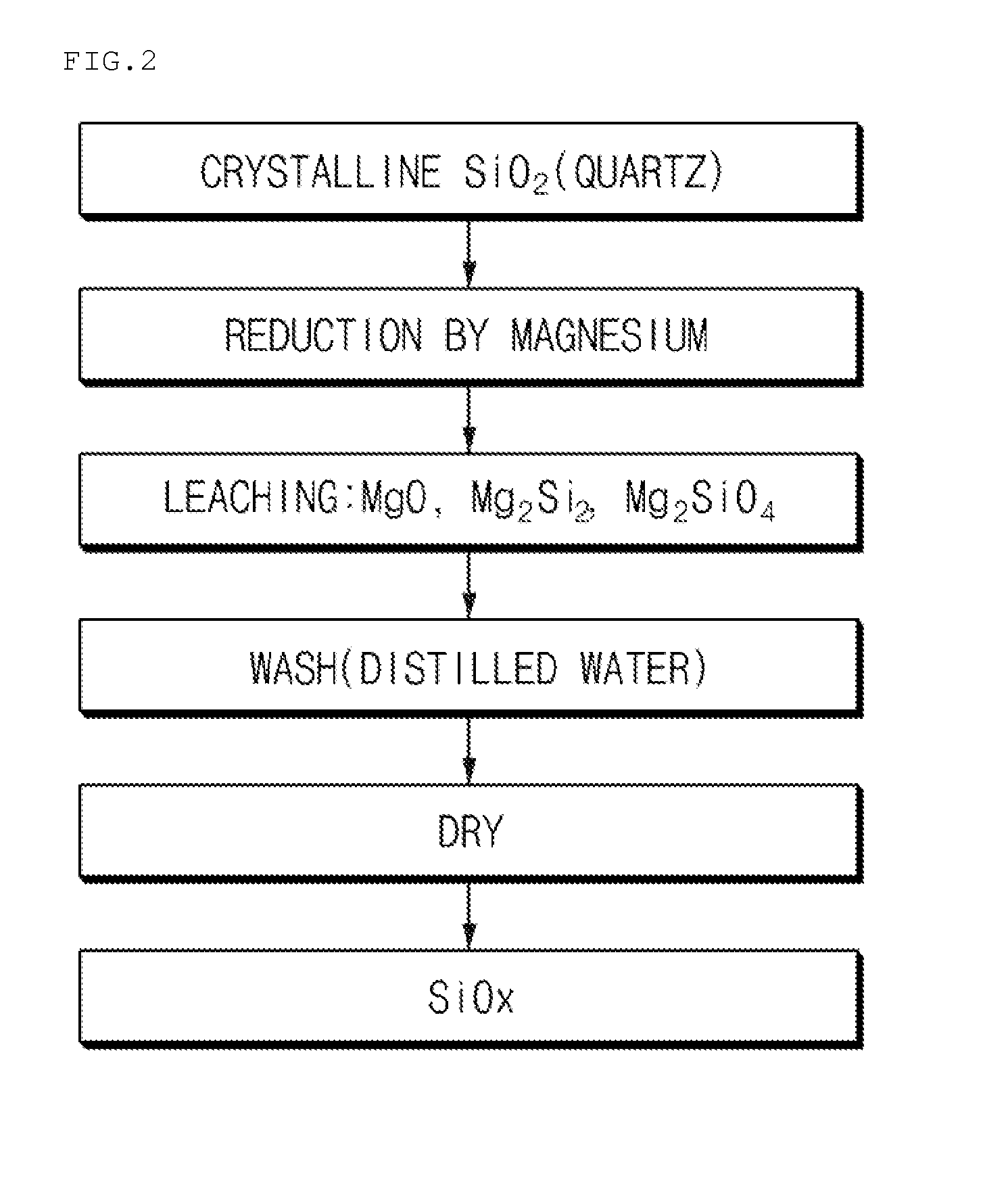

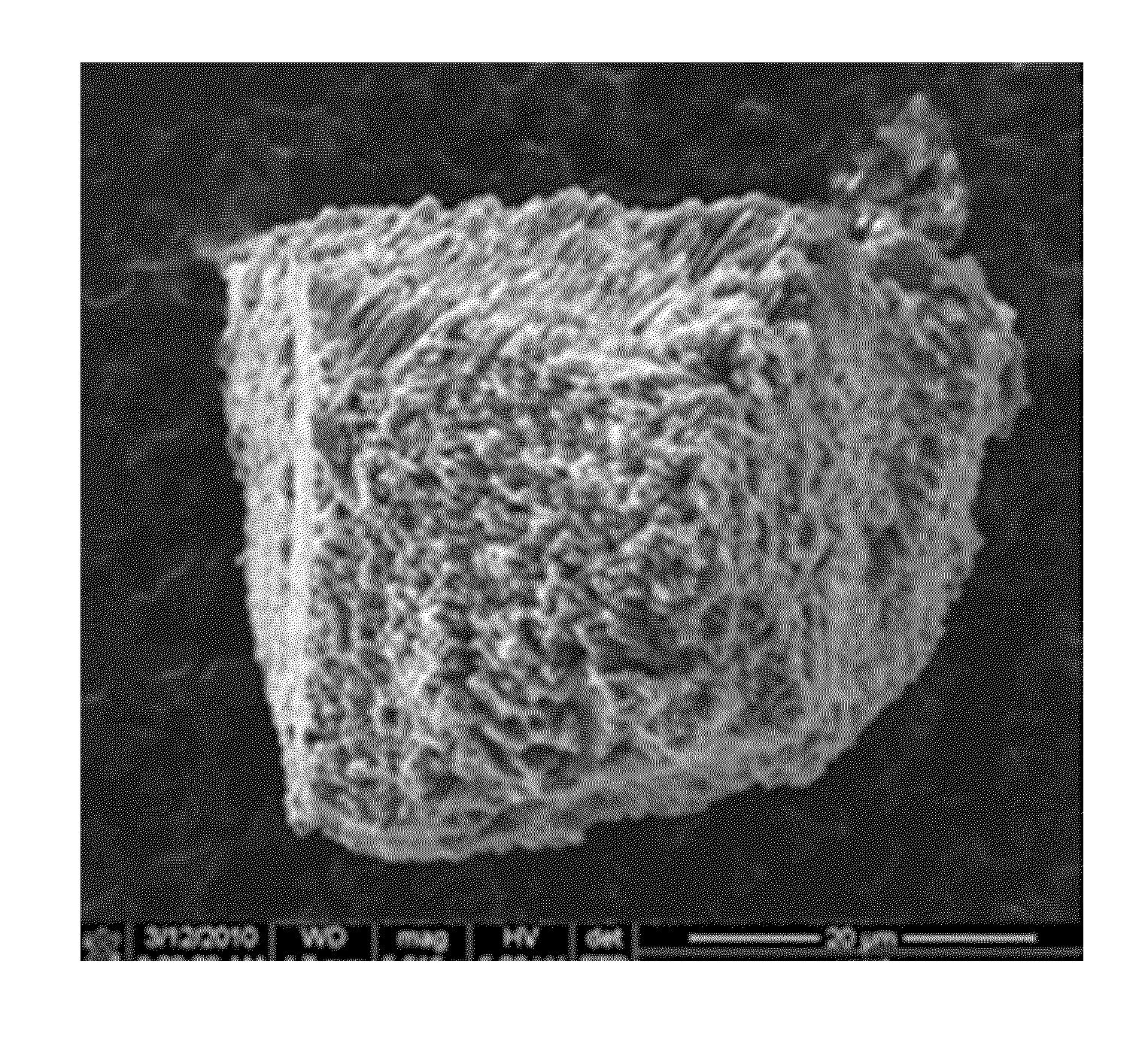

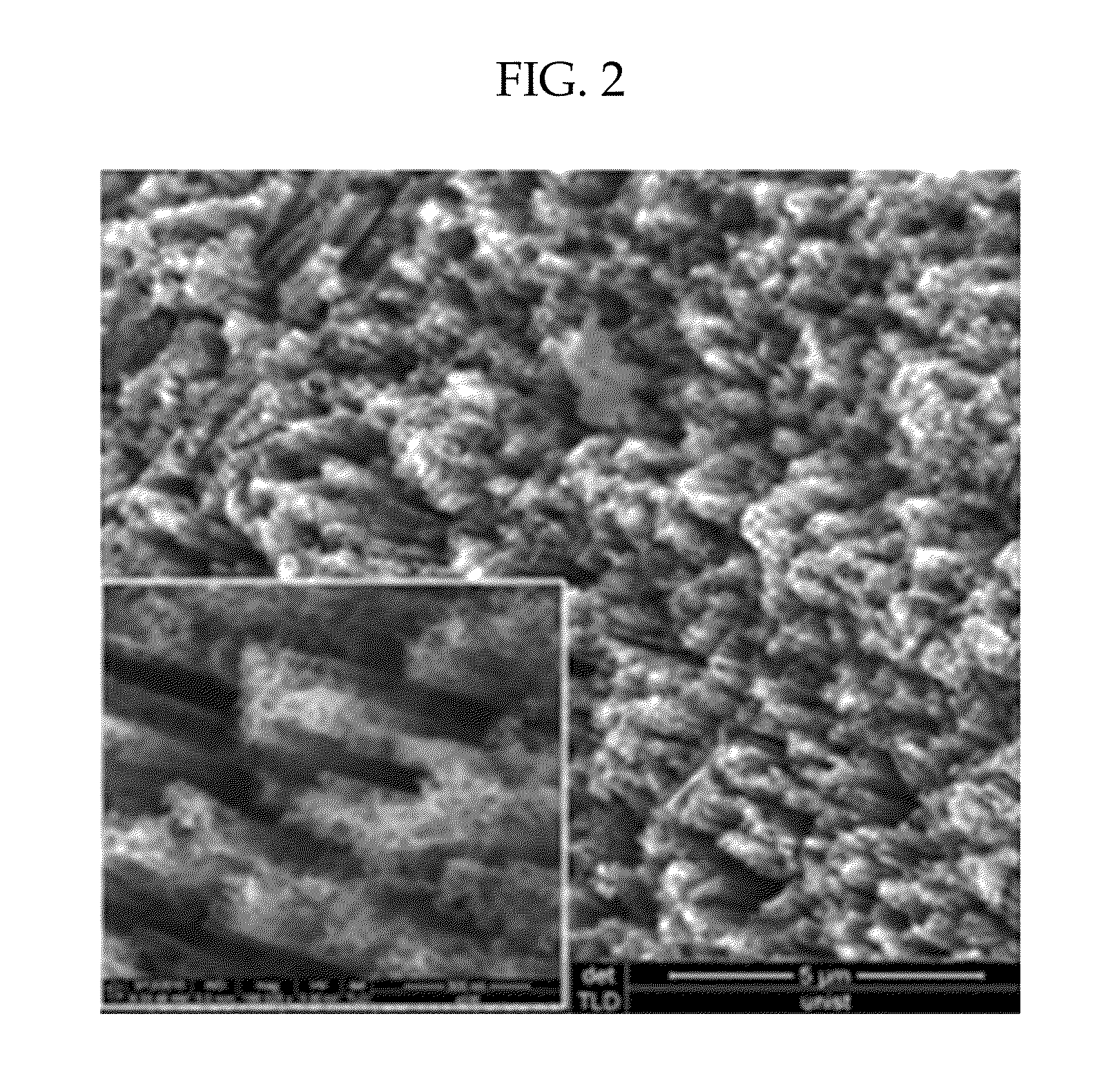

Anode active material for nonaqueous electrolyte secondary battery comprising silicon oxide composite and method for producing same

PendingCN111418095APrevents rapid deterioration of lifespanExcellent capacity characteristicsMagnesium silicatesSilicaPhysical chemistrySilicon oxide

The present invention relates to an anode active material for a nonaqueous electrolyte secondary battery. An anode active material for a nonaqueous electrolyte secondary battery, according to an embodiment of the present invention, comprises a silicon oxide composite including silicon, silicon oxide (SiOx, 0 < x <= 2), and magnesium silicate, wherein the silicon oxide composite includes pores having a size of 50 nm to 300 nm thereinside. The anode active material for a nonaqueous electrolyte secondary battery comprising the silicon oxide composite according to the present invention solves a swelling problem because the internal pores serve to buffer swelling during a charging process, and allows stress caused by the swelling and contraction occurring during charging and discharging processes to be concentrated in the internal pores such that volume swelling is controlled efficiently, and therefore, the lifetime characteristics of a lithium secondary battery can be improved.

