C-axis crystal igzo thin film and preparation method thereof

A thin film and indium oxide film technology, which is applied in semiconductor/solid-state device manufacturing, coating, gaseous chemical plating, etc., can solve the problems of unfavorable large-scale application of C-axis crystal IGZO, so as to promote large-scale application and reduce production costs , the effect of good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

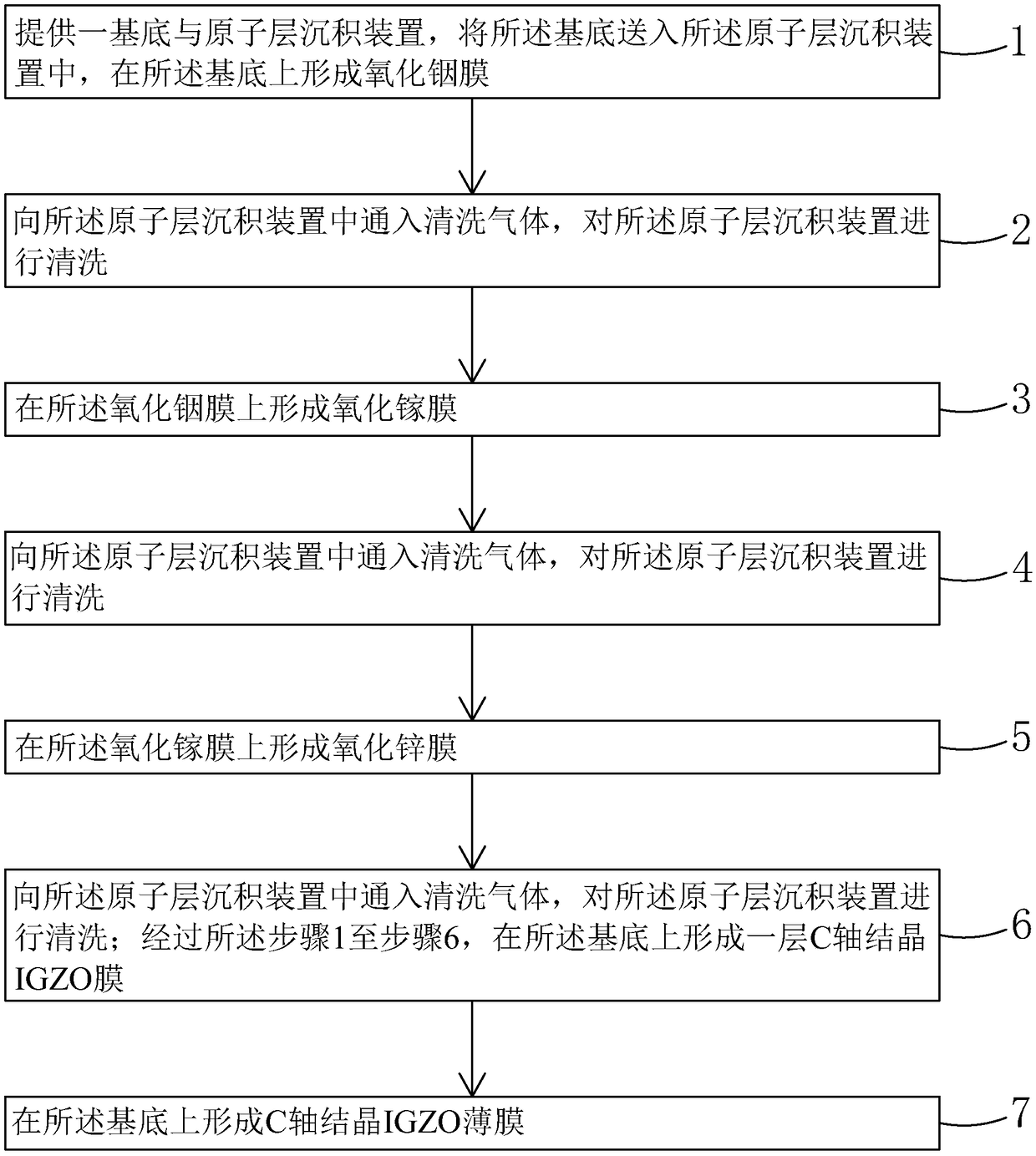

