Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

608 results about "Product Part" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A subdivision of a product.

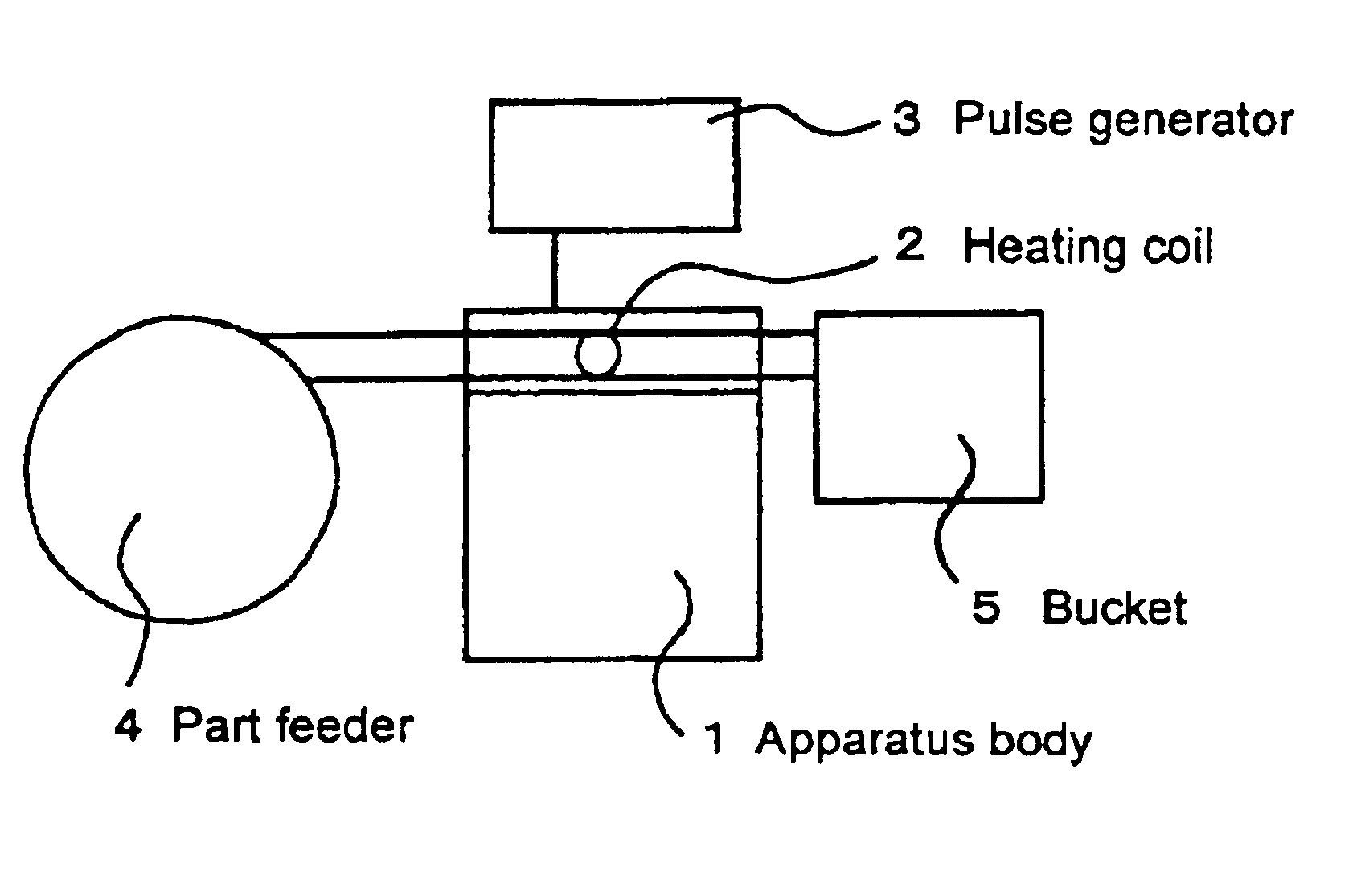

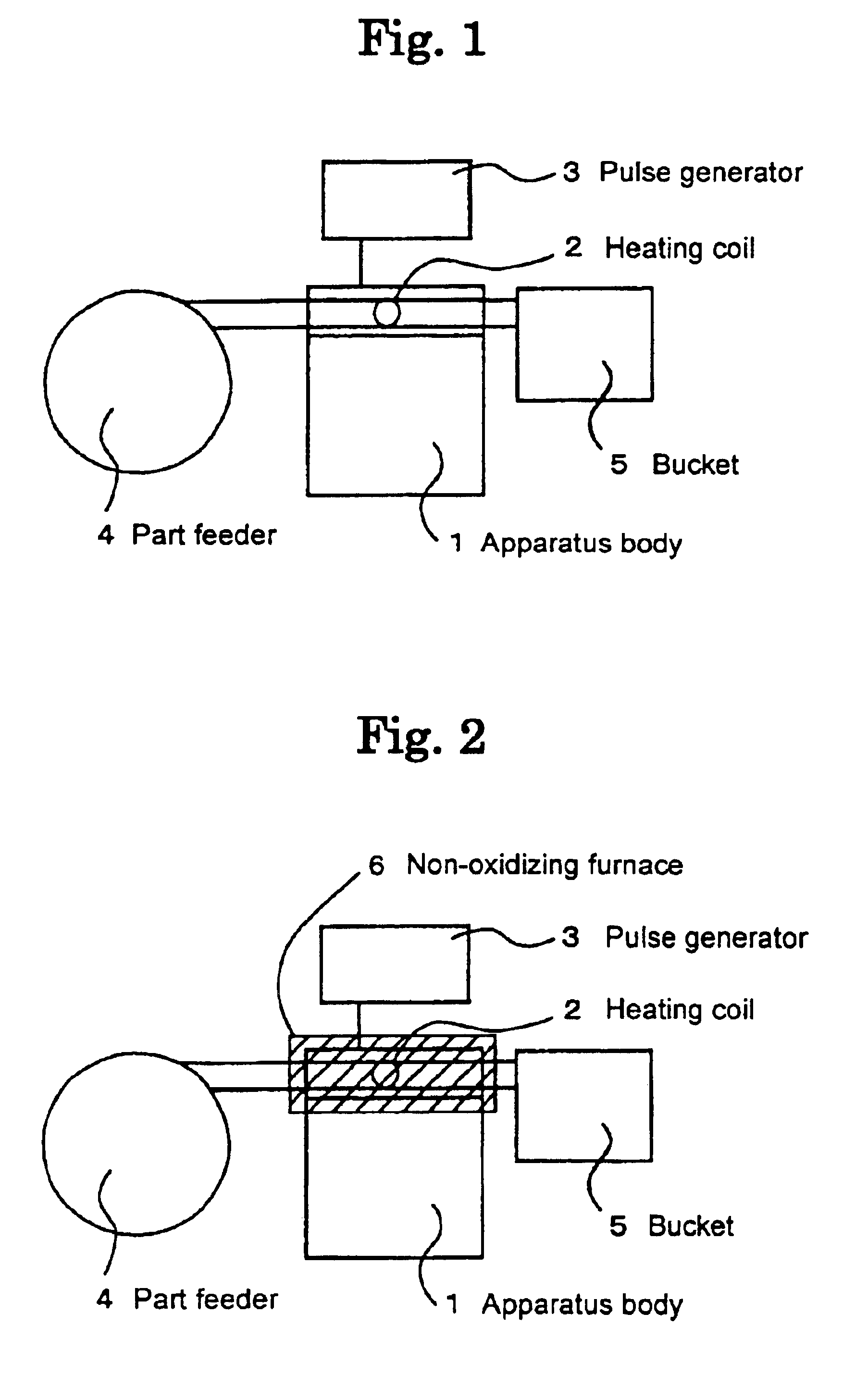

Method of baking treatment of steel product parts

InactiveUS6855217B2Shorten the timeImprove facilitiesIncreasing energy efficiencyFurnace typesSurface layerMetallurgy

The present invention relates to a method of baking treatment of steel product parts using a high frequency or ultra-high frequency for preventing delayed fracture from occurring due to diffusive hydrogen occluded in steel parts, for example, screws, bolts and the like, or for heating surface layers of the steel parts to generate a difference in temperature between the surface layers and interiors of the steel parts, thereby causing distortion in lattices, wherein the surface layers of the steel parts are rapidly heated to 100 to 300° C. with a high frequency or ultra-high frequency at 10 KHz or higher to remove the diffusive hydrogen which is involved in hydrogen embrittlement, or to transfer an existing state to non-diffusive hydrogen which is not involved in the hydrogen embrittlement.

Owner:AOYAMA SEISAKUSHO CO LTD

Process for preparing biological diesel oil from waste animal and plant oil

InactiveCN1382762AEliminate emissionsSimple production processLiquid hydrocarbon mixture productionBio-feedstockOil and greaseBiodiesel

A process for preparing biologic diesel oil from waste plant or animal oil includes alcoholysis and esterifying reactions under the existance of acidic catalyst, separating out the excessive non-product part to obtain coarse product, adding saturated equeous solution of edible salt containing sodium carbonate (10%), neutralizing reaction, adding industrial sodium carbonat4e, heating distillation and collecting the gas-phase fraction at 22-320 deg.C to obtain biologic diesel oil. Its advantages are high performance no pollution, and simple preparing process.

Owner:叶活动 +1

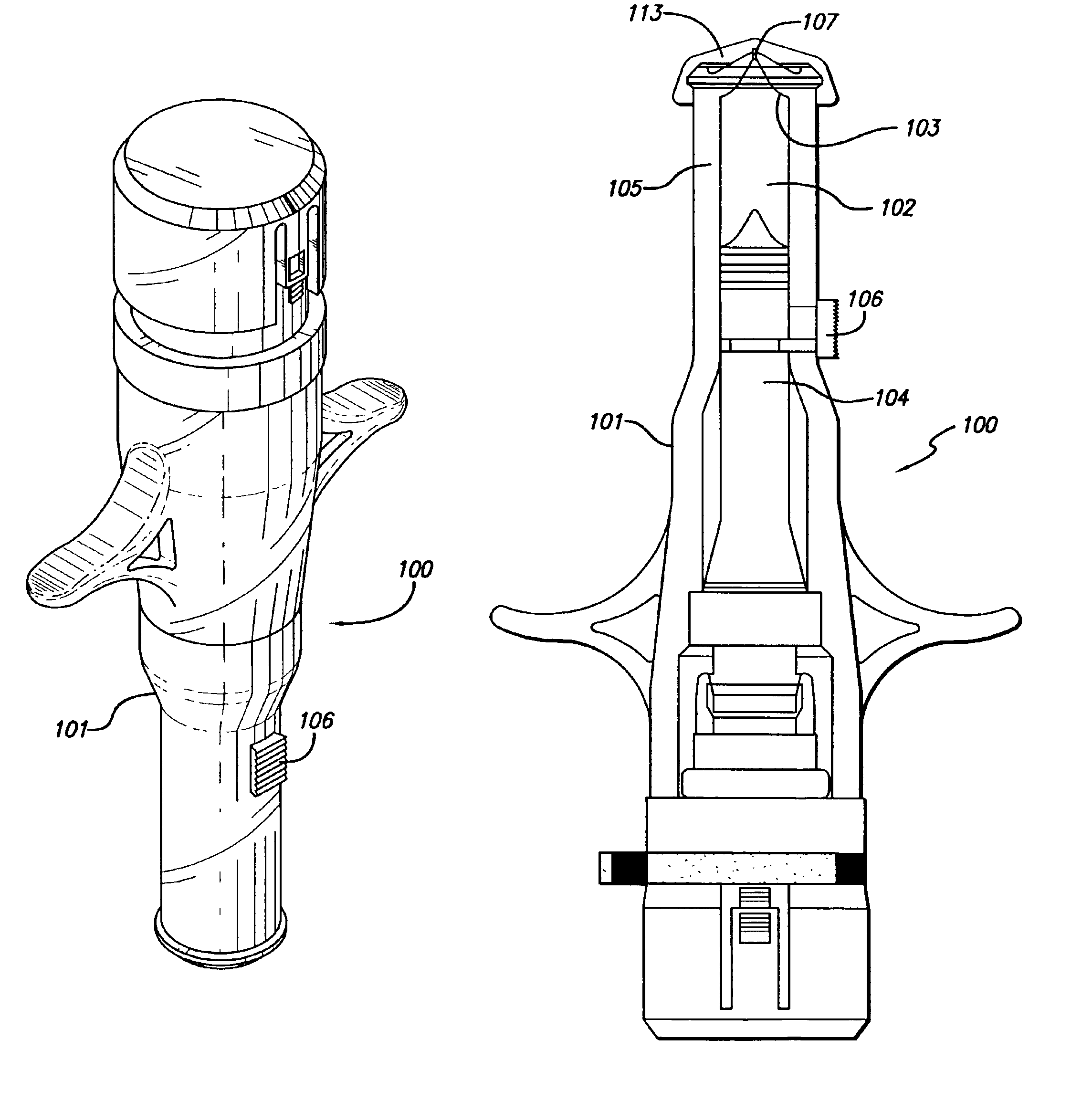

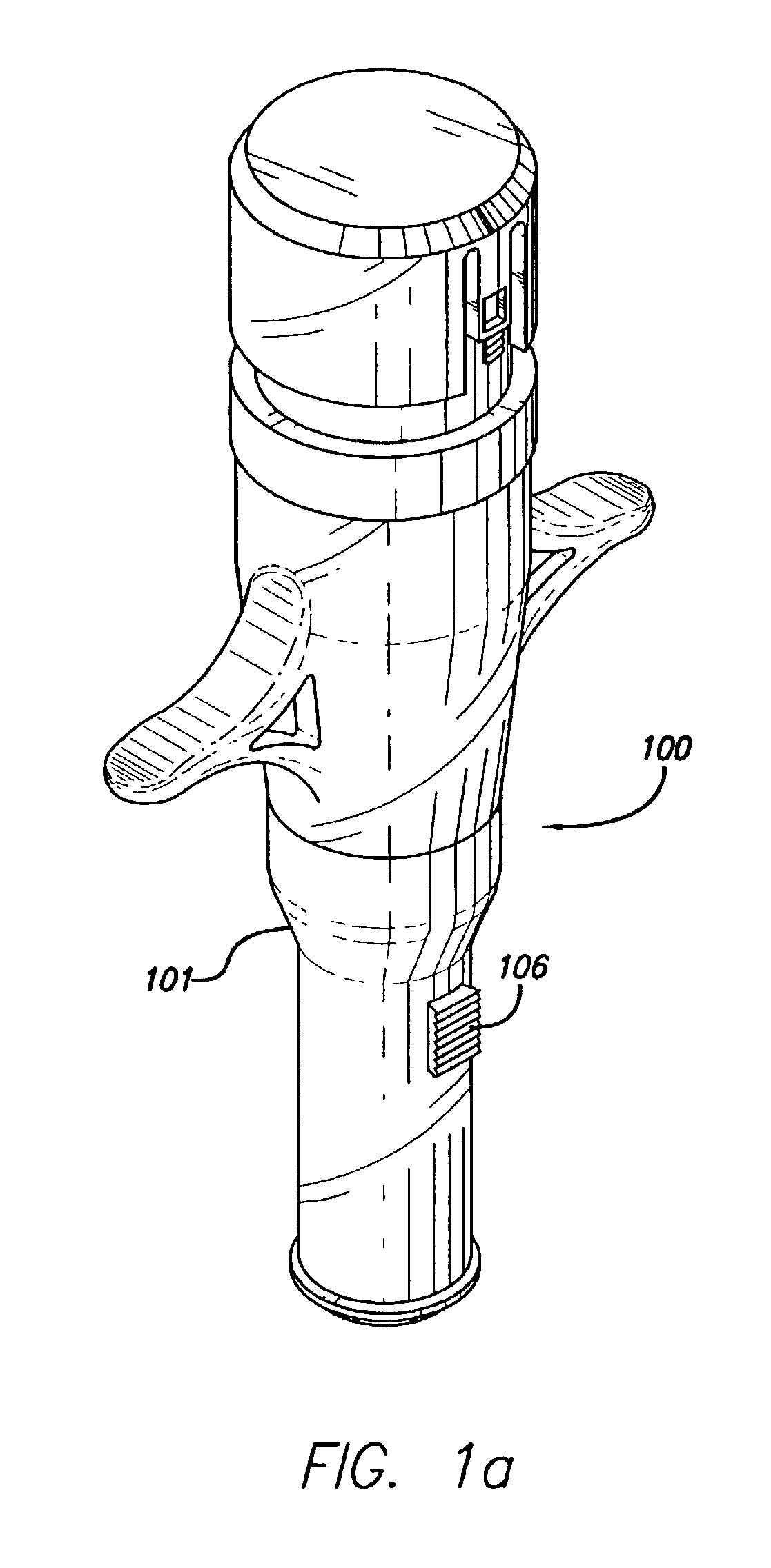

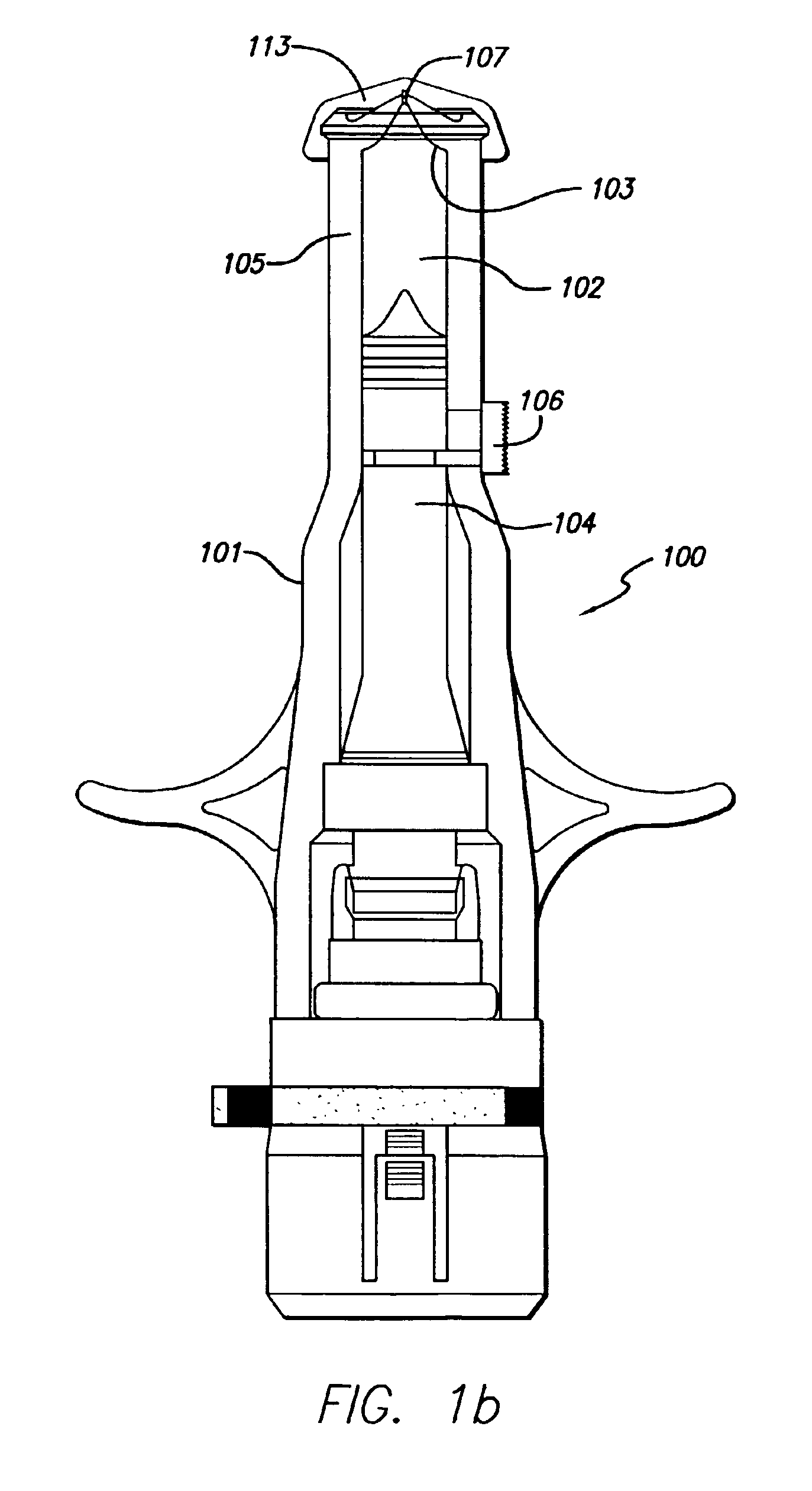

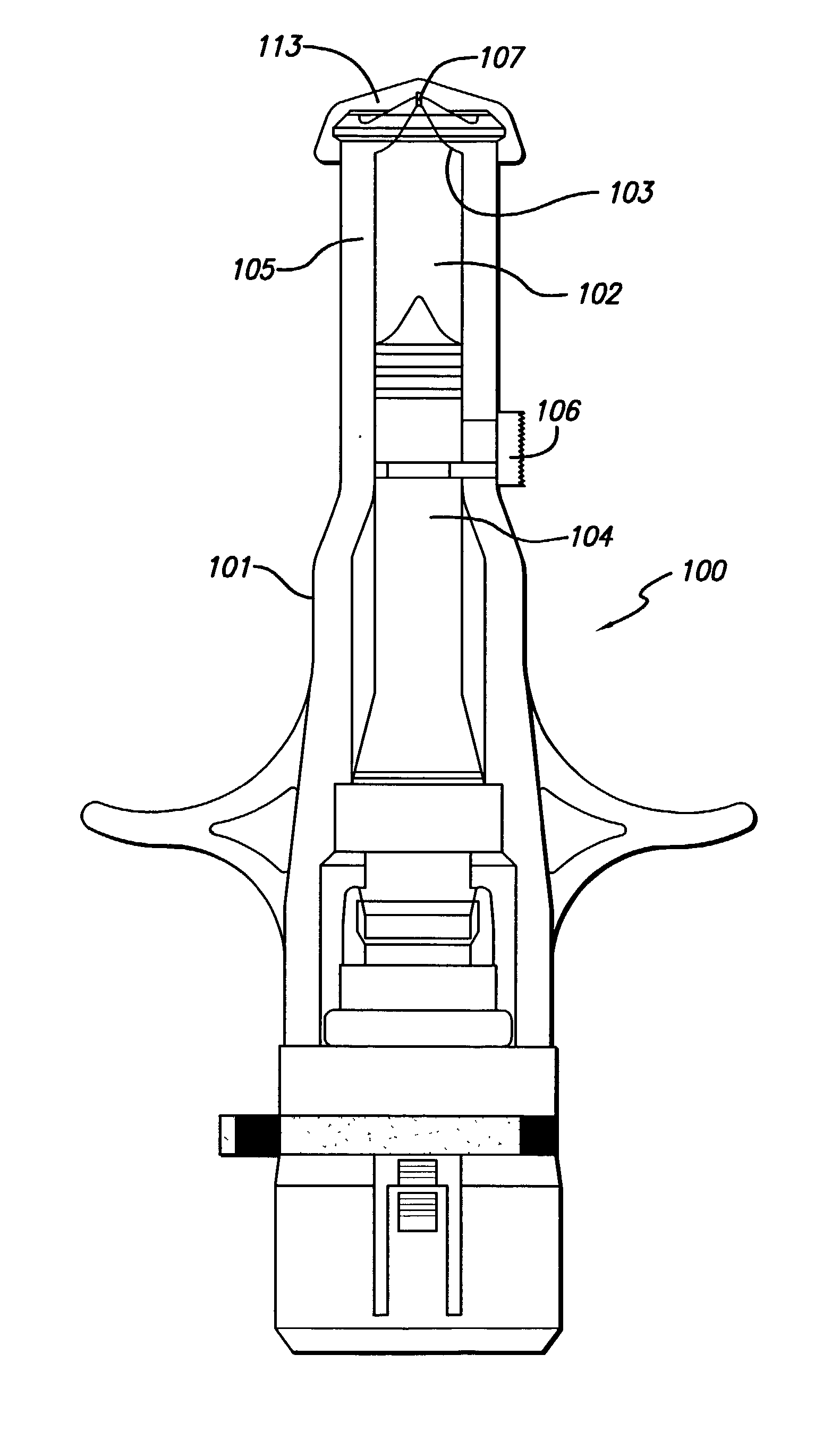

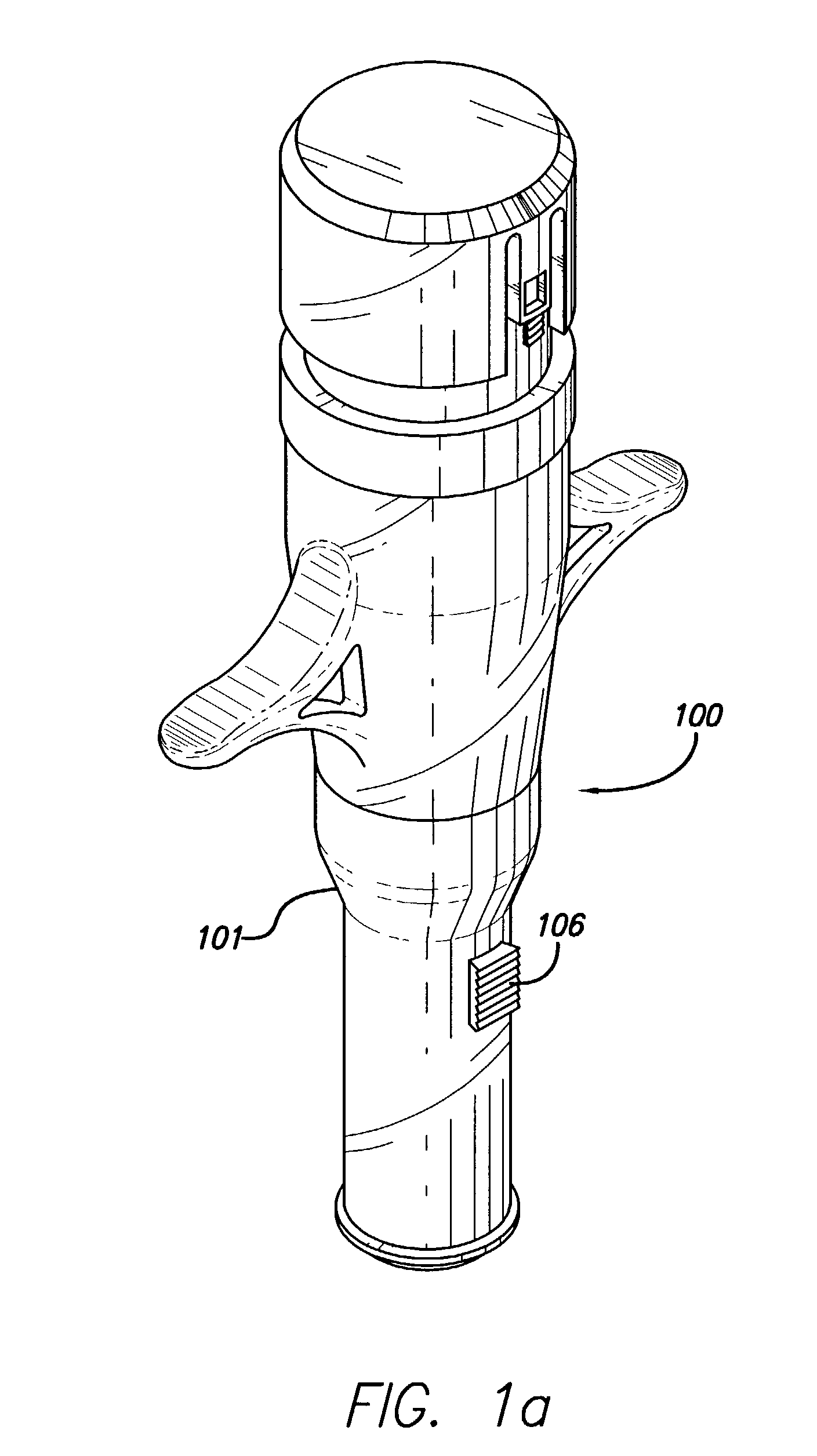

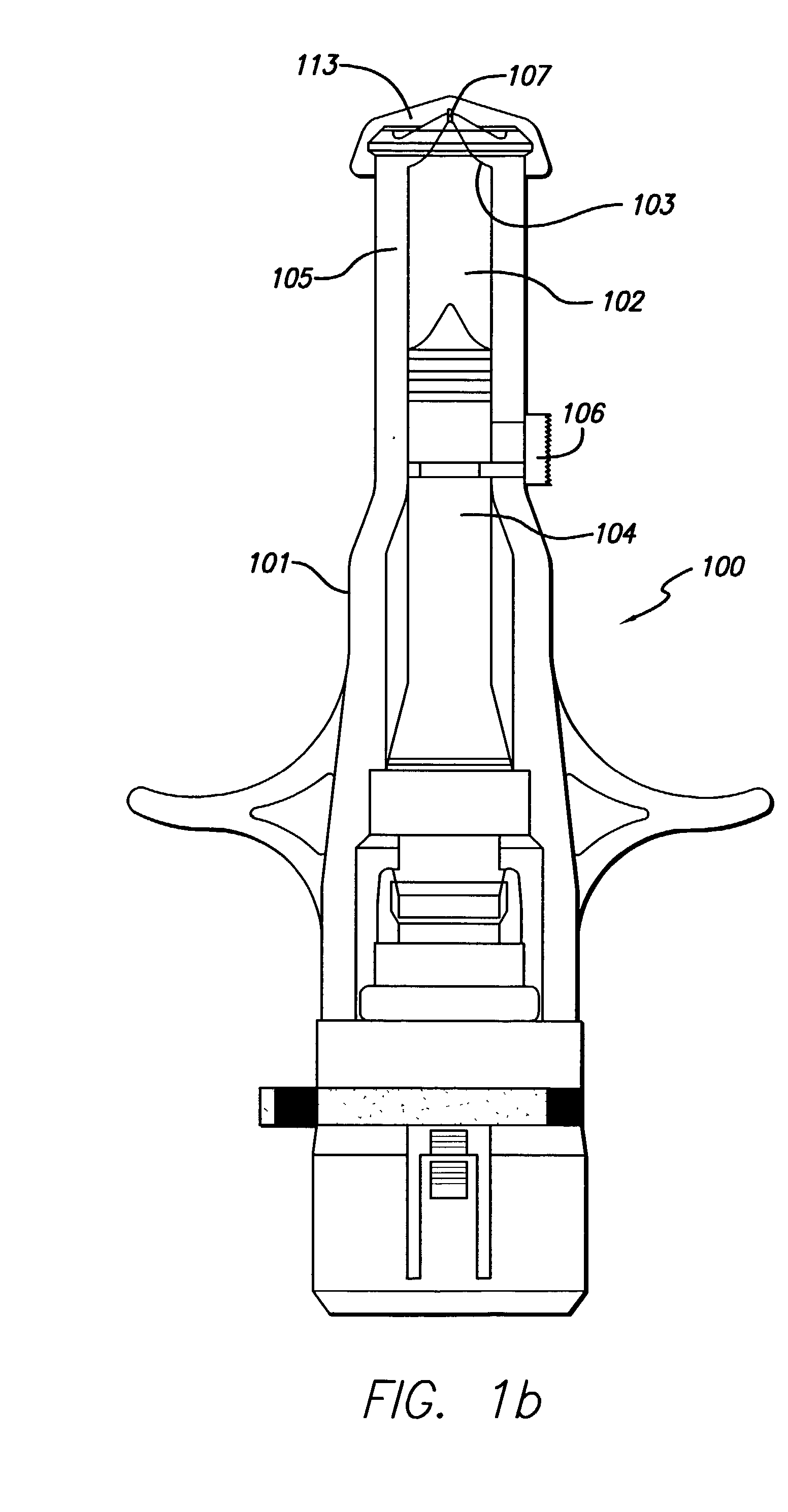

Method and apparatus for adjusting the contents of a needle-less injector

InactiveUS7018356B2Lower the volumeJet injection syringesMedical devicesNeedle Free InjectionEngineering

A method and apparatus for adjusting the contents of a needle-less injector that contains an injectable product are described. A needle-less injector includes an adjustment switch in mechanical contact with the driver of a needle-less injector. A user may displace the adjustment switch to expel air or gas contained in the product section of the needle-less injector prior to administration of a needle-less injection with the same. The adjustment switch may alternatively or additionally be used to expel at least a portion of the injectable product contained in the needle-less injector to reduce the volume of the product to be injected with the needle-less injector.