Owner:DAEJOO ELECTRONICS MATERIALS CO LTD

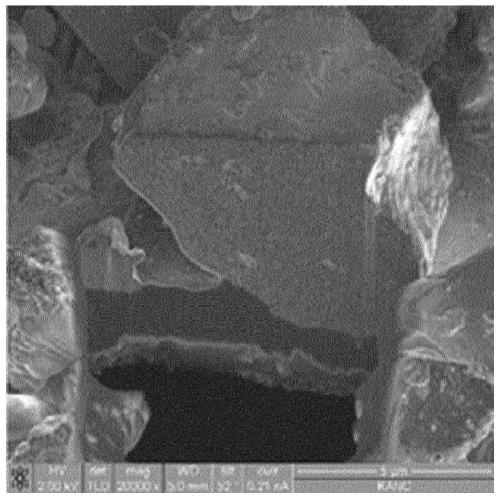

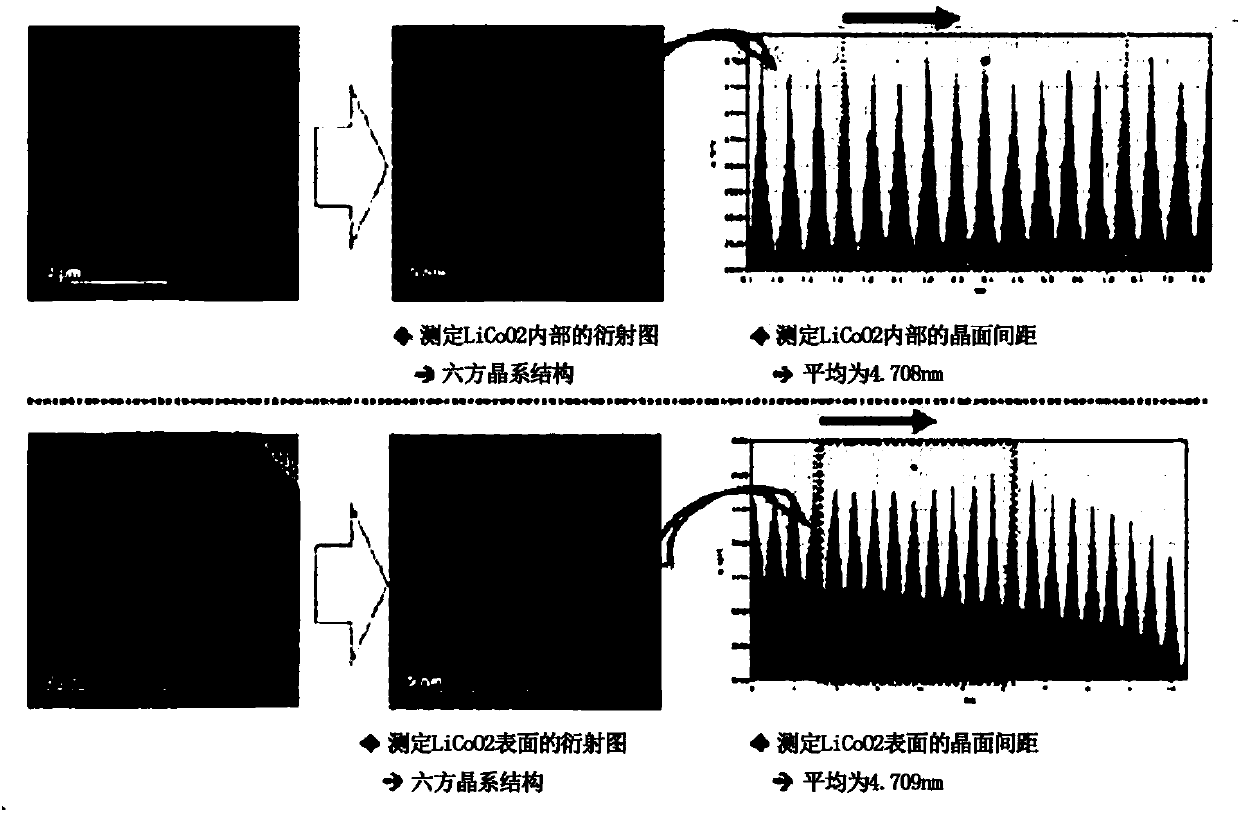

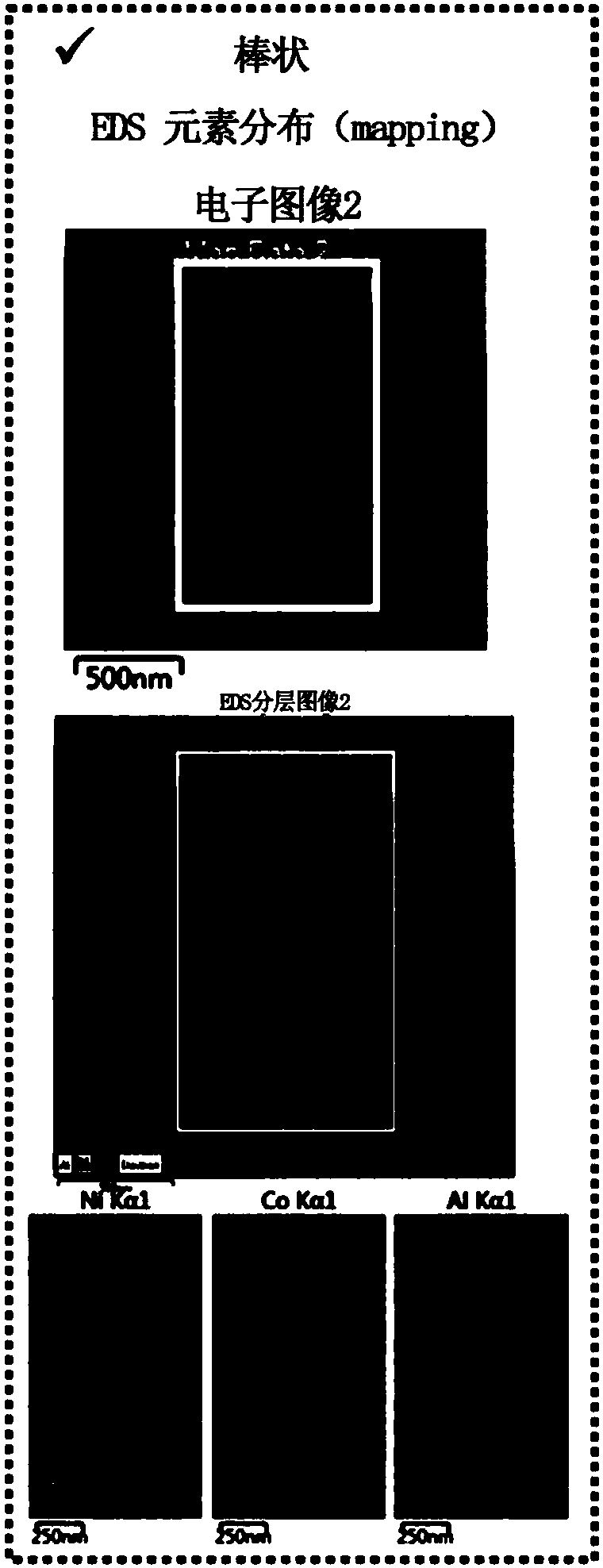

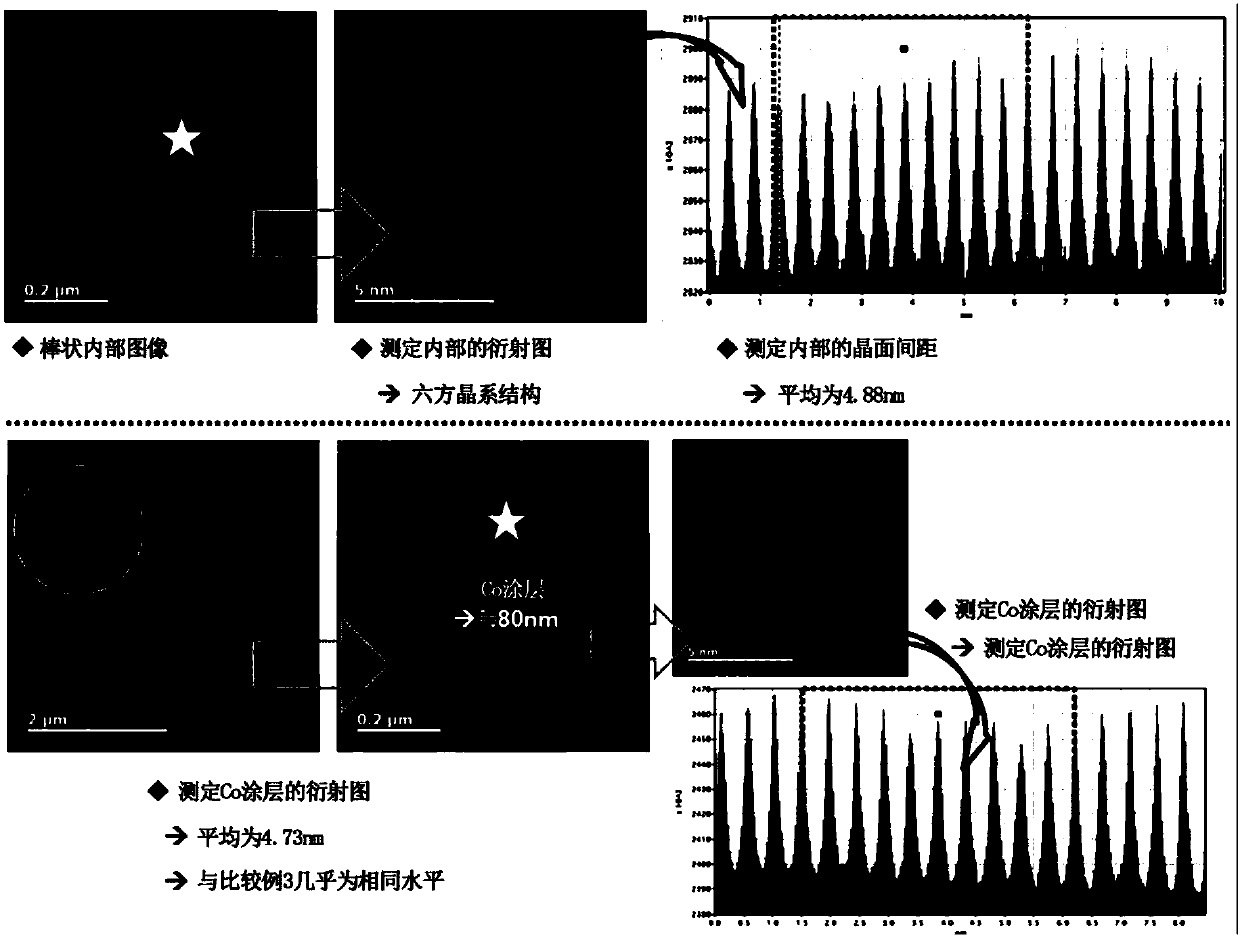

Lithium Complex Oxide For Lithium Secondary Battery Positive Active Material And Method Of Preparing The Same

ActiveCN107681127AExcellent capacity characteristicsImprove impedance characteristicsSecondary cellsPositive electrodesLithiumCrystal structure

Disclosed is a lithium complex oxide and method of manufacturing the same, more particularly, a lithium complex oxide effective in improving the characteristics of capacity, resistance, and lifetime with reduced residual lithium and with different interplanar distances of crystalline structure between a primary particle locating in a internal part of secondary particle and a primary particle locating on the surface part of the secondary particle, and a method of preparing the same.

