Method for preparing anode material for lithium ion battery

A cathode material, lithium-ion technology, applied in the field of preparation of cathode materials for lithium-ion batteries, can solve the problems of low 5V capacity, capacity loss, and failure to solve the problem of crystallized oxygen defects in cathode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

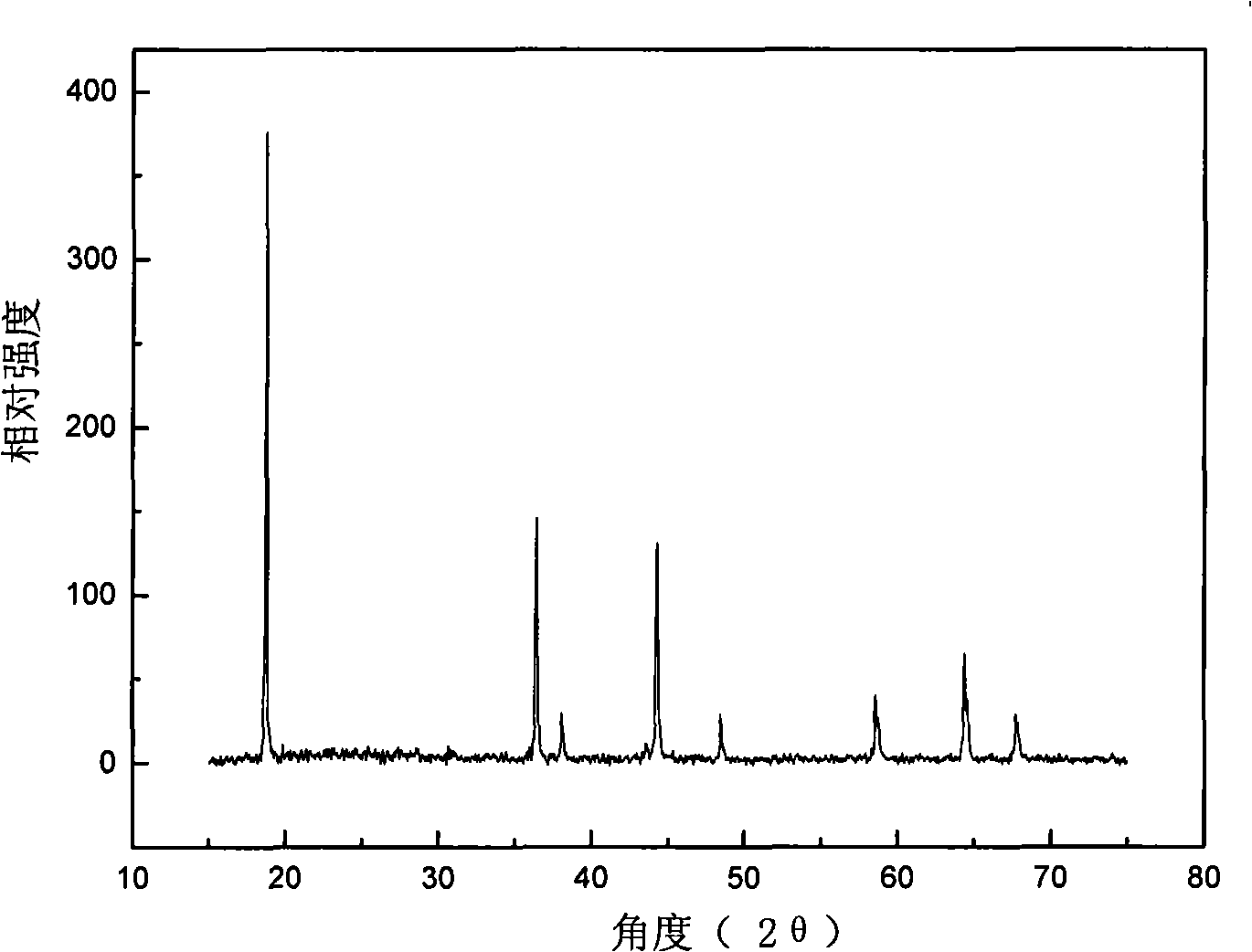

[0028] Embodiment 1: lithium-ion battery positive electrode material LiNi 0.5 mn 1.5 o 3.975 f 0.05 Preparation of:

[0029] (a) Weigh 2.0404g lithium acetate (LiAC 2H 2 O), 2.4886g nickel acetate (Ni(AC) 2 4H 2 O), 7.3527g manganese acetate (Mn(AC) 2 4H 2 (0) and 0.0259g lithium fluoride (LiF), dissolved in 50ml deionized water, stirred for 4 hours, the stirring temperature was 80°C until a gel was formed;

[0030] (b) Put it into a quartz cup, in the air atmosphere of the tubular heating furnace, after calcining at 480°C for 5 hours, cool, and mix 3.05g (0.02 mole) of the product with 0.0092g (0.0002 mole) of lithium peroxide , grind evenly;

[0031] (c) Put it into a quartz cup, in the air atmosphere of a tubular heating furnace, calcinate at 800°C for 15 hours, cool, and grind to obtain LiNi, the positive electrode material for lithium-ion batteries. 0.5 mn 1.5 o 3.975 f 0.05 .