Owner:WISE ROGER R +1

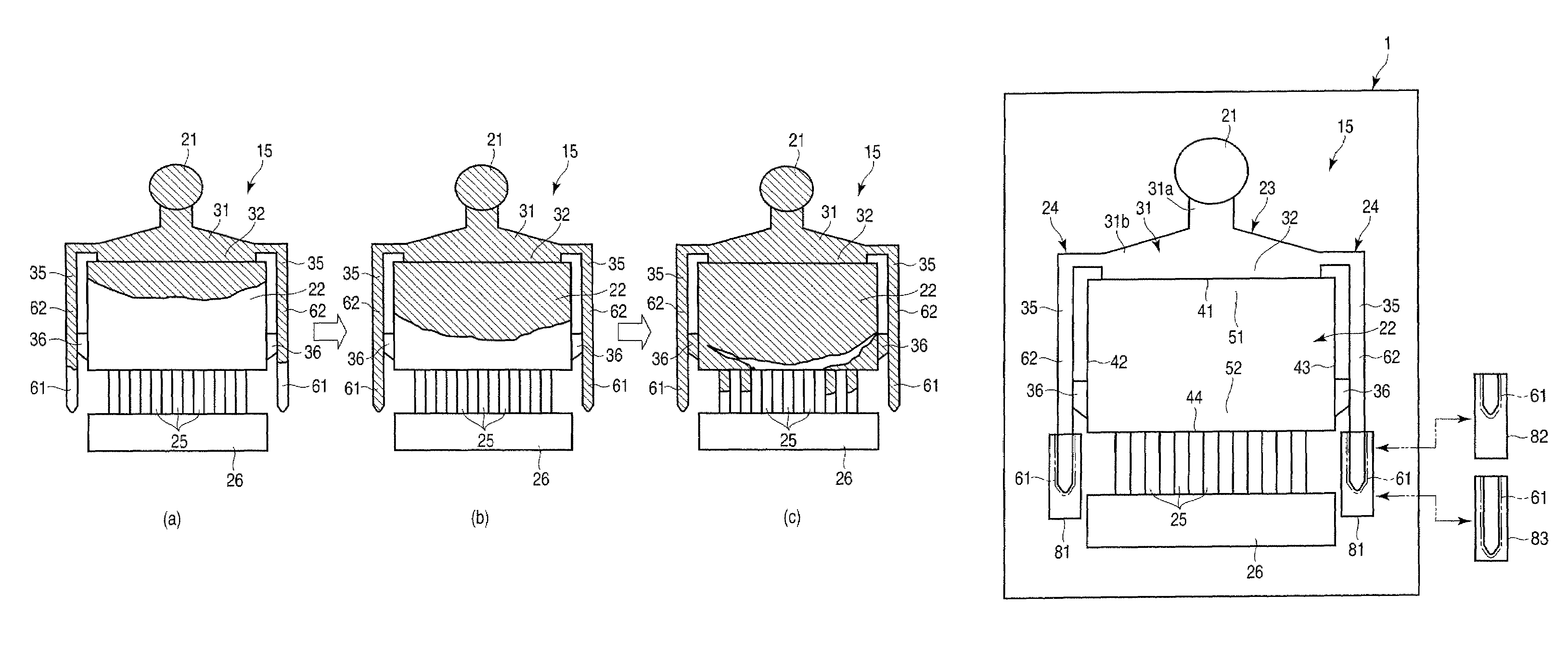

Die and method of manufacturing cast product

Owner:KK TOSHIBA

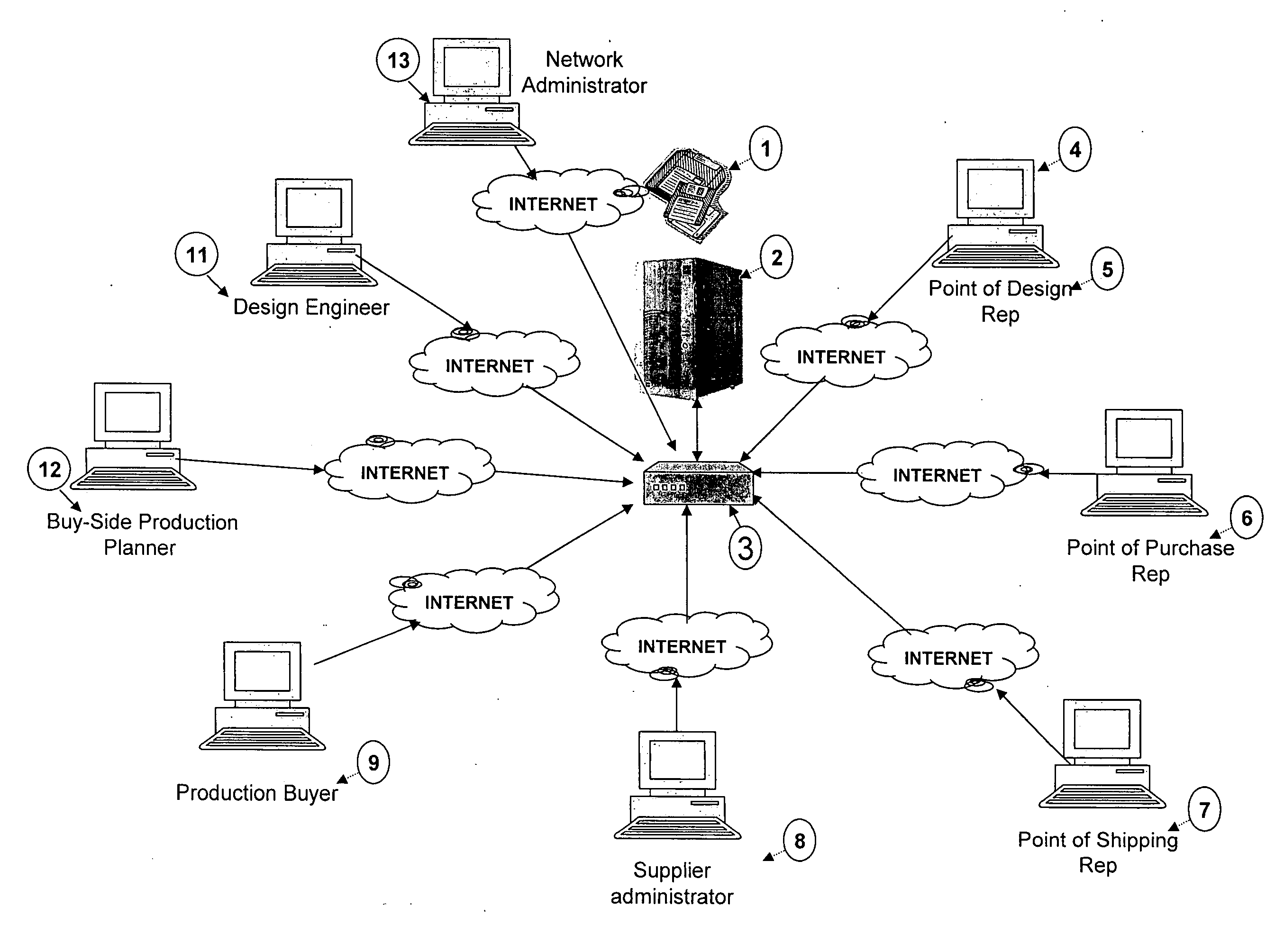

Searching industrial component data, building industry networks, and generating and tracking design opportunities

InactiveUS20060074919A1Increase speedEasy accessSpecial data processing applicationsMarketingWeb siteData mining

Processes (and system) are disclosed for aggregation of product part number, associated description, and product parameter for a plurality of products from plurality of web sites. One embodiment includes identifying a product manufacturer web site and executing crawler to extract information from databases exposed on the manufacturer web site. Also disclosed is processes (and system) for tracking sales opportunities through a sales cycle. One embodiment includes receiving input relating to a sales opportunity from a first buyer having a first role, the input comprising requirements for the sales opportunity including predefined checkpoints and transmitting to the first buyer a request for updated information relating to the sales opportunity, the updated information corresponding to the predefined checkpoints.

Owner:BEGANTO

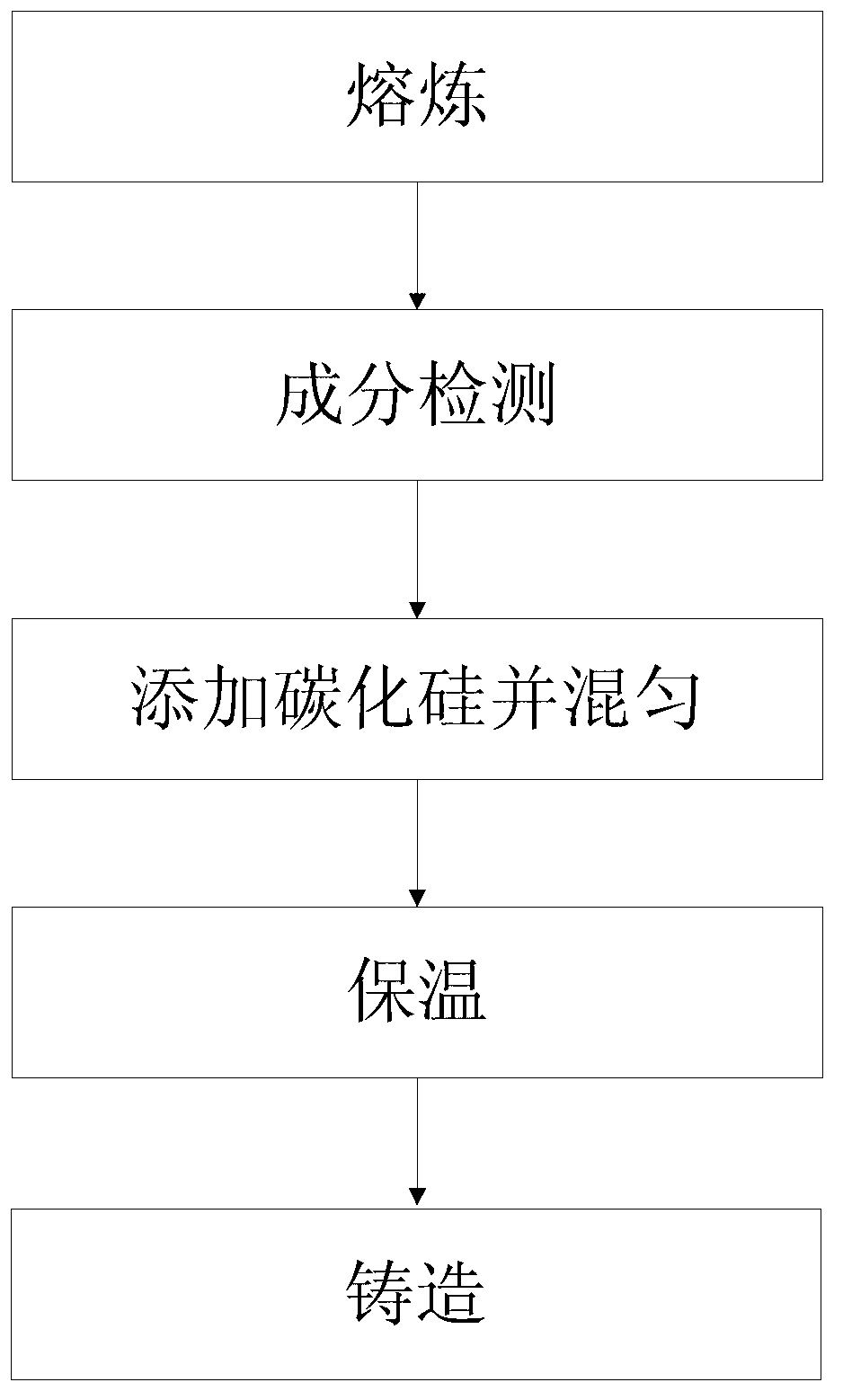

Method for preparing nanoscale silicon carbide copper alloy material

The invention provides a method for preparing a nanoscale silicon carbide copper alloy material. A nano silicon carbide copper alloy material which is 5-10% of total volume is evenly distributed in a copper alloy material; and the performance of the alloy material is further promoted by utilizing high hardness, high abrasive resistance, good self-lubricating property and high-temperature and high-strength performance of the nano silicon carbide. The invention also provides the nanoscale silicon carbide copper alloy material prepared by the method for preparing the nanoscale silicon carbide copper alloy material. The nanoscale silicon carbide copper alloy material comprises the following components in percentage by total volume: 5-10% of nanoscale silicon carbide (SiC) and 90-95% of copper alloy material ZQAL9-4. The novel nano alloy material prepared by the preparation method has high strength, hardness, abrasive resistance and corrosion resistance. Thus, the service life of an aerospace high-strength pressure product, wear part products of petroleum engineering equipment, and anticorrosion product parts of marine engineering equipment is prolonged.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

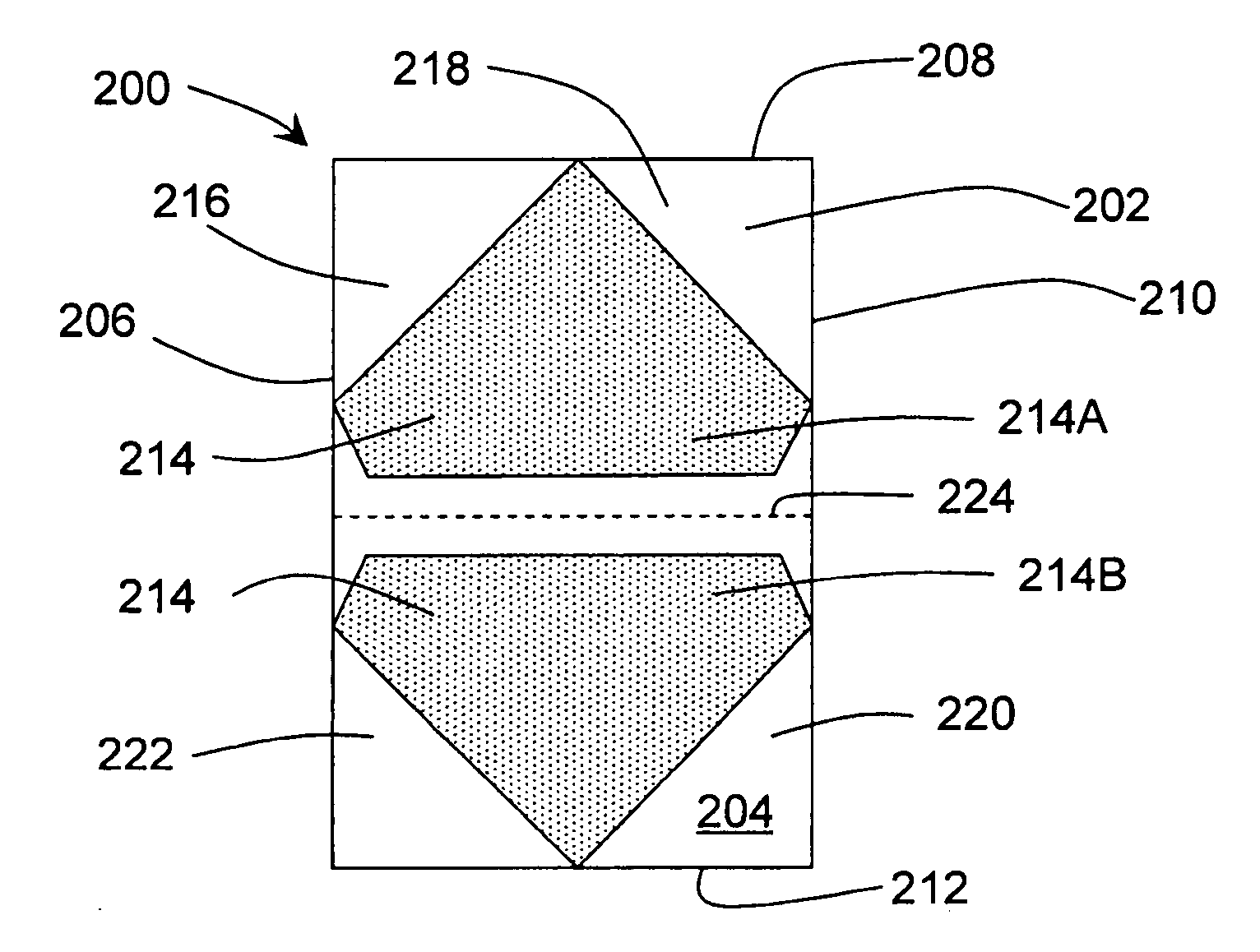

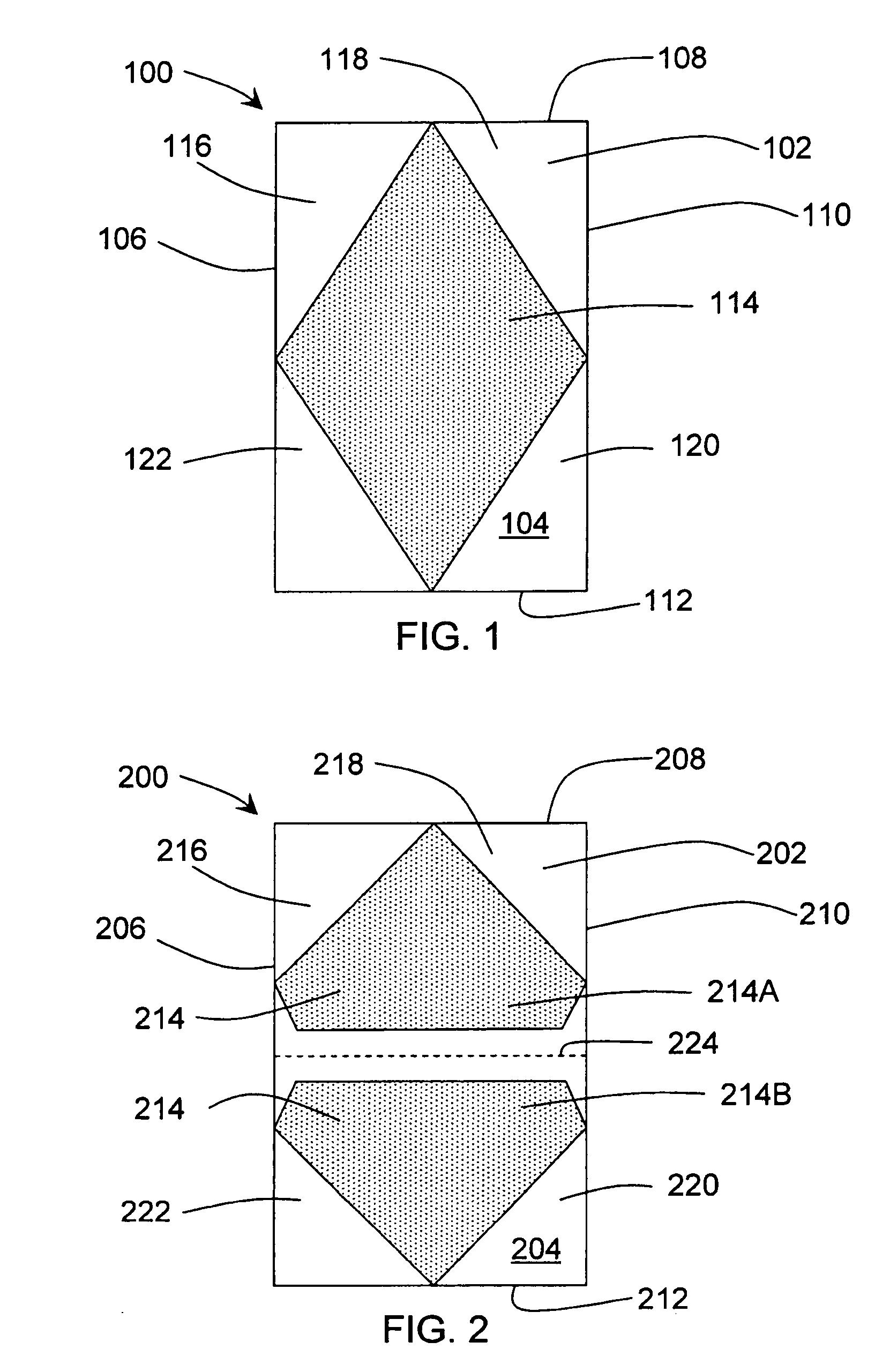

Surface treated paper product

InactiveUS20050241789A1Natural cellulose pulp/paperPaper after-treatmentProduct PartBiomedical engineering

A soft tissue product includes a surface treatment composition disposed on a treated portion that extends to the edges of the product, but which leaves the corners of the product untreated. The shape of the treated portion effectively ensures consumer benefit while reducing the total amount of additive composition on the product by placing the treatment composition in the portion of the product that is most likely to come into contact with the skin of a user.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Intelligent flexible manufacturing system and method for automobile bodies

InactiveCN106249718AImprove utilization efficiencyReduce usageTotal factory controlProgramme total factory controlControl signalThe Internet

The invention discloses an intelligent flexible manufacturing system and a method for automobile bodies. The manufacturing method comprises the steps of searching the information of product parts and process data in a product data management system by means of a production resource central control system; generating operation instructions for each of all intelligent equipment, and respectively outputting the operation instructions to each of all manufacturing resources through the internet of things; and starting corresponding programs to finish the machining process by each manufacturing resource after the manufacturing resources receive corresponding operation instructions according to manufacturing resource codes. The manufacturing system comprises a product data management system, an internet of things system, an intelligent container, a modular intelligent tool and an industrial robot. According to the technical scheme of the invention, the intelligentization of a container tool is realized. Based on the distributed data management and the central control of the internet of things system, the rapid switching among welding robot programs is realized. Therefore, the mixed production of automobile parts of different configuration modes and different types can be realized, so that the production efficiency is improved. The error rate is lowered. Moreover, the number of special welding robots is reduced and the field utilization efficiency is improved. Furthermore, the manufacturing cost is reduced.