Owner:ECOPRO BM CO LTD

Composite metal oxide, method for producing composite metal oxide, and sodium secondary battery

ActiveUS20150333363A1Excellent capacity characteristicsImprove charging capacitySecondary cellsEnergy inputMaterials scienceMetal

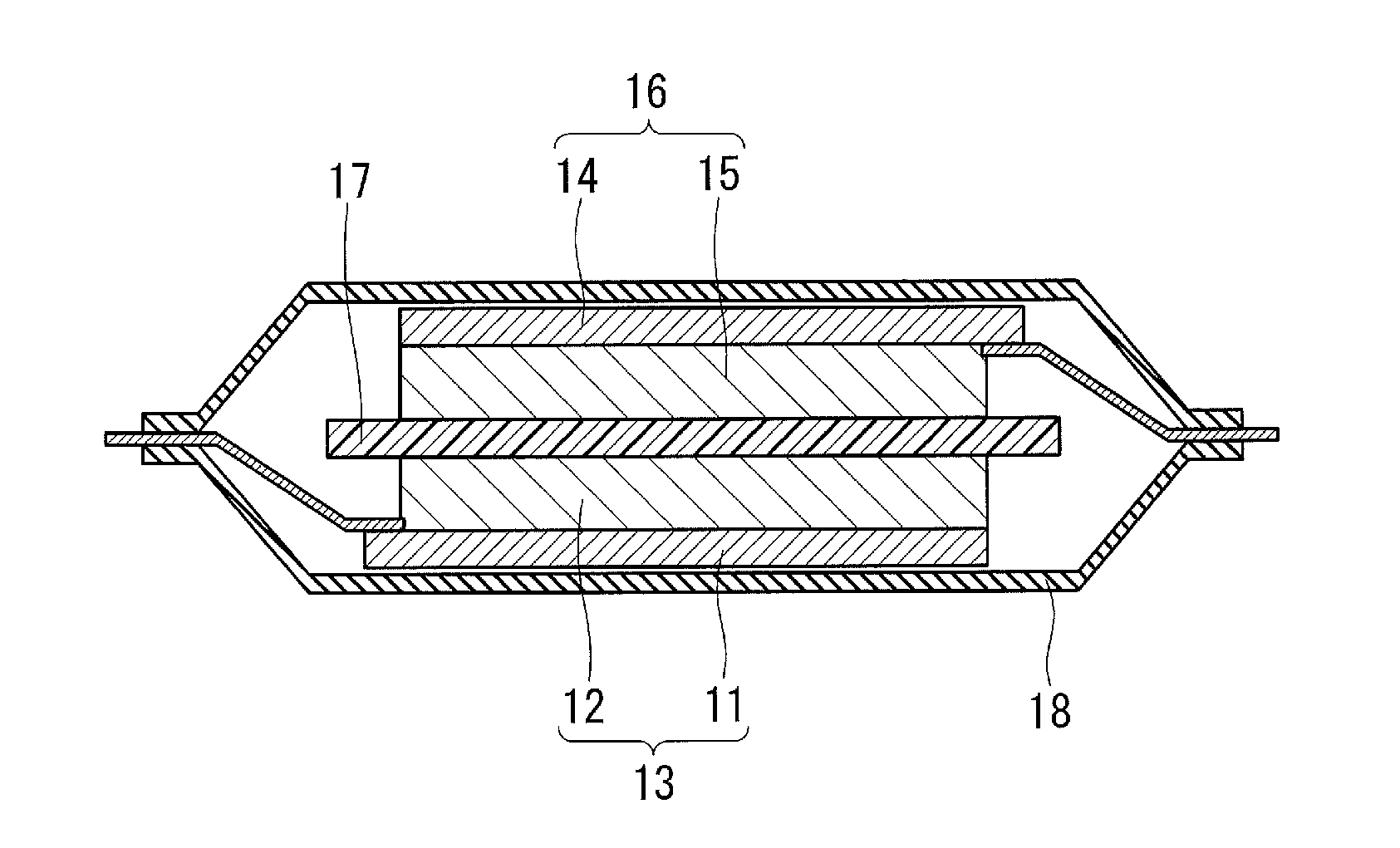

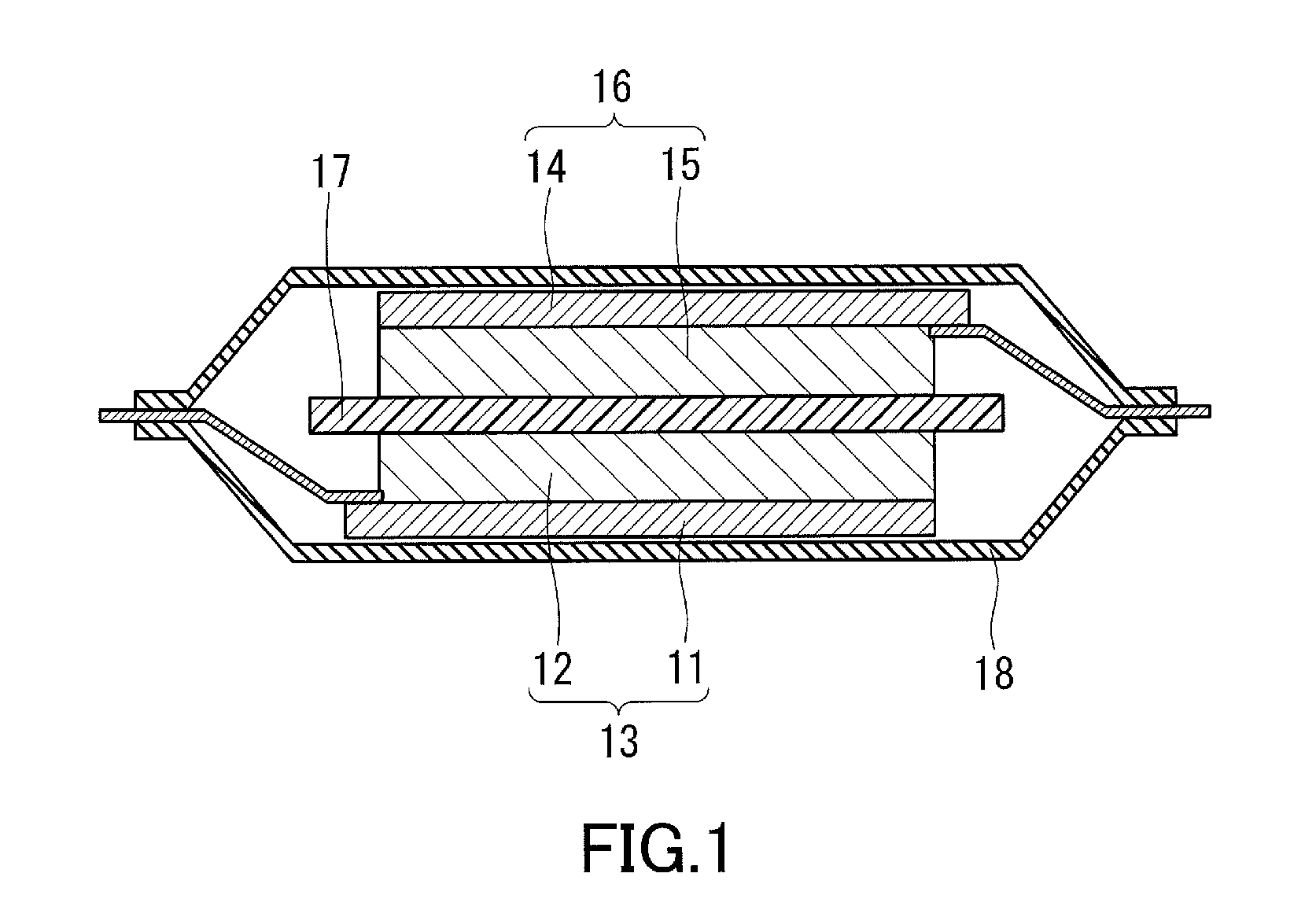

An object of the present invention or a problem to be solved by the present invention is to provide, as a material for use as a positive electrode of a sodium secondary battery, a novel material that allows the resulting battery to have capacity characteristics superior to those of conventional batteries. The composite metal oxide of the present invention has a composition represented by the general formula NaxMeyO2, where Me is at least one selected from the group consisting of Fe, Mn, and Ni, x satisfies 0.8<x≦1.0, and y satisfies 0.95≦y<1.05, and consists of a P2 structure. The sodium secondary battery of the present invention includes: a positive electrode (13) containing the composite metal oxide of the present invention; a negative electrode (16) containing a material capable of absorbing and desorbing Na ions; and an electrolyte containing Na ions and anions.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

