Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce oxygen deficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing spinel lithium manganate serving as cathode material of lithium ion power battery

InactiveCN102306767AThe crystal structure has good cycle stabilityImprove high temperature cycle performanceCell electrodesSource materialManganate

The invention relates to a method for preparing spinel lithium manganate serving as a cathode material of a lithium ion power battery. The method comprises the following steps of: 1) selecting raw materials, namely mixing manganese oxide, a lithium source material and doped metal element oxide; and 2) uniformly mixing the mixture obtained in the step 1), feeding into a continuous sintering furnace, performing high-temperature gradient sintering (namely sintering at the temperature of between 1,000 and 1,200 DEG C for 3 to 5 hours in the first sintering step, sintering at the temperature of between 800 and 900 DEG C for 4 to 6 hours in the second step and sintering at the temperature of between 500 and 700 DEG C for 5 to 8 hours in the third step), introducing compressed air simultaneously, naturally cooling after the sintering is finished, grinding, performing grading treatment, and thus obtaining the cathode material. The invention has the advantages that: the method has a simple process; the crystallinity and the surface state of lithium manganate are controlled through the high-temperature sintering, so that the dissolving rate of manganese is reduced; and then oxygen defects are controlled or overcome through low-temperature sintering.

Owner:WUHAN UNIV OF TECH

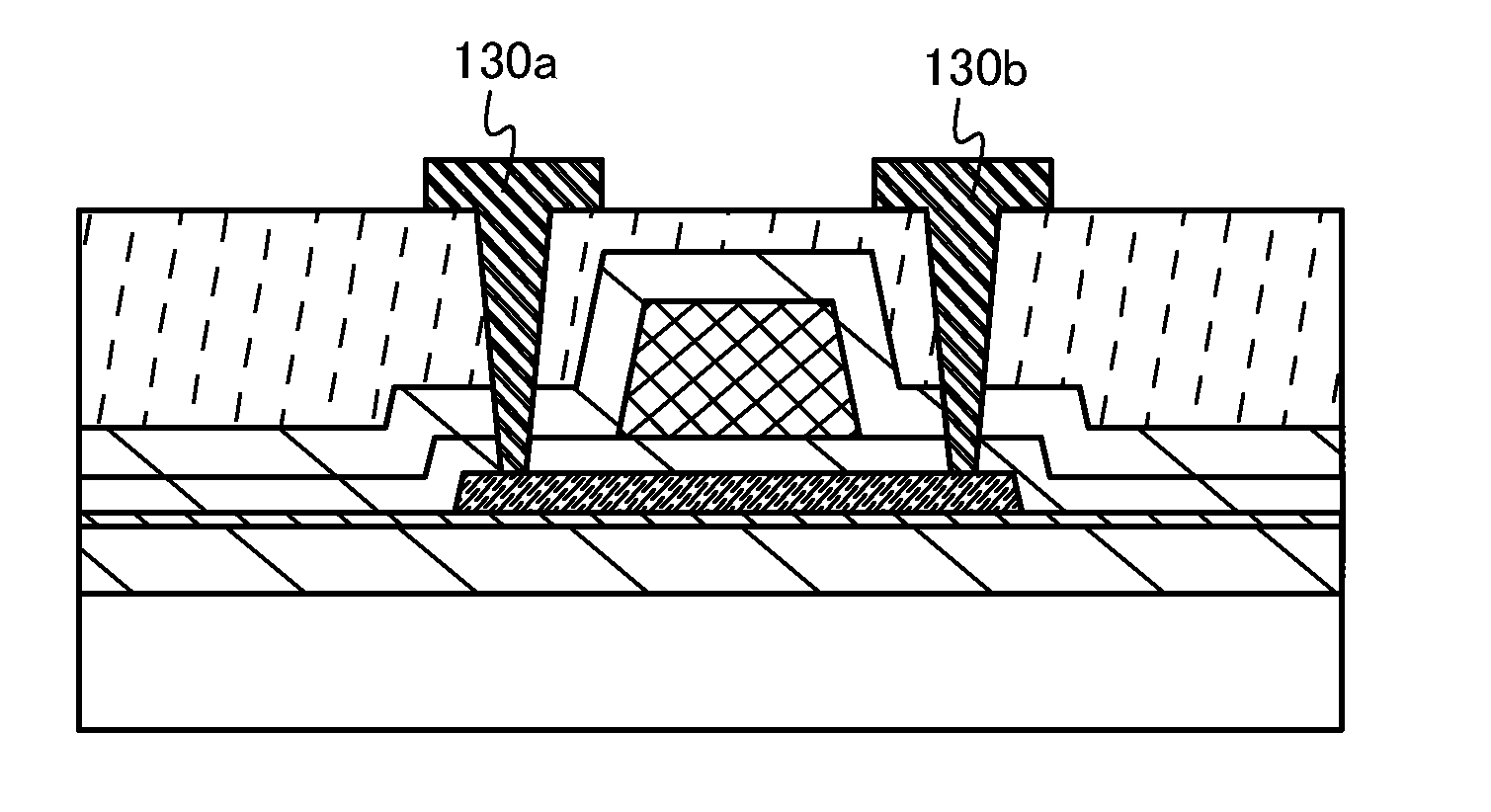

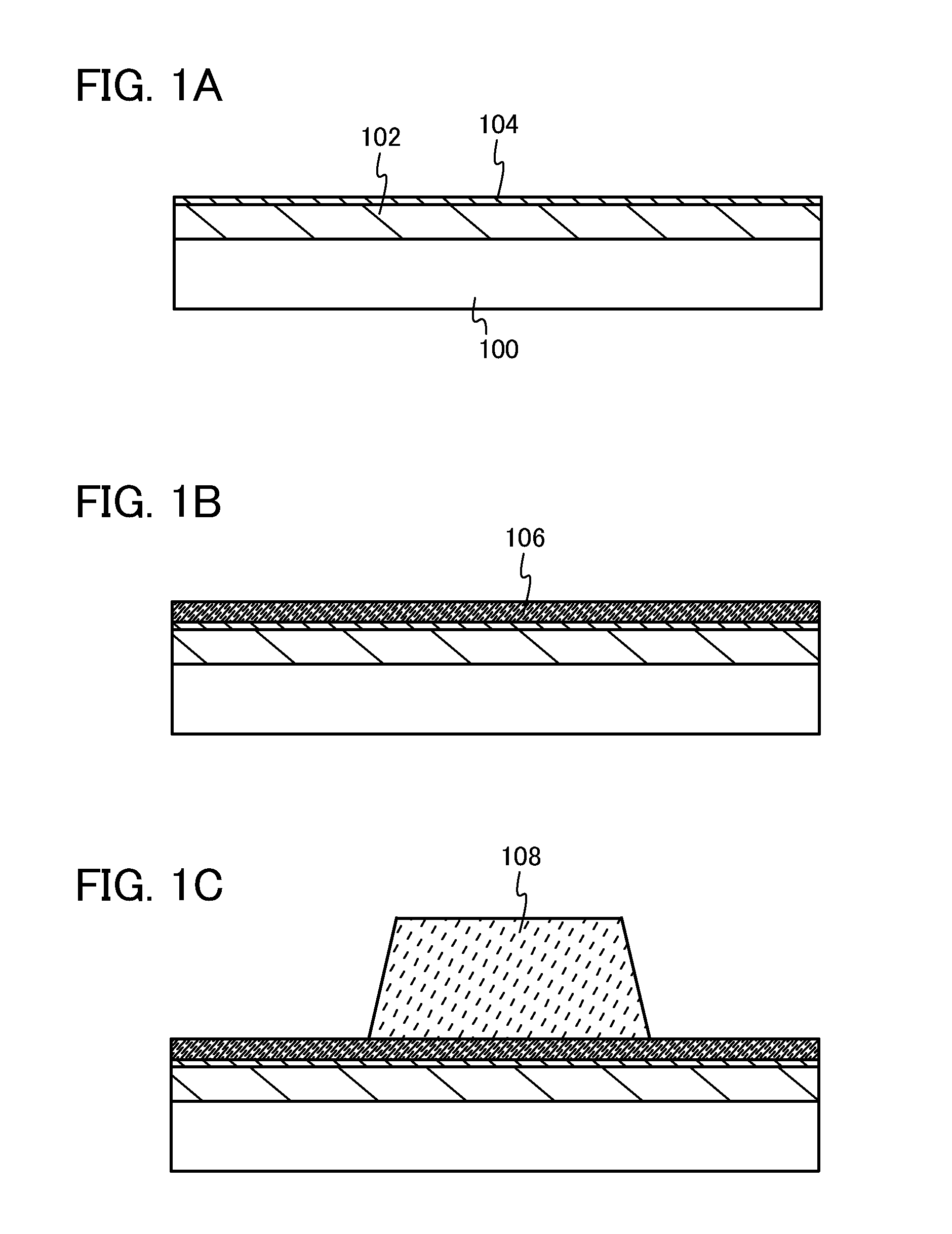

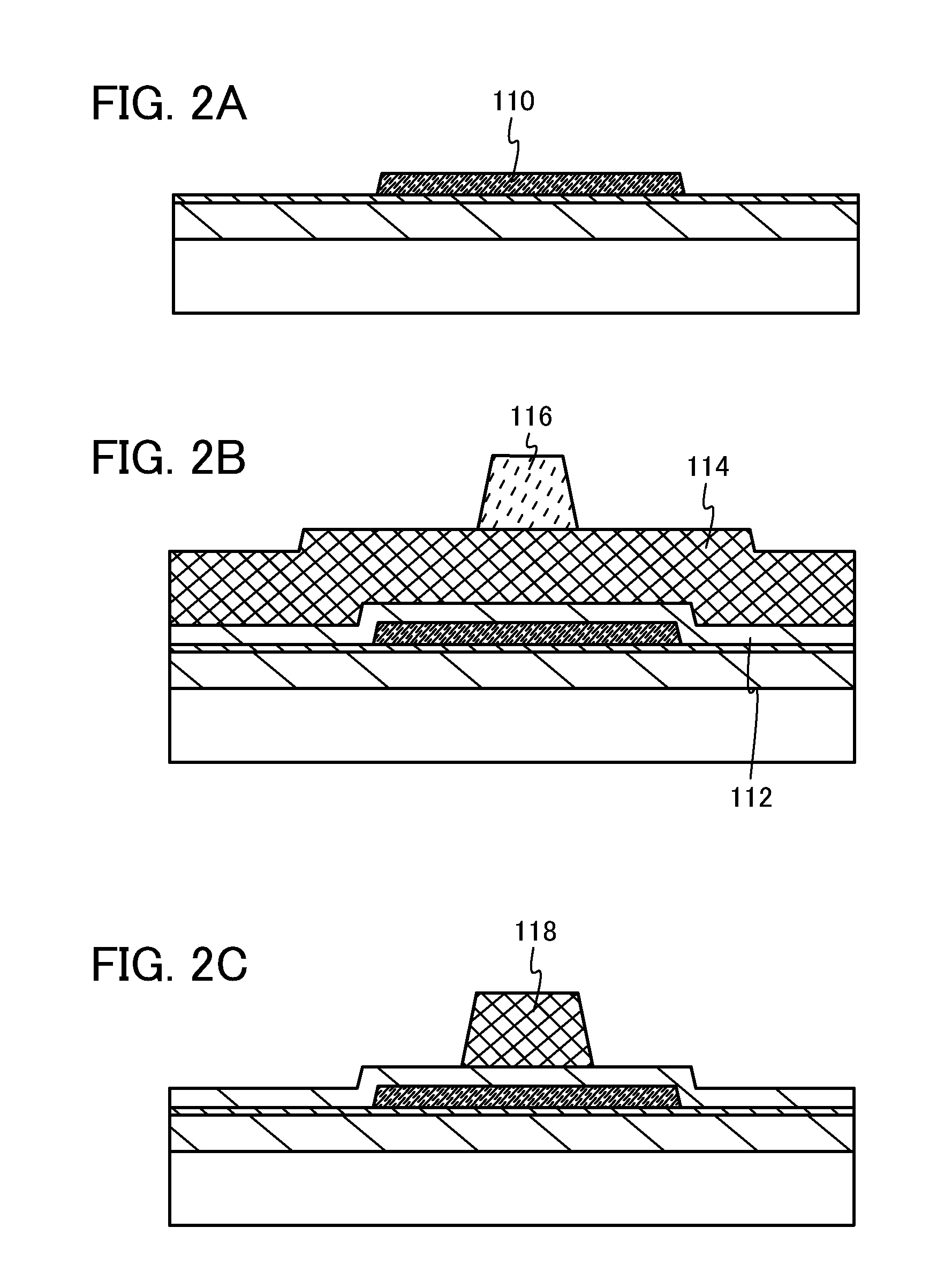

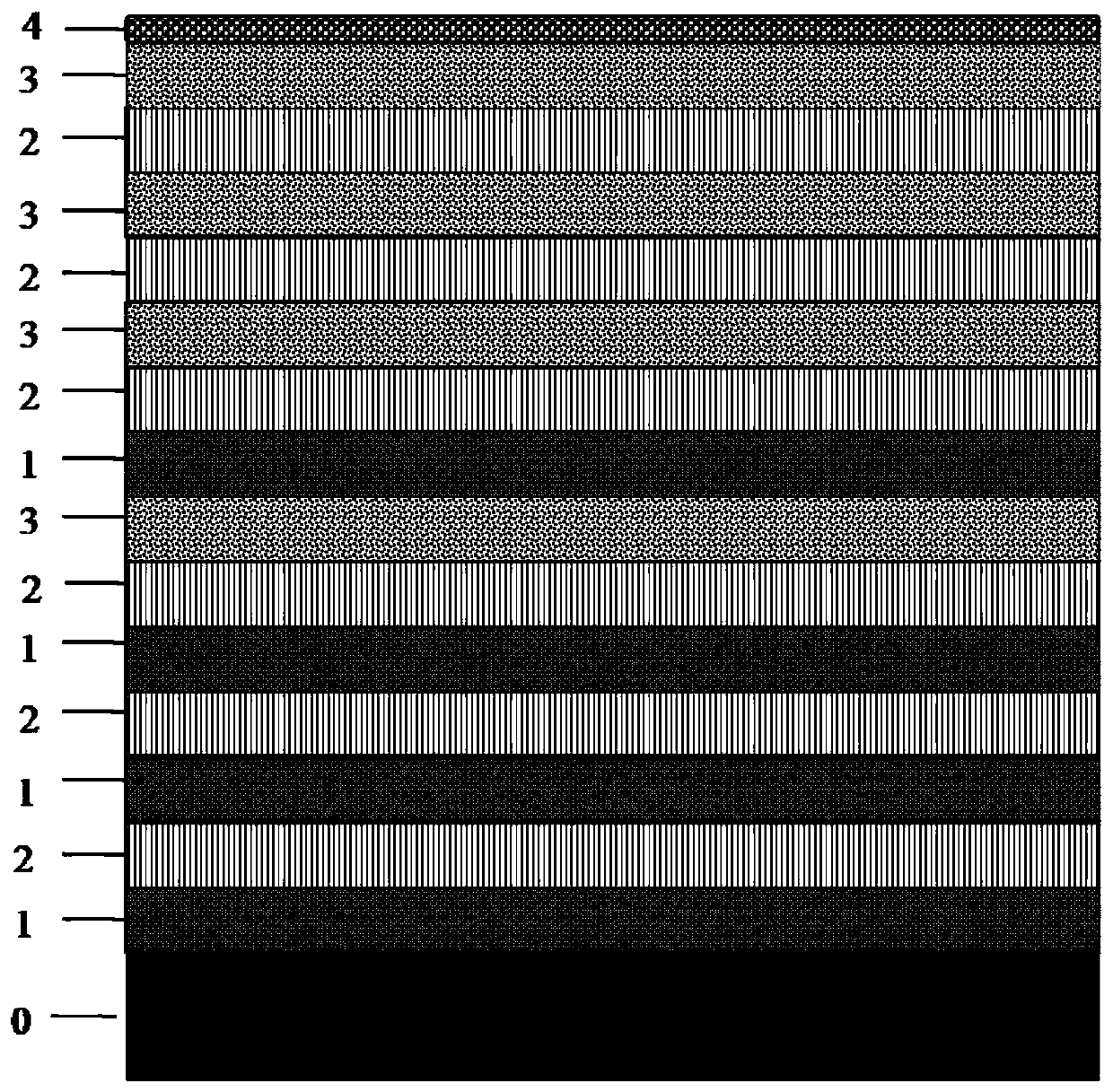

Method for manufacturing semiconductor device

ActiveUS20120252173A1Reduce amount of waterReduce oxygen deficiencySemiconductor/solid-state device manufacturingSemiconductor devicesOxygen deficiencyOxide semiconductor

The amount of water and hydrogen contained in an oxide semiconductor film is reduced, and oxygen is supplied sufficiently from a base film to the oxide semiconductor film in order to reduce oxygen deficiencies. A stacked base film is formed, a first heat treatment is performed, an oxide semiconductor film is formed over and in contact with the stacked base film, and a second heat treatment is performed. In the stacked base film, a first base film and a second base film are stacked in this order. The first base film is an insulating oxide film from which oxygen is released by heating. The second base film is an insulating metal oxide film. An oxygen diffusion coefficient of the second base film is smaller than that of the first base film.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing high-heat-conduction aluminum nitride ceramic substrate by adding compound sintering auxiliary

InactiveCN106830945AReduce oxygen contentReduce the formation of oxygen vacanciesCeramic substrateAluminium nitride

The invention relates to a method for preparing a high-heat-conduction aluminum nitride ceramic substrate by adding a compound sintering auxiliary. A preparation method comprises the following steps of (1), confecting of aluminum nitride ceramic powder, wherein a Li2O-MgO-CaO-YF3 system is adopted for the added compound sintering auxiliary; (2), ball milling; (3), vacuum bubble removal; (4), primary tape casting; (5), hydrostatic molding; (6), rubber discharge; (7), sintering. The method has the advantages that, according to the preparation method provided by the invention, through changing the formula of a sintering auxiliary, the compound sintering auxiliary can greatly improve heat conduction efficiency; moreover, the densification of aluminum nitride ceramic is further promoted; meanwhile, after the primary tape casting, the hydrostatic molding step is added; the consistency of performance is further improved.