Owner:CHONGQING TECH & BUSINESS UNIV

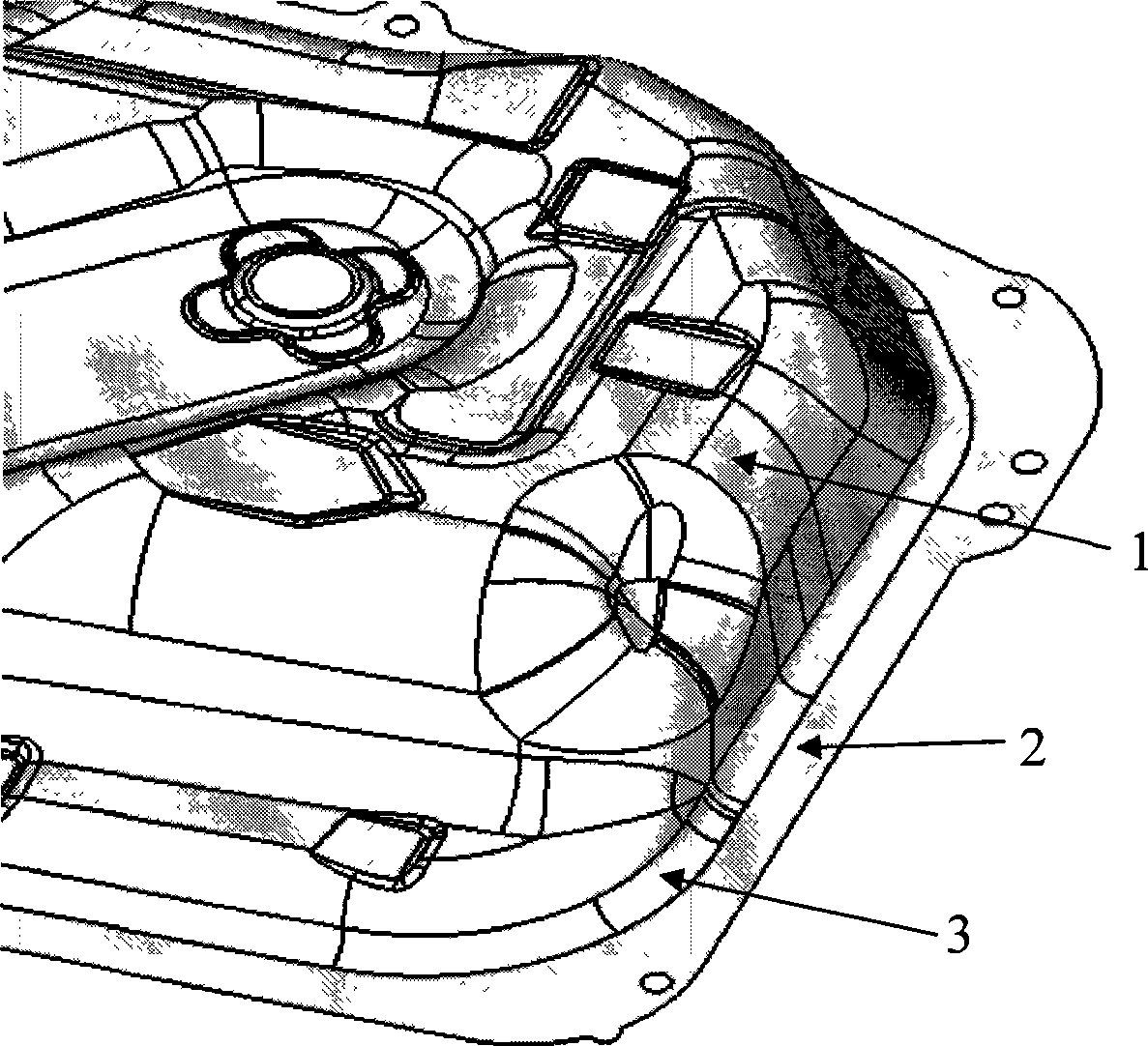

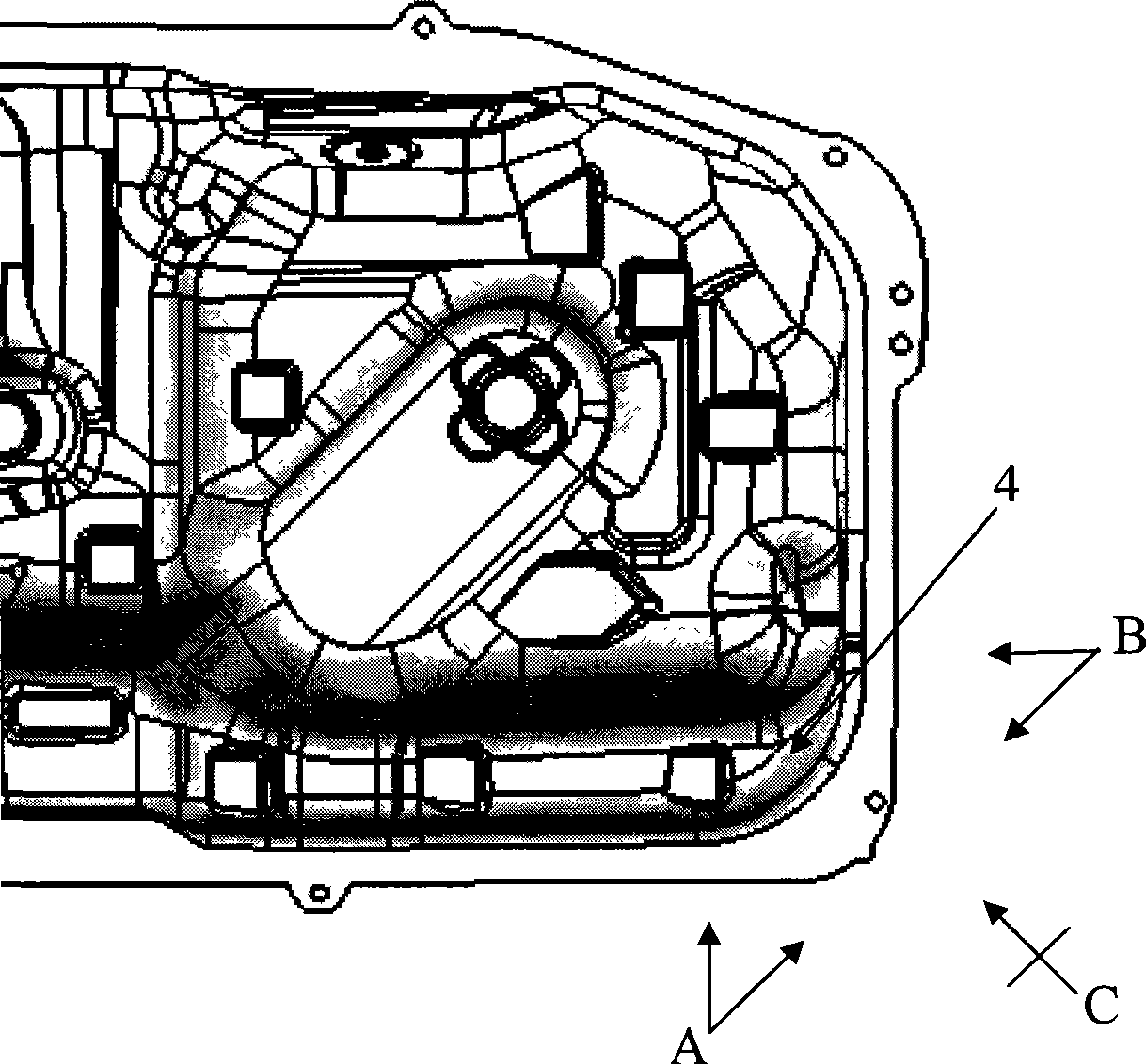

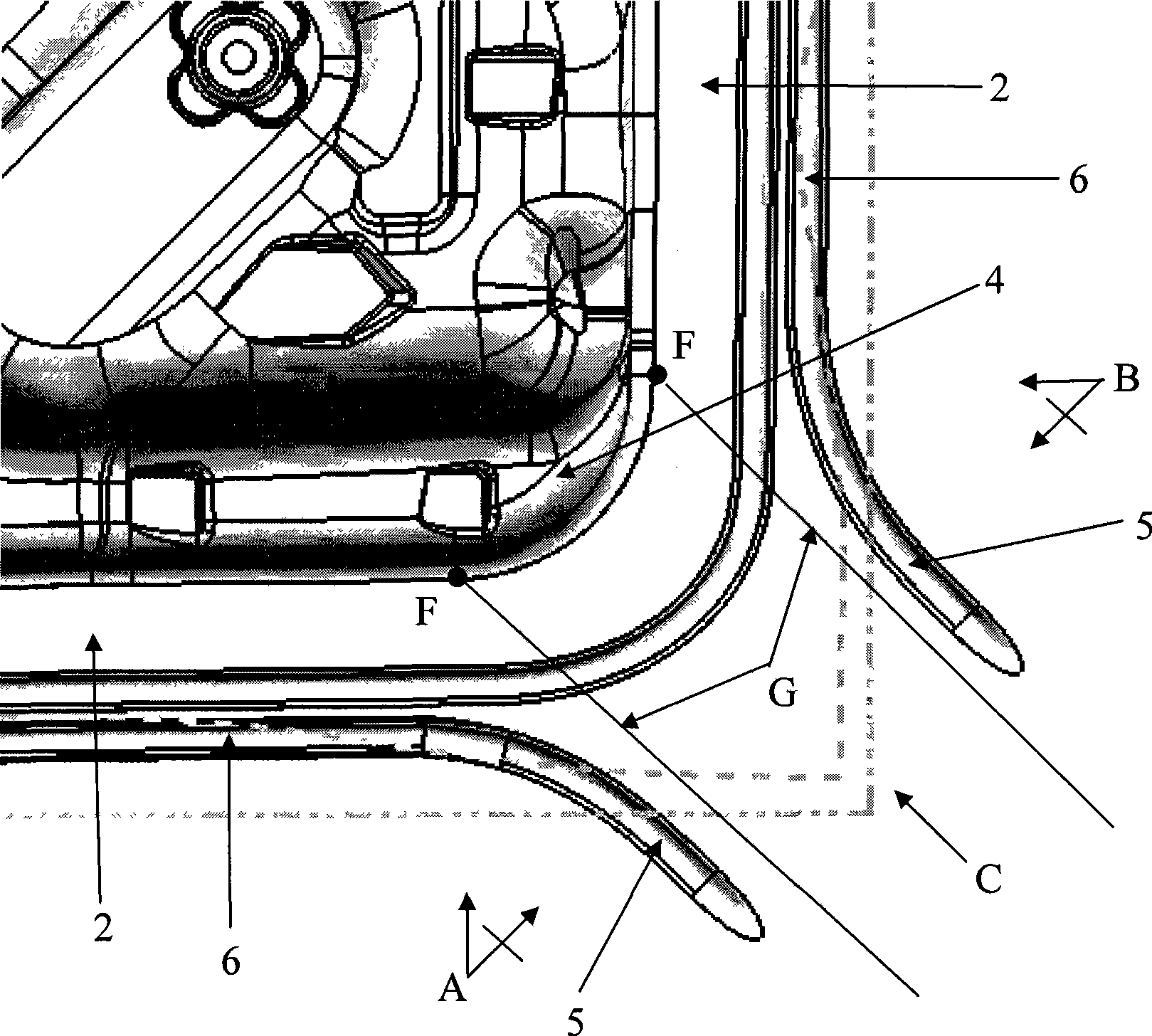

Additional method of draw-bead technique for corner part of external covering of vehicle

InactiveCN101439376AImprove surface qualitySolve the problem of obvious wrinkling on the flange surface during drawingWrinkle skinEngineering

The invention provides a drawing reinforcement process supplementing method for a corner part of an outer cover part of a vehicle. In the method, two tangent points (F) are assured on an arc sideline of the corner part, wherein, the tangent points are arranged at the tangent part of the arc sideline and a straight sideline of the outer cover part which is adjacent to the arc sideline; straight lines (G) are respectively made at the two tangent points, wherein, the extending direction of the straight lines is basically vertical to the connecting direction of the two tangent points; two oblique drawing reinforcements (5) which are respectively arranged at the external side of the two straight lines and are basically parallel with the straight lines are arranged. The drawing reinforcement process supplementing method provided by the invention is used for the drawing reinforcement process supplement on the corner part of the outer cover part of the vehicle. The obvious wrinkle in the drawing process of a flange surface around the corner part of the outer cover part can be effectively avoided. The surface quality of drawing pieces is improved. Therefore, the surface quality of finished product parts is improved.

Owner:广州庆达汽车零部件有限公司

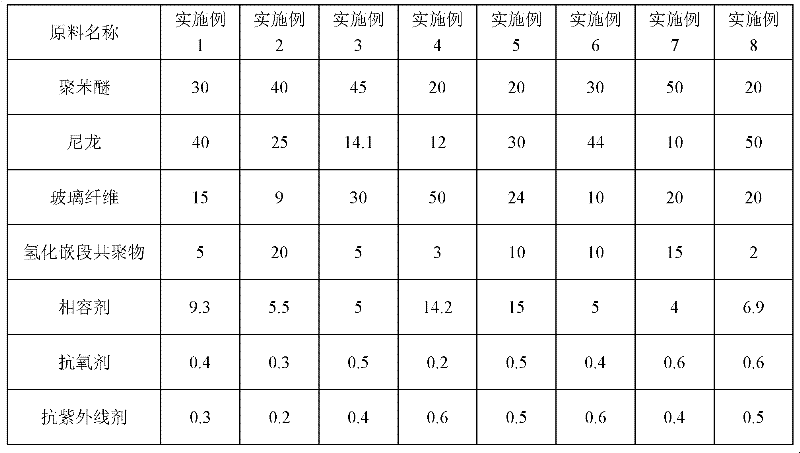

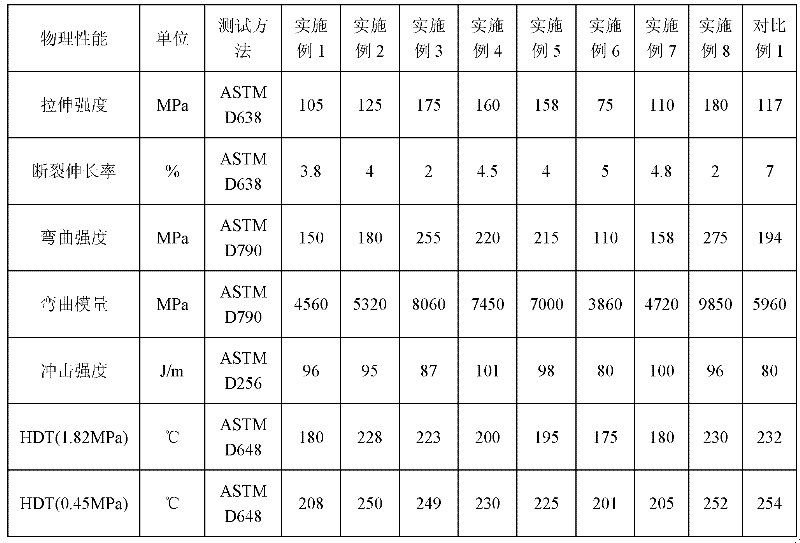

High-performance glass fiber reinforcement polyphenyl ether/polyamide alloy and production method thereof

InactiveCN102417720AGood high and low temperature mechanical propertiesGood weather resistancePolyamideAlloy

The invention relates to a high-performance glass fiber reinforcement polyphenyl ether / polyamide alloy and a production method thereof, wherein the alloy comprises the following components in part by weight: 20-50% of polyphenyl ether (PPO), 10-50% of polyamide (PA), 2-20% of hydrogenation segmented copolymer, 10-40% of glass fibre, 5-15% of polyphenyl ether-polyamide compatilizer, 0.2-0.6% of antioxygen and 0.2-0.6% of uvioresistant. The production technology of the reinforcement PPO / PA alloy comprises the following processes that: firstly, raw materials are mixed according to the proportion, and then are added into a double-screw extruder through a feeder, the glass fibre is added through a side feeder, the temperature is controlled between 240-280 DEG C, then granulation is carried out, so the high-performance glass fiber reinforcement polyphenyl ether / polyamide alloy can be obtained. The invention has the advantages of good high and low temperature mechanical property, heat resistance, weather resistance, creep resistance, insulativity, easiness in machine shaping and the like, and is applicable to electric product parts, automobile parts, office parts and the like.

Owner:SHANGHAI SUNNY

Method and apparatus for adjusting the contents of a needle-less injector

InactiveUS20040087896A1Lower the volumeMaintaining the sterility of the adjustment slotJet injection syringesMedical devicesNeedle Free InjectionEngineering

A method and apparatus for adjusting the contents of a needle-less injector that contains an injectable product are described. A needle-less injector includes an adjustment switch in mechanical contact with the driver of a needle-less injector. A user may displace the adjustment switch to expel air or gas contained in the product section of the needle-less injector prior to administration of a needle-less injection with the same. The adjustment switch may alternatively or additionally be used to expel at least a portion of the injectable product contained in the needle-less injector to reduce the volume of the product to be injected with the needle-less injector.

