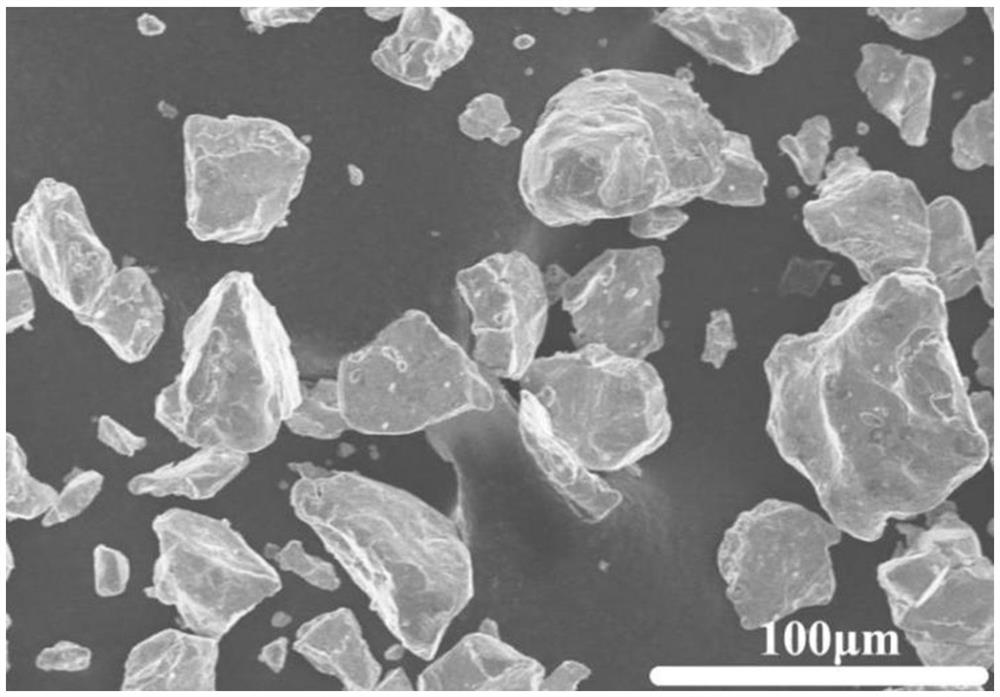

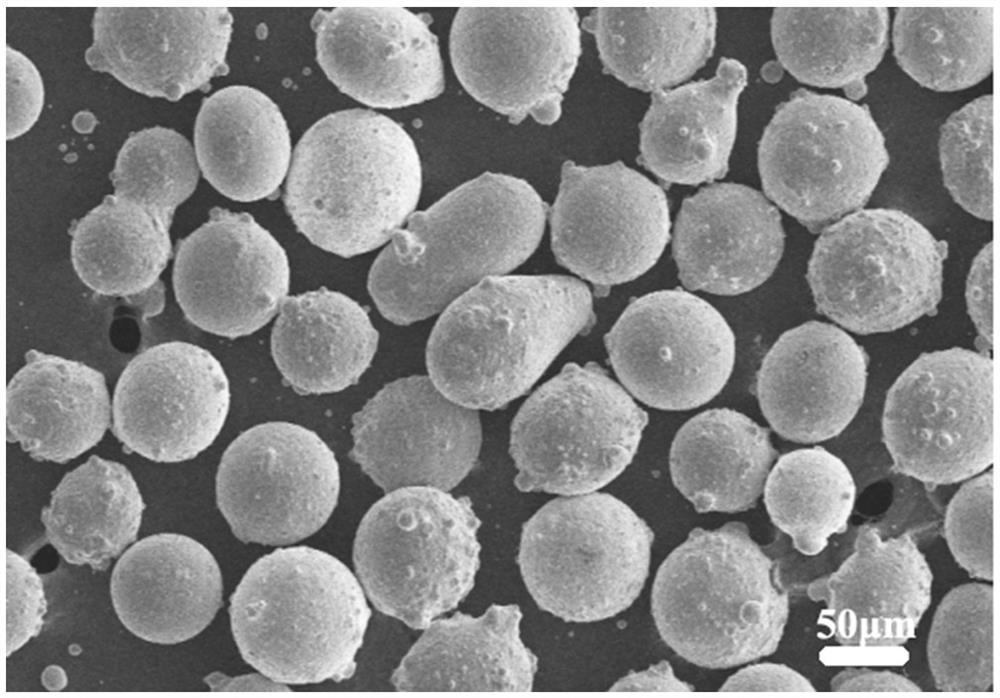

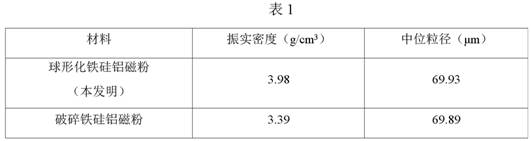

Spheroidizing preparation method of crushed Fe-Si-Al magnetic powder particles

An iron-silicon-aluminum, spheroidization technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of low DC bias performance, low pressing density, high production cost, and achieve high sphericity, The effect of eliminating internal stress and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of spheroidization preparation operation steps of crushed sendust magnetic powder particles are as follows:

[0025] (1) Put conventional crushed sendust magnetic powder into acetone solution, ultrasonically clean it for 10 minutes, and dry it at 40°C to obtain clean magnetic powder. The purpose is to remove the oil and impurities adsorbed on the surface of the magnetic powder.

[0026] (2) Add 100 g of clean magnetic powder into an aqueous solution of nitric acid with a mass concentration of 31 wt.%. In order to prevent the particles of clean magnetic powder from sticking to each other, perform ultrasonic treatment for 7 minutes. During ultrasonication, 10 ml of distilled water was added dropwise to the mixed solution every 3 minutes for dilution, and the number of drops was 2 times. Then the magnetic powder was filtered out, washed with ethanol for 3 times, and dried at 50° C. to obtain the acidified magnetic powder.

[0027] (3) Put the acidified magnetic po...

Embodiment 2

[0031] A kind of spheroidization preparation operation steps of crushed sendust magnetic powder particles are as follows:

[0032] (1) Put conventional crushed sendust magnetic powder into acetone solution, ultrasonically clean it for 15 minutes, and dry it at 50°C to obtain clean magnetic powder. The purpose is to remove the oil and impurities adsorbed on the surface of the magnetic powder.

