Method for preparing spinel lithium manganate serving as cathode material of lithium ion power battery

A technology of spinel lithium manganese oxide and power battery, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle stability of lithium manganate materials, and achieve good cycle stability of crystal structure, low manganese dissolution, The effect of small oxygen deficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 10.4 kg of Li 2 CO 3 , with 44 kg of electrolytic MnO 2 and 3 kg Al 2 o 3 Add it into the mixing container and mix evenly, then send it into the high-temperature sintering furnace, firstly heat up to 1050°C for sintering for 4 hours, then slowly cool down to 900°C for sintering for 4 hours, then slowly cool down to 600°C for 6 hours, and at the same time pass into Compressed air, naturally cooled to room temperature after sintering, crushed and classified to obtain spinel lithium manganate material.

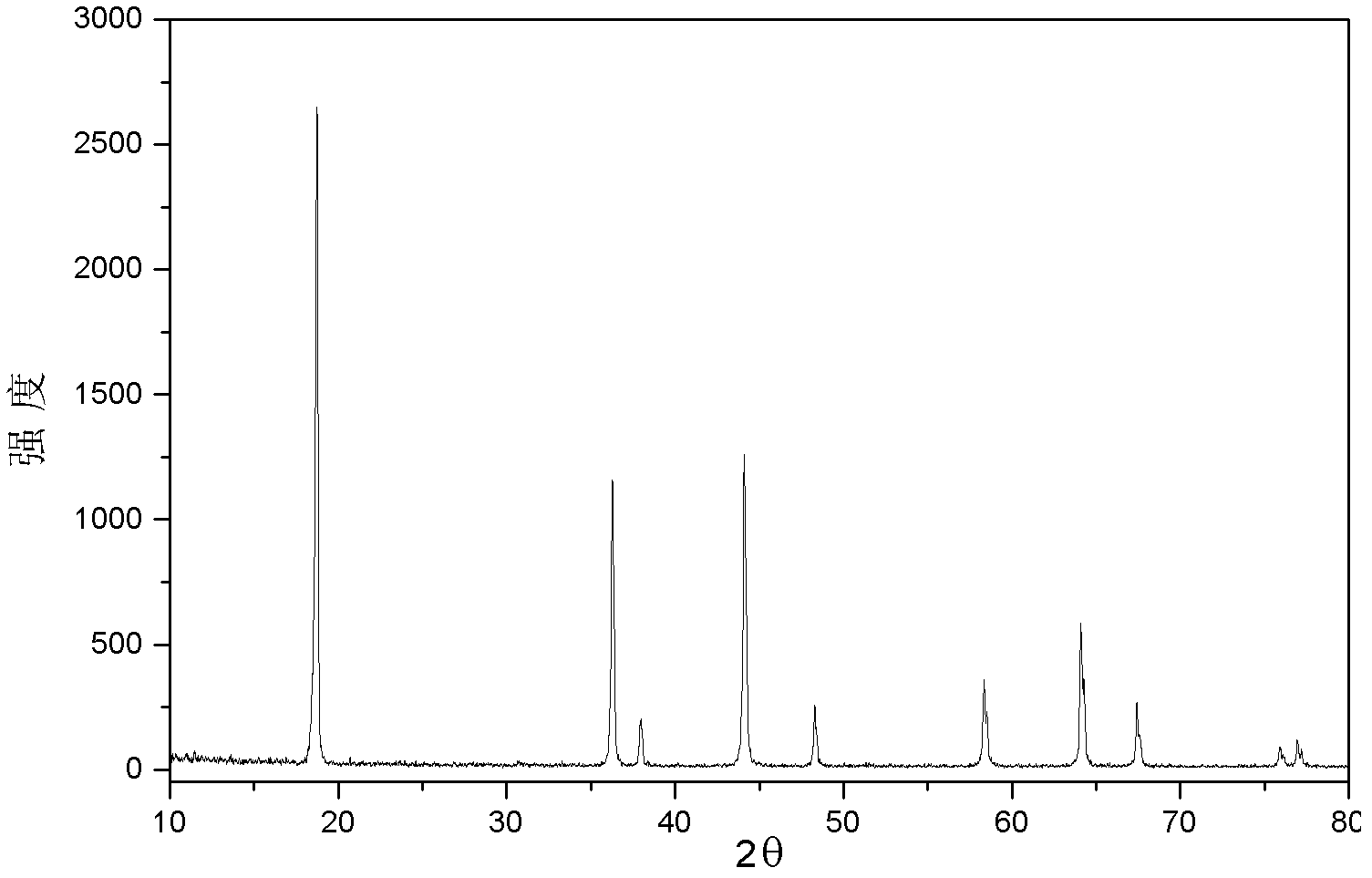

[0020] The spinel structure of the synthetic material is RIGAKU, D / MAX-IIIA X-ray diffractometer, CuKα, 40KV tube voltage, 50mA current, and the scanning range of diffraction angle 2θ is 10°~80°. From figure 1 It can be seen that the material synthesized by high-temperature gradient sintering has a spinel cubic structure without impurity phases.

