High-performance powder metallurgy material and preparation method thereof

A technology of powder metallurgy and powder materials, applied in the field of high-performance powder metallurgy materials and their preparation, can solve the problems of low strength, high price and poor plasticity of sintered steel, and achieve high sintered density, low price, high strength and plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The mechanical ball milling method is used, that is, the ferrochrome powder is first crushed by high-energy ball milling. With the prolongation of ball milling time, the particle size of the powder becomes smaller and more uniform. However, if the powder is too fine, in view of the well-developed specific surface, it will cause the agglomeration of particles, which will not be well dispersed, and will have an adverse effect on the subsequent pressing and sintering processes. Therefore, it is enough to make the particles reach an appropriate particle size.

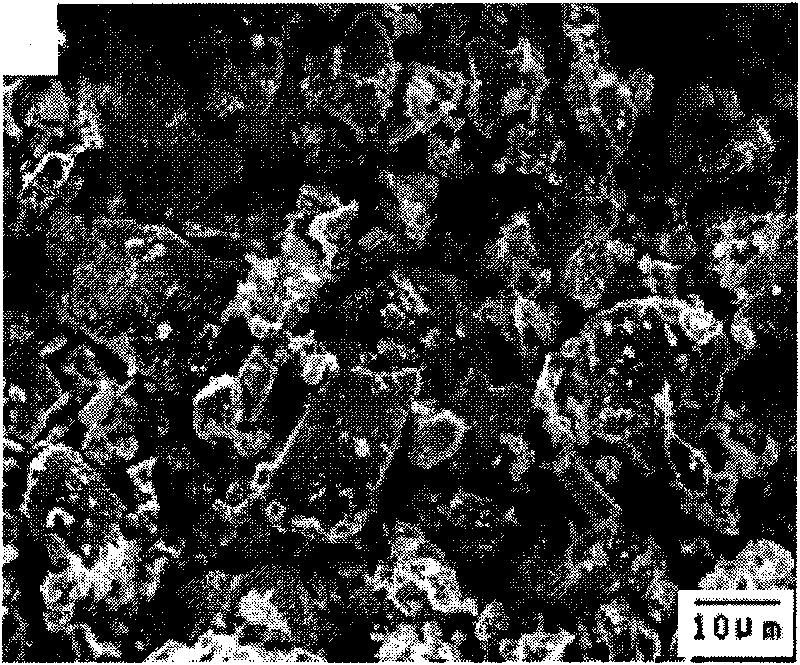

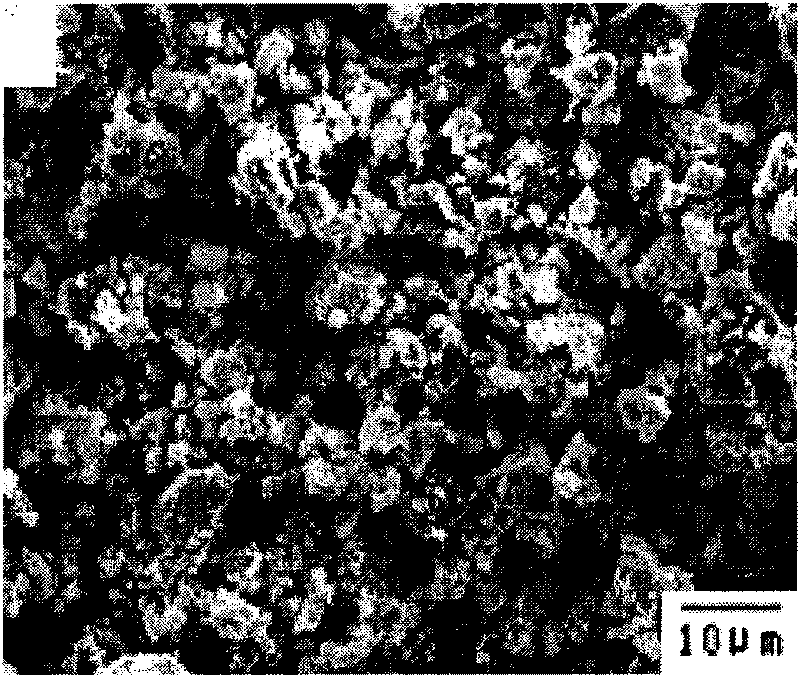

[0036] Referring to the figure, it can be seen that the particle size of the original ferrochrome powder is mostly about 30 μm, and most of them are irregular block particles, which will limit the relative sliding of the particles, thereby affecting the loose specific gravity of the powder, and the obtained green compact density is low. figure 2 It shows that after 20h of ball milling, the particles become smaller, t...

Embodiment 2

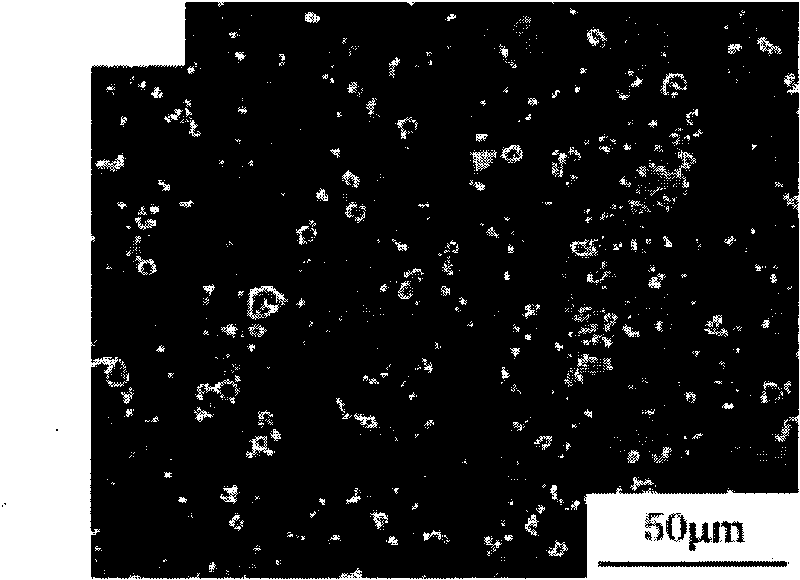