Owner:WISE ROGER R +1

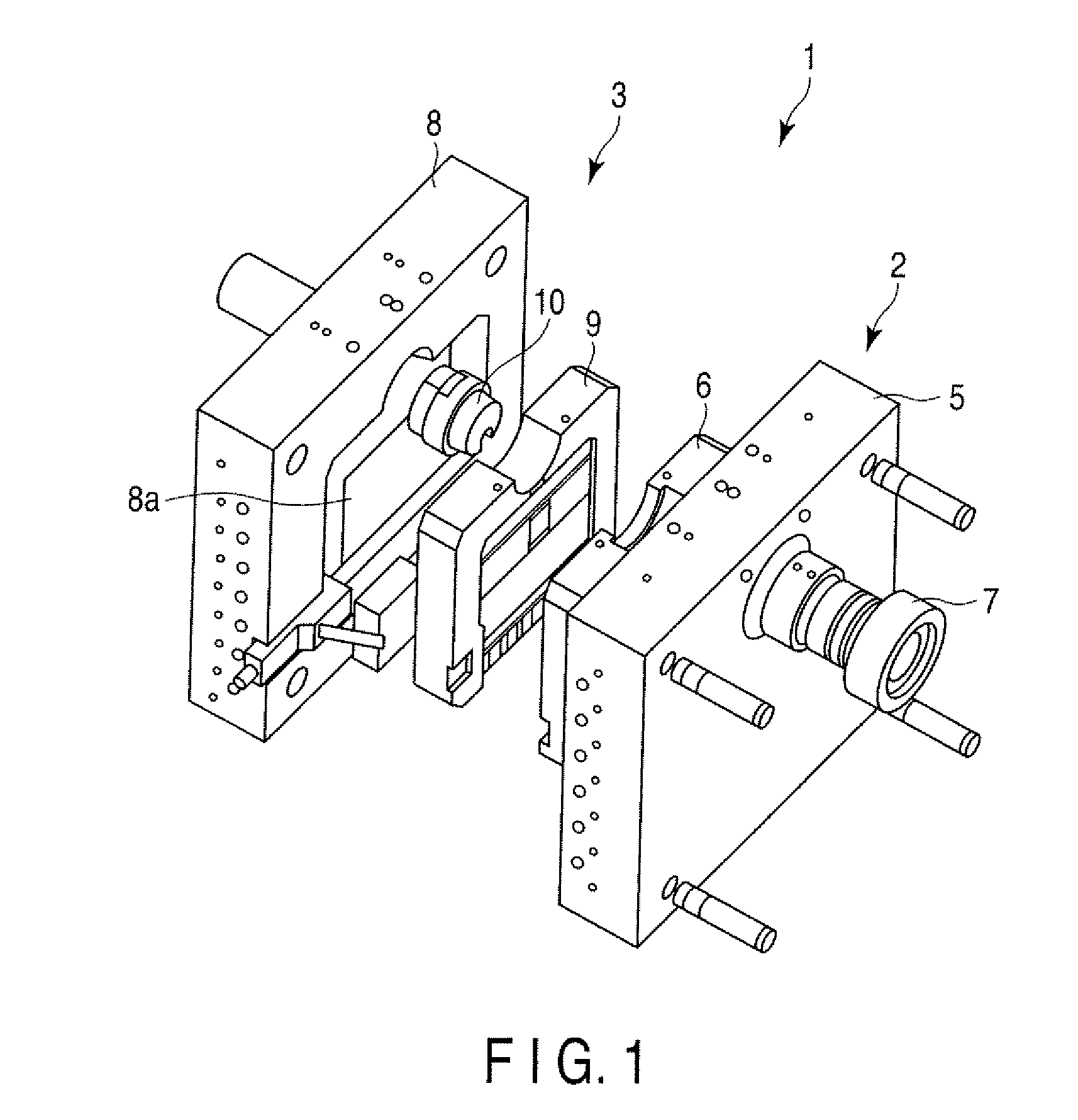

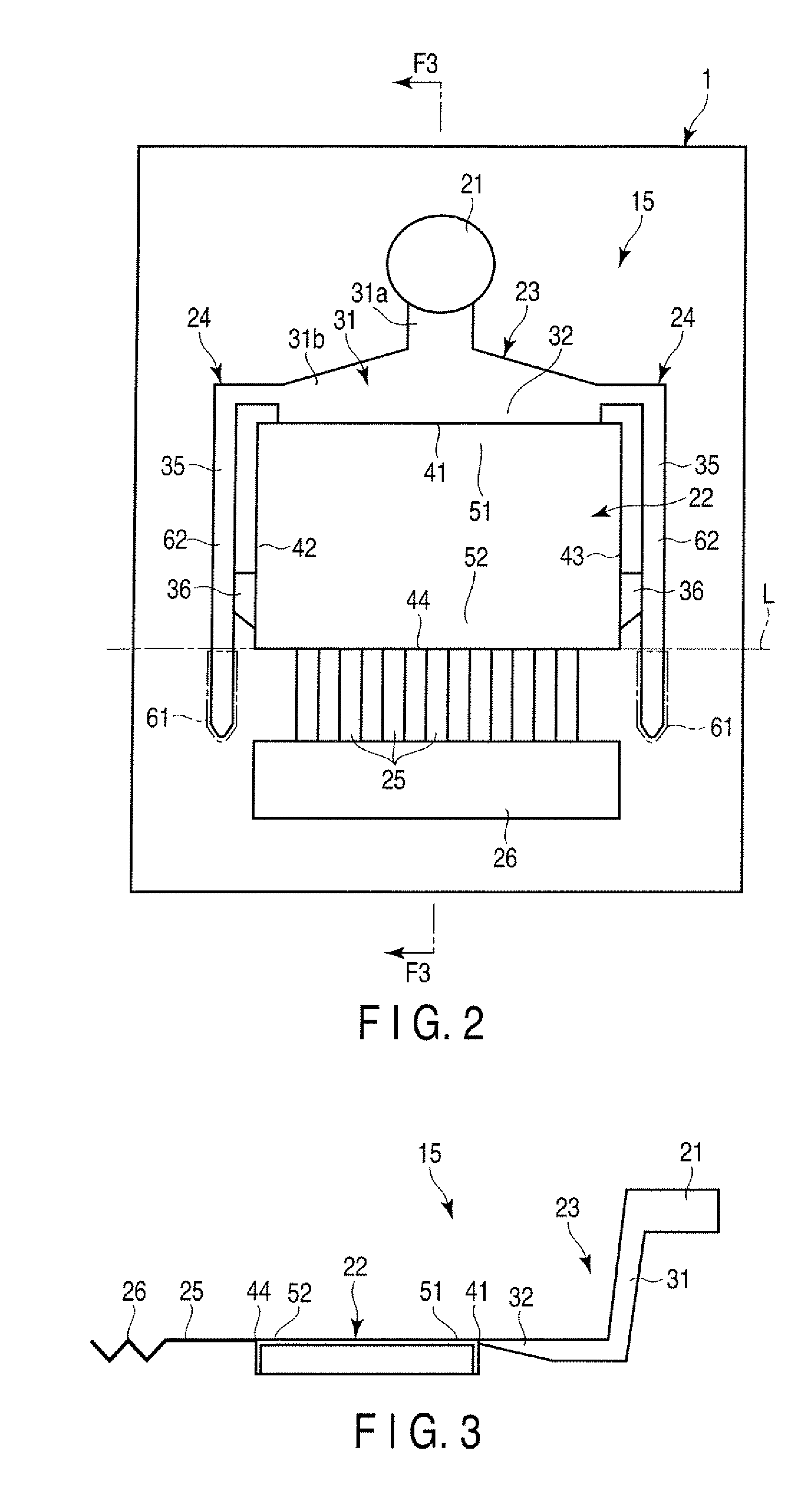

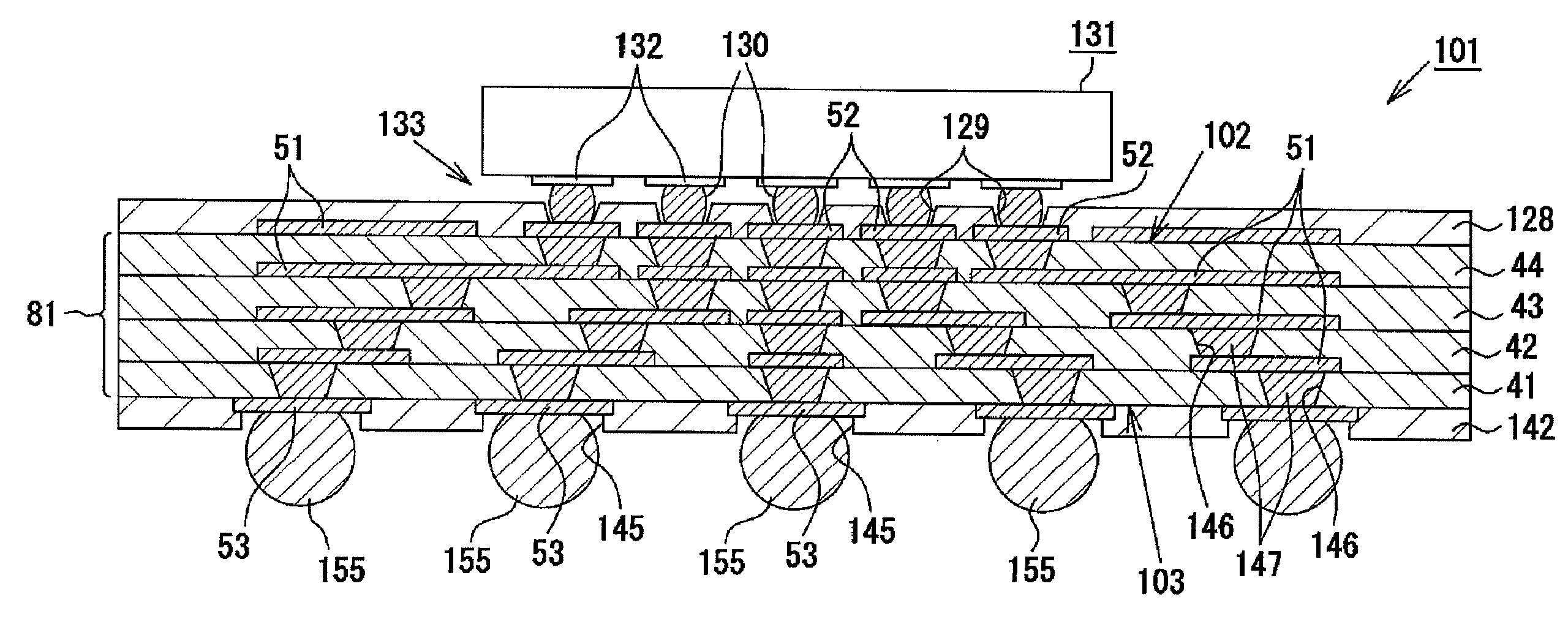

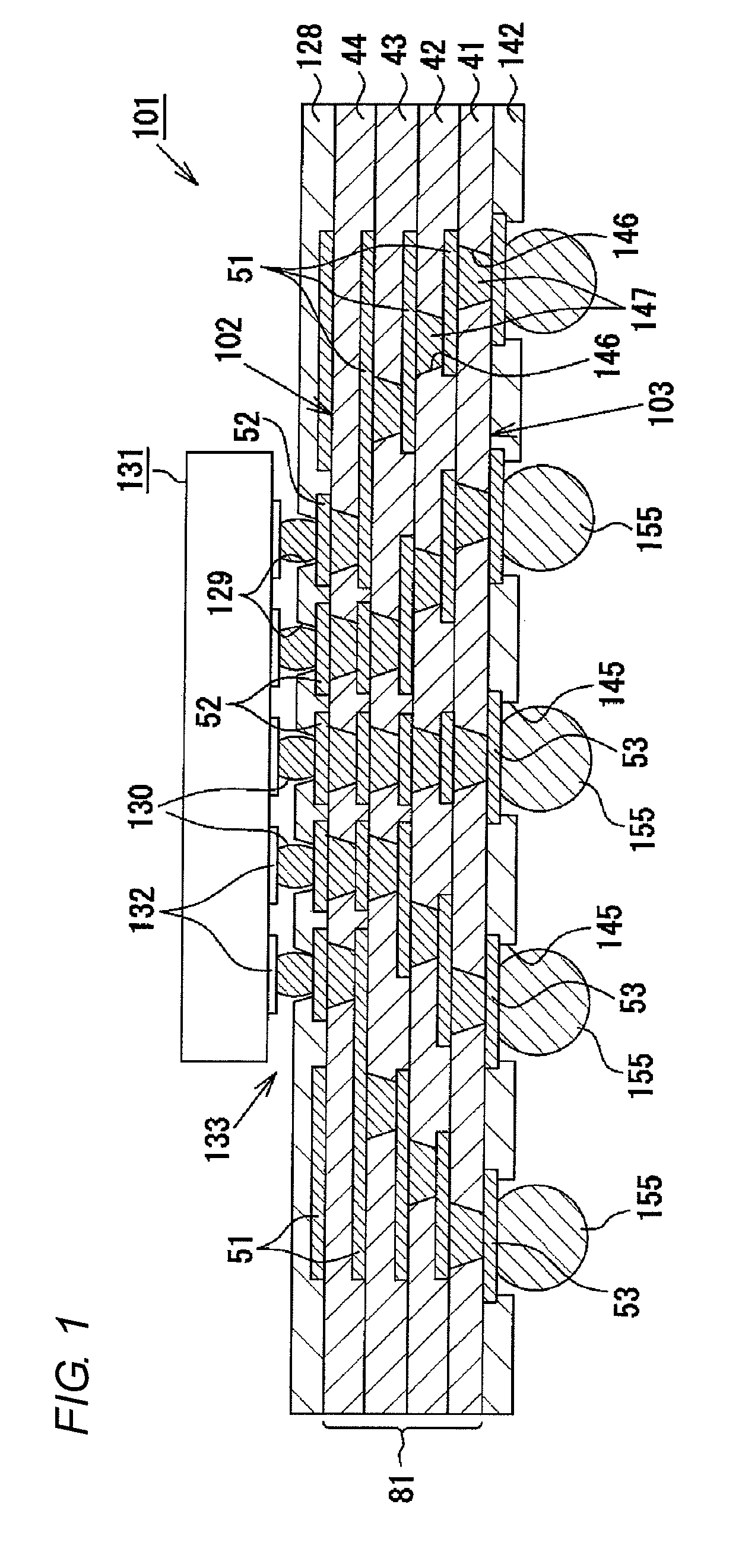

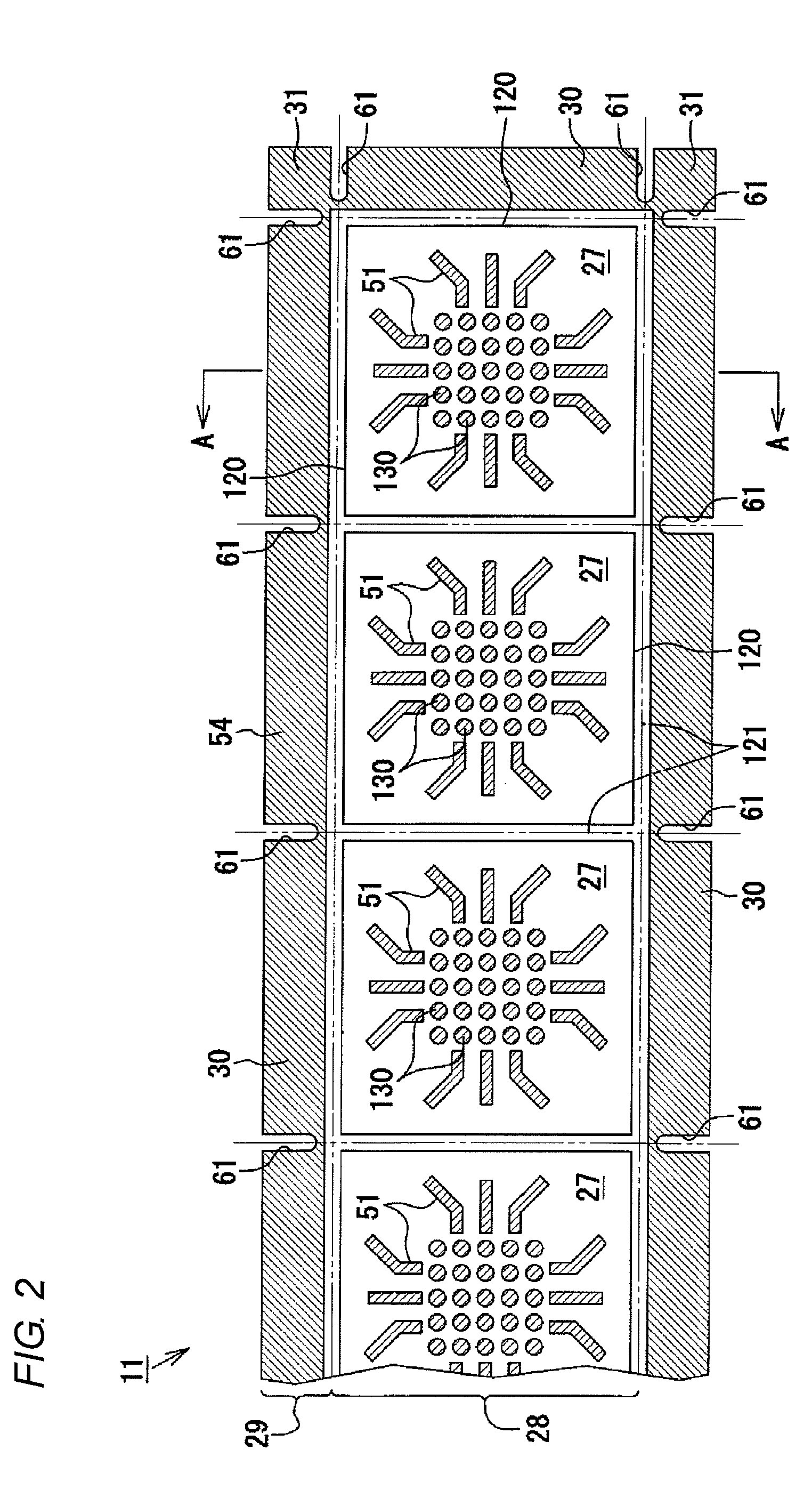

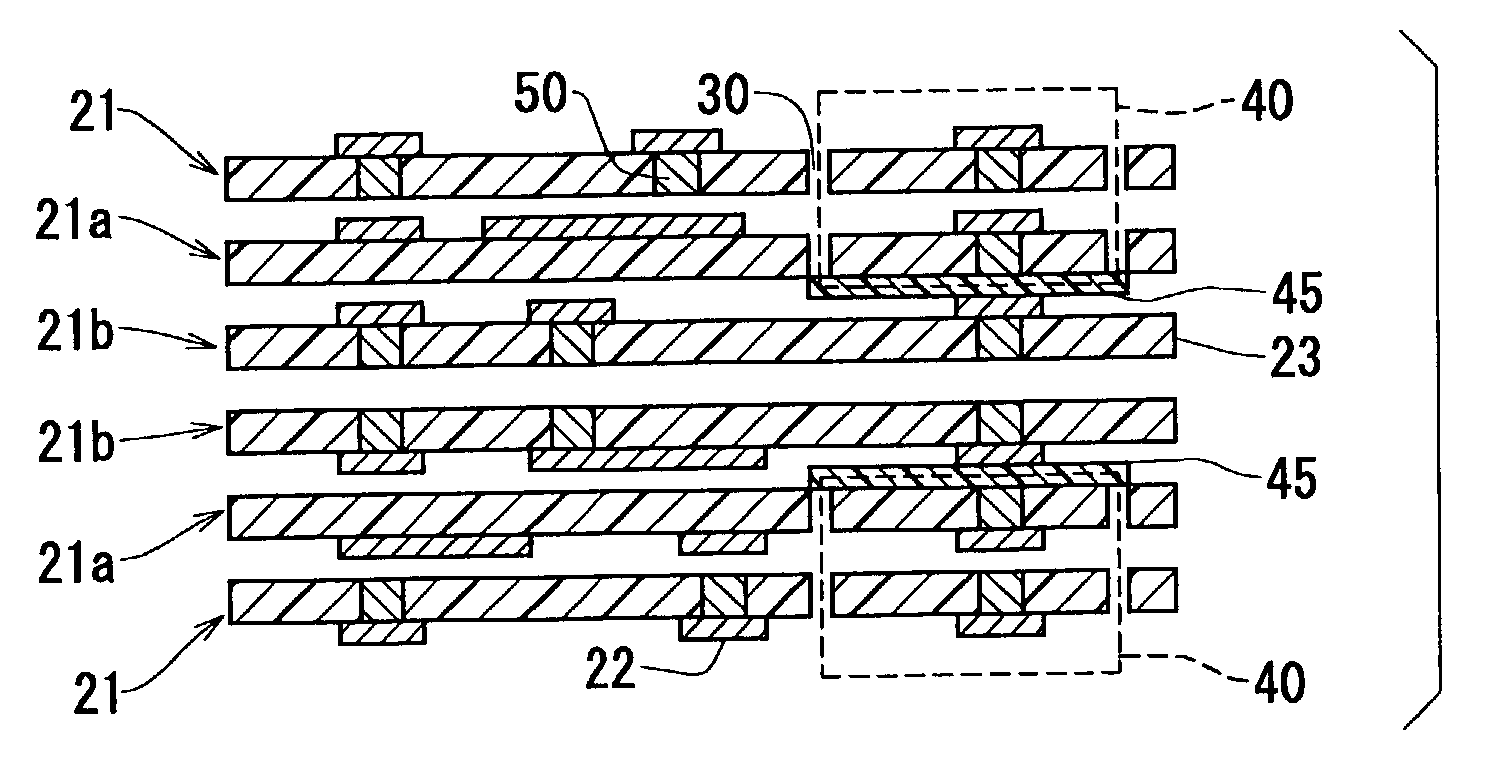

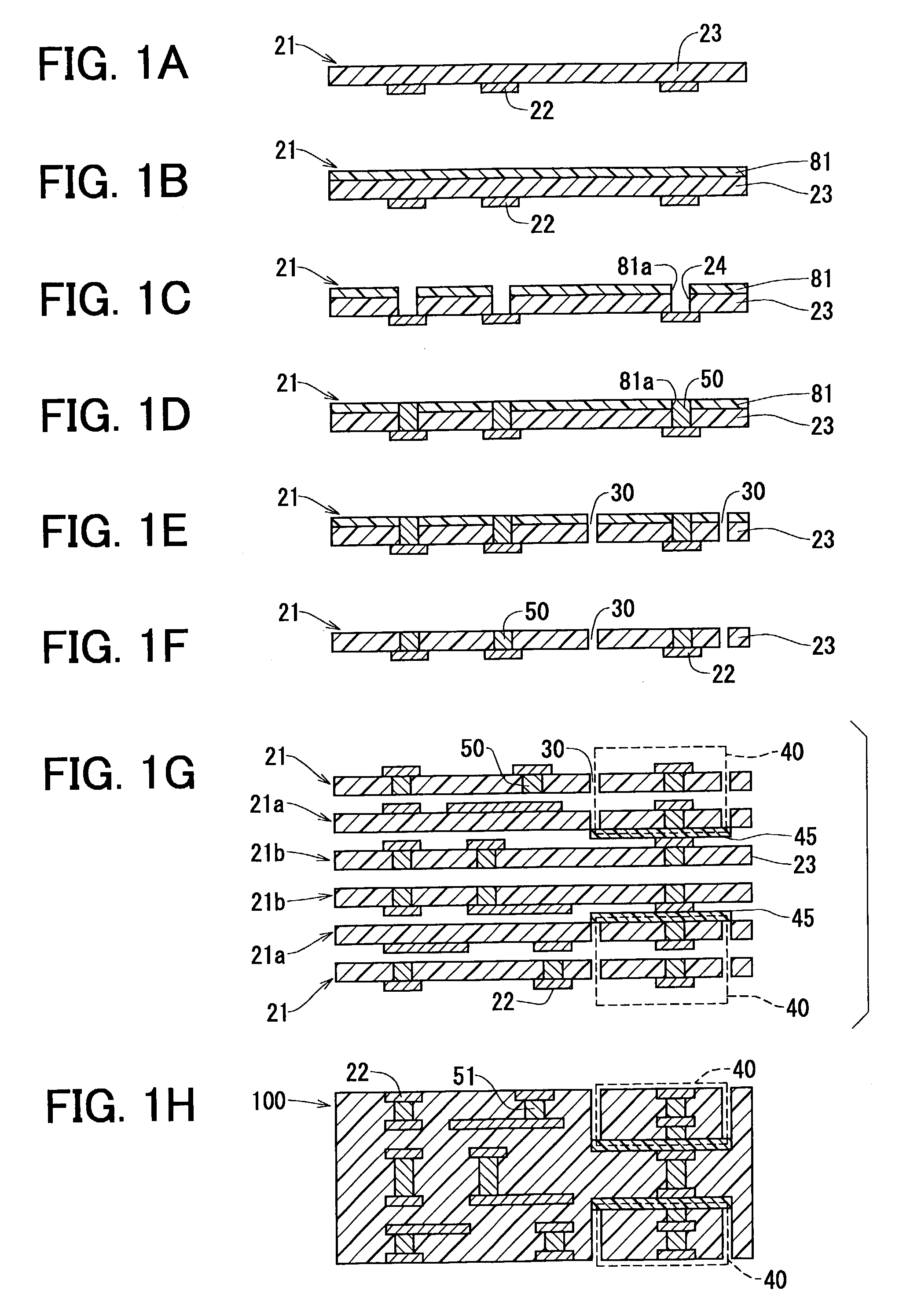

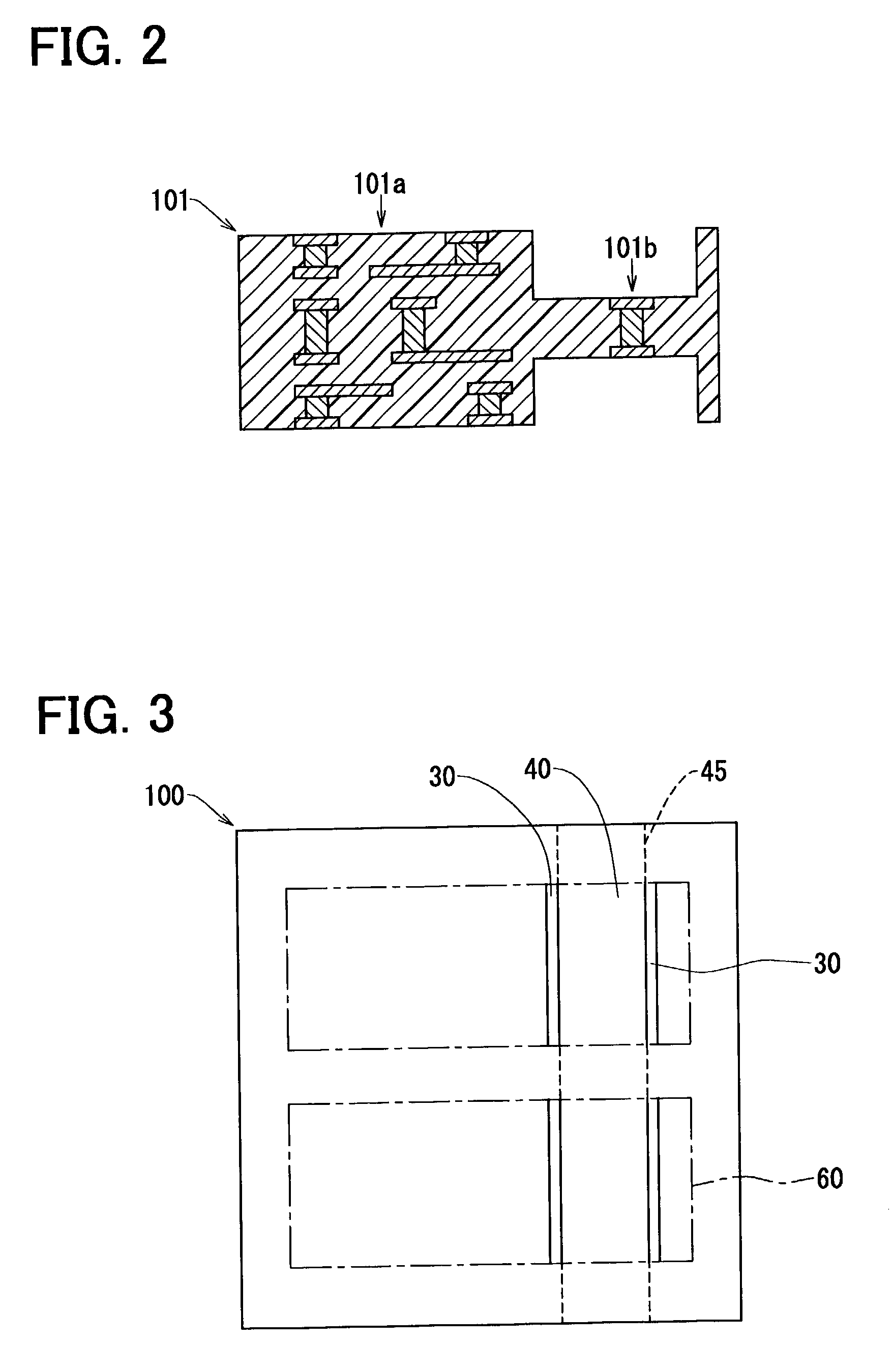

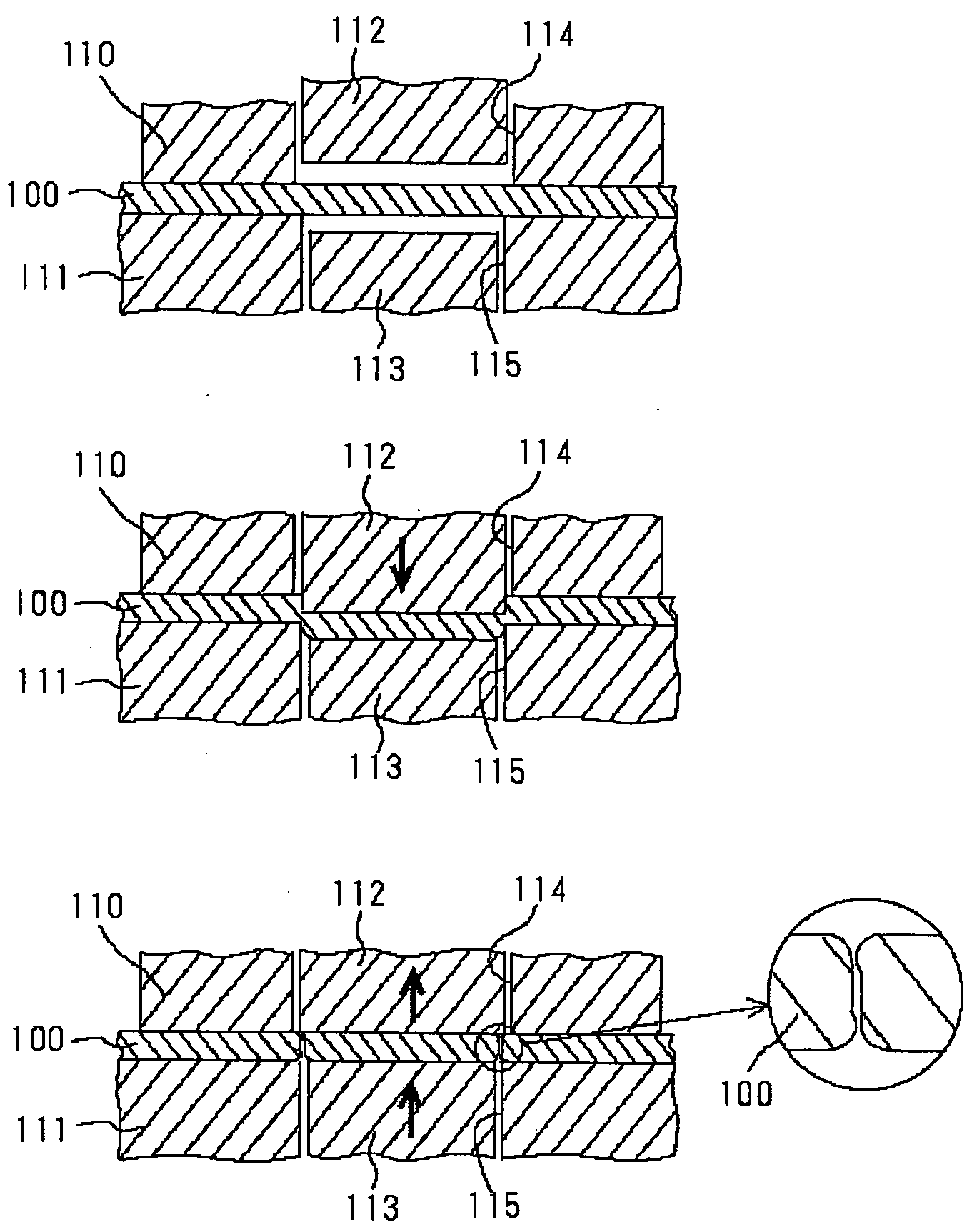

Intermediate multilayer wiring board product, and method for manufacturing multilayer wiring board

InactiveUS20090294156A1Reduce processDecrease metal resistancePrinted electric component incorporationSemiconductor/solid-state device detailsElectrical conductorProduct formation

An intermediate multilayer wiring board product includes: a stack of a plurality of resin insulating layers, a first conductor layer, and a second conductor layer. The stack includes: a product forming region comprising a plurality of product portions arranged along a major surface of the stack, each of the plurality of product portions to become a product of the multilayer wiring board; and a frame portion surrounding the product forming region. The first conductor layer is formed on at least one of the plurality of resin insulating layers within each of the plurality of product portions. The second conductor layer is formed on at least one of the plurality of resin insulating layers within the frame portion. The frame portion has a plurality of cuts penetrating the frame portion in a thickness direction thereof, the plurality of cuts being arranged at substantially equal intervals.

Owner:NGK SPARK PLUG CO LTD

Manufacturing method of rigid-flexible printed circuit board and structure thereof

ActiveUS7036214B2Easy to disassembleIncrease flexibilityPrinted circuit assemblingLine/current collector detailsFlexible electronicsPrinted circuit board

In a manufacturing method of a rigid-flexible printed circuit board, slits for defining two sides of a removing portion are formed in a part of plural resin films, and the plural resin films are stacked and bonded to form a circuit board. Then, a product portion is cut from the circuit board. Before the bonding, a separation sheet is disposed between predetermined adjacent layers of the plural resin films to separate the removing portion from a residual portion of the product portion. Accordingly, while the product portion is cut from the circuit board, the removing portion is separated from the product portion, because the removing portion are defined by the separation sheet, the slits, and a cutting outline of the product portion.

Owner:DENSO CORP

Shearing method for thin plate

A shearing method for a thin plate including forming a protruded product part having a first sagging part when the thin plate with a thickness of not more than approximately 0.3 mm is performed with a half die cutting by pressing the half die cutting punch slightly larger than the half die cutting hole to form a shallow recessed part, fixing the product part by a fixing member, forming a second sagging part at an edge portion of the thin plate by pressurizing a scrap part by moving a pressure punch which is provided with a gap between the fixing member and the pressure punch and by being bent between the scrap part and the product part, and then separating the scrap part from the product part.

Owner:NAKAMURA IND MFG CO LTD

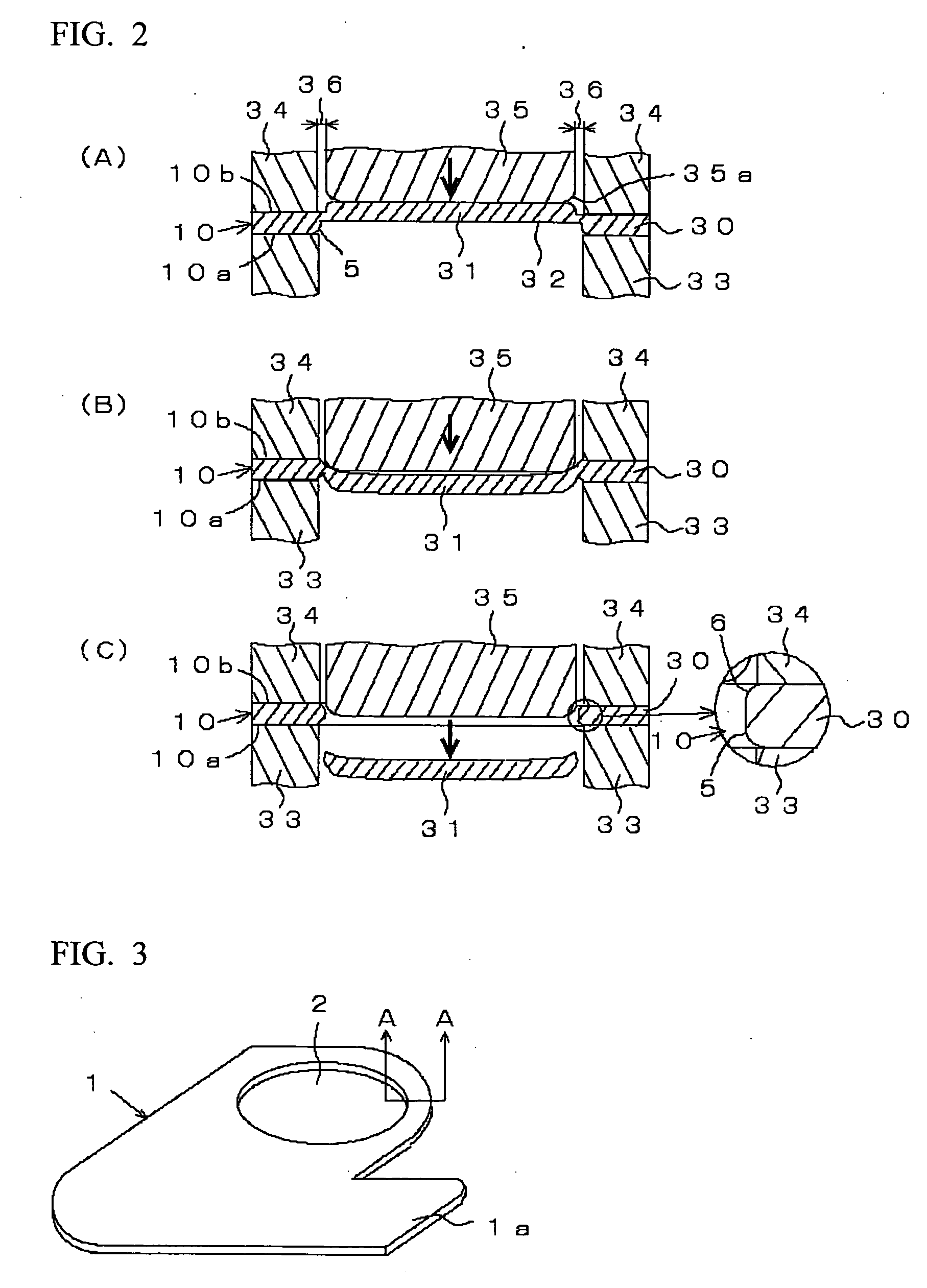

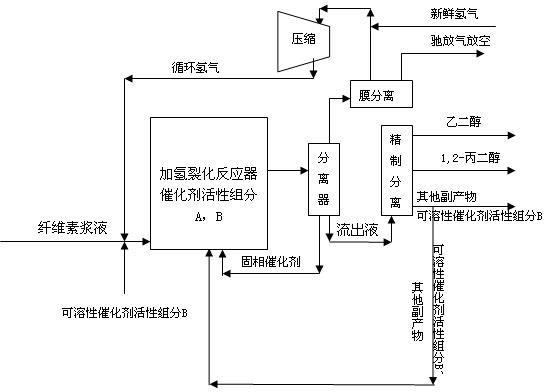

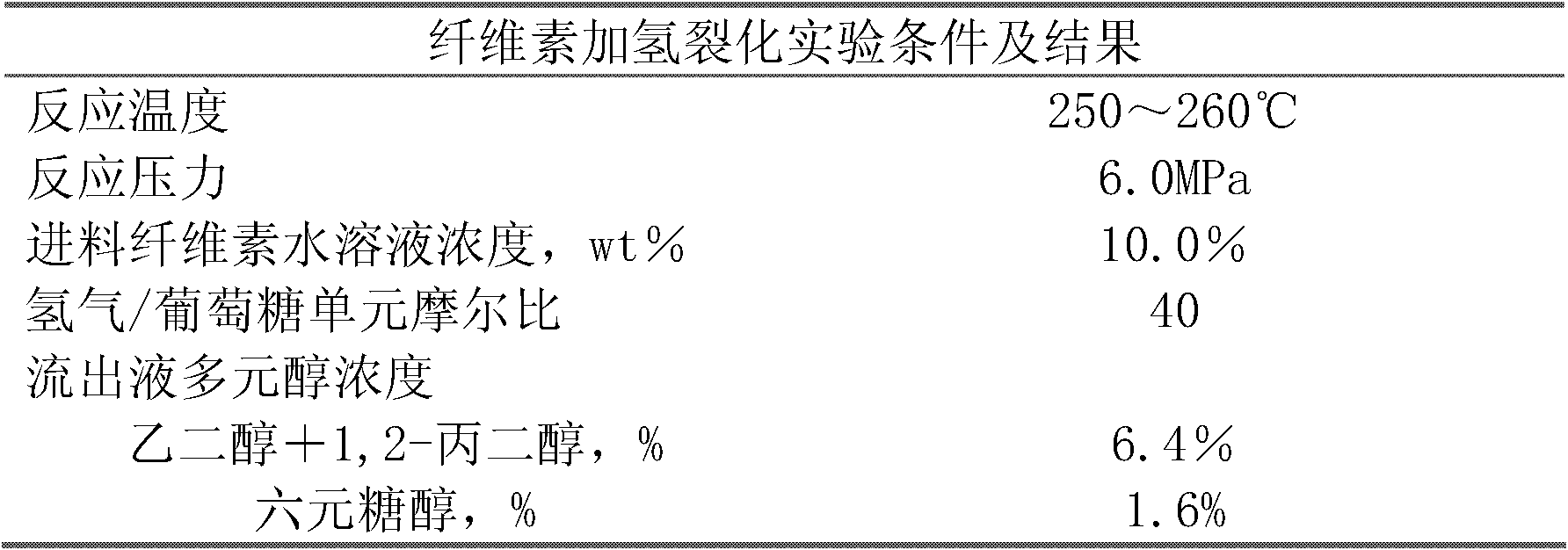

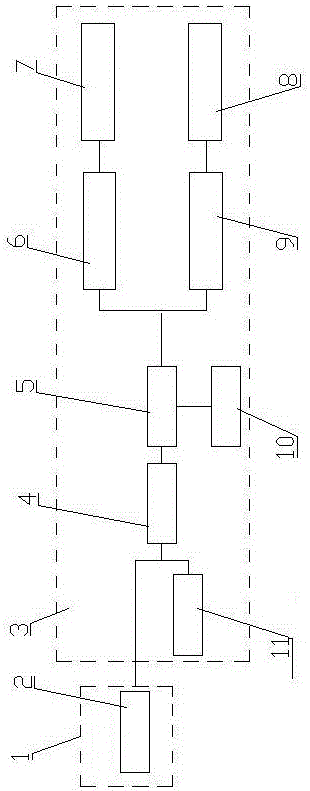

Method for producing ethylene glycol and 1,2-propylene glycol by continuously hydrocracking cellulose

ActiveCN102643164ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationCelluloseHydrogen

The invention provides a method for producing ethylene glycol and 1,2-propylene glycol by continuously hydrocracking cellulose and particularly relates to a continuous reaction technological process for producing ethylene glycol and 1,2-propylene glycol by virtue of transformation of semi-homogeneous catalyzed and hydrocracked cellulose. In the technological process, the cellulose is hydrocracked in the presence of a catalyst in a reactor and then enters into a separation system; hydrogen in a gas phase is recycled by separation and recovery; a liquid-phase product part is refluxed to the reactor, the other liquid-phase products are refined so as to separate out glycol, propylene glycol and other polyatomic; and the concentrated soluble catalyst component existing in the refined and separated residual heavy component liquid phase can be partially circulated to the reactor.

Owner:中科柏易金(郑州)新能源科技有限责任公司

Concentrated customization method based on small-amount multi-type household products

InactiveCN105976040ARealize automatic generationRealize centralized customizationReservationsBuying/selling/leasing transactionsMathematical modelComputer module

The invention relates to a concentrated customization method based on small-amount multi-type household products. The method comprises that a hierarchical structure of the household products is established via a BOM module, association between different hierarchies of parts are processed by corresponding mathematical models, and a basic database of the household products is generated; a user places an order via an order production module in an order operation platform, and an order database including specifications of the different parts is generated automatically; information of different batches of household products is extracted from the order database, recombined, and then stored in a production plan module; and an order master-control module extracts information of the different household product parts from the order database, and stores the information in a part processing plan module. The household products are classified and decomposed by the BOM module and an order recombination module according to characteristics of the household products, hierarchy and details of customized products are generated automatically, and thus, a factory can realize concentrated customization of small amount of multi-type household products.