[0021] The surface morphology and particle size of the synthesized materials were observed with JSM-5610SV scanning elect...

Embodiment 2~10

[0027] Synthesize a series of different spinel lithium manganate materials LiMn under different conditions according to the method of the present invention 2-x Me x o 4-z (Me stands for doping metal elements, including Li, Mg, Al, Cr, etc.).

[0028] Table 1 lists the synthesis conditions, chemical composition and electrochemical capacity of a series of different spinel lithium manganate materials prepared according to the present invention.

[0029]

[0030]

Embodiment 11

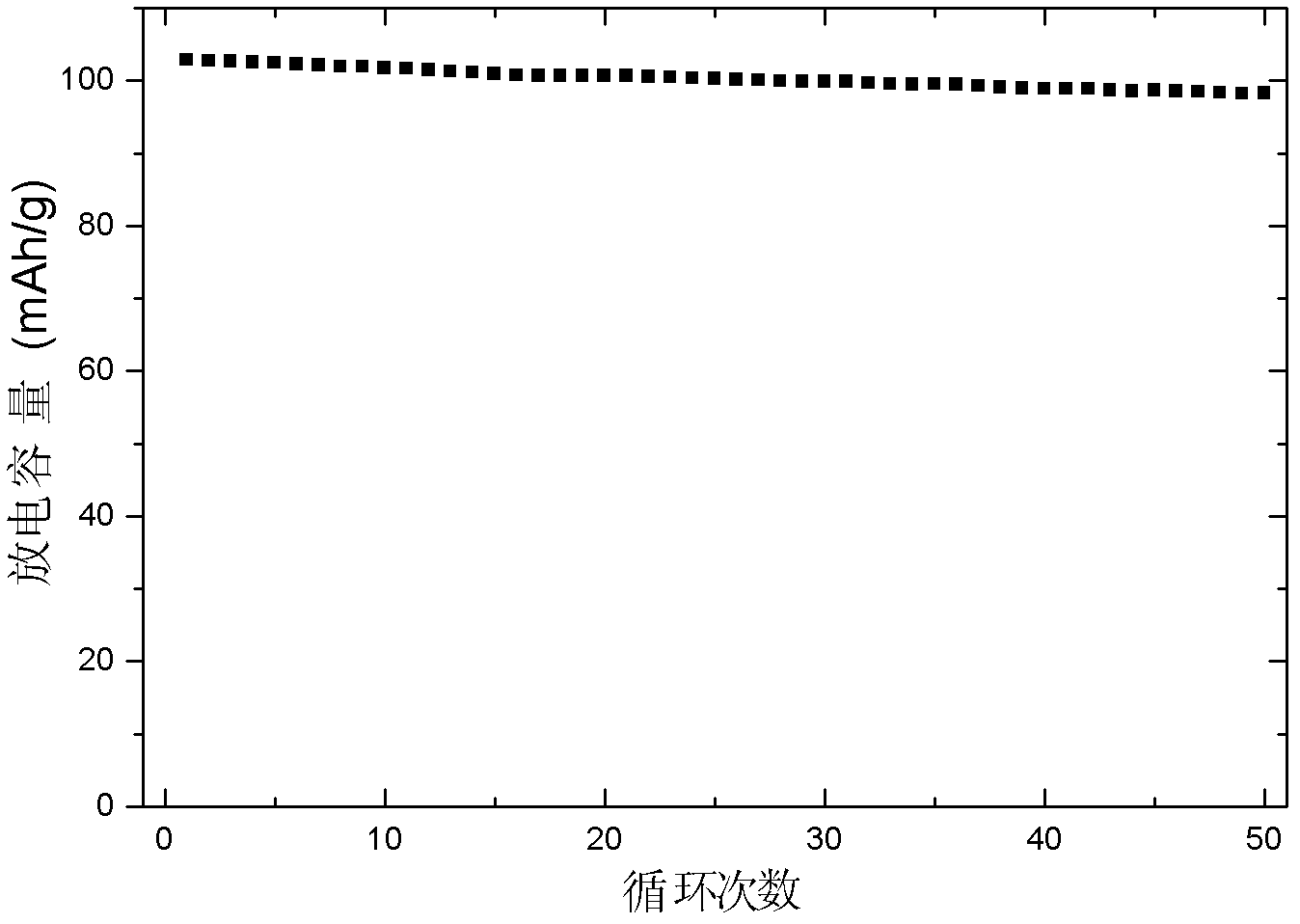

[0032] 12 kg of LiOH, and 67.6 kg of Mn 3 o 4Add 3.5 kg of MgO into the mixing container and mix evenly, then send it into a high-temperature sintering furnace, first heat up to 1100°C for sintering for 3.5 hours, then slowly cool down to 850°C for 5 hours, then slowly cool down to 700°C for 5 hours At the same time, compressed air is introduced, and after sintering, it is naturally cooled to room temperature to obtain a spinel lithium manganese oxide material for lithium-ion power batteries. Its chemical composition is LiMn 1.825 Mg 0.175 o 4 , the electrochemical discharge capacity is 100mAh / g, and the manganese dissolution is 3.5ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com