Owner:莱鼎电子材料科技有限公司

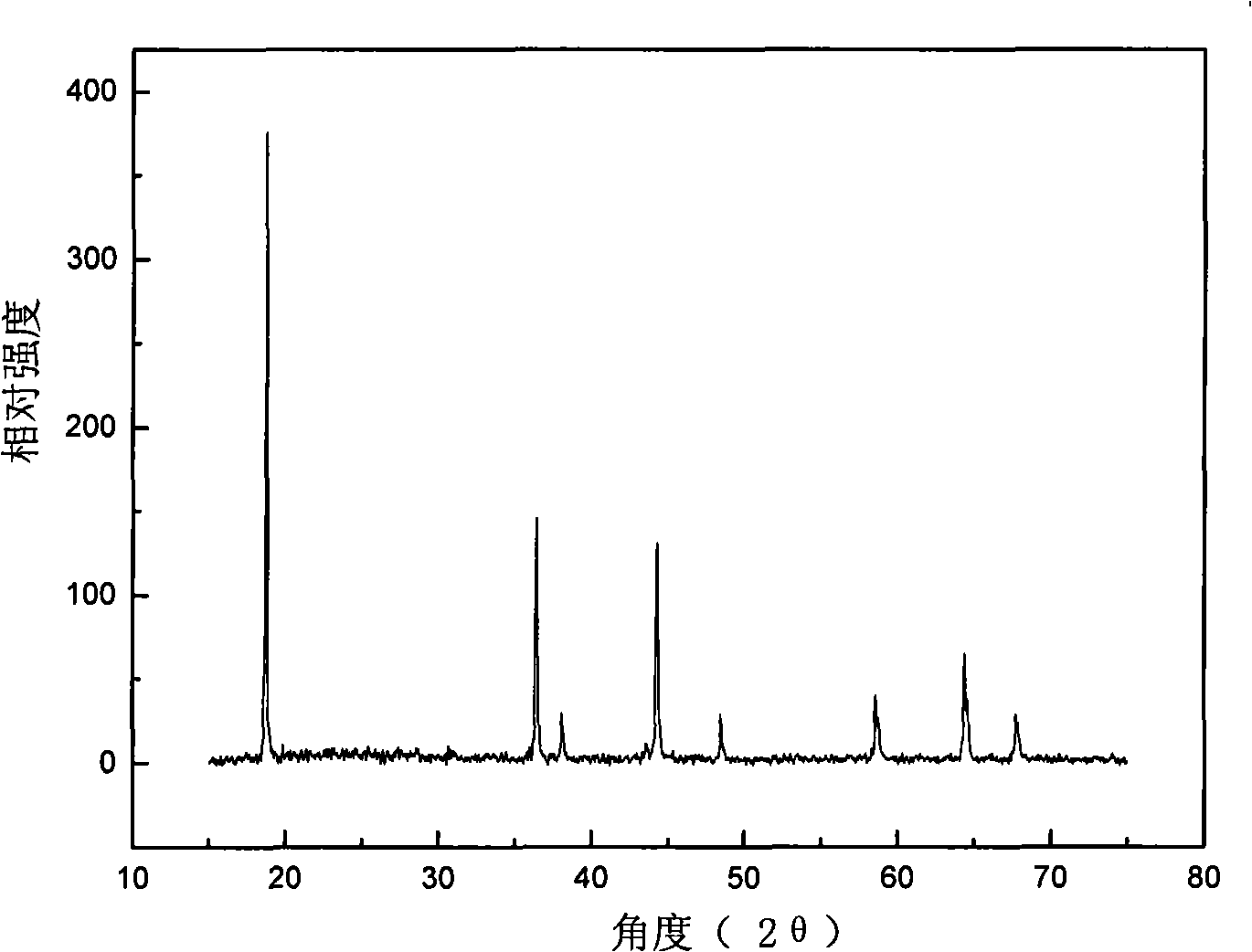

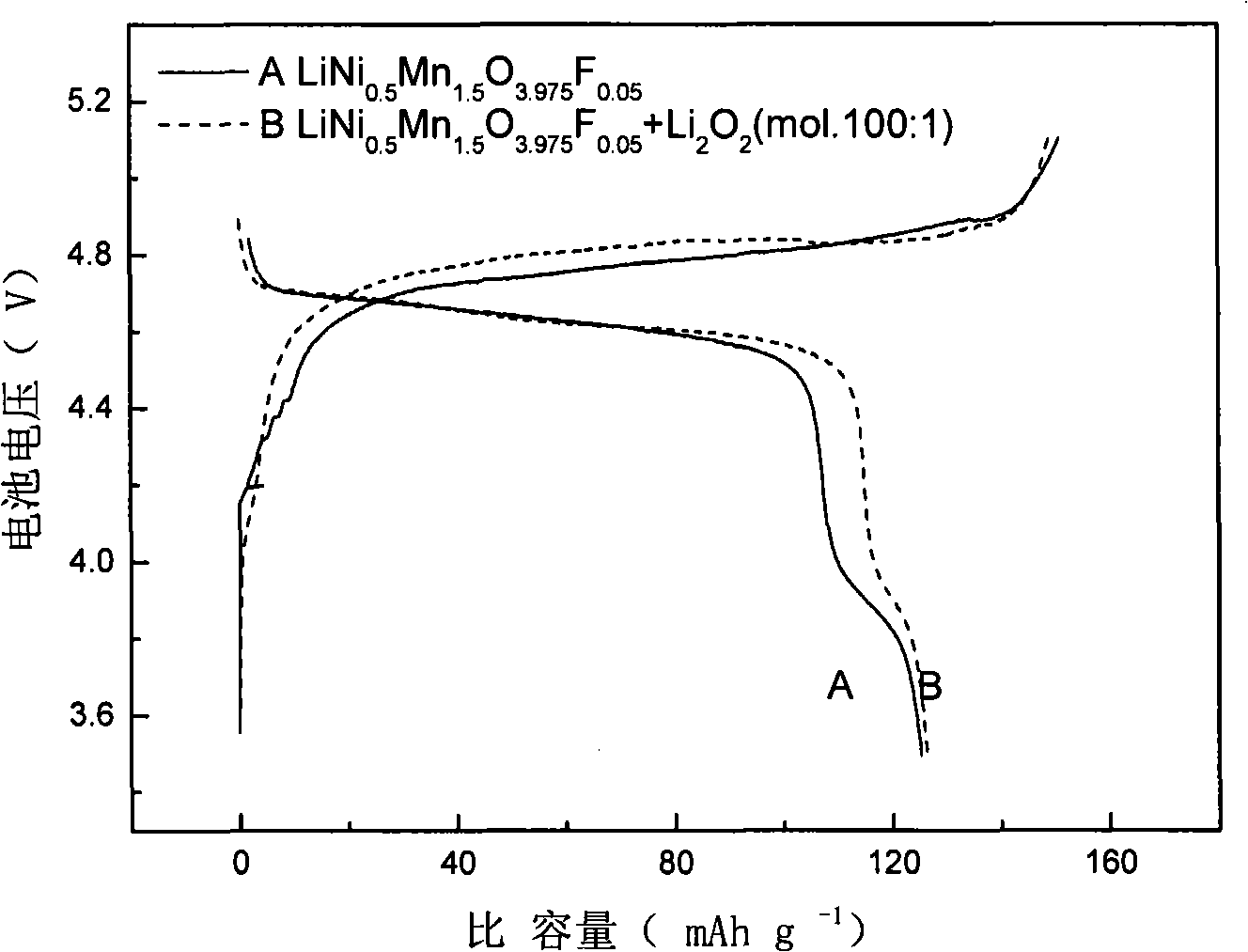

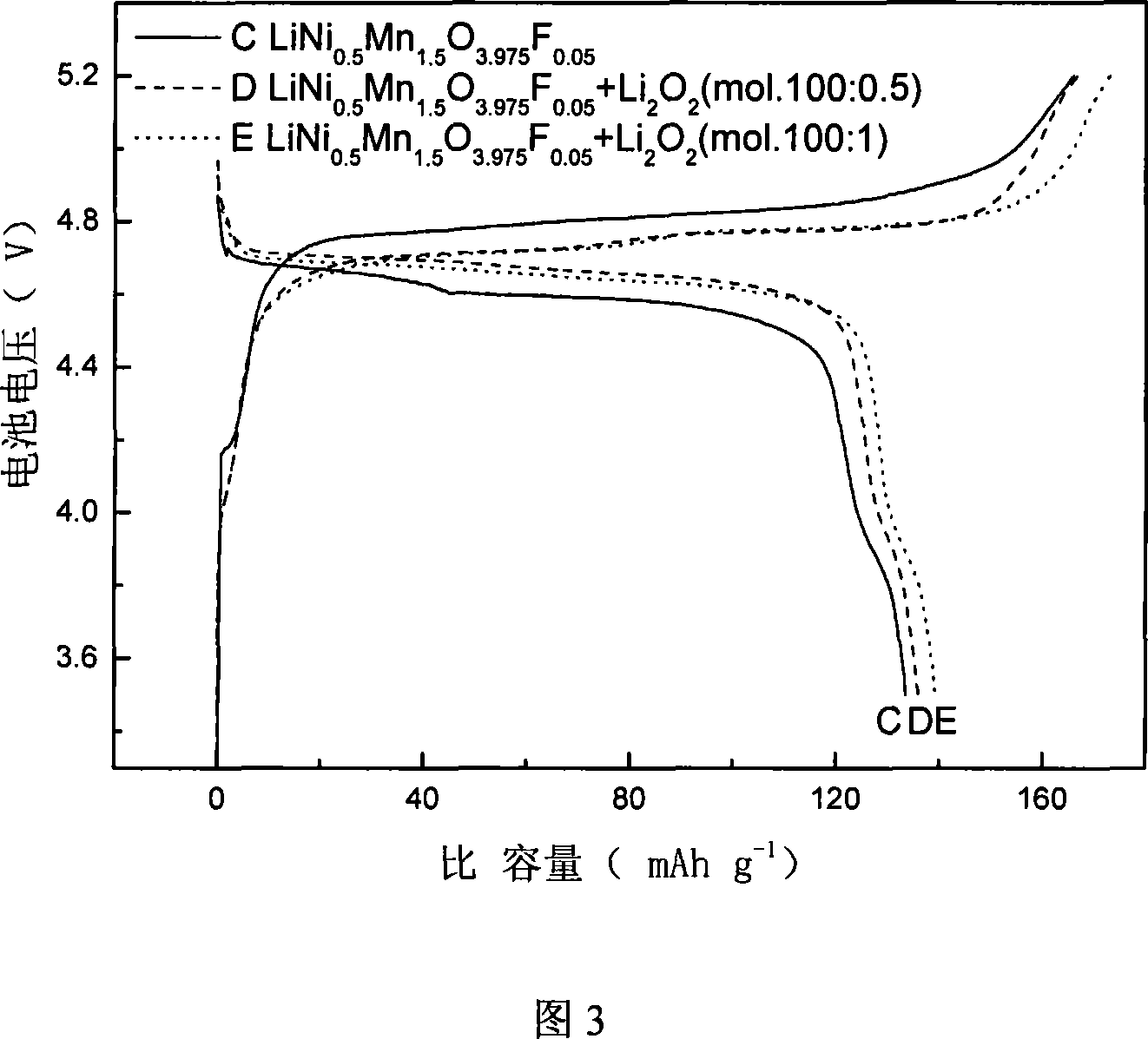

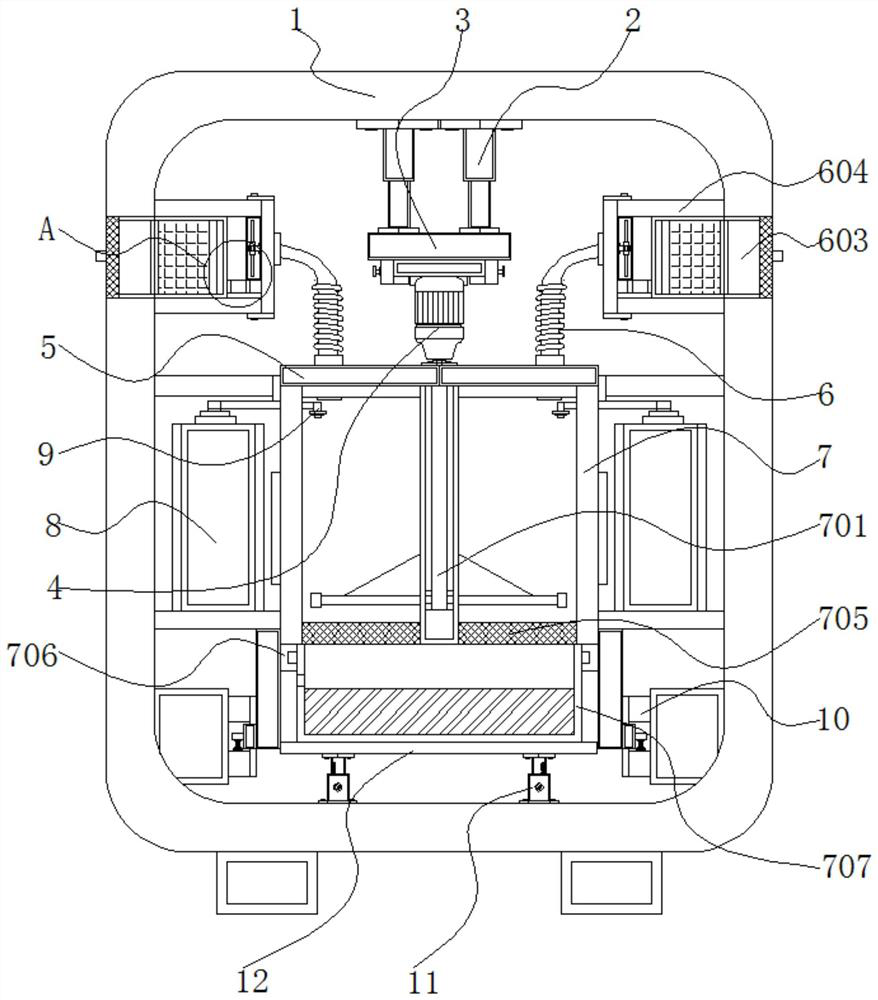

Method for preparing anode material for lithium ion battery

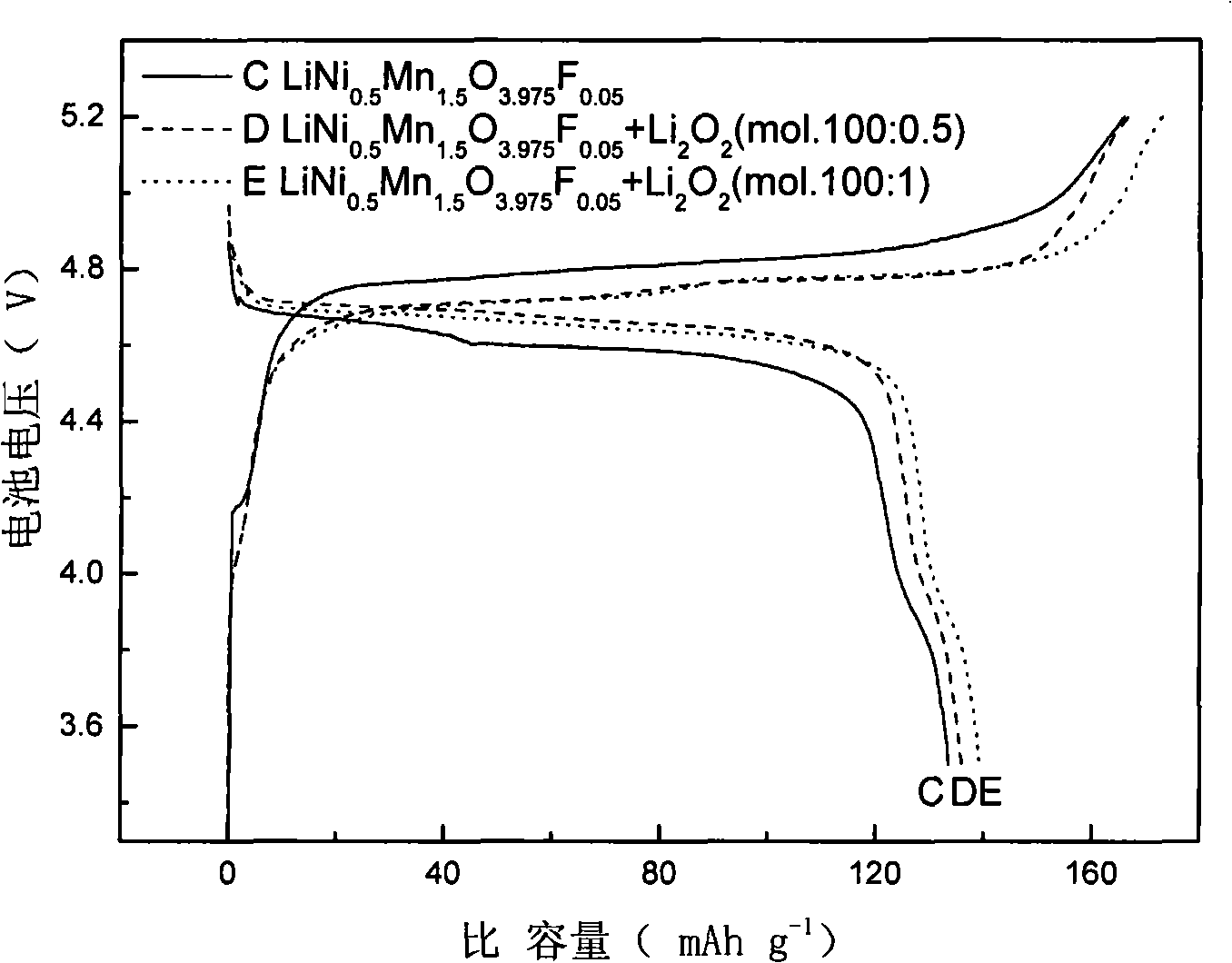

InactiveCN101409346AIncrease capacityImprove cycle stabilityElectrode manufacturing processesNickel compoundsChemistryCharge and discharge

The invention relates to a preparation method of an anode material for a lithium ion battery. Component of the anode material is LiNi0.5Mn1.5O4-deltaFx, wherein, the delta equals 0.5x, and x is not less than 0.01 and not more than 0.08; the anode material is prepared by combining gel and lithium peroxide under high-temperature heat treatment; the process is simple and the preparation course is easy to be controlled. The first discharge capacity of the material can reach 140mAh / g<-1>, wherein, 5V voltage platform characteristic is obviously improved, and 4V voltage platform is well removed, the charge and discharge efficiency reach more than 96% after repeating the previous cycles, and the material has excellent cycle performance.

Owner:PANASONIC CORP +1

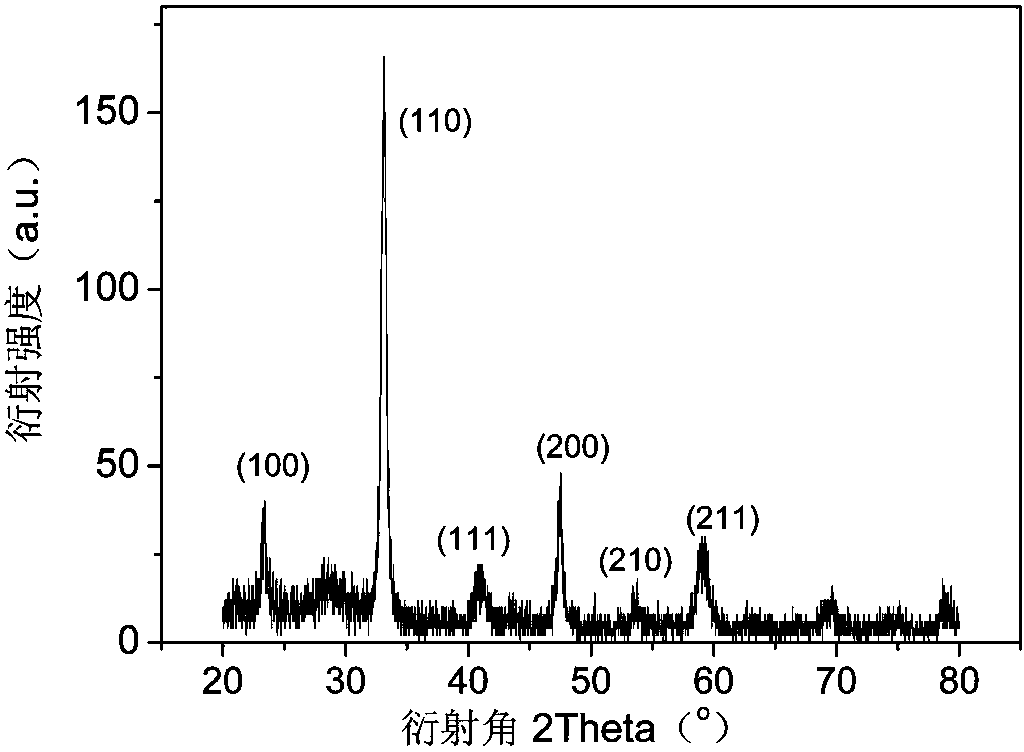

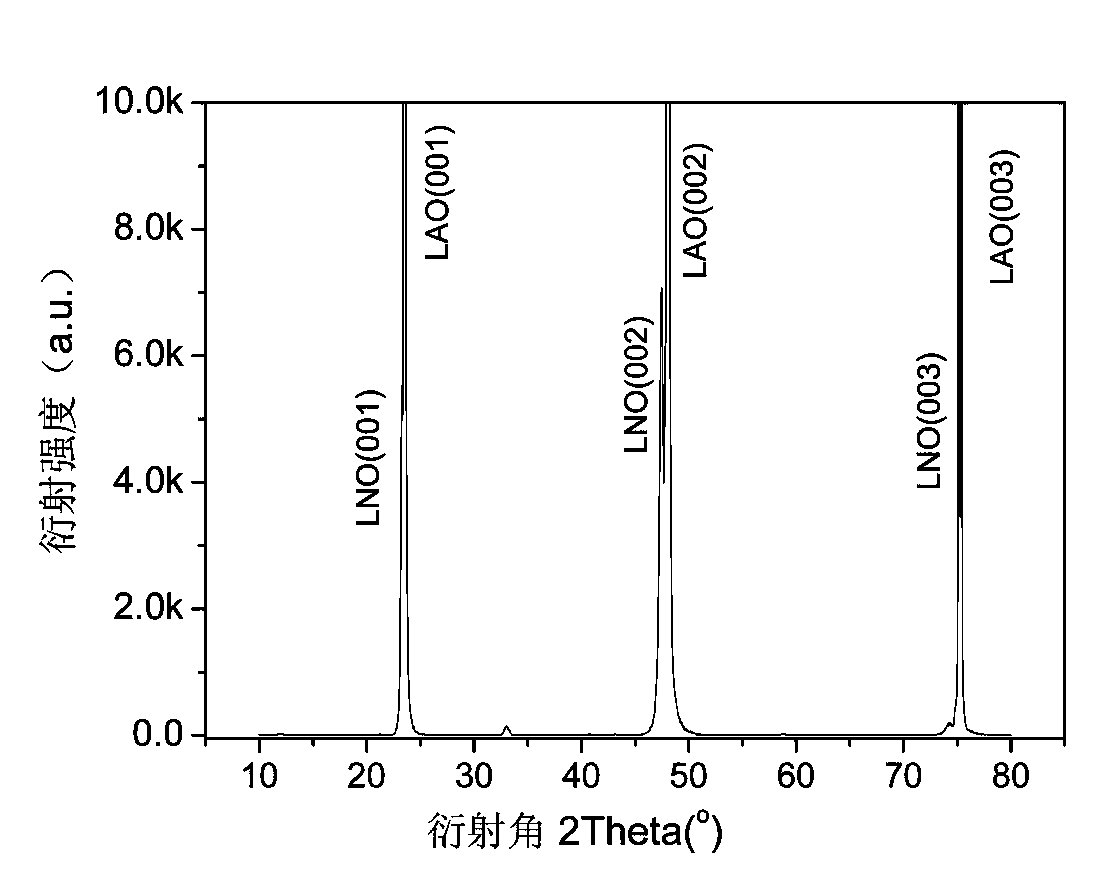

Preparation method of lanthanum nickelate conductive film by chemical solution deposition

ActiveCN103833416AIncrease contentReduce proportional imbalancesConductive layers on insulating-supportsCzochralski methodHeating furnace

The invention relates to a preparation method of a lanthanum nickelate conductive film by chemical solution deposition, belonging to the technical field of microelectronic manufacture. The step mainly includes the preparation of LaNiO3 sol, comprising: preparing a LaNiO3 gel film on a substrate by using a dipping Czochralski method or a spin-coating method, then drying the gel film to form a LaNiO3 gel dry film; transferring the substrate coated with the LaNiO3 gel dry film to a quartz tube heating furnace, performing thermolysis in a mixed atmosphere of H2O and O2; finally putting the thermolyzed gel dry film and the substrate into a quartz tube sintering furnace, performing high temperature calcining in the mixed atmosphere of H2O and O2, so as to form the conductive film on the substrate. The conductive film formed by the method has lower resistivity.

Owner:高俊萍

Preparation of low-resistance / high-resistance composite film through ultrasonic spray pyrolysis

InactiveCN1544691APromote decompositionPromote oxidation reactionLiquid/solution decomposition chemical coatingHigh resistanceElectrical resistance and conductance

The invention prepares transparent low-distance and high-distance films by ultrasonic spray thermolysis technique. It uses a technique of ultrasonic spray deposition, and has the characters of large area and high deposition ratio. By improving the film forming device by ultrasonic spray thermolysis, it changes the spout from one point to one slot, which makes gas uniformly ejected on a line. The sample moves at uniform speed in the direction of the vertical spraying slot so that the thickness of the deposited film can be made uniform and consistent. It can be used in preparation of the transparent low-resistance films and transparent intrinsic high-resistance films of solar energy batteries and LCDs.