Owner:LIANYUNGANG MOBO HOUSEHOLD

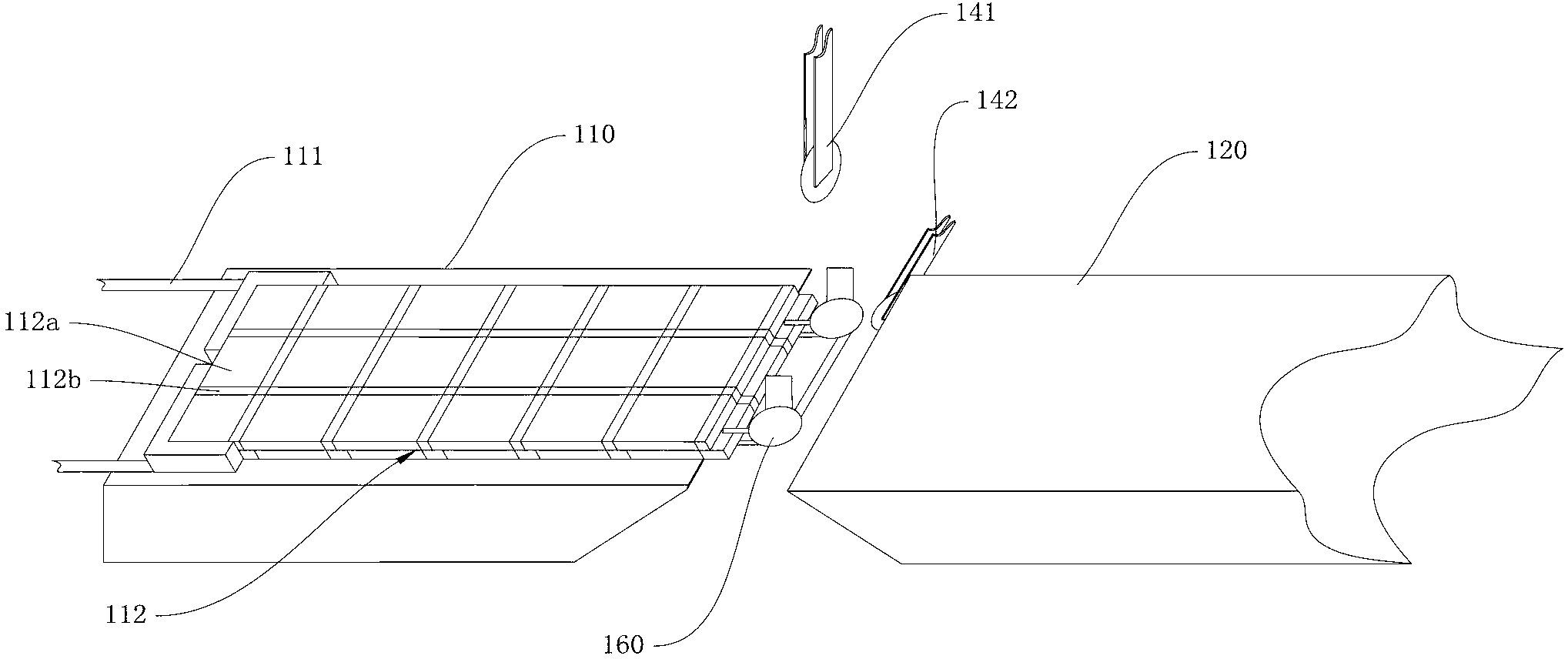

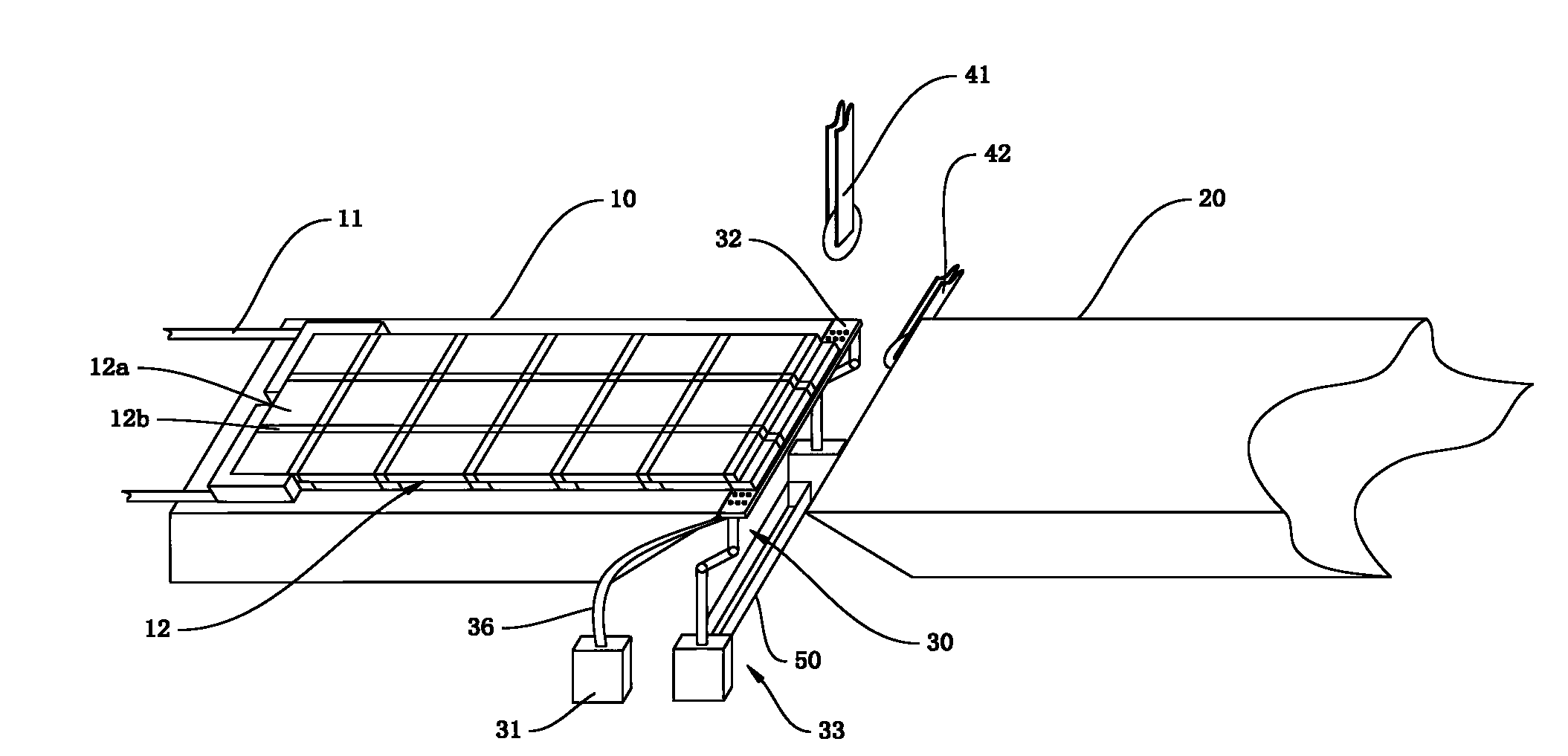

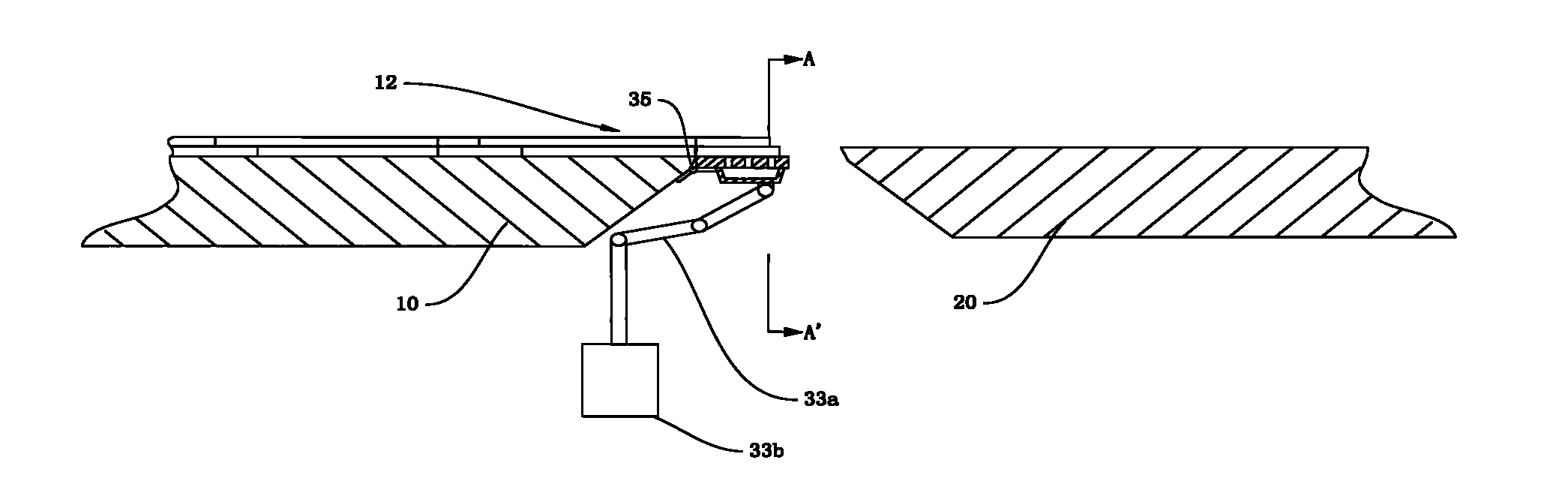

Glass substrate cutting system

ActiveCN103288342AUniform and stable forceQuality improvementConveyorsGlass severing apparatusPulp and paper industryVacuum pump

The invention provides a glass substrate cutting system. The glass substrate cutting system comprises an upstream suction platform, a movable device, an upper cutter head and a lower cutter head, wherein a downstream suction platform is arranged in front of the upstream suction platform at interval and is used for receiving a finished-product part cut from a glass substrate; the movable device is used for pushing the glass substrate to move from the upstream suction platform to the downstream suction platform; the upper cutter head and the lower cutter head are arranged between the upstream suction platform and the downstream suction platform. The glass substrate cutting system further comprises an unloading device arranged between the upstream suction platform and the downstream suction platform; the unloading device comprises a vacuum pump, a suction plate provided with a through hole, and a displacement component connected with the suction plate, wherein the bottom of the suction plate is connected with an adsorption cavity; the adsorption cavity is respectively communicated with the through hole and the vacuum pump so that a residual material part placed on the surface of the suction plate is adsorbed on the suction plate; and the displacement component is used for driving the suction plate adsorbed with the residual material part to rotate, so as to remove the residual material part. According to the glass substrate cutting system, the scratches of a cutting face of the glass substrate cutting system can be effectively avoided and the quality of a cut finished-product is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Mixed child-mother core assembly molding technology

ActiveCN107350429ASlow down depreciationIncrease the number ofAdditive manufacturing apparatusFoundry mouldsUltimate tensile strengthProduct Part

The invention discloses a mixed child-mother core assembly molding technology. A 3D printing molding technology and a sand mixing molding technology are combined, a part which is close to a product part having a plurality of structural features adopts 3D printing, and the other parts which have less structural features adopt the traditional sand mixing molding technology method, therefore an assembled sand mold which works through cooperative using of a mother core and a child core is formed. Based on the advantages of an original 3D printing molding technology, a traditional sand mixer production technology is introduced, the two molding technologies are combined with each other, further the cost of raw materials and the equipment investment cost are lowered, and meanwhile, child-mother separated core combination is conducted on a sand molding part which is brought out of a casting and the mold thickness which is brought out of a casting system and improves the strength so as to widen thinking for later multi-technology combination; the number of castings in a single sand box is increased, the sand box utilization ratio and the production efficiency are improved, the dependence on manual work is reduced at the same time, the cost of 3D printing raw materials and the depreciation of the equipment are reduced, and meanwhile, waste of molten iron is avoided, and the purposes of cost reduction and efficiency improvement are achieved.

Owner:四川共享铸造有限公司

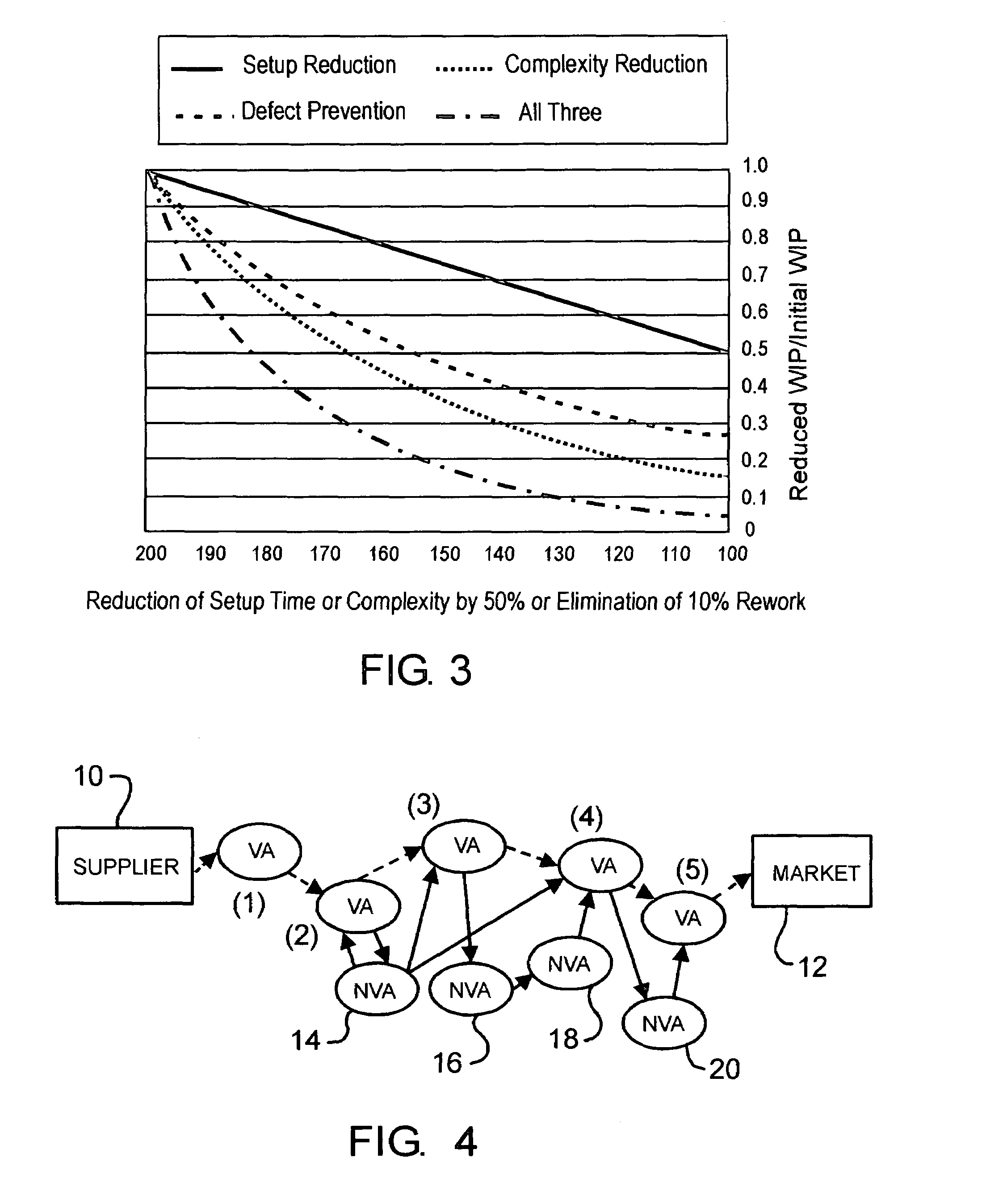

Method for determining and eliminating the drivers of non-value added cost due to product complexity and process parameters

A method for measuring and reducing the cost of complexity in producing products or providing a service by comparing selected non-value added steps in the manufacturing or service process with the number of different products or services provided, so as to provide the non-value added cost of the product or service for various selected complexities. The number of products required to be processed or held in inventory for a particular demand, or the number of different specific services required for a particular demand of the service is determined by comparing the number of different product part numbers, or service categories offered, with selected non-value added steps in the respective processes. Mathematical analyses are derived from equations of motion of process improvement including the first derivative of process velocity.

Owner:ACCENTURE GLOBAL SERVICES LTD

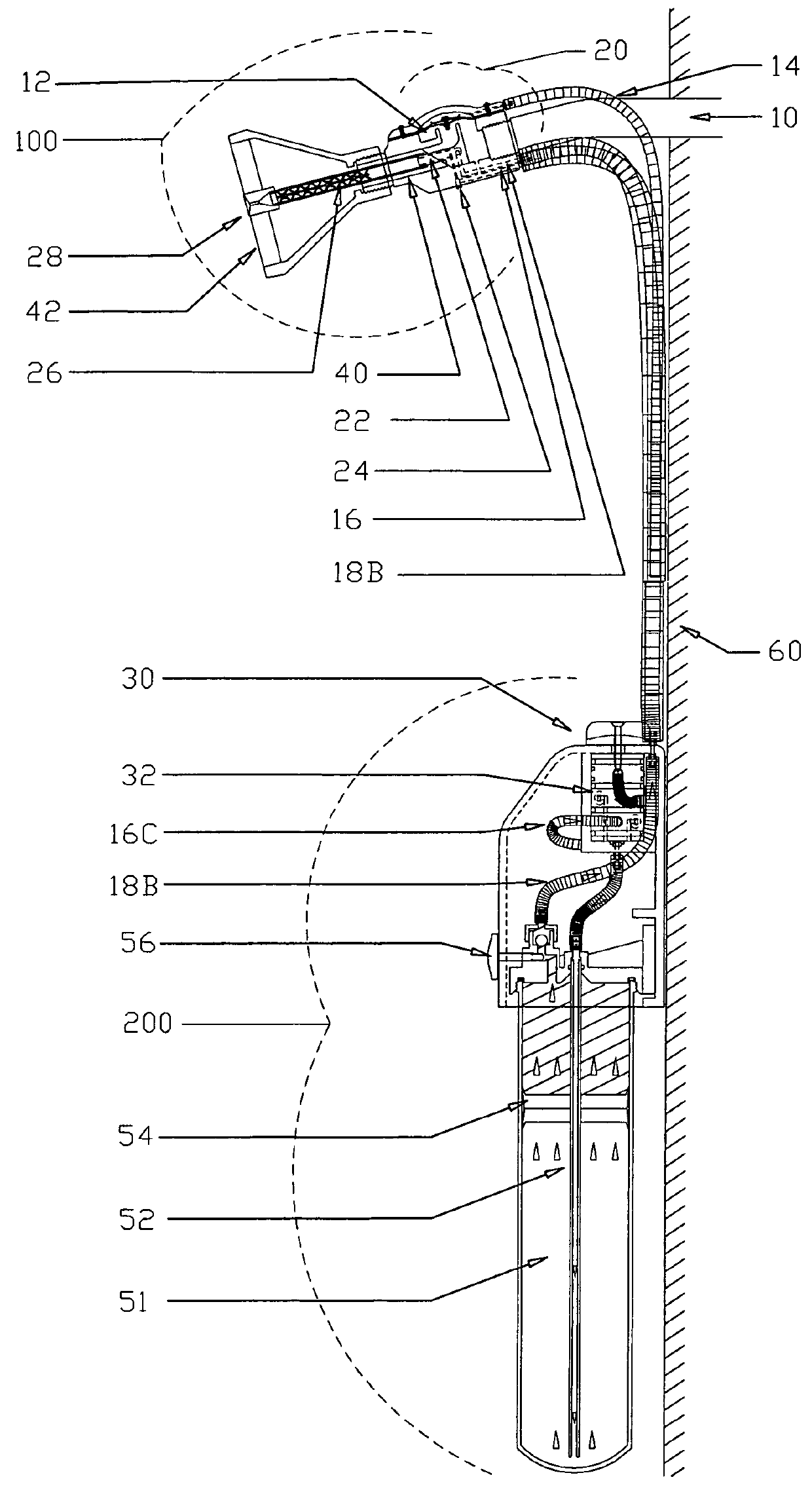

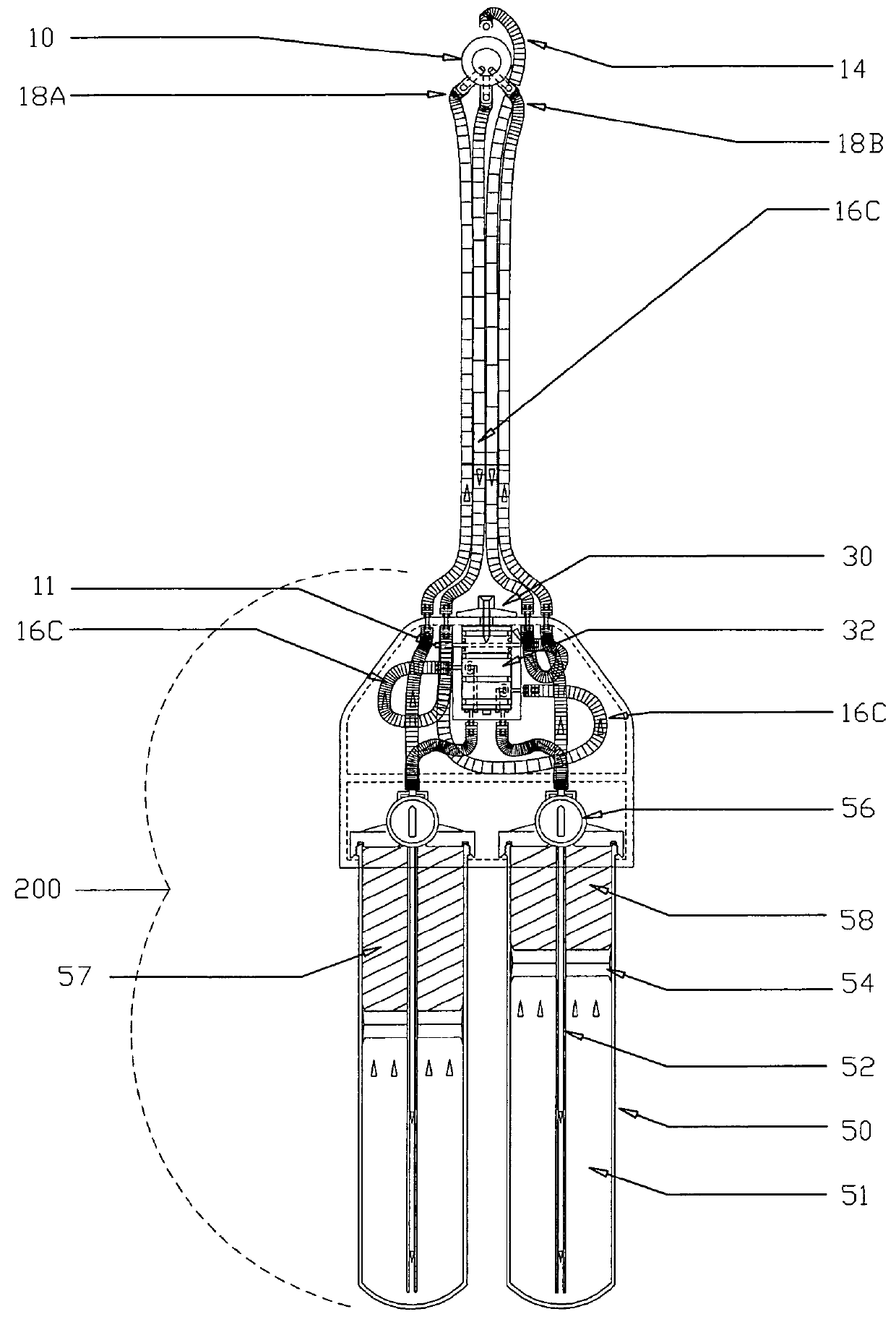

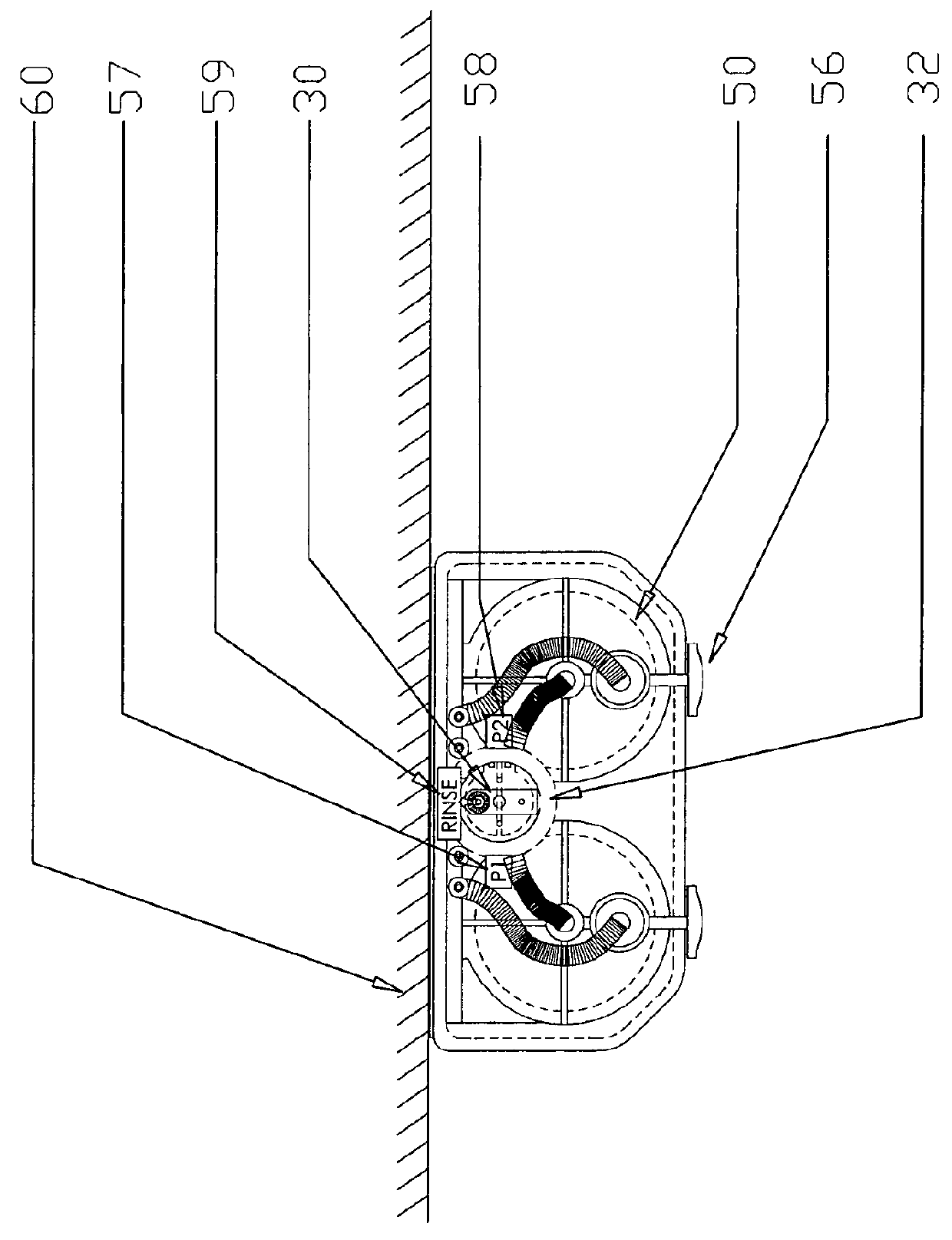

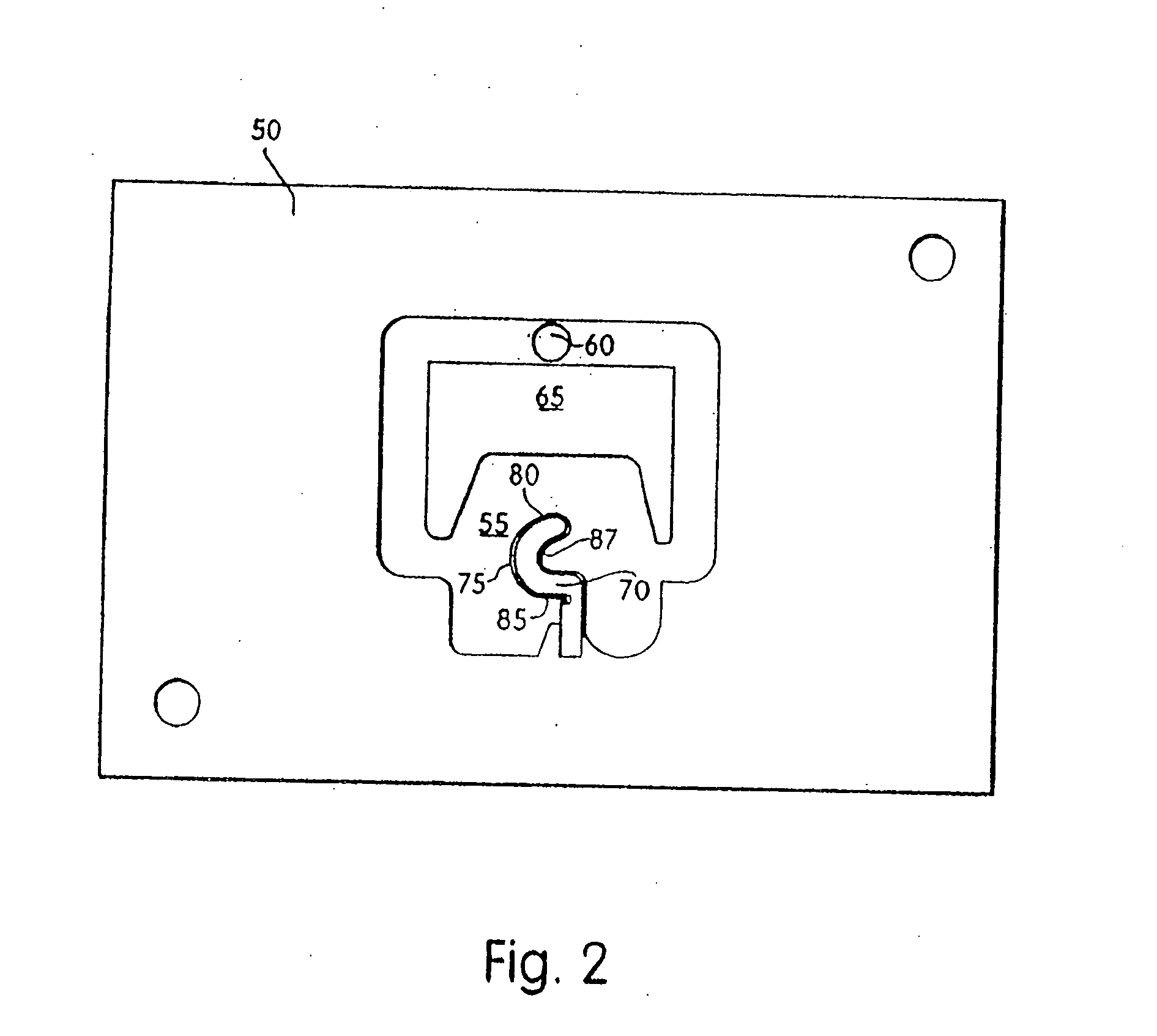

Shower device with multi-product dispensing capability

ActiveUS9359748B1Efficient use of waterEfficient use ofDomestic plumbingSpray nozzlesSpool valveWater flow

A two-stage coaxial shower head that allows conventional water flow through the shower head or a mixture of product and water through a product low flow nozzle. The product may be such liquids as soap, moisturizer, shampoo, or hair conditioner. Products are contained within product pressure reservoirs each with a product section and a piston. During a shower, a user rotates a selector dial at the multi-ported spool valve to select a product or conventional water flow for rinsing. When a product is selected water flow through a water supply tube from the multi-ported spool valve to the shower head will cease and pressure to force water down to the lower part of a product reservoir to raise the piston in the product pressure reservoir to reject product that is transported to a shower head section. A version using electronics instead of hydraulics is also presented.