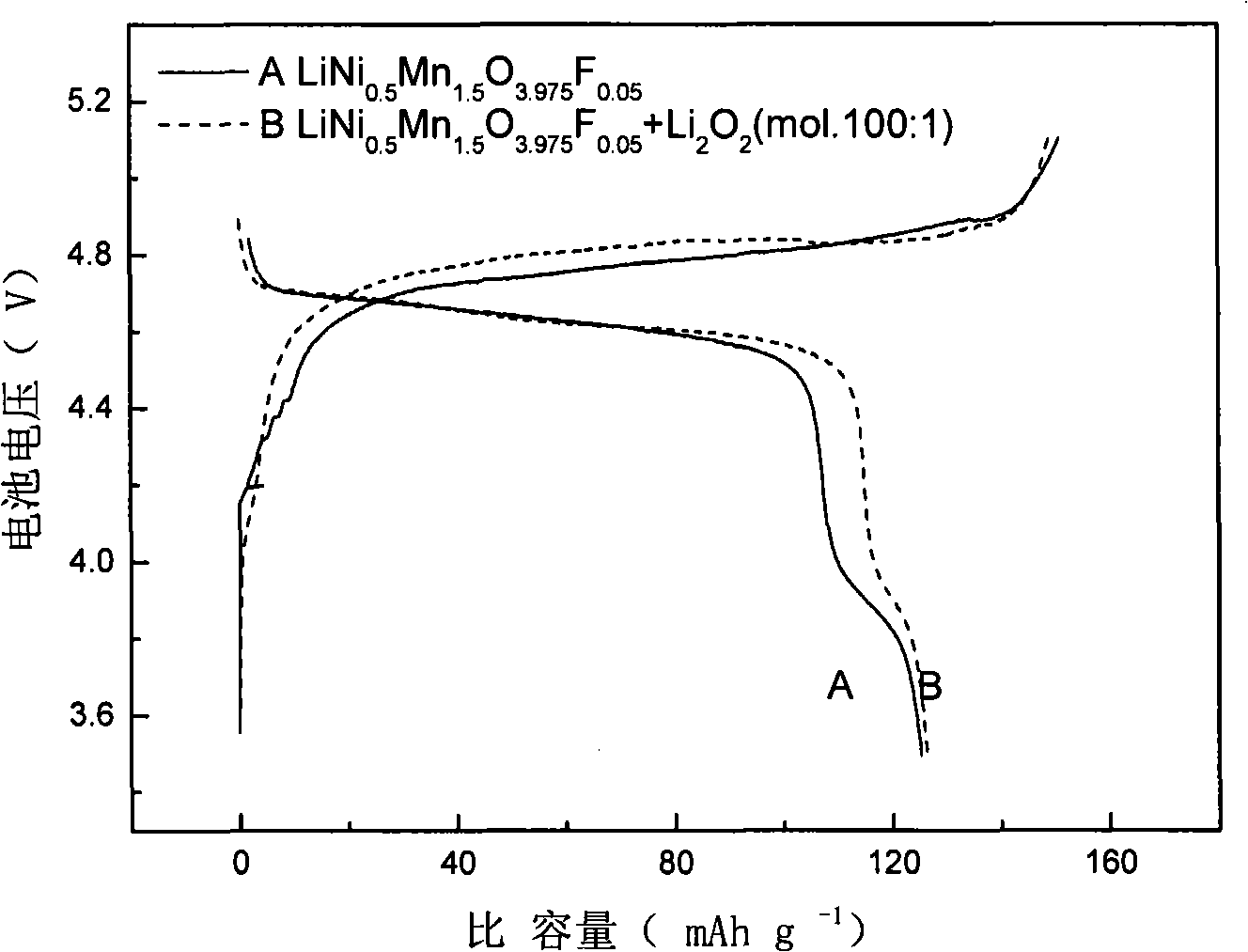

[0032] figure 2 Represents the LiNi prepared according to Comparative Example ...

Embodiment 2

[0033] Embodiment 2: positive electrode material LiNi for lithium ion battery 0.5 mn 1.5 o 3.975 f 0.05 Preparation of:

[0034] (a) Weigh 4.0808g lithium acetate (LiAC 2H 2 O), 4.9772g nickel acetate (Ni(AC) 2 4H 2 O), 14.7054g manganese acetate (Mn(AC) 2 4H 2 (0) and 0.0519g lithium fluoride (LiF), dissolved in 100ml deionized water, stirred for 4 hours, the stirring temperature was 80°C until a gel was formed;

[0035] (b) Put it into a quartz cup, in an air atmosphere in a tubular heating furnace, calcinate at 450° C. for 5 hours, cool, mix 6.0579 g of the resulting product with 0.0092 g of lithium peroxide, and grind evenly;

[0036] (c) Put it into a quartz cup, in an oxygen atmosphere in a tubular heating furnace, calcinate at 850°C for 12 hours, cool, and grind finely to obtain LiNi, a positive electrode material for lithium-ion batteries. 0.5 mn 1.5 o 3.975 f 0.05 .