Owner:SICHUAN UNIV

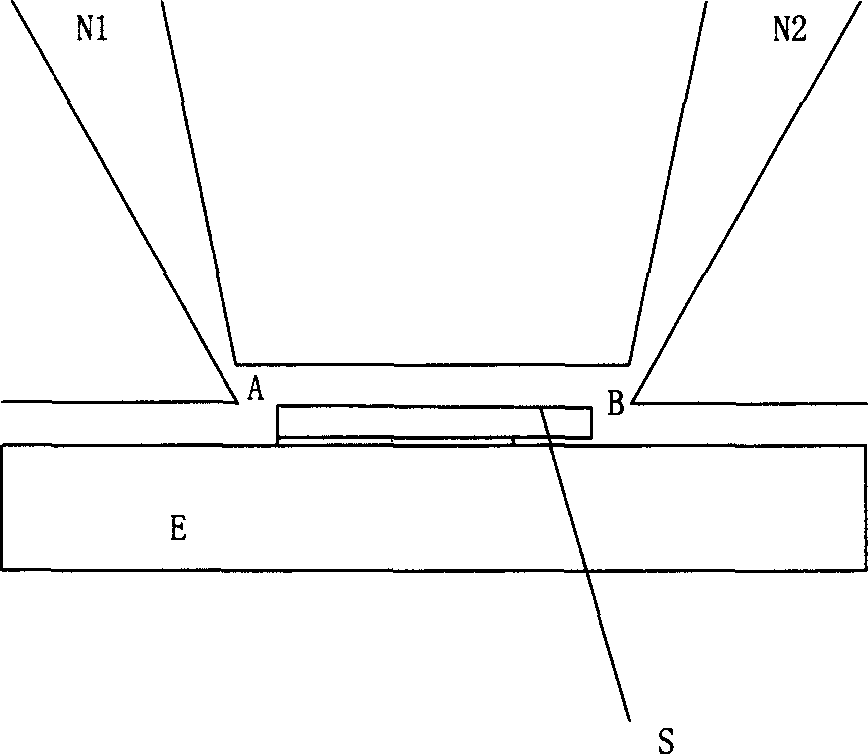

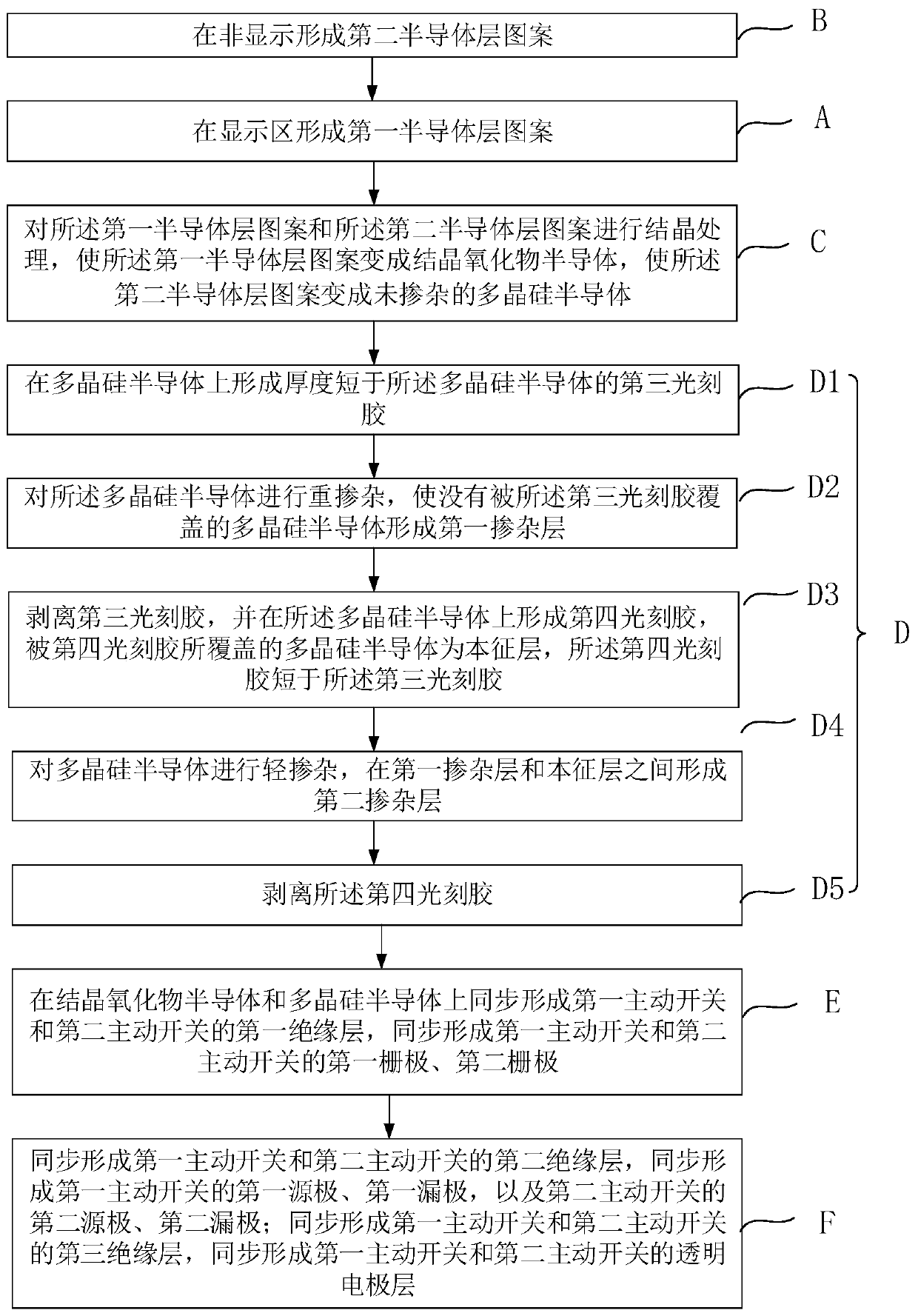

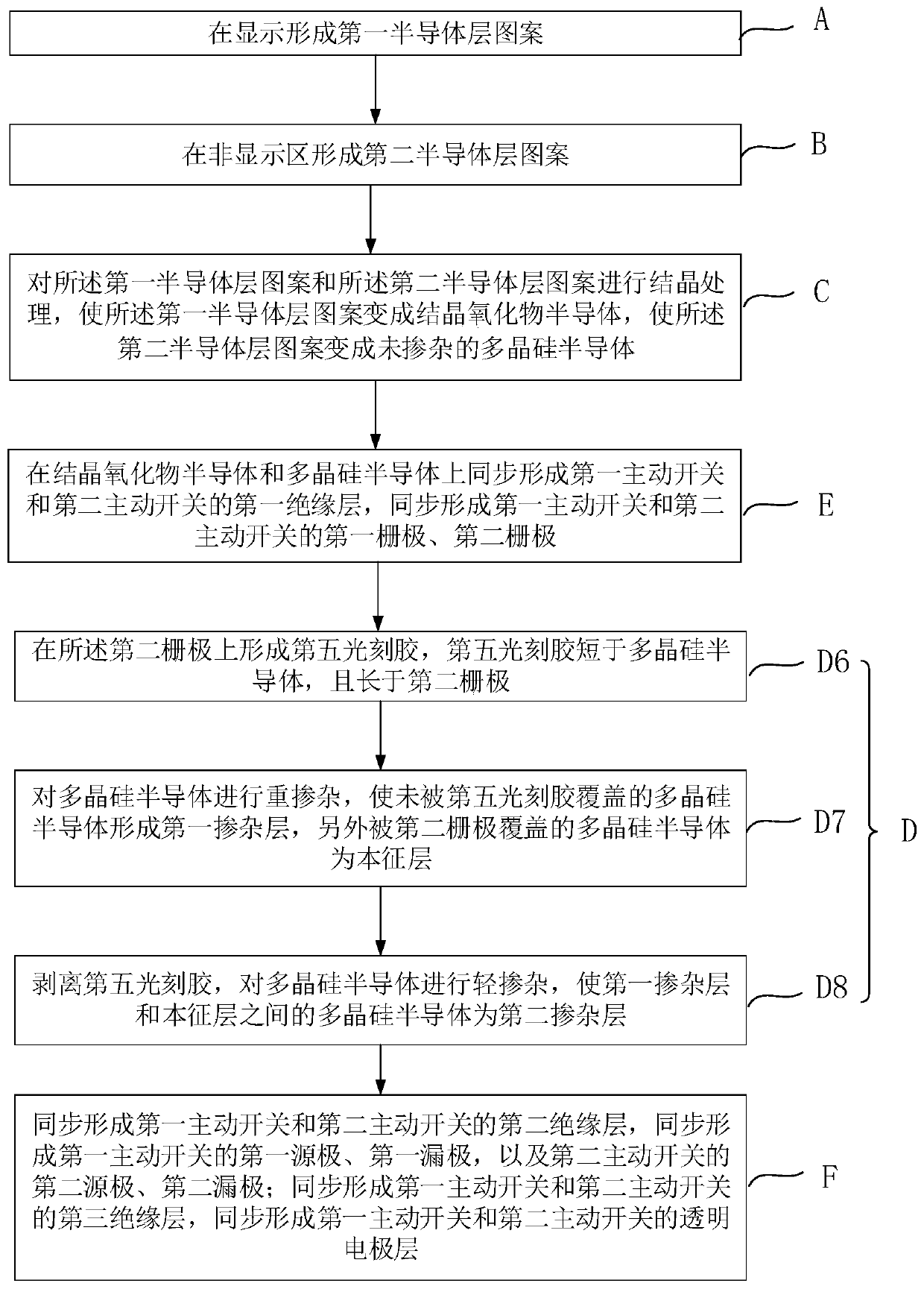

Array substrate and manufacturing method thereof, and display panel

PendingCN110137182AReduce power consumptionImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingCrystalline oxideAmorphous silicon

The invention discloses an array substrate and manufacturing method thereof, and a display panel. The manufacturing method of the array substrate comprises the steps of: forming a first active switchcontaining a crystalline oxide semiconductor at the display region of an array substrate, and forming a second active switch containing a polysilicon semiconductor at the non-display region of the array substrate, wherein the crystalline oxide semiconductor and the polysilicon semiconductor are formed on the same layer. The power consumption of the circuit in the display region is reduced while the narrow frame is achieved; and moreover, after the oxide conductor and an amorphous silicon semiconductor are prepared on the same layer and then are subjected to crystallization process at the sametime so that the manufacture procedure of converting the amorphous silicon to the polycrystalline silicon is not influenced and the stability of the array substrate is increased.

Owner:HKC CORP LTD +1

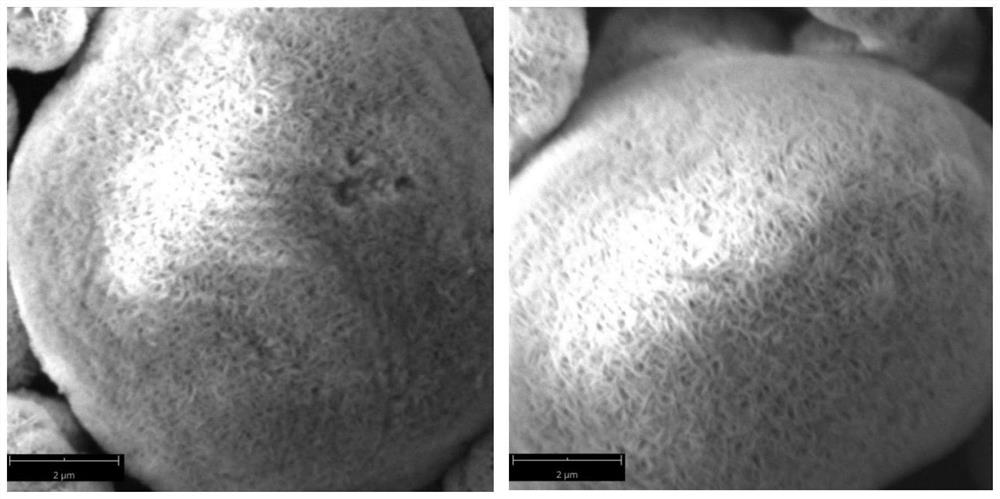

High-magnification monocrystal-like lithium nickel cobalt aluminate positive electrode material with coating layer and preparation method thereof

ActiveCN111009646AReduce usageReduce pollutionCell electrodesSecondary cellsAluminium hydroxideLithium hydroxide

The invention discloses a high-magnification monocrystal-like lithium nickel cobalt aluminate positive electrode material with a coating layer and a preparation method thereof, the preparation methodcomprises the following steps: (1) uniformly mixing a cobalt nickel hydroxide precursor and aluminum hydroxide, then adding lithium hydroxide, and continuously mixing to obtain a mixture; and (2) putting the material into a high-temperature-resistant container, sintering in an oxygen-enriched environment, cooling to room temperature, and sieving to obtain the monocrystal-like lithium nickel cobaltaluminate positive electrode material, (3) mixing the material with cold water, and controlling the washing time and the drying temperature to obtain the washed monocrystal-like lithium nickel cobaltaluminate positive electrode material; and (4) uniformly mixing the materials with a coating agent, continuously sintering under an oxygen-enriched condition, cooling to room temperature, and sievingto obtain a finished product. According to the invention, the stability of the monocrystal-like lithium nickel cobalt aluminate positive electrode material can be improved, so that the cycle performance and the rate capability of the positive electrode material are improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