Owner:LAMY ANTHONY J +1

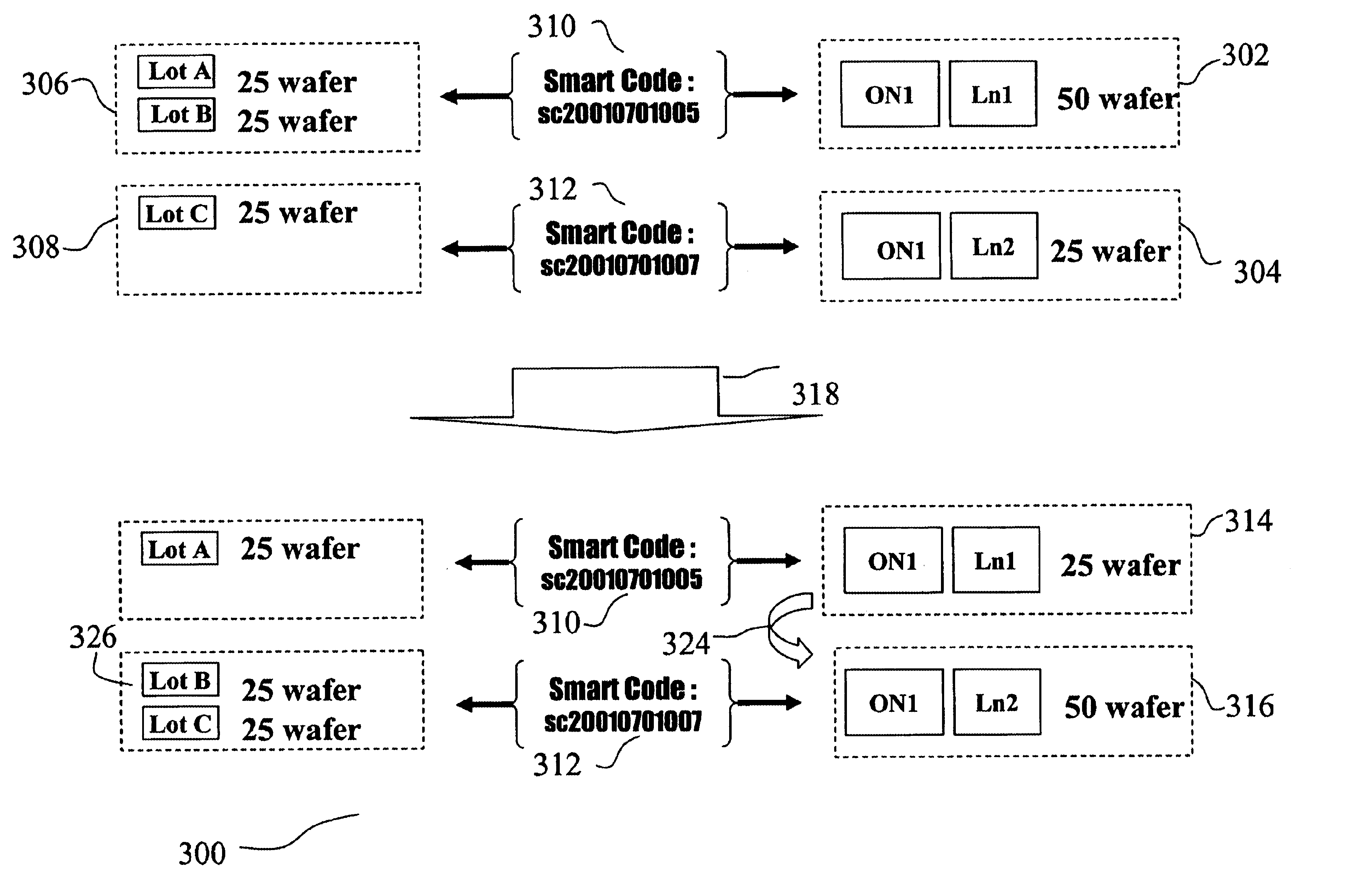

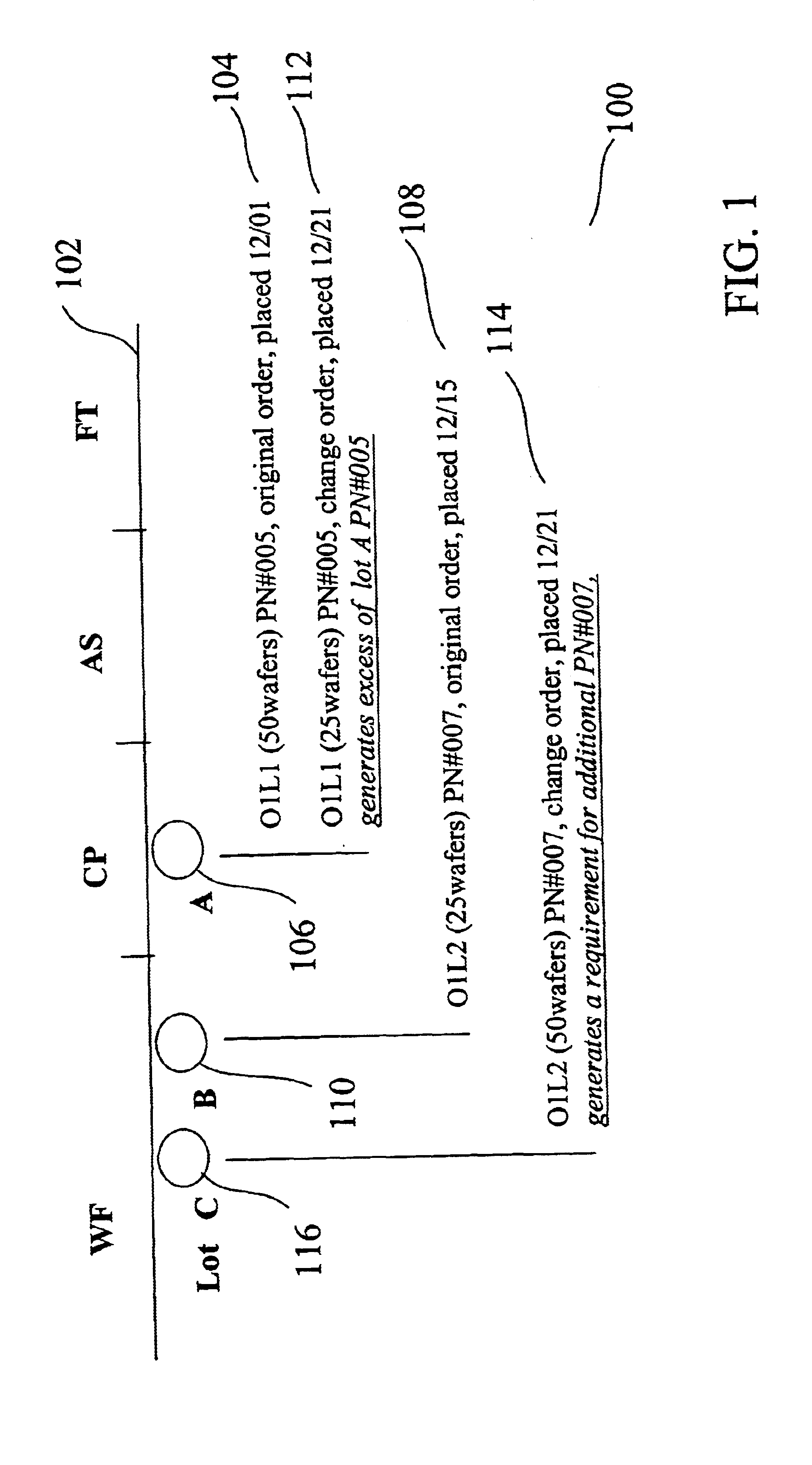

Method and system for efficiently coordinating orders with product materials progressing through a manufacturing flow

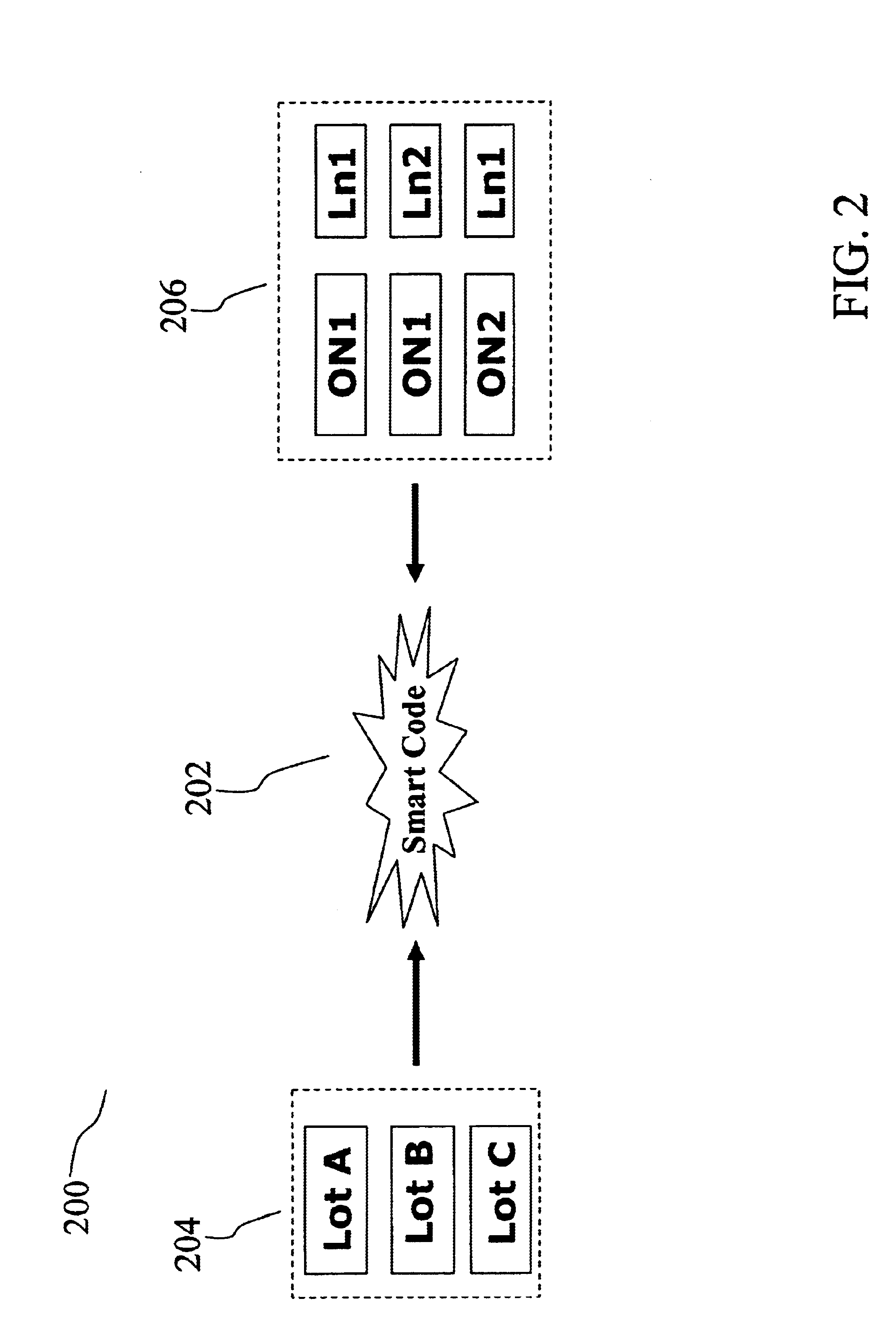

InactiveUS6871110B1Resource can be very expensiveLow costResourcesSpecial data processing applicationsProduct orderOrder form

A method and system is provided for dynamically coordinating one or more product orders with product parts progressing through a manufacturing process flow. After identifying a first order for generating one or more lots of parts for manufacturing a first product, wherein the first order identifies a predetermined base feature, one or more customer specific features, one or more order specific features, and the quantity of the first product, A smart code is assigned to the first order and the lots of parts, wherein the smart code identifies an association between the first order and the lots of parts. An analysis is then performed, based on the smart codes assigned thereto, to see whether one or more available lots of parts of a second order in production are ready to be converted to produce the first product. The smart code of the available lots is changed to the smart code of the first order if the available lots of the second order are chosen to be further processed for fulfilling the first order.

Owner:TAIWAN SEMICON MFG CO LTD

Double-beam five-axis numerically controlled laser polishing method

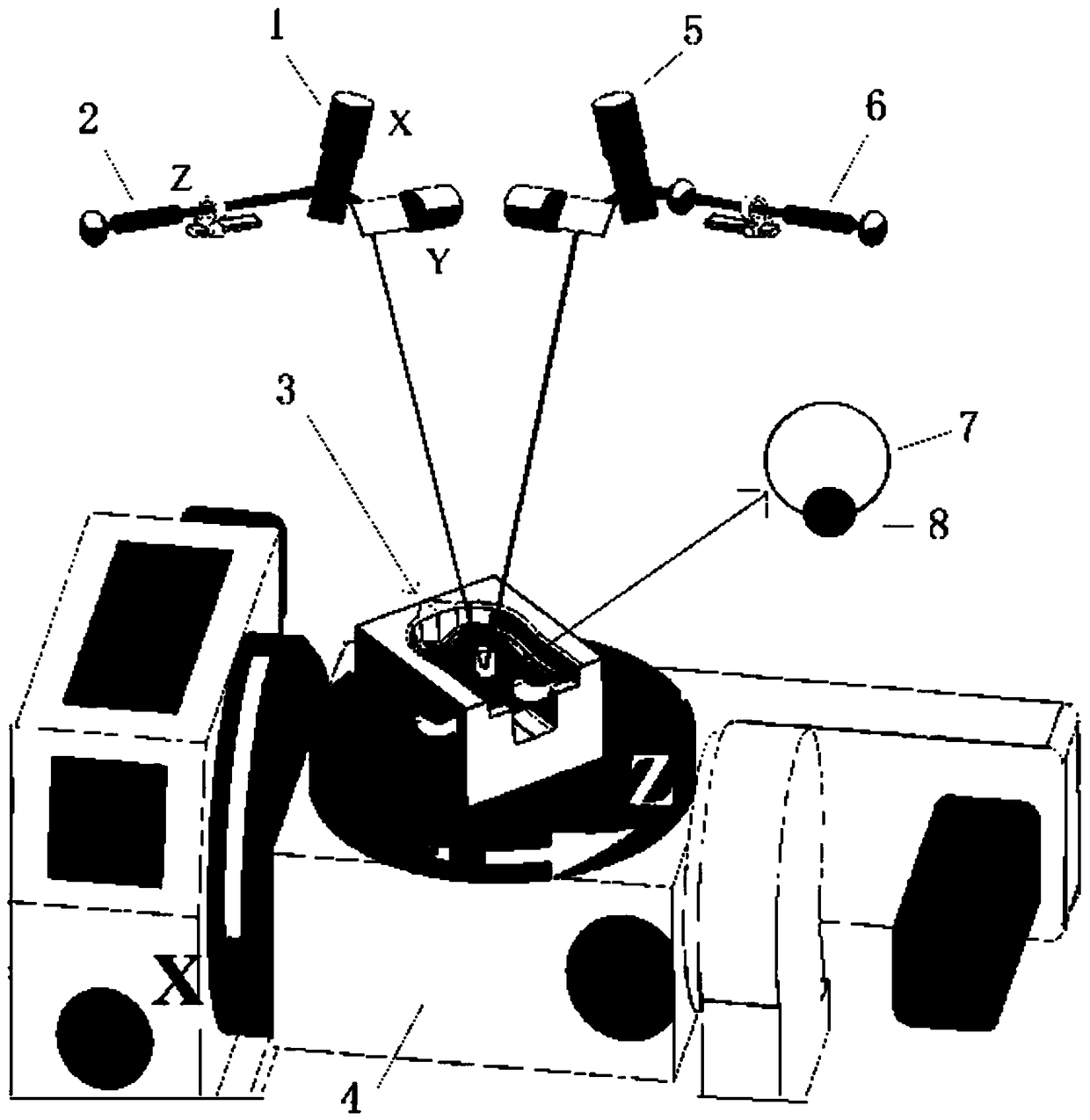

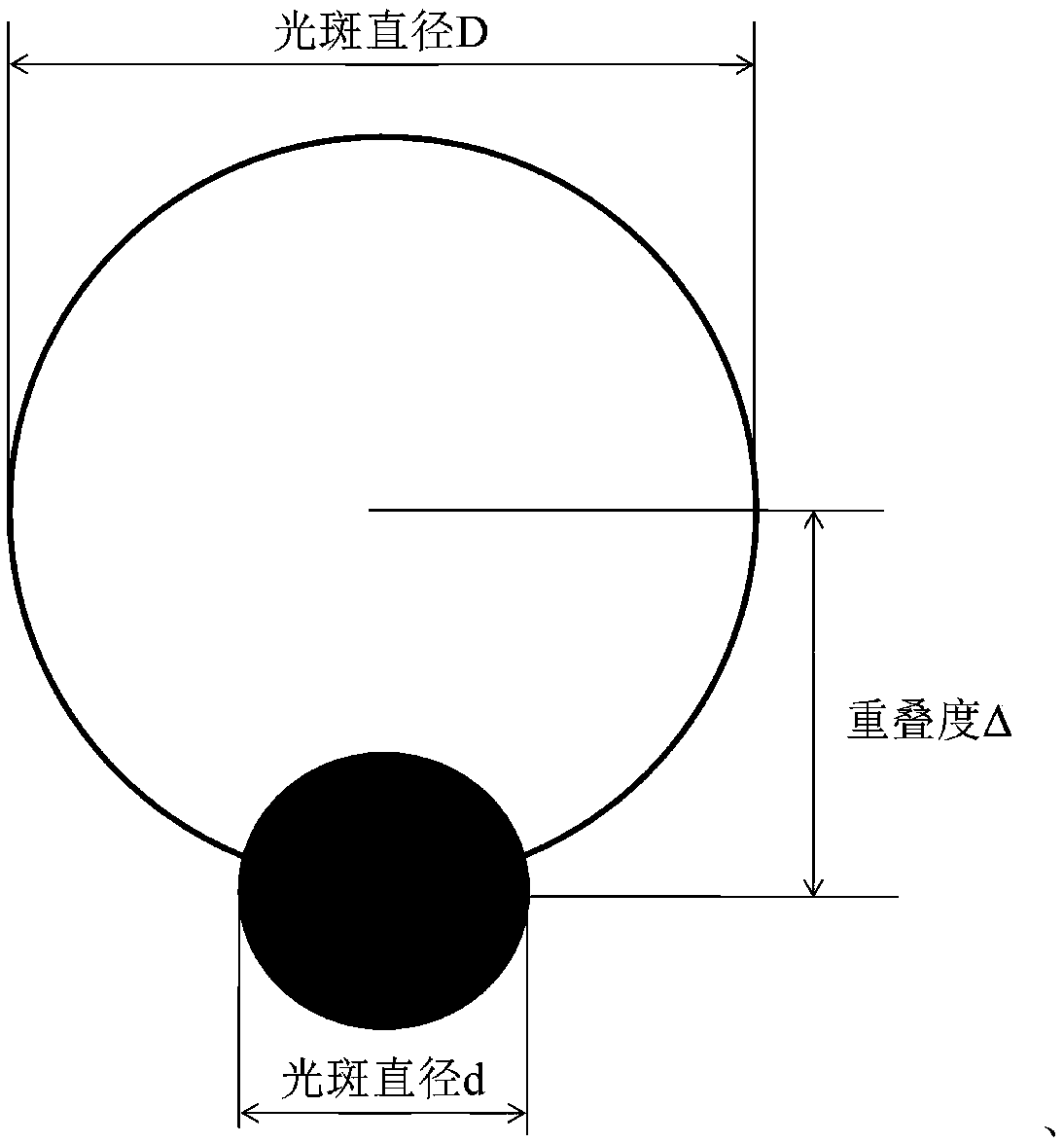

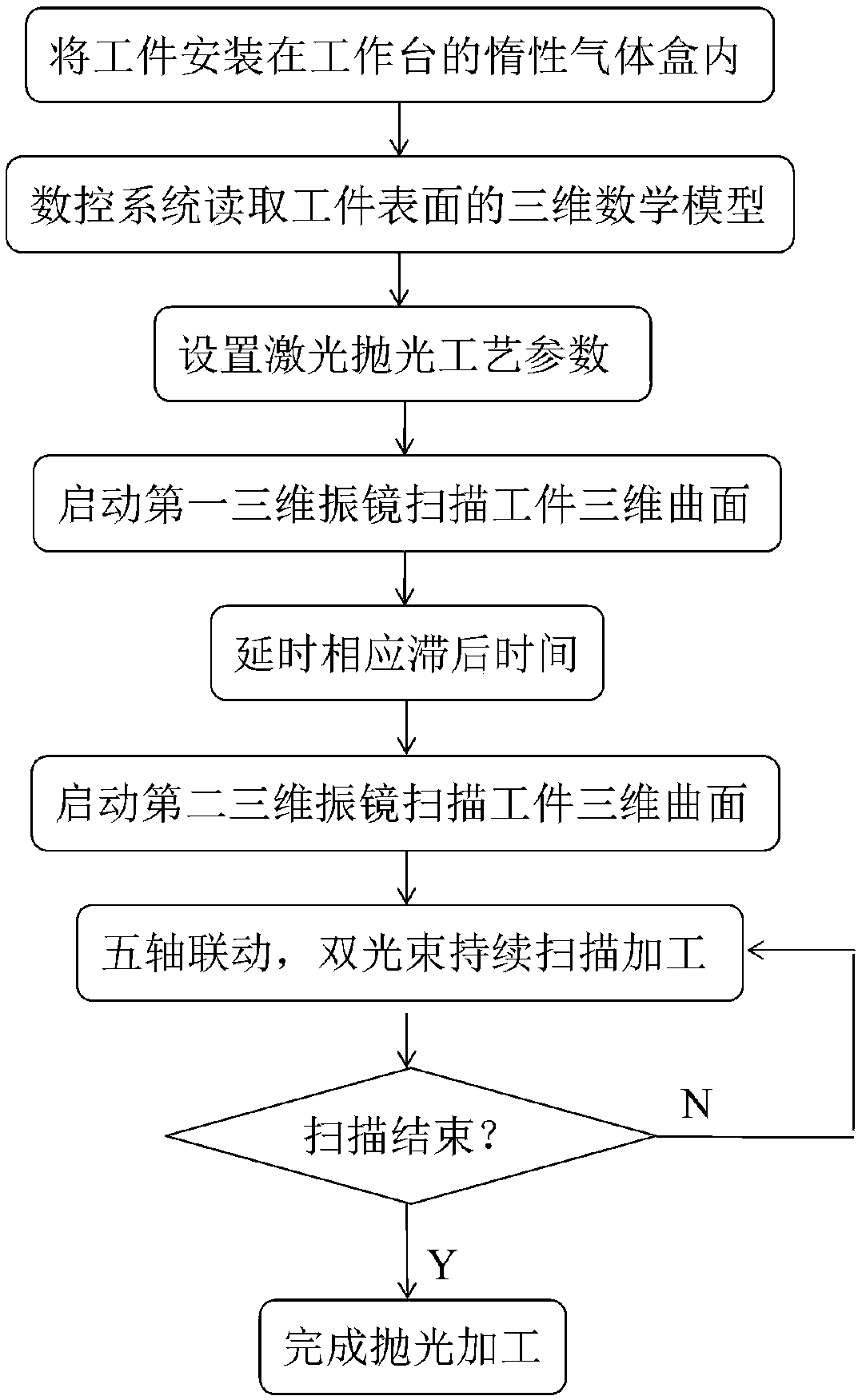

The invention discloses a double-beam five-axis numerically controlled laser polishing method. The method comprises the following steps that A, firstly, two three-dimensional galvanometer systems capable of performing three numerically controlled moving shafts are arranged on laser polishing equipment to form a double-beam three-dimensional galvanometer system, a fiber infrared continuous laser passes through the first three-dimensional galvanometer system and applies a focused light spot on a three-dimensional curved surface of a to-be-polished workpiece, a multi-band pulsed laser passes through the second three-dimensional galvanometer system and also applies a focused light spot on the three-dimensional curved surface of the to-be-polished workpiece. The double-beam five-axis numerically controlled laser polishing method has the advantages that 1, the method can be applied to laser polishing of a plastic injection mold cavity and a blow mold cavity; 2, laser polishing can be performed on a 3D glass shell of a mobile phone; 3, precise laser polishing can be performed on optical glass; 4, polishing can be performed on the three-dimensional curved surface of parts processed by additive manufacturing (3D printing); 5, laser polishing can be performed on the three-dimensional shaped curved surface of other product parts.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