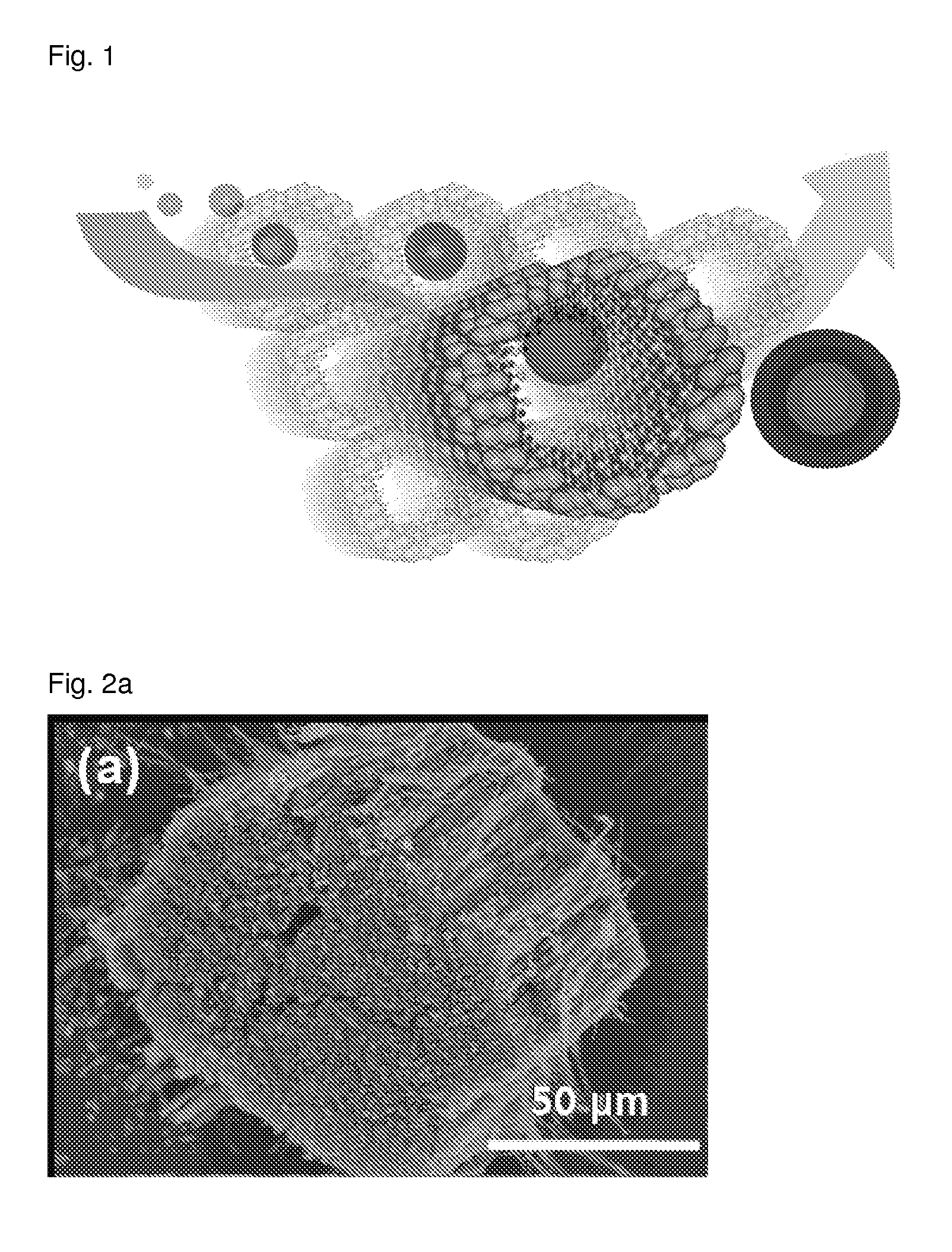

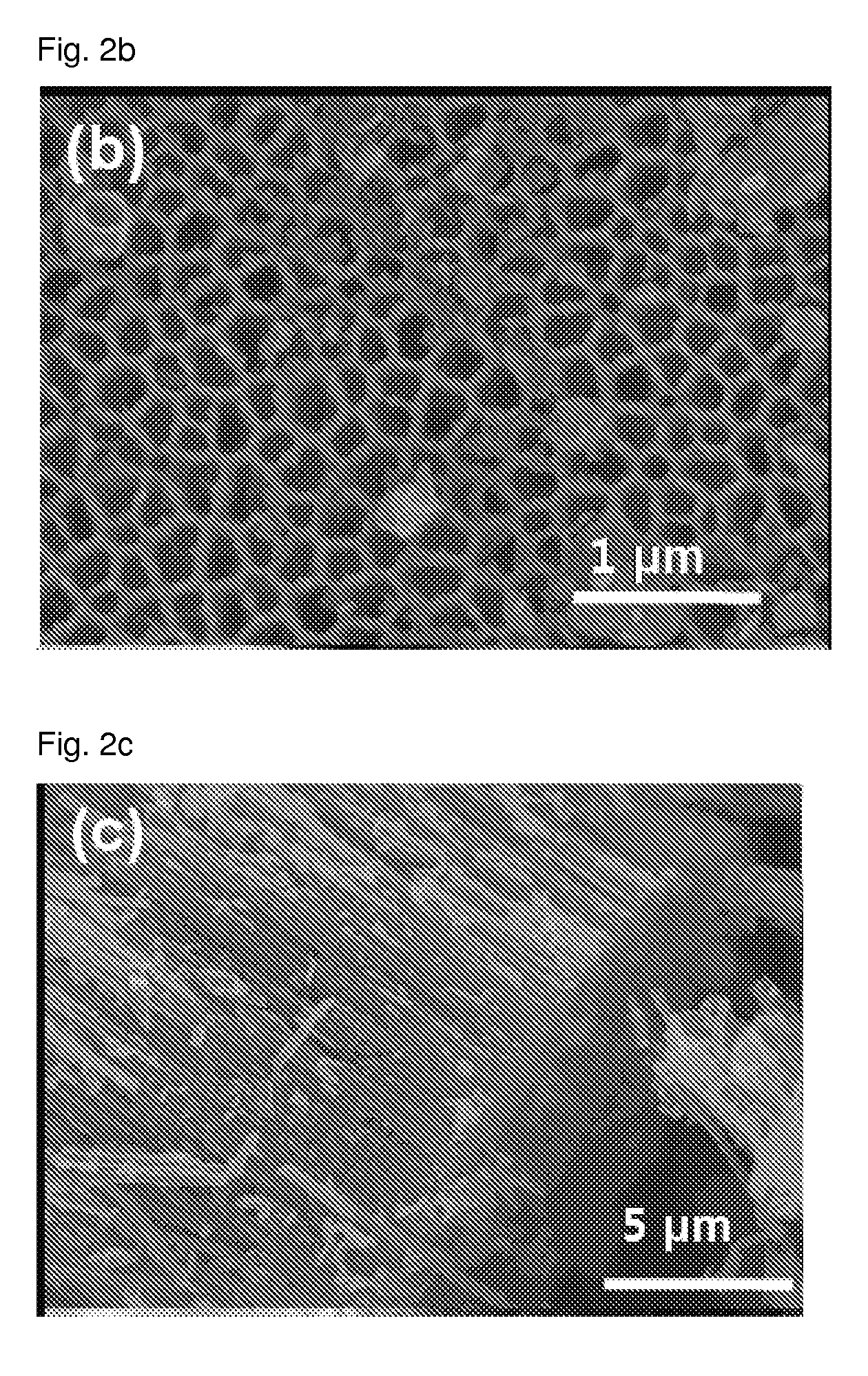

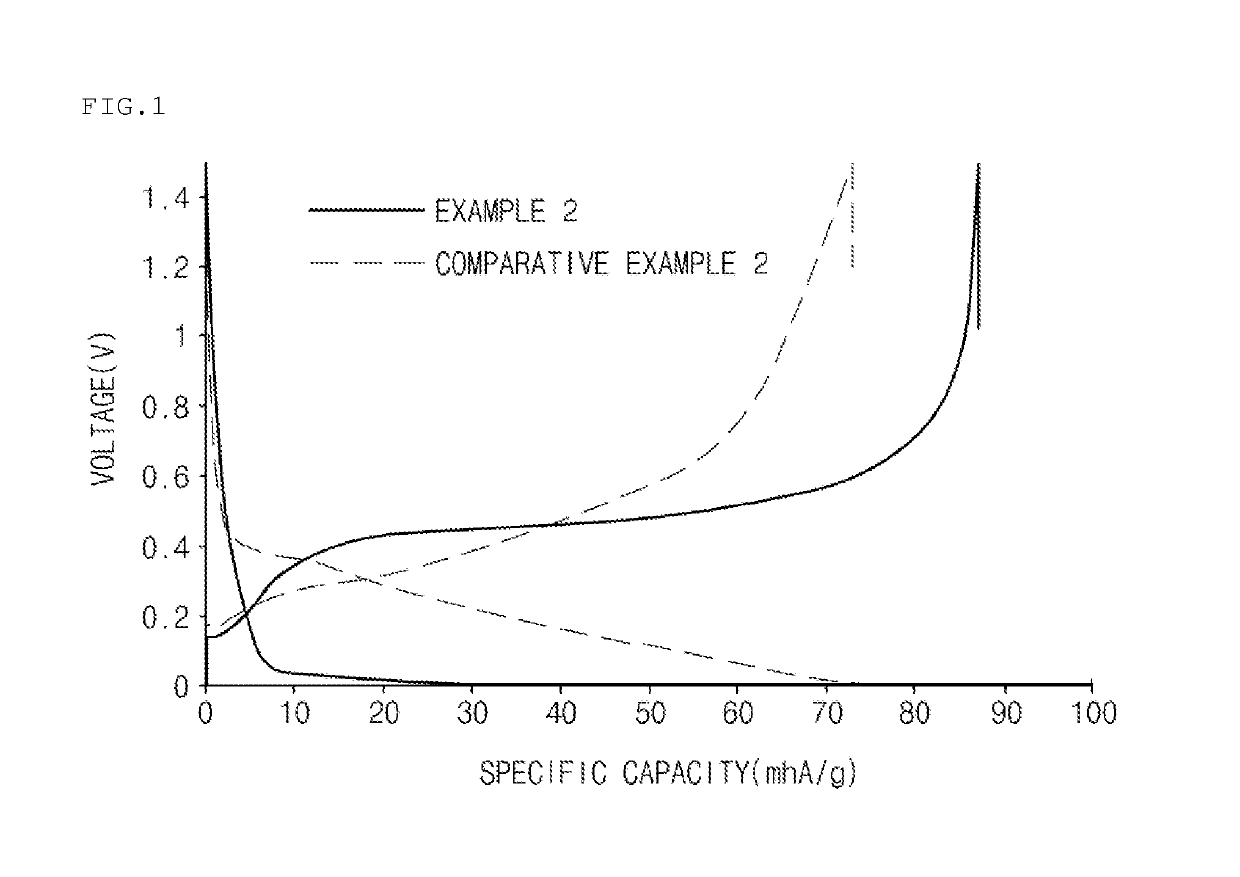

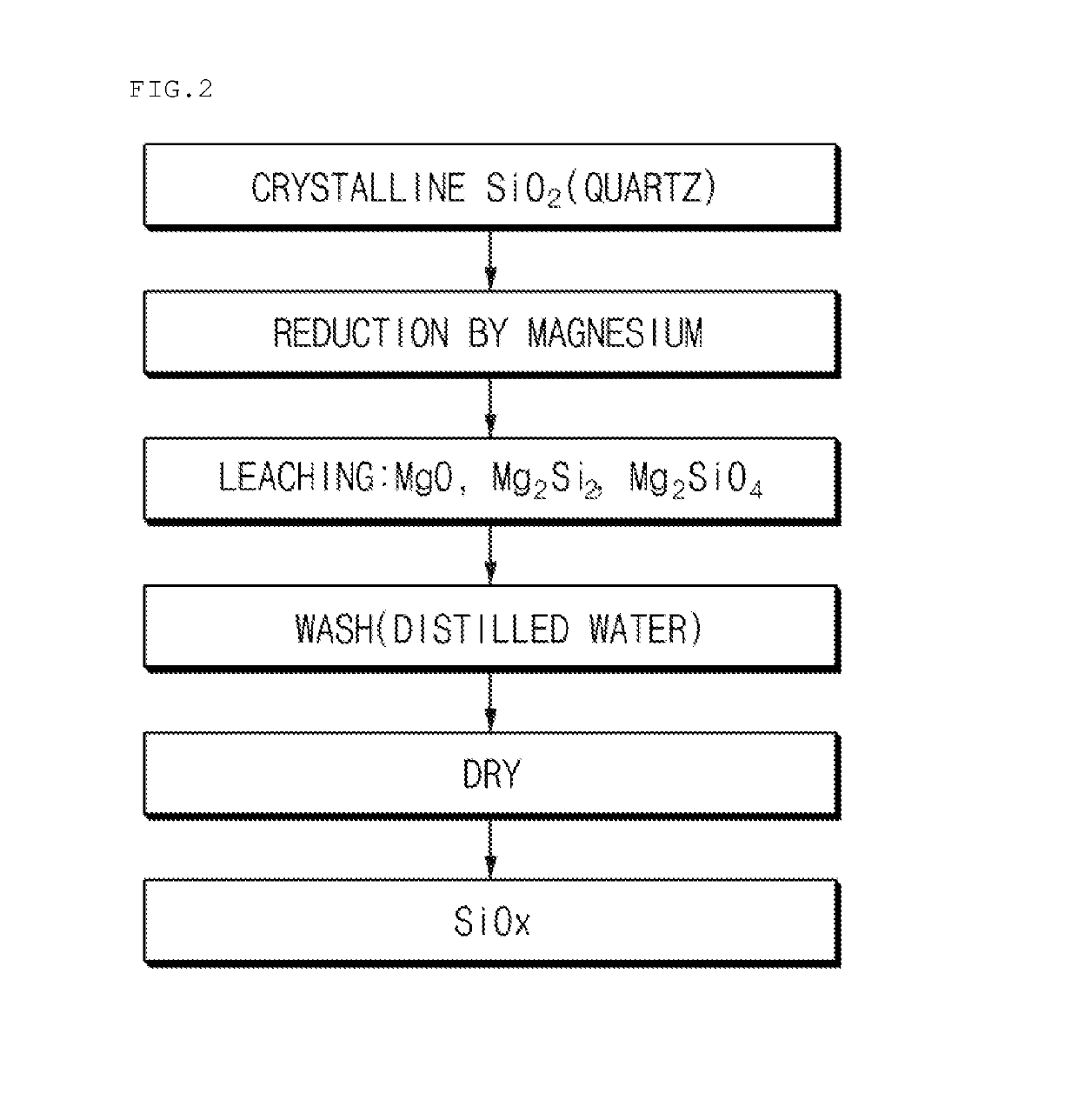