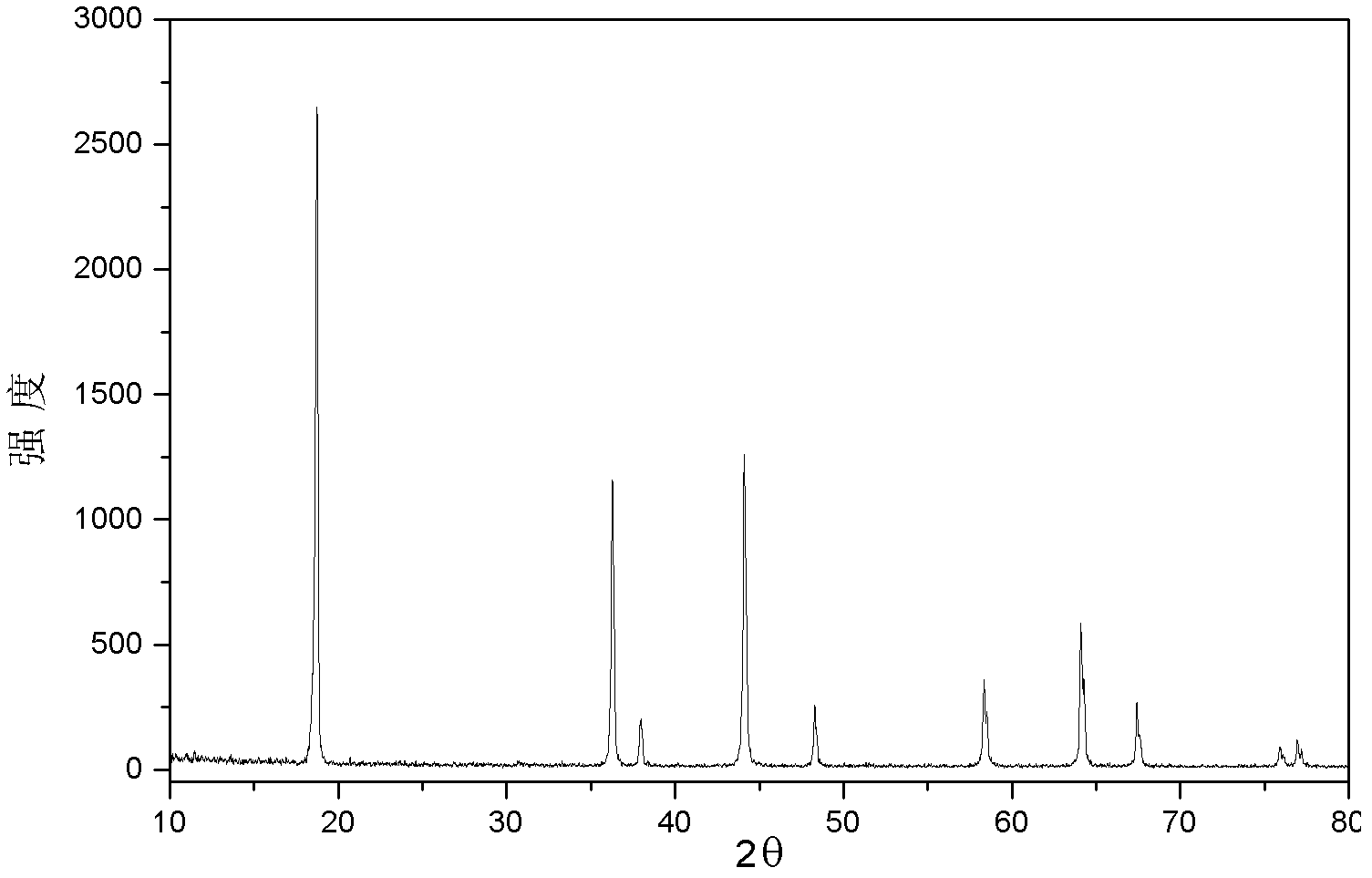

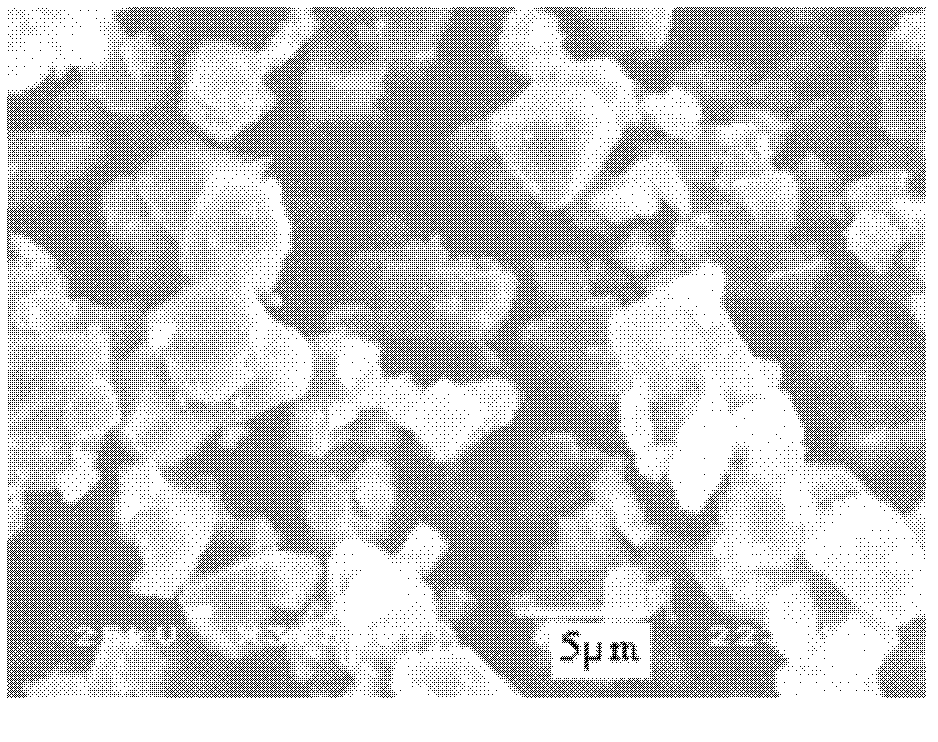

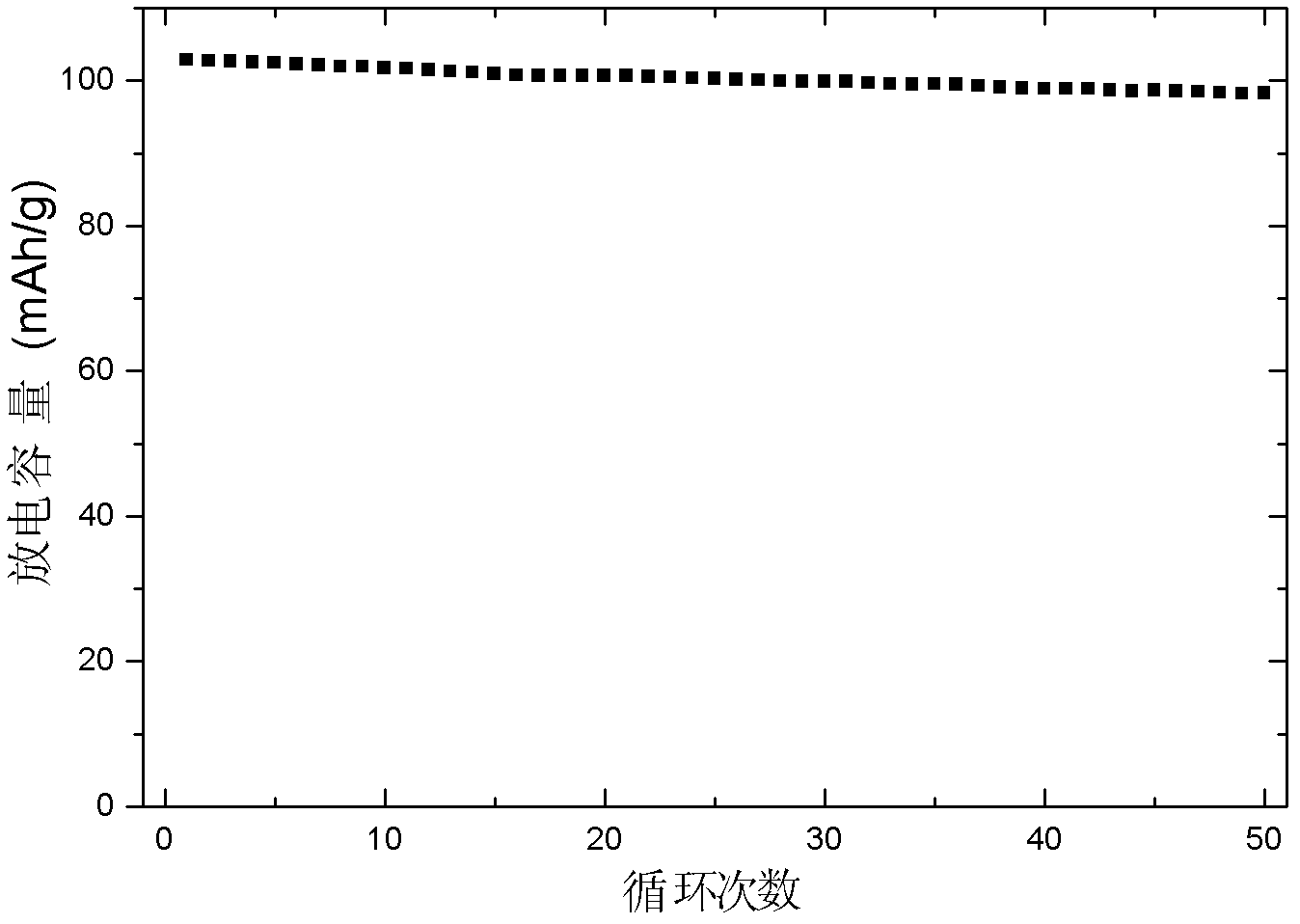

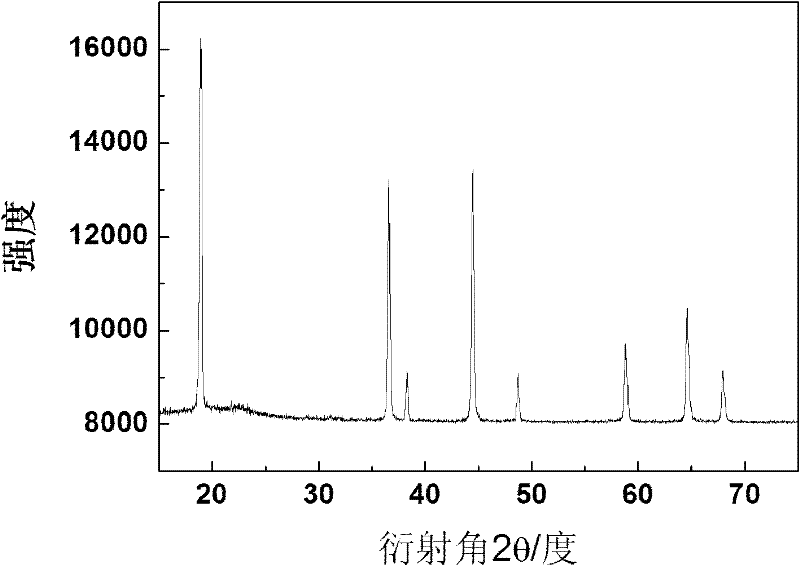

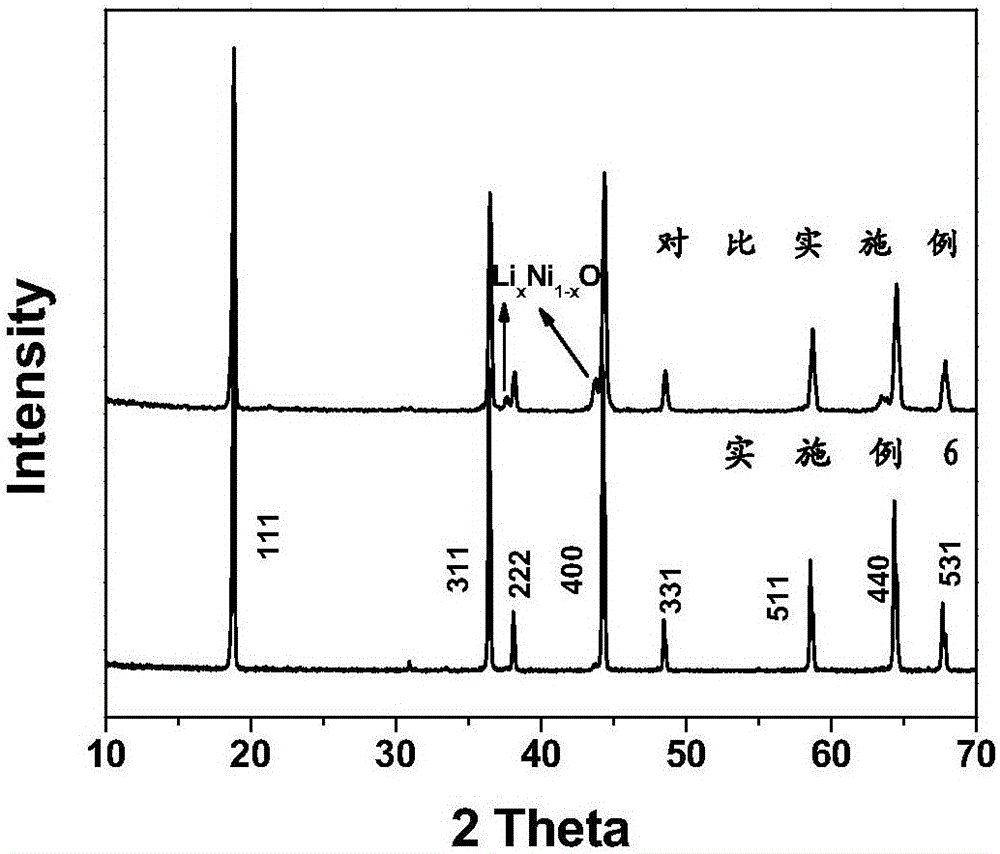

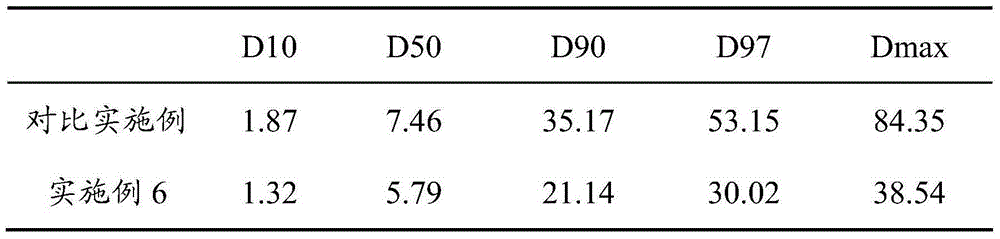

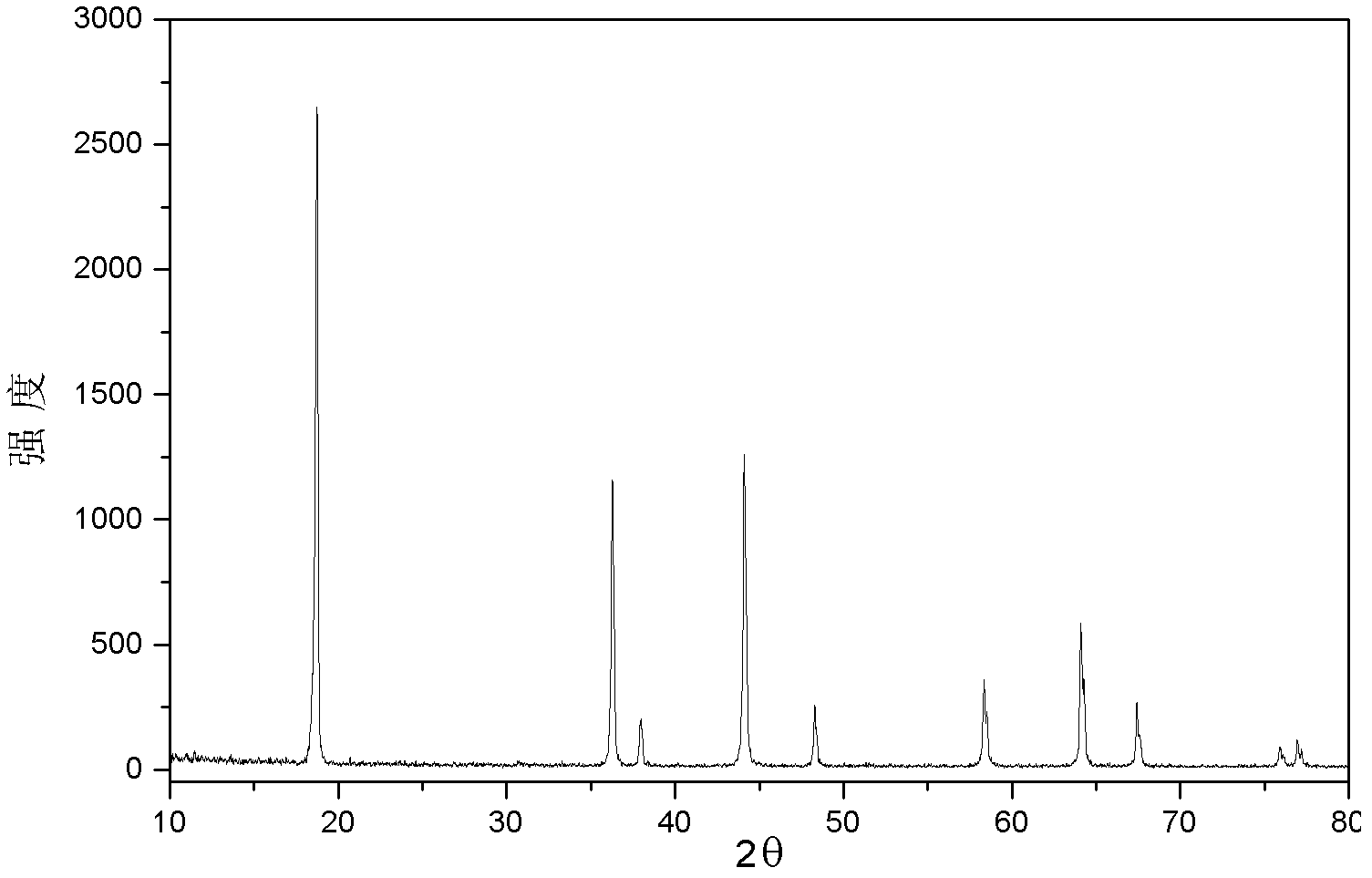

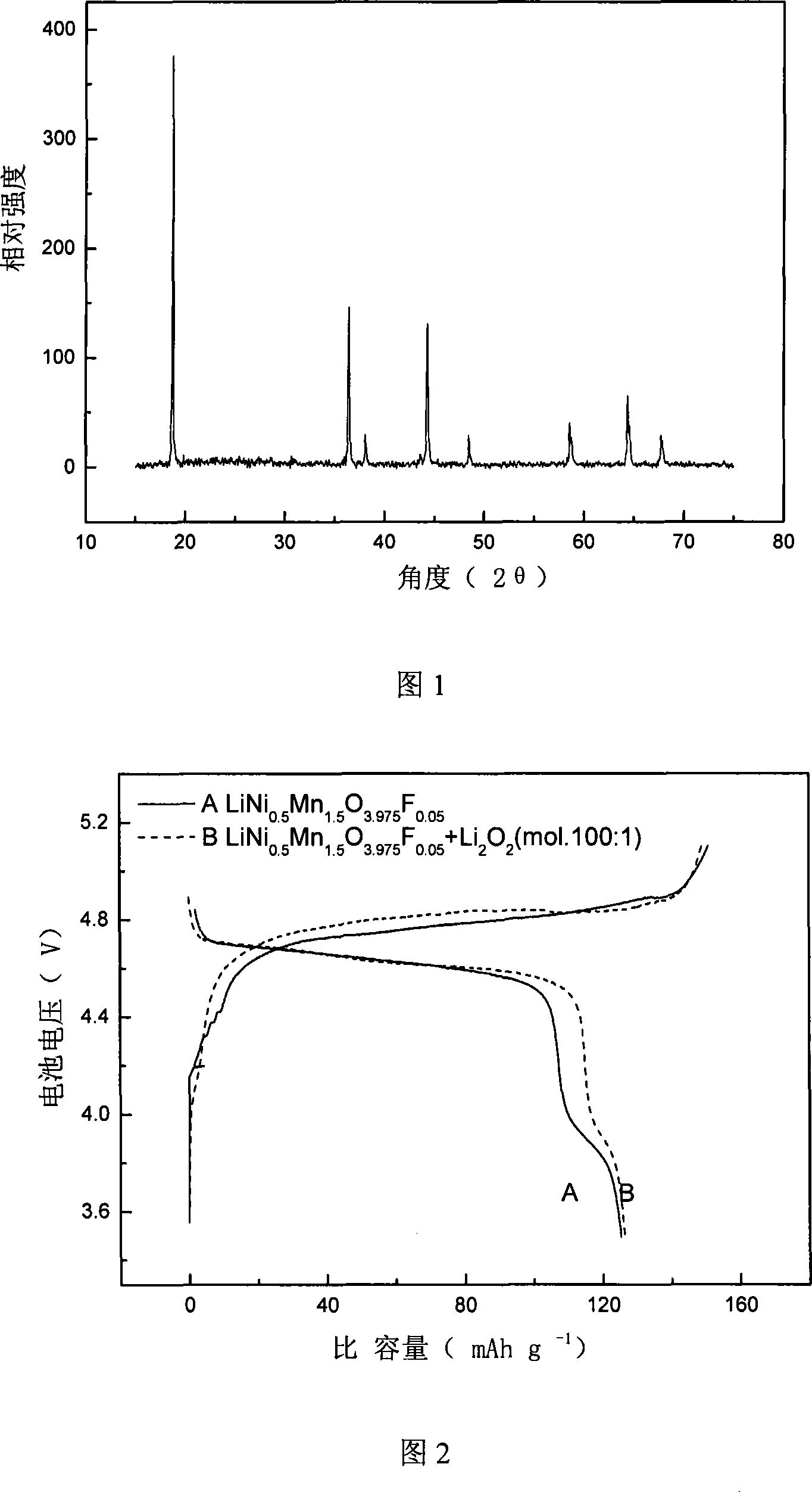

Preparation method for LiNi0.5Mn1.5O4

InactiveCN102479941AHigh purityReduce oxygen deficiencyCell electrodesLithium compoundManganese oxide

The embodiments of the invention disclose a preparation method for LiNi0.5Mn1.5O4. According to the method, a mixture containing nickel and manganese is prepared; the mixture is calcined at a temperature of 900-1000 DEG C to obtain a nickel manganese oxide precursor; the nickel manganese oxide precursor and a lithium compound are mixed and calcined at the temperature of 650-750 DEG C, and then an annealing treatment is performed in the oxygen atmosphere to obtain the LiNi0.5Mn1.5O4. According to the present invention, the nickel manganese oxide precursor is firstly prepared, and then the lithium compound is added, such that the direct contact of the lithium compound and the manganese compound, and the direct contact of the lithium compound and the nickel compound are avoided so as to avoid the generations of NiO, Li(1+x)Ni(1-x)O2 and other impurity phases; the annealing treatment is performed in the oxygen atmosphere so as to compensate the oxygen defects generated during the sintering process, such that the purity of the prepared LiNi0.5Mn1.5O4 is high, and the oxygen defects are less.

Owner:SUZHOU UNIV +1

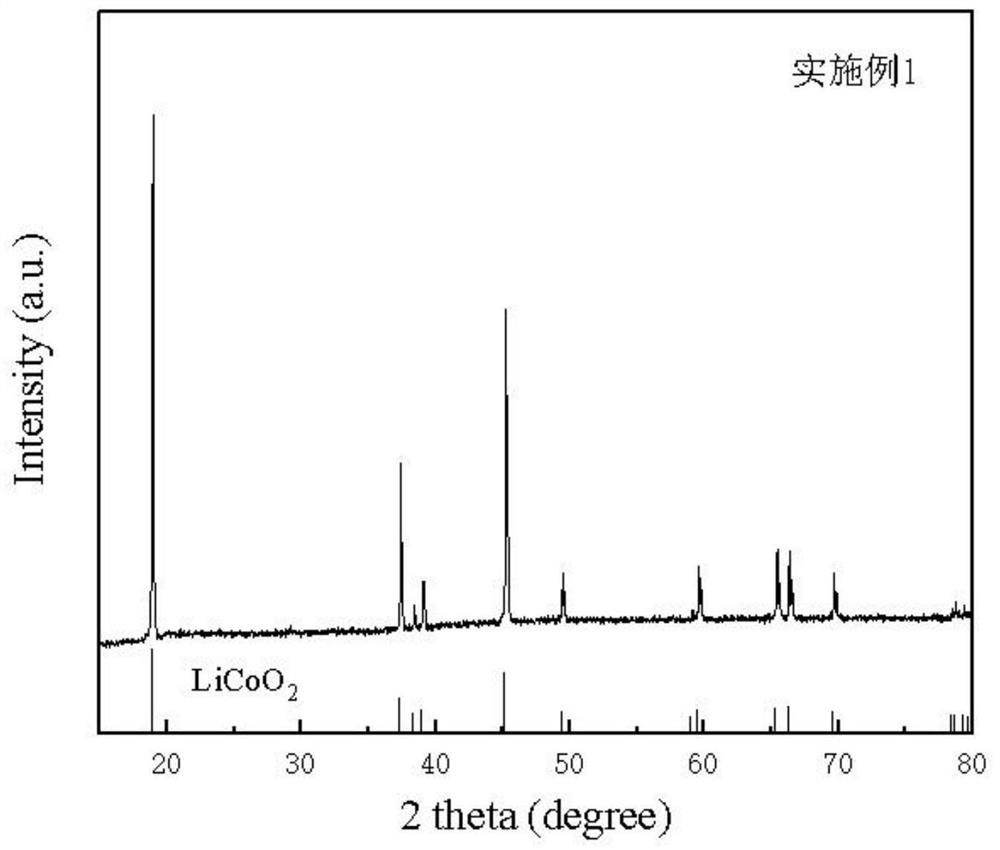

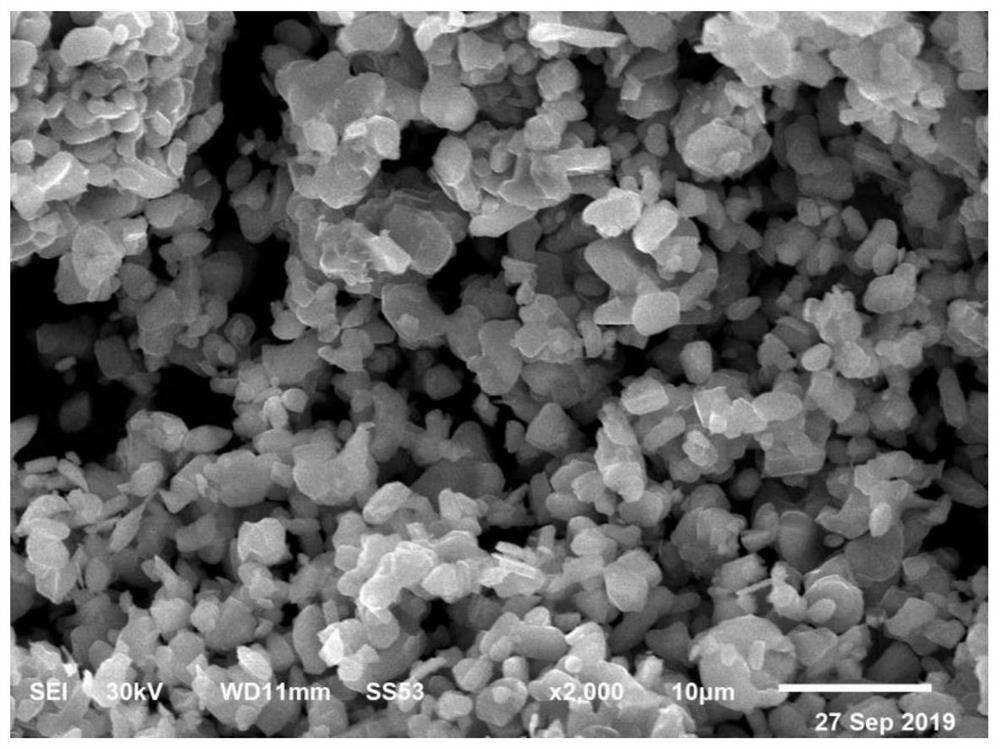

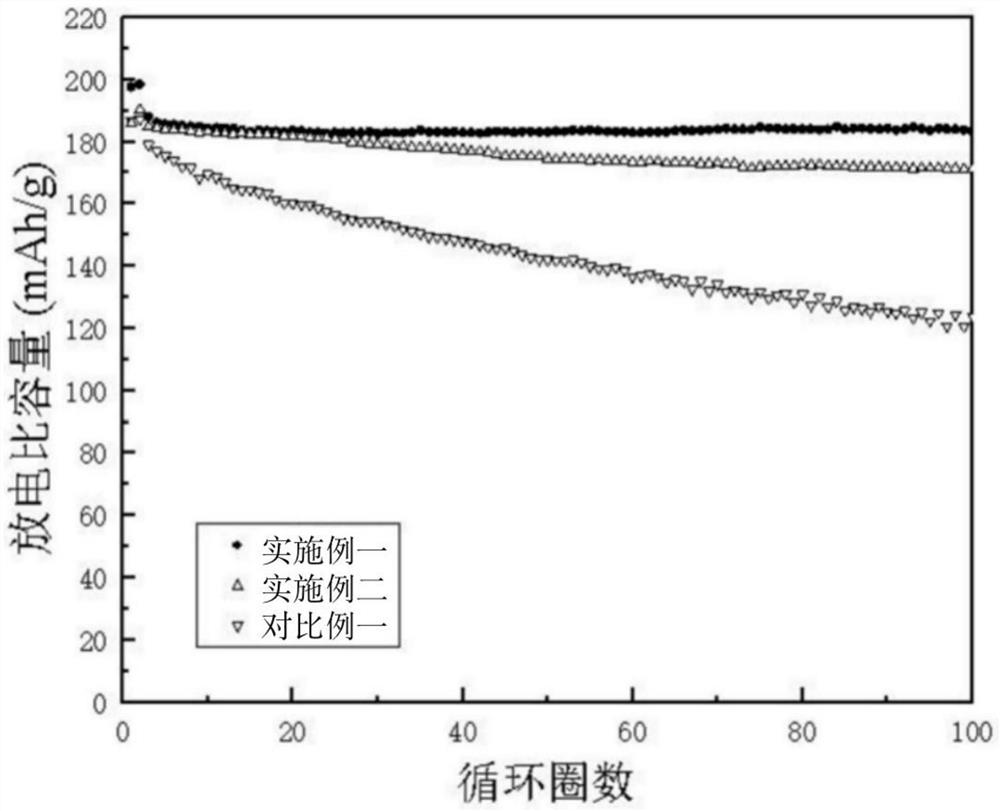

Doped high-voltage lithium cobalt oxide cathode material and preparation method thereof