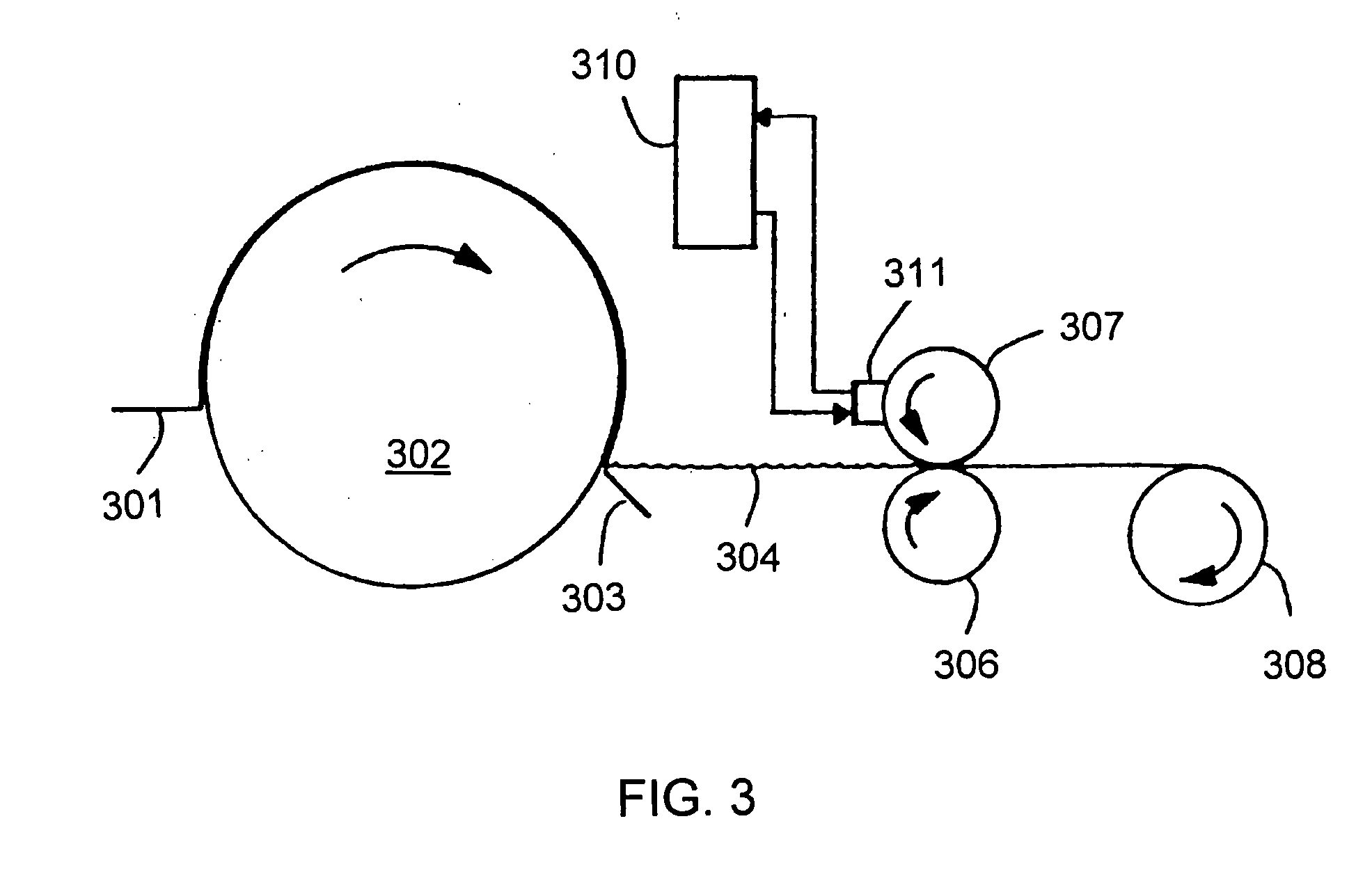

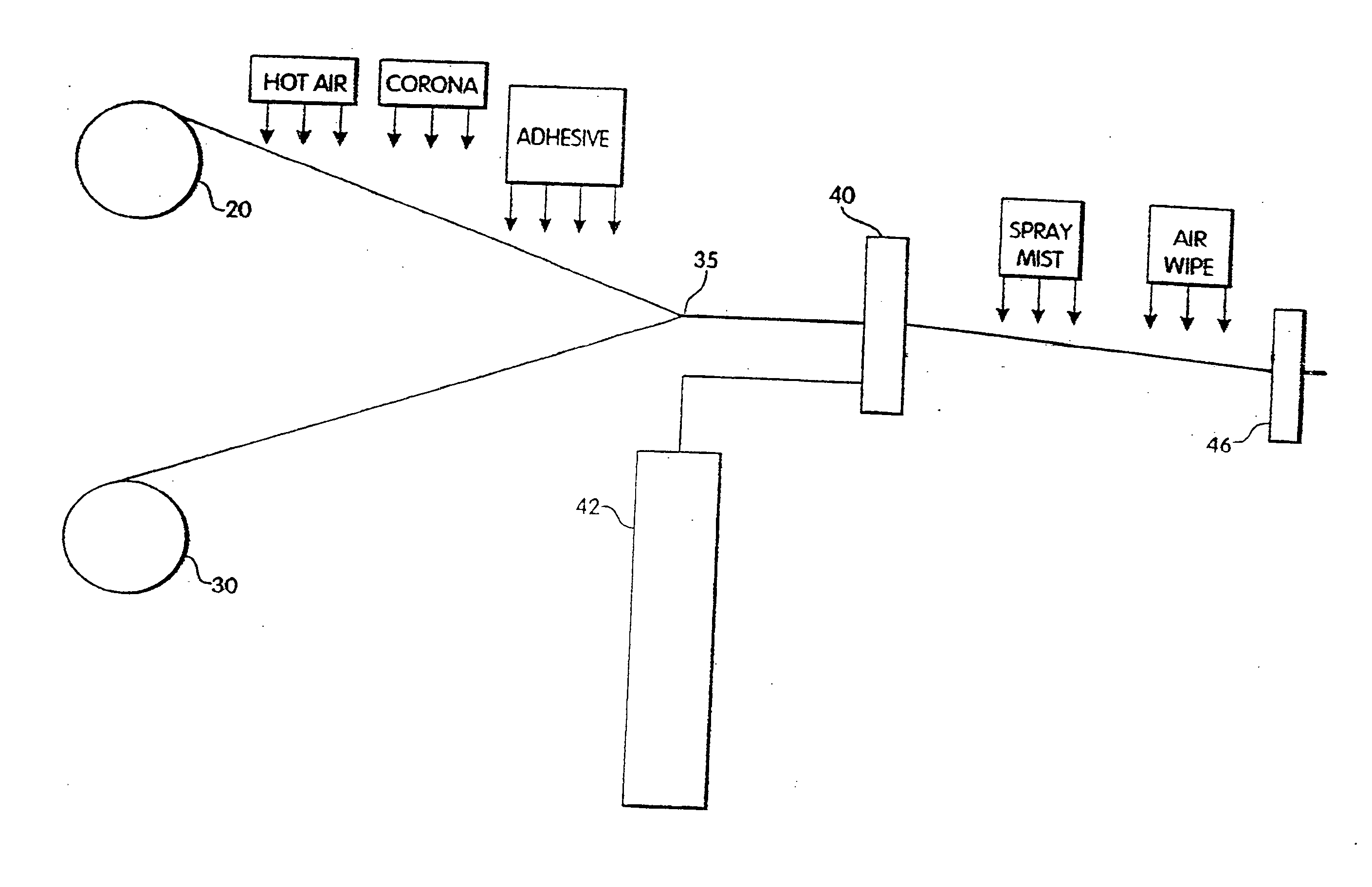

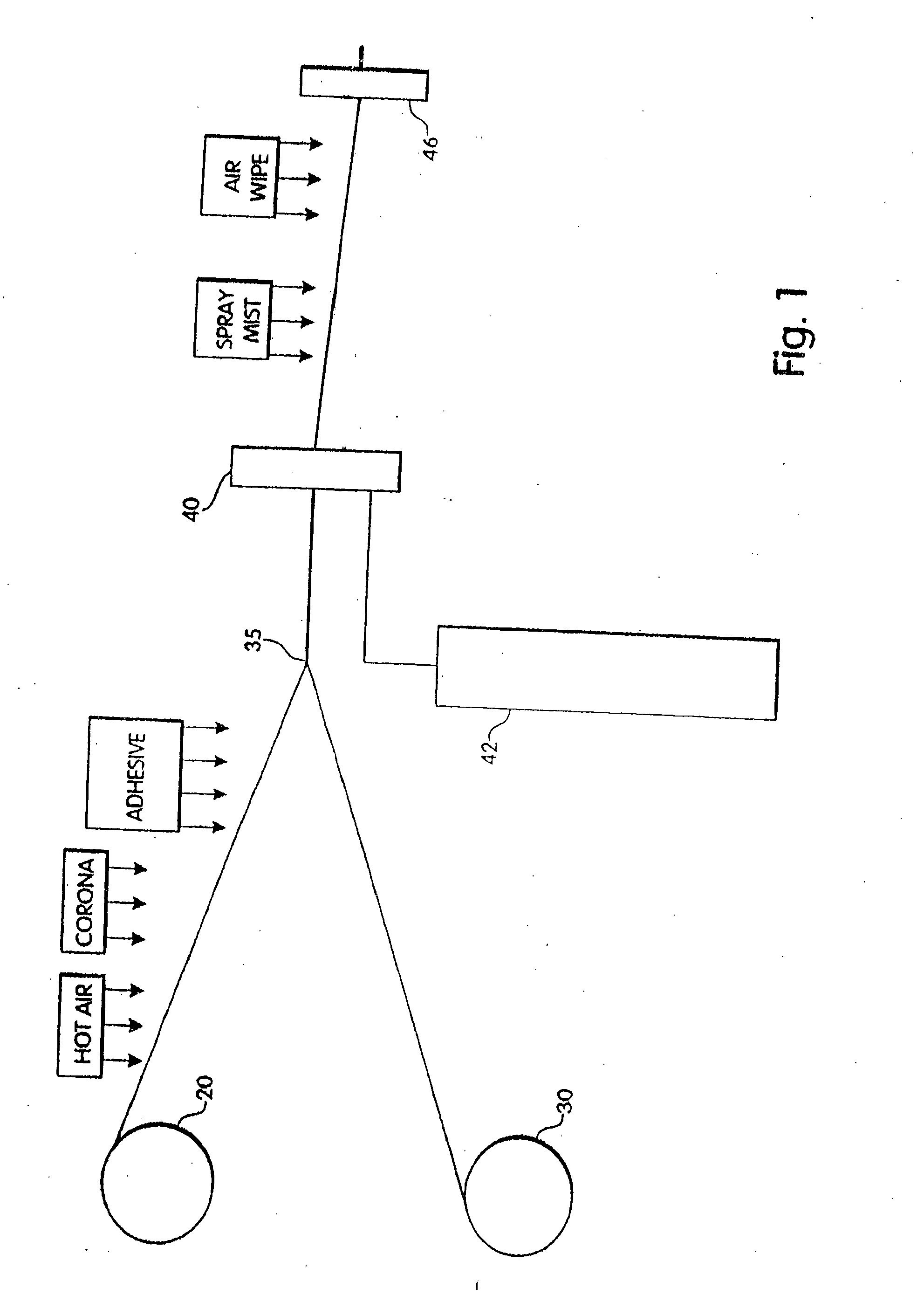

Systems and methods for manufacturing reinforced weatherstrip

ActiveUS20070218270A1Unprecedented performance characteristicQuiet operationAdhesive processesLamination ancillary operationsMolten stateUltrasonic welding

Methods for manufacturing fabric-reinforced weatherstrip include incorporating a fabric application step into a process for making coated substrates. In one embodiment, a strip of the fabric from a roll of material may be applied directly onto a coating after it has been applied in a coat die to a foam profile, while the coating is still in the molten state. Alternatively, a fabric application plate may be attached to an upstream side of coating die with a fabric feed channel cut into the plate. The fabric follows the channel to contact and mate with the foam profile. The fabric applicator plate may be configured so as to exert pressure on only the part of the product where the fabric is being applied. Ultrasonic welding techniques may also be employed.

Owner:AMESBURY GROUP

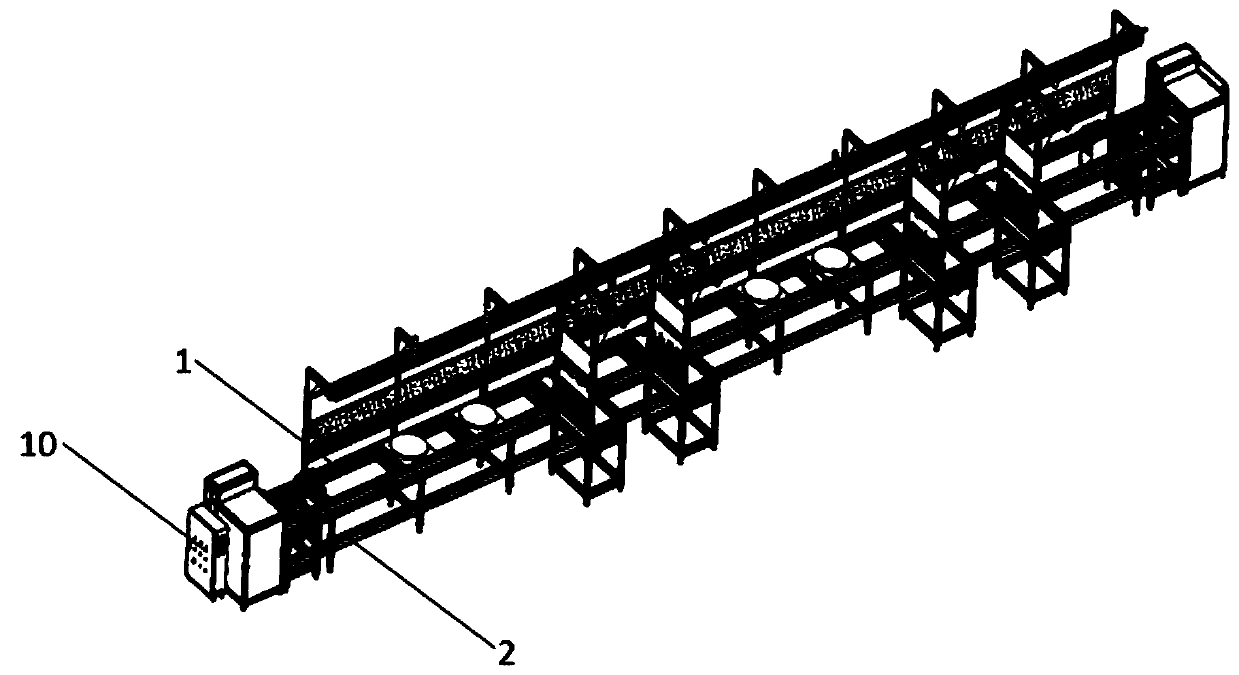

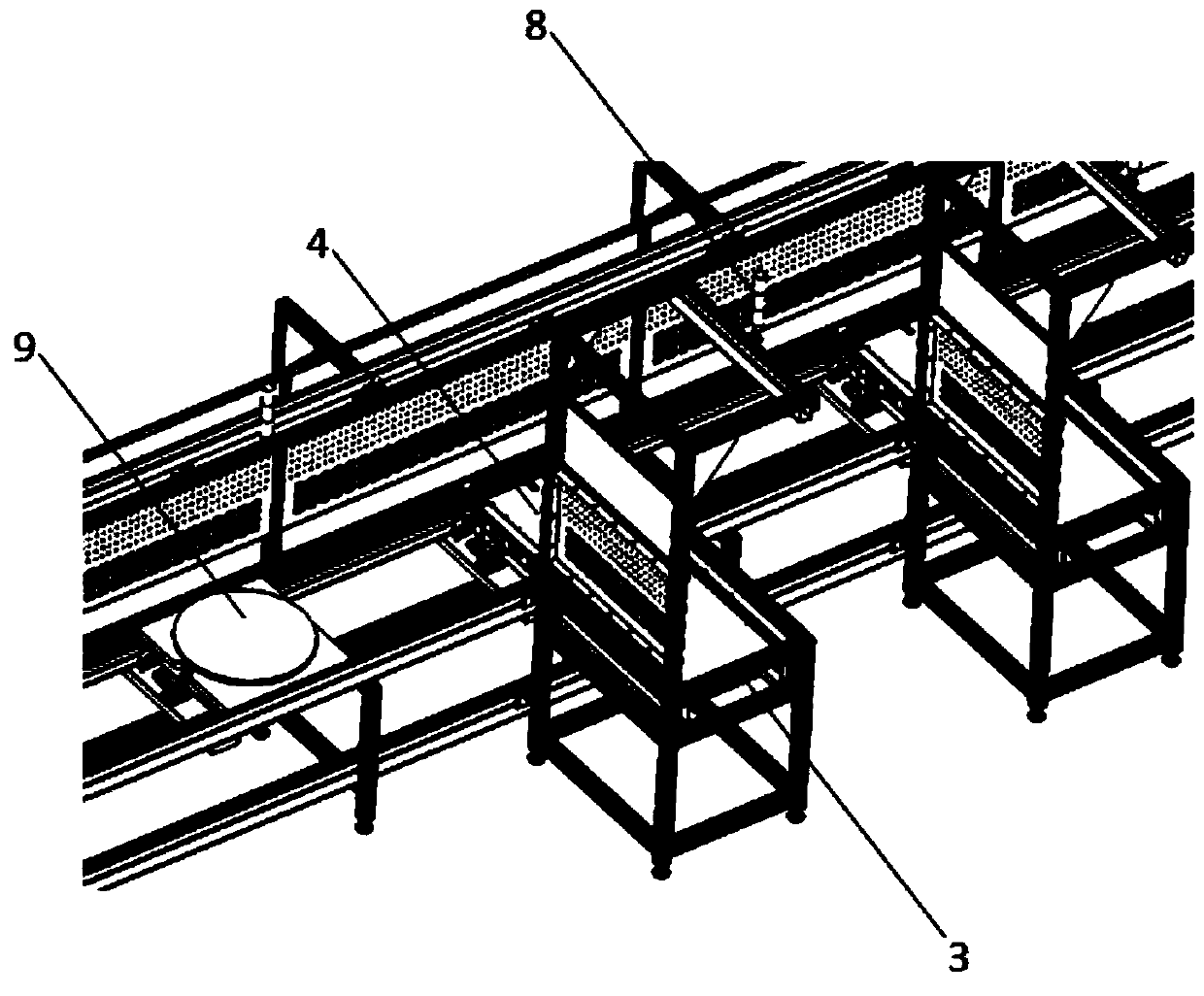

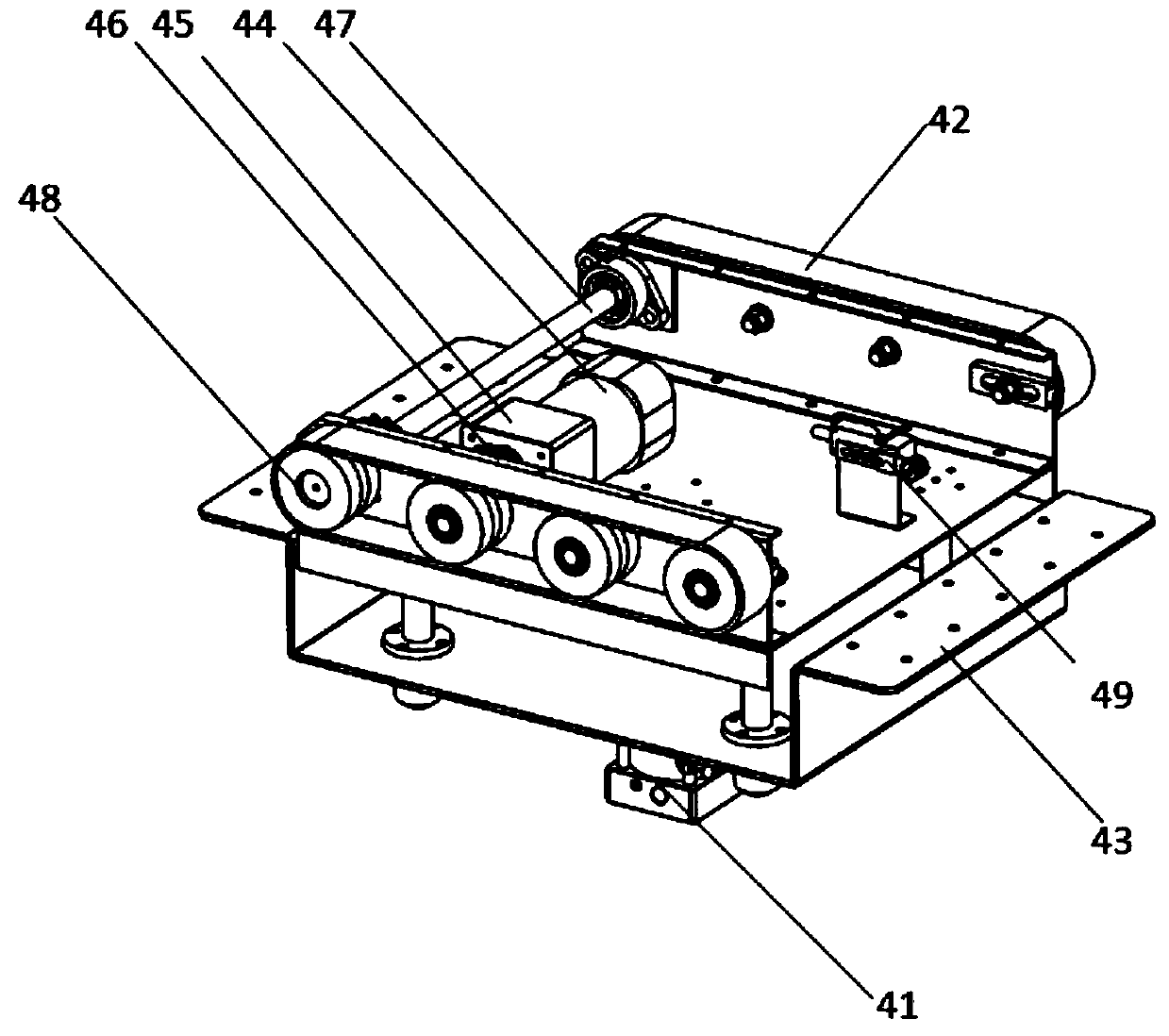

Double-layer circulating conveying device and control method thereof

PendingCN110294280ALow costShorten the timeControl devices for conveyorsMechanical conveyorsProduction lineEngineering

The invention provides a double-layer circulating conveying device and a control method thereof. The conveying device comprises a transfer device, a circulating lifting device and a parallel device, wherein the circulating lifting device is arranged at two ends of the transfer device; the transfer device comprises an upper line body and a lower line body; the parallel device comprises a parallel station and a vertical jacking steering tool; the parallel station is arranged at one side of the transfer device; the position of the vertical jacking steering tool is opposite to the parallel station; the vertical jacking steering tool comprises a jacking cylinder and a conveyor belt; the conveyor belt is connected with a lifting end of the jacking cylinder and perpendicular to the upper layer line body; the parallel station comprises a top plate chain; and the top plate chain is butted with the conveyor belt after the lifting end is lifted. According to the conveying device and the control method thereof, the parallel device is arranged, parts can be guided to the parallel station from an original production line, if the product parts are renewed and replaced, the conveying device does not need to be redesigned, and the compatibility is better.

Owner:SUZHOU IND PARK GAGB MANDE CO LTD

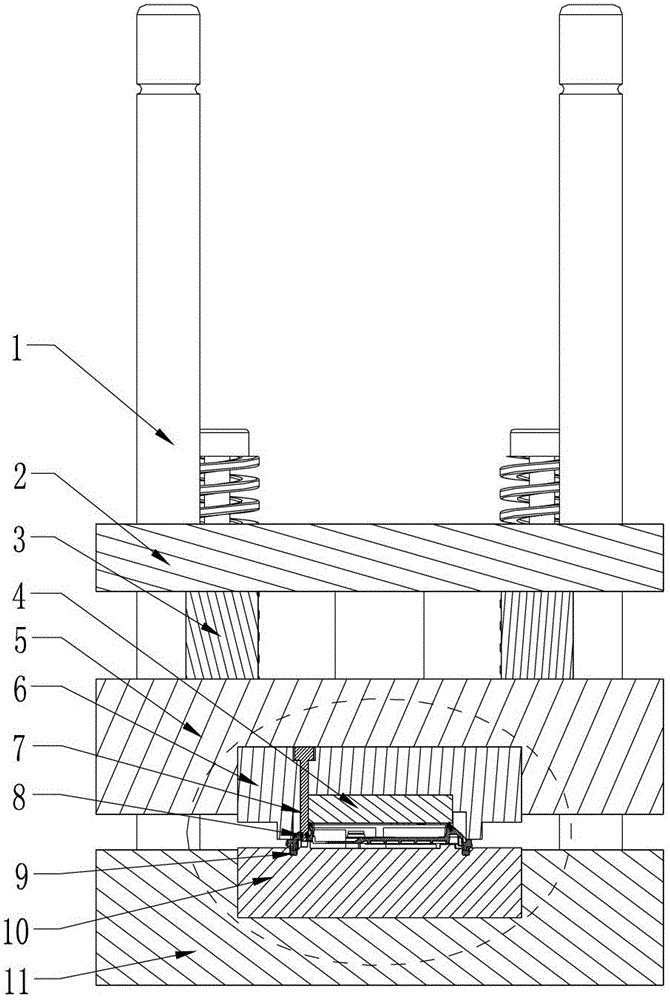

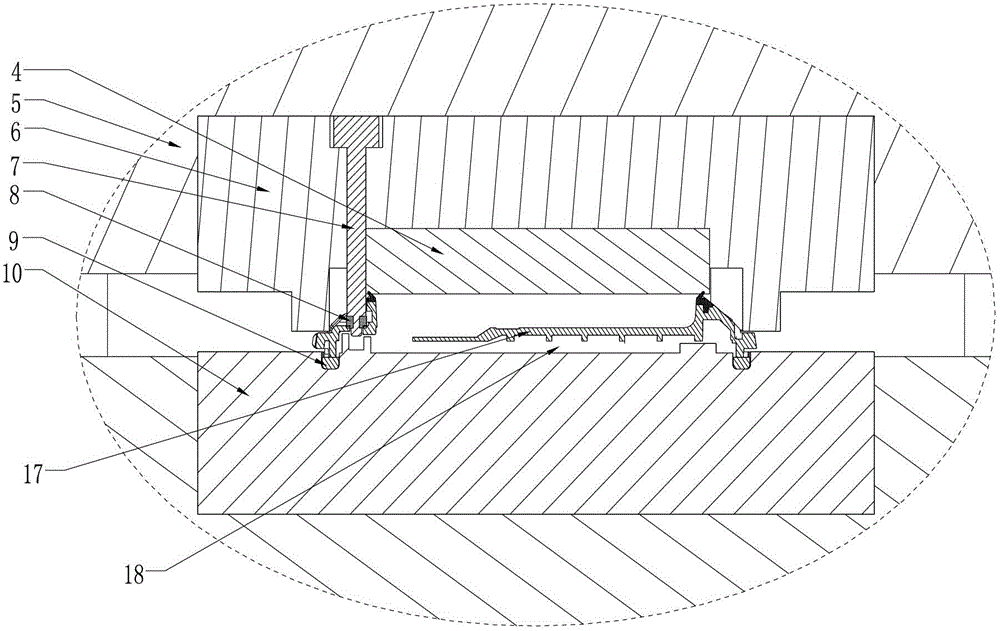

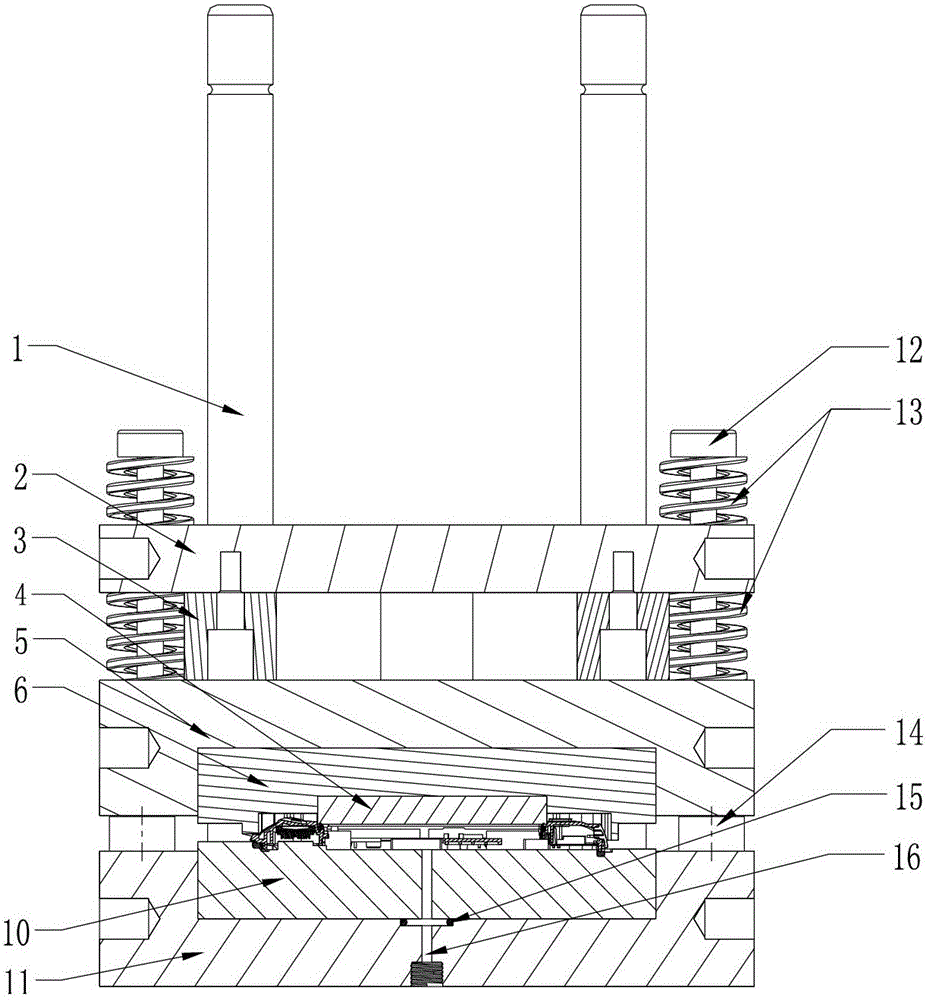

Sealing detection fixture

InactiveCN102721517AImprove machining accuracyExtended service lifeMeasurement of fluid loss/gain rateInternal pressureEngineering

The invention provides a sealing detection fixture. The sealing detection fixture comprises a lower die and an upper die, wherein an annular sealing member which is contacted with a parting surface of a product to be tested is arranged on the upper surface of the lower die; and an exhaust hole is formed in the lower die in a ring of the annular sealing member. The upper die is mounted and connected with an air cylinder; when the upper die presses towards the lower die, a closed cavity from which air can be extracted is formed between the product to be tested and the sealing detection fixture; a sealing ring for sealing a screw hole of the product to be tested is arranged on the upper die; and a mold core insert for sealing a battery compartment of the product to be tested is arranged on the upper die. The sealing detection fixture can be used for integrally checking product parts and assemblies and testing at a time to judge whether the parts meet the requirement or not. The negative pressure generated by exhausting from the inside is matched with the stress on an actual product in deep water, and thus the simulation is more vivid. The internal air pressure is displayed in real time by using a barometer; the quantitative judgment is realized by the change of an air pressure value and is fed back to the computer, and thus automatic judgment is finished.

