Anode active material for nonaqueous electrolyte secondary battery comprising silicon oxide composite and method for producing same

A negative electrode active material and non-aqueous electrolyte technology, which is applied in the field of negative electrode active materials for non-aqueous electrolyte secondary batteries containing silicon oxide composites and its preparation, and can solve the problem of reduced life characteristics, reduced life characteristics, and loss of conductive paths And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

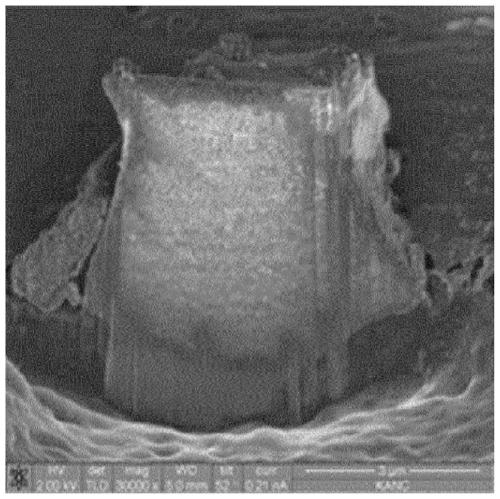

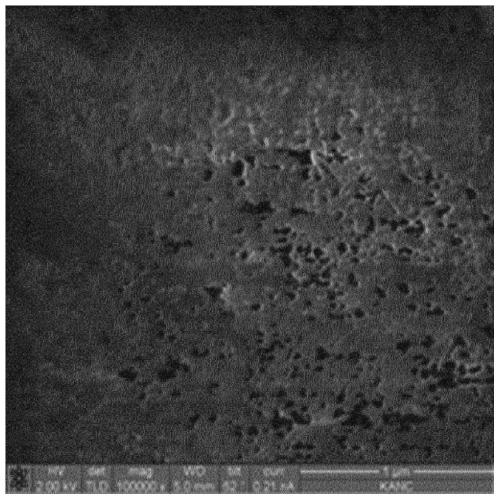

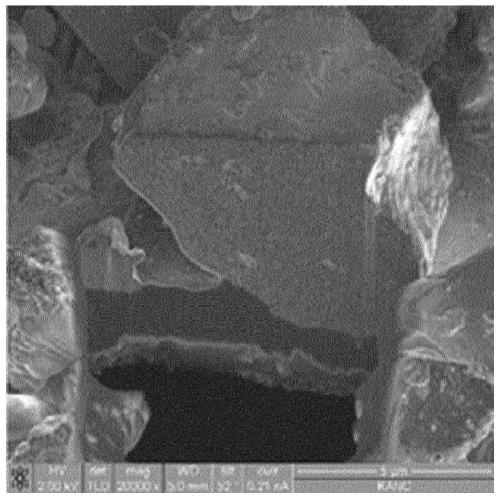

[0070] Example 1. Preparation of silicon oxide composites containing magnesium

[0071] Heat-treat 15kg of silicon powder and silicon dioxide (SiO 2 ) powder powder and 1.5kg of magnesium, the above silicon, silicon dioxide (SiO 2 ) of the mixed powder of silicon oxide vapor and magnesium vapor are simultaneously generated to react in the gas phase, cooled at a temperature of 700°C and then precipitated, and then crushed and classified with a jet mill to obtain an average particle size (D 50 ) is magnesium-silicon oxide composite powder of 6.3 μm.

[0072] In order to form a carbon-containing coating layer, the recycled silicon oxide composite powder containing magnesium is placed in argon (Ar) and methane (CH 4 ) in a mixed gas, and processed by chemical vapor deposition (CVD) for 2 hours, thereby preparing a silicon oxide composite (sample 1).

[0073] It was confirmed from the above silica composite (sample 1) containing magnesium that the BET specific surface area was ...

Embodiment 2

[0074] Example 2. Preparation of silica composites containing magnesium

[0075] Except for precipitation after cooling at a temperature of 800°C, a silicon oxide composite (sample 2) containing 9% by weight of magnesium was prepared by the same method as in Example 1 above, and a carbon content of 5% by weight was prepared. Percent carbon coating layer of silicon oxide composite powder.

[0076] It was confirmed from the above silica composite (sample 2) containing magnesium that the BET specific surface area was 6.2m 2 / g, the specific gravity is 2.3g / cm 3 , average particle size (D 50 ) was 6.5 μm, and the silicon crystal size measured by X-ray diffraction analysis (CuKα) was 8 nm.

Embodiment 3

[0077] Example 3. Preparation of silica composites containing magnesium

[0078] Except for precipitation after cooling at a temperature of 900°C, a silicon oxide composite (sample 3) containing 4% by weight of magnesium was prepared by the same method as in Example 1 above, and a carbon content of 10% by weight was prepared. Percent carbon coating layer of silicon oxide composite powder.

[0079] It was confirmed from the above silica composite (sample 3) containing magnesium that the BET specific surface area was 6.3m 2 / g, the specific gravity is 2.4g / cm 3 , average particle size (D 50 ) was 6.2 μm, and the size of silicon crystals measured by X-ray diffraction analysis (CuKα) was 11 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com