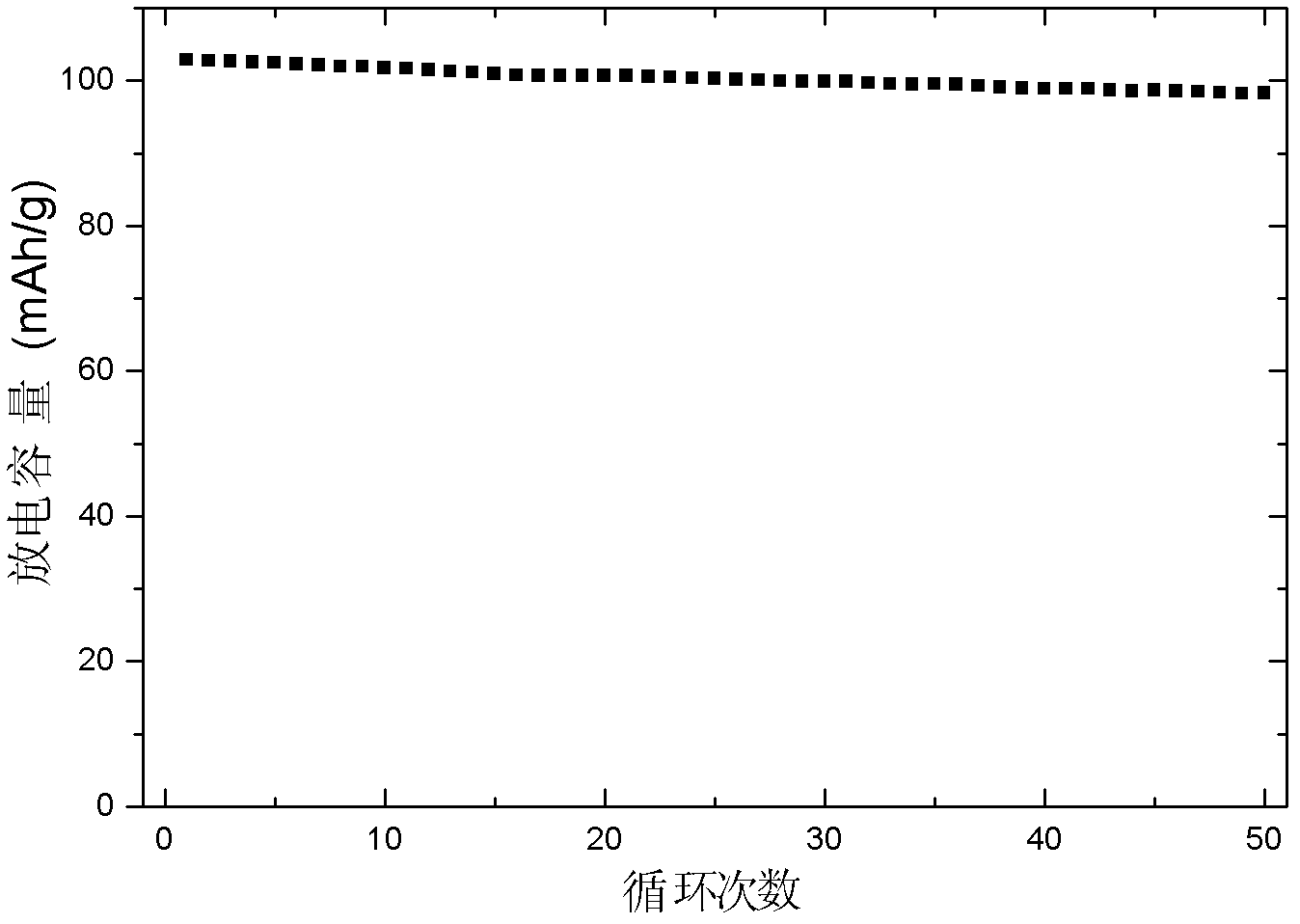

InactiveCN111769275AImprove cycle lifeImprove securityCell electrodesSecondary cellsPhysical chemistrySpecific discharge

The invention discloses a doped high-voltage lithium cobalt oxide cathode material and a preparation method thereof. One or more of a zinc source, a yttrium source, a terbium source and a praseodymiumsource are selected and evenly mixed with a lithium source and a cobalt source, then high-temperature calcination is conducted, and the doped high-voltage lithium cobalt oxide positive electrode material is obtained. In the preparation process of the positive electrode material, Zn, Y, Tb and Pr are doped, so that the structural stability, the cycle life and the safety of the obtained lithium cobalt oxide positive electrode material under high voltage can be effectively improved. The specific discharge capacity of the prepared zinc-yttrium-terbium co-doped lithium cobalt oxide positive electrode material is 185mAh / g and the capacity retention ratio is 98% after 100 circles of circulation at high voltage, the structure is still kept complete after 300 circles, and the zinc-yttrium-terbiumco-doped lithium cobalt oxide positive electrode material can show good cycling stability under the condition of high voltage.

Owner:WUHAN UNIV

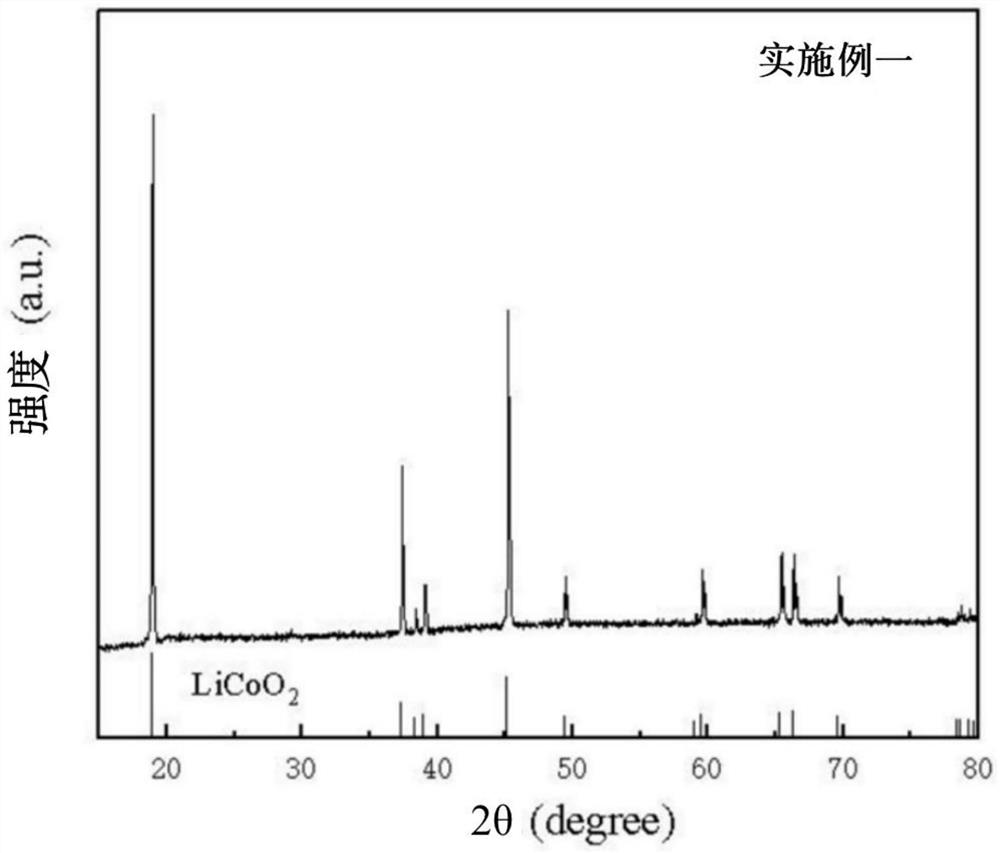

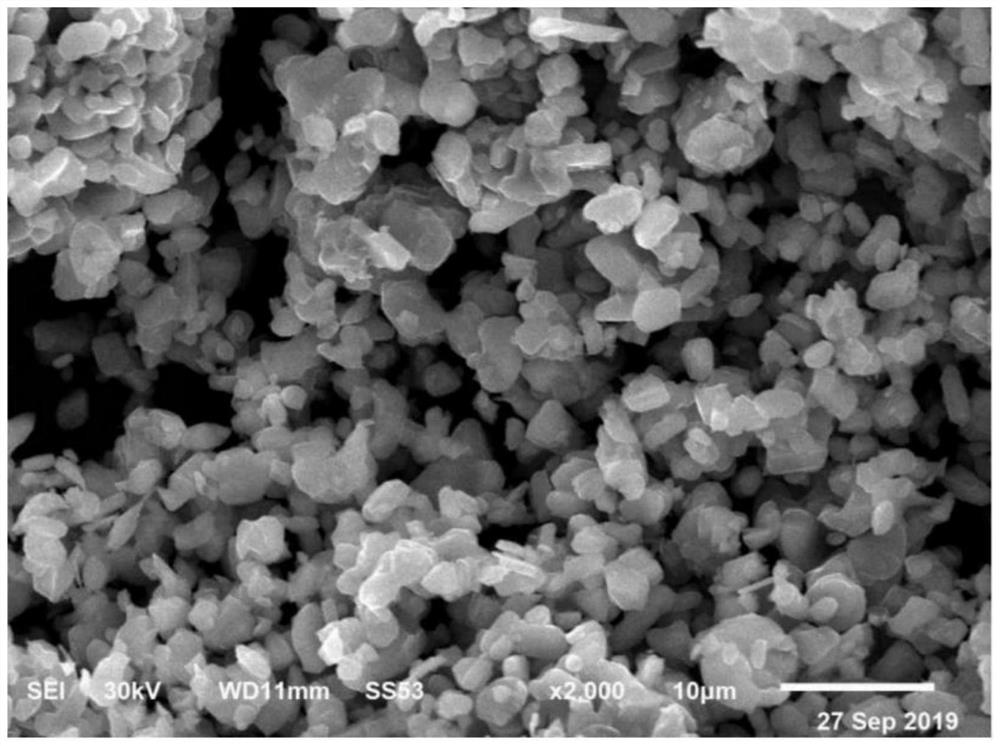

Doped high-voltage positive electrode material and preparation methods thereof

ActiveCN112290010AImprove cycle lifeImprove securityCell electrodesSecondary cellsMetallurgyPhysical chemistry

The invention provides a doped high-voltage positive electrode material and a preparation method thereof, and specifically includes a doped high-voltage lithium cobalt oxide and a high-nickel ternarypositive electrode material and preparation methods thereof. The chemical general formula of the doped high-voltage lithium cobalt oxide is LiaCoMbO2, in the formula, a is greater than or equal to 0.9and smaller than or equal to 1.2, b is greater than 0.000001 and less than 0.5, and M is one of Y, Tb and Pr, or two or more of Zn, Y, Tb and Pr. The doped high-voltage high-nickel ternary positive electrode material is characterized in that: the chemical general formula is Lia[Ni1-x-yCoxMny]MbO2, in the formula, a is greater than or equal to 0.9 and smaller than or equal to 1.2, x is greater than 0 and less than or equal to 1, y is greater than 0 and less than or equal to 1, x+y is greater than 0 and less than or equal to 1, b is is greater than 0.00001 and less than 0.5, and M is one or twoof Tb and Pr.