Owner:赛龙通信技术(深圳)有限公司

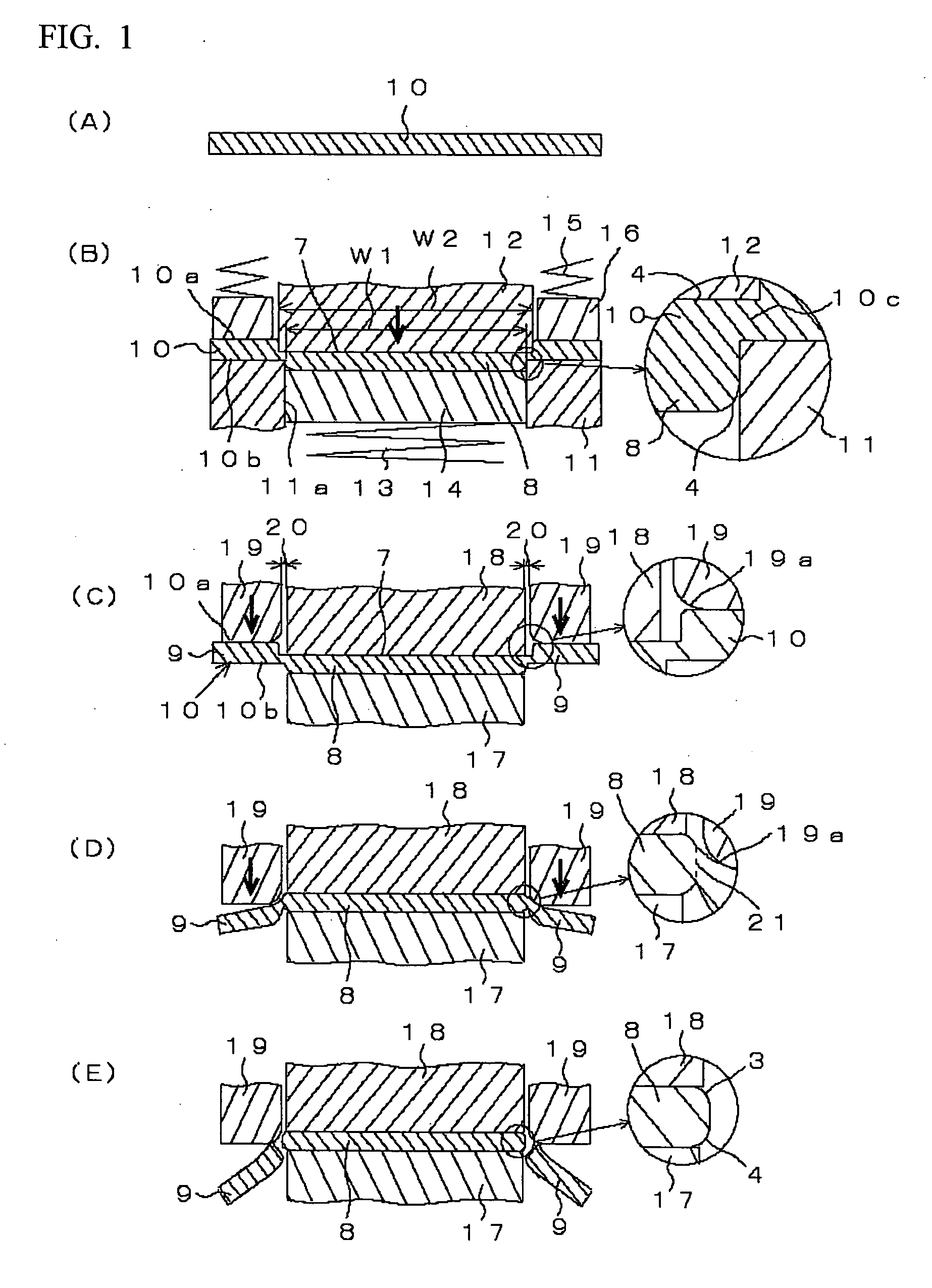

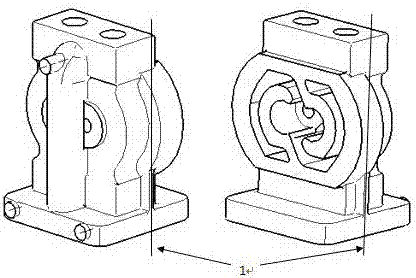

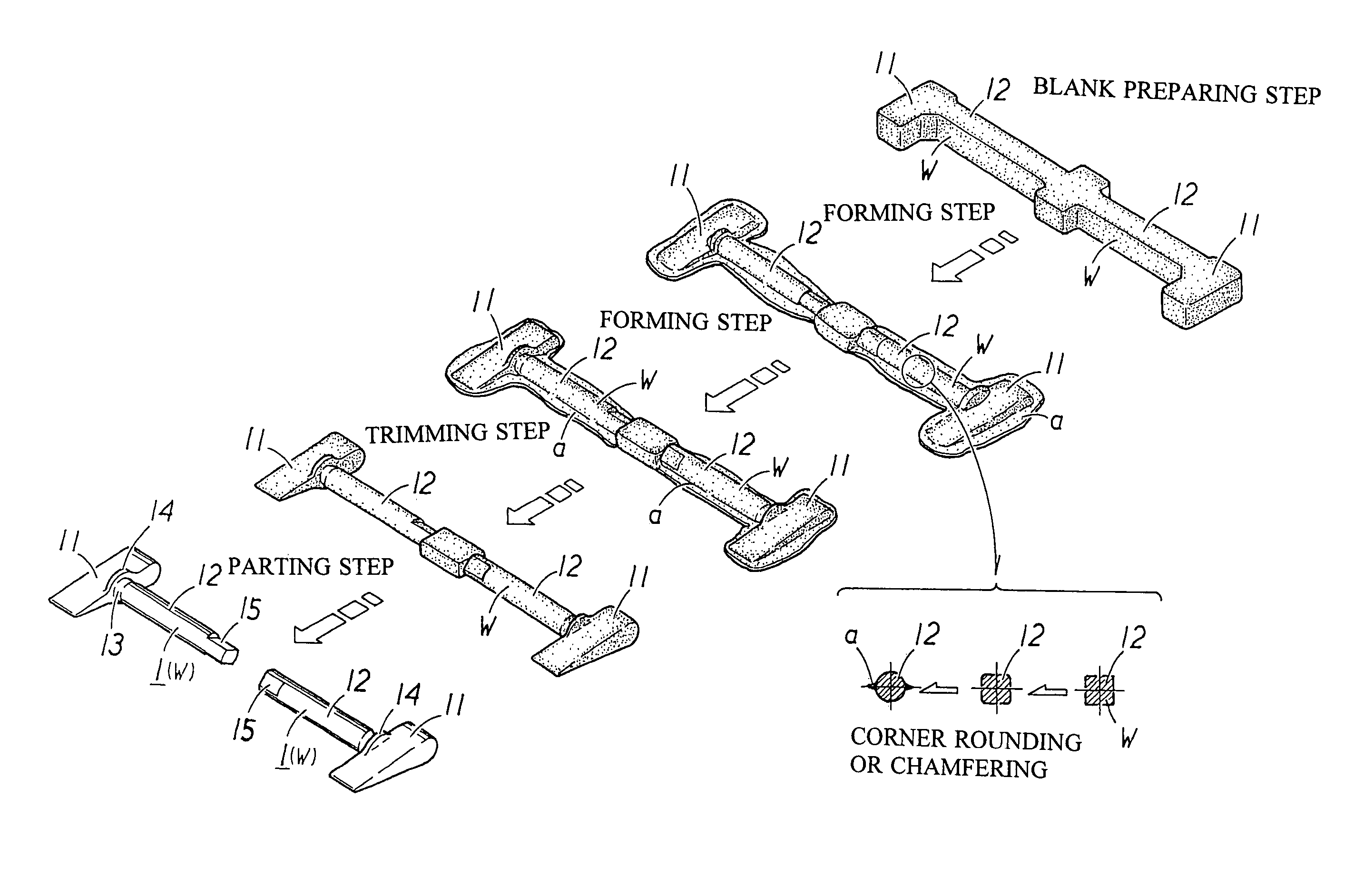

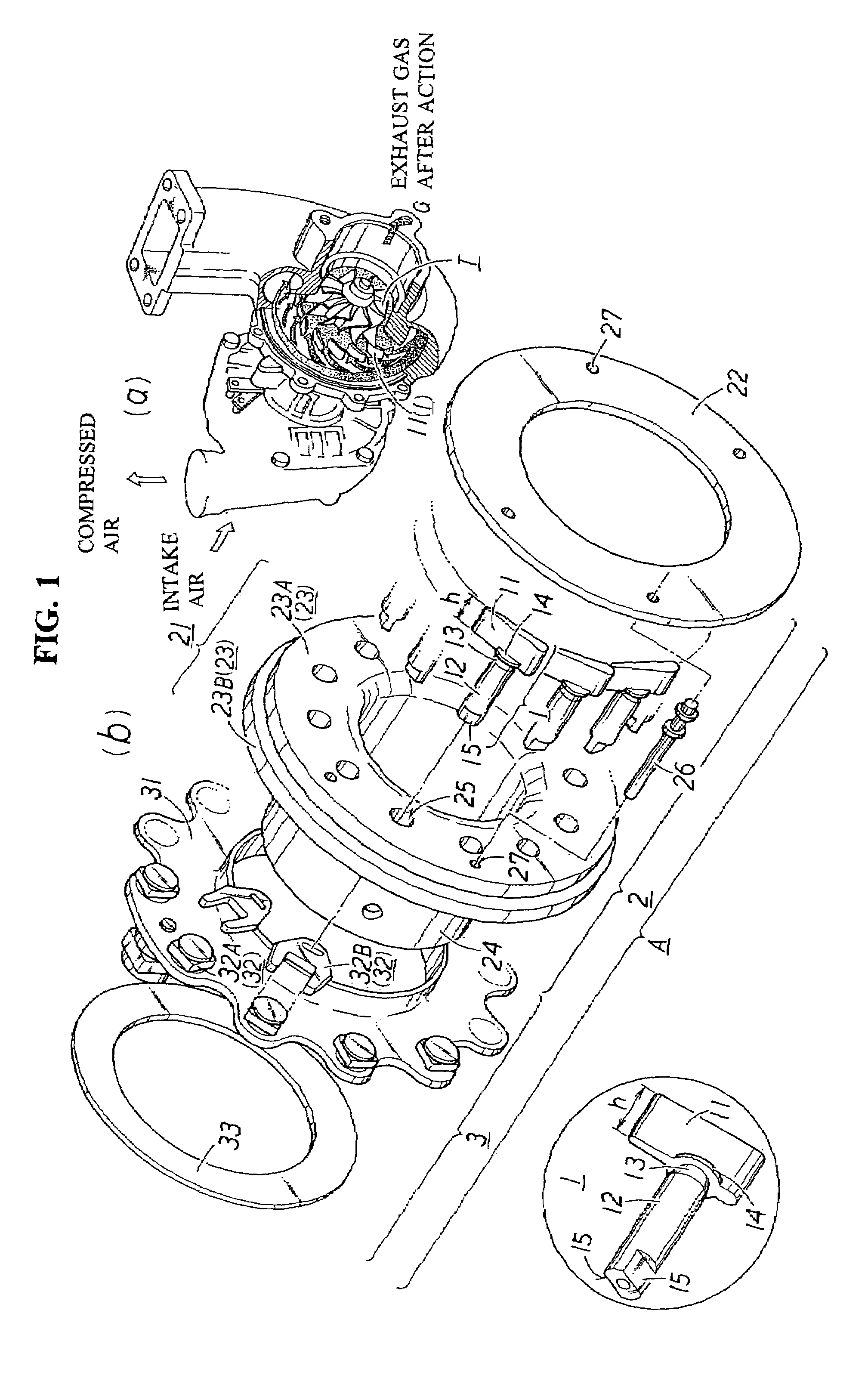

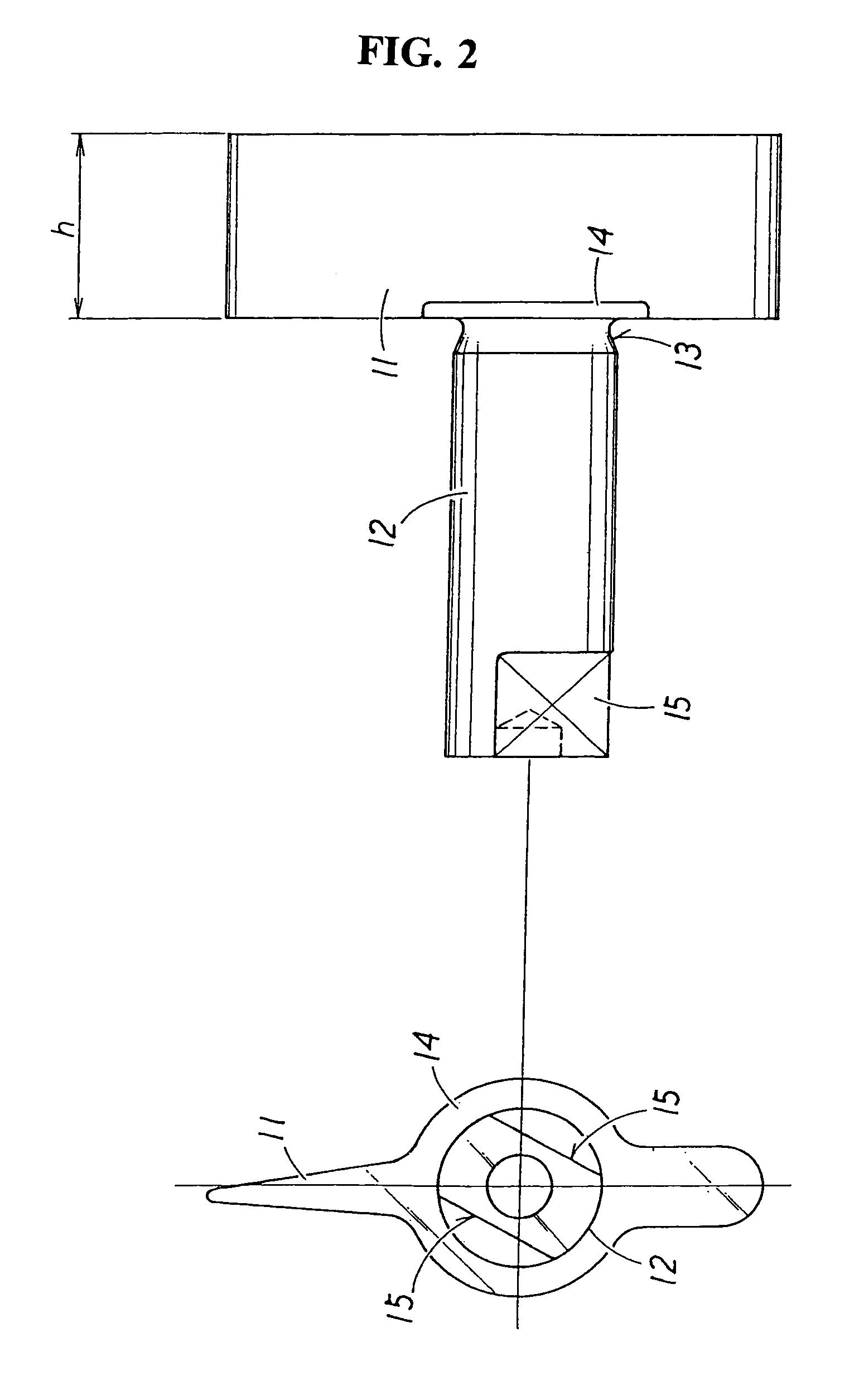

Variable blade manufacturing method and variable blade in VGS type turbo charger

InactiveUS7089664B2Improve heat resistanceAccurately and securely regulateInternal combustion piston enginesEngine controllersMetallic materialsEngineering

A manufacturing method based on a plastic working technique which can eliminate cutting and welding as much as possible in manufacturing an adjustable blade incorporated in a VGS turbocharger. In the method a blank is punched out from a metal material having a substantially constant thickness to be a shaped material (W) as a starting form for an adjustable blade (1); thereafter, the shaped material (W) is compressed between a pair of opposed dies to form a blade portion (11), a shaft portion (12) and the like having desired shapes; thereafter a non-product portion protruding from a product portion is trimmed; then the shaft portion (12) is rolled by pressing the shaft portion (12) of the shaped material (W) against a pair of dies to have a desired diametrical thickness and a near net shape having a shape and dimensions thereof made close to the aimed at adjustable blade. In a finishing operation the shaped material (W), having the near net shape, is pressed by a pair of opposed dies, so that a desired accuracy of a vane height in a completed state can be achieved.

Owner:AKITA FINE BLANKING

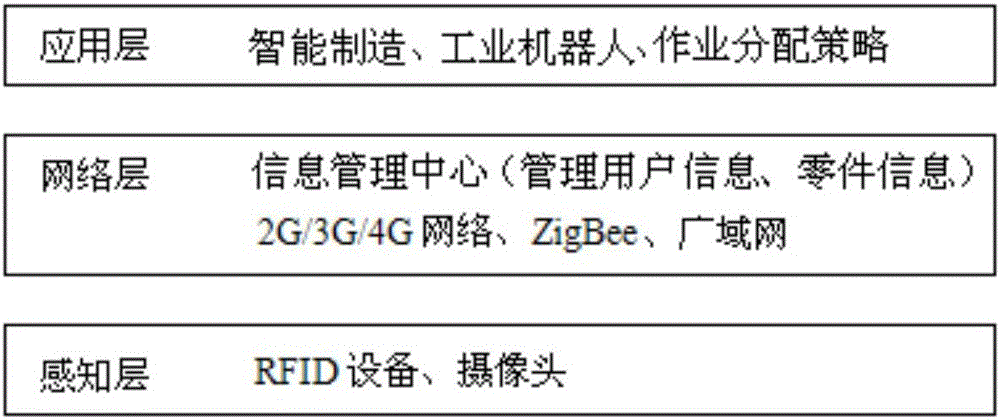

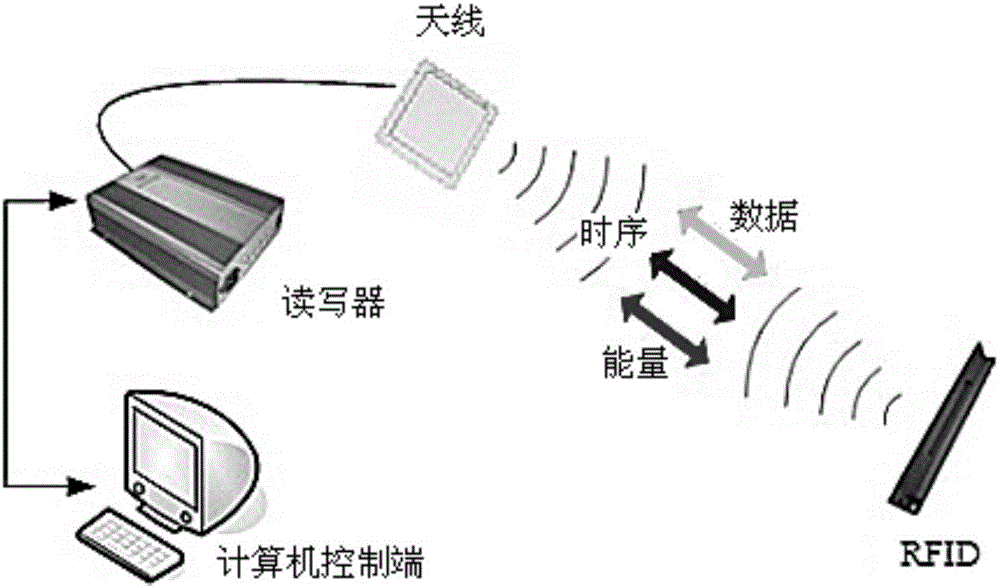

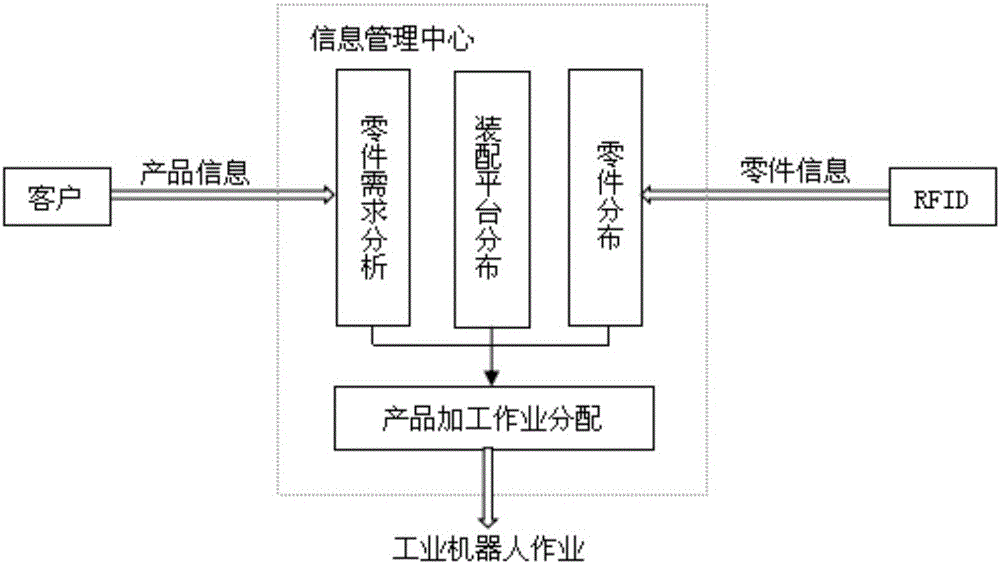

Industrial robot product assembling method based on internet of things

InactiveCN105759766AHigh degree of intelligenceAchieve acquisitionNetworks interconnectionTotal factory controlEmbedded technologyResource utilization

The invention discloses an industrial robot product assembling method based on an internet of things. Combined with an RFID technology, a mobile communication technology and an embedded technology, the internet of things and a communication gateway thereof are established, the information of product parts to be assembled accesses an internet through a perception layer thereof, and the information obtaining, transmission and interaction among all elements in the production and manufacturing process are realized; and then production resources, client product demands and product part information are integrated, an information management center is constructed to manage the information of product parts to be assembled and the client product demand information, and based on the information and data, an operation distribution algorithm is generated for product part assembling. According to the invention, the utilization of production resources such as industrial robots is more reasonable, the production efficiency, the resource utilization rate and the intelligent degree of industrial robot operation are effectively improved, and a feasible scheme is provided for a future intelligent factory to basically realize intelligence and interconnection.

Owner:SOUTH CHINA UNIV OF TECH

Method and apparatus for displaying and selling products

A method and apparatus for displaying and selling products from different product segments within a planogram for products of only one product segment. A product display interrupter is provided in a product display of products from a single product segment to interrupt the display to draw the consumer's attention to another product not of that product segment. The product display interrupter may be in the form of a stand-alone display structure. Preferably, the products to be displayed are framed by and within the product display interrupter. Indicia, such as information on how the products are to be used in conjunction with one another, may be provided on the product display interrupter.

Owner:MCNEIL PPC INC

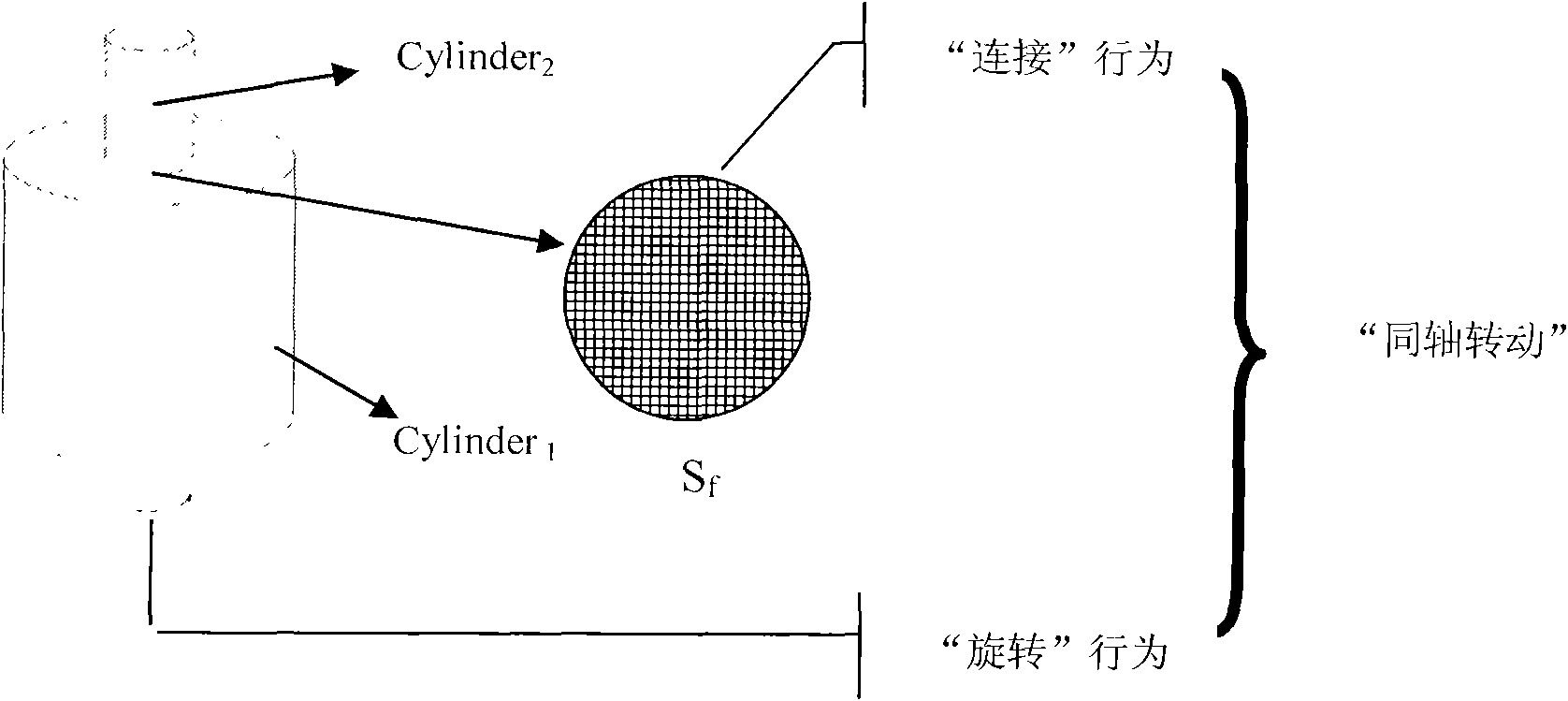

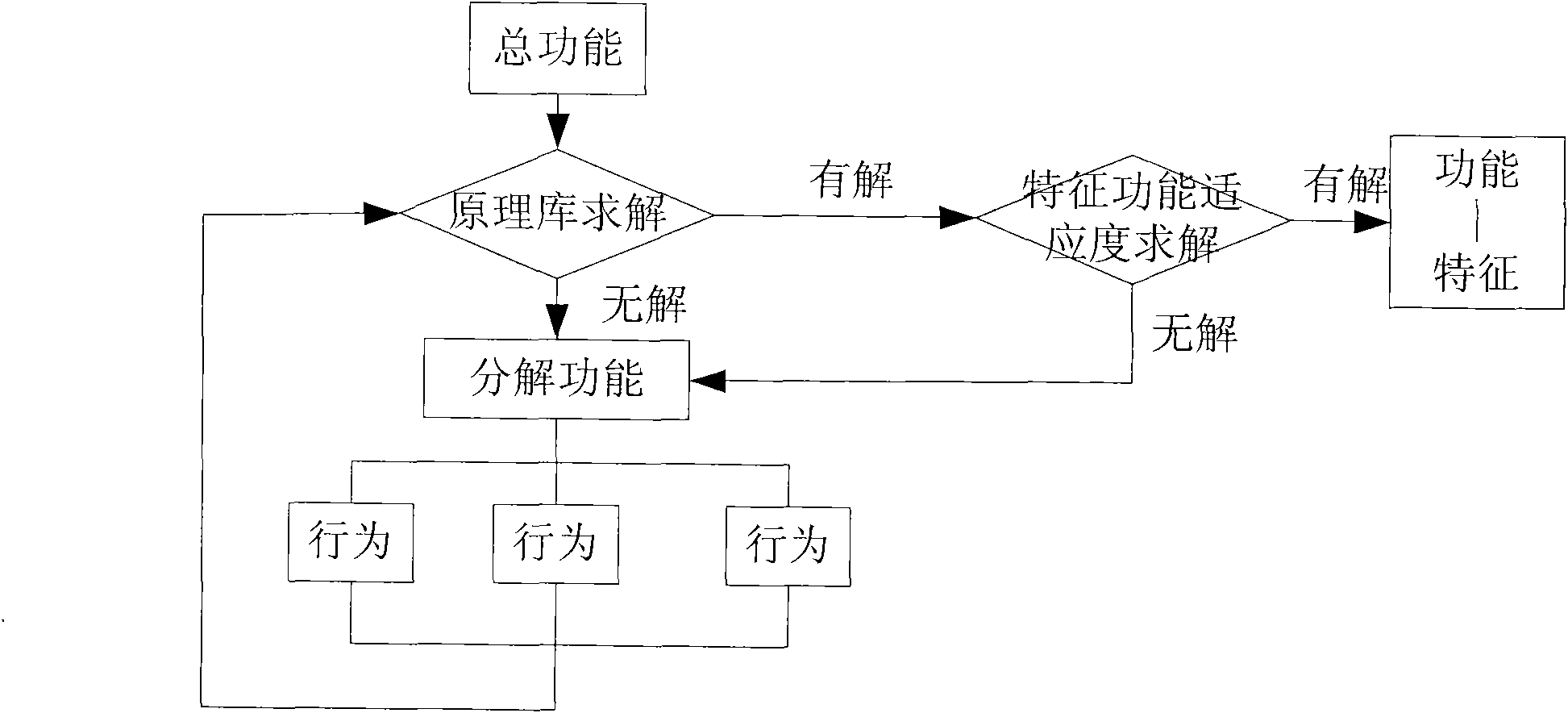

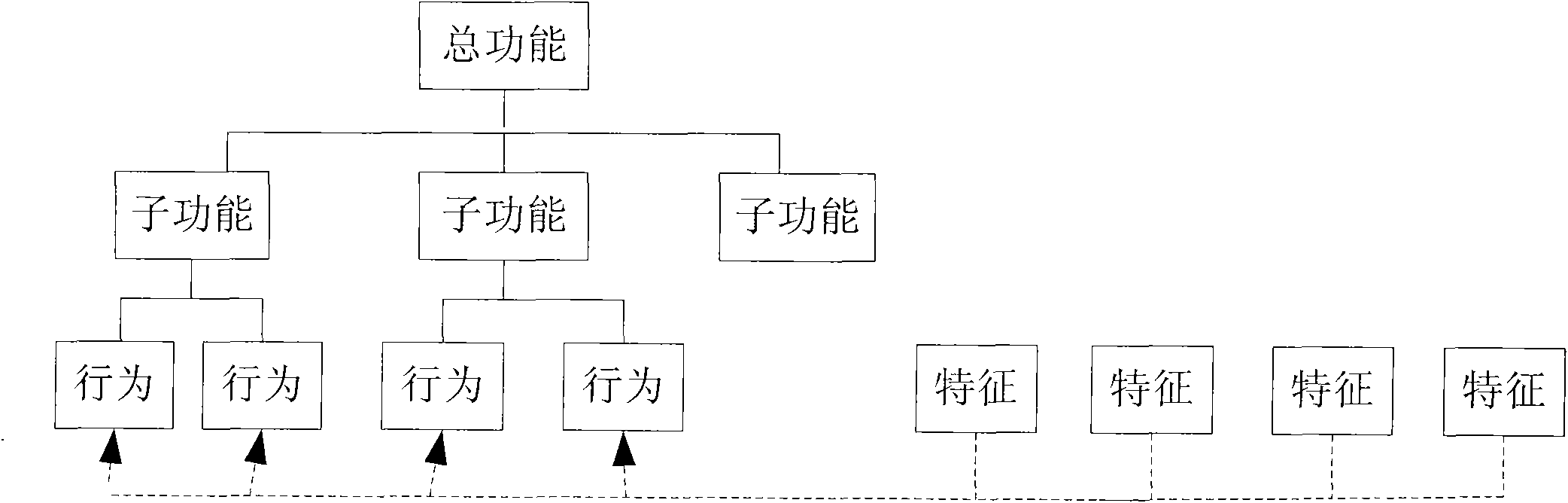

Product function gene modeling system and method

InactiveCN101777087AGenetic modelsSpecial data processing applicationsFunctional modelingFunctional relation

The invention discloses a product function gene modeling system and method. The system comprises a behavior describing unit, a overall function determining unit and a overall function decomposing unit, wherein the behavior describing unit is used for describing the functional relation of parts among products; the overall function determining unit is used for analyzing functional requirements suggested by users, grasping the core of the overall design task to obtain the design requirements of the products and abstracting the overall function of the products; the overall function decomposing unit is used for decomposing the overall function into a plurality of simple subfunctions. The system also comprises a product function reasoning module which further comprises an FTML file reading unit, a function element matrix converting unit, a matrix adjusting unit and an FTML film converting unit. Aiming at function design knowledge and design object knowledge, the invention provides the function modeling method based on gene encoding and adopts an extensive makeup language (XML) and a matrix to represent and establish an evolving and reasoning method of the product parts on the basis of encoding.

Owner:TONGJI UNIV

Tubular product hydraulic forming device capable of achieving inside and outside pressurization

The invention discloses a tubular product hydraulic forming device capable of achieving inside and outside pressurization and relates to a tubular product part forming device. The device solves the difficult problems that a traditional inner high-pressure forming die can achieve tubular product axial feeding but can not achieve tubular product outside pressure sealing, and a whole sealing container can be used for achieving the outside pressure sealing but not achieving the axial feeding. The tubular product hydraulic forming device comprises an upper die of a die, a lower die of the die, an upper template, a lower template, a left side punch and a right side punch, wherein a ring-shaped groove surrounding a cavity of the die is formed in the upper die, a ring-shaped protrusion is formed in the lower die, the groove is in clearance fit with the protrusion, a ring-shaped elastic sealing ring between the groove and the protrusion and a sealing ring among the left side punch, the right side punch and a boss of the lower die jointly ensure the tubular product outside pressure sealing, a die splitting mode that the groove is in clearance fit with the boss is adopted to ensure that no leakage of the tubular product outside pressure happens, under the joint effects of the inside pressure, the outside pressure and the axial feeding, plastic deformation occurs in the tubular product, and formability of the low-plastic tubular product is improved.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com