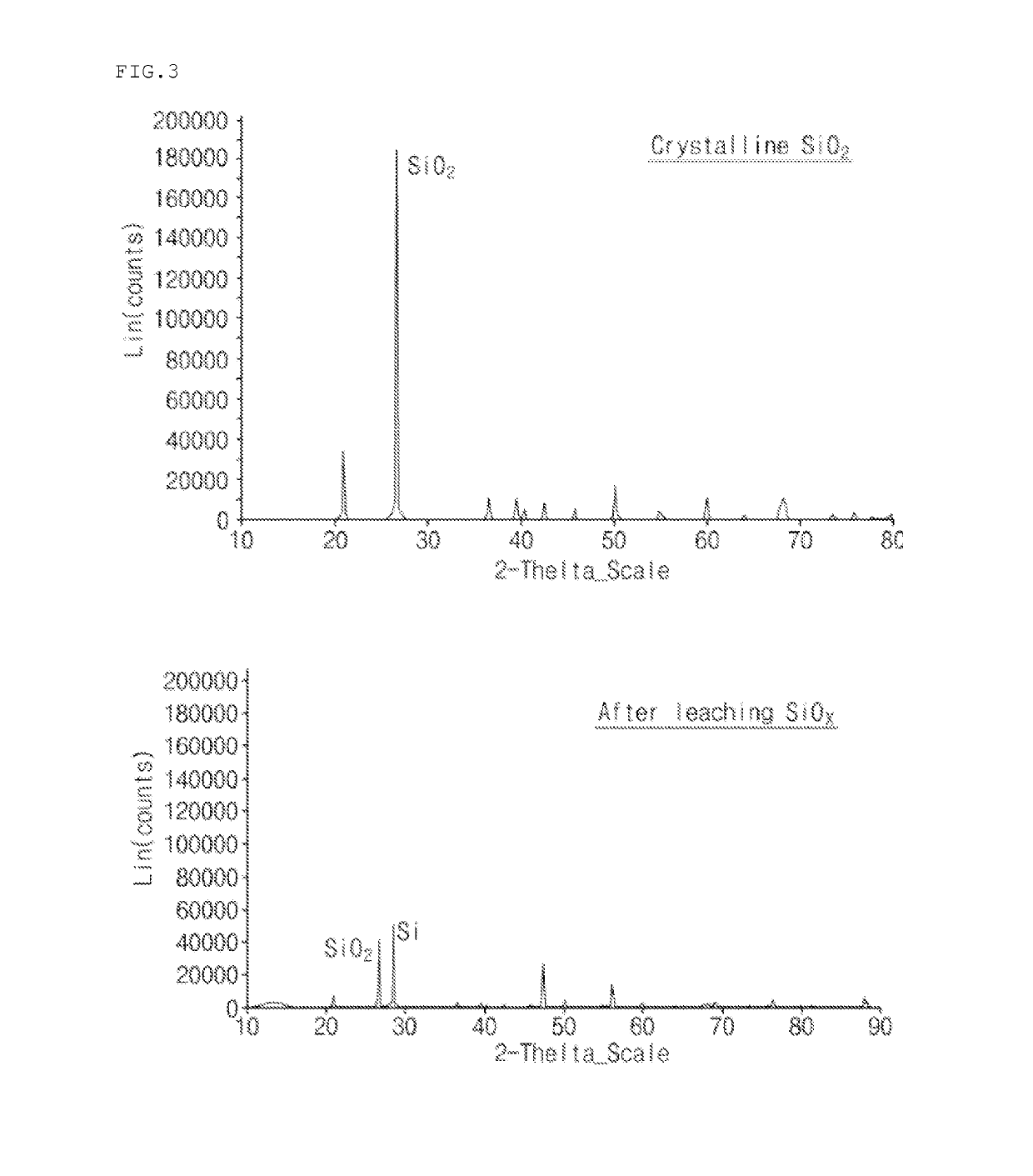

Anode active material for lithium secondary battery and method of preparing the same