Owner:WUHAN UNIV

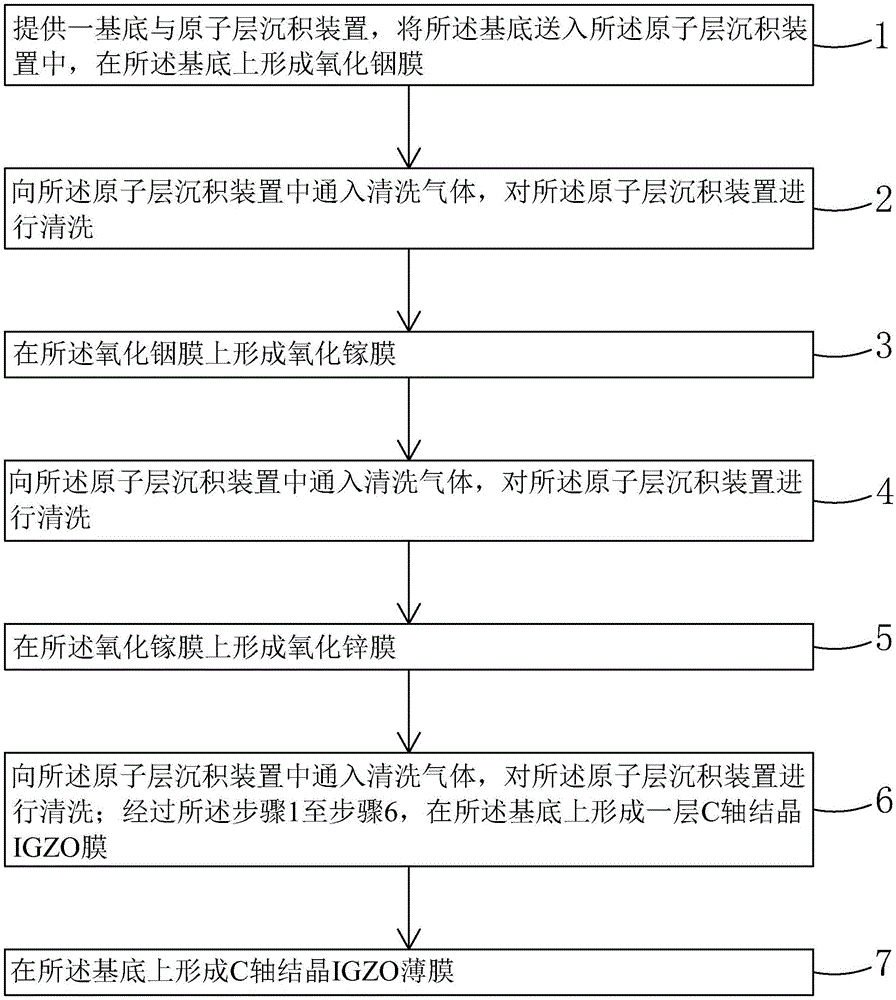

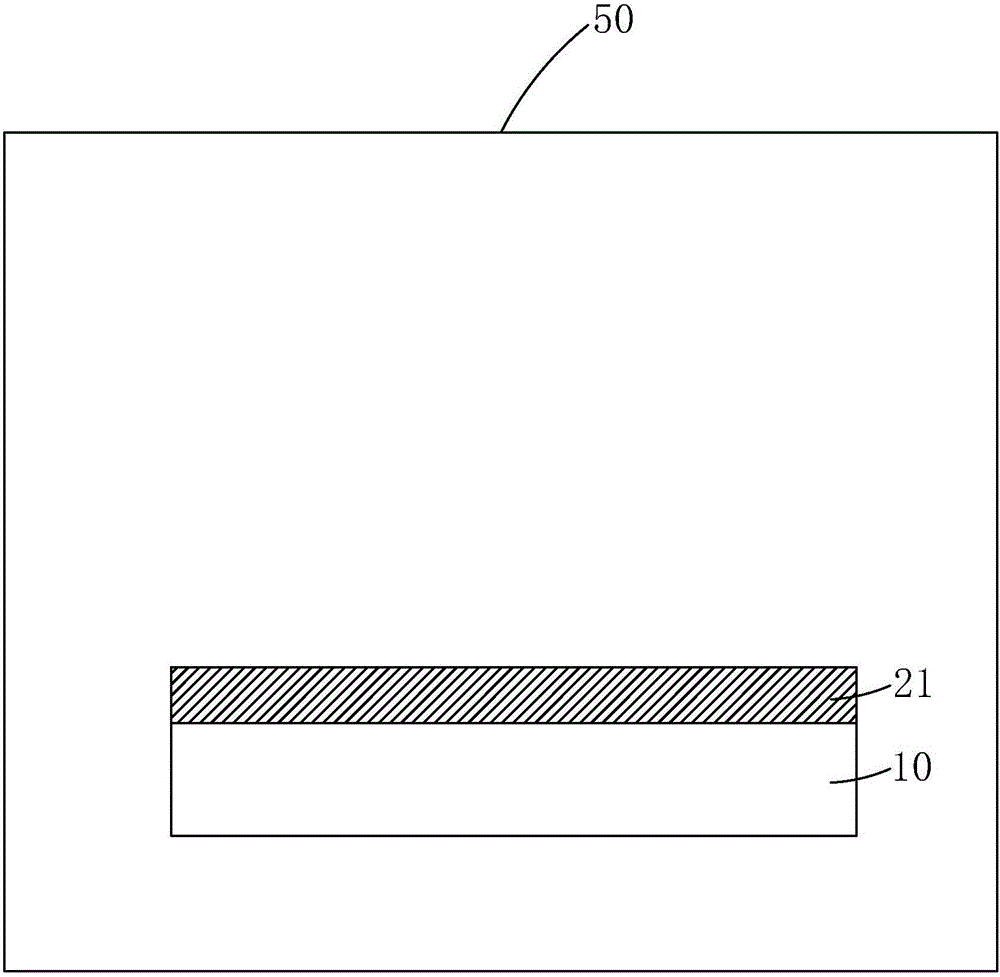

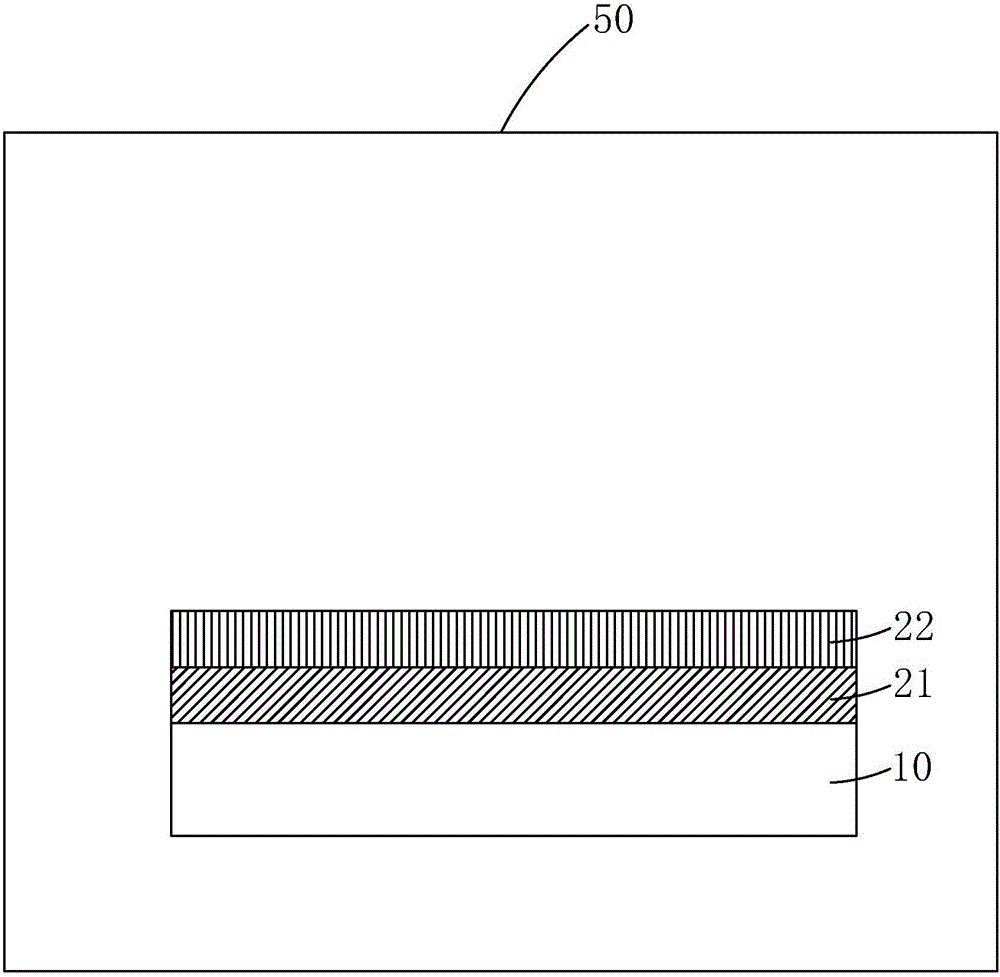

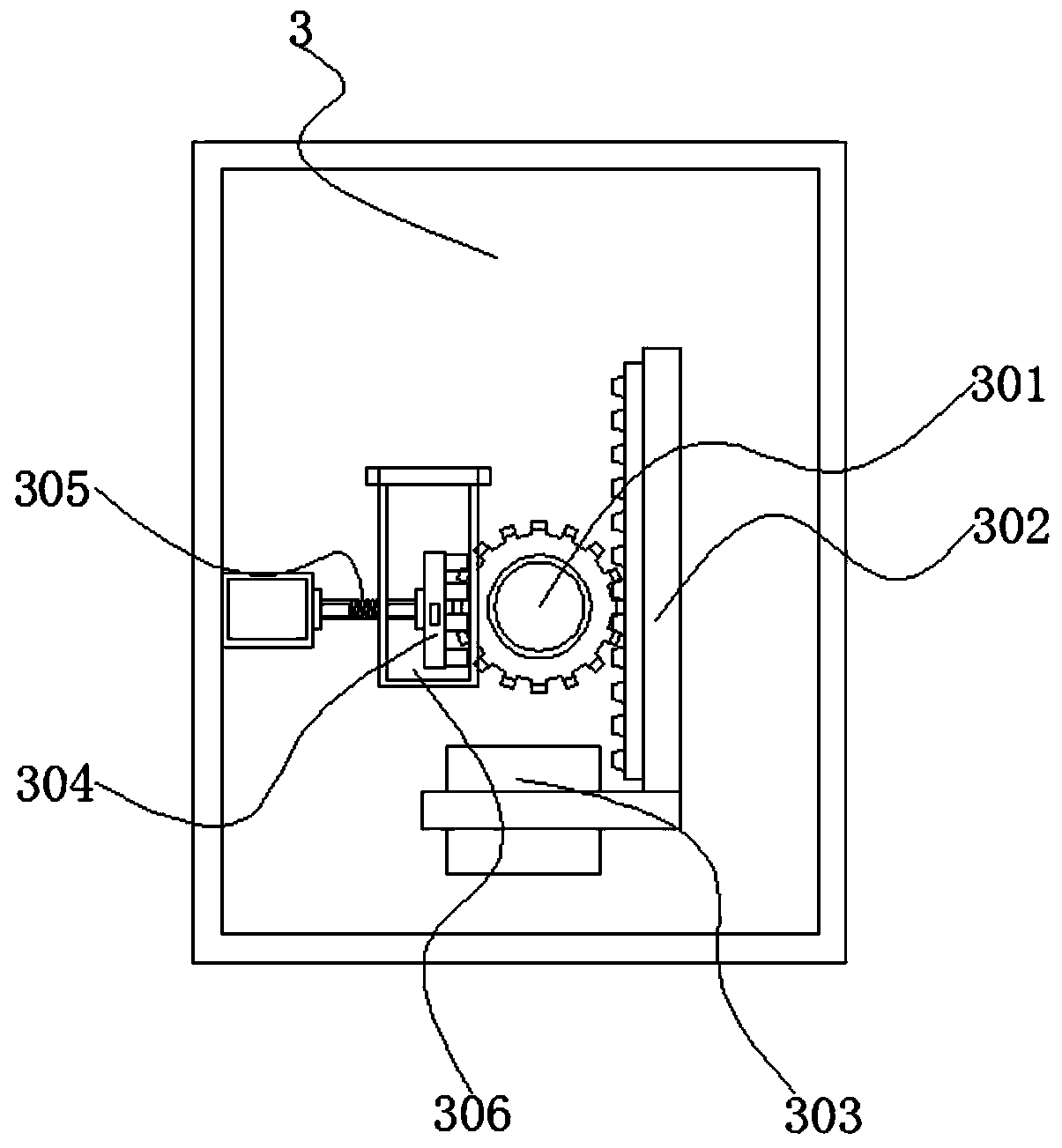

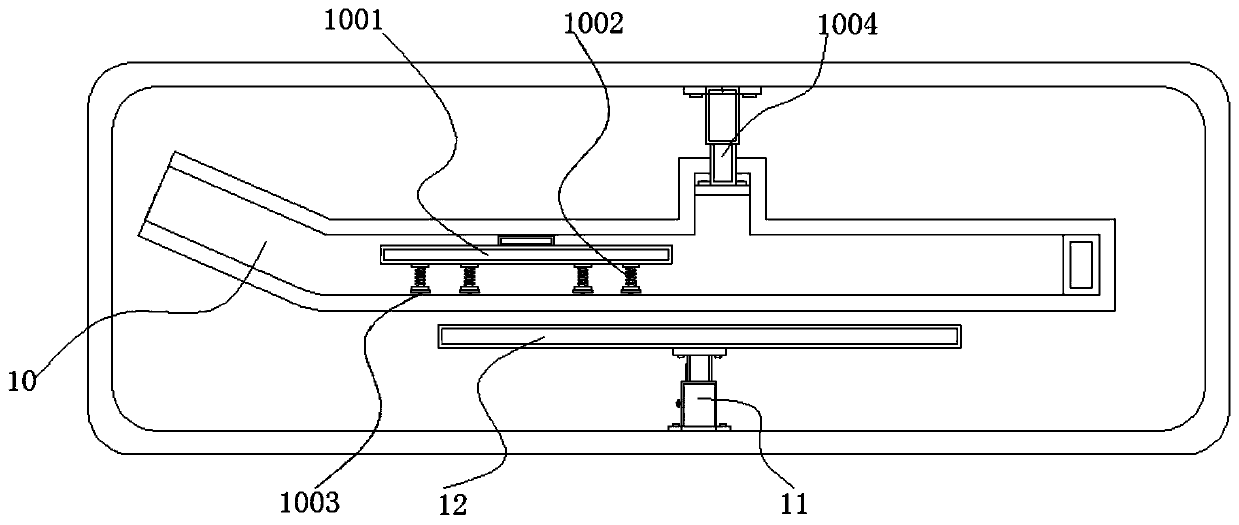

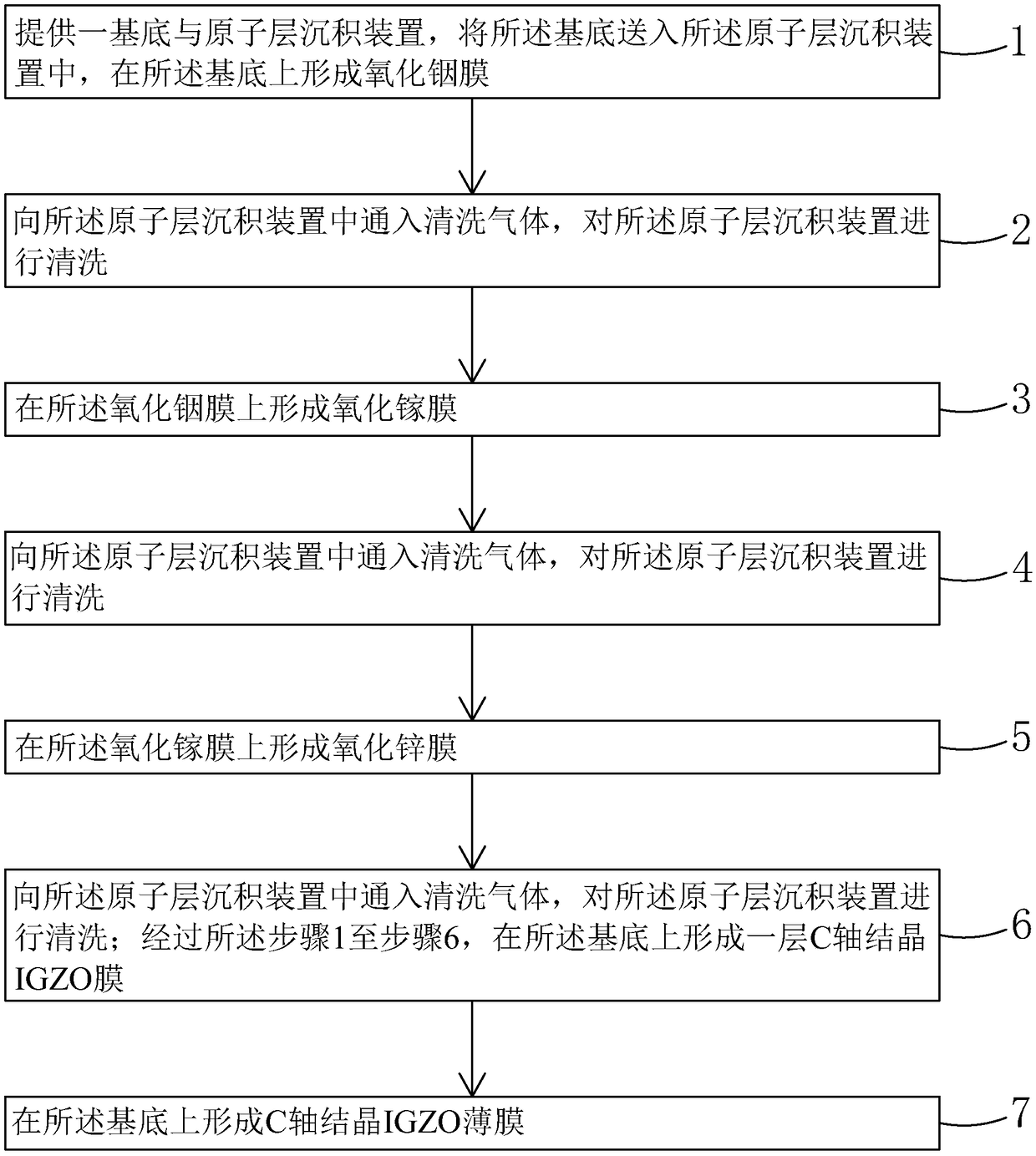

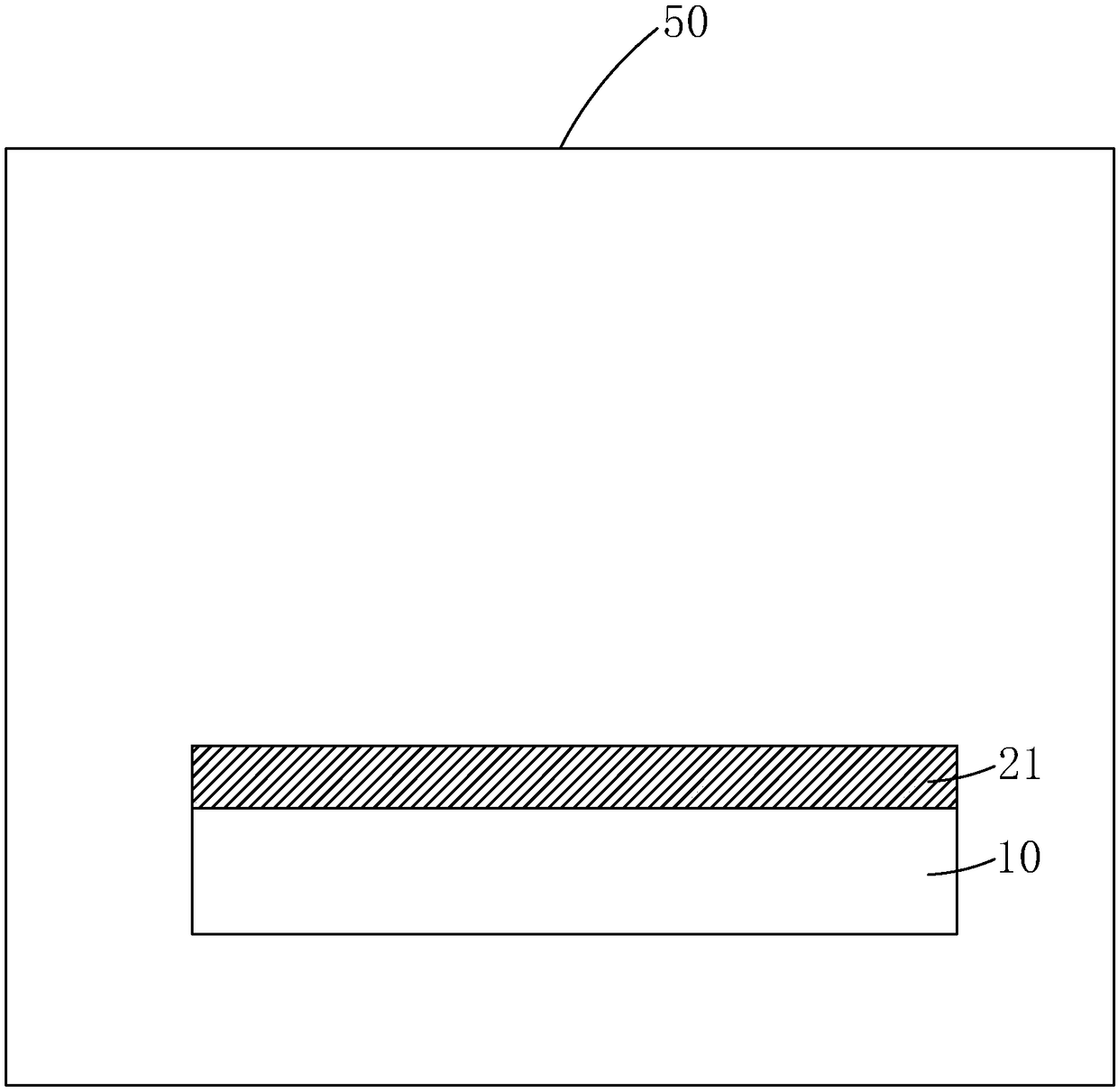

C-axis aligned crystalline IGZO thin film and preparation method thereof

ActiveCN106756877AImprove crystal qualityReduce oxygen deficiencySolid-state devicesSemiconductor/solid-state device manufacturingOxygen vacancyProcess conditions

The invention provides a C-axis aligned crystalline IGZO thin film and a preparation method of the C-axis aligned crystalline IGZO thin film. According to the preparation method of the C-axis aligned crystalline IGZO thin film, the C-axis aligned crystalline IGZO thin film is prepared through an atomic layer deposition method, the structure of C-axis aligned crystalline IGZO can be precisely controlled at the atomic level, the crystalline mass of the prepared C-axis aligned crystalline IGZO is good, the number of the oxygen vacancies is small, and the TFT stability can be improved; due to the fact that the area of a crystalline region in the prepared C-axis aligned crystalline IGZO thin film is larger, the hundred-micron level to the millimeter level is reached, and thus the large-scale application of the C-axis aligned crystalline IGZO can be promoted; and meanwhile the C-axis aligned crystalline IGZO thin film is prepared by the adoption of the optimum process condition, the production yield can be increased, and the production cost is lowered. According to the C-axis aligned crystalline IGZO thin film, the crystalline quality of the C-axis aligned crystalline IGZO is good, the number of the oxygen vacancies is small, the TFT stability can be improved, meanwhile the area of the crystalline region is larger, and thus the mass application of the C-axis aligned crystalline IGZO is facilitated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for synthesizing lithium battery cathode material through solvent-free solid-phase method

ActiveCN105206840AIncrease fluffinessReduce compactionCell electrodesSecondary cellsOxygen vacancySolvent free

The invention relates to a preparation method for synthesizing a lithium battery cathode material through a solvent-free solid-phase method. The method comprises the following steps that solid-state high-hydrocarbon fatty acid and / or solid-state high-hydrocarbon fatty acid salt and flake graphite are mixed evenly to obtain a multifunctional auxiliary; the multifunctional auxiliary and raw materials are added into mixing equipment together to prepare a precursor; high-temperature sintering is performed on the precursor after heat treatment is performed on the precursor, and then the lithium battery cathode material is obtained. According to the method, by adding the multifunctional auxiliary of which the main components comprise the solid-state high-hydrocarbon fatty acid and / or the solid-state high-hydrocarbon fatty acid salt in the mixing stage, the problem that diversified scattering of the raw materials is difficult is solved through the lubrication action of high-hydrocarbon fatty acid radicals, metal ions carried by the high-hydrocarbon fatty acid salt can also be evenly dispersed in the precursor in the mixing process to serve as a doping ion source in body doping, and the high-hydrocarbon fatty acid radicals can be decomposed at high temperature to generate gas, so that the fluffy degree of the precursor is increased and hardening is relieved; therefore, generation of oxygen vacancy is reduced in the sintering process, and the prepared lithium battery cathode material has the advantages of being few in defect, excellent in electrochemical performance and the like.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of lithium-rich manganese positive electrode material with controllable lithium content

ActiveCN110683584AEasy to controlHigh puritySecondary cellsPositive electrodesMetallic lithiumOrganic solvent

The invention discloses a preparation method of a lithium-rich manganese positive electrode material with a controllable lithium content. The method is characterized in that manganese dioxide, a conductive agent and a binder are mixed uniformly in N-methylpyrrolidone, coating is performed on an aluminum foil and oven-drying is performed, the coated aluminum foil is connected with a positive electrode of a discharge instrument as a positive electrode sheet, a negative electrode of the discharge instrument is connected with metal lithium, the positive electrode sheet and metal lithium are placedin the same container, an organic solvent that dissolves a lithium salt is added, and two precursors with a controllable lithium-manganese ratio are prepared by controlling the discharge capacity; and mixed sintering is performed to obtain the lithium-rich manganese positive electrode material, and the lithium-rich manganese positive electrode materials with different lithium contents can be obtained through controlling a mass ratio of the two precursors. The method can realize accurate control of a lithium-manganese ratio, is convenient for realizing large-scale production, can adjust a lithium content at any time according to customer needs, and has wide applicability.

Owner:SUZHOU PHYLION BATTERY

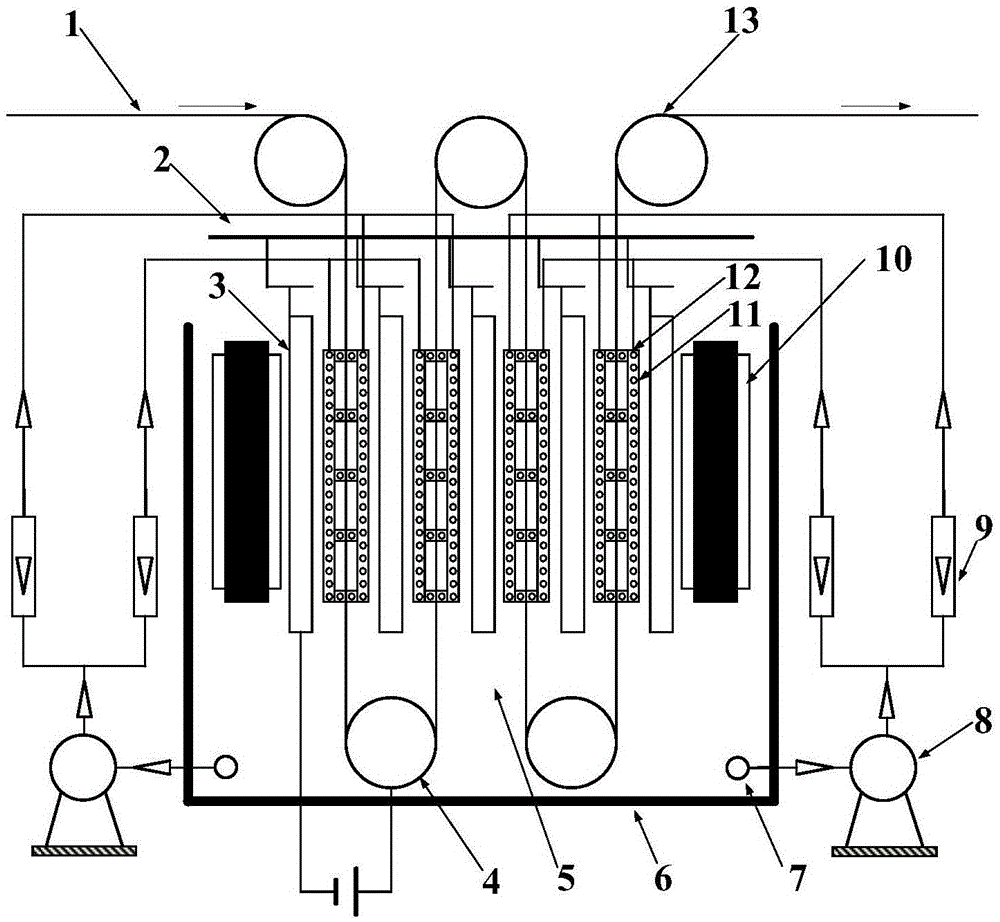

Anode aluminum foil forming device

InactiveCN105648515ATemperature controlControl concentrationCapacitor electrodesOxygen vacancySpecific volume

The invention discloses an anode aluminum foil forming device. The anode aluminum foil forming device comprises multiple electrode plates (3), inner circulation pipe networks (11) and a circulation pump (8) connected with the inner circulation pipe networks, wherein the electrode plates (3) and the inner circulation pipe networks (11) are arranged in a forming tank (6). The anode aluminum foil forming device further comprises direct-current electromagnets (10) arranged in the forming tank (6). The direct-current electromagnets (10) are soaked in forming liquid (5) in the forming tank. Multiple heat uniformization holes are evenly distributed in each electrode plate (3). The anode aluminum foil forming device has the beneficial effects that forming liquid circulating performance is good, electrical conductivity is high, interface tension is large, and the concentration and temperature of the forming liquid are uniform in distribution, so that the number of oxygen vacancies of forming films is small, the thickness of oxide films is uniform, the specific volume is large, bending performance is good, and the high-temperature service life is long.