[0038] Such as Figure 4 Shown is the microstructure and pore morphology after cold pressing and sintering of mixed powder with coarse ferrochrome powder (particle size about 30 μm). Depend on Figure 4 It can be seen that the structure of the coarse powder contains a large number of pores, most of which are polygonal pores with large sizes, and most of the pores are around the undissolved FeCr particles. FeCr powder without ball milling is mostly large polygonal particles, so the addition of coarse powder restricts the flow of powder during compaction, and forms large pores between particles, which affects the densification of the compact.

[0039] refer to Figure 5 It can be seen that in the tissue added with 0.6% fine FeCr powder, the pores are evenly distributed in the tissue in the form of a network, no large polygonal pores are formed, and there are more near-spherical isolated pores, the porosity is obviously reduced, and the density is higher. have a favorable effe...

Embodiment 3

[0042] Figure 8 It is a photo of the cold-pressed sintered metallographic structure with a chromium content of 0.6%. from Figure 8It can be seen that the sintered structure is composed of ferrite and pearlite (sorbite). However, the morphology of pearlite is different from that of general low-alloy forged steel, and no typical lamellar shape is formed, indicating that the diffusion distance of carbon and other alloying elements in γ-Fe is relatively short, and the matrix structure tends to be more granular.

[0043] refer to Figure 9 It can be seen that the results of transmission electron diffraction analysis show that there are ferrite and cementite in the structure. The cementite is short rod-shaped and granular, very small, and the electron diffraction results in this area show intermittent ring-shaped diffraction spots, which is the result of fine polycrystals participating in the diffraction, indicating that the carbide grains are very small.

[0044] Figure 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com