Method used

Image

Examples

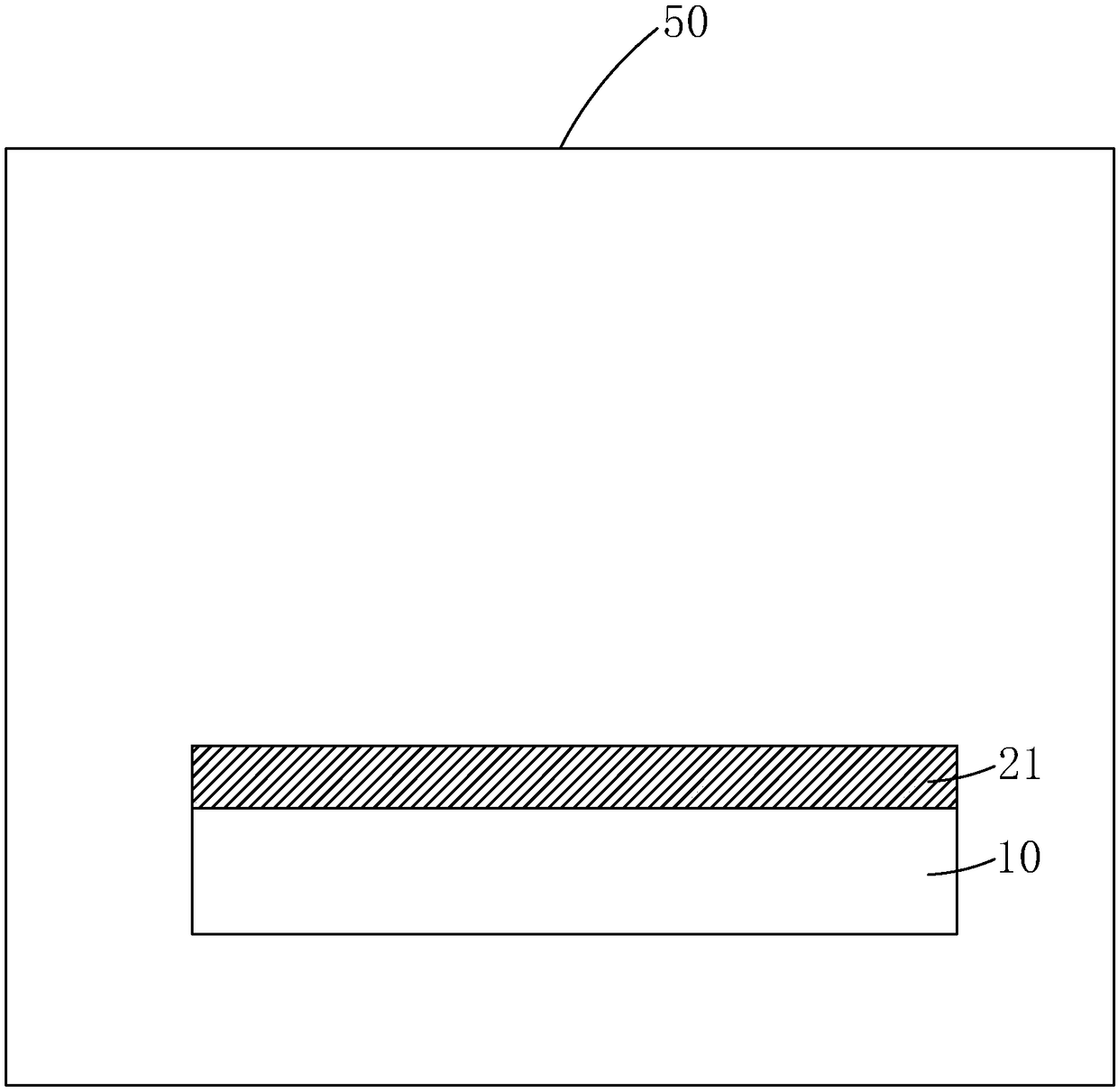

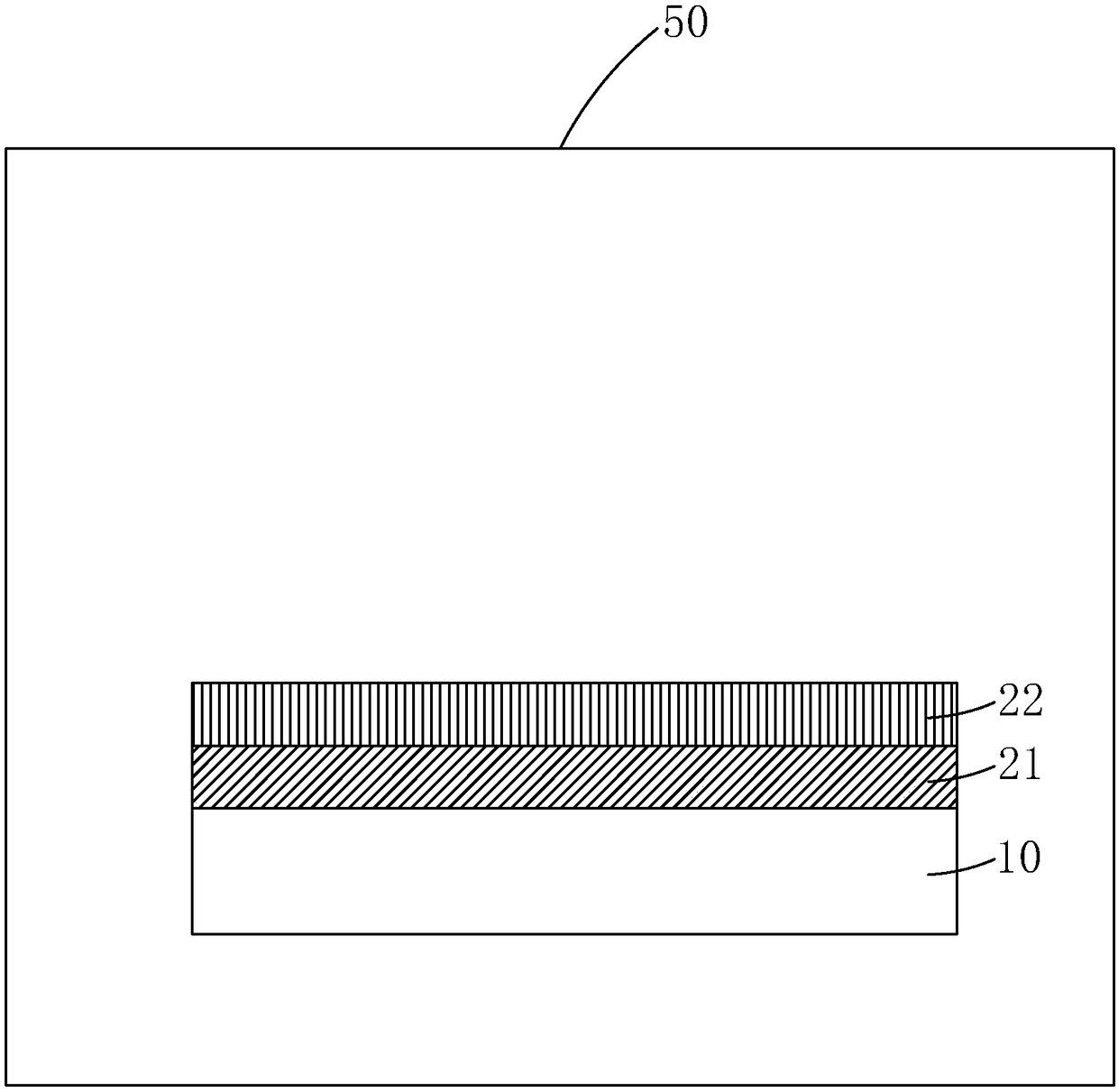

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0037] Atomic layer deposition (Atomic Layer Deposition, ALD) is a method of forming a deposited film by pulsating gaseous precursors alternately into the reactor to chemically adsorb and react on the deposition substrate. When the precursors reach the surface of the deposition substrate, they chemisorb and undergo surface reactions on the surface. The ALD reactor needs to be purged with an inert gas between precursor pulses. It can be seen that whether the precursor substances of the deposition reaction can be chemically adsorbed on the surface of the deposited material is the key to the realization of atomic layer deposition. The adsorption characteristics of gaseous substances on the surface of the matrix material can be seen that any gase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com