Owner:YANGZHOU UNIV

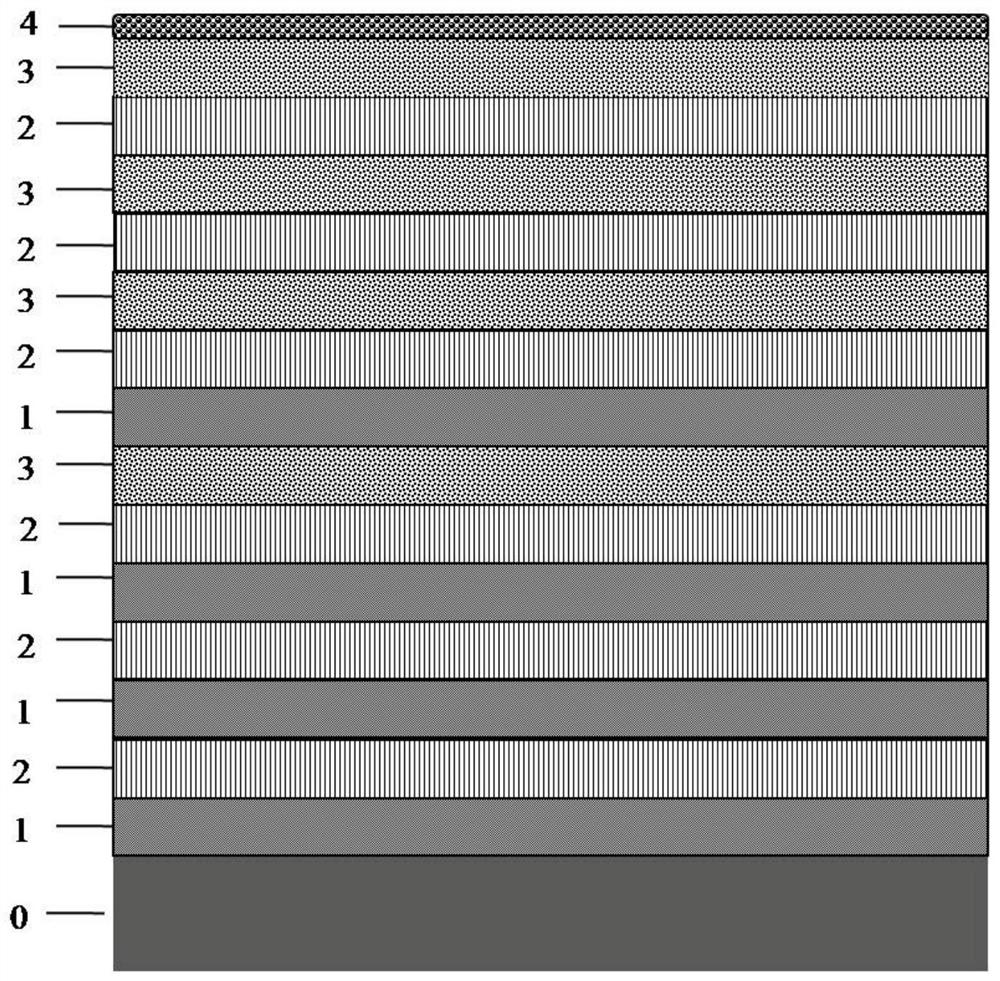

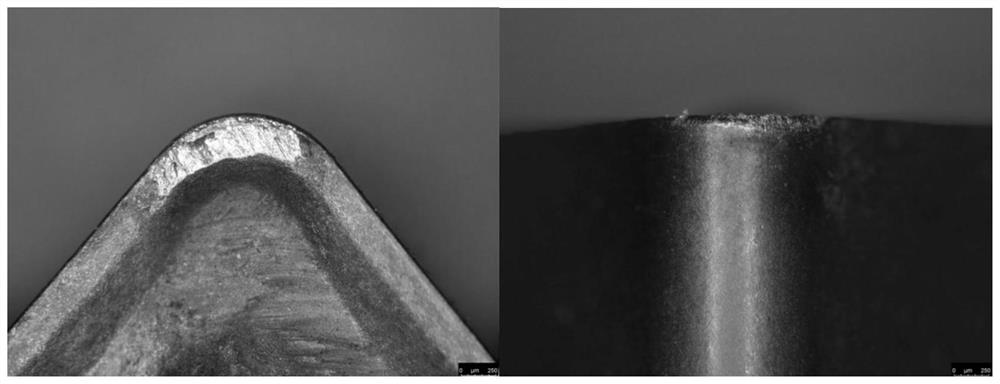

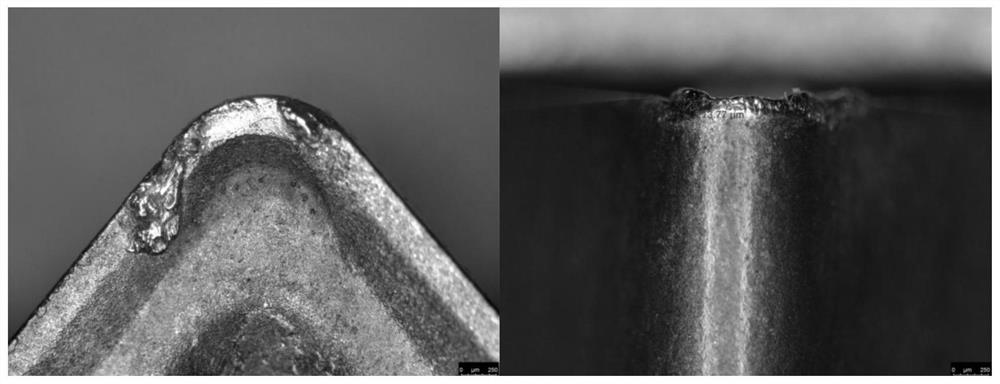

Coating with multilayer gradient structure, applied to cutting tool, and preparation method for same

ActiveCN110616402AImprove thermal stabilityReduce oxygen deficiencyVacuum evaporation coatingSputtering coatingOxidation resistantIon plating

The invention provides a coating with a multilayer gradient structure, applied to a cutting tool, and a preparation method for the same. The coating comprises an m (AlCrN / TiAlTaN) layer, an n (AlCrN / TiAlTaN / TiAlSiN) layer and a k (TiAlTaN / TiAlSiN) layer which are deposited in a periodical and alternative manner, wherein the coating thickness is 0.7-9 mum; m, n and k are modulation periods; 1<=m<=1500; 0<=n<=1000; and 0<=k<=1500. The method comprises the steps that contaminated substances on the surface of the cutting tool are removed, and the surface of the cutting tool is activated; the abovecoating layers are deposited successively in a periodical and alternative manner on a matrix of the cutting tool through a cathode arc ion plating technology; and through furnace cooling, the coatingwith the multilayer gradient structure, which is applied to the cutting tool, can be obtained. The coating with the multilayer gradient structure has the beneficial effects that a contradiction of atraditional hard coating which cannot have wear resistance and toughness at the same time can be overcome; and the coating manifests high oxidation resistance and high-temperature stability.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

Method for preparing spinel lithium manganate serving as cathode material of lithium ion power battery

InactiveCN102306767BThe crystal structure has good cycle stabilityImprove high temperature cycle performanceCell electrodesSource materialManganate

The invention relates to a method for preparing spinel lithium manganate serving as a cathode material of a lithium ion power battery. The method comprises the following steps of: 1) selecting raw materials, namely mixing manganese oxide, a lithium source material and doped metal element oxide; and 2) uniformly mixing the mixture obtained in the step 1), feeding into a continuous sintering furnace, performing high-temperature gradient sintering (namely sintering at the temperature of between 1,000 and 1,200 DEG C for 3 to 5 hours in the first sintering step, sintering at the temperature of between 800 and 900 DEG C for 4 to 6 hours in the second step and sintering at the temperature of between 500 and 700 DEG C for 5 to 8 hours in the third step), introducing compressed air simultaneously, naturally cooling after the sintering is finished, grinding, performing grading treatment, and thus obtaining the cathode material. The invention has the advantages that: the method has a simple process; the crystallinity and the surface state of lithium manganate are controlled through the high-temperature sintering, so that the dissolving rate of manganese is reduced; and then oxygen defects are controlled or overcome through low-temperature sintering.

Owner:WUHAN UNIV OF TECH

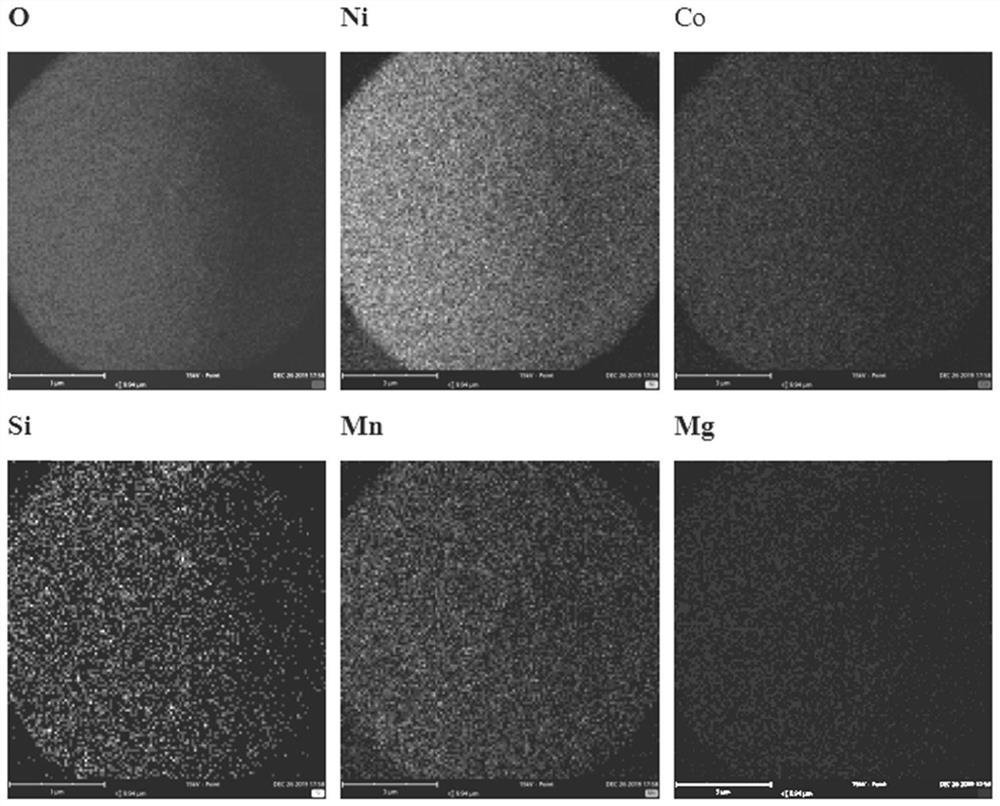

Composite coated ternary precursor as well as preparation method and application thereof

PendingCN114242970AFavorable for attachment growthImprove stabilityPositive electrodesImpregnation manufacturingElectrolytic agentPhysical chemistry

The invention discloses a composite coated ternary precursor and a preparation method and application thereof, the material comprises a ternary precursor and a coating layer attached to the surface of the ternary precursor, and the coating layer is obtained by precipitation reaction of first metal ions and first polyanions; metal ions and polyanions can be subjected to precipitation reaction to form precipitates, the surface of the ternary precursor has a large number of active sites and high specific surface energy, and the precipitates are easy to adhere and grow, so that a uniformly distributed coating layer is formed on the surface of the ternary precursor. After the coated precursor is sintered into the positive electrode material, one part of the coating can form a protective layer on the surface of the material, so that the dissolution of Ni and Co is reduced, the side reaction of the positive electrode material and electrolyte is inhibited, and the irreversible phase change of the surface of the material is reduced, thereby improving the stability of the ternary material; and the other part of the coating can permeate into the material to form bulk phase doping.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Lithium ion battery positive electrode material and preparation method thereof

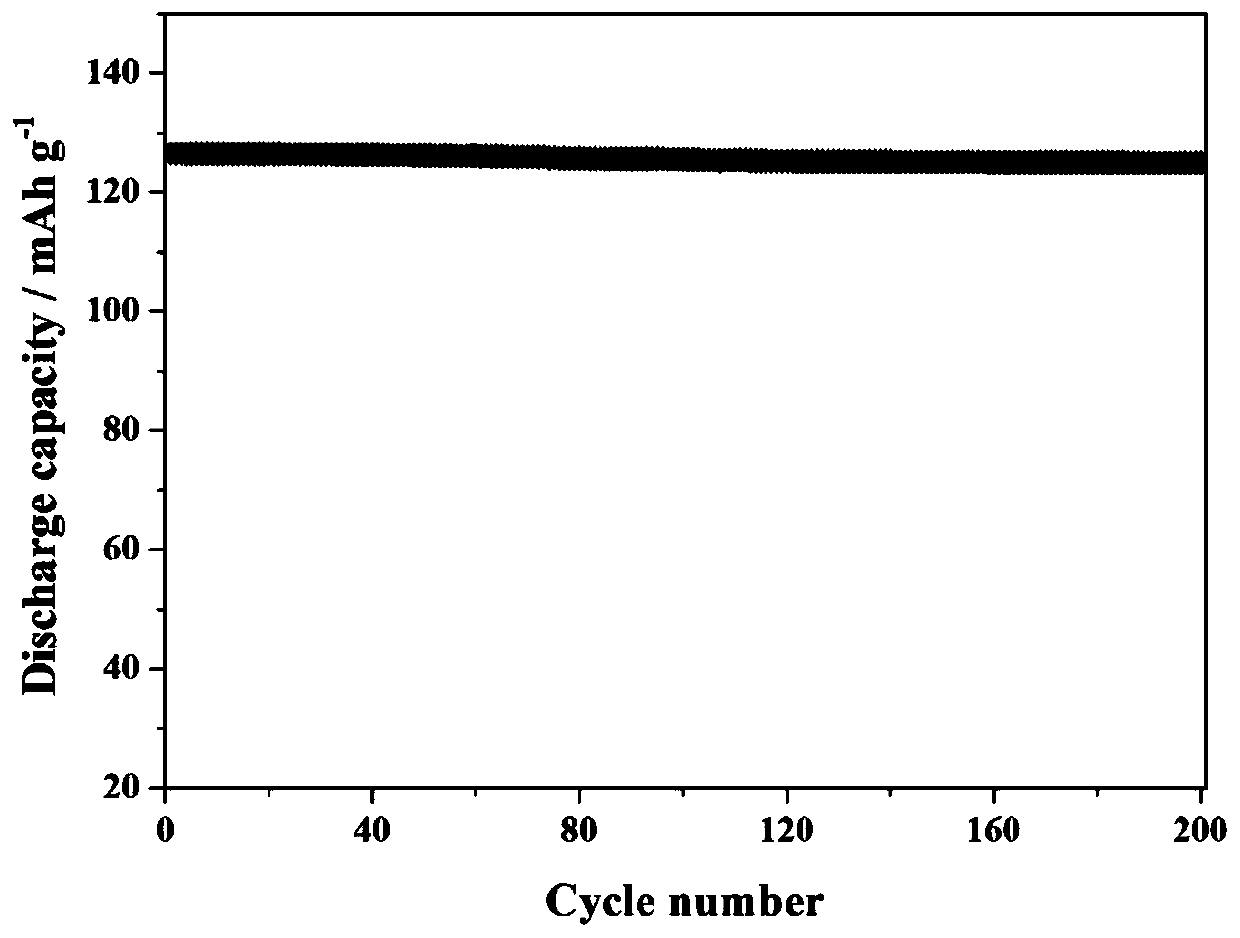

ActiveCN110061234AReduce oxygen deficiencyImprove structural stabilityCell electrodesSecondary cellsCarbon nanotubeLithium electrode

The invention provides a lithium ion battery positive electrode material and a preparation method thereof, and belongs to the field of positive electrode materials. The lithium ion battery positive electrode material provided by the invention is of a core-shell structure and consists of a core and a coating layer, wherein the core comprises a doped modified lithium manganate and a carbon nano tube, and the carbon nano tube is in three-dimensional contact and solid-junction doping with modified lithium manganate to form a micron-scale spherical material; and the coating layer comprises a double-phase flexible polymer. The lithium ion battery positive electrode material provided by the invention has excellent cycling stability and high rate performance, and after 200 cycles, the capacity retention rate can be up to 98.9%; and in addition, the positive electrode material of the lithium ion battery still has a large discharge specific capacity at a high rate, and when the charging rate isincreased from 0.5C to 30 C, the retention rate of the first-time discharge specific capacity is 84.5%.