[0033] (2) Add 300 g of clean magnetic powder into an aqueous solution of nitric acid with a mass concentration of 42 wt.%. In order to prevent the particles of the clean magnetic powder from sticking to each other, perform ultrasonic treatment for 10 minutes. During ultrasonication, 15 ml of distilled water was added dropwise to the mixed solution every 3 minutes to dilute the nitric acid solution, and the number of drops was 3 times. Then the magnetic powder was filtered out, washed with ethanol for 3 times, and dried at 60°C to obtain the acidified magnetic powder.

[0034] (3) Put ...

Embodiment 3

[0038] A kind of spheroidization preparation operation steps of crushed sendust magnetic powder particles are as follows:

[0039] (1) Put conventional crushed sendust magnetic powder into acetone solution, ultrasonically clean it for 20 minutes, and dry it at 60°C to obtain clean magnetic powder. The purpose is to remove the oil and impurities adsorbed on the surface of the magnetic powder.

[0040] (2) Add 500 g of clean magnetic powder into an aqueous solution of nitric acid with a mass concentration of 48 wt.%. In order to prevent the particles of clean magnetic powder from sticking to each other, perform ultrasonic treatment for 15 minutes. During ultrasonication, 20 ml of distilled water was added dropwise to the mixed solution every 3 minutes to dilute the nitric acid solution, and the number of drops was 4 times. Then the magnetic powder was filtered out, washed with ethanol for 4 times, and dried at 80° C. to obtain the acidified magnetic powder.

[0041] (3) Put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com