Embodiment 3

[0037] Embodiment 3: positive electrode material LiNi for lithium ion battery 0.5 mn 1.5 o 3.975 f 0.05 Preparation of:

[0038] (a) Weigh 4.0808g lithium acetate (LiAC 2H 2 O), 4.9772g nickel acetate (Ni(AC) 2 4H 2 O), 14.7054g manganese acetate (Mn(AC) 2 4H 2 (0) and 0.0519g lithium fluoride (LiF), dissolved in 100ml deionized water, stirred for 4 hours, the stirring temperature was 80°C until a gel was formed;

[0039] (b) Put it into a quartz cup, in an air atmosphere in a tubular heating furnace, calcinate at 450° C. for 5 hours, cool, mix 6.0579 g of the resulting product with 0.0184 g of lithium peroxide, and grind evenly;

[0040] (c) Put it into a quartz cup, in an oxygen atmosphere in a tubular heating furnace, calcinate at 850°C for 12 hours, cool, and grind finely to obtain LiNi, a positive electrode material for lithium-ion batteries. 0.5 mn 1.5 o 3.975 f 0.05 .

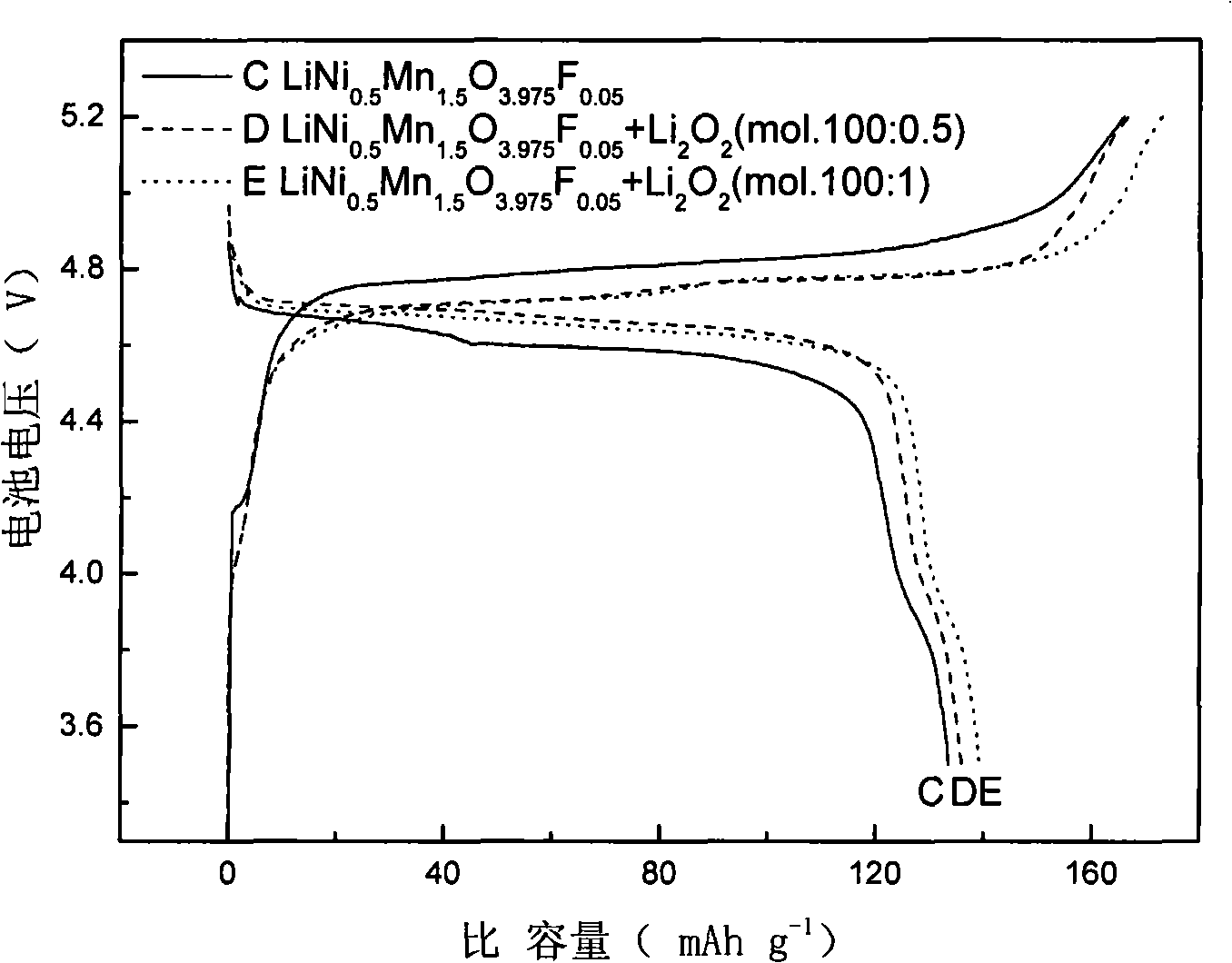

[0041] image 3 Represents the LiNi prepared according to Comparative Example 1 (sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com