Owner:HENAN INST OF SCI & TECH

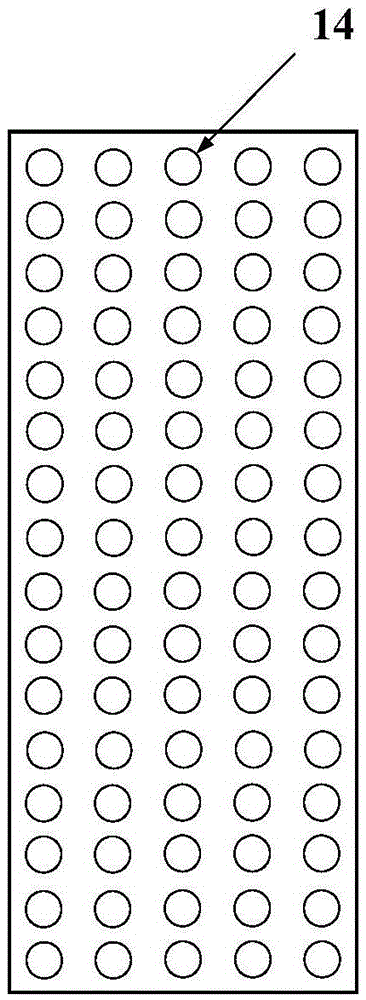

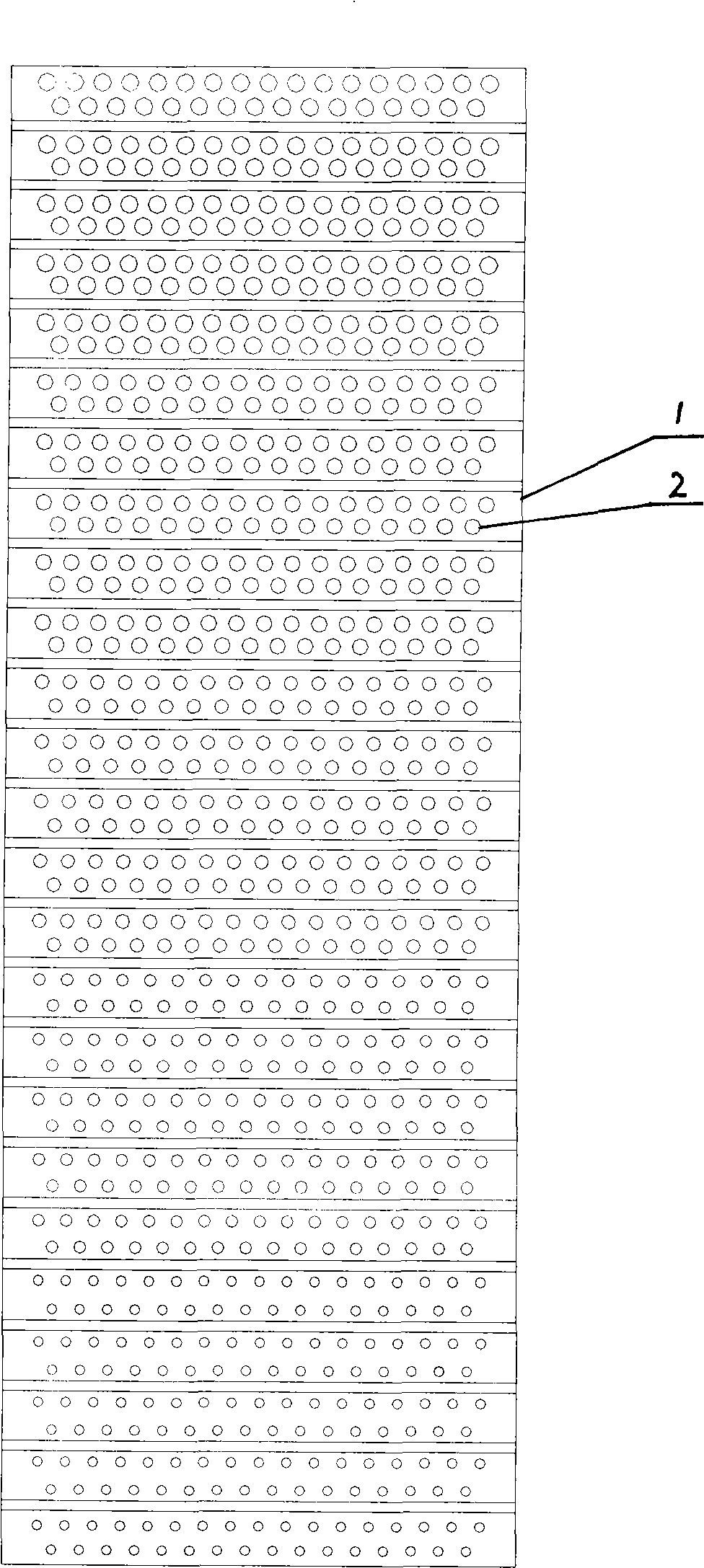

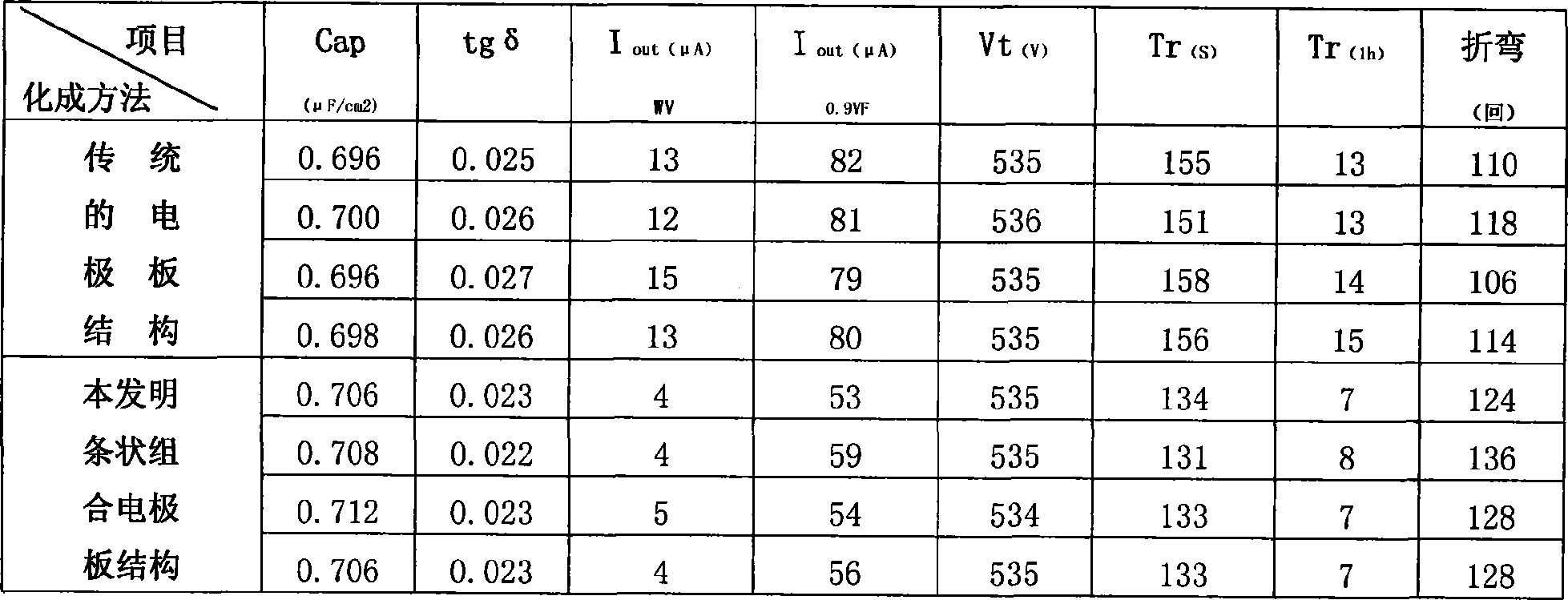

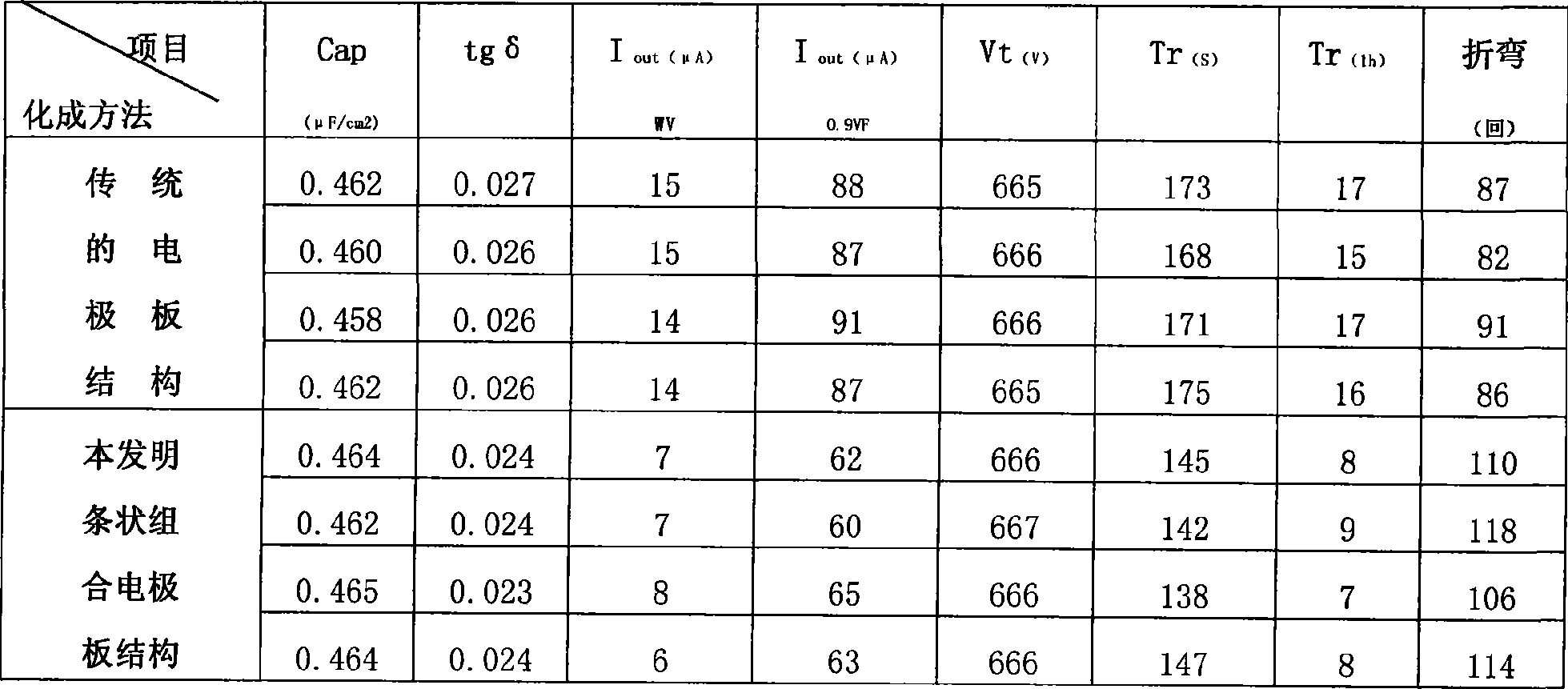

Bar-shaped combination electrode in aluminum foil formation energy-endowing groove and preparation method thereof

ActiveCN101532158APlay the role of diversionUniform temperatureAnodisationCapacitor dielectric layersElectrolytic agentAluminum foil

The invention discloses a bar-shaped combination electrode in aluminum foil formation energy-endowing groove and preparation method thereof. The bar-shaped combination electrode is characterized in that plate electrodes of 1500*520mm in the energy-endowing groove are separated to more than two bar-shaped electrode plates of 50*120mm with distance of 10mm, two ends of the each two bar-shaped electrode plate are welded on stainless steel material like ladder, and holes with different specifications are arranged on the bar-shaped electrode plates according to distribution rule of current density on the aluminum foil. The invention has advantages that the bar-shaped combination electrode not only can shunt, but also can make electrolyte between and round the electrodes fully cycle and temperature and concentration uniform, so that current density on the aluminum foil is reasonably distributed, and temperature and concentration of the electrolyte is easily to control in process range, thereby improving oxide film structure, increasing density, reducing oxygen omission in the film, and increasing performances of the aluminum foil.

Owner:新疆广投桂东电子科技有限公司

Composite sintering aid for producing aluminum nitride ceramic substrate

InactiveCN106631046AHigh thermal conductivityReduce oxygen contentAlkaline earth metalRare earth metal compounds

The invention relates to a composite sintering aid for producing an aluminum nitride ceramic substrate. The composite sintering aid is prepared from an alkali metal compound, an alkaline-earth metal compound and a rare-earth metal compound, and the molar ratio of the alkali metal compound to the alkaline-earth metal compound to the rare-earth metal compound is equal to 250 to (80-86) to 1000, wherein the alkali metal compound is Li2O, the alkaline-earth metal compound is a mixture of MgO and CaO, and the rare-earth metal compound is YF3. The composite sintering aid has the advantages that the YF3 is selected to be used as the rare-earth metal compound, and the mixture of the MgO and the CaO is selected to be used as the alkaline-earth metal compound, so that the composite sintering aid can greatly improve the heat conduction efficiency, and further promotes the densification of aluminum nitride ceramics.

Owner:莱鼎电子材料科技有限公司

MgGa2O4 ultraviolet detector and preparation method thereof

PendingCN111816720AImprove crystal qualityReduce dark currentFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsThin membrane

The invention provides an MgGa2O4 ultraviolet detector and a preparation method thereof. The method comprises steps S1, taking an organic magnesium compound as a magnesium source, an organic gallium compound as a gallium source, taking high-purity oxygen as an oxygen source, and growing an MgGa2O4 film on a surface of a substrate through employing a metal organic compound chemical vapor depositionmethod; S2, forming an interdigital electrode mask on the MgGa2O4 film by using negative photoresist photoetching, and removing the interdigital electrode mask after metal sputtering of the interdigital electrode mask to form an interdigital electrode; and S3, pressing In particles on the interdigital electrode to obtain the MgGa2O4 ultraviolet detector with the MSM structure. Compared with the prior art, the MgGa2O4 film is prepared by using a metal organic compound chemical vapor deposition method, by increasing the oxygen flow, increasing the oxygen partial pressure and reducing the oxygendefect, the prepared MgGa2O4 film has characteristics of high crystallization quality, no phase splitting, steep absorption cut-off edge and the like, so the ultraviolet detector containing the MgGa2O4 film has lower dark current and higher photoresponse speed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

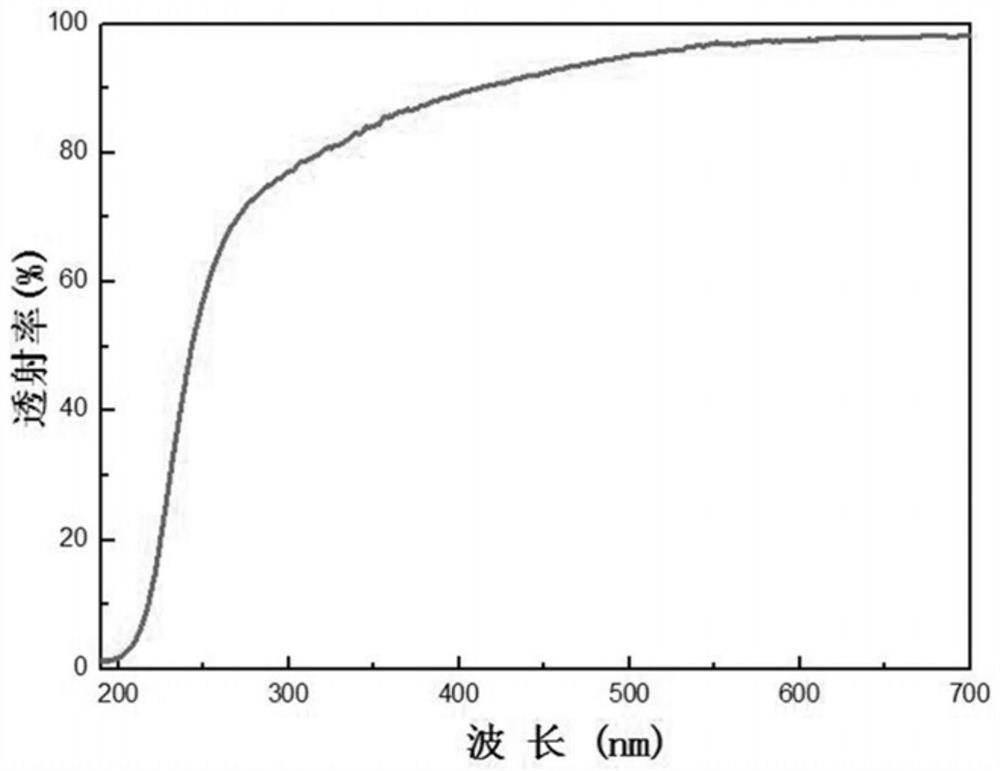

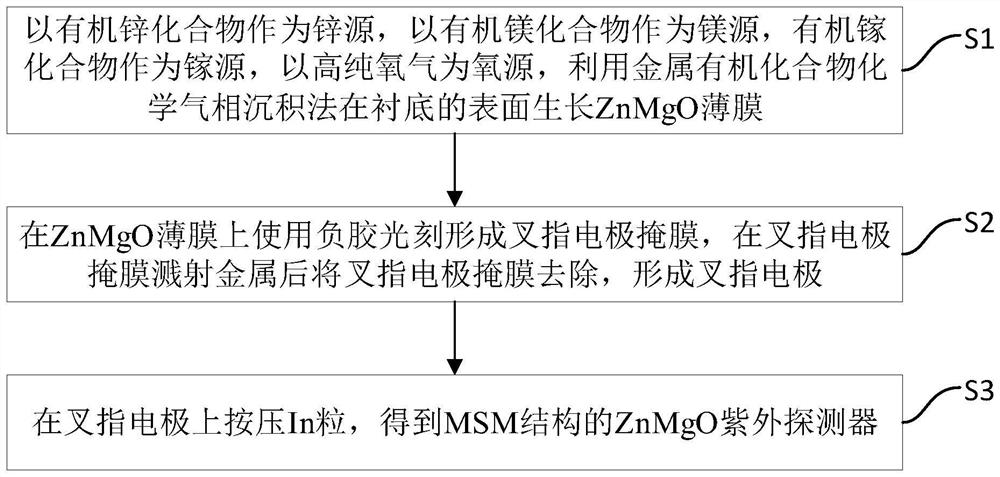

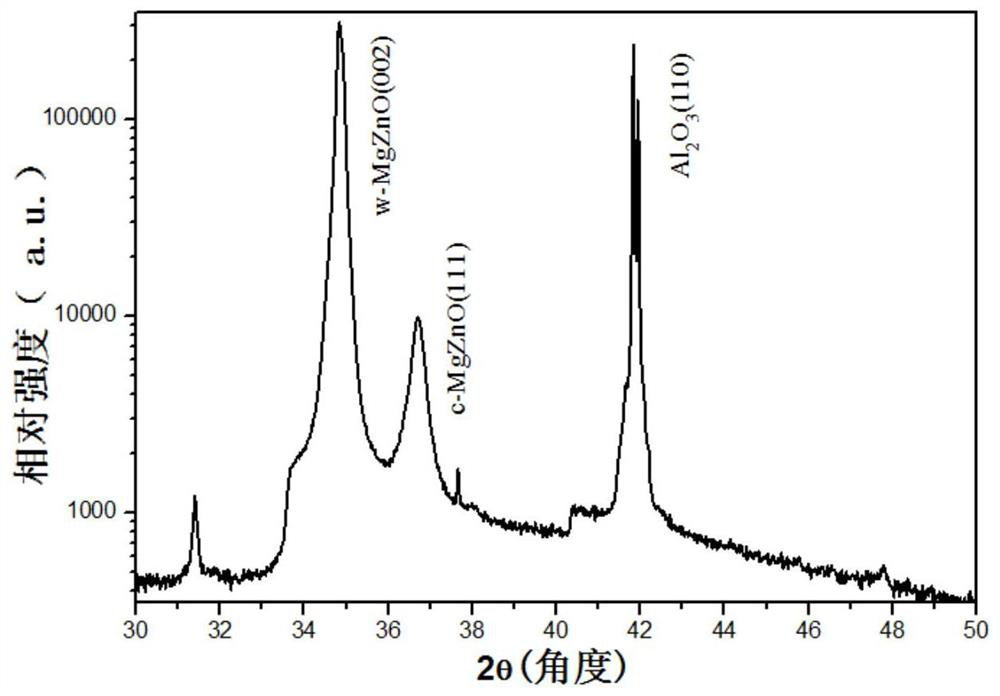

ZnMgO ultraviolet detector and preparation method thereof

InactiveCN111785793AImprove crystal qualityAbsorption cut-off is steepFinal product manufactureSemiconductor/solid-state device manufacturingOrganozinc compoundZinc compounds

The invention provides a ZnMgO ultraviolet detector and a preparation method thereof, and the method comprises the steps: S1, taking an organic zinc compound as a zinc source, taking an organic magnesium compound as a magnesium source, taking high-purity oxygen as an oxygen source, and growing a ZnMgO film on the surface of a substrate by adopting a metal organic compound chemical vapor depositionmethod; S2, forming an interdigital electrode mask on the ZnMgO film by using negative photoresist photoetching, and removing the interdigital electrode mask after sputtering metal on the interdigital electrode mask to form an interdigital electrode; and S3, pressing In particles on the interdigital electrode to obtain the ZnMgO ultraviolet detector with the MSM structure. Compared with the priorart, the oxygen flow is increased, the oxygen partial pressure is increased, and oxygen defects are reduced; the prepared ZnMgO film has the characteristics of high crystallization quality, no phasesplitting, steep absorption cut-off edge and the like, and the ZnMgO film 2 with the mixed-phase structure can simultaneously meet high responsivity and low dark current, so that the ZnMgO ultravioletphotoelectric detector has lower dark current and higher photoresponse speed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Solid waste treatment device with filtering structure and easy to maintain

The invention relates to a solid waste treatment device with a filtering structure and easy to maintain. The solid waste treatment device comprises a main body, a drive motor and a cover plate. A separation cylinder is fixed on the inner wall of the main body. A fixing frame is connected to the bottom of the separation cylinder. The separation cylinder is connected with the fixing frame through screws. The drive motor is mounted on the inner side of the fixing frame. The fixing frame is movably connected with the drive motor. The cover plate is arranged at the bottom of the drive motor. Corrugated tubes penetrate the outer side of the cover plate. The cover plate is connected with the drive motor through screws. The cover plate is fixedly connected with the corrugated tubes. An incineratorbarrel is arranged below the cover plate. The solid waste treatment device has the beneficial effects that the solid waste treatment device with the filtering structure and easy to maintain is provided with a filtering box, the filtering box can filter harmful gas generated during the operation of the device, so that environmental pollution caused by direct discharge is avoided, and the safety ofthe operation of the device is improved.

Owner:毛渊

C-axis crystal igzo thin film and preparation method thereof

ActiveCN106756877BImprove crystal qualityReduce oxygen deficiencySolid-state devicesSemiconductor/solid-state device manufacturingOxygenProcess conditions

The invention provides a C-axis crystalline IGZO thin film and a preparation method thereof. The preparation method of the C-axis crystalline IGZO thin film of the present invention prepares the C-axis crystalline IGZO thin film by adopting the method of atomic layer deposition, which can precisely control the structure of the C-axis crystalline IGZO at the atomic level, and the crystallization of the obtained C-axis crystalline IGZO Good quality, less oxygen defects, can improve the stability of TFT; and because the area of the crystalline region in the C-axis crystalline IGZO film prepared by the present invention is relatively large, reaching hundreds of microns to millimeters, it can promote C-axis crystallization Large-scale application of IGZO; at the same time, the present invention utilizes optimized process conditions to prepare C-axis crystalline IGZO thin films, which can improve production yield and reduce production costs. The C-axis crystalline IGZO thin film of the present invention has good crystallization quality of the C-axis crystalline IGZO, less oxygen defects, can improve the stability of TFT, and meanwhile has a larger crystallization area, which is beneficial to the large-scale application of the C-axis crystalline IGZO.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Multi-layer gradient structure coating for cutting tool and preparation method thereof

ActiveCN110616402BImprove antioxidant capacityImprove bindingVacuum evaporation coatingSputtering coatingOxidation resistantWear resistance

The invention provides a multilayer gradient structure coating for a cutting tool and a preparation method thereof. The coating comprises m(AlCrN / TiAlTaN) layers, n(AlCrN / TiAlTaN / TiAlSiN) layers and k(AlCrN / TiAlTaN / TiAlSiN) layers and k( TiAlTaN / TiAlSiN) layer, the thickness of the coating is 0.7-9 μm; wherein, m, n, k are modulation periods, 1≤m≤1500; 0≤n≤1000; 0≤k≤1500. The method includes: removing dirt on the surface of the cutting tool, and activating the surface of the cutting tool; using cathode arc ion plating technology to periodically and alternately deposit the above-mentioned coatings on the cutting tool substrate; Floor. The above-mentioned multi-layer gradient structure coating overcomes the contradiction that the traditional hard coating cannot have both wear resistance and toughness, and at the same time exhibits excellent oxidation resistance and high temperature stability.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

Method for preparing anode material for lithium ion battery

InactiveCN101409346BIncrease capacityImprove cycle stabilityElectrode manufacturing processesNickel compoundsLithium oxideChemical physics

Owner:PANASONIC CORP +1

A solid waste treatment device with filter structure for easy maintenance

ActiveCN110094740BAvoid harmEasy to fixIncinerator apparatusElectric machineEnvironmental engineering

The invention relates to a solid waste treatment device with a filtering structure for easy maintenance, comprising a main body, a driving motor and a cover plate, a separation cylinder is fixed on the inner wall of the main body, and a fixing frame is connected to the bottom of the separation cylinder, and the separation cylinder is connected to the bottom of the separation cylinder The fixed frames are connected by screws, the driving motor is installed on the inside of the fixed frame, and the fixed frame and the driving motor are connected flexibly. There is a screw connection between the cover plate and the drive motor, and a fixed connection between the cover plate and the bellows, and an incineration bucket is installed under the cover plate. The beneficial effects of the present invention are: the solid waste treatment device with a filter structure for easy maintenance is provided with a filter box, which can filter the harmful gas generated during the operation of the device, avoiding environmental pollution caused by direct discharge, thereby improving Safety of device operation.

Owner:毛渊

A kind of method that solvent-free solid-phase method synthesizes lithium battery anode material

ActiveCN105206840BIncrease fluffinessReduce compactionCell electrodesSecondary cellsOxygen vacancySolvent free

The invention relates to a preparation method for synthesizing a lithium battery cathode material through a solvent-free solid-phase method. The method comprises the following steps that solid-state high-hydrocarbon fatty acid and / or solid-state high-hydrocarbon fatty acid salt and flake graphite are mixed evenly to obtain a multifunctional auxiliary; the multifunctional auxiliary and raw materials are added into mixing equipment together to prepare a precursor; high-temperature sintering is performed on the precursor after heat treatment is performed on the precursor, and then the lithium battery cathode material is obtained. According to the method, by adding the multifunctional auxiliary of which the main components comprise the solid-state high-hydrocarbon fatty acid and / or the solid-state high-hydrocarbon fatty acid salt in the mixing stage, the problem that diversified scattering of the raw materials is difficult is solved through the lubrication action of high-hydrocarbon fatty acid radicals, metal ions carried by the high-hydrocarbon fatty acid salt can also be evenly dispersed in the precursor in the mixing process to serve as a doping ion source in body doping, and the high-hydrocarbon fatty acid radicals can be decomposed at high temperature to generate gas, so that the fluffy degree of the precursor is increased and hardening is relieved; therefore, generation of oxygen vacancy is reduced in the sintering process, and the prepared lithium battery cathode material has the advantages of being few in defect, excellent in electrochemical performance and the like.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Cold core shouldering micropulling proparation method of large size sapphire single crystal

ActiveCN1323195CSmall sizeLow costPolycrystalline material growthBy pulling from meltSingle crystal growthHigh-temperature corrosion

The invention relates to sapphire single crystal growth method. The feature is that: the temperature of cooling water output is stabilized at 15-35 degree centigrade and during the whole technology process the vacuum pressure is less than 6*0.001Pa. Using tungsten heating body and crucible, tungsten molybdenum separating shield and high temperature component, the sapphire crystal is made in the single crystal furnace. In the crystal seeding process, it includes slowly adjusting the seed crystal to make the bottom above the melt liquid surface 5-20mm, preheating and removing thermal stress; using the classic crystal pulling method technology, after 5-15 times crystal seeding along the cold core departure direction to transferring the crystallizing center to cold core, cooperating rotating controlling and the rotating speed is 2-16 round per minute.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com