Preparation method of low-loss soft magnetic composite material

A soft magnetic composite material, low-loss technology, applied in the fields of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low level, difficult hysteresis loss and eddy current loss, etc., to reduce hysteresis loss , The effect of reducing eddy current loss and high compression density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Select 60g of magnesium chloride, 60g of aluminum chloride, and 600g of iron-silicon magnetic powder (mass ratio is 1:1:10). The particle size of the iron-silicon magnetic powder is 20-180μm, and then add 300g of 98% ethanol solution, After mixing, stir evenly to obtain a mixed solution.

[0032] (2) Add 51g of ammonia water to the mixed solution, the amount of ammonia water added is 5% of the mass of the mixed solution, fully react, dry at a temperature of 80°C, and pass through a 80-mesh sieve to obtain a composite powder.

[0033] (3) Put the obtained composite powder into a tube furnace, first raise the temperature to 600°C under a protective atmosphere of nitrogen, and keep it for 60 minutes;

[0034] (4) Preparation of low-loss soft magnetic composite materials

[0035] (4.1) Pass the heat-treated powder through a 80-mesh sieve, and carry out two-way floating pressing under a pressure of 2100MPa in a hydraulic press to obtain a green body of soft magnetic com...

Embodiment 2

[0039] The preparation operation steps of a kind of low-loss soft magnetic composite material are as follows:

[0040] (1) Select 30g of magnesium chloride, 30g of aluminum chloride, and 600g of gas-atomized sendust magnetic powder (mass ratio: 1:1:20), in which the particle size of the gas-atomized sendust magnetic powder is 20-180μm, and then add 300g of 98% ethanol solution was mixed and stirred evenly to obtain a mixed solution.

[0041] (2) Add 28.8g of ammonia water to the mixed solution, the amount of ammonia water added is 3% of the mass of the mixed solution, fully react, dry at 90°C, and pass through a 80-mesh sieve to obtain a composite powder.

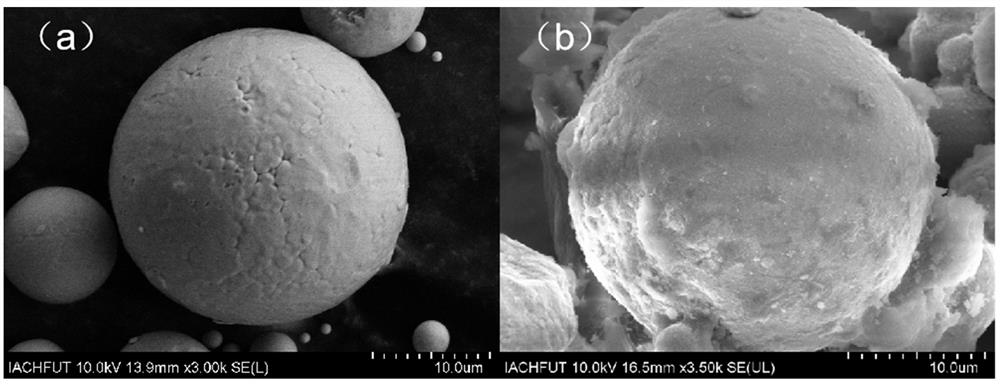

[0042] (3) Put the composite powder into a tube furnace, first raise the temperature to 500°C under a protective atmosphere of nitrogen, and keep it for 120 minutes; then raise the temperature to 900°C, keep it for 120 minutes, and cool with the furnace to obtain heat-treated powder. see figure 1 (b), a uniform and dense ...

Embodiment 3

[0048] The preparation operation steps of a kind of low-loss soft magnetic composite material are as follows:

[0049] (1) Select 20g of magnesium chloride, 20g of aluminum chloride, and 600g of iron-nickel magnetic powder (mass ratio: 1:1:30). The particle size of the original magnetic powder is 20-180μm, and then add 300g of 98% ethanol solution, mix Then stir evenly to obtain a mixed solution.

[0050] (2) Add 9.4g of ammonia water to the mixed solution, the amount of ammonia water added is 1% of the mass of the mixed solution, fully react, dry at 100°C, and pass through a 80-mesh sieve to obtain a composite powder.

[0051] (3) Put the composite powder into a tube furnace, first raise the temperature to 400°C under a protective atmosphere of nitrogen, and keep it for 180 minutes;

[0052] (4) Preparation of low-loss soft magnetic composite materials

[0053] (4.1) Pass the heat-treated powder through a 80-mesh sieve, and carry out two-way floating pressing under a pressu...

PUM

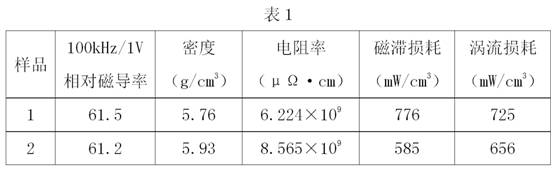

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com