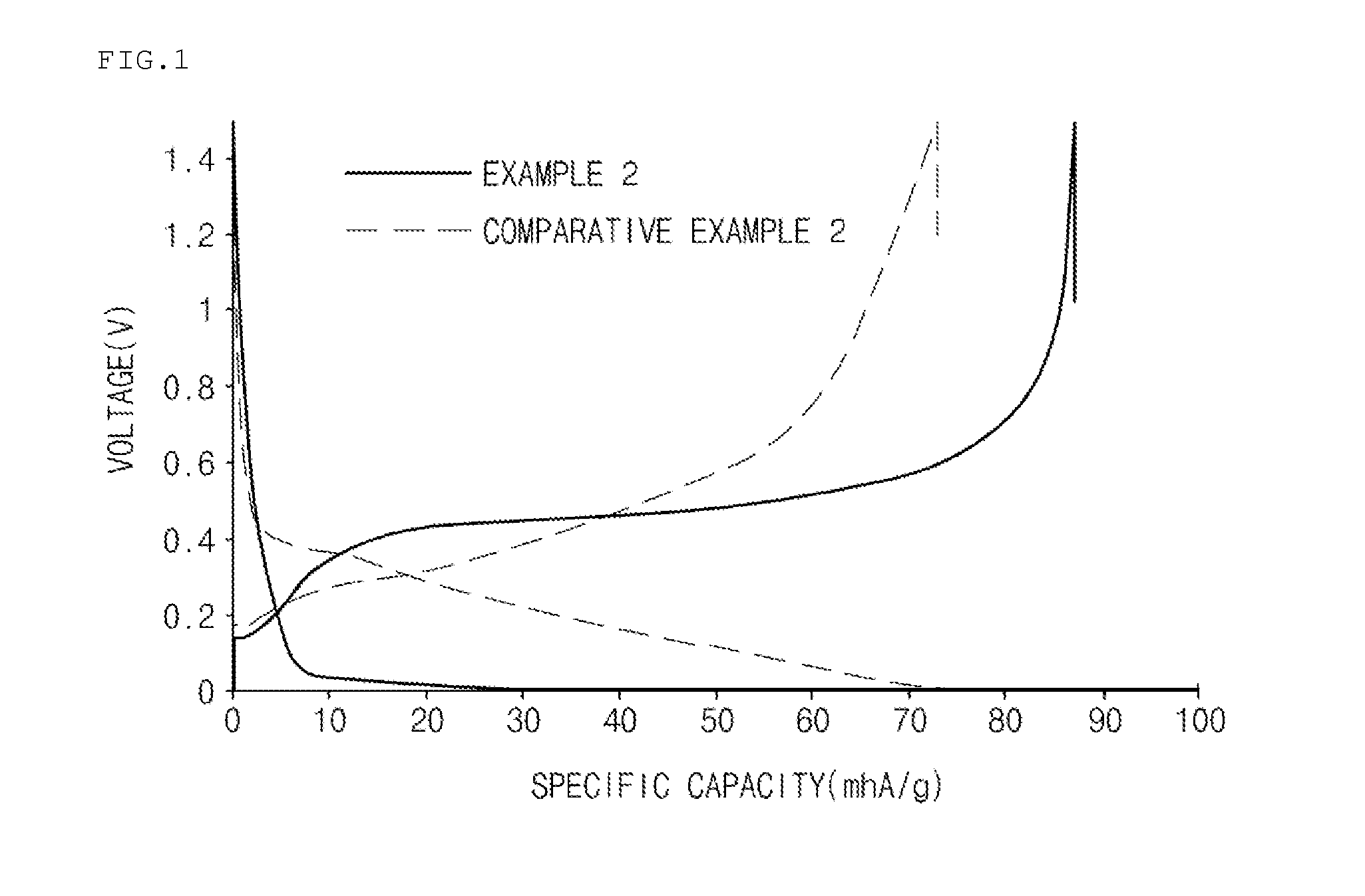

ActiveUS20160028085A1Excellent capacity characteristicsImprove initial efficiencySiliconSilicon oxidesLithiumElectrolyte

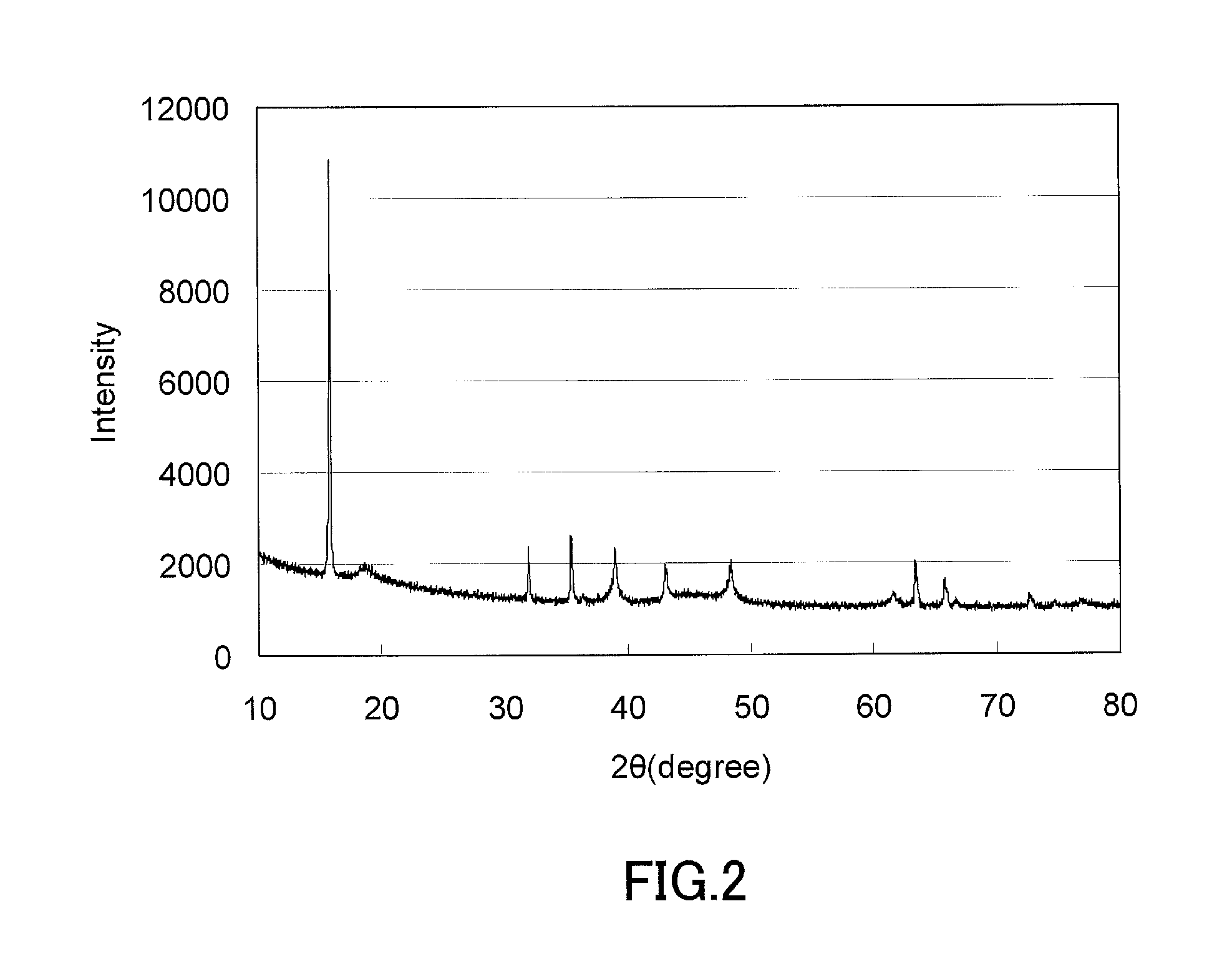

Provided are an anode active material for a lithium secondary battery including a silicon-based composite formed of silicon (Si) and crystalline SiO2, wherein the Si and crystalline SiO2 are in the form of grains, a method of preparing the same, and a lithium secondary battery including the anode active material.Since an anode active material according to an embodiment of the present invention includes a silicon-based composite including Si and SiO2 in a grain state and the SiO2 is crystalline SiO2, the reaction between amorphous SiO2 and lithium in an electrolyte may be excluded. Thus, since the crystalline SiO2 is included in the silicon-based composite, excellent capacity characteristics of a secondary battery may be maintained and initial efficiency and life characteristics may be improved when the silicon-based composite is used as an anode active material.

Owner:LG ENERGY SOLUTION LTD

Manufacture of web superabsorbent polymer and fiber

InactiveUS20050131367A1Improve liquid retention capacityIncrease capacityNon-fibrous pulp additionPaper/cardboardSuperabsorbent polymerChemistry

A web of superabsorbent polymer and fiber made by an in situ neutralization, wet-laid process, wherein the degree of neutralization of the superabsorbent polymer is partial, preferably less than about 80 mol %. The web exhibits an excellent centrifuge retention capacity property, as compared to prior webs of superabsorbent polymer and cellulosic fiber made by in situ neutralization, wherein the degree of neutralization is total, such as 100 mol % or more.

Owner:STOCKHAUSEN GMBH & CO KG

Negative active material for rechargeable lithium battery, method of preparing the same, and rechargeable lithium battery including the same

InactiveUS20130224599A1Easy to processImprove economyElectrode manufacturing processesActive material electrodesMetal particleMaterials science

Disclosed are a method of preparing a negative active material for a rechargeable lithium battery that includes: preparing a powder including a material being capable of doping and dedoping lithium; coating the powder including the material being capable of doping and dedoping lithium with metal particles; and etching the powder including the material being capable of doping and dedoping lithium and coated with the metal particles, a negative active material for a rechargeable lithium battery prepared in this method, and a rechargeable lithium battery including the negative active material.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

Anode active material for lithium secondary battery and method of preparing the same

ActiveUS10355272B2Excellent capacity characteristicsImprove efficiencySiliconSilicon oxidesLithium-ion batteryElectrolyte

Provided are an anode active material for a lithium secondary battery including a silicon-based composite formed of silicon (Si) and crystalline SiO2, wherein the Si and crystalline SiO2 are in the form of grains, a method of preparing the same, and a lithium secondary battery including the anode active material.Since an anode active material according to an embodiment of the present invention includes a silicon-based composite including Si and SiO2 in a grain state and the SiO2 is crystalline SiO2, the reaction between amorphous SiO2 and lithium in an electrolyte may be excluded. Thus, since the crystalline SiO2 is included in the silicon-based composite, excellent capacity characteristics of a secondary battery may be maintained and initial efficiency and life characteristics may be improved when the silicon-based composite is used as an anode active material.

Owner:LG ENERGY SOLUTION LTD

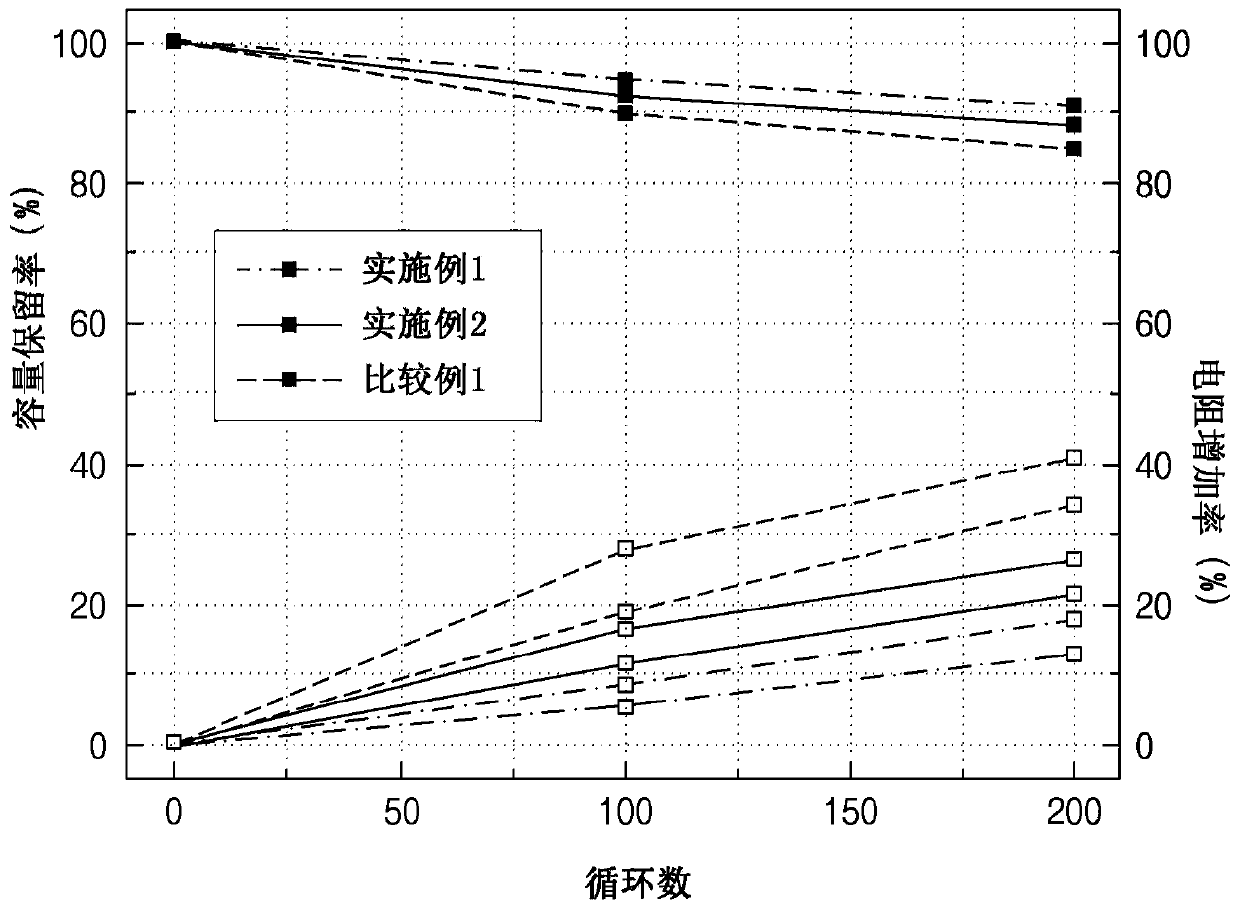

Positive Electrode Active Material For Secondary Battery, Manfuacturing Method Thereof, And Secondary Battery Including Same

ActiveUS20190300382A1Excellent capacity characteristicsLow in resistance increasing rateFinal product manufactureSecondary cellsLithiumManganese

The present invention provides a positive electrode active material for a secondary battery, which includes a lithium transition metal oxide including nickel (Ni) and cobalt (Co), and at least one selected from the group consisting of aluminum (Al), manganese (Mn), and a combination thereof. The lithium transition metal oxide is characterized in that the content of nickel (Ni) in the total transition metal elements is 80 mol % or more, and the cation mixing ratio of Ni cations in a lithium layer in the lithium transition metal oxide structure is 1